Kellenberger KelAccess User Manual

®

KEL-ACCESS

ACCESSORIES FOR KELLENBERGER CYLINDRICAL GRINDING MACHINES

THE KEL-VARIA® ACCESSORIES:

PRACTICAL, UNIVERSAL, OPTIMAL.

Precision Grinding Machines and Systems

®

KEL-ACCESS

®

Standard Accessories

Standard Accessories

■ 1 set of open ended spanner

■ 1 ring spanner, size 19

■ 1 open ended spanner, size 40

■ 1 set of hex head socket spanners

■ 1 hex head socket spanner, size 8

■ 1 Allan key, size 8

■ 1 balancing arbour

■ 1 box spanner, size 46

■ 1 assembly arbour

■ 1 wheel-changing aid. for ø 500 (20“) only

■ 1 pulling off tool

■ 1 reduction sleeve MT5 / MT4

■ 1 assembly ring

■ 1 driver

■ 1 taperhole wiper MT5

■ 1 taperhole wiper MT4

■ 2 carbide tipped centre-points MT4

■ 1 carbide tipped half centre-points MT4

■ 1 round belt

■ 1 drain-off tube

■ 1 ejector bar

■ 1 manual drawbar

■ 1 set of operating instructions

Height of centres

175 / 225 mm (6.89 / 8.86“)

Distance between centres

600 / 1000 / 1500 mm (24 / 40 / 60“)

Power supply

3 x 400 V 50 Hz / 3 x 460 V 60 Hz

Painting

Enclosure /cabinet:

NCS 2502-B /

grey

blue

NCS 3050-B

Machine base / auxiliary equipment:

dark grey

NCS 7502-B

2

TECHNOLOGY FOR THE FUTURE

®

KEL-ACCESS

®

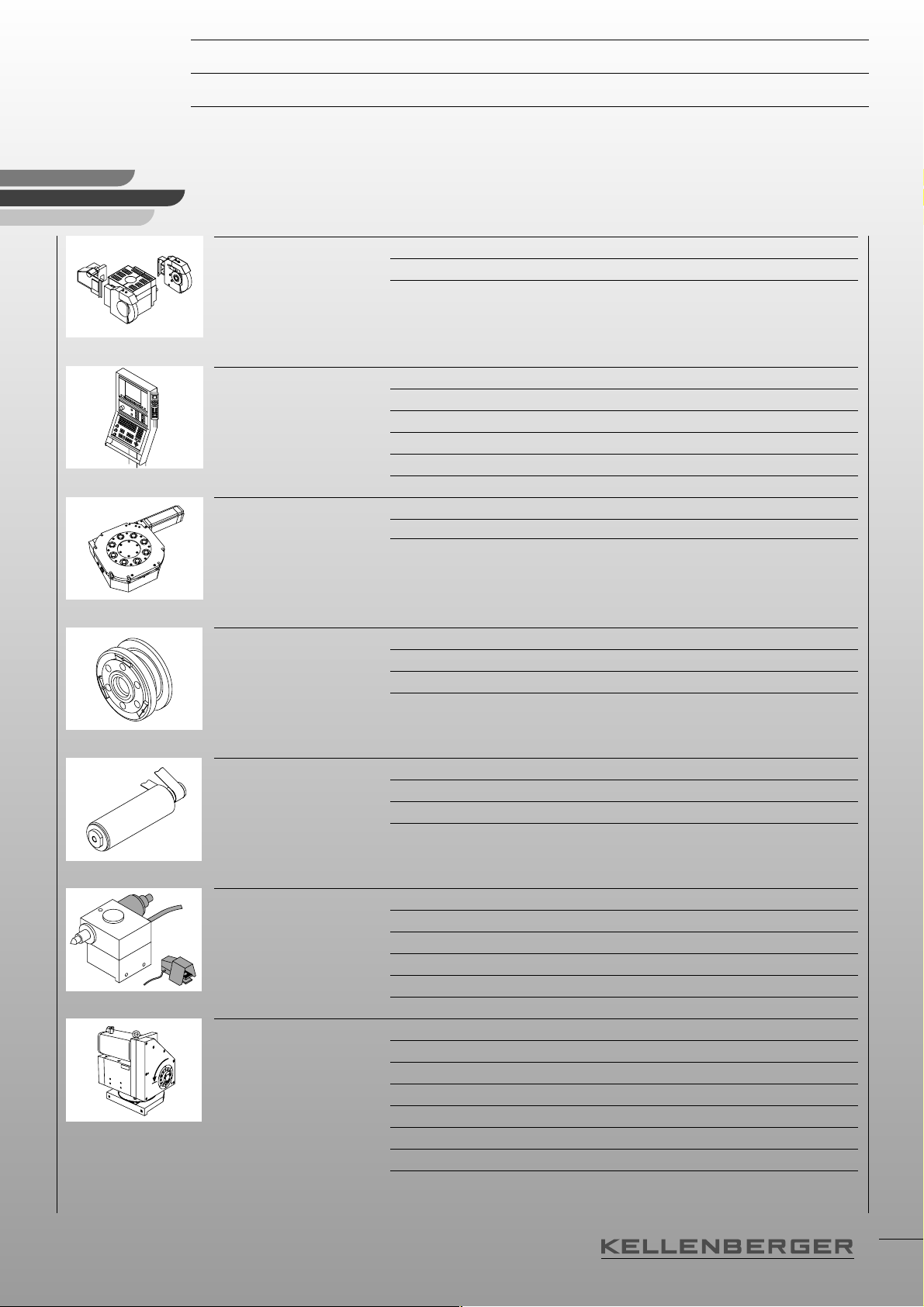

Contents

Wheelhead variants R and UR 5

RS and URS 6

CNC control units and KELCO 110 7

PC software KELCO 120

FANUC

KEL-ASSIST 100 8

KEL-POLY

Personal computer (laptop)

Swiveling-devices for Indexing swivelling systems 9

wheelheads CNC controlled B axis

Equipment for wheelheads Grinding wheel flanges 10

Constant surface speed

Automatic balancing

Internal grinding spindles Internal grinding spindles 11

and accessories Quills 12

Collet chuck, face grinding quill 13

Equipment for the tailstock Hydraulic sleeve retraction 14

Micro-adjustment

Spring preloaded center

Air-cushioning 15

Cooling system for upper table

Extra equipment for Increased working accuracy 16

workhead CNC-controlled C axis

Positioned spindle stop

Sine bar

Swivelling lower section 17

Micro fine adjustment

Coolant supply through the workhead spindle

TECHNOLOGY FOR THE FUTURE

®

3

KEL-ACCESS

®

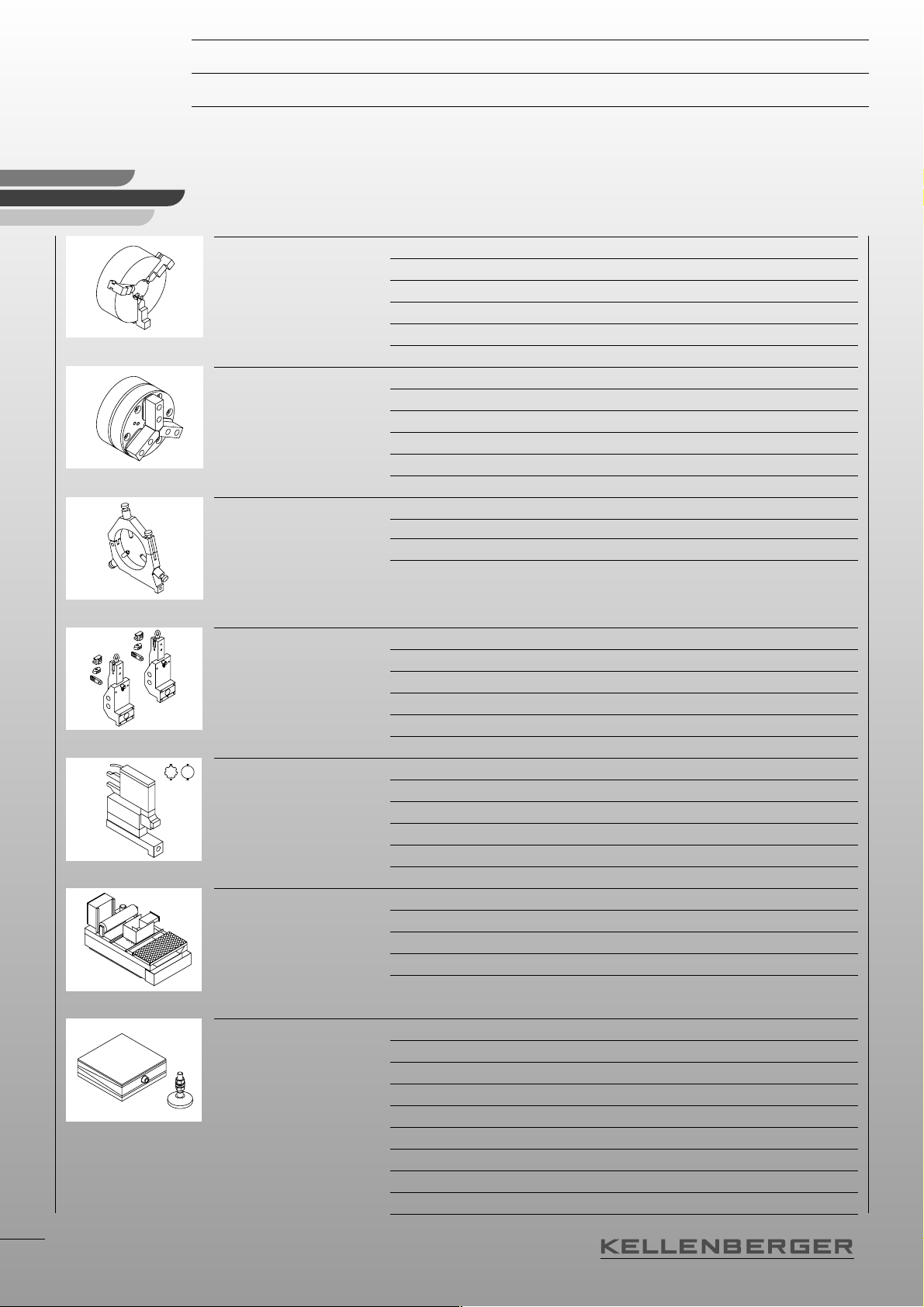

Contents

Manual clamping devices 3-jaw chucks 18

and related accessories Permanent magnetic chucks

Blank flange

Spring collet adapters 19

Spring collets

Driving dogs

Power-actuated clamping Power-clamping system 20

devices and related 3-jaw power chuck

accessories Jaws

Power-clamping system / sets of jaws / chuck simulator 21

Driving dogs, devoid of shearing force 22

Spring collet adapter / spring collets

Steady-rests and supports 2-point steady rest 23

for components 3-point steady rest

Support for components

Dressing devices with Dressing device mounted on longitudinal slide 24

related accessories and Dressing device mounted on upper table

tools Adapter for diamond-holder

Diamond-holder 25

Dressing tools 26 / 27

Dressing devices 28

Gauging, flagging and Active flagging device KEL-POS 29

gap-control units Tool measuring system KEL-SET

Gap control sensor unit 30

Passive flagging device

In-process gauging system 30 / 31

Coolant-filtration units and Paper tape filter with magnetic swarf separator 32

related accessories Paper tape roll

Continuous-band filtration unit 33

Kit of connecting parts for filtration unit DARENTH 1040

Miscellaneous equipment Full enclosure for machine 34

Dust extration unit

Machine paint to customers specification

Special connection voltage and balancing unit

Vibration damping bases 35

Lubricant for first filling

Spare belts

Technical documentation / Services

Competence and global partnership 36

4

TECHNOLOGY FOR THE FUTURE

®

KEL-ACCESS

®

Wheelhead variants R and UR

Equipment for right-hand side of wheelhead

■ Automatic ginding wheel protection ■ 1 grinding wheel

■ Coolant shut-off device ■ 1 grinding wheel flange

Only available with 1110.01 and 1110.02*

Wheelhead variant R Only available with basic equipment

Equipment for grinding wheel on righthand side of ø 300 x 40 x 127 mm (12 x 1.6 x 5“) 1111.01

wheelhead ø 400 x 50 x 127 mm * (16 x 2.0 x 5“) 1111.03

Only available with 1310.01 and 1310.02*

Wheelhead variant UR Only available with basic equipment

Equipment for grinding wheel on righthand side of ø 300 x 40 x 127 mm (12 x 1.6 x 5“) 1311.01

wheelhead ø 400 x 50 x 127 mm * (16 x 2.0 x 5“) 1311.03

ø 400 x 63 x 127 mm * (16 x 2.5 x 5“) 1111.02

ø 400 x 63 x 127 mm * (16 x 2.5 x 5“) 1311.02

Equipment for grinding wheel on lefthand side of wheelhead ø 500 x 80 x 203.2 mm (20 x 3.2 x 8“) or

ø 500 x 100 x 203.2 mm (20 x 4 x 8“).

■ Motor output 9.2 kW

■ Peripheral grinding wheel speed 45 m/s (148 sfpm)

■ Instead of 400 mm (16“) / 7.5 kW / 35 m/s (115 sfpm)

Wheelhead variant R Only available with basic equipment

Equipment for grinding wheel on lefthand side of ø 500 x 80 x 203.2 mm (20 x 3.2 x 8“) 1110.01

wheelhead ø 500 x 100 x 203.2 mm (20 x 4.0 x 8“) 1110.02

Wheelhead variant UR Only available with basic equipment

Equipment for grinding wheel on lefthand side of ø 500 x 80 x 203.2 mm (20 x 3.0 x 8“) 1310.01

wheelhead ø 500 x 100 x 203.2 mm (20 x 4.0 x 8“) 1310.02

Internal grinding attachment with adapter ø 120 mm (4 23/32“) for high-frequency internal grinding

spindles.

■ Automatic grinding wheel protections

■ Coolant shut-off device

Only available with machine version type UR Only available with basic equipment

Internal grinding attachment with adapter ø 120 mm (4

23

/32“) 1012.01

Height of centres 225 mm (8.86“)

■ Max. grindable diameter with grinding wheel ø 500 mm (20“) and

grinding wheel position 0° is 432 mm (17“).

Only available with basic equipment

Increase of centre height to 225 mm (8.86“) 1018.01

TECHNOLOGY FOR THE FUTURE

®

5

KEL-ACCESS

®

Wheelhead variant RS and URS

Equipment for grinding wheel on righthand side of wheelhead

■ Motor output 9.2 kW

■ Peripheral grinding wheel speed 45 m/s (148 sfpm)

■ Instead of 400 mm (16“) / 7.5 kW / 35 m/s (115 sfpm)

Wheelhead variant RS Only available with basic equipment

Equipment for grinding wheel on righthand side of ø 500 x 80 x 203.2 mm (20 x 3.2 x 8“) 1211.01

wheelhead ø 500 x 100 x 203.2 mm (20 x 4.0 x 8“) 1211.02

Wheelhead variant URS Only available with basic equipment

Equipment for grinding wheel on righthand side of ø 500 x 80 x 203.2 mm (20 x 3.2 x 8“) 1411.01

wheelhead ø 500 x 100 x 203.2 mm (20 x 4.0 x 8“) 1411.02

Internal grinding attachment with adapter ø 120 mm (4 23/32“) for high-frequency internal grinding

spindles.

■ Automatic grinding wheel protections

■ Coolant shut off

Only available with machine version type URS Only available with basic equipment

Internal grinding attachment with adapter ø 120 mm (4

23

/32“) 1012.01

Height of centres 225 mm (8.86“)

■ Max. grindable diameter with grinding wheel ø 500 mm (20“) and

grinding wheel position 0° is 432 mm (17“).

Only available with basic equipment

Increase of centre height to 225 mm (8.86“) 1018.01

6

TECHNOLOGY FOR THE FUTURE

®

KEL-ACCESS

®

CNC control units and PC software

CNC control unit KELCO 110

Dialogue-supported Z-axes, CNC control unit for X- and Z-axis. Graphic assisted or ISO 6983 /

DIN 66025 programming, including specific grinding cycles.

■ 10.4" colour LC display

■ Harddisc 1.5 Gb, main memory 32 Mb RAM

CNC control unit KELCO 110 1020.02

Only available with basic equipment

CNC control unit KELCO 120

Dialogue-supported, multi-axis CNC control unit for X-, Z-, B- and C-axis. Graphic assisted or ISO 6983 /

DIN 66025 programming including specific grinding cycles.

■ Constant peripheral grinding wheel speed

■ 10.4" colour LC display

■ Harddisc 1.5 Gb, main memory 32 Mb RAM

Only available with basic equipment

CNC control unit KELCO 120 1021.02

CNC control unit GE FANUC

Dialogue-supported, multi-axis CNC control unit for X-, Z- and B-axis. Graphic assisted or ISO 6983 /

DIN 66025 programming including specific grinding cycles.

■ 10.4" colour LC display

■ Harddisc: 512 Kb

Only available with basic equipment

CNC control unit GE FANUC 1022.01

TECHNOLOGY FOR THE FUTURE

®

7

KEL-ACCESS

®

CNC control units and PC software

KEL-ASSIST 100

Software package supporting the generation of profile dressing and contour grinding programmes for

KELCO 110, KELCO 120 and GE FANUC.

■ Includes CAD “vector”

■ Data transfer via RS 232 interface

■ Contour grinding

■ Profile dressing

KEL-ASSIST 100 1024.04

Available at any time

KEL-POLY

Software for grinding of unround or eccentrics polyhedrons, polygons and continuous and free contours.

■ DXF interface for reading CAD data

■ Data transfer via RS 232 interface

Only available with the C-axis, ref. 1026.01 and KELCO 120 Available at any time

KEL-POLY 1024.03

Personal Computer (Laptop)

■ Including the installation of software, e.g. KEL-ASSIST 100 or KEL-POLY

■ 1 connecting cable (length 5 m)

Available at any time

Personal Computer 1025.01

8

TECHNOLOGY FOR THE FUTURE

®

KEL-ACCESS

®

Swivelling devices for the wheelheads

Swivelling system with manual indexing.

■ Positioning devices every 2.5 ° with Hirth coupling and hydraulic cushioning

■ Swivelling range +30° / -205°

■ Spring pre-loaded clamping

Swivelling device with manual indexing for wheelhead R 1114.01

Only available with basic equipment

Swivelling device for automatic indexing

■ Positioning every 2.5 ° with Hirth-coupling and hydraulic cushioning

■ Swivelling range +30° / -205°

■ Spring pre-loaded clamping

Only available with basic equipment

Swivelling device with automatic indexing for wheelhead R 1114.02

Swivelling device with automatic indexing for wheelhead UR / URS / RS 1014.01

CNC-controlled B-axis

Swivelling system for automatically swivelling in any position with hydraulic clamping without radial

tension. No vertical movement, e.g. can be swivelled in an I.D. without first being removed.

■ Positioning accuracy +/- 5"

■ Swivelling range +30° / -205°

Only available with basic equipment

CNC controlled B axis for wheelhead R 1114.03

CNC controlled B axis for wheelhead UR / URS / RS 1014.02

TECHNOLOGY FOR THE FUTURE

®

9

KEL-ACCESS

®

Equipment for wheelheads

Grinding wheel flange with balancing segments on outside

Outer ø x I.D. Clamping capacity

ø 300 or ø 400 x 127 mm (ø 12 or ø 16 x 5“) 21 - 62 mm (

ø 500 x 203.2 mm (ø 20 x 8.1“) 24 - 67 mm (1 - 2 5/8“)

Grinding wheel flange ø 300 or ø 400 mm (ø 12 or ø 16“) 0015.01

Grinding wheel flange ø 500 mm (20“) 0015.02

13

/16 - 2 7/16“)

Available at any time

V = constant

Spindle speed V-constant, setting infinitely variable between 1150 - 2150 rpm.

■ ø 400 / 35 m/s (ø 16“ / 115 sfpm)

■ ø 500 / 45 m/s (ø 20“ / 148 sfpm)

Only available with basic equipment

V-constant for KELCO 110 1016.03

V-constant for FANUC 1016.02

Automatic balancing unit for dynamic balancing of grinding wheels.

■ Balancing head

■ Vibration sensor with touchfree transmission of signals

■ Display and operating unit integrated in cockpit

■ Integrated gap control sensor

10

Only available with basic equipment

Balancing unit ELASO, type EB 7003 1017.01

Balancing unit MARPOSS, type E 82 1017.02

®

TECHNOLOGY FOR THE FUTURE

KEL-ACCESS

®

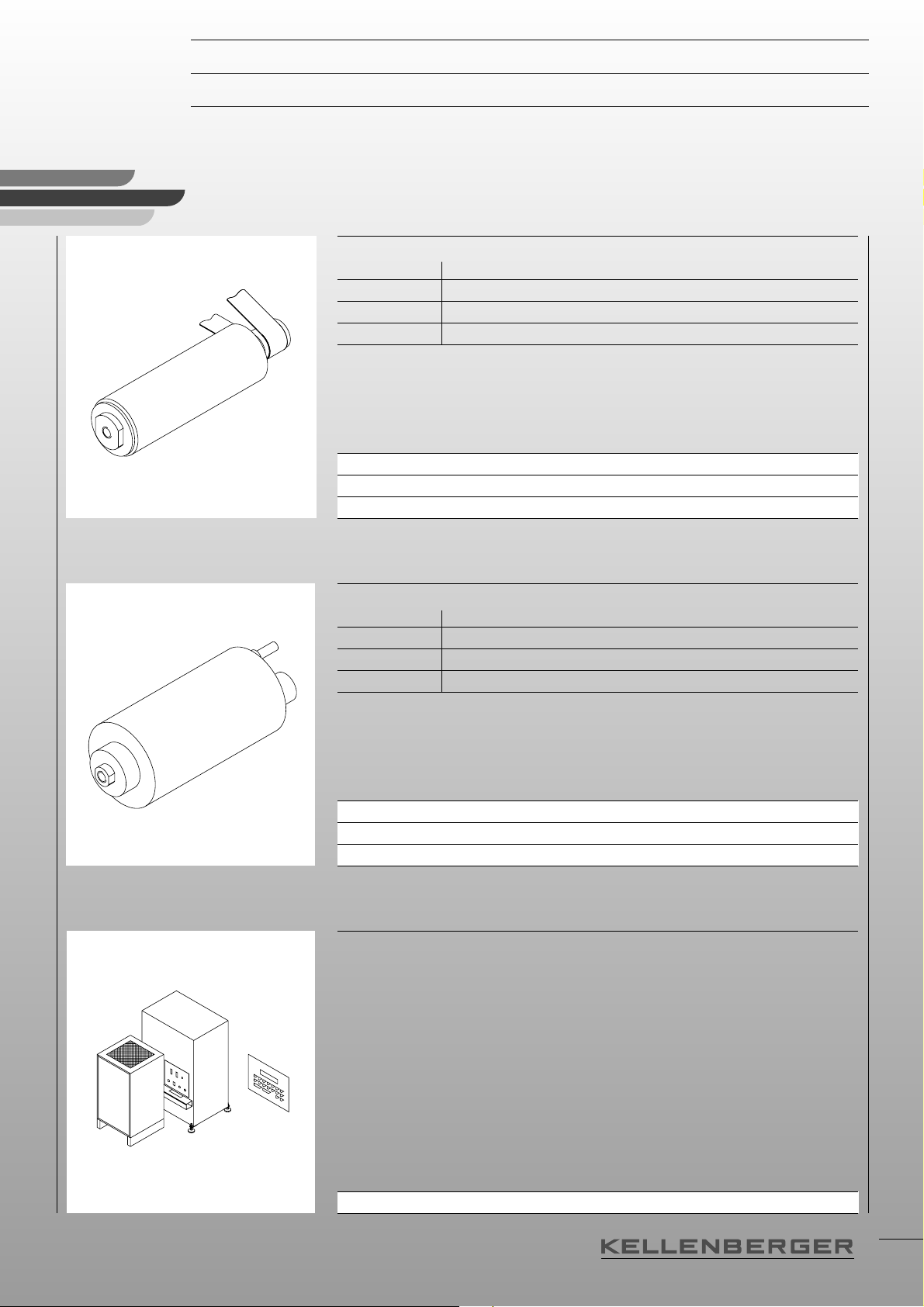

Internal grinding spindles and accessories

Belt-driven internal grinding spindles

For ID Type Dimensions Max. rpm

> ø 20 HJN 828 ø 80 x 240 mm 28000

ø 6 - 30 HJN 842 ø 80 x 230 mm 42000

ø 3 - 20 HJN 860 ø 80 x 220 mm 60000

■ consignment includes 1 set of pulleys, 1 set of flat belts and standard equipment

Available at any time

HJN 828 0013.01

HJN 842 0013.02

HJN 860 0013.03

High frequency internal grinding spindles

For ID Type Dimensions Max. rpm

> ø 20 MFV 1230 ø 120 x 265 mm 30000

ø 3 - 30 MFV 1260 ø 120 x 235 mm 60000

ø 2 - 15 MFZ 1090 ø 100 x 200 mm 90000

Requirements

■ Internal grinding equipment ø 120 mm, 1012.01

■ Operating unit 1013.04

Only available with basic equipment

MFV 1230 1013.01

MFV 1260 1013.02

MFZ 1090 1013.03

Operating unit for high frequency internal grinding spindles.

■ Operating unit

■ Gap control sensor

■ Frequency converter

■ Lubrication and coolant systems

Only available with basic equipment

Operating unit 1013.04

TECHNOLOGY FOR THE FUTURE

®

11

Loading...

Loading...