Page 1

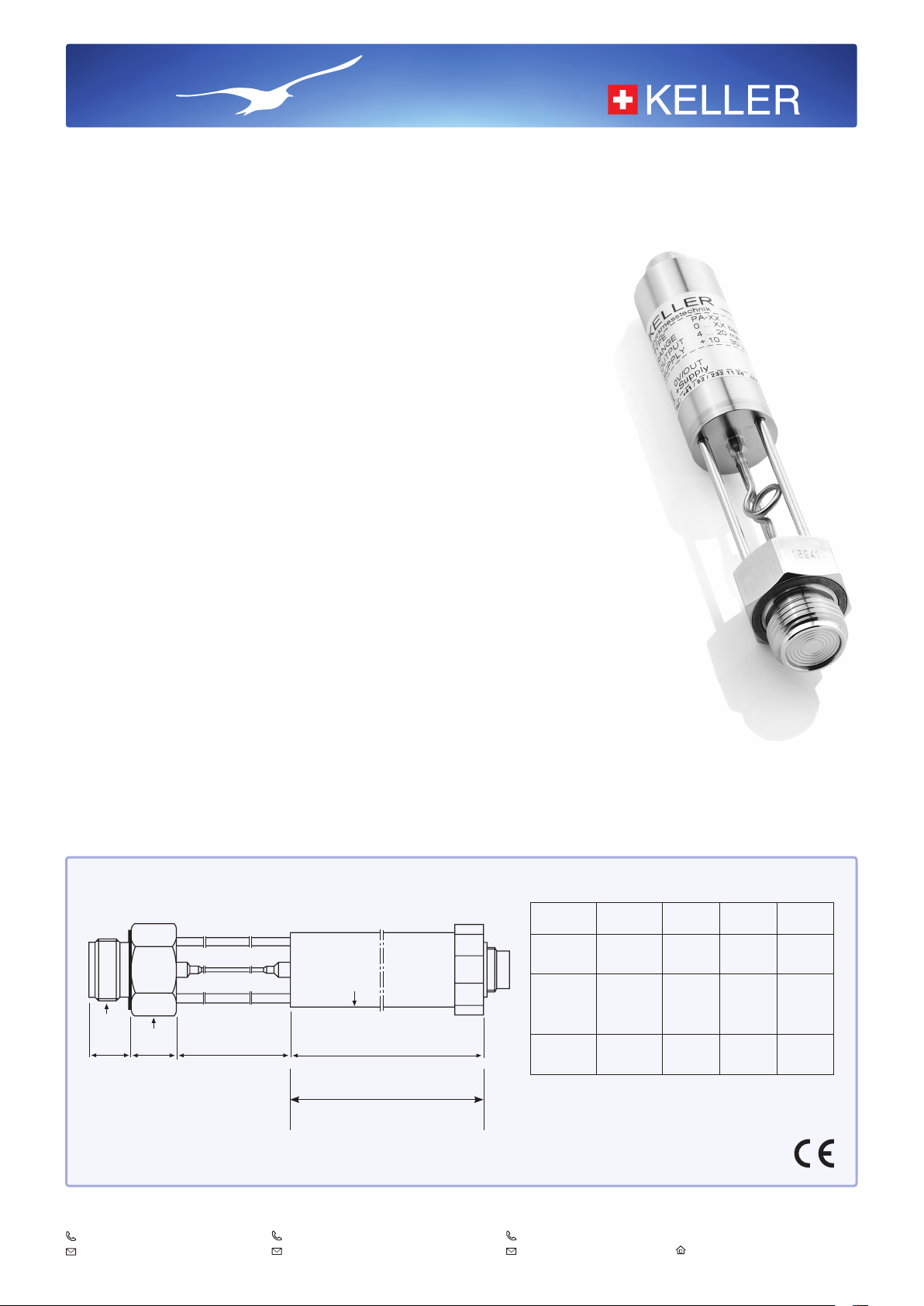

HigH TemperaTure pressure TransmiTTer

for bioTecHnology / food-indusTries

This piezoresistive high temperature transmitter is suited for media temperatures up to 300 °C.

The pressure, acting onto the ush diaphragm, is transferred over an oil-lled capillary onto

the silicon measuring cell. The capillary has the function of a cooling spiral, allowing media

temperatures of up to 300 °C. The temperature of the electronics, which can be read out with

the PROG30 software, may not exceed 120 °C. For highly aggressive media, KELLER offers

pressure ports in different materials.

Digital Output of Transmitter

These Series are based on the stable, piezoresisitive transducer and a micro-processor electro-

nics with integrated 16 bit A/D converter. Temperature dependencies and non-linearities of the

sensor are mathematically compensated. With the READ30 software and the KELLER cable

K-107, the calculated pressure can be displayed on a Palmtop, Laptop or PC. The READ30

software also allows the recording of pressure signals and the graphic display on the PC. Up to

128 transmitters can be hooked together to a Bus-system.

Transmitter with Analog Output

The micro-processor integrates a D/A converter of 16 bit for analog signal outputs of 4…20 mA

or 0…10 V. The output rate is 100 Hz (adjustable). The digital output is available on all transmit-

ters with analog output.

serie 35 X HTc

Programming

With the KELLER software READ30 and PROG30, a RS485 converter (i.e. K-102, K-104 or

K-107 from KELLER) and a PC, the pressure can be displayed, the units changed, a new gain or

zero set. The analog output can be set to any range within the compensated range.

PIN ASSIGNMENT

Output Function

4…20 mA OUT/GND 1 1 C

2 Wire +Vcc 3 3 A

G 1/2"

ø 25

HEX 27

15

14

50

90

Housing Electronics

0…10 V GND 1 1 C

3 Wire OUT 2 2 B

Digital RS485A 4 D

Binder

723

+Vcc 3 3 A

RS485B 5 F

DIN

43650

C-26482

MIL

KELLER AG für Druckmesstechnik

CH-8404 Winterthur

+41 52 235 25 25

info@keller-druck.com

KELLER Ges. für Druckmesstechnik mbH

D-79798 Jestetten

+49 7745 9214 0

eurocenter@keller-druck.com

KELLER America

Newport News, Virginia

1 877 253 5537

sales@kelleramerica.com

Edition 08/2016

Subject to alterations

Companies approved to ISO 9001

www.keller-druck.com

Page 2

Specications

Standard Pressure Ranges (FS) and Overpressure in Bar

PR 35 X HTC 3 10 30

PAA 35 X HTC 10 30 100 300 1000

Overpressure 5 20 60 200 400 1100

All intermediate ranges for the analog output are

realizable with no surcharge by spreading the

standard ranges.

Option: Adjustment directly to intermediate ranges

(below 20 pieces against surcharge).

(digital) (analog) (analog)

Output RS 485 4…20 mA (2 Wire) 0…10 V (3 Wire)

Supply (U) 8…28 Vcc 8…28 Vcc 13…28 Vcc

Accuracy, Error Band1) (20...300 °C)2) 0,5 %FS 0,5 %FS 0,5 %FS

1)

Linearity + Hysteresis + Repeatability + Temp. Coeff. + Zero + Span Tolerance

2)

Media Temperature (temperature of electronics max. 120 °C)

Linearity (best straight line) 0,05 %FS

True Output Rate 100 Hz

Resolution 0,002 %FS

Long Term Stability typ. 0,2 %FS

Load Resistance (Ω) <(U-7V) / 0,02A (2-wire) > 5’000 (3-wire)

Electrical Connection – Binder-Plug 723 (5 pole)

– DIN 43650 Plug (4 pole)

– MIL C-26482-Plug (6 pole)

Insulation > 10 MΩ / 50 V

Storage- / Operating Temperature Range

Media: 0…300 °C Electronics: 0…120 °C

Pressure Endurance 10 Million Pressure Cycles 0…100 %FS at 25 °C

Vibration Endurance, IEC 68-2-6 20 g (5...2000 Hz, max. amplitude ± 3 mm)

Shock Endurance 20 g (11 ms)

Protection IP 65 optional: IP 67

CE-Conformity EN 61000-6-1 to -6-4

Material in Contact with Media Stainless Steel 316L (DIN 1.4435) / Copper

Weight ≈ 300 g

Dead Volume Change < 0,1 mm

3

Mounting – Horizontal position (carrying-off of heat)

– Cooling spiral exposed to room temperature

Remark: –

RS485 pins (for digital output and for programming) is available on all types.

Options: – Switch output, programmable via interface

– Special calculations with pressure and temperature

– Different housing-material, oil lling, pressure thread or connector

Polynomial Compensation

This uses a mathematical model to derive the

precise pressure value (P) from the signals

measured by the pressure sensor (S) and the

temperature sensor (T). The microprocessor in

the transmitter calculates P using the following

polynomial:

P(S,T) = A(T)xS0 + B(T)xS1 + C(T)xS2 + D(T)xS

3

With the following coefcients A(T)…D(T)

depending on the temperature:

A(T) = A

B(T) = B

C(T) = C

D(T) = D

x

T0 + A

0

x

T0 + B

0

x

T0 + C

0

x

T0 + D

0

x

T1 + A

1

x

T1 + B

1

x

T1 + C

1

x

T1 + D

1

x

T2 + A

2

x

T2 + B

2

x

T2 + C

2

x

T2 + D

2

3

x

T

3

3

x

T

3

3

x

T

3

3

x

T

3

The transmitter is factory-tested at various levels

of pressure and temperature. The corresponding

measured values of S, together with the exact

pressure and temperature values, allow the

coefcients A0...D3 to be calculated. These are

written into the EEPROM of the microprocessor.

When the pressure transmitter is in service, the

microprocessor measures the signals (S) and

(T), calculates the coefcients according to the

temperature and produces the exact pressure

value by solving the P(S,T) equation.

Calculations and conversions are performed at

least 400 times per second.

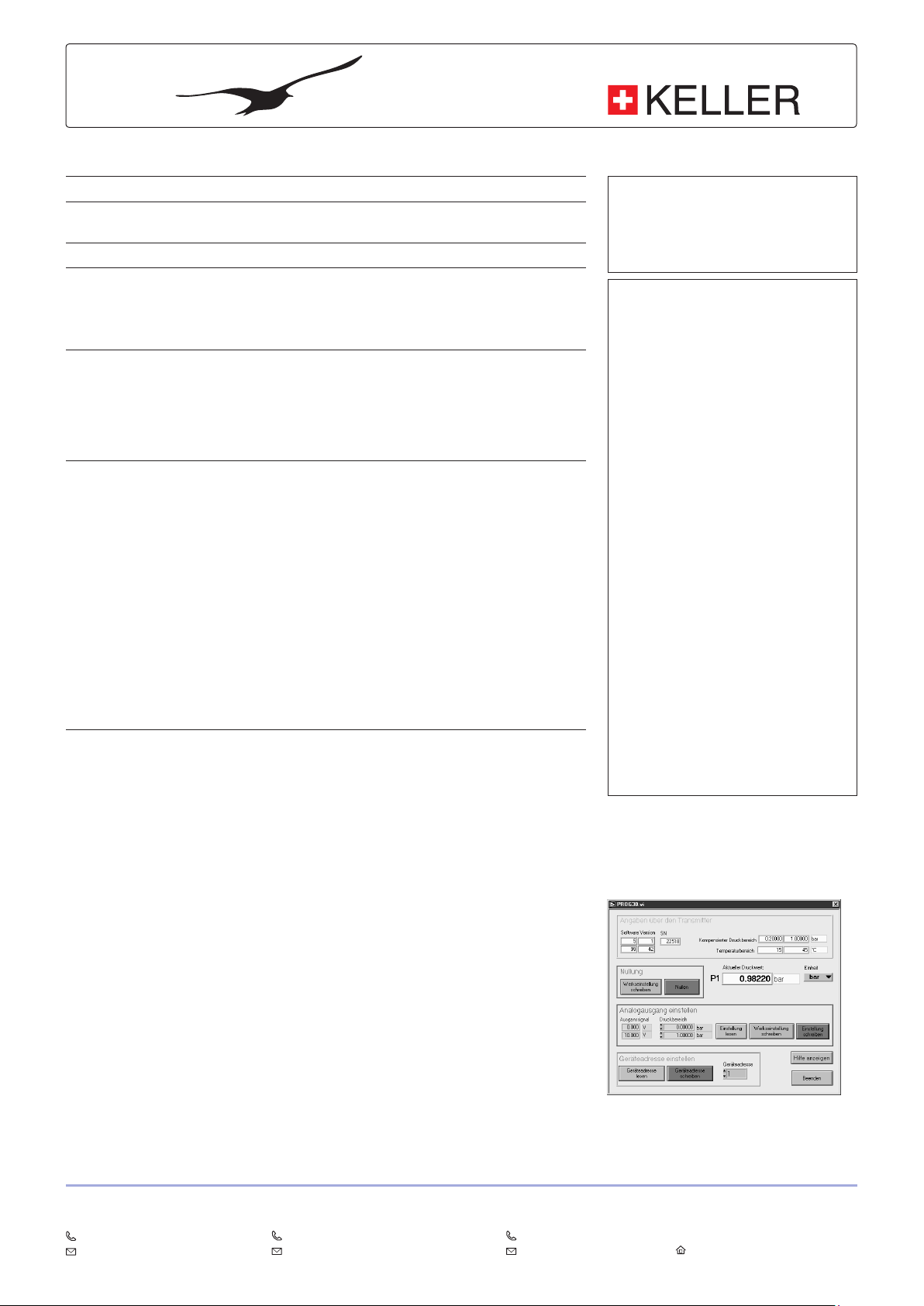

Accessories Series 30

Each Series 30 transmitter also integrates a digital interface (RS485 halfduplex) which you can make use of: Connect the transmitter to a PC or

Laptop via a converter RS232-RS485 (i.e. K-102, K-104 or K-107). Two programs are offered:

PROG30: Instrument Settings

•

Call up of information (pressure- and temperature range, version of software etc.)

• Indication of actual pressure value

• Selection of the units

•

Setting of a new zero and gain for the

transmitter

READ30: Data collection with graphs

• Fast read-out and viewing of the pressure

signals in a graph

• Documentation of dynamic measurements

• Up to 16 transmitters on one serial connec-

tion (Bus-operation)

Software PROG30

• Reprogramming of the analog output

(i.e. different unit, other pressure range)

• Programming of the switch output

• Changing the output rate

You can also tie up the transmitters into your own software. You have then a documentation,

a DLL and numerous examples at your disposal.

Changing the plug connector (optional)

Laboratory applications require the same transmitter to be used at different measurement points with different electrical connection arrangements. To accommodate such applications, KELLER can supply different connectors matching with the internal standard plug. This makes it

easy to exchange the electrical connector of the transmitter.

KELLER AG für Druckmesstechnik

CH-8404 Winterthur

+41 52 235 25 25

info@keller-druck.com

KELLER Ges. für Druckmesstechnik mbH

D-79798 Jestetten

+49 7745 9214 0

eurocenter@keller-druck.com

KELLER America

Newport News, Virginia

1 877 253 5537

sales@kelleramerica.com

Edition 08/2016

Subject to alterations

Companies approved to ISO 9001

www.keller-druck.com

Loading...

Loading...