Page 1

Series 2600

System SourceMeter®

Instruments

Semiconductor Device Test

Applications Guide

Contains Programming Examples

A GREATER MEASURE OF CONFIDENCE

Page 2

Table of Contents

Section 1 General Information

1.1 Introduction. . . . . . . . . . . . . . . . . . . . . .1-1

1.2 Hardware Configuration . . . . . . . . . . . . . . .1-1

1.2.1 System Configuration . . . . . . . . . . . . .1-1

1.2.2 Remote/Local Sensing Considerations. . . . .1-2

1.3 Graphing. . . . . . . . . . . . . . . . . . . . . . . .1-2

Section 2 Two-terminal Device Tests

2.1 Introduction. . . . . . . . . . . . . . . . . . . . . .2-1

2.2 Instrument Connections . . . . . . . . . . . . . . .2-1

2.3 Voltage Coefficient Tests of Resistors . . . . . . . .2-1

2.3.1 Test Configuration . . . . . . . . . . . . . . .2-1

2.3.2 Voltage Coefficient Calculations . . . . . . . .2-1

2.3.3 Measurement Considerations . . . . . . . . .2-2

2.3.4 Example Program 1:

Voltage Coefficient Test . . . . . . . . . . . .2-2

2.3.5 Typical Program 1 Results . . . . . . . . . . .2-3

2.3.6 Program 1 Description . . . . . . . . . . . . .2-3

2.4 Capacitor Leakage Test . . . . . . . . . . . . . . . .2-3

2.4.1 Test Configuration . . . . . . . . . . . . . . .2-3

2.4.2 Leakage Resistance Calculations . . . . . . . .2-3

2.4.3 Measurement Considerations . . . . . . . . .2-4

2.4.4 Example Program 2:

Capacitor Leakage Test . . . . . . . . . . . . .2-4

2.4.5 Typical Program 2 Results . . . . . . . . . . .2-4

2.4.6 Program 2 Description . . . . . . . . . . . . .2-5

2.5 Diode Characterization. . . . . . . . . . . . . . . .2-5

2.5.1 Test Configuration . . . . . . . . . . . . . . .2-5

2.5.2 Measurement Considerations . . . . . . . . .2-5

2.5.3 Example Program 3:

Diode Characterization . . . . . . . . . . . .2-5

2.5.4 Typical Program 3 Results . . . . . . . . . . .2-6

2.5.5 Program 3 Description . . . . . . . . . . . . .2-6

2.5.6 Using Log Sweeps . . . . . . . . . . . . . . .2-7

2.5.7 Using Pulsed Sweeps . . . . . . . . . . . . . .2-7

Section 3 Bipolar Transistor Tests

3.1 Introduction. . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Instrument Connections . . . . . . . . . . . . . . 3-1

3.3 Common-Emitter Characteristics . . . . . . . . . 3-1

3.3.1 Test Configuration . . . . . . . . . . . . . . 3-2

3.3.2 Measurement Considerations . . . . . . . . 3-2

3.3.3 Example Program 4:

Common-Emitter Characteristics . . . . . . 3-2

3.3.4 Typical Program 4 Results . . . . . . . . . . 3-3

3.3.5 Program 4 Description . . . . . . . . . . . . 3-3

3.4 Gummel Plot . . . . . . . . . . . . . . . . . . . . 3-3

3.4.1 Test Configuration . . . . . . . . . . . . . . 3-3

3.4.2 Measurement Considerations . . . . . . . . 3-4

3.4.3 Example Program 5: Gummel Plot. . . . . . 3-4

3.4.4 Typical Program 5 Results . . . . . . . . . . 3-5

3.4.5 Program 5 Description . . . . . . . . . . . . 3-5

3.5 Current Gain . . . . . . . . . . . . . . . . . . . . 3-6

3.5.1 Gain Calculations . . . . . . . . . . . . . . 3-6

3.5.2 Test Configuration for Search Method . . . . 3-6

3.5.3 Measurement Considerations . . . . . . . . 3-6

3.5.4 Example Program 6A: DC Current Gain

Using Search Method. . . . . . . . . . . . . 3-6

3.5.5 Typical Program 6A Results . . . . . . . . . 3-7

3.5.6 Program 6A Description . . . . . . . . . . . 3-7

3.5.7 Modifying Program 6A . . . . . . . . . . . . 3-7

3.5.8 Configuration for Fast Current Gain Tests. . 3-8

3.5.9 Example Program 6B: DC Current Gain

Using Fast Method . . . . . . . . . . . . . . 3-8

3.5.10 Program 6B Description . . . . . . . . . . . 3-9

3.5.11 Example Program 7: AC Current Gain . . . . 3-9

3.5.13 Typical Program 7 Results . . . . . . . . . . 3-10

3.5.14 Program 7 Description . . . . . . . . . . . . 3 -10

3.5.15 Modifying Program 7. . . . . . . . . . . . . 3-10

3.6 Transistor Leakage Current . . . . . . . . . . . . 3 -10

3.6.1 Test Configuration . . . . . . . . . . . . . . 3-10

3.6.2 Example Program 8: I

CEO

Test . . . . . . . . 3 -11

3.6.3 Typical Program 8 Results . . . . . . . . . . 3-11

3.6.4 Program 8 Description . . . . . . . . . . . . 3-11

3.6.5 Modifying Program 8. . . . . . . . . . . . . 3-12

Section 4 FET Tests

4.1 Introduction. . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Instrument Connections . . . . . . . . . . . . . . 4-1

Page 3

4.3 Common-Source Characteristics . . . . . . . . . 4-1

4.3.1 Test Configuration . . . . . . . . . . . . . . 4-1

4.3.2 Example Program 9: Common-Source

Characteristics . . . . . . . . . . . . . . . . 4-1

4.3.3 Typical Program 9 Results . . . . . . . . . . 4-2

4.3.4 Program 9 Description . . . . . . . . . . . . 4-2

4.3.5 Modifying Program 9. . . . . . . . . . . . . 4-3

4.4 Transconductance Tests . . . . . . . . . . . . . . 4-3

4.4.1 Test Configuration . . . . . . . . . . . . . . 4-3

4.4.2 Example Program 10: Transconductance

vs. Gate Voltage Test . . . . . . . . . . . . . 4-4

4.4.3 Typical Program 10 Results . . . . . . . . . 4-5

4.4.4 Program 10 Description . . . . . . . . . . . 4-5

4.5 Threshold Tests . . . . . . . . . . . . . . . . . . . 4-6

4.5.1 Search Method Test Configuration. . . . . . 4-6

4.5.2 Example Program 11A: Threshold Voltage

Tests Using Search Method. . . . . . . . . . 4-6

4.5.3 Program 11A Description . . . . . . . . . . 4-7

4.5.4 Modifying Program 11A . . . . . . . . . . . 4-7

4.5.5 Self-bias Threshold Test Configuration . . . 4-7

4.5.6 Example Program 11B: Self-bias

Threshold Voltage Tests . . . . . . . . . . . 4-8

4.5.7 Program 11B Description . . . . . . . . . . 4-9

4.5.8 Modifying Program 11B . . . . . . . . . . . 4-9

Section 5 Using Substrate Bias

5.1 Introduction. . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Substrate Bias Instrument Connections . . . . . 5-1

5.2.1 Source-Measure Unit Substrate Bias

Connections and Setup . . . . . . . . . . . 5-1

5.2.2 Voltage Source Substrate Bias Connections . 5-2

5.3 Source-Measure Unit Substrate Biasing . . . . . 5-2

5.3.1 Program 12 Test Configuration . . . . . . . 5-2

5.3.2 Example Program 12: Substrate Current

vs. Gate-Source Voltage . . . . . . . . . . . 5-2

5.3.3 Typical Program 12 Results . . . . . . . . . 5-4

5.3.4 Program 12 Description . . . . . . . . . . . 5-4

5.3.5 Modifying Program 12 . . . . . . . . . . . . 5-5

5.3.6 Program 13 Test Configuration . . . . . . . 5-5

5.3.7 Example Program 13: Common-Source

Characteristics with Source-Measure Unit

Substrate Bias . . . . . . . . . . . . . . . . 5-5

5.3.8 Typical Program 13 Results . . . . . . . . . 5-7

5.3.9 Program 13 Description . . . . . . . . . . . 5-7

5.3.10 Modifying Program 13 . . . . . . . . . . . . 5-7

5.4 BJT Substrate Biasing. . . . . . . . . . . . . . . . 5-7

5.4.1 Program 14 Test Configuration . . . . . . . 5-7

5.4.2 Example Program 14: Common-Emitter

Characteristics with a Substrate Bias . . . . 5-7

5.4.3 Typical Program 14 Results. . . . . . . . . . 5-9

5.4.4 Program 14 Description . . . . . . . . . . . 5-9

5.4.5 Modifying Program 14 . . . . . . . . . . . . 5-10

Section 6 High Power Tests

6.1 Introduction. . . . . . . . . . . . . . . . . . . . . 6-1

6.1.1 Program 15 Test Configuration . . . . . . . 6-1

6.1.2 Example Program 15: High Current

Source and Voltage Measure . . . . . . . . . 6-1

6.1.3 Program 15 Description . . . . . . . . . . . 6-2

6.2 Instrument Connections . . . . . . . . . . . . . . 6-2

6.2.1 Program 16 Test Configuration . . . . . . . 6-2

6.2.2 Example Program 16: High Voltage

Source and Current Measure . . . . . . . . 6-2

6.2.3 Program 16 Description . . . . . . . . . . . 6-3

Appendix A Scripts

Section 2. Two-Terminal Devices . . . . . . . . . . . . . A-1

Program 1. Voltage Coefficient of Resistors . . . . . A-1

Program 2. Capacitor Leakage Test . . . . . . . . . A-5

Program 3. Diode Characterization . . . . . . . . . A-8

Program 3A. Diode Characterization Linear Sweep . A-8

Program 3B. Diode Characterization Log Sweep . . A -11

Program 3C. Diode Characterization Pulsed Sweep . A-14

Section 3. Bipolar Transistor Tests . . . . . . . . . . . . A-19

Program 4. Common-Emitter Characteristics . . . . A -19

Program 5. Gummel Plot . . . . . . . . . . . . . . . A-24

Section 6. High Power Tests. . . . . . . . . . . . . . . . A-28

Program 6. Current Gain . . . . . . . . . . . . . . . A-28

Program 6A. Current Gain (Search Method). . . . . A-28

Program 6B. Current Gain (Fast Method) . . . . . . A-32

Program 7. AC Current Gain . . . . . . . . . . . . . A-36

Program 8. Transistor Leakage (ICEO). . . . . . . . A-39

Section 4. FET Tests . . . . . . . . . . . . . . . . . . . . A-43

Program 9. Common-Source Characteristics . . . . A-43

Program 10. Transconductance . . . . . . . . . . . A-48

Page 4

Program 11. Threshold . . . . . . . . . . . . . . . . A-52

Program 11A. Threshold (Search) . . . . . . . . . . A-52

Program 11B. Threshold (Fast). . . . . . . . . . . . A-56

Section 5. Using Substrate Bias . . . . . . . . . . . . . . A-60

Program 12. Substrate Current vs. Gate-Source

Voltage (FET ISB vs. VGS) . . . . . . . . . . . A-60

Program 13. Common-Source Characteristics

with Substrate Bias . . . . . . . . . . . . . A-64

Program 14. Common-Emitter Characteristics

with Substrate Bias . . . . . . . . . . . . . . A -71

Section 6. High Power Tests. . . . . . . . . . . . . . . . A-7 8

Program 15. High Current with

Voltage Measurement . . . . . . . . . . . . A-78

Program 16. High Voltage with

Current Measurement . . . . . . . . . . . . A-80

Page 5

Page 6

List of Illustrations

Section 1 General Information

Figure 1-1. Typical system configuration for applications. . .1-1

Section 2 Two-terminal Device Tests

Figure 2-1. Series 2600 two-wire connections

(local sensing) . . . . . . . . . . . . . . . . . . . . . . .2-1

Figure 2-2. Voltage coefficient test configuration . . . . . . .2-1

Figure 2-3. Test configuration for capacitor leakage test . . .2-3

Figure 2-4. Staircase sweep . . . . . . . . . . . . . . . . . .2-5

Figure 2-5. Test configuration for diode characterization. . .2-5

Figure 2-6. Program 3 results: Diode forward

characteristics . . . . . . . . . . . . . . . . . . . . . . .2-6

Section 3 Bipolar Transistor Tests

Figure 3-1. Test configuration for common-emitter tests . . 3-1

Figure 3-2. Program 4 results: Common-emitter

characteristics . . . . . . . . . . . . . . . . . . . . . . 3-3

Figure 3-3. Gummel plot test configuration. . . . . . . . . 3-4

Figure 3-4. Program 5 results: Gummel plot . . . . . . . . 3-5

Figure 3-5. Test configuration for current gain tests

using search method . . . . . . . . . . . . . . . . . . . 3-6

Figure 3-6. Test configuration for fast current gain tests . . 3-8

Figure 3-7. Configuration for I

CEO

tests . . . . . . . . . . . 3-11

Figure 3-8. Program 8 results: I

CEO

vs. V

CEO

. . . . . . . . . 3-12

Section 4 FET Tests

Figure 4-1. Test configuration for common-source tests . . 4-2

Figure 4-2. Program 9 results: Common-source

characteristics . . . . . . . . . . . . . . . . . . . . . . 4-3

Figure 4-3. Configuration for transductance tests . . . . . 4-4

Figure 4-4. Program 10 results: Transconductance vs. VGS . 4-5

Figure 4-5. Program 10 results: Transconductance vs. ID . . 4-5

Figure 4-6. Configuration for search method

threshold tests . . . . . . . . . . . . . . . . . . . . . . 4-6

Figure 4-7. Configuration for self-bias threshold tests . . . 4-8

Section 5 Using Substrate Bias

Figure 5-1. TSP-Link connections for two instruments . . . 5-1

Figure 5-2. TSP-Link instrument connections . . . . . . . . 5-2

Figure 5-3. Program 12 test configuration . . . . . . . . . 5-3

Figure 5-4. Program 12 typical results: ISB vs. VGS . . . . . 5-4

Figure 5-5. Program 13 test configuration. . . . . . . . . . 5-5

Figure 5-6. Program 13 typical results: Common-source

characteristics with substrate bias . . . . . . . . . . . . 5-6

Figure 5-7. Program 14 test configuration . . . . . . . . . . 5-8

Figure 5-8. Program 14 typical results: Common-emitter

characteristics with substrate bias . . . . . . . . . . . . 5-9

Section 6 High Power Tests

Figure 6-1. High current (SMUs in parallel). . . . . . . . . 6-1

Figure 6-2. High voltage (SMUs in series) . . . . . . . . . . 6-2

Appendix A Scripts

Page 7

Page 8

1-1

Section 1

General Information

1.1 Introduction

The following paragraphs discuss the overall hardware and software configurations of the system necessary to run the example

application programs in this guide.

1.2 Hardware Configuration

1.2.1 System Configuration

Figure 1-1 shows the overall hardware configuration of a typical

test system. The various components in the system perform a

number of functions:

Series 2600 System SourceMeter Instruments: System Source Meter instruments are specialized test instruments capable

of sourcing current and simultaneously measuring voltage, or

sourcing current and simultaneously measuring voltage. A single

Source-Measure Unit (SMU) channel is required when testing twoterminal devices such as resistors or capacitors. Three- and fourterminal devices, such as BJTs and FETs, may require two or more

SMU channels. Dual-channel System SourceMeter instruments,

such as the Models 2602, 2612, and 2636, provide two SMUs in a

half-rack instrument. Their ease of programming, flexible expansion, and wide coverage of source/measure signal levels make

them ideal for testing a wide array of discrete components. Before

starting, make sure the instrument you are using has the source

and measurement ranges that will fit your testing specifications.

Test fixture: A test fixture can be used for an external test circuit.

The test fixture can be a metal or nonmetallic enclosure, and is

typically equipped with a lid. The test circuit is mounted inside

the test fixture. When hazardous voltages (>30Vrms, 42Vpeak)

will be present, the test fixture must have the following safety

requirements:

WAR NING

To provide protection from shock hazards, an enclosure should be provided that surrounds all live

parts. Nonmetallic enclosures must be constructed

of materials suitably rated for flammability and

the voltage and temperature requirements of the

test circuit. For metallic enclosures, the test fixture

chassis must be properly connected to safety earth

ground. A grounding wire (#18 AWG or larger)

must be attached securely to the test fixture at a

screw terminal designed for safety grounding. The

other end of the ground wire must be attached to a

known safety earth ground.

Construction Material: A metal test fixture must be connected to a

known safety earth ground as described in the WARNING above.

WAR NING

A nonmetallic test fixture must be constructed

of materials that are suitable for flammability,

voltage, and temperature conditions that may exist

in the test circuit. The construction requirements

for a nonmetallic enclosure are also described in

the WARNING above.

Test Circuit Isolation: With the lid closed, the test fixture must

completely surround the test circuit. A metal test fixture must be

electrically isolated from the test circuit. Input/output connectors

mounted on a metal test fixture must also be isolated from the test

fixture. Internally, Teflon® standoffs are typically used to insulate

the internal pc-board or guard plate for the test circuit from a

metal test fixture.

Interlock Switch: The test fixture must have a normally open interlock switch. The interlock switch must be installed so that, when

the lid of the test fixture is opened, the switch will open, and

when the lid is closed, the switch will close.

WAR NING

When an interlock is required for safety, a separate

circuit should be provided that meets the requirements of the application to protect the operator reliably from exposed voltages. The output enable pin

Series 2600

System

SourceMeter

CPU

w/GPIB

GPIB

Cable

Output

HI

Output

LO

DUT

Figure 1-1. Typical system configuration for applications

Page 9

1-2

SECTION 1

General Information

on the digital I/O port on the Models 2601 and 2602

System SourceMeter instruments is not suitable for

control of safety circuits and should not be used to

control a safety interlock. The Interlock pin on the

digital I/O port for the Models 2611, 2612, 2635, and

2636 can be used to control a safety interlock.

Computer: The test programs in this document require a PC with

IEEE-488 (GPIB) communications and cabling.

Software: Series 2600 System SourceMeter instruments each

use a powerful on-board test sequencer known as the Test Script

Processor (TSP™). The TSP is accessed through the instrument

communications port, most often, the GPIB. The test program, or

script, is simply a text file that contains commands that instruct

the instrument to perform certain actions. Scripts can be written

in many different styles as well as utilizing different programming

environments. This guide discusses script creation and management using Keithley Test Script Builder (TSB), an easy-to-use program that allows you to create, edit, and manage test scripts. For

more information on TSB and scripting, see Section 2: Using Test

Script Builder of the Series 2600 Reference Manual.

Connections and Cabling: High quality cabling, such as the

Keithley Model 2600-BAN or Model 7078-TRX-3 triaxial cables,

should be used whenever possible.

1.2.2 Remote/Local Sensing

Considerations

In order to simplify the test connections, most applications in

this guide use local sensing for the SMUs. Local sensing requires

connecting only two cables between the SMUs and the test fixture

(OUTPUT HI and OUTPUT LO).

When sourcing and/or measuring voltage in a low impedance

test circuit, there can be errors associated with IR drops in the

test leads. Using four-wire remote sense connections optimizes

voltage source and measure accuracy. When sourcing voltage,

four-wire remote sensing ensures that the programmed voltage is

delivered to the DUT. When measuring voltage, only the voltage

drop across the DUT is measured. Use four-wire remote sensing

for the following source-measure conditions:

Sourcing and/or measuring voltage in low impedance (<1k• W)

test circuits.

Enforcing voltage compliance limit directly at the DUT.•

1.3 Graphing

All of the programs in this guide print the data to the TSB Instrument Console. In some cases, graphing the data can help you visualize the characteristics of the DUT. One method of graphing is to

copy and paste the data from the TSB Instrument Console and

place it in a spreadsheet program such as Microsoft Excel.

After the script has run, and the data has been returned to the

Instrument Console, you can highlight it by using the PC’s mouse:

depress the Control and c (commonly written as Ctrl+c) keys on

the keyboard simultaneously, switch to an open Excel worksheet,

and depress Control and v simultaneously (Ctrl+v). The data

should now be placed in the open worksheet columns so you can

use the normal graphing tools available in your spreadsheet program to graph the data as needed.

This Applications Guide is designed for Series 2600 instrument users who want to create their own scripts using the Test Script

Builder software. Other options include LabTracer® 2 software, the Automated Characterization Suite (ACS), and a LabVIEW driver.

Page 10

2-1

Section 2

Two-terminal Device Tests

2.1 Introduction

Two-terminal device tests discussed in this section include voltage

coefficient tests on resistors, leakage tests on capacitors, and diode

characterization.

2.2 Instrument Connections

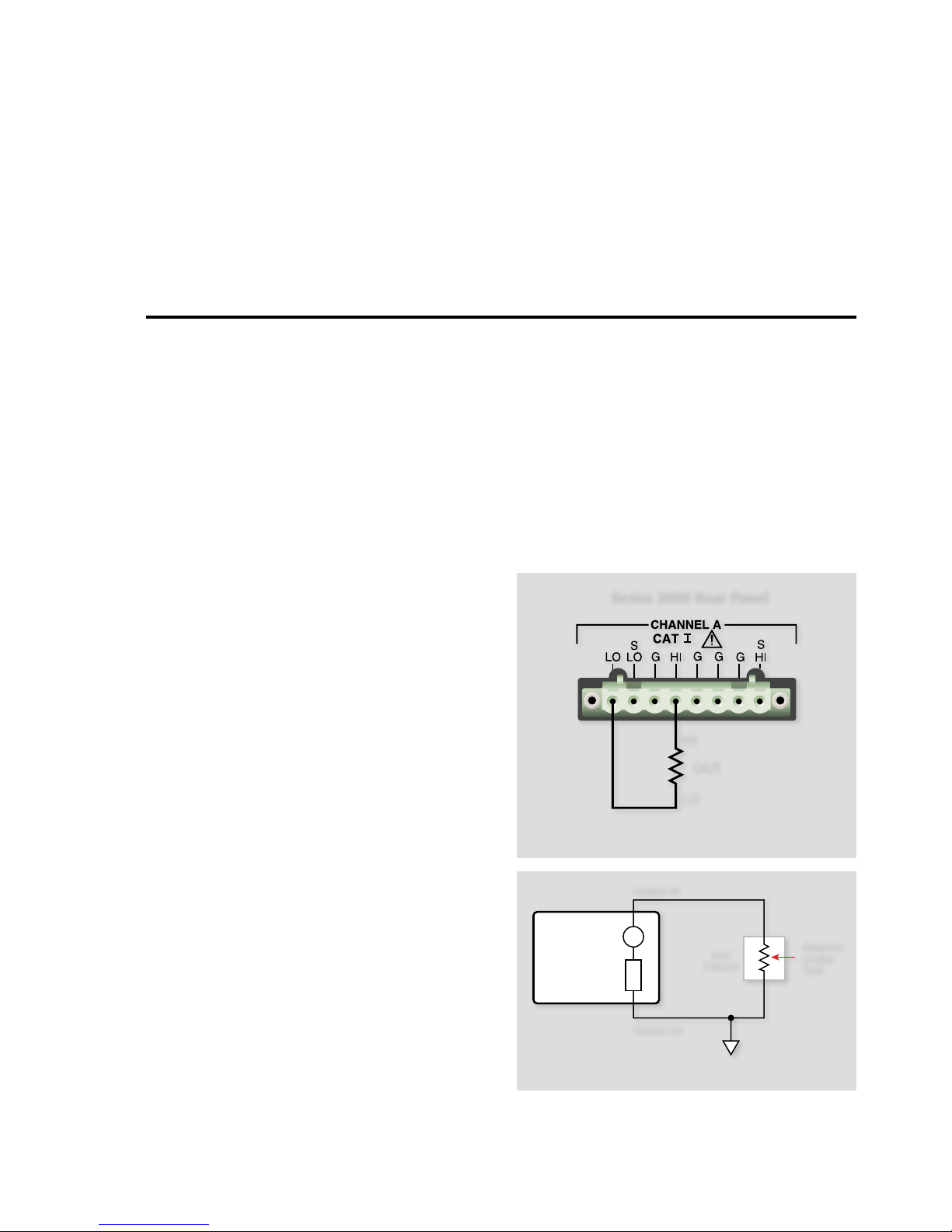

Figure 2-1 shows the instrument connections for two-terminal

device tests. Note that only one channel of a Source-Measure Unit

(SMU) is required for these applications. Be aware that multichannel models, such as the Model 2602, can be used, but are not

required to run the test program.

WAR NING

Lethal voltages may be present. To avoid a possible

shock hazard, the test system should be equipped

with protective shielding and a safety interlock

circuit. For more information on interlock techniques, see Section 10 of the Series 2600 Reference

manual.

Turn off all power before connecting or disconnecting wires or cables.

NOTES

Remote sensing connections are recommended for optimum 1.

accuracy. See paragraph 1.2.2 for details.

If measurement noise is a problem, or for critical, low level 2.

applications, use shielded cable for all signal connections.

2.3 Voltage Coefficient

Tests of Resistors

Resistors often show a change in resistance with applied voltage

with high megohm resistors (>109W) showing the most pronounced effects. This change in resistance can be characterized as

the voltage coefficient. The following paragraphs discuss voltage

coefficient tests using a single-channel Model 2601 System SourceMeter instrument. The testing can be performed using any of the

Series 2600 System SourceMeter instruments.

2.3.1 Test Configuration

The test configuration for voltage coefficient measurements is

shown in Figure 2-2. One SMU sources the voltage across the

resistor under test and measures the resulting current through

the resistor.

2.3.2 Voltage Coefficient Calculations

Two different current readings at two different voltage values are

required to calculate the voltage coefficient. Two resistance read-

HI

LO

DUT

Series 2600 Rear Panel

Figure 2-1. Series 2600 two-wire connections (local

sensing)

Series 2600

System

SourceMeter

Channel A

Source V,

Measure I

R = V/I

I

V

R

Test

Fixture

Resistor

Under

Test

Output HI

Output LO

Figure 2-2. Voltage coefficient test configuration

Page 11

2-2

SECTION 2

Two-terminal Device Tests

ings, R1 and R2, are then obtained, and the voltage coefficient in

%/V can then be calculated as follows:

100 (R2 – R1)

Voltage Coefficient (%/V) =

__________

R

1

(V2 – V1)

where: R1 = resistance calculated with first applied voltage (V1).

R

2

= resistance calculated with second applied voltage

(V2).

For example, assume that the following values are obtained:

R

1

= 1.01 × 1010W

R

2

= 1 × 1010W

(V2 – V1) = 10V

The voltage coefficient is:

100 (1×103)

Voltage Coefficient (%/V) =

__________

= 0.1%/V

1×1 010 (10)

2.3.3 Measurement Considerations

A couple of points should be noted when using this procedure to

determine the voltage coefficient of high megohm resistors. Keep

in mind that any leakage resistance in the test system will degrade

the accuracy of your measurements. To avoid such problems, use

only high quality test fixtures that have insulation resistances

greater than the resistances being measured. Using isolation resistances 10× greater than the measured resistance is a good rule of

thumb. Also, make certain that the test fixture sockets are kept

clean and free of contamination as oils and dirt can lower the

resistance of the fixture and cause error in the measurement.

There is an upper limit on the resistance value that can be

measured using this test configuration. For one thing, even a

well- designed test fixture has a finite (although very high) path

isolation value. Secondly, the maximum resistance is determined

by the test voltage and current-measurement resolution of the test

instrument. Finally, the instrument has a typical output impedance of 1015W. To maximize measurement accuracy with a given

resistor, use the highest test voltages possible.

2.3.4 Example Program 1: Voltage

Coefficient Test

Program 1 demonstrates programming techniques for voltage

coefficient tests. Follow the steps that follow to use the test program. To reiterate, this test requires a single Source-Measure

channel. For this example, we will refer to the single-channel

Model 2601 System SourceMeter instrument. The test program

can be used with the multi-channel members of the Series 2600

family with no modification.

With the power off, connect the Model 2601 System Source-1.

Meter instrument to the computer’s IEEE-488 interface.

Connect the test fixture to the instrument using appropriate 2.

cables (see Figure 2-1).

Turn on the instrument, and allow the unit to warm up for 3.

two hours for rated accuracy.

Turn on the computer and start Test Script Builder (TSB). Once 4.

the program has started, open a session by connecting to the

instrument. For details on how to use TSB, see the Series 2600

Reference Manual.

You can simply copy and paste the code from Appendix A 5.

in this guide into the TSB script editing window (Program

1: Voltage Coefficient), manually enter the code from the

appendix, or import the TSP file ‘Volt_Co.tsp’ after downloading it to your PC.

If your computer is currently connected to the Internet, you

can click on this link to begin downloading: http://www.

keithley.com/data?asset=50914.

Install the resistor being tested in the test fixture. The first 6.

step in the operation requires us first to send the code to the

instrument. The simplest method is to right-click in the open

script window of TSB, and select ‘Run as TSP file’. This will

compile the code and place it in the volatile run-time memory

of the instrument. To store the program in non-volatile

memory, see the “TSP Programming Fundamentals” section of

the Series 2600 Reference Manual.

Once the code has been placed in the instrument run-time 7.

memory, we can run it simply by calling the function ‘

Volt _

Co()

’. This can be done by typing the text ‘

Volt _ Co()

’ after

the active prompt in the Instrument Console line of TSB.

In the program 8. ‘Volt_ Co.tsp’, the function

Volt _

Co(v1src, v2src)

is created. The variables

v1src

and

v2src

represent the two test voltage values applied to the

device-under-test (DUT). If they are left blank, the function

will use the default values given to these variables, but you can

specify what voltages are applied by simply sending voltages

that are in-range in the function call. As an example, if you

wanted to source 2V followed by 10V, simply send

Volt _

Co(2, 10)

to the instrument.

The instrument will then source the programmed voltages 9.

and measure the respective currents through the resistor. The

calculated voltage coefficient and two resistance values will

then be displayed in the Instrument Console window of TSB.

Page 12

2-3

SECTION 2

Two-terminal Device Tests

2.3.5 Typical Program 1 Results

The actual voltage coefficient you obtain using the program will,

of course, depend on the resistor being tested. The typical voltage

coefficient obtained for a 10GW resistor (Keithley part number

R-319-10G) was about 8ppm/V (0.008%/V).

2.3.6 Program 1 Description

At the start of the program, the instrument is reset to default conditions, and the error queue and data storage buffers are cleared.

The following configuration is then applied before the data collection begins:

Source V, DC mode•

Local sense•

100mA compliance, autorange measure•

1NPLC line cycle integration•

v1src:

• 100V

v2src:

• 200V

The instrument then sources

v1src

, checks the source for com-

pliance in the function named

Check _ Comp()

, and performs a

measurement of the current if compliance is false. The source then

applies

v2src

and performs a second current measurement.

The function

Calc _ Val()

then performs the calculation of the

voltage coefficient based on the programmed source values and

the measured current values as described in Section 2.3.2, Voltage

Coefficient Calculations.

The instrument output is then turned off and the function

Pri nt _ Data()

is run to print the data to the TSB window.

Note: If the compliance is true, the instrument will abort the program and print a warning to the TSB window. Check the DUT

and cabling to make sure everything is connected correctly and

re-run the test.

2.4 Capacitor Leakage Test

One important parameter associated with capacitors is leakage

current. Once the leakage current is known, the insulation resistance can be easily calculated. The amount of leakage current in

a capacitor depends both on the type of dielectric as well as the

applied voltage. With a test voltage of 100V, for example, ceramic

dielectric capacitors have typical leakage currents in the nanoamp

to picoamp range, while polystyrene and polyester dielectric

capacitors exhibit a much lower leakage current—typically in the

femtoamp (10

–15

A) range

2.4.1 Test Configuration

Figure 2-3 shows the test configuration for the capacitor leakage

test. The instrument sources the test voltage across the capacitor,

and it measures the resulting leakage current through the device.

The resistor, R, is included for current limiting, and it also helps

to reduce noise. A typical value for R is 1MW, although that value

can be decreased for larger capacitor values. Note, however, that

values less than 10kW are not recommended.

2.4.2 Leakage Resistance Calculations

Once the leakage current is known, the leakage resistance can

easily be calculated from the applied voltage and leakage current

value as follows:

R = V/I

Resistor R required to

limit current and

reduce noise.

Typical value: 1MΩ

Minimum value: 10kΩ

Series 2600

System

SourceMeter

Channel A

Source V,

Measure I

I

V

R

C

Test

Fixture

Capacitor

Under

Test

Output HI I

LKG

Output LO

Figure 2-3. Test configuration for capacitor leakage test

Page 13

2-4

SECTION 2

Two-terminal Device Tests

For example, assume that you measured a leakage current of 25nA

with a test voltage of 100V. The leakage resistance is simply:

R =100/25nA = 4GW (4 × 109W)

2.4.3 Measurement Considerations

After the voltage is applied to the capacitor, the device must be

allowed to charge fully before the current measurement can be

made. Otherwise, an erroneous current, with a much higher

value, will be measured. The time period during which the capacitor charges is often termed the “soak” time. A typical soak time is

seven time constants, or 7RC, which would allow settling to less

than 0.1% of final value. For example, if R is 1MW, and C is 1µF,

the recommended soak time is seven seconds. With small leakage

currents (<1nA), it may be necessary to use a fixed measurement

range instead of auto ranging.

2.4.4 Example Program 2:

Capacitor Leakage Test

Program 2 performs the capacitor leakage test described above.

Follow the steps that follow to run the test using this program.

WAR NING

Hazardous voltage may be present on the capacitor

leads after running this test. Discharge the capacitor before removing it from the test fixture.

With the power off, connect the instrument to the computer’s 1.

IEEE-488 interface.

Connect the test fixture to the instrument using appropriate 2.

cables.

Turn on the instrument, and allow the unit to warm up for 3.

two hours for rated accuracy.

Turn on the computer and start Test Script Builder (TSB). Once 4.

the program has started, open a session by connecting to the

instrument. For details on how to use TSB, see the Series 2600

Reference Manual.

You can simply copy and paste the code from Appendix A in 5.

this guide into the TSB script editing window (Program 2),

manually enter the code from the appendix, or import the TSP

file ‘Cap_Leak.tsp’ after downloading it to your PC.

If your computer is currently connected to the Internet, you

can click on this link to begin downloading: http://www.

keithley.com/data?asset=50927.

Discharge and install the capacitor being tested, along with 6.

the series resistor, in the appropriate axial component sockets

of the test fixture.

WAR NING

Care should be taken when discharging the capacitor, as the voltage present may represent a shock

hazard!

Now, we must send the code to the instrument. The simplest 7.

method is to right-click in the open script window of TSB,

and select ‘Run as TSP file’. This will compile the code and

place it in the volatile run-time memory of the instrument.

To store the program in non-volatile memory, see the “TSP

Programming Fundamentals” section of the Series 2600 Reference Manual.

Once the code has been placed in the instrument run-time 8.

memory, we can run it at any time simply by calling the function ‘

Cap _ Le a k()

’. This can be done by typing the text

‘

Cap _ Le a k()

’ after the active prompt in the Instrument

Console line of TSB.

In the program ‘9. Cap_Leak.tsp’, the function

Cap _

Lea k(v sr c)

is created. The variable

vsrc

represents the

test voltage value applied to the device-under-test (DUT). If

it is left blank, the function will use the default value given

to the variable, but you can specify what voltage is applied

by simply sending a voltage that is in-range in the function

call. As an example, if you wanted to source 100V, simply send

Cap _ Le a k(100)

to the instrument.

The instrument will then source the programmed voltage and 10.

measure the respective current through the capacitor. The

measured current leakage and calculated resistance value will

then be displayed in the Instrument Console window of TSB.

NOTE

The capacitor should be fully discharged before running the test. This can be accomplished by sourcing 0V

on the device for the soak time or by shorting the leads

together. Care should be taken because some capacitors

can hold a charge for a significant period of time and

could pose an electrocution risk.

The soak time, denoted in the code as the variable

l _ soak

,

has a default value of 10s. When entering the soak time, choose

a value of at least 7RC to allow settling to within 0.1% of final

value. At very low currents (<500fA), a longer settling time may

be required to compensate for dielectric absorption, especially at

high voltages.

2.4.5 Typical Program 2 Results

As pointed out earlier, the exact value of leakage current will

depend on the capacitor value as well as the dielectric. A typical

value obtained for 1µF aluminum electrolytic capacitor was about

80nA at 25V.

Page 14

2-5

SECTION 2

Two-terminal Device Tests

2.4.6 Program 2 Description

At the start of the program, the instrument is reset to default conditions, the error queue, and data storage buffers are cleared. The

following configuration is then applied before the data collection

begins:

Source V, DC mode•

Local sense•

10mA compliance, autorange measure•

1 NPLC Line cycle integration•

vsrc:

• 40V

The instrument then sources

vsrc

, checks the source for compli-

ance in the function named

Check _ Comp()

, and performs a

measurement of the current if compliance is false.

The function

Calc _ Val()

then performs the calculation of

the leakage resistance based on the programmed source value

and the measured current value as described in paragraph 2.4.2,

Leakage Resistance Calculations.

The instrument output is then turned off and the function

Pri nt _ Data()

is run to print the data to the TSB window.

Note: If the compliance is true, the instrument will abort the program and print a warning to the TSB window. Check the DUT

and cabling to make sure everything is connected correctly and

re-run the test.

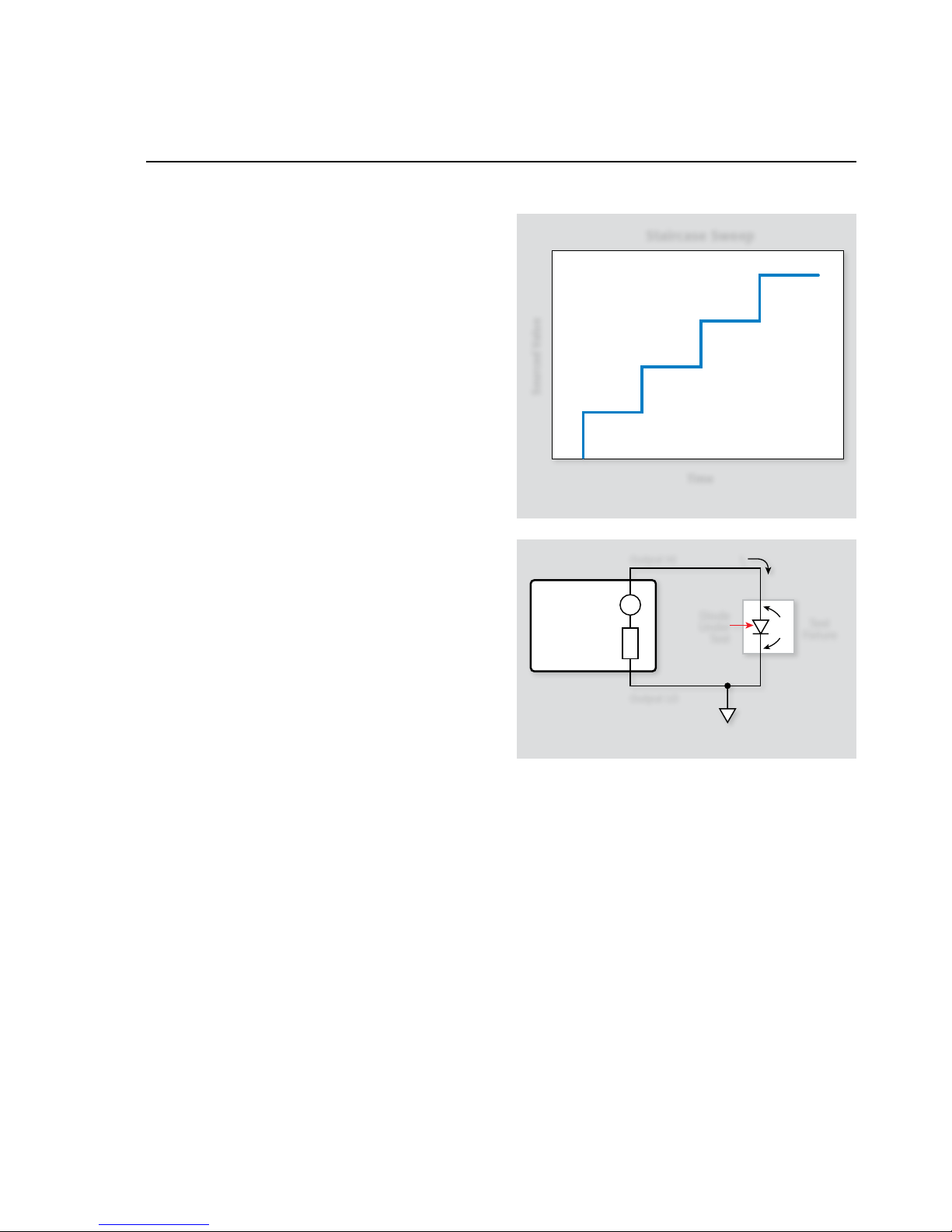

2.5 Diode Characterization

The System SourceMeter instrument is ideal for characterizing

diodes because it can source a current through the device, and

measure the resulting forward voltage drop (VF) across the device.

A standard technique for diode characterization is to perform a

staircase sweep (Figure 2-4) of the source current from a starting

value to an end value while measuring the voltage at each current

step. The following paragraphs discuss the test configuration and

give a sample test program for such tests.

2.5.1 Test Configuration

Figure 2-5 shows the test configuration for the diode characterization test. The System SourceMeter instrument is used to source

the forward current (IF) through the diode under test, and it also

measures the forward voltage (VF) across the device. IF is swept

across the desired range of values, and VF is measured at each current. Note that the same general configuration could be used to

measure leakage current by reversing the diode, sourcing voltage,

and measuring the leakage current.

2.5.2 Measurement Considerations

Because the voltages being measured will be fairly small (≈0.6V),

remote sensing can be used to minimize the effects of voltage

drops across the test connections and in the test fixture. Remote

sensing requires the use of the Sense connections on the System

SourceMeter channel being used, as well as changing the code to

reflect remote sensing. For more information on remote sensing,

see the Series 2600 Reference Manual.

2.5.3 Example Program 3:

Diode Characterization

Program 3 demonstrates the basic programming techniques for

running the diode characterization test. Follow these steps to use

this program:

Staircase Sweep

Time

Sourced Value

Figure 2-4. Staircase sweep

I

V

Test

Fixture

Diode

Under

Test

Output HI

Output LO

Series 2600

System

SourceMeter

Channel A

Sweep I

F

,

Measure V

F

I

F

V

F

Figure 2-5. Test configuration for diode characterization

Page 15

2-6

SECTION 2

Two-terminal Device Tests

With the power off, connect the instrument to the computer’s 1.

IEEE-488 interface.

Connect the test fixture to the instrument using appropriate 2.

cables.

Turn on the instrument, and allow the unit to warm up for 3.

two hours for rated accuracy.

Turn on the computer and start Test Script Builder (TSB). Once 4.

the program has started, open a session by connecting to the

instrument. For details on how to use TSB, see the Series 2600

Reference Manual.

You can simply copy and paste the code from Appendix A in 5.

this guide into the TSB script editing window (Program 3A,

Diode Forward Characterization), manually enter the code

from the appendix, or import the TSP file ‘Diode_Fwd_Char.

tsp’ after downloading it to your PC.

If your computer is currently connected to the Internet, you

can click on this link to begin downloading: http://www.

keithley.com/data?asset=50924.

Install a small-signal silicon diode such as a 1N914 or 1N4148 6.

in the appropriate axial socket of the test fixture.

Now, we must send the code to the instrument. One method 7.

is simply to right-click in the open script window of TSB, and

select ‘Run as TSP file’. This will compile the code and place

it in the volatile run-time memory of the instrument. To store

the program in non-volatile memory, see the “TSP Programming Fundamentals” section of the Series 2600 Reference

Manual.

Once the code has been placed in the instrument run-time 8.

memory, we can run it at any time simply by calling the function ‘Diode_Fwd_Char()’. This can be done by typing the text

‘

Dio de _ F w d _ Ch ar()

’ after the active prompt in the

Instrument Console line of TSB.

In the program ‘Diode_Fwd_Char.tsp’, the function 9.

Diode _

Fwd _ Char(ilevel, start, stop, steps)

is

created. The variable

ilevel

represents the current value

applied to the device-under-test (DUT) both before and after

the staircase sweep has been applied. The

start

variable

represents the starting current value for the sweep, stop represents the end current value, and steps represents the number

of steps in the sweep. If any values are left blank, the function

will use the default value given to that variable, but you can

specify what voltage is applied by simply sending a voltage that

is in-range in the function call.

As an example, if you wanted to configure a test that would 10.

source 0mA before and after the sweep, with a sweep start

value of 1mA, stop value of 10mA, and 10 steps, you would

simply send

Diode _ Fwd _ Char(0, 0.001, 0.01,

10)

to the instrument.

The instrument will then source the programmed current 11.

staircase sweep and measure the respective voltage at each

step. The measured and sourced values are then printed to

the screen (if using TSB). To graph the results, simply copy

and paste the data into a spreadsheet such as Microsoft Excel

and chart.

2.5.4 Typical Program 3 Results

Figure 2-6 shows typical results obtained using Example Program

3. These results are for a 1N914 silicon diode.

2.5.5 Program 3 Description

At the start of the program, the instrument is reset to default conditions, the error queue, and data storage buffers are cleared. The

following configuration is then applied before the data collection

begins:

Source I•

Local sense•

10V compliance, autorange measure•

Ile v el:

• 0A

star t:

• 0.001 A

stop:

• 0.01A

steps:

• 10

The instrument then sources

ilevel

, dwells

l _ delay

sec-

onds, and begins the staircase sweep from

start

to

stop

in

steps. At each current step, both the current and voltage are

measured.

Diode Forward Characteristics

Current (Amps)

Voltage Data (V)

Voltage (Volts)

9.00E–01

8.00E–01

7.00E–01

6.00E–01

5.00E–01

4.00E–01

3.00E–01

2.00E–01

1.00E–01

0.00E–00

0.00E+00 2.00E–03 4.00E–03 6.00E–03 8.00E–03 1. 00E–02

Figure 2-6. Program 3 results: Diode forward

characteristics

Page 16

2-7

SECTION 2

Two-terminal Device Tests

The instrument output is then turned off and the function

Pri nt _ Data()

is run to print the data to the TSB window. To

graph the results, simply copy and paste the data into a spreadsheet such as Microsoft Excel and chart.

2.5.6 Using Log Sweeps

With some devices, it may be desirable to use a log sweep because

of the wide range of currents necessary to perform the test. Pro-

gram 3B performs a log sweep of the diode current.

If your computer is currently connected to the Internet, you can

click on this link to begin downloading ‘Diode_Fwd_Char_Log.

tsp’: http://www.keithley.com/data?asset=50923.

Note that the start and stop currents are programmed just as

before, although with a much wider range than would be practical

with a linear sweep. With log sweep, however, the

points

pa rameter, which defines the number of points per decade, replaces the

steps parameter that is used with the linear sweep.

To run the Log sweep, we must send the code to the instrument.

One method is simply to right-click in the open script window

of TSB, and select ‘Run as TSP file’. This will compile the code

and place it in the volatile run-time memory of the instrument.

To store the program in non-volatile memory, see the “TSP Programming Fundamentals” section of the Series 2600 Reference

Manual.

Once the code has been placed in the instrument run-time

memory, we can run it at any time simply by calling the function

‘Diode_Fwd_Char_Log()’. This can be done by typing the text

‘

Diode _ Fwd _ Char _ Log()

’ after the active prompt in the

Instrument Console line of TSB.

2.5.7 Using Pulsed Sweeps

In some cases, it may be desirable to use a pulsed sweep to avoid

device self-heating that could affect the test results. Program 3C

performs a staircase pulse sweep. In this program, there are two

additional variables ton and toff, where ton is the source on duration and toff is the source off time for the pulse. During the toff

portions of the sweep, the source value is returned to the ilevel

bias value.

If your computer is currently connected to the Internet, you can

click on this link to begin downloading ‘Diode_Fwd_Char_Pulse.

tsp’: http://www.keithley.com/data?asset=50922.

Page 17

2-8

SECTION 2

Two-terminal Device Tests

Page 18

3-1

Section 3

Bipolar Transistor Tests

3.1 Introduction

Bipolar transistor tests discussed in this section include: tests to

generate common-emitter characteristic curves, Gummel plot,

current gain, and transistor leakage tests.

3.2 Instrument Connections

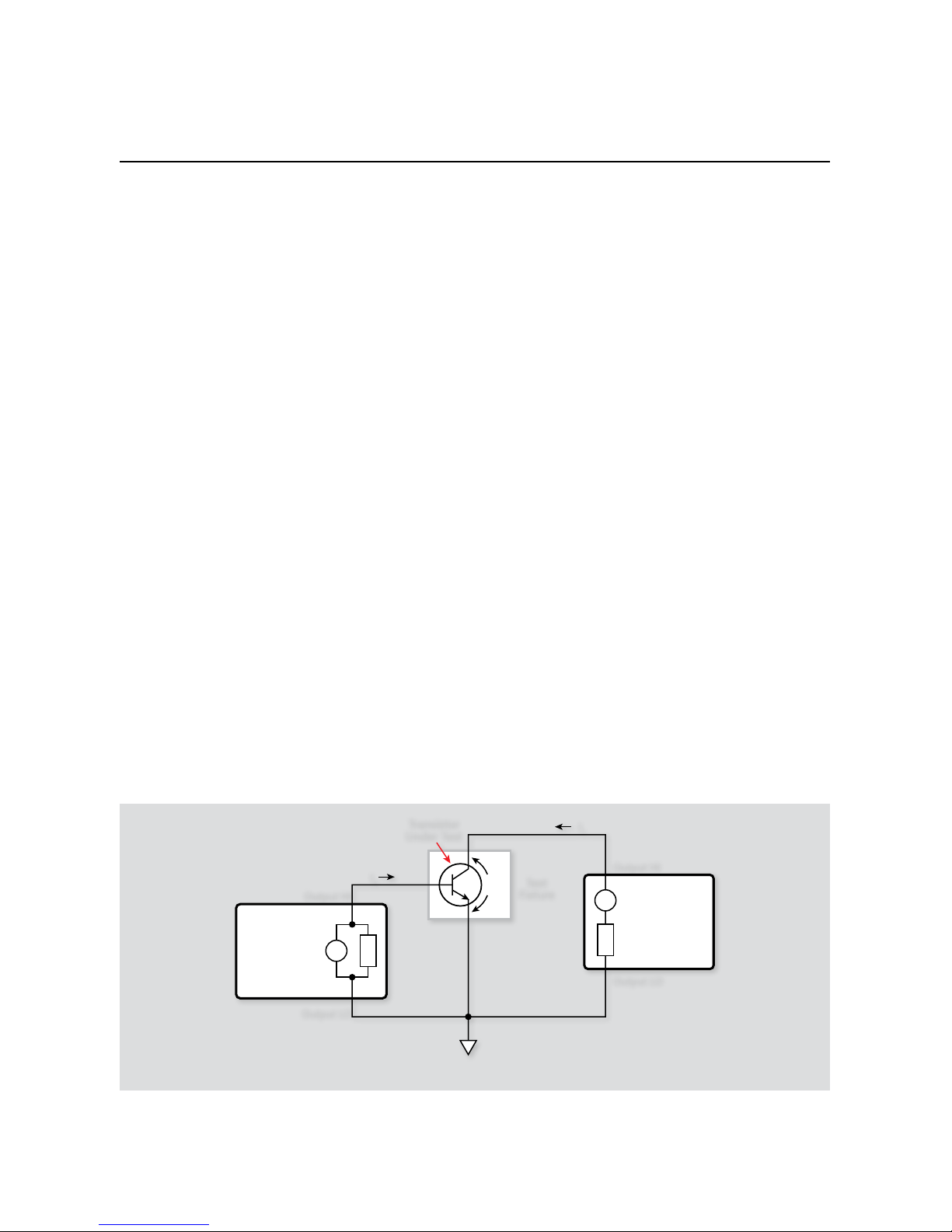

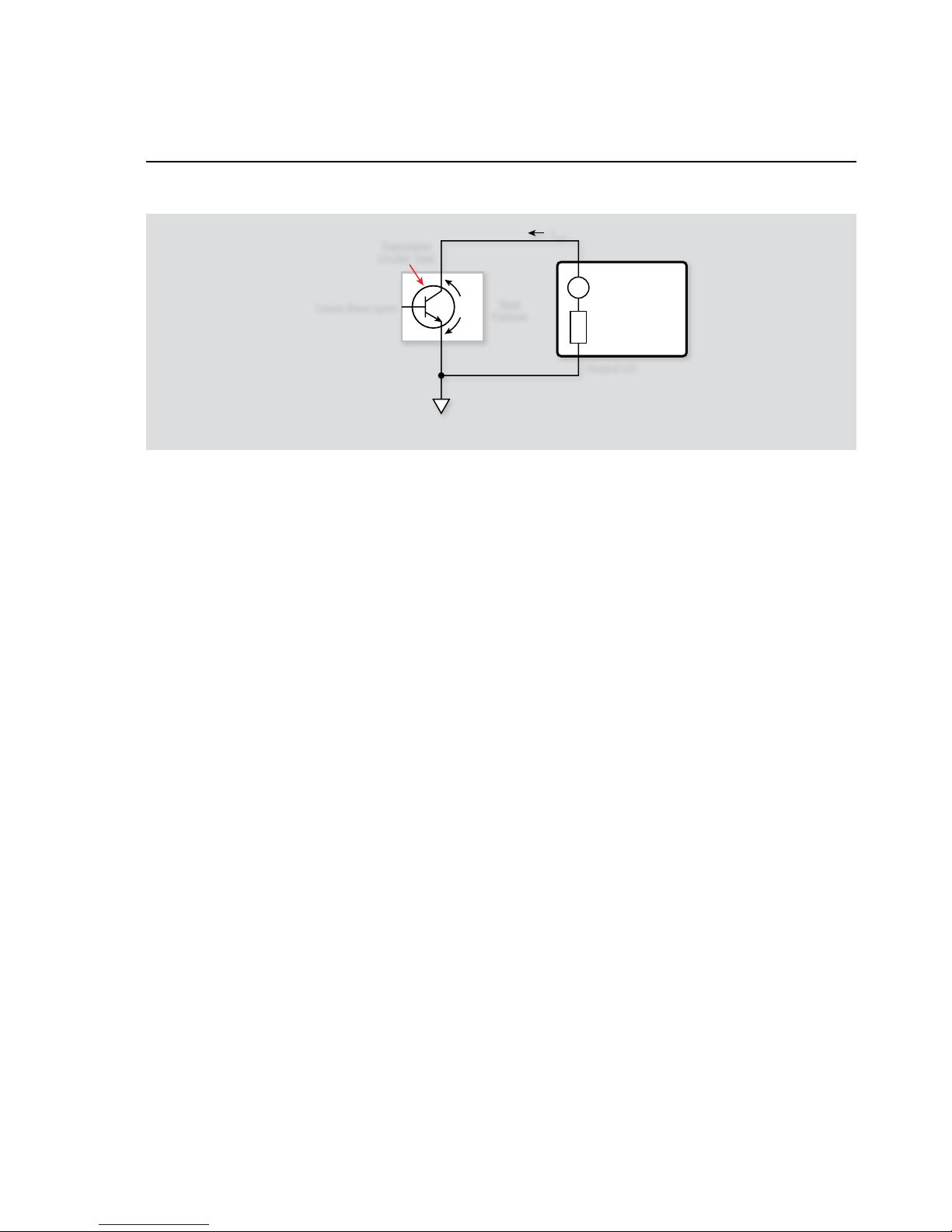

Figure 3-1 shows the instrument connections for the bipolar

transistor tests outlined in this section. Two Source-Measure

channels are required for the tests (except for the leakage current

test, which requires only one Source-Measure channel).

Keithley Model 2600-BAN cables or Model 7078-TRX-3 low noise

triaxial cables are recommended to make instrument-to-test fixture connections. In addition, the safety interlock connecting

cables must be connected to the instrument and fixture if using

instrumentation capable of producing greater than 42V.

WAR NING

Lethal voltages may be exposed when working with

test fixtures. To avoid a possible shock hazard, the

fixture must be equipped with a working safety

interlock circuit. For more information on the

interlock of the Series 2600, please see the Series

2600 Reference Manual.

NOTES

Remote sensing connections are recommended for

optimum accuracy. See paragraph 1.2.2 for details.

If measurement noise is a problem, or for critical, low

level applications, use shielded cable for all signal

connections.

3.3 Common-Emitter

Characteristics

Common-emitter characteristics are probably the most familiar

type of curves generated for bipolar transistors. Test data used to

generate these curves is obtained by sweeping the base current

(IB) across the desired range of values at specific increments. At

each be current value, the collector-emitter voltage (VCE) is swept

across the desired range, again at specific increments. At each VCE

value, the collector current (IC) is measured.

Once the data is collected, it is conveniently printed (if using TSB).

You can then use the copy-and-paste method to place the data

into a spreadsheet program such as Microsoft Excel. Common

I

V

Series 2600

System

SourceMeter

Channel A

Sweep V

CE

,

Measure I

C

Series 2600

System

SourceMeter

Channel B

Sweep I

B

VI

V

CE

Test

Fixture

Transistor

Under Test

Output HI

Output HI

Output LO

Output LO

I

B

I

C

Figure 3-1. Test configuration for common-emitter tests

Page 19

3-2

SECTION 3

Bipolar Transistor Tests

plotting styles include graphing IC vs. VCE for each value of IB. The

result is a family of curves that shows how IC varies with VCE at

specific IB values.

3.3.1 Test Configuration

Figure 3-1 shows the test configuration for the common-emitter

characteristic tests. Many of the transistor tests performed require

two Source-Measure Units (SMUs). The Series 2600 System

SourceMeter instruments have dual-channel members such as the

Model 2602, 2612, and 2636. This offers a convenient transistor

test system all in one box. The tests can be run using two singlechannel instruments, but the code will have to be modified to

do so.

In this test, SMUB sweeps IB across the desired range, and SMUA

sweeps VCE and measures IC. Note that an NPN transistor is shown

as part of the test configuration. A small-signal NPN transistor

with an approximate current gain of 500 (such as a 2N5089) is

recommended for use with the test program below. Other similar

transistors such as a 2N3904 may also be used, but the program

may require modification.

3.3.2 Measurement Considerations

A fixed delay period of 100ms, which is included in the program,

may not be sufficient for testing some devices. Also, it maybe necessary to change the programmed current values to optimize the

tests for a particular device.

3.3.3 Example Program 4:

Common-Emitter Characteristics

Program 4 can be used to run common-emitter characteristic tests

on small-signal NPN transistors. In order to run the program,

follow these steps:

With the power off, connect a dual-channel System Source-1.

Meter instrument to the computer’s IEEE-488 interface.

Connect the test fixture to both units using appropriate cables 2.

(see Figure 3-1).

Turn on the instrument and allow the unit to warm up for two 3.

hours for rated accuracy.

Turn on the computer and start Test Script Builder (TSB). Once 4.

the program has started, open a session by connecting to the

instrument. For details on how to use TSB, see the Series 2600

Reference Manual.

You can simply copy and paste the code from Appendix A in 5.

this guide into the TSB script editing window (Program 4),

manually enter the code from the appendix, or import the TSP

file ‘BJT_Comm_Emit.tsp’ after downloading it to your PC.

If your computer is currently connected to the Internet, you

can click on this link to begin downloading: http://www.

keithley.com/data?asset=50930.

Install an NPN transistor such as a 2N5089 in the appropriate 6.

transistor socket of the test fixture.

Now, we must send the code to the instrument. The simplest 7.

method is to right-click in the open script window of TSB,

and select ‘Run as TSP file’. This will compile the code and

place it in the volatile run-time memory of the instrument.

To store the program in non-volatile memory, see the “TSP

Programming Fundamentals” section of the Series 2600 Reference Manual.

Once the code has been placed in the instrument run-time 8.

memory, we can run it at any time simply by calling the function ‘

BJT _ Comm _ Emit()

’. This can be done by typing

the text ‘

BJT _ Comm _ Emit()

’ after the active prompt in

the Instrument Console line of TSB.

In the program ‘9. BJT_Comm_Emit.tsp’, the function

BJT _

Comm _ Emit(istart, istop, isteps, vstart,

vstop, vsteps)

is created.

istart

• represents the sweep start current value on the

base of the transistor

istop

• represents the sweep stop value

isteps

• is the number of steps in the base current sweep

vstart

• represents the sweep start voltage value on the

collector-emitter of the transistor

vstop

• represents the sweep stop voltage value

vsteps

• is the number of steps in the base current sweep

If these values are left blank, the function will use the default

values given to the variables, but you can specify each variable

value by simply sending a number that is in-range in the function call. As an example, if you wanted to have the base current

swept from 1µA to 100µA in 10 steps, and the collector-emitter

voltage (V

CEO

) to be swept from 0 to 10V in 1V steps, you would

send

BJT _ Comm _ Emit(1E-6, 100E-6, 10, 0, 10,

10)

to the instrument.

The instrument will then source the programmed start current 10.

on the base, sweep the voltage on the collector-emitter, and

measure the respective current through the collector-emitter.

The base current will be incremented and the collector-emitter

sweep will take place again. After the final base source value

and associated collector-emitter sweep, the collector-emitter

voltage (VCE), measured collector-emitter current (ICE), and

base current (IB) values will then be displayed in the Instrument Console window of TSB.

Page 20

3-3

SECTION 3

Bipolar Transistor Tests

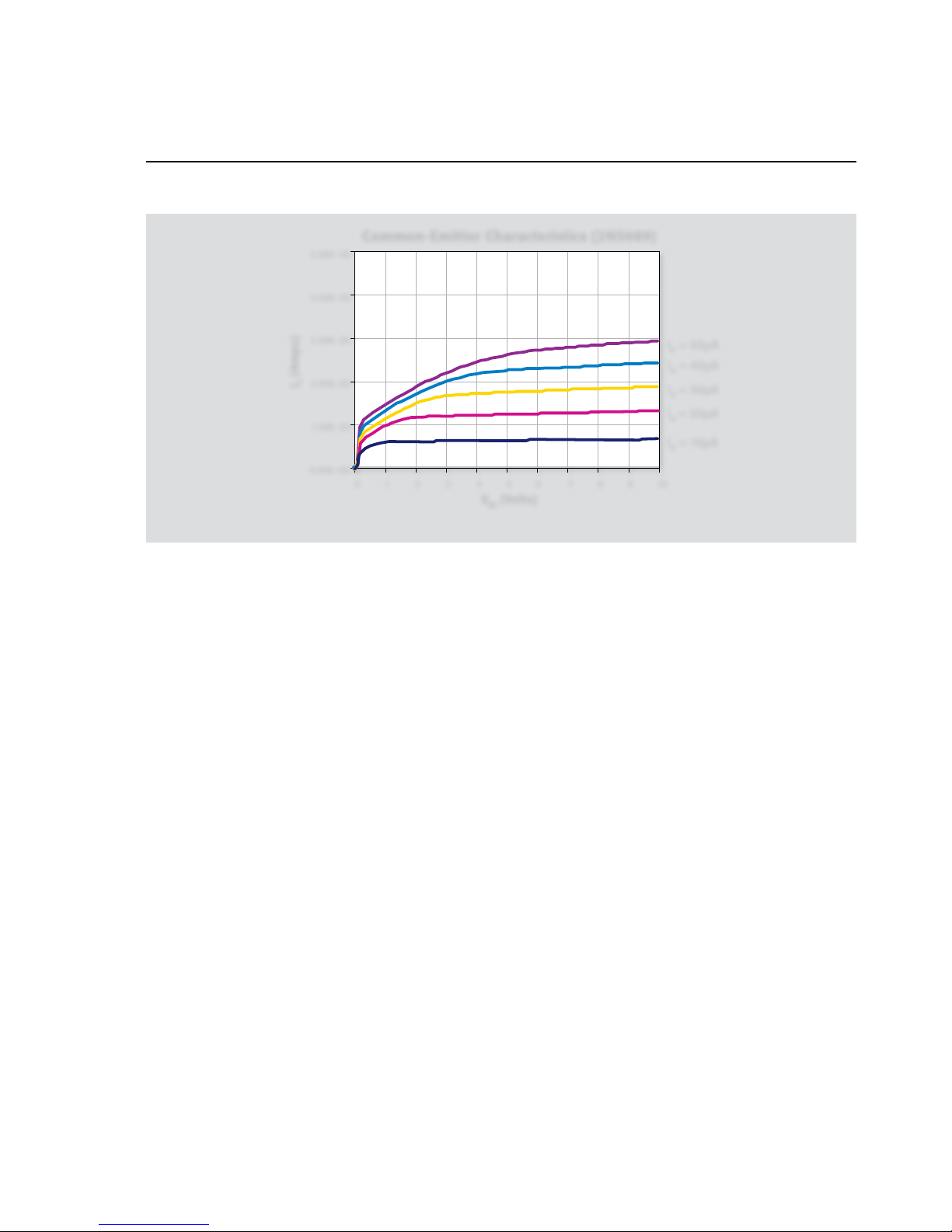

3.3.4 Typical Program 4 Results

Figure 3-2 shows typical results generated by Example Program 4.

A 2N5089 NPN transistor was used to generate these test results.

3.3.5 Program 4 Description

For the following program description, refer to the program

listing below.

Source I•

IV compliance, 1.1V range•

Local sense•

istart

• current: 10M

istop

• current: 50µA

isteps

• : 5

Following SMUB setup, SMUA, which sweeps VCE and measures

IC, is programmed as follows:

Source V•

Local sensing•

100mA compliance, autorange measure•

1 NPLC Line cycle integration (to reduce noise)•

vstart

• : 0V

vstop

• : 10V

vsteps

• : 100

Once the two units are configured, the SMUB sources

istart

,

SMUA sources

vstart

, and the voltage (VCE) and current (ICE)

for SMUA are measured. The source value for SMUA is then

incremented by

l _ vstep

, and the sweep is continued until

the source value reaches

vstop

. Then, SMUB is incremented by

l_istep

and SMUA begins another sweep from

vstart

to

vstop

in

vsteps

. This nested sweeping process continues until

SMUB reaches

istop

.

The instrument output is then turned off and the function

Pri nt _ Data()

is run to print the data to the TSB window. To

graph the results, simply copy and paste the data into a spreadsheet such as Microsoft Excel and chart.

3.4 Gummel Plot

A Gummel plot is often used to determine current gain variations

of a transistor. Data for a Gummel plot is obtained by sweeping

the base-emitter voltage (VBE) across the desired range of values at

specific increments. At each VBE value, both the base current (IB)

and collector current (IC) are measured.

Once the data are taken, the data for IB, IC, and VBE is returned to

the screen. If using TSB, a plot can be generated using the “copyand-paste” method in a spreadsheet program such as Microsoft

Excel. Because of the large differences in magnitude between IB

and IC, the Y axis is usually plotted logarithmically.

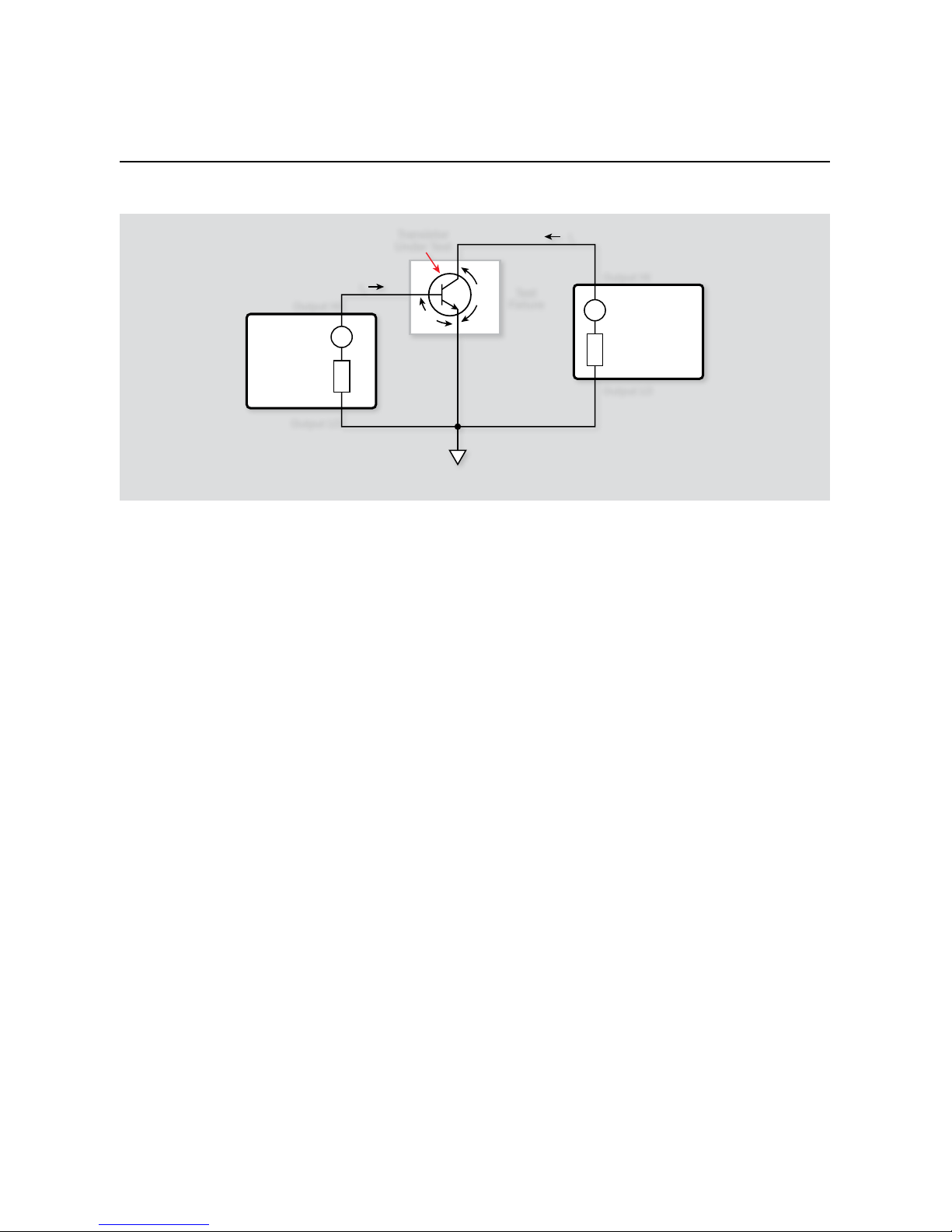

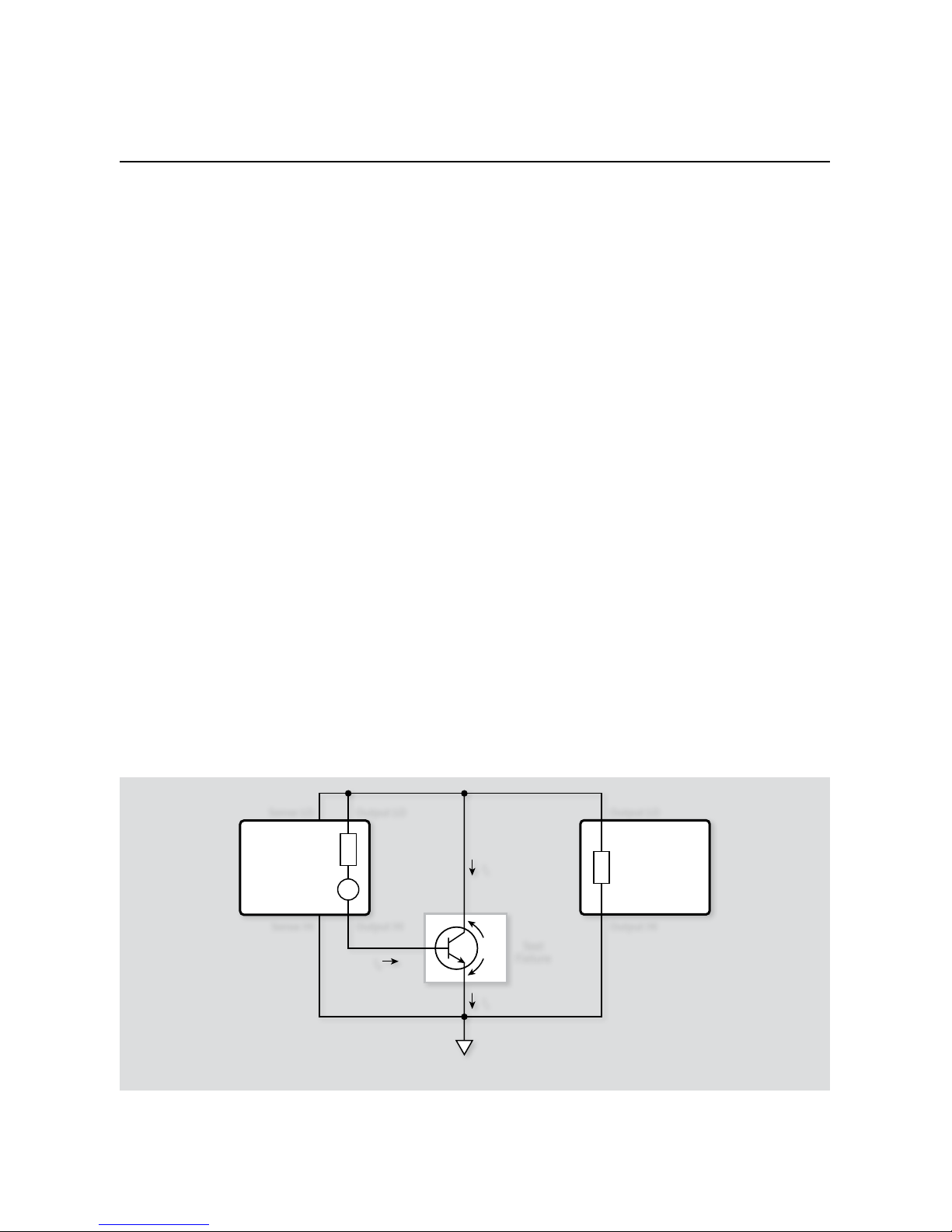

3.4.1 Test Configuration

Figure 3-3 shows the test configuration for Gummel plot tests.

SMUB is used to sweep VBE across the desired range, and it also

Common-Emitter Characteristics (2N5089)

VBE (Volts)

IB = 10µA

I

B

= 20µA

I

B

= 30µA

I

B

= 40µA

IB = 50µA

I

C

(Amps)

5.00E–02

4.00E–02

3.00E–02

2.00E–02

1.00E–02

0.00E+00

0 1 2 3 4 5 6 7 8 9 10

Figure 3-2. Program 4 results: Common-emitter characteristics

Page 21

3-4

SECTION 3

Bipolar Transistor Tests

measures IB. SMUA sets VCE to the desired fixed value, and it also

measures IC.

Due to the low current measurements associated with this type of

testing, the Keithley Model 2636 System SourceMeter instrument

is recommended. Its low level current measurement capabilities

and dual-channel configuration are ideal for producing high

quality Gummel plots of transistors.

3.4.2 Measurement Considerations

As written, the range of VBE test values is from 0V to 0.7V in 0.01V

increments. It may be necessary, however, to change these limits

for best results with your particular device. Low currents will be

measured so take the usual low current precautions.

3.4.3 Example Program 5: Gummel Plot

Program 5 demonstrates the basic programming techniques

for generating a Gummel plot. Follow these steps to run this

program:

With the power off, connect a dual-channel System Source-1.

Meter instrument to the computer’s IEEE-488 interface.

Connect the test fixture to both units using appropriate 2.

c a b l e s .

Turn on the instrument and allow the unit to warm up for two 3.

hours for rated accuracy.

Turn on the computer and start Test Script Builder (TSB). Once 4.

the program has started, open a session by connecting to the

instrument. For details on how to use TSB, see the Series 2600

Reference Manual.

You can simply copy and paste the code from Appendix A in 5.

this guide into the TSB script editing window (Program 5),

manually enter the code from the appendix, or import the TSP

file ‘Gummel.tsp’ after downloading it to your PC.

If your computer is currently connected to the Internet, you

can click on this link to begin downloading: http://www.

keithley.com/data?asset=50918

Install an NPN transistor such as a 2N5089 in the appropriate 6.

transistor socket of the test fixture.

Now, we must send the code to the instrument. The simplest 7.

method is to right-click in the open script window of TSB,

and select ‘Run as TSP file’. This will compile the code and

place it in the volatile run-time memory of the instrument.

To store the program in non-volatile memory, see the “TSP

Programming Fundamentals” section of the Series 2600 Reference Manual.

Once the code has been placed in the instrument run-time 8.

memory, we can run it at any time simply by calling the

function ‘Gummel()’. This can be done by typing the text

‘

G u m m e l()

’ after the active prompt in the Instrument Con-

sole line of TSB.

In the program ‘Gummel.tsp’, the function 9.

Gummel

(vbestart, vbestop, vbesteps, vcebias)

is

created.

vbestart

• represents the sweep start voltage value on

the base of the transistor

vbestop

• represents the sweep stop value

vbesteps

• is the number of steps in the base

voltage sweep

I

V

I

V

Series 2600

System

SourceMeter

Channel A

Source V

CE

,

Measure I

C

Series 2600

System

SourceMeter

Channel B

Sweep V

BE

Measure I

B

V

CE

V

BE

Test

Fixture

Transistor

Under Test

Output HI

Output HI

Output LO

Output LO

I

B

I

C

Figure 3-3. Gummel plot test configuration

Page 22

3-5

SECTION 3

Bipolar Transistor Tests

vcebias

• represents the voltage bias value on the

collector-emitter of the transistor

If these values are left blank, the function will use the default

values given to the variables, but you can specify each variable

value by simply sending a number that is in-range in the function call. As an example, if you wanted to have the base voltage

swept from 0.1V to 1V in 10 steps, and the collector-emitter

voltage (VCE) to be biased 5V, you would send

G u m m e l(0.1,

1, 10, 5)

to the instrument.

The base-emitter voltage will be swept between 0V and 0.7V in 10.

0.01V increments, and both IB and IC will be measured at each

VBE value. Note that a fixed collector-emitter voltage of 10V is

used for the tests.

Once the sweep has been completed, the data (I11.

B

, IC, and VBE)

will be presented in the Instrument Console window of TSB.

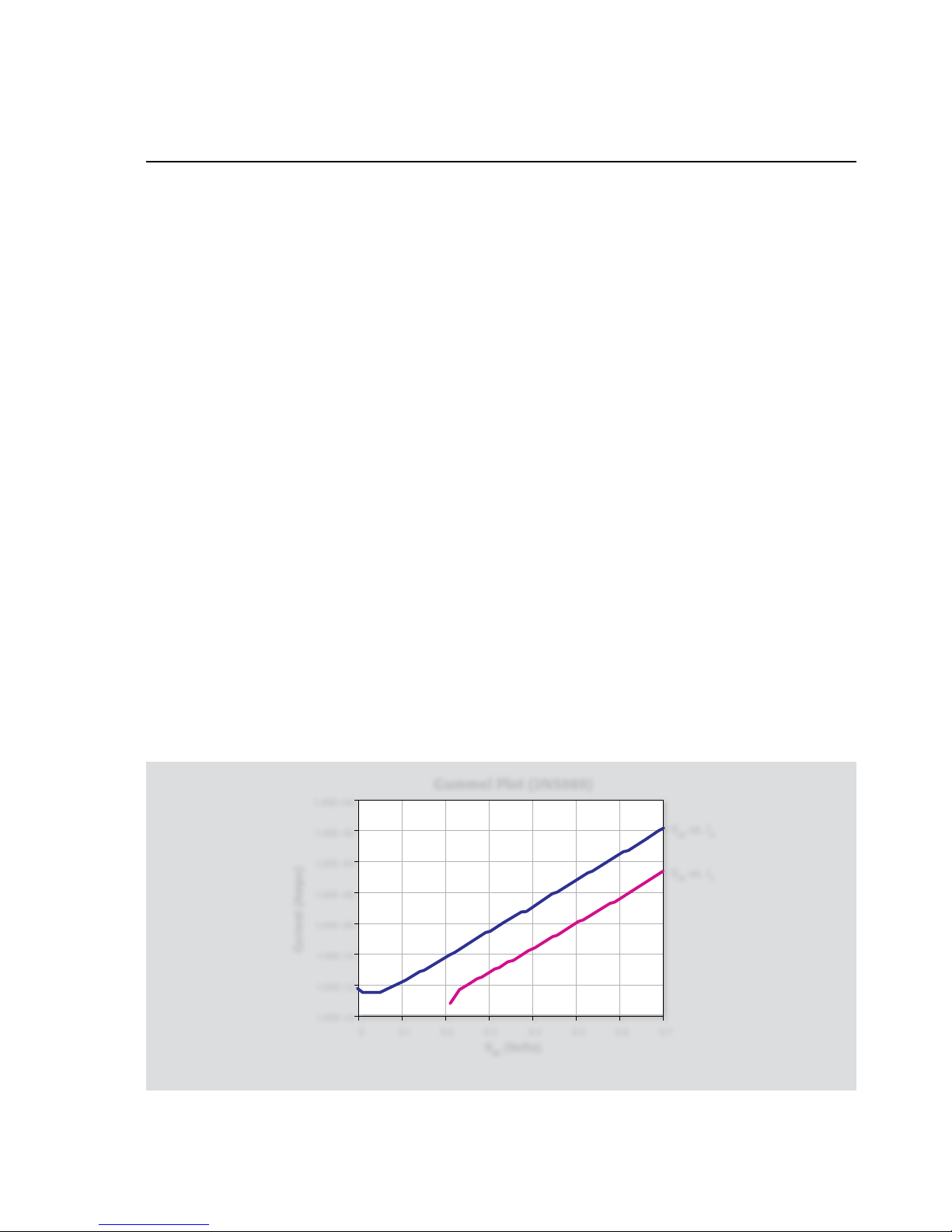

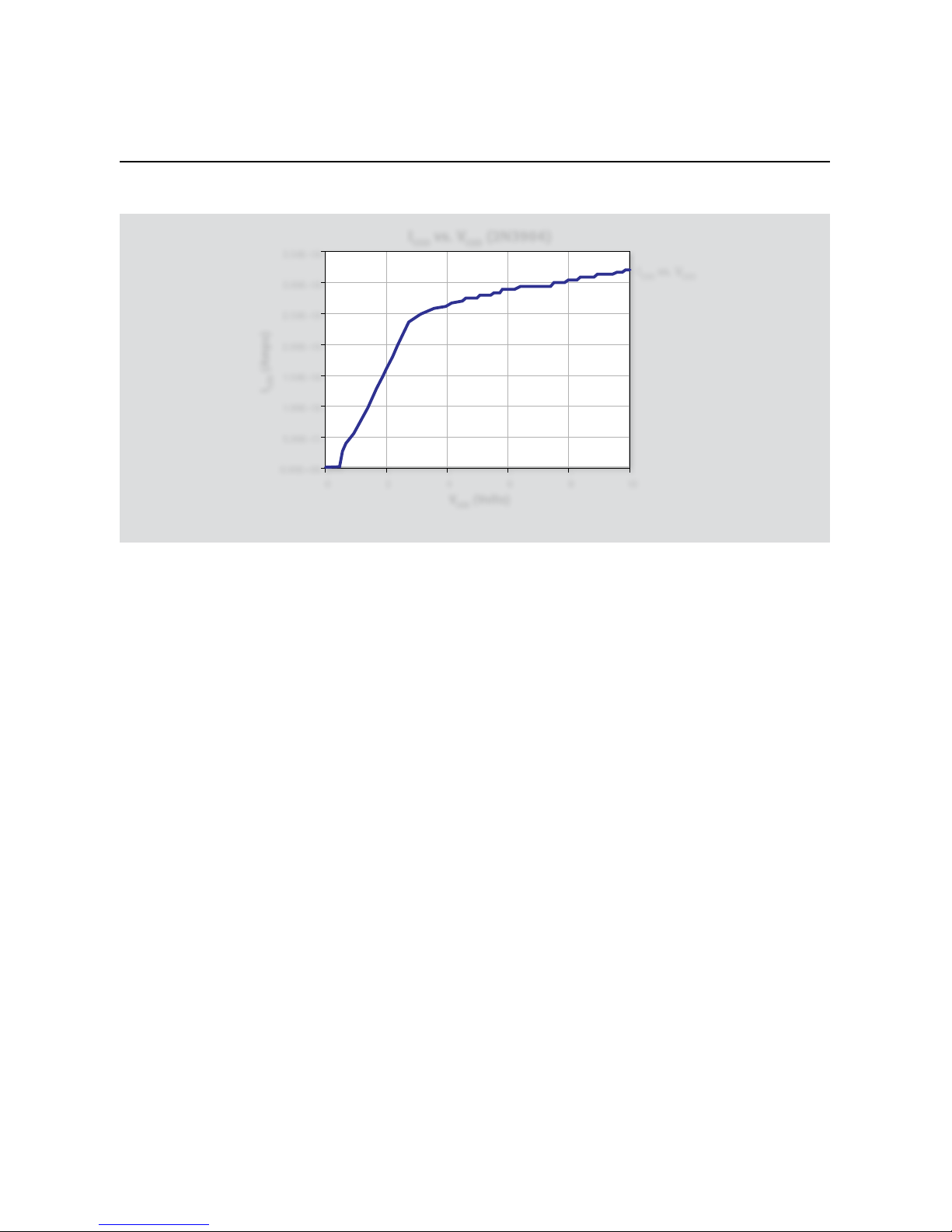

3.4.4 Typical Program 5 Results

Figure 3-4 displays a typical Gummel plot as generated by

Example Program 5. Again, the transistor used for this example

was a 2N5089 NPN silicon transistor.

3.4.5 Program 5 Description

SMUB, which sweeps VBE and measures IB, is set up as follows:

Source V•

1mA compliance, autorange measure•

Local sensing•

1 NPLC Line cycle integration•

vbestart

• : 0V

vbestop

• : 0.7V

vbesteps

• : 70

SMUA, which sources VCE and measures IC, is programmed in the

following manner:

Source V•

Local sensing•

100mA compliance, autorange measure•

1 NPLC Line cycle integration•

Constant sweep (number of points programmed to 71), •

VCE = 10V

vcebias

• : 10V

Following unit setup, both unit triggers are armed, and the instruments are placed into the operate mode (lines 320 and 330).

Once triggered, SMUB sets VBE to the required value, and SMUA

then sets VCE and measures IC at IB. At the end of its measurement,

SMUB increments VBE and the cycle repeats until VBE reaches the

value set for

vbestop

.

During the test, VBE, IB, and IC are measured. Once the test has

completed, the data is written to the Instrument Console of TSB

and can be graphed in a spreadsheet program using the “copyand-paste” method of data transfer.

Gummel Plot (2N5089)

VBE (Volts)

V

BE

vs. I

B

VBE vs. I

C

Current (Amps)

1.00E+00

1.00E–02

1.00E–04

1.00E–06

1.00E–08

1.00E–10

1.00E–12

1.00E–14

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

Figure 3-4. Program 5 results: Gummel plot

Page 23

3-6

SECTION 3

Bipolar Transistor Tests

3.5 Current Gain

The following paragraphs discuss two methods for determining

DC current gain, as well as ways to measure AC current gain.

3.5.1 Gain Calculations

The common-emitter DC current gain of a bipolar transistor is

simply the ratio of the DC collector current to the DC base current

of the device. The DC current gain is calculated as follows:

IC

ß = __

I

B

where: ß = current gain

IC = DC collector current

IB = DC base current

Often, the differential or AC current gain is used instead of the

DC value because it more closely approximates the performance

of the transistor under small-signal AC conditions. In order to

determine the differential current gain, two values of collector

current (IC1 and IC2) at two different base currents (IB1 and IB2) are

measured. The current gain is then calculated as follows:

∆IC

ßac =

___

∆I

B

where: ßa = AC current gain

∆IC = IC2 – I

C1

∆IB = IB2 – I

B1

Tests for both DC and AC current gain are generally done at one

specific value of VCE. AC current gain tests should be performed

with as small a ∆IB as possible so that the device remains in the

linear region of the curve.

3.5.2 Test Configuration for

Search Method

Figure 3-5 shows the test configuration for the search method of

DC current gain tests and AC gain tests. A dual-channel System

SourceMeter instrument is required for the test. SMUB is used

to supply IB1 and IB2. SMUA sources VCE, and it also measures the

collector currents IC1 and IC2.

3.5.3 Measurement Considerations

When entering the test base currents, take care not to enter values

that will saturate the device. The approximate base current value

can be determined by dividing the desired collector current value

by the typical current gain for the transistor being tested.

3.5.4 Example Program 6A: DC Current

Gain Using Search Method

Use Program 6A to perform DC current gain tests on bipolar transistors. Proceed as follows:

With the power off, connect a dual-channel System Source-1.

Meter instrument to the computer’s IEEE-488 interface.

Connect the test fixture to both units using appropriate 2.

c a b l e s .

Turn on the System SourceMeter instrument and allow the 3.

unit to warm up for two hours for rated accuracy.

I

V

Series 2600

System

SourceMeter

Channel A

Source V

CE

,

Measure I

C

Series 2600

System

SourceMeter

Channel B

Set I

B

for

desired I

C

VI

V

CE

Test

Fixture

Transistor

Under Test

Output HI

Output HI

Output LO

Output LO

I

B

I

C

Figure 3-5. Test configuration for current gain tests using search method

Page 24

3 -7

SECTION 3

Bipolar Transistor Tests

Turn on the computer and start Test Script Builder (TSB). Once 4.

the program has started, open a session by connecting to the

instrument. For details on how to use TSB, see the Series 2600

Reference Manual.

You can simply copy and paste the code from Appendix A in 5.

this guide into the TSB script editing window (Program 6A),

manually enter the code from the appendix, or import the TSP

file ‘DC_Gain_Search.tsp’ after downloading it to your PC.

If your computer is currently connected to the Internet, you

can click on this link to begin downloading: http://www.

keithley.com/data?asset=50925

Install an NPN transistor such as a 2N5089 in the appropriate 6.

transistor socket of the test fixture.

Now, we must send the code to the instrument. The simplest 7.

method is to right-click in the open script window of TSB,

and select ‘Run as TSP file’. This will compile the code and

place it in the volatile run-time memory of the instrument.

To store the program in non-volatile memory, see the “TSP

Programming Fundamentals” section of the Series 2600 Reference Manual.

Once the code has been placed in the instrument run-time 8.

memory, we can run it at any time simply by calling the function ‘DC_Gain_Search()’. This can be done by typing the text

‘

DC _ Gain _ Se a r c h()

’ after the active prompt in the

Instrument Console line of TSB.

In the program ‘9. DC_Gain_Search.tsp’, the function

DC _

Gain _ Search(vcesource, lowib, highib,

targetic)

is created.

vcesource

• represents the voltage value on the

collector-emitter of the transistor

lowib

• represents the base current low limit for the

search algorithm

highib

• represents the base current high limit for the

search algorithm

targetic

• represents the target collector current for the

search algorithm

If these values are left blank, the function will use the default 10.

values given to the variables, but you can specify each variable value by simply sending a number that is in-range in

the function call. As an example, if you wanted the collectoremitter voltage (VCE) to be 2.5V, the base current low value

at 10nA, the base current high value at 100nA, and the

target collector current to be 10µA, you would send

DC _

Gain _ Search(2.5,10E-9, 100E-9, 10E–6)

to the

instrument.

The sources will be enabled, and the collector current of 11.

the device will be measured. The program will perform an

iterative search to determine the closest match to the target

IC (within ±5%). The DC current gain of the device at specific

IB and IC values will then be displayed on the computer CRT.

If the search is unsuccessful, the program will print “Iteration Level Reached”. This is an error indicating that the search

reached its limit. Recheck the connections, DUT, and variable

values to make sure they are appropriate for the device.

Once the sweep has been completed, the data (I12.

B

, IC, and ß)

will be presented in the Instrument Console window of TSB.

3.5.5 Typical Program 6A Results

A typical current gain for a 2N5089 would be about 500. Note,

however, that the current gain of the device could be as low as

300 or as high as 800.

3.5.6 Program 6A Description

Initially, the iteration variables are defined and the instrument is

returned to default conditions. SMUB, which sources IB, is set up

as follows:

Source I•

IV compliance, 1.1V range•

Local sense•

SMUA, which sources VCE and measures IC, is configured as

follows:

Source V•

Local sense•

100mA compliance, autorange measure•

Once the SMU channels have been configured, the sources values

are programmed to 0 and the outputs are enabled. The base current (IB) is sourced and the program enters into the binary search

algorithm for the target IC by varying the VCE value, measuring the

IC, comparing it to the target IC, and adjusting the V

CE

value, if necessary. The iteration counter is incremented each cycle through

the algorithm. If the number of iterations has been exceeded, a

message to that effect is displayed, and the program halts.

Assuming that the number of iterations has not been exceeded,

the DC current gain is calculated and displayed in the Instrument

Console window of the TSB.

3.5.7 Modifying Program 6A

For demonstration purposes, the IC target match tolerance is set

to ±5%. You can, of course, change this tolerance as required.

Similarly, the iteration limit is set to 20. Again, this value can be

adjusted for greater or fewer iterations as necessary. Note that it

Page 25

3-8

SECTION 3

Bipolar Transistor Tests

may be necessary to increase the number of iterations if the target

range is reduced.

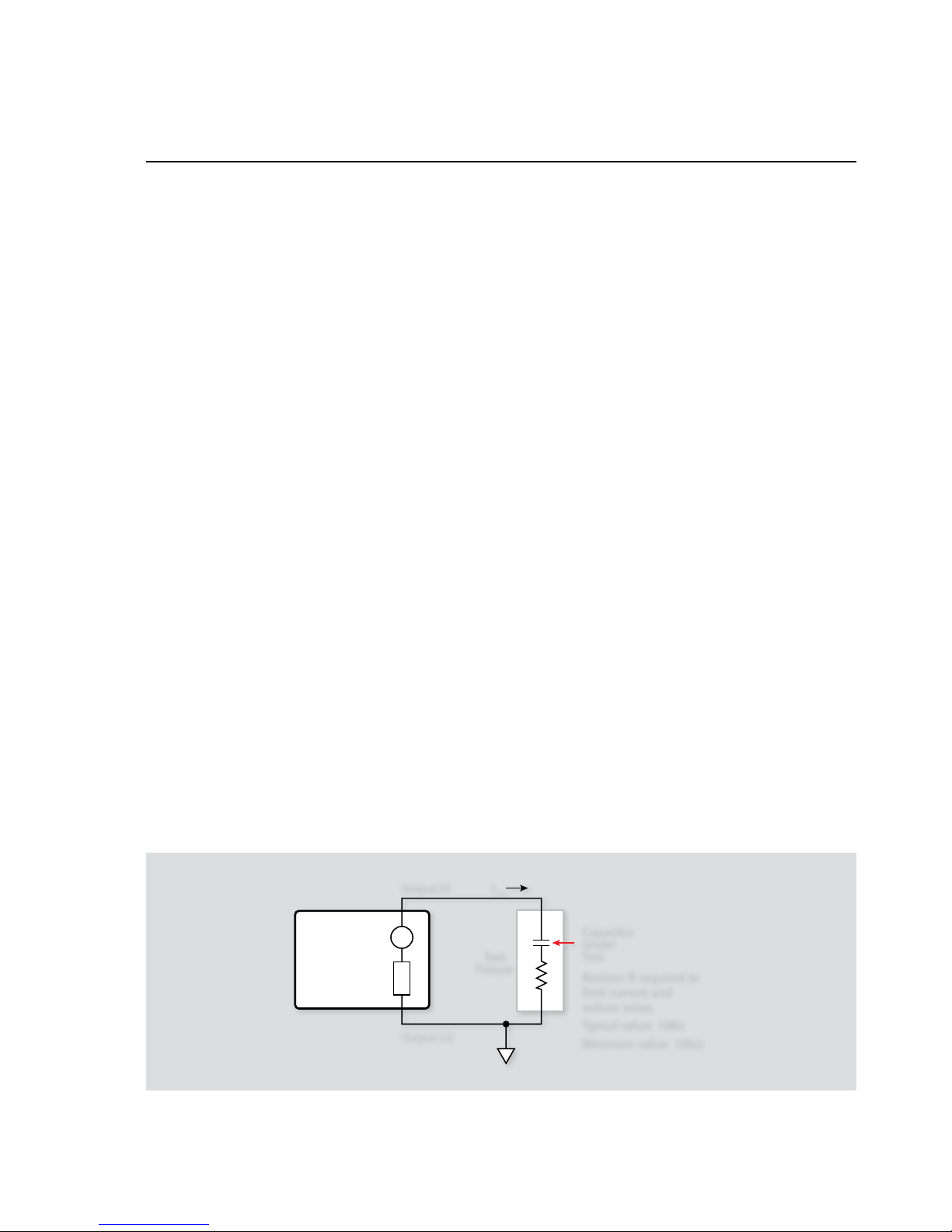

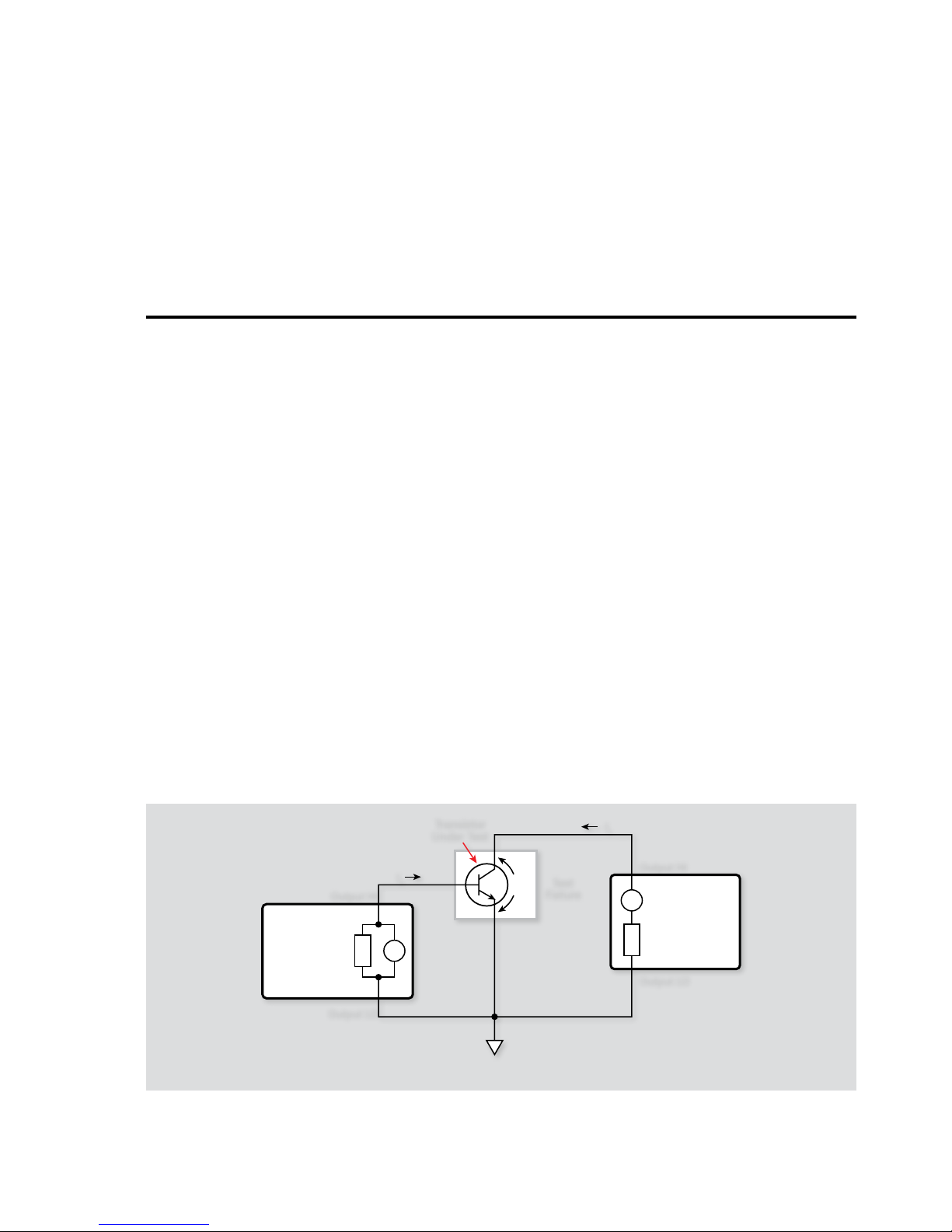

3.5.8 Configuration for Fast

Current Gain Tests

Figure 3-6 shows the test configuration for an alternate method

of current gain tests—one that is much faster than the search

method discussed previously. SMUB is used to supply VCE, and

it also measures IB. SMUA sources the emitter current (IE) rather

than the collector current (IC). Because we are sourcing emitter

current instead of collector current, the current gain calculations

must be modified as follows:

IE – IB

ß =

_____

I

B

WAR NING

When a System SourceMeter instrument is programmed for remote sensing, hazardous voltage

may be present on the SENSE and OUTPUT terminals when the unit is in operation regardless of the

programmed voltage or current. To avoid a possible

shock hazard, always turn off all power before

connecting or disconnecting cables to the SourceMeasure Unit or the associated test fixture.

NOTE

Because of the connection convention used, IE and

VCE must be programmed for opposite polarity than

normal. With an NPN transistor, for example, both VCE

and IE must be negative.

3.5.9 Example Program 6B: DC Current

Gain Using Fast Method

Use Program 6B in Appendix A to demonstrate the fast method of

measuring current gain of bipolar transistors. Proceed as follows:

With the power off, connect a dual-channel System Source-1.

Meter instrument to the computer’s IEEE-488 interface.

Connect the test fixture to both units using appropriate cables. 2.

Note that OUTPUT HI of SMUB is connected to the base of the

DUT, and SENSE HI of SMUB is connected to the emitter.

Turn on the System SourceMeter instrument and allow the 3.

unit to warm up for two hours for rated accuracy.

Turn on the computer and start Test Script Builder (TSB). Once 4.

the program has started, open a session by connecting to the

instrument. For details on how to use TSB, see the Series 2600

Reference Manual.

You can simply copy and paste the code from Appendix A in 5.

this guide into the TSB script editing window (Program 6B),

manually enter the code from the appendix, or import the TSP

file ‘DC_Gain_Fast.tsp’ after downloading it to your PC.

If your computer is currently connected to the Internet, you

can click on this link to begin downloading: http://www.

keithley.com/data?asset=50926

Install an NPN transistor such as a 2N5089 in the appropriate 6.

transistor socket of the test fixture.

Now, we must send the code to the instrument. The simplest 7.

method is to right-click in the open script window of TSB,

and select ‘Run as TSP file’. This will compile the code and

place it in the volatile run-time memory of the instrument.

I

Series 2600

System

SourceMeter

Channel A

Source I

E

Series 2600

System

SourceMeter

Channel B

Source V

CE

,

Measure I

B

V

CE

Test

Fixture

Output LO Output LO

Output HI

Sense LO

Sense HI Output HI

I

B

I

C

I

E

I

V

Figure 3-6. Test configuration for fast current gain tests

Page 26

3-9

SECTION 3

Bipolar Transistor Tests

To store the program in non-volatile memory, see the “TSP

Programming Fundamentals” section of the Series 2600 Reference Manual.

Once the code has been placed in the instrument run-time 8.

memory, we can run it at any time simply by calling the function ‘DC_Gain_Search_Fast()’. This can be done by typing

the text ‘

DC _ Gain _ Search _ Fast()

’ after the active

prompt in the Instrument Console line of TSB.

In the program ‘9. DC_Gain_Search_Fast.tsp’, the function

DC _ Gain _ Search _ Fast(vcesource, istart,

istop, isteps)

is created.

vcesource

• represents the voltage value on the

collector-emitter of the transistor

istart

• represents the start value for the base current

sweep

istop

• represents the stop value for the base current

sweep

isteps

• represents the number of steps in the base

current sweep

If these values are left blank, the function will use the default

values given to the variables, but you can specify each variable value by simply sending a number that is in-range in

the function call. As an example, if you wanted to have the

collector-emitter voltage (VCE) be 2.5V, the base current sweep

start value at 10nA, the base current sweep stop value at

100nA, and the number of steps to be 10, you would send

DC _ Gain _ Search _ Fast(2.5,10E-9, 100E-9,

10)

to the instrument.

The sources will be enabled, and the collector current of the 10.

device will be measured.

Once the sweep has been completed, the data (I11.

B

, IC, and ß)

will be presented in the Instrument Console window of TSB.