UCM-420A

Setpoint Controller

Operating and

Installation Instructions

April 1994

TM

A LARGE number

of applications in a

SMALL package...

LOCAL SETPOINT

CONTROLLER

UCM-420A

REMOTE SETPOINT

CONTROLLER

REMOTE SETPOINT

CONTROLLER WITH

LOCAL ADJUSTMENT

4-20 mA SIGNAL

GENERATOR

PULSE-WIDTH

TO ANALOG

CONVERTER

OUTPUT EXPANDER

SAMPLE AND HOLD

Section Page

How to Use This Manual ........................................... 2

Features ......................................................................2

Specifications ............................................................ 2

Installation Instructions and Dimensions ................3

General Wiring Instructions ......................................4

General Wiring Diagrams ..........................................4

Modes of Operation - Descriptions

A Remote Setpoint Controller ..............................................8

B Local Setpoint Controller ..................................................9

C Remote Setpoint Controller with Local Adjustment ..........10

D Output Expander (Multiplexed PWM) ...............................11

E Sample and Hold ..............................................................12

F PWM to 4-20 mA Converter (Single Unit or Multiplexed) 12

G 4-20 mA Signal Generator ............................................... 12

Set-up Instructions

A Remote Setpoint Controller ..............................................13

B Local Setpoint Controller ..................................................16

C Remote Setpoint Controller with Local Adjustment...........18

D Output Expander (Multiplexed PWM) ...............................22

E Sample and Hold ..............................................................26

F PWM to 4-20 mA Converter (Single Unit or Multiplexed) 27

G 4-20 mA Signal Generator ............................................... 29

Ordering Information .................................................30

1

About the

UCM-420A

The UCM-420A is a low-cost

microprocessor-based controller that uses industry-standard 4-20 mA or 1-5 VDC

input/output signals to provide

stand-alone P/I control or output

expansion.

When used as a Stand-Alone

Controller with Local Setpoint,

the UCM-420A provides proportional/integral control of VFDs,

valves, actuators, or any device

that accepts a 4-20 mA or 1-5 VDC

signal. Input may be 4-20 mA,

1-5 VDC, or PreCon Type 3

Thermistor.

When used as a Stand-Alone

Controller with Remote Setpoint

for P/I control, the setpoints

may be adjusted by a 1-5 VDC,

4-20 mA, or pulse-width modulated signal.

When used as a Remote

Setpoint Controller with Local

Adjustment, the remote setpoint

can have 100% control, or can

establish a base setpoint with the

local setpoint having a ±12.5%

adjustment.

When used as an Output

Expander, one AC or DC timebased PWM signal can control up

to eight groups of UCM-420As

independently. This produces

eight analog outputs from one

PWM controller output. Five

common jumper-selectable time

bases are available.

Table of Contents

KELE

P.O. Box 34817

Memphis, TN 38184

Phone: 901-382-4300

FAX: 901-372-2531

• Proportional / Integral Control

• DIP switch / Jumper Programming

• Sample and Hold for Failsafe

• 6-Hour Memory on Loss of Power

• Selectable Throttling Range

• Selectable Reset Rates

• Selectable Direct- or Reverse-Acting

• 4-20 mA or 1-5 VDC* Output

• 4-20 mA, 1-5 VDC or Thermistor Input

• Selectable Pulse-Width Time Base

• Status LED Indication

• Multiplex Input Operation

• Pulse-Width to 4-20 mA Converter

• Remote and/or Local Setpoint

• Local Setpoint Potentiometer Mounted on

Unit (Standard)

• Optional DIN Rail Mount

• Optional Setpoint Potentiometer on

Stainless Steel Plate

Supply voltage 24 VAC ±10% @ 100 mA (130 mA if PWM input is used) or

24 VDC ±10% @ 50 mA (65 mA if PWM input is used)

Remote setpoint input 4-20 mA, 1-5 VDC, PWM or Multiplexed PWM

Local setpoint input 4-20 mA, 1-5 VDC, three-wire potentiometer or PreCon two-wire potentiometer

PWM time base 0.1-2.65, 5.2, 12.85, 25.6 seconds or 0.59-2.93 seconds

Output 4-20 mA sourcing (1-5 VDC with 250 ohm resistor)

Output resolution 256 steps

Output burden 650 ohm maximum

Input 4-20 mA, 1-5 VDC or PreCon Type 3 Thermistor (thermistor range 50° to 90°F)*

Input impedance 250 ohms (mA)/10,000 ohms (voltage)

Accuracy ±1%

Operating temperature 32° to 158°F (0° to 70°C)

Humidity limit 95% noncondensing

How to Use This Manual

2

The UCM-420A is a very versatile product designed

to cover a wide variety of control applications. To

properly apply the UCM-420A, refer to the MODES

OF OPERATION (beginning on page 8) and select

the configuration you desire for your control system.

Then proceed to the section and page number indicated for the proper application, wiring and set-up of

the UCM-420A.

* Other ranges available

* Requires external 250 ohm resistor

FEATURES

SPECIFICATIONS

INSTALLATION

Mount the UCM-420A using the

mounting tabs on the unit. If purchased with the UCO-47 DIN Rail

Mounting Option, mount on a DIN rail.

The UCM-420A must be installed in a

clean, dry location, avoiding areas of

temperature extremes, corrosive

vapors, or electromagnetic interference.

Failure to follow these directions could

result in damage to the UCM-420A or

other connected equipment, as well as

affect the manufacturer's warranty.

MOUNTING

TABS

Installation and Dimensions

DIN RAIL

MOUNTING

OPTION

3

DIMENSIONS

in

(cm)

SIDE VIEW

4.8

(12.19)

TOP VIEW

MOUNTING

SLOTS FOR

OPTIONAL

DIN RAIL

ADAPTER

1.5

(3.81)

2.0

(5.08)

2.9

(7.37)

3.4

(8.64)

(11.68)

4.0

(10.16)

4.6

PWM

INPUT

PWM

INPUT

REM SPT

INPUT

LOC SPT

POT +

LOC SPT

INPUT

LOC SPT

POT –

FEEDBK

INPUT

24V PWR

COMMON

MA SIG

OUTPUT

1

2

11

12

JUMPER

POSITION

NUMBER

JUMPER

PINS

24 VAC

OR

24 VDC

+

–

CONTACT AT BAS CONTROLLER

7

8

9

10

3

4

5

6

4

PWM

INPUT

PWM

INPUT

REM SPT

INPUT

LOC SPT

POT +

LOC SPT

INPUT

LOC SPT

POT –

COMMON

MA SIG

OUTPUT

24 VAC

OR

24 VDC

+

–

CONTACT AT BAS CONTROLLER

FEEDBK

INPUT

24V PWR

1

2

11

12

JUMPER

POSITION

NUMBER

JUMPER

PINS

7

8

9

10

3

4

5

6

Make all connections according to wiring diagrams and in compliance with national and local codes. Make all con-

nections with power removed. Failure to do so may result in circuit board damage. Shielded cable is recommended

for input and analog setpoint wiring. The shield should be connected to the UCM-420A "common" terminal. At the

opposite end, the shield is not to be connected, and should be taped back. In cases where more wires are required

to be connected to the common terminal block of the UCM-420A than will fit under the screw on the terminal block,

connect as follows:

A. Place the 24 VDC minus power wire directly under the "common" screw.

B. Place one or two short splice wires directly under the "common" screw and tighten screw.

C. Make all required "common" connections to the splice wires using crimp connections or

wire nuts.

Make all wiring connections for local and/or remote setpoint, input, power, and outputs per the General Wiring

Diagrams which follow.

The PWM Remote Setpoint Signal may be powered by the UCM-420A power supply or by a separate power

source. If a separate power source is used, the PWM signal may be 24 VAC or 24 VDC. There is no polarity on the

PWM terminals. Either leg of the PWM signal may be switched by the controller.

(See General Wiring Diagrams 1, 2 & 3.)

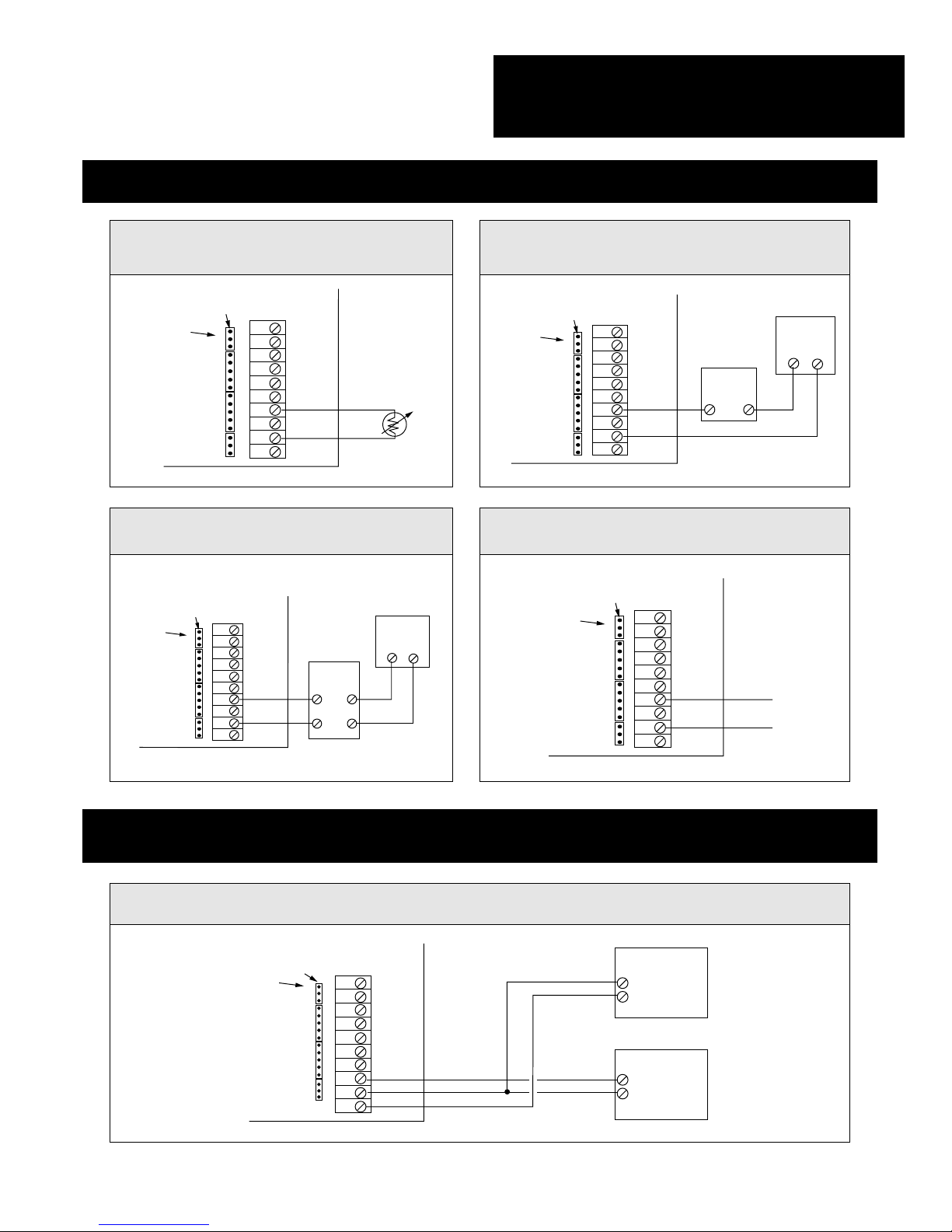

REMOTE SETPOINT WIRING - PULSE-WIDTH SETPOINT (DIAGRAMS 1, 2 & 3)

GENERAL WIRING DIAGRAM 1 - Using the UCM-420A power supply for PWM pulse and switching

positive leg of the PWM pulse circuit.

GENERAL WIRING DIAGRAM 2 - Using the UCM-420A power supply for PWM pulse and switching

negative leg of the PWM pulse circuit.

General Wiring

Instructions & Diagrams

5

General Wiring

Diagrams (Cont.)

PWM

INPUT

PWM

INPUT

REM SPT

INPUT

LOC SPT

POT +

LOC SPT

INPUT

LOC SPT

POT –

COMMON

MA SIG

OUTPUT

24 VAC

OR

24 VDC

+

–

24 VAC

OR

24 VDC

+

–

CONTACT AT BAS CONTROLLER

(EITHER LEG MAY BE SWITCHED)

FEEDBK

INPUT

24V PWR

1

2

11

12

JUMPER

POSITION

NUMBER

JUMPER

PINS

7

8

9

10

3

4

5

6

PWM

INPUT

PWM

INPUT

REM SPT

INPUT

LOC SPT

POT +

LOC SPT

INPUT

LOC SPT

POT –

COMMON

MA SIG

OUTPUT

24 VAC

OR

24 VDC

+

–

+

–

4-20 MA REMOTE

SETPOINT SIGNAL

FEEDBK

INPUT

24V PWR

1

2

11

12

JUMPER

POSITION

NUMBER

JUMPER

PINS

7

8

9

10

3

4

5

6

PWM

INPUT

PWM

INPUT

REM SPT

INPUT

LOC SPT

POT +

LOC SPT

INPUT

LOC SPT

POT –

COMMON

MA SIG

OUTPUT

24 VAC

OR

24 VDC

+

–

+

–

1-5 VDC REMOTE

SETPOINT SIGNAL

FEEDBK

INPUT

24V PWR

1

2

11

12

JUMPER

POSITION

NUMBER

JUMPER

PINS

7

8

9

10

3

4

5

6

GENERAL WIRING DIAGRAM 3 - Completely separate PWM and UCM-420A circuits.

REMOTE SETPOINT - ANALOG SETPOINT WIRING (DIAGRAMS 4 & 5)

GENERAL WIRING DIAGRAM 4 - 4-20 mA remote setpoint

GENERAL WIRING DIAGRAM 5 - 1-5 VDC remote setpoint

6

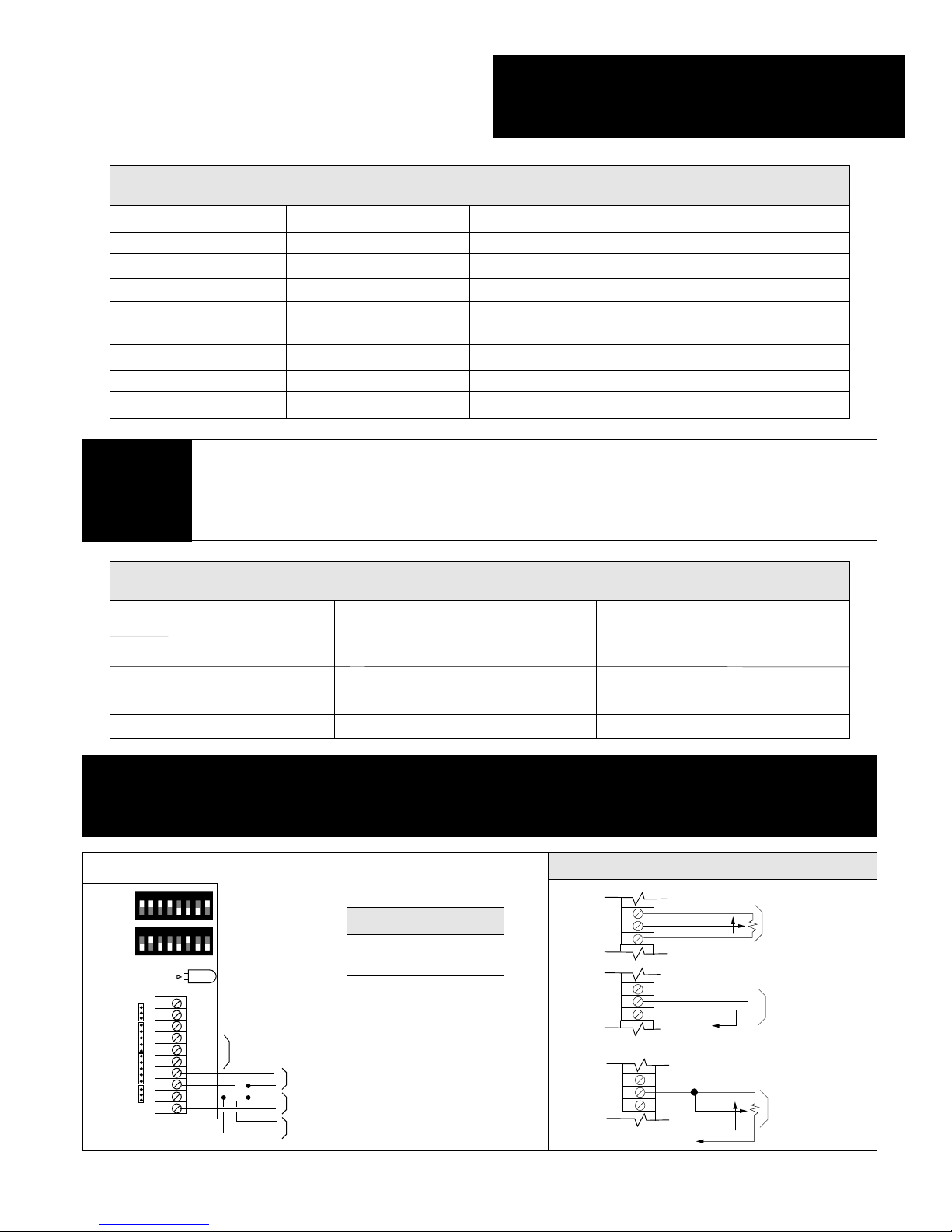

LOCAL SETPOINT WIRING (DIAGRAMS 6-9)

PWM

INPUT

PWM

INPUT

REM SPT

INPUT

LOC SPT

POT +

LOC SPT

INPUT

LOC SPT

POT –

COMMON

MA SIG

OUTPUT

1-5 VDC

LOCAL

SETPOINT

SIGNAL

+

–

FEEDBK

INPUT

24V PWR

1

2

11

12

JUMPER

POSITION

NUMBER

JUMPER

PINS

7

8

9

10

3

4

5

6

PWM

INPUT

PWM

INPUT

REM SPT

INPUT

LOC SPT

POT +

LOC SPT

INPUT

LOC SPT

POT –

COMMON

MA SIG

OUTPUT

4-20 MA

LOCAL

SETPOINT

SIGNAL

+

–

FEEDBK

INPUT

24V PWR

1

2

11

12

JUMPER

POSITION

NUMBER

JUMPER

PINS

7

8

9

10

3

4

5

6

PWM

INPUT

PWM

INPUT

REM SPT

INPUT

LOC SPT

POT +

LOC SPT

INPUT

LOC SPT

POT –

COMMON

MA SIG

OUTPUT

INCREASE SETPOINT

FEEDBK

INPUT

24V PWR

PRECON TWO-WIRE

POTENTIOMETER

("XA" OPTION ON

TEMPERATURE SENSOR)

1

2

11

12

JUMPER

POSITION

NUMBER

JUMPER

PINS

7

8

9

10

3

4

5

6

PWM

INPUT

PWM

INPUT

REM SPT

INPUT

LOC SPT

POT +

LOC SPT

INPUT

LOC SPT

POT –

COMMON

MA SIG

OUTPUT

INCREASE SETPOINT

*WHEN A THREE-WIRE POTENTIOMETER

IS USED, JUMPER PLUGS MUST BE LEFT

OFF POSITIONS 3, 4, 5 AND 6.

FEEDBK

INPUT

24V PWR

THREE-WIRE

POTENTIOMETER

5 KW TO 50 KW

MAXIMUM

RESISTANCE

RED

GREEN

BLACK

1

2

11

12

JUMPER

POSITION

NUMBER

JUMPER

PINS

7

8

9

10

3

4

5

6

GENERAL WIRING DIAGRAM 6 - Using a three-wire potentiometer for local setpoint. (The UCM-420A

is shipped with a three-wire potentiometer mounted and wired per this diagram.)

GENERAL WIRING DIAGRAM 7 - Using a PreCon two-wire potentiometer ("XA" option on a temperature sensor) for local setpoint.

GENERAL WIRING DIAGRAMS 8 & 9 - Using an analog (4-20 mA or 1-5 VDC) signal for local setpoint.

Analog signals are normally used as remote setpoints. However, the UCM-420A may be configured to

accept an analog signal for a local setpoint if this is required.

GENERAL WIRING DIAGRAM 8 -

4-20 mA local setpoint

GENERAL WIRING DIAGRAM 9 -

1-5 VDC local setpoint

General Wiring

Diagrams (Cont.)

PWM

INPUT

PWM

INPUT

REM SPT

INPUT

LOC SPT

POT +

LOC SPT

INPUT

LOC SPT

POT –

COMMON

MA SIG

OUTPUT

1

2

3

4

5

6

7

8

9

10

11

12

JUMPER

POSITION

NUMBER

JUMPER

PINS

24 VAC

OR

24 VDC

+

–

–

+

CONTROLLED

DEVICE

FEEDBK

INPUT

24V PWR

7

General Wiring

Diagrams (Cont.)

INPUT WIRING (DIAGRAMS 10-12)

PWM

INPUT

PWM

INPUT

REM SPT

INPUT

LOC SPT

POT +

LOC SPT

INPUT

LOC SPT

POT –

COMMON

MA SIG

OUTPUT

TWO-WIRE

4-20 MA

DEVICE

– +

+ –

24 VDC

POWER

SUPPLY

FEEDBK

INPUT

24V PWR

1

2

11

12

JUMPER

POSITION

NUMBER

JUMPER

PINS

7

8

9

10

3

4

5

6

PWM

INPUT

PWM

INPUT

REM SPT

INPUT

LOC SPT

POT +

LOC SPT

INPUT

LOC SPT

POT –

COMMON

MA SIG

OUTPUT

1-5 VDC

INPUT

SIGNAL

+

–

FEEDBK

INPUT

24V PWR

1

2

11

12

JUMPER

POSITION

NUMBER

JUMPER

PINS

7

8

9

10

3

4

5

6

PWM

INPUT

PWM

INPUT

REM SPT

INPUT

LOC SPT

POT +

LOC SPT

INPUT

LOC SPT

POT –

COMMON

MA SIG

OUTPUT

PRECON TYPE 3

THERMISTOR

FEEDBK

INPUT

24V PWR

1

2

11

12

JUMPER

POSITION

NUMBER

JUMPER

PINS

7

8

9

10

3

4

5

6

PWM

INPUT

PWM

INPUT

REM SPT

INPUT

LOC SPT

POT +

LOC SPT

INPUT

LOC SPT

POT –

COMMON

MA SIG

OUTPUT

FOUR-WIRE

4-20 MA

DEVICE

+ +

+ –

24 VDC

POWER

SUPPLY

– –

FEEDBK

INPUT

24V PWR

1

2

11

12

JUMPER

POSITION

NUMBER

JUMPER

PINS

7

8

9

10

3

4

5

6

GENERAL WIRING DIAGRAM 10 PreCon Type 3 Thermistor input

GENERAL WIRING DIAGRAM 11B 4-20 mA input from a four-wire device

POWER SUPPLY & OUTPUT WIRING (DIAGRAM 13)

GENERAL WIRING DIAGRAM 13 - Power supply and output wiring

GENERAL WIRING DIAGRAM 11A 4-20 mA input from a two-wire device

GENERAL WIRING DIAGRAM 12 1-5 VDC input signal

8

The UCM-420A is a versatile, low-cost microprocessor-based proportional/integral controller which may be used for a wide variety of control applications.

To select the mode of operation required, please review the descriptions on the following

pages.

EXAMPLE: REMOTE SETPOINT CONTROLLER - Hot Water Reset

In this example, a BAS controller is monitoring outdoor air temperature and sending a time-based pulsewidth signal to the UCM-420A to set the system hot water temperature. By using this control system, the

BAS may also control the hot water temperature based on time of day, minimum space temperature, etc.

The UCM-420A accepts the setpoint signal from the BAS and the input from the hot water temperature

sensor and sends a proportional/integral control signal to the three-way valve to maintain the system hot

water temperature as programmed.

HOT WATER

RESET VALVE

4-20 MA P/I

CONTROL SIGNAL

UCM-420A

HOT WATER SUPPLY

FROM BOILER

PWM REMOTE SETPOINT SIGNAL

4-20 MA TEMPERATURE

INPUT SIGNAL

BAS

CONTROLLER

RTD &

TRANSMITTER

HOT WATER

SUPPLY

TO SYSTEM

HOT WATER

RETURN

FROM SYSTEM

A

Remote Setpoint Controller

When the UCM-420A is used as a remote setpoint controller, a 4-20 mA, 1-5 VDC or time-based pulse-width signal

from a BAS controller sends a setpoint signal to the UCM-420A. The UCM-420A monitors a 4-20 mA, 1-5 VDC, or

thermistor input from the process being controlled to provide a proportional/integral control signal to the controlled

device. This signal may be direct- or reverse-acting. See page 13 for instructions on operating the UCM-420A in

this mode.

Modes of Operation

VFD

UCM-420A

T30-030

AC POWER

IN

STATIC

PRESSURE

TUBING

4-20 MA

P/I

CONTROL

SIGNAL

SUPPLY

AIR

RETURN

AIR

VAV TERMINAL

VAV TERMINAL

VAV TERMINAL

9

When the UCM-420A is used as a local setpoint controller, the potentiometer mounted on the unit may control the

setpoint. If this is not desired, a UCM-SPA setpoint potentiometer or PreCon "XA" Setpoint Option on a temperature sensor may be wired to the "Local Setpoint" terminals as shown in the wiring diagrams. (The local setpoint may

also be configured to accept a 4-20 mA or 1-5 VDC signal, although these signals would normally be used as a

remote setpoint). A 4-20 mA, 1-5 VDC, or thermistor input (with a range of 50 to 90°F)* from the process being controlled allows the UCM-420A to monitor the system and provide a proportional/integral, direct- or reverse-acting

signal to the device being controlled. See page 16 for instructions on operating the UCM-420A in this mode.

*Other ranges available

Local Setpoint Controller

Modes of Operation (Cont.)

EXAMPLE: LOCAL SETPOINT CONTROLLER - Static Pressure Control

In this example, the input to the UCM-420A is a 4-20 mA signal from a pressure transducer that monitors duct pressure. The setpoint is adjusted by using the setpoint potentiometer mounted on the UCM-420A. The UCM-420A then

sends a 4-20 mA control signal to the VFD which controls the AHU fan speed, which in turn, determines duct pressure.

B

10

Remote Setpoint Controller With Local Adjustment

C

When the UCM-420A is used as a remote setpoint controller with local adjustment, a 4-20 mA, 1-5 VDC, or timebased pulse-width signal from a BAS controller sends a setpoint signal to the UCM-420A. The setpoint potentiometer on the UCM-420A or a UCM-SPA setpoint potentiometer wired to the "Local Setpoint" terminals may then

be used to adjust the setpoint ±12.5% of the input range, or a PreCon "XA" Setpoint Option on a temperature

sensor may be used as a local setpoint and may adjust the setpoint ±9.4% of the input range. (A 4-20 mA or 1-5 VDC

signal may also be used as the "Local Setpoint" signal, although these are normally remote setpoint signals. When

these are used as local setpoints in this mode, they have the authority to adjust the setpoint ±12.5% of the input

range.) A 4-20 mA, 1-5 VDC, or thermistor input (with a range of 50 to 90°F)* from the process being controlled

allows the UCM-420A to monitor the system and provide a proportional/integral, direct- or reverse-acting signal to

the device being controlled. See page 18 for instructions on operating the UCM-420A in this mode.

* Other ranges available

EXAMPLE: REMOTE SETPOINT CONTROLLER WITH LOCAL ADJUSTMENT - VAV Control

In this example, a PreCon ST-S3E-XA Thermistor with setpoint adjustment is located in the space being controlled. The setpoint is a 4-20 mA signal from a BAS controller. The PreCon "XA" setpoint adjuster will have

authority to adjust the setpoint ±3.76°F. [(90 to 50°F*) x 0.094 = 3.76°F] In this example, the BAS controller could

be programmed to send a setpoint signal for 72°F (12.8 mA) during the day, 82°F (16.8 mA) at night, etc.

Modes of Operation (Cont.)

BAS

CONTROLLER

SUPPLY

AIR

4-20 MA P/I

CONTROL

SIGNAL

ACT.

VAV

TERMINAL

4-20 MA REMOTE

SETPOINT SIGNAL

UCM-420A

SUPPLY

AIR

THERMISTOR

TEMP INPUT

LOCAL SETPOINT

ADJUST

ST-S3E-XA

TEMPERATURE SENSOR

WITH SETPOINT ADJUST

11

Modes of Operation (Cont.)

SUPPLY

AIR

VAV

TERMINAL

ACT.

SUPPLY

AIR

UCM-420A

ST-S3P

SUPPLY

AIR

VAV

TERMINAL

ACT.

SUPPLY

AIR

UCM-420A

ST-S3P

SUPPLY

AIR

VAV

TERMINAL

ACT.

SUPPLY

AIR

UCM-420A

ST-S3P

TEMPERATURE

SENSOR

4-20 MA P/I

CONTROL

SIGNAL

+

–

CONTROLLER

N.O. PWM

CONTACT

In this example, one time-based

pulse-width output from a BAS controller is used to send a setpoint

signal to three UCM-420A setpoint

controllers. Each of these may have

a different setpoint. Each UCM-420A

also accepts an input from a PreCon

Type 3 Temperature Sensor in the

space being controlled. The

UCM-420As send 4-20 mA proportional/integral control signals to the

VAV terminals so that the input

matches the setpoint. Multiple

UCM-420As may be assigned the

same address so that they have the

same setpoint. Eight different

addresses are available so that up to

eight groups of UCM-420As may be

controlled by one BAS output.

Instructions on setting UCM-420A

addresses and how to update the

setpoint with the BAS pulse-width

signal are on page 22.

EXAMPLE: UCM-420As USED AS OUTPUT EXPANDERS - Multiplexed VAV Control

The UCM-420A may be operated in a multiplexed pulse-width modulation mode so that one BAS output may control

up to eight groups of UCM-420As with each group able to have a different setpoint. When operated in this mode,

each UCM-420A accepts a 4-20 mA, 1-5 VDC, or thermistor input (with a range of 50 to 90°F)* from the process

being controlled. The "PWM INPUT" terminals are wired to the normally open contacts on a BAS controller. The

BAS controller is programmed to send a series of 24 VAC or 24 VDC time-based pulse-width signals to the

UCM-420As. These PWM signals select which units are to be addressed, and adjust their setpoints as required.

The UCM-420As which are not being addressed ignore the new setpoint signal and continue to control based on

their previous setpoint. Each UCM-420A will monitor its input signal and send a P/I control signal to the controlled

device to maintain the required setpoint. When operated in this mode, the local setpoint may also be used to adjust

the setpoint which has been set by the BAS controller. The setpoint potentiometer on the UCM-420A or a UCM-

SPA setpoint potentiometer wired to the "Local Setpoint" terminals may be used to adjust the setpoint ±12.5% of the

input range, or a PreCon "XA" Setpoint Option on a temperature sensor may be used as a local setpoint and may

adjust the setpoint ±9.4% of the input range. (A 4-20 mA or 1-5 VDC signal may also be used as the "Local

Setpoint" signal, although these are normally remote setpoint signals. When these are used as local setpoints in this

mode, they have the authority to adjust the setpoint ±12.5% of the input range.) See page 22 for instructions on

operating the UCM-420A in this mode.

* Other ranges available

D

Output Expander (Multiplexed PWM)

12

If the device to be controlled by the UCM-420A needs to be calibrated before the system is started up, the UCM-420A

may be used to generate a 4-20 mA output signal in 1 mA steps. In this mode the UCM-420A ignores all input and

setpoint signals and outputs a signal from 4-20 mA when DIP switches are turned off or on as required. See Page

29 for instructions on operating the UCM-420A in this mode.

THIS CONCLUDES MODES OF OPERATION. THE FOLLOWING SET-

UP INSTRUCTIONS WILL GUIDE YOU THROUGH THE STEPS NECESSARY TO ACHIEVE THE MODE OF OPERATION YOU REQUIRE.

E

Sample and Hold

The UCM-420A may be used to monitor and pass through a 4-20 mA or 1-5 VDC signal. If the signal being monitored is lost, the UCM-420A will output the last valid value for the signal until the signal returns. On a power loss, the

signal is remembered up to six hours. When used in this mode the UCM-420A may be programmed to either

reverse the signal being monitored, or pass it through direct. See page 26 for instructions on operating the UCM-420A

in this mode.

F

Pulse-Width to 4-20 mA Converter (Single or Multiplexed)

G

4-20 mA Signal Generator

In this mode the UCM-420A converts a time-based pulse-width AC or DC signal to a 4-20 mA output. By using the

multiplexed mode, multiple UCM-420As may be controlled by one BAS output. In this mode all setpoint and input

signals are ignored and the output signal is based on the pulse-width signal only. The output signal is retained up to

6 hours on a loss of power. Upon a power return, the saved value is output until a new pulse signal is received. The

output may be direct- or reverse-acting. See page 27 for instructions on operating the UCM-420A in this mode.

Modes of Operation (Cont.)

If remote setpoint is set for pulse-width modulation, select the pulse-width time base from

TABLE 2. If remote setpoint is by 4-20 mA or 1-5 VDC, proceed to Step A-3.

Mode Switch Switch Switch Switch Set jumper

A1 A2 B1 B2 plugs on

4-20 mA Remote setpoint ON OFF OFF OFF Position 1

1-5 VDC Remote setpoint ON OFF OFF OFF Position 2

PWM Remote setpoint

(no multiplex mode) ON OFF ON OFF Position 1

13

Set-Up Instructions

A

SET-UP OF THE UCM-420A AS A REMOTE SETPOINT

CONTROLLER (SEE PAGE 8)

Set the DIP switches and jumpers as shown in TABLE 1 for the remote setpoint to be used.

FAILSAFE FEATURE

On a loss of power, the remote setpoint value is retained for up to 6 hours. Upon power return on a unit with

PWM remote setpoint, the saved value will be used for control until a new PWM pulse is received.

Upon power return on a unit with analog remote setpoint, the saved value will be used to control until a new

analog setpoint signal is received.

If power is not lost, but the analog remote setpoint signal is suddenly lost (because of a loose wire or

Building Automation System failure), the UCM-420A will continue to control with the previous setpoint until a

valid signal returns.

STEP

A-2

Time base B6 B7 B8

0.1-2.65 seconds OFF OFF OFF

0.1-5.2 seconds OFF OFF ON

0.1-12.85 seconds OFF ON OFF

0.1-25.6 seconds OFF ON ON

0.59-2.93 seconds ON OFF OFF

STEP

A-1

Setpoint = (pulse length) (input range)

+ input lower value

time base

Example: If pulse length is 12.8 sec., time base is 25.6 sec., and the input sensor has a 4-20 mA range of

20° to 120°F, the setpoint could be determined as follows: Setpoint = (12.8) (120-20)

+ 20 = 70.2°F

(25.6 - 0.1)

TABLE 2

TABLE 1

Throttling Range Switch A6 Switch A7 Switch A8

10% OFF OFF OFF

20% OFF OFF ON

35% OFF ON OFF

50% OFF ON ON

65% ON OFF OFF

80% ON OFF ON

90% ON ON OFF

100% ON ON ON

Input Set jumper plugs on

4-20 mA Positions 7 and 11

1-5 VDC Positions 8 and 11

PreCon Type 3 Thermistor Positions 10 and 12

14

Select the type of input to be used and set the jumper per TABLE 3. The input may be a 4-20 mA

or 1-5 volt signal that measures temperature, pressure, humidity, etc., or a PreCon Type 3

Thermistor. If the thermistor is used, the range of the thermistor is 50° to 90°F.*

*Other ranges available

STEP

A-3

TABLE 3

TABLE 4

Set switch A3 in the "ON" position for Direct-Acting Control and in the "OFF" position for

Reverse-Acting Control. (

Direct-Acting Control

is when an increase in the input signal above set-

point causes the output signal to increase.

Reverse-Acting Control

is when an increase in the input

signal above setpoint causes the output signal to decrease.)

STEP

A-4

Set the proportional throttling range per TABLE 4. The throttling range is the amount of signal

change at the input required to cause the output signal to go through its entire range (4-20 mA).

For example, a 20% throttling range means that a 1 mA change in the input causes a 5 mA change

in the output signal. When using the optional thermistor input, a 1°F change in input is the equivalent of 0.4 mA change in the mA input mode. The correct throttling range cannot be calculated, but

must be adjusted for each application. Generally, systems that respond quickly should have a narrower throttling range than systems that respond slowly.

STEP

A-5

Set-Up Instructions (Cont.)

Resets/Minute Switch A4 Switch A5

Reset OFF OFF OFF

0.5 Resets/Minute OFF ON

1 Resets/Minute ON OFF

2 Resets/Minute ON ON

15

PWM

INPUT

PWM

INPUT

REM SPT

INPUT

LOC SPT

POT +

LOC SPT

INPUT

LOC SPT

POT –

FEEDBK

INPUT

24 PWR

COMMON

MA SIG

OUTPUT

1

2

3

4

5

6

7

8

9

10

11

12

B3

0

0

0

0

1

1

1

1

B6

0

0

0

0

1

B7

0

0

1

1

X

B8

0

1

0

1

X

B4

0

0

1

1

0

0

1

1

B5

0

1

0

1

0

1

0

1

MUX

ADDR

1

2

3

4

5

6

7

8

A6

0

0

0

0

1

1

1

1

A7

0

0

1

1

0

0

1

1

A8

0

1

0

1

0

1

0

1

PROP

T.R.

10%

20%

35%

50%

65%

80%

90%

100%

UCM-420A

TIME

BASE

2.65

5.2

12.85

25.6

.59-2.93

A4

0

0

1

1

A5

0

1

0

1

RESET

PER MIN

OFF

0.5

1

2

"1" MEANS

TURN SWITCH ON

"0" MEANS

TURN SWITCH OFF

SWITCH OFF

SWITCH ON

A3

A2

A1

B1

B2

REVERSE ACTING

BOTH OFF >> REMOTE SETPT

SAMPLE AND HOLD MODE

BOTH OFF >> ANALOG

REMOTE SETPOINT

DIRECT ACTING

LOCAL SETPT ENABLE

REMOTE SETPT ENABLE

PWM REM SETPT SGLE UNIT

PWM REM SETPT MUX MODE

LOCAL

SETPOINT

FEEDBACK

REMOTE

SETPOINT

STATUS

B

A

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

24 VAC OR 24 VDC POWER

4-20 MA, 1-5 VOLT OR THERMISTOR INPUT SIGNAL

4-20 MA SOURCING OUTPUT SIGNAL TO

CONTROLLED DEVICE

4-20 MA OR 1-5 VOLT REMOTE SETPOINT SIGNAL

(ONLY IF REMOTE SETPOINT IS ANALOG SIGNAL)

24 VAC OR 24 VDC PWM SIGNAL FROM BAS

(ONLY IF REMOTE SETPOINT IS PWM)

CONTACT AT CONTROLLER*

+

–

+

–

–

+

+

–

+

–

Steady Green - Power On

Dark - Power Loss

Steady Red - PWM Signal Present

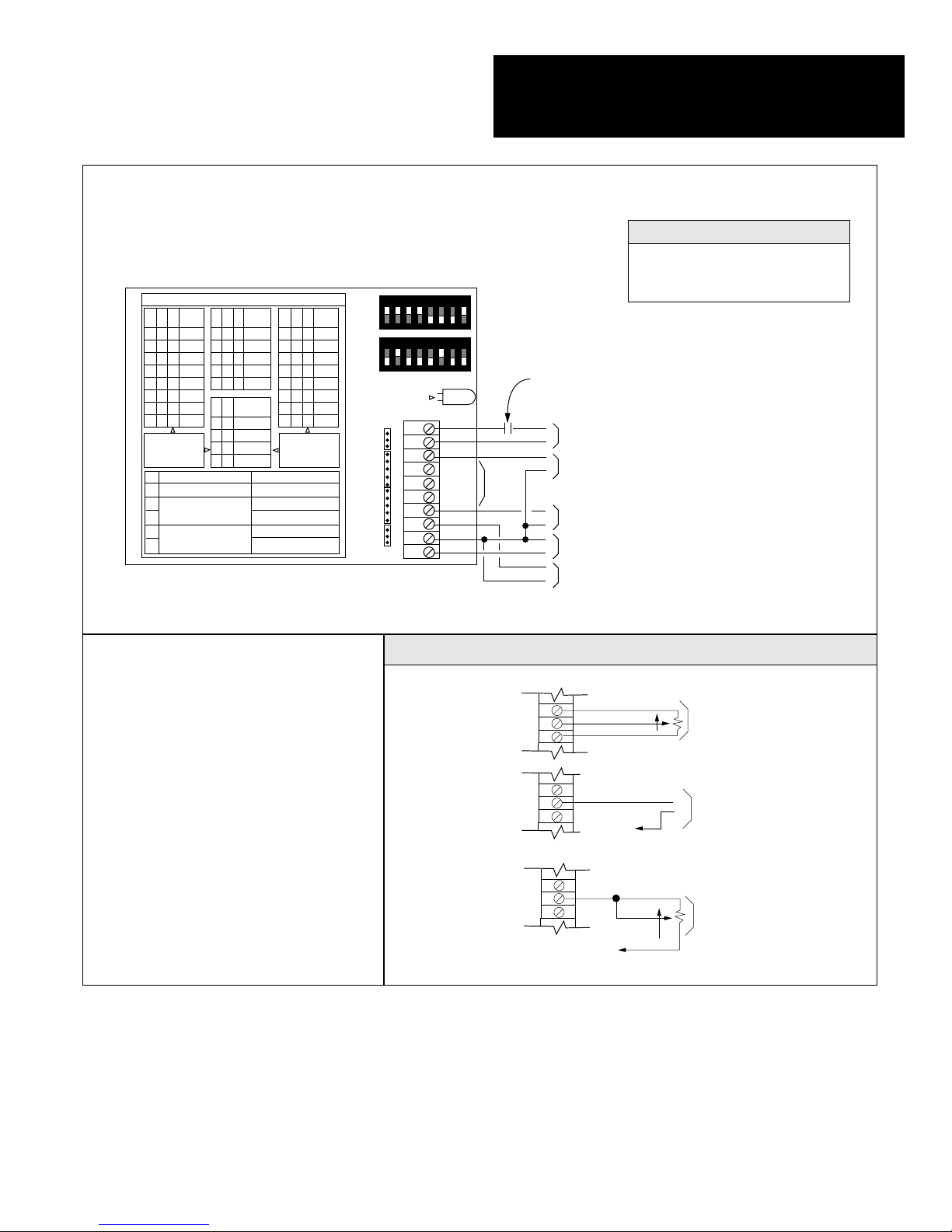

WIRING THE UCM-420A AS A REMOTE SETPOINT CONTROLLER

Set the integral reset rate per TABLE 5. The integral reset feature corrects the output of the

UCM-420A to compensate for the offset inherent in proportional-only controllers. The integral reset

ramps the output in the direction that forces the input signal to exactly match the setpoint. The

number of times per minute this offset is overcome by the output signal is the integral reset rate. If

the output of the UCM-420A is used for digital control, set the integral reset "OFF."

STEP

A-6

Set-Up Instructions (Cont.)

TABLE 5

THIS CONCLUDES SET-UP OF THE UCM-420A AS A REMOTE SETPOINT CONTROLLER. WIRE THE UCM-420A PER THE WIRING

DIAGRAM BELOW AND PER GENERAL WIRING DIAGRAMS.

LED INDICATION

*NOTE: PWM contact at controller may switch either positive or negative leg of circuit, and PWM

circuit may use the same power supply as the UCM-420A, or a separate power supply. See the

General Wiring Diagram Section for detailed wiring.

Input Set jumper plugs on

4-20 mA Positions 7 &11

1-5 VDC Positions 8 & 11

PreCon Type 3 Thermistor Positions 10 & 12

Mode Switch Switch Set jumper

A1 A2 plugs on

Three-wire pot Local setpoint OFF ON Position 1 (No jumper on 3-6)

4-20 mA* Local setpoint OFF ON Positions 1 & 3

1-5VDC* Local setpoint OFF ON Positions 1 & 4

Two-wire pot* Local setpoint OFF ON Positions 1 & 6

16

B

SET-UP OF THE UCM-420A AS A LOCAL SETPOINT

CONTROLLER (SEE PAGE 9)

Set the DIP switches and jumpers as shown in TABLE 6 for the local setpoint to be used.

STEP

B-1

TABLE 6

TABLE 7

*UCM-420A comes from the factory with an integral three-wire local setpoint potentiometer. To use any

other local setpoint option, installer must first remove existing three wires from local setpoint terminals on

UCM-420A terminal block.

Select the type of input to be used and set the jumpers per TABLE 7. The input may be a 4-20 mA

or 1-5 volt signal which measures temperature, pressure, humidity, etc. or a PreCon Type 3

Thermistor. If the thermistor is used, the range of the thermistor input is 50 to 90°F.*

*Other ranges available

STEP

B-2

Set switch A3 in the "ON" position for Direct-Acting Control and in the "OFF" position for

Reverse-Acting Control. (

Direct-Acting Control

is when an increase in the input signal above set-

point causes the output signal to increase.

Reverse-Acting Control

is when an increase in the input

signal above setpoint causes the output signal to decrease.)

STEP

B-3

Set the proportional throttling range per TABLE 8. The throttling range is the amount of signal

change at the input required to cause the output signal to go through its entire range (4-20 mA).

For example, a 20% throttling range means that a 1 mA change in the input causes a 5 mA change

in the output signal. When using the optional thermistor input, a 1°F change in input is the equivalent of 0.4 mA change in the mA input mode. The correct throttling range cannot be calculated, but

must be adjusted for each application. Generally, systems that respond quickly should have a narrower throttling range than systems that respond slowly.

STEP

B-4

Set-Up Instructions (Cont.)

Resets/Minute Switch A4 Switch A5

Reset OFF OFF OFF

0.5 Resets/Minute OFF ON

1 Resets/Minute ON OFF

2 Resets/Minute ON ON

Throttling Range Switch A6 Switch A7 Switch A8

10% OFF OFF OFF

20% OFF OFF ON

35% OFF ON OFF

50% OFF ON ON

65% ON OFF OFF

80% ON OFF ON

90% ON ON OFF

100% ON ON ON

17

PWM

INPUT

PWM

INPUT

REM SPT

INPUT

LOC SPT

POT +

LOC SPT

INPUT

LOC SPT

POT –

FEEDBK

INPUT

24 PWR

COMMON

MA SIG

OUTPUT

1

2

3

4

5

6

7

8

9

10

11

12

LOCAL

SETPOINT

FEEDBACK

REMOTE

SETPOINT

STATUS

B

A

24 VAC OR 24 VDC POWER

4-20 MA, 1-5 VOLT OR THERMISTOR INPUT SIGNAL

4-20 MA SOURCING OUTPUT SIGNAL TO

CONTROLLED DEVICE

+

–

–

+

+

–

SEE

LOCAL

SETPOINT

WIRING

OPTIONS

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

WIRING THE UCM-420A AS A LOCAL SETPOINT CONTROLLER

LOCAL SETPOINT WIRING OPTIONS

Steady Green - Power On

Dark - Power Loss

LED INDICATION

TABLE 8

Set the integral reset rate per TABLE 9. The integral reset feature corrects the output of the

UCM-420A to compensate for the offset inherent in proportional-only controllers. The integral reset

ramps the output in the direction that forces the input signal to exactly match the setpoint. The

number of times per minute this offset is overcome by the output signal is the integral reset rate. If

the output of the UCM-420A is used for digital control, set the integral reset rate "OFF."

STEP

B-5

TABLE 9

THIS CONCLUDES SET-UP OF THE UCM-420A AS A LOCAL SETPOINT CONTROLLER. WIRE THE UCM-420A PER THE WIRING DIAGRAM BELOW AND

PER GENERAL WIRING DIAGRAMS.

Set-Up Instructions (Cont.)

LOC SPT POT +

LOC SPT INPUT

LOC SPT POT –

LOC SPT POT +

LOC SPT INPUT

LOC SPT POT –

INCREASE SETPONT

+

–

COMMON

THREE-WIRE POTENTIOMETER

(5KW TO 50 KW )

LOCAL SETPOINT

(FACTORY INSTALLED

ON BASIC MODEL)

4-20 MA OR 1-5 VOLT

LOCAL SETPOINT

LOC SPT POT +

LOC SPT INPUT

LOC SPT POT –

COMMON

INCREASE

SETPONT

TWO-WIRE POTENTIOMETER

LOCAL SETPOINT

("XA OPTION ON

PRECON THERMISTOR)

Setpoint = (pulse length) (input range)

+ input lower value

time base

Example: If pulse length is 12.8 sec., time base is 25.6 sec., and the input sensor has a 4-20 mA range of

20 to 120°F, the setpoint could be determined as follows: Setpoint = (12.8) (120-20)

+ 20 = 70.2°F

(25.6 - 0.1)

Time base Switch B6 Switch B7 Switch B8

0.1-2.65 seconds OFF OFF OFF

0.1-5.2 seconds OFF OFF ON

0.1-12.85 seconds OFF ON OFF

0.1-25.6 seconds OFF ON ON

0.59-2.93 seconds ON OFF OFF

18

C

SET-UP OF THE UCM-420A AS A REMOTE SETPOINT

CONTROLLER WITH LOCAL ADJUSTMENT (SEE PAGE 10)

Set Switch A1 and Switch A2 both in the "ON" position.

STEP

C-1

Set the DIP switches and jumpers as shown in TABLE 10 for the remote setpoint to be used.

STEP

C-2

Remote Setpoint Signal Switch B1 Switch B2 Set jumper plugs on

4-20 mA OFF OFF Position 1

1-5 VDC OFF OFF Position 2

PWM ON OFF Position 1

TABLE 10

TABLE 11

FAILSAFE FEATURE

On a loss of power the remote setpoint value is retained for up to 6 hours. Upon power return on a unit with

PWM remote setpoint, the saved value will be used for control until a new PWM pulse is received. Upon

power return on a unit with analog remote setpoint, the saved value will be used to control until a new

analog setpoint signal is received. If power is not lost, but the analog remote setpoint signal is suddenly lost

(because of a loose wire or Building Automation System failure) the UCM-420A will continue to control with

the previous setpoint until a valid signal returns.

If Remote Setpoint is set for Pulse-Width Modulation, select the pulse-width time base from

TABLE 11. If remote setpoint is by 4-20 mA or 1-5 VDC, proceed to Step C-4.

STEP

C-3

Set-Up Instructions (Cont.)

*NOTE: The UCM-420A comes from the factory with an integral three-wire local setpoint potentiometer installed and wired. To use any other local setpoint option (or three-wire potentiometer

separate from the UCM-420A) installer must first remove the existing three wires from the "LOCAL

SETPOINT" terminals on the UCM-420A.

Input Set jumper plugs on

4-20 mA Positions 7 & 11

1-5 VDC Positions 8 & 11

PreCon Type 3 Thermistor Positions 10 & 12

Local Setpoint Signal Set jumper plugs on

Three-wire pot* local setpoint No jumper on positions 3-6

4-20 mA* local setpoint Position 3

1-5 VDC* local setpoint Position 4

Two-wire* ("XA") pot local setpoint Position 6

19

Set-Up Instructions (Cont.)

Set the DIP switches and jumpers as shown in TABLE 12 for the local setpoint to be used.

STEP

C-4

Select the type of input to be used per TABLE 13. The input may be a 4-20 mA or 1-5 volt signal

which measures temperature, pressure, humidity, etc. or a PreCon Type 3 Thermistor. If the thermistor is used, the range of the thermistor input is 50 to 90° F.*

*Other ranges available

STEP

C-5

Set switch A3 in the "ON" position for Direct-Acting Control and in the "OFF" position for

Reverse-Acting Control. (

Direct-Acting Control

is when an increase in the input signal above the

setpoint causes the output signal to increase.

Reverse-Acting Control

is when an increase in the

input signal above the setpoint causes the output signal to decrease.)

STEP

C-6

TABLE 12

TABLE 13

Resets/Minute Switch A4 Switch A5

Reset OFF OFF OFF

0.5 Resets/Minute OFF ON

1 Resets/Minute ON OFF

2 Resets/Minute ON ON

Throttling range Switch A6 Switch A7 Switch A8

10% OFF OFF OFF

20% OFF OFF ON

35% OFF ON OFF

50% OFF ON ON

65% ON OFF OFF

80% ON OFF ON

90% ON ON OFF

100% ON ON ON

20

Set the proportional throttling range per TABLE 14. The throttling range is the amount of signal

change at the input required to cause the output signal to go through its entire range (4-20 mA).

For example, a 20% throttling range means that a 1 mA change in the input causes a 5 mA change

in the output signal. When using the optional thermistor input, a 1°F change in input is the equivalent of 0.4 mA change in the mA input mode. The correct throttling range cannot be calculated, but

must be adjusted for each application. Generally, systems that respond quickly should have a narrower throttling range than systems that respond slowly.

STEP

C-7

Set the integral reset rate per TABLE 15. The integral reset feature corrects the output of the

UCM-420A to compensate for the offset inherent in proportional-only controllers. The integral reset

ramps the output in the direction which forces the input signal to exactly match the setpoint. The

number of times per minute this offset is overcome by the output signal is the integral reset rate. If

the output of the UCM-420A is used for digital control, set the integral reset rate "OFF."

STEP

C-8

TABLE 14

TABLE 15

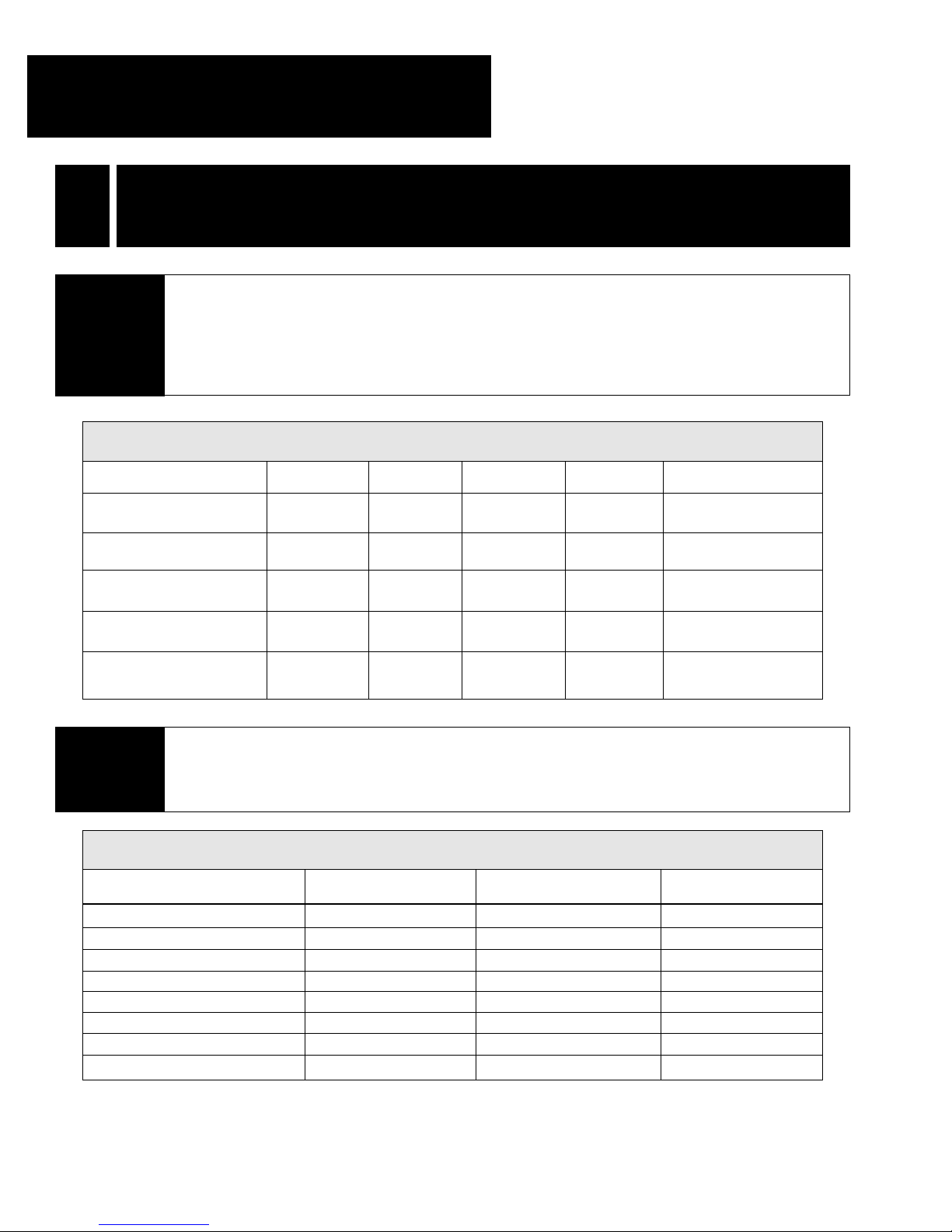

THIS CONCLUDES SET-UP OF THE UCM-420A AS A REMOTE SETPOINT

CONTROLLER WITH LOCAL ADJUSTMENT. WIRE THE UCM-420A PER THE

WIRING DIAGRAM BELOW AND PER GENERAL WIRING DIAGRAMS.

Set-Up Instructions (Cont.)

WIRING DIAGRAM - UCM-420A AS A REMOTE SETPOINT CONTROLLER WITH LOCAL ADJUSTMENT

21

LOCAL SETPOINT WIRING OPTIONS

Set-Up Instructions (Cont.)

*NOTE: PWM contact at controller may

switch either positive or negative leg of

circuit, and PWM circuit may use the

same power supply as the UCM-420A

or a separate power supply. See the

General Wiring Diagram Section for

detailed wiring.

Steady Green - Power On

Dark - Power Loss

Steady Red - PWM Signal Present

LED INDICATION

MUX

B3

B4

B5

ADDR

0

0

0

1

0

0

1

2

0

1

0

3

0

1

1

4

1

0

0

5

1

0

1

6

1

1

0

7

1

1

1

8

"1" MEANS

TURN SWITCH ON

SWITCH OFF

A3

REVERSE ACTING

A2

BOTH OFF >> REMOTE SETPT

A1

SAMPLE AND HOLD MODE

B1

BOTH OFF >> ANALOG

B2

REMOTE SETPOINT

UCM-420A

TIME

BASE

B6

B7

B8

2.65

0

0

0

5.2

0

0

1

12.85

0

1

0

25.6

0

1

1

.59-2.93

1

X

X

RESET

PER MIN

A4

A5

OFF

0

0

0.5

0

1

1

1

0

2

1

1

PROP

A6

A7

A8

T.R.

0

0

0

10%

0

0

1

20%

0

1

0

35%

0

1

1

50%

1

0

0

65%

1

0

1

80%

1

1

0

90%

1

1

1

100%

"0" MEANS

TURN SWITCH OFF

SWITCH ON

DIRECT ACTING

LOCAL SETPT ENABLE

REMOTE SETPT ENABLE

PWM REM SETPT SGLE UNIT

PWM REM SETPT MUX MODE

1 2 3 4 5 6 7 8

A

1 2 3 4 5 6 7 8

B

1

2

REMOTE

SETPOINT

3

4

5

6

LOCAL

SETPOINT

7

8

9

10

FEEDBACK

11

12

STATUS

PWM

INPUT

PWM

INPUT

REM SPT

INPUT

LOC SPT

POT +

LOC SPT

INPUT

LOC SPT

POT –

FEEDBK

INPUT

24 PWR

COMMON

MA SIG

OUTPUT

SEE

LOCAL

SETPOINT

WIRING

OPTIONS

CONTACT AT CONTROLLER*

24 VAC OR 24 VDC PWM SIGNAL FROM BAS

+

(ONLY IF REMOTE SETPOINT IS PWM)

–

+

4-20 MA OR 1-5 VOLT REMOTE SETPOINT SIGNAL

–

(ONLY IF REMOTE SETPOINT IS ANALOG SIGNAL)

+

4-20 MA, 1-5 VOLT OR THERMISTOR INPUT SIGNAL

–

4-20 MA SOURCING OUTPUT SIGNAL TO

–

+

CONTROLLED DEVICE

+

24 VAC OR 24 VDC POWER

–

LOC SPT POT +

LOC SPT INPUT

LOC SPT POT –

LOC SPT POT +

LOC SPT INPUT

LOC SPT POT –

LOC SPT POT +

LOC SPT INPUT

LOC SPT POT –

INCREASE SETPONT

COMMON

INCREASE

SETPONT

COMMON

THREE-WIRE POTENTIOMETER

(5KW TO 50 KW )

LOCAL SETPOINT

(FACTORY INSTALLED

ON BASIC MODEL)

+

4-20 MA OR 1-5 VOLT

LOCAL SETPOINT

–

TWO-WIRE POTENTIOMETER

LOCAL SETPOINT

("XA OPTION ON

PRECON THERMISTOR)

Multiplex Address Switch B3 Switch B4 Switch B5

1 OFF OFF OFF

2 OFF OFF ON

3 OFF ON OFF

4 OFF ON ON

5 ON OFF OFF

6 ON OFF ON

7 ON ON OFF

8 ON ON ON

Mode Switch A1 Switch A2 Switch B1 Switch B2 Set jumper plugs on

MUX Remote setpoint,

no local setpoint ON OFF OFF ON NONE

MUX Remote setpoint,

4-20 mA local setpoint ON ON OFF ON Positions 1 & 3

MUX Remote setpoint,

1-5V local setpoint ON ON OFF ON Positions 1 & 4

MUX Remote setpoint, Position 1

three-wire local setpoint ON ON OFF ON (no jumper on 3-6)

MUX Remote setpoint,

two-wire local setpoint ON ON OFF ON Positions 1 & 6N

22

Select either a multiplexed remote setpoint with no local adjustment or a multiplexed remote setpoint with local adjustment and set DIP switches and jumpers per TABLE 16. If remote and local

setpoints are both enabled, the remote setpoint establishes the setpoint and the local setpoint has

±12.5% of the input adjustment around this point. If the local setpoint adjustment is by a PreCon

Two-Wire Potentiometer (as used in the “XA” option on PreCon Temperature Sensors) the local

setpoint adjustment is ±9.4% instead of ±12.5%.

STEP

D-1

In the multiplexed PWM mode, each UCM-420A is assigned an address 1-8 so that it may be independently updated by the Building Automation System. Multiple UCM-420As may be assigned the

same address. Assign each UCM-420A an address per TABLE 17. All UCM-420As with the same

address must have the same setpoint.

STEP

D-2

TABLE 16

TABLE 17

D

SET-UP OF THE UCM-420A AS AN OUTPUT EXPANDER WITH

MULTIPLEXED PWM INPUT (SEE PAGE 11)

Set-Up Instructions (Cont.)

Address 2.65 sec* 5.2 sec 12.85 sec 25.6 sec

time base time base time base time base

1 0.2 0.4 0.9 1.6

2 0.6 1.0 2.5 4.8

3 0.9 1.7 4.1 8

4 1.2 2.3 5.7 11.2

5 1.5 3.0 7.3 14.4

6 1.9 3.6 8.9 17.6

7 2.2 4.3 10.5 20.9

8 2.5 4.9 12.1 24

* The 2.65 second time base is not recommended for the MUX mode unless the BAS guarantees an

accuracy of 0.05 seconds or better on its PWM output.

MULTIPLEXED OPERATION

The pulse-width input is optoisolated and can accept an 24 VAC or 24 VDC signal from any source with or

without a common ground. The sequence for updating a UCM-420A setpoint in the multiplexed mode is as

follows:

1. The BAS Controller sends an “Attention” pulse which is one second longer than the maximum pulse for

the time base selected.

2. The BAS Controller then sends a “Select” pulse of one of eight possible time periods to select which

UCM-420A address’s to be updated. See TABLE 19 for the “Address” pulse times for the different time

bases. The UCM-420As which receive a “Select” pulse which matches their address then wait for a setpoint pulse. All other UCM-420As ignore the setpoint pulse and return to the normal operating mode.

3. The BAS Controller then sends the new “Setpoint” pulse to the UCM-420A which has been selected.

The UCM-420A accepts the new setpoint and returns to the normal operating mode. Multiple

UCM-420As may be assigned the same address. In this case, all UCM-420As with the selected address

will receive the new setpoint. Setpoint = pulse length (input range)

+ input lower value

time base

Example: If pulse length is 12.8 sec., time base is 25.6 sec., and the input sensor has a 4-20 mA range of

20 to 120°F, the setpoint could be determined as follows: Setpoint = 12.8 (120-20)

+20 = 70.2°F

(25.6 - 0.1)

Time base B6 B7 B8

0.1-2.65 seconds OFF OFF OFF

0.1-5.2 seconds OFF OFF ON

0.1-12.85 seconds OFF ON OFF

0.1-25.6 seconds OFF ON ON

23

Set-Up Instructions (Cont.)

Select the pulse-width time base per TABLE 18 and set each UCM-420A for the time base

required. The 2.65 second time base is not recommended for multiplexed operation unless the

BAS controller guarantees an accuracy of 0.05 seconds or better on its PWM output.

STEP

D-3

TABLE 18

TABLE 19

SETTING THROTTLING RANGE

Throttling Range Switch A6 Switch A7 Switch A8

10% OFF OFF OFF

20% OFF OFF ON

35% OFF ON OFF

50% OFF ON ON

65% ON OFF OFF

80% ON OFF ON

90% ON ON OFF

100% ON ON ON

Input Set jumper plugs on

4-20 mA Positions 7 & 11

1-5 VDC Positions 8 & 11

PreCon Type 3 Thermistor Positions 10 & 12

24

Select the type of input to be used and set jumpers per TABLE 20. The input may be a 4-20 mA or

1-5V signal which measures temperature, pressure, humidity, etc. or a PreCon Type 3 Thermistor.

STEP

D-4

Set switch A3 in the “ON” position for DIrect-Acting Control and in the “OFF” position for

Reverse-Acting Control. (

Direct-Acting Control

is when an increase in the input signal above set-

point causes the output signal to increase.

Reverse-Acting Control

is when an increase in the input

signal above setpoint causes the output signal to decrease.

STEP

D-5

Set the proportional throttling range per TABLE 21. The throttling range is the amount of signal

change of the input required to cause the output signal to go through its entire range (4-20 mA).

For example, a 20% throttling range means that a 1 mA change in the input signal causes a 5 mA

change in the output signal. When using the optional thermistor input, a 1°F change in input is the

equivalent of 0.4 mA change in the mA input mode. The correct throttling range cannot be calculated, but must be adjusted for each application. Generally, systems that respond quickly should

have a narrower throttling range than systems that respond slowly.

STEP

D-6

TABLE 20

TABLE 21

Set-Up Instructions (Cont.)

Resets/Minute Switch A4 Switch A5

Reset OFF OFF OFF

0.5 Resets/Minute OFF ON

1 Reset/Minute ON OFF

2 Resets/Minute ON ON

25

PWM

INPUT

PWM

INPUT

REM SPT

INPUT

LOC SPT

POT +

LOC SPT

INPUT

LOC SPT

POT –

COMMON

MA SIG

OUTPUT

1

2

3

4

5

6

7

8

9

10

11

12

B3

0

0

0

0

1

1

1

1

B6

0

0

0

0

1

B7

0

0

1

1

X

B8

0

1

0

1

X

B4

0

0

1

1

0

0

1

1

B5

0

1

0

1

0

1

0

1

MUX

ADDR

1

2

3

4

5

6

7

8

A6

0

0

0

0

1

1

1

1

A7

0

0

1

1

0

0

1

1

A8

0

1

0

1

0

1

0

1

PROP

T.R.

10%

20%

35%

50%

65%

80%

90%

100%

UCM-420A

TIME

BASE

2.65

5.2

12.85

25.6

.59-2.93

A4

0

0

1

1

A5

0

1

0

1

RESET

PER MIN

OFF

0.5

1

2

"1" MEANS

TURN SWITCH ON

"0" MEANS

TURN SWITCH OFF

LOCAL

SETPOINT

FEEDBACK

REMOTE

SETPOINT

STATUS

24 VAC OR 24 VDC POWER

4-20 MA, 1-5 VOLTS OR THERMISTOR INPUT SIGNAL

4-20 MA SOURCING OUTPUT SIGNAL TO

CONTROLLED DEVICE

24 VAC OR 24 VDC PWM SIGNAL FROM BAS

(ONLY IF REMOTE SETPOINT IS PWM)

CONTACT AT CONTROLLER*

+

–

–

+

+

–

+

–

SEE

LOCAL

SETPOINT

WIRING

OPTIONS

FEEDBK

INPUT

24 PWR

SWITCH OFF

SWITCH ON

A3

A2

A1

B1

B2

REVERSE ACTING

BOTH OFF >> REMOTE SETPT

SAMPLE AND HOLD MODE

BOTH OFF >> ANALOG

REMOTE SETPOINT

DIRECT ACTING

LOCAL SETPT ENABLE

REMOTE SETPT ENABLE

PWM REM SETPT SGLE UNIT

PWM REM SETPT MUX MODE

B

A

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

Steady Green - Power On

Dark - Power Loss

Steady Red - PWM Signal Present

Slow Green Blink - Attention Mode, No PWM Signal

Slow Red/Green Blink - Attention Mode, PWM Signal Present

Rapid Green Blink - Select Mode, No PWM Signal

Rapid Red/Green Blink - Select Mode, PWM Signal Present

LED INDICATION

Set-Up Instructions (Cont.)

Set the integral reset rate per TABLE 22. The integral reset feature corrects the output of the

UCM-420A to compensate for the offset inherent in proportional controllers. The integral reset

ramps the output in the direction that forces the input signal to exactly match the setpoint. The

number of times per minute this offset is overcome by the output signal is the integral reset rate. If

the output of the UCM-420A is used for digital control, set the integral reset rate “OFF.”

STEP

D-8

TABLE 22

THIS CONCLUDES SET-UP OF THE UCM-420A AS AN OUTPUT EXPANDER

(MUX OPERATION). WIRE THE UCM-420A PER THE WIRING DIAGRAM

BELOW AND PER GENERAL WIRING DIAGRAMS.

*NOTE: PWM contact at controller may switch either positive or negative leg of circuit, and PWM

circuit may use the same power supply as the UCM-420A or a separate power supply. See the

General Wiring Diagram Section for detailed wiring.

WIRING OF THE UCM-420 AS AN OUTPUT EXPANDER (MUX OPERATIONS)

Signal Monitored Set jumper plugs on

4-20 mA Positions 1, 7, & 11

1-5 VDC Positions 2, 7, & 11

26

PWM

INPUT

PWM

INPUT

REM SPT

INPUT

LOC SPT

POT +

LOC SPT

INPUT

LOC SPT

POT –

COMMON

MA SIG

OUTPUT

1

2

3

4

5

6

7

8

9

10

11

12

B3

0

0

0

0

1

1

1

1

B6

0

0

0

0

1

B7

0

0

1

1

X

B8

0

1

0

1

X

B4

0

0

1

1

0

0

1

1

B5

0

1

0

1

0

1

0

1

MUX

ADDR

1

2

3

4

5

6

7

8

A6

0

0

0

0

1

1

1

1

A7

0

0

1

1

0

0

1

1

A8

0

1

0

1

0

1

0

1

PROP

T.R.

10%

20%

35%

50%

65%

80%

90%

100%

UCM-420A

TIME

BASE

2.65

5.2

12.85

25.6

.59-2.93

A4

0

0

1

1

A5

0

1

0

1

RESET

PER MIN

OFF

0.5

1

2

"1" MEANS

TURN SWITCH ON

"0" MEANS

TURN SWITCH OFF

LOCAL

SETPOINT

FEEDBACK

REMOTE

SETPOINT

STATUS

B

A

24 VAC OR 24 VDC POWER

OUTPUT SIGNAL

TO SYSTEM

+

–

+

–

INPUT SIGNAL

MONITORED

–

+

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

FEEDBK

INPUT

24 PWR

SWITCH OFF

SWITCH ON

A3

A2

A1

B1

B2

REVERSE ACTING

BOTH OFF >> REMOTE SETPT

SAMPLE AND HOLD MODE

BOTH OFF >> ANALOG

REMOTE SETPOINT

DIRECT ACTING

LOCAL SETPT ENABLE

REMOTE SETPT ENABLE

PWM REM SETPT SGLE UNIT

PWM REM SETPT MUX MODE

WIRING OF THE UCM-420A IN THE SAMPLE AND HOLD MODE

Steady Green - Signal O.K.

Dark - Power Loss

Steady Red - Signal Lost, Output Being Held

Slow Red/Green Blink - Signal Changing Rapidly.

Output Being Held

LED INDICATION

For Direct-Acting Output (4-20 mA in and 4-20 mA out or 1-5 VDC in and 1-5 VDC out) switch A3

and A4 should be “ON” and all other switches ”OFF”. For Reverse Acting Output (4-20 mA in and

20-4 mA out or 1-5 VDC in and 5-1 VDC out) switch A4 should be “ON” and all other switches “OFF.”

STEP

E-1

Set the jumpers as shown in TABLE 23 for the signal being monitored.

STEP

E-2

D

SET-UP OF THE UCM-420A IN THE SAMPLE AND HOLD

MODE (SEE PAGE 12)

TABLE 23

OPERATION

The UCM-420A may be used to sample an analog signal and hold the value on a loss of signal. In this mode of

operation, the analog remote setpoint signal is sampled and the local setpoint and input signals are ignored. The

“lost” threshold for the sampled signal is 3.2 mA or 0.8 volts.

The remote setpoint signal is sampled once per second. If the new value is within 6% of the previous reading, the

new value is passed through to the output.

If the new sample of the signal is more than 6% higher or lower than the previous sample but is not “lost” (the input

signal is moving), the old output value is held. The new sample is then saved for comparison against the next

sample. When the input signal stops moving so that two consecutive samples are within 6% of each other, the

output updates.

When the newest sample of the signal drops below the “lost” threshold value, the old value is held at the current

output.

On power loss, the current output value is remembered up to 6 hours. On power return, if the sampled signal is

“lost,” the old value will be output until a good signal is received.

Set-Up Instructions (Cont.)

Time base B6 B7 B8

0.1-2.65 seconds OFF OFF OFF

0.1-5.2 seconds OFF OFF ON

0.1-12.85 seconds OFF ON OFF

0.1-25.6 seconds OFF ON ON

0.59-2.93 seconds ON ON ON

Mode Switch Switch Switch Switch

A1 A2 B1 B2

Single Unit PWM OFF OFF ON OFF

Multiplexed PWM OFF OFF OFF ON

27

Set-Up Instructions (Cont.)

The UCM-420A may be used to convert a time-based pulse-width AC or DC input signal to a 4-20

mA output signal. By using the multiplexed mode, multiple UCM-420As may be controlled by one

BAS output. In this mode, the UCM-420A output is based solely on the pulse-width signal and

selected time base. Remote setpoint, local setpoint and input are ignored. The output value is

retained up to 6 hours on a loss of power. Upon power return, the saved value is output until a new

pulse signal is received. The output may be direct- or reverse-acting. Select single unit PWM or

multiplexed PWM by setting the switches as shown in TABLE 24.

STEP

F-1

Select the time base for the control signal by setting DIP switches per TABLE 25.

STEP

F-2

If the output is to be Direct-Acting, switch A3 is to be in the “ON” position. If the output is to be

Reverse-Acting, A3 is to be in the “OFF” position. In the

Direct-Acting mode

, the minimum pulse

input causes a 4 mA output signal. As the length of the pulse-width input signal is increased, the

output signal will increase. In the

Reverse-Acting mode

, the minimum pulse input causes a 20 mA

output signal. As the length of the pulse-width input signal is increased, the output signal will

decrease.

STEP

F-3

If the UCM-420As are to be multiplexed, set the address of each unit from TABLE 26. Multiple

units may have the same address.

STEP

F-4

TABLE 25

F

SET-UP OF THE UCM-420A AS A PULSE WIDTH TO 4-20 MA

CONVERTER (SEE PAGE 12)

TABLE 24

See "Multiplexed Operation" on

page 11 for a description of the

UCM-420A operation in the

multiplexed mode.

Multiplex Address Switch B3 Switch B4 Switch B5

1 OFF OFF OFF

2 OFF OFF ON

3 OFF ON OFF

4 OFF ON ON

5 ON OFF OFF

6 ON OFF ON

7 ON ON OFF

8 ON ON ON

PWM

INPUT

PWM

INPUT

REM SPT

INPUT

LOC SPT

POT +

LOC SPT

INPUT

LOC SPT

POT –

COMMON

MA SIG

OUTPUT

1

2

3

4

5

6

7

8

9

10

11

12

B3

0

0

0

0

1

1

1

1

B6

0

0

0

0

1

B7

0

0

1

1

X

B8

0

1

0

1

X

B4

0

0

1

1

0

0

1

1

B5

0

1

0

1

0

1

0

1

MUX

ADDR

1

2

3

4

5

6

7

8

A6

0

0

0

0

1

1

1

1

A7

0

0

1

1

0

0

1

1

A8

0

1

0

1

0

1

0

1

PROP

T.R.

10%

20%

35%

50%

65%

80%

90%

100%

UCM-420A

TIME

BASE

2.65

5.2

12.85

25.6

.59-2.93

A4

0

0

1

1

A5

0

1

0

1

RESET

PER MIN

OFF

0.5

1

2

"1" MEANS

TURN SWITCH ON

"0" MEANS

TURN SWITCH OFF

LOCAL

SETPOINT

FEEDBACK

REMOTE

SETPOINT

STATUS

24 VAC OR 24 VDC POWER

4-20 MA SOURCING OUTPUT SIGNAL TO

CONTROLLED DEVICE

24 VAC OR 24 VDC PWM SIGNAL FROM BAS

(ONLY IF REMOTE SETPOINT IS PWM)

CONTACT AT CONTROLLER*

–

+

+

–

+

–

FEEDBK

INPUT

24 PWR

SWITCH OFF

SWITCH ON

A3

A2

A1

B1

B2

REVERSE ACTING

BOTH OFF >> REMOTE SETPT

SAMPLE AND HOLD MODE

BOTH OFF >> ANALOG

REMOTE SETPOINT

DIRECT ACTING

LOCAL SETPT ENABLE

REMOTE SETPT ENABLE

PWM REM SETPT SGLE UNIT

PWM REM SETPT MUX MODE

B

A

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

*NOTE: PWM contact

at controller may

switch either positive or negative leg

of circuit, and PWM

circuit may use the

same power supply

as the UCM-420A or

a separate power

supply. See the

General Wiring

Diagram Section for

detailed wiring.

28

STEP F-5

THIS CONCLUDES THE SET-UP OF THE UCM-420A AS A PULSE WIDTH TO

4-20 MA CONVERTER. WIRE THE UCM-420A PER THE WIRING DIAGRAM

BELOW AND THE GENERAL WIRING DIAGRAMS.

WIRING OF THE UCM-420A AS A PWM TO 4-20 mA CONVERTER

TABLE 27

See page 25 for LED indication in MUX

Mode

Steady Green - Power On

Dark - Power Loss

Steady Red - PWM Signal Present

LED INDICATION (No MUX)

TABLE 26

Set-Up Instructions (Cont.)

20 MA

16 MA

12 MA

8 MA

4 MA

0.1

0.1

0.1

0.1

0.59

This table provides the output signal

corresponding to various input pulses

for the different time bases available.

0.66

1.3

3.21

6.4

1.18

1.33

2.6

6.43

12.8

1.76

1.99

3.9

9.64

38.4

4.69

2.65

5.2

12.85

25.6

2.93

29

Set-Up Instructions (Cont.)

Remove power from the UCM-420A.

STEP

G-1

Set all sixteen DIP switches in the "OFF" position.

STEP

G-2

Power up the unit. The status LED will flash RED and the output will go to 4 mA.

STEP

G-3

Any even mA value can then be output by turning on the DIP switch shown in TABLE 28. The

UCM-420A will output a signal for the highest value switch that is turned on; the status of lower

value switches makes no difference. For example, if all switches are off except A6 and A5, the

UCM-420A will output the value for A6 which is 10 mA.

STEP

G-4

Dark - Power Loss

Slow Red Blink - Signal Generator

Mode Selected

LED INDICATION

G

SET-UP OF THE UCM-420A AS A SIGNAL GENERATOR

(SEE PAGE 12)

The UCM-420A may be used as a 4-20 mA signal generator with no input or setpoint signals. This allows equipment

driven by the UCM-420A to be calibrated before system start-up. This mode of operation supplies a 4-20 mA signal in

1 mA steps. If the UCM-420A is installed when the signal generator mode is to be used, wiring should be done in

accordance with the proper wiring diagram for the mode of operation for which the UCM-420A is to be used. If the

UCM-420A is not installed when the signal generator mode is to be used, wire per the wiring diagram below.

WIRING OF THE UCM-420A AS A 4-20 MA SIGNAL GENERATOR

PWM

INPUT

PWM

INPUT

REM SPT

INPUT

LOC SPT

POT +

LOC SPT

INPUT

LOC SPT

POT –

COMMON

MA SIG

OUTPUT

1

2

3

4

5

6

7

8

9

10

11

12

B3

0

0

0

0

1

1

1

1

B6

0

0

0

0

1

B7

0

0

1

1

X

B8

0

1

0

1

X

B4

0

0

1

1

0

0

1

1

B5

0

1

0

1

0

1

0

1

MUX

ADDR

1

2

3

4

5

6

7

8

A6

0

0

0

0

1

1

1

1

A7

0

0

1

1

0

0

1

1

A8

0

1

0

1

0

1

0

1

PROP

T.R.

10%

20%

35%

50%

65%

80%

90%

100%

UCM-420A

TIME

BASE

2.65

5.2

12.85

25.6

.59-2.93

A4

0

0

1

1

A5

0

1

0

1

RESET

PER MIN

OFF

0.5

1

2

"1" MEANS

TURN SWITCH ON

"0" MEANS

TURN SWITCH OFF

LOCAL

SETPOINT

FEEDBACK

REMOTE

SETPOINT

STATUS

24 VAC OR 24 VDC POWER

4-20 MA SIGNAL

OUTPUT

+

–

FEEDBK

INPUT

24 PWR

SWITCH OFF

SWITCH ON

A3

A2

A1

B1

B2

REVERSE ACTING

BOTH OFF >> REMOTE SETPT

SAMPLE AND HOLD MODE

BOTH OFF >> ANALOG

REMOTE SETPOINT

DIRECT ACTING

LOCAL SETPT ENABLE

REMOTE SETPT ENABLE

PWM REM SETPT SGLE UNIT

PWM REM SETPT MUX MODE

B

A

12345678

12345678

UCM-420A Basic model including thermistor input and built-in local setpoint potentiometer

UCO-47 DIN rail mount (mounts on DIN 3F)

UCM-SPA Local setpoint potentiometer on stainless steel plate

DIP switch mA Output

All OFF 4

A1 5

A2 6

A3 7

A4 8

A5 9

A6 10

A7 11

A8 12

DIP switch mA Output

B1 13

B2 14

B3 15

B4 16

B5 17

B6 18

B7 19

B8 20

30

TABLE 28

ORDERING INFORMATION

The standard unit stocked by Kele is the UCM-420A which includes a local setpoint potentiometer and accepts a

thermistor input. On large quantities (100 minimum), special configurations are available. Contact Kele for special

pricing.

Set-Up Instructions (Cont.)

Ordering Information

Post Office Box 34817 (Zip: 38184)

2975 Brother Blvd.

Memphis, Tennessee 38133

Phone: 901-382-4300 Fax: 901-372-2531

TM

Loading...

Loading...