Page 1

tek.com/keithley

S540 Power Semiconductor Test System

Administrative Guide

S540-924-01 Rev. D / January 2019

*PS540-924-01D*

S540-924-01D

Page 2

Power Semiconductor Test System

S540

Administrative Guide

Page 3

© 2019, Keithley Instruments, LLC

Cleveland, Ohio, U.S.A.

All rights reserved.

Any unauthorized reproduction, photocopy, or use of the information herein, in whole or in part,

without the prior written approval of Keithley Instruments, LLC, is strictly prohibited.

These are the original instructions in English.

All Keithley Instruments product names are trademarks or registered trademarks of Keithley

Instruments, LLC. Other brand names are trademarks or registered trademarks of their respective

holders.

Document number: S540-924-01 Rev. D / January 2019

Page 4

Safety precautions

The following safety precautions should be observed before using this product and any associated instrumentation. Although

some instruments and accessories would normally be used with nonhazardous voltages, there are situations where hazardous

conditions may be present.

This product is intended for use by personnel who recognize shock hazards and are familiar with the safety precautions required

to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using the

product. Refer to the user documentation for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product warranty may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the

equipment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the

instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line

voltage or replacing consumable materials. Maintenance procedures are described in the user documentation. The procedures

explicitly state if the operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel are trained to work on live circuits, perform safe installations, and repair products. Only properly trained

service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that are measurement, control, and data I/O connections, with low

transient overvoltages, and must not be directly connected to mains voltage or to voltage sources with high transient

overvoltages. Measurement Category II (as referenced in IEC 60664) connections require protection for high transient

overvoltages often associated with local AC mains connections. Certain Keithley measuring instruments may be connected to

mains. These instruments will be marked as category II or higher.

Unless explicitly allowed in the specifications, operating manual, and instrument labels, do not connect any instrument to mains.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test

fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than

30 V RMS, 42.4 V peak, or 60 VDC are present. A good safety practice is to expect that hazardous voltage is present in any

unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators

are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential

human contact. Product operators in these circumstances must be trained to protect themselves from the risk of electric shock. If

the circuit is capable of operating at or above 1000 V, no conductive part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance-limited

sources. NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective

devices to limit fault current and voltage to the card.

Before operating an instrument, ensure that the line cord is connected to a properly-grounded power receptacle. Inspect the

connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input

power disconnect device must be provided in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under

test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting

cables or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth)

ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the

voltage being measured.

Page 5

For safety, instruments and accessories must be used in accordance with the operating instructions. If the instruments or

accessories are used in a manner not specified in the operating instructions, the protection provided by the equipment may be

impaired.

Do not exceed the maximum signal levels of the instruments and accessories. Maximum signal levels are defined in the

specifications and operating information and shown on the instrument panels, test fixture panels, and switching cards.

When fuses are used in a product, replace with the same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as protective earth (safety ground)

connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use

of a lid interlock.

The symbol on an instrument means caution, risk of hazard. The user must refer to the operating instructions located in the

user documentation in all cases where the symbol is marked on the instrument.

The symbol on an instrument means warning, risk of electric shock. Use standard safety precautions to avoid personal

contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

The symbol indicates a connection terminal to the equipment frame.

If this symbol is on a product, it indicates that mercury is present in the display lamp. Please note that the lamp must be

properly disposed of according to federal, state, and local laws.

The WARNING heading in the user documentation explains hazards that might result in personal injury or death. Always read

the associated information very carefully before performing the indicated procedure.

The CAUTION heading in the user documentation explains hazards that could damage the instrument. Such damage may

invalidate the warranty.

The CAUTION heading with the symbol in the user documentation explains hazards that could result in moderate or minor

injury or damage the instrument. Always read the associated information very carefully before performing the indicated

procedure. Damage to the instrument may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits — including the power

transformer, test leads, and input jacks — must be purchased from Keithley. Standard fuses with applicable national safety

approvals may be used if the rating and type are the same. The detachable mains power cord provided with the instrument may

only be replaced with a similarly rated power cord. Other components that are not safety-related may be purchased from other

suppliers as long as they are equivalent to the original component (note that selected parts should be purchased only through

Keithley to maintain accuracy and functionality of the product). If you are unsure about the applicability of a replacement

component, call a Keithley office for information.

Unless otherwise noted in product-specific literature, Keithley instruments are designed to operate indoors only, in the following

environment: Altitude at or below 2,000 m (6,562 ft); temperature 0 °C to 50 °C (32 °F to 122 °F); and pollution degree 1 or 2.

To clean an instrument, use a cloth dampened with deionized water or mild, water-based cleaner. Clean the exterior of the

instrument only. Do not apply cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that

consist of a circuit board with no case or chassis (e.g., a data acquisition board for installation into a computer) should never

require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board

should be returned to the factory for proper cleaning/servicing.

Safety precaution revision as of June 2017.

Page 6

S540 system ............................................................................................................. 1-1

Table of contents

Introduction .......................................................................................................................... 1-1

Systems documentation ....................................................................................................... 1-1

System description ............................................................................................................... 1-1

Optional accessories ............................................................................................................ 1-3

S540 site preparation and installation .................................................................... 2-1

Site preparation checklist ..................................................................................................... 2-1

Unpacking the S540 system ................................................................................................ 2-2

Unpacking system components ................................................................................................ 2-3

Unpacking the S540 system accessories ................................................................................ 2-12

Keithley field service engineer installation tasks ................................................................ 2-15

Example Series 500 System Installation Form ........................................................................ 2-16

Power and operating conditions ......................................................................................... 2-19

Supplied power cords .............................................................................................................. 2-19

Line power requirements ......................................................................................................... 2-19

System power dissipation........................................................................................................ 2-20

Operating environment conditions ........................................................................................... 2-20

Triaxial connector handling and avoiding contamination ................................................... 2-21

Lockout and tagout ............................................................................................................. 2-21

Installation and connections ............................................................................................... 2-23

Position the system cabinet..................................................................................................... 2-23

Cable harness routing ............................................................................................................. 2-24

Floor plan ........................................................................................................................... 2-24

System cabinet size and weight ......................................................................................... 2-26

Physically securing the system .......................................................................................... 2-27

Optional advanced seismic securement ............................................................................ 2-29

Equipment startup ................................................................................................... 3-1

Introduction .......................................................................................................................... 3-1

Initial equipment startup ....................................................................................................... 3-1

System startup ..................................................................................................................... 3-2

Before starting system software ........................................................................................... 3-3

Using Telnet .............................................................................................................................. 3-3

Start the KTE software ......................................................................................................... 3-4

IC process log messages .......................................................................................................... 3-4

Stopping the IC process ............................................................................................................ 3-4

Start the ACS software......................................................................................................... 3-5

Shut down using ACS .......................................................................................................... 3-5

Shut down using KTE ........................................................................................................... 3-6

Page 7

Table of contents S540 Power Semiconductor Test System Administrative Guide

Emergency OFF button ........................................................................................................ 3-6

Emergency shutdown procedure ............................................................................................... 3-6

Recovering from an emergency shutdown ................................................................................ 3-7

Safety interlocks ................................................................................................................... 3-7

Additional probe card adapter safety interlock cable ................................................................. 3-9

9140A-PCA interlock connections for S540 systems .............................................................. 3-10

LO patch panel ................................................................................................................... 3-11

Prober safety ...................................................................................................................... 3-11

Network information ........................................................................................................... 3-12

Maintenance ............................................................................................................. 4-1

Hardware replacement ......................................................................................................... 4-1

Handling and cleaning precautions ...................................................................................... 4-2

Special handling of static-sensitive devices .............................................................................. 4-3

Electrical hazard tasks ......................................................................................................... 4-3

Types of electrical hazard tasks ................................................................................................ 4-4

Repair and replacement ............................................................................................................ 4-4

Instrument removal and installation ..................................................................................... 4-4

Remove system power .............................................................................................................. 4-4

Heavy instrument removal and installation ................................................................................ 4-5

General replacement procedure ................................................................................................ 4-6

Adjustment ................................................................................................................................ 4-7

Restore system power .............................................................................................................. 4-7

Fuses ........................................................................................................................................ 4-8

Power distribution and emergency off .................................................................................. 4-9

Power distribution unit connections and power distribution basics .......................................... 4-10

System emergency off circuit .................................................................................................. 4-12

Data hub license ................................................................................................................ 4-13

Editing the icconfig_<QMO>.ini file .................................................................................... 4-13

Using NPLCs to adjust speed and accuracy ..................................................................... 4-14

Setting the number of power line cycles .................................................................................. 4-14

Setting a custom system speed .............................................................................................. 4-15

NPLC default differences ........................................................................................................ 4-15

Decommissioning an S540 test system ............................................................................. 4-16

Instrument specifications and documentation ...................................................... 5-1

Introduction .......................................................................................................................... 5-1

Switching .............................................................................................................................. 5-2

Model 707B Switch Matrix Mainframe ....................................................................................... 5-2

HVM1212A High-Voltage Switch Matrix .................................................................................... 5-2

Sourcing and measuring ...................................................................................................... 5-3

Model 2657A High-Power System SourceMeter Instrument ..................................................... 5-3

Optional instrumentation ...................................................................................................... 5-4

Typical matrix connections ................................................................................................... 5-4

S540 3000 V high-voltage system ............................................................................................. 5-5

S540 3000 V high-voltage, low-current system ......................................................................... 5-6

Page 8

S540 Power Semiconductor Test System Administrative Guide Table of contents

S540 high-voltage, low-current system using an RSA306B spectrum analyzer ........................ 5-7

S540 KTE communications .................................................................................................. 5-8

S540 ACS communications diagrams ................................................................................. 5-9

Page 9

In this section:

Introduction .............................................................................. 1-1

Systems documentation ........................................................... 1-1

System description ................................................................... 1-1

Optional accessories ................................................................ 1-3

Introduction

Section 1

S540 system

If you have any questions after reviewing this information, please contact your local Keithley

Instruments office, sales partner, or distributor. You can also call the corporate headquarters of

Keithley Instruments (toll-free inside the U.S. and Canada only) at 1-800-935-5595, or from outside

the U.S. at +1-440-248-0400. For worldwide contact numbers, visit the Keithley Instruments website

(tek.com/keithley).

Systems documentation

Documentation for your system is available at tek.com/keithley. Following is a list of documentation

for your system, including the document part numbers.

S540 Power Semiconductor Test System Administrative Guide (S540-924-01)

S540 Power Semiconductor Test System Reference Manual (S540-901-01)

Keithley Test Environment (KTE) Programmer's Manual (S500-904-01)

System description

The Keithley Instruments S540 Power Semiconductor Test System is a configurable,

instrument-based system for power semiconductor parametric characterization and testing. There are

two different S540 systems available:

S540 3000 V high-voltage parametric test system with a 3-kV switching matrix (12 pins)

S540 3000 V high-voltage, low-current parametric test system with a 3-kV switching matrix

(12 pins) and a low-current switching matrix (12, 24, or 36 pins)

Page 10

Section 1: S540 system S540 Power Semiconductor Test System Administrative Guide

1-2

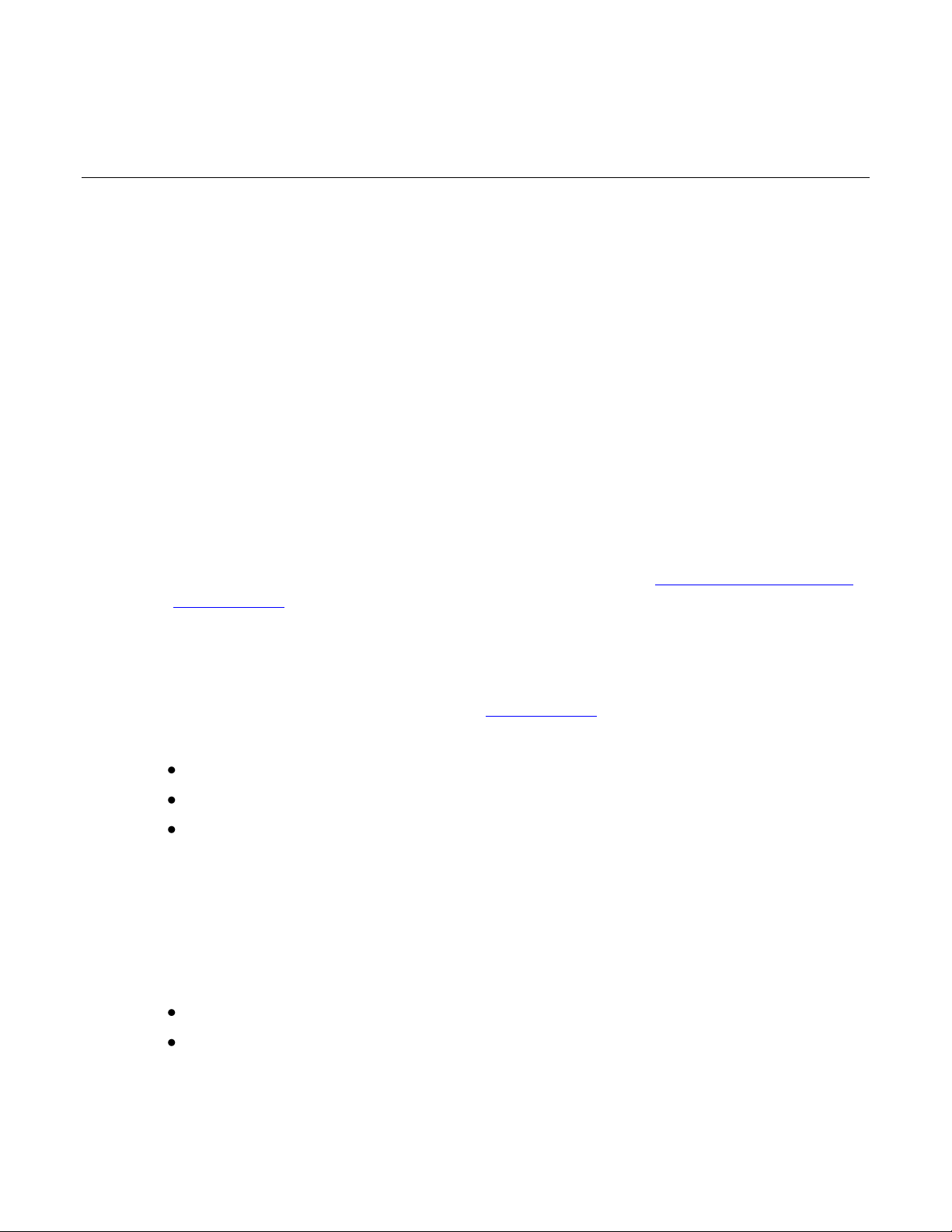

The S540 systems have flexible hardware configurations that allow you to customize them to your

S540 3000 V high-voltage system configuration options

DC source-measure units (SMU)

Maximum number of SMUs depends on other items in

the system rack

Model 2636B System SourceMeter

®

instrument

(quantity: 0 to 4)

Model 2657A High-Power System SourceMeter

®

instrument (quantity: 2)

Switching matrices

One Model HVM1212A 12 × 12 high-voltage switch matrix

Optional capacitance/voltage (C-V)

One channel of C-V (using one Model 4200A-SCS with one

Model 4210-CVU card)

Optional instruments

Model 4220-PGU dual-channel pulse cards (quantity: 0 to

3)

RSA306B USB Spectrum Analyzer (quantity: 0 to 1) for

frequency and ring oscillator measurements

Included with each system

Computer inside cabinet

External 24-inch flat-panel monitor and keyboard tray

mounted on exterior of cabinet

Keithley Test Environment (KTE) or Automated

Characterization Suite (ACS) system software

LO patch panel

Safety interlock system

Adjustable cable support arm

Other options

Advanced seismic securement kit for additional resistance to

seismic forces

specific needs. See the following table for a description of the main system configuration options, and

see the following figure for an example of a typical system configuration.

S540-924-01 Rev. D / January 2019

Page 11

S540 Power Semiconductor Test System Administrative Guide Section 1: S540 system

1-3

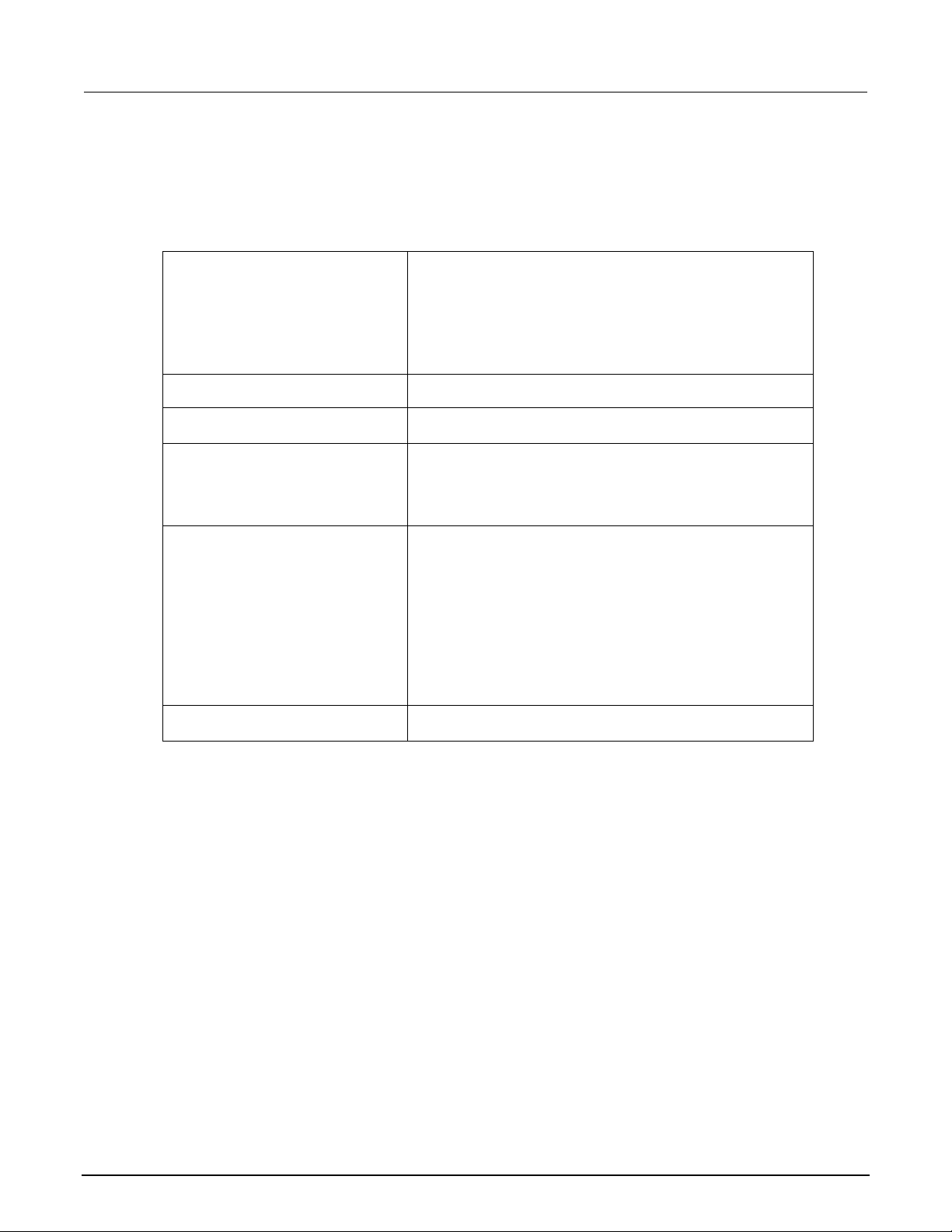

S540 3000 V high-voltage, low-current system configuration options

DC source-measure units (SMU)

Maximum number of units depends on other items in the

system rack

2636B System SourceMeter

®

instrument (quantity: 1 to 4)

2657A High-Power System SourceMeter

®

instrument

(quantity: 2)

6-slot switching matrix

One Model HVM1212A 12 × 12 high-voltage switch matrix and

one Model 707B system switch mainframe with:

Model 7531 switch cards (quantity: 2 to 6, depending on

instruments and number of low-voltage pins in the

system); one card is used as an interconnect card

Optional capacitance/voltage (C-V)

Two channels of C-V (using one Model 4200A-SCS with two

Model 4210-CVU cards)

Optional instruments

Model DMM7510 7-1/2 Digit Graphical Sampling

Multimeter

(quantity: 0 to 1)

Model 4220-PGU dual-channel pulse cards (quantity: 0 to

3)

Frequency measurement option

Included with each system

Computer inside cabinet

External 24-inch flat-panel monitor and keyboard tray

mounted on exterior of cabinet

Keithley Test Environment (KTE) or Automated

Characterization Suite (ACS) system software

LO patch panel

Interlock system

Adjustable cable support arm

Other options

Advanced seismic securement kit for additional resistance to

seismic forces

Optional accessories

Optional items and accessories that may accompany the S540 system:

Cables to connect to the test fixture or the probe card adapter

9140A-PCA probe card adapter (12 3-kV pins to 36 200-V pins) or Celadon Systems

VersaCoreTM VC20 probe card adapter (12 3-kV pins to 32 200-V pins)

RSA306B USB Spectrum Analyzer

Advanced seismic securement kit

S540-924-01 Rev. D / January 2019

Page 12

In this section:

Site preparation checklist ......................................................... 2-1

Unpacking the S540 system..................................................... 2-2

Keithley field service engineer installation tasks .................... 2-15

Power and operating conditions ............................................. 2-19

Triaxial connector handling and avoiding contamination ........ 2-21

Lockout and tagout ................................................................. 2-21

Installation and connections ................................................... 2-23

Floor plan ............................................................................... 2-24

System cabinet size and weight ............................................. 2-26

Physically securing the system .............................................. 2-27

Optional advanced seismic securement ................................. 2-29

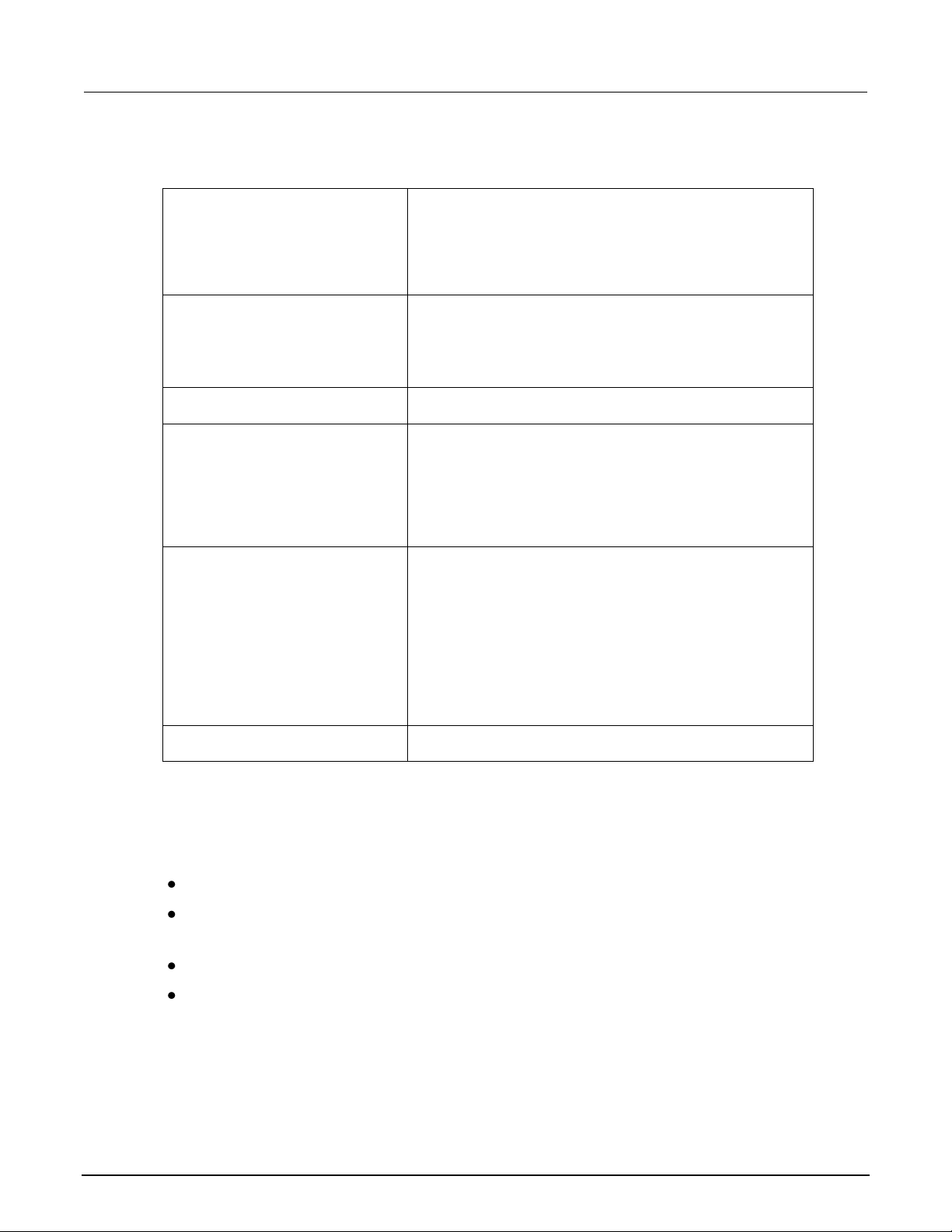

Site preparation checklist

S540 system preparation checklist

Site

Item

Is it necessary to have lifting equipment?

Is the flooring adequate and able to support the weight of the system while moving from receiving to the final

destination (see Floor plan (on page 2-24) for specifications)?

Are all of the corridors and hallways large enough to allow clearance for the system?

Are stairways adequate for moving the system through?

Are elevators needed to move the system? Can they support the size and weight of the system?

Are the doorways wide enough for the system?

If you are using a Keithley probe card adapter, you must supply a vacuum connection (50.80 cm Hg / 20 in.).

Floor plan

Item

Did you complete the system layout (see Floor plan (on page 2-24) for specifications)?

Does your layout show all of the locations for all of the equipment?

Does your system layout show the locations of all doors and aisles?

Does your layout allow for the proper clearance of the system for the front, rear, and the keyboard/monitor

arm?

Is there enough space for personnel safety, comfort, and freedom of movement?

Section 2

S540 site preparation and installation

The following site preparation checklist will help you prepare your site for the S540 system in your

facility. If you find that an item listed is not valid for your site, you can indicate it with "N/A."

Page 13

Section 2: S540 site preparation and installation S540 Power Semiconductor Test System Administrative Guide

2-2

S540 system preparation checklist (continued)

Floor plan

Did you take future expansions into consideration?

Electrical

power

Item

Is there sufficient space for any supplies or manuals?

Is adequate and proper electrical power available (see Line power requirements (on page 2-19) for

specifications)?

Is anything connected to the same power source that generates noise?

Is anything that requires substantial amounts of current connected to the same power source?

Did you prepare power outlets for service, testing, or maintenance?

Unpacking the S540 system

The Keithley field service engineer (FSE) is responsible for unpacking the S540 system cabinet and

the accessories. However, we recommend that you move the crate and the accessories box to the

area where the system is going to be used.

Here is a list of tools needed for unpacking:

Safety glasses

Gloves

Standard screwdriver

Socket wrench

Socket head: 19 mm (3/4 in.)

S540-924-01 Rev. D / January 2019

Page 14

S540 Power Semiconductor Test System Administrative Guide Section 2: S540 site preparation and installation

2-3

The following information will help the FSE unpack the system. Series 500 systems are shipped in a

wooden crate (see the following figure).

Figure 1: S540 system cabinet in shipping crate

Unpacking system components

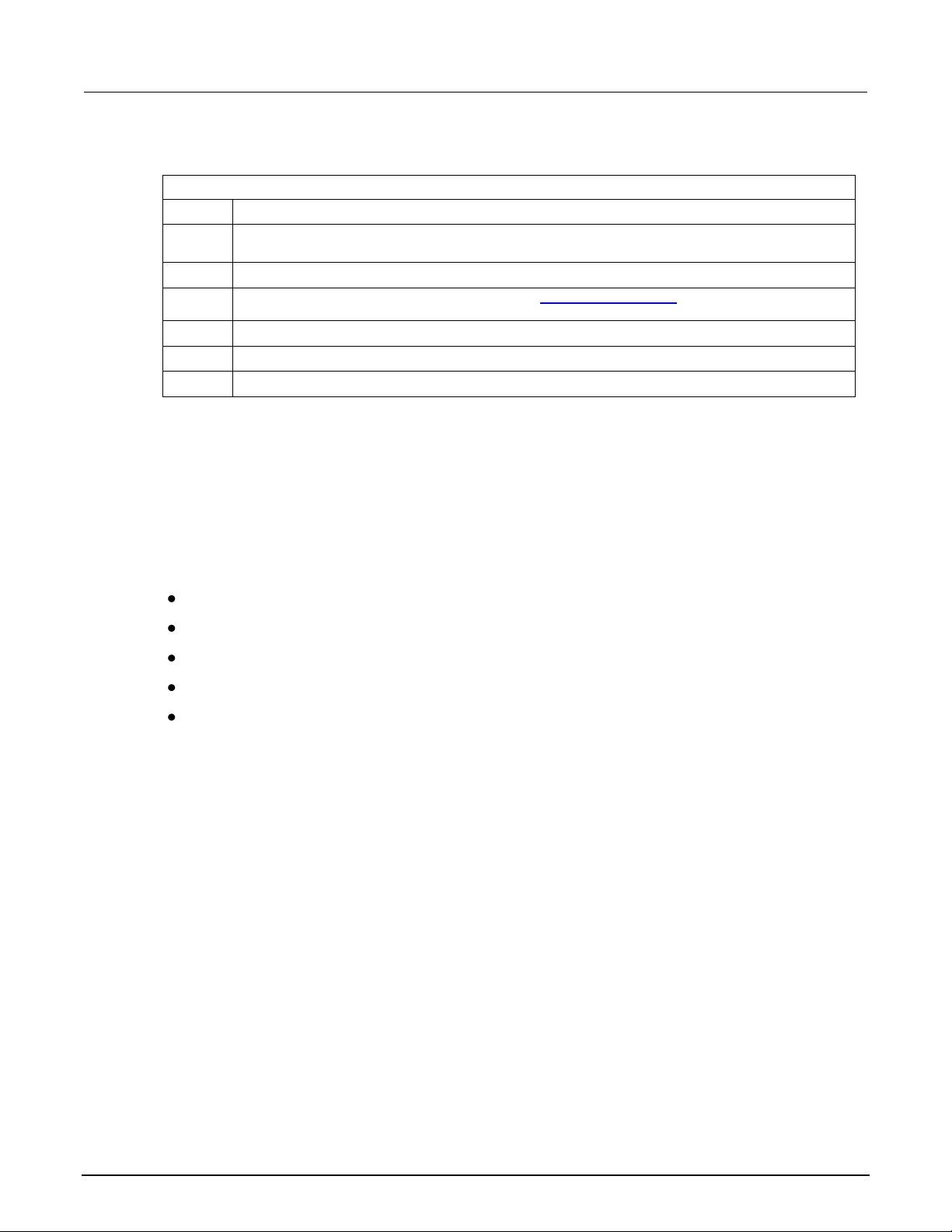

Inspect the shock sensor on the outside of the shipping crate (see the following figure). If the shock

sensor indicates a shock condition, do a thorough inspection of all components in the system cabinet.

Figure 2: S540 crate shock sensor

S540-924-01 Rev. D / January 2019

Page 15

Section 2: S540 site preparation and installation S540 Power Semiconductor Test System Administrative Guide

2-4

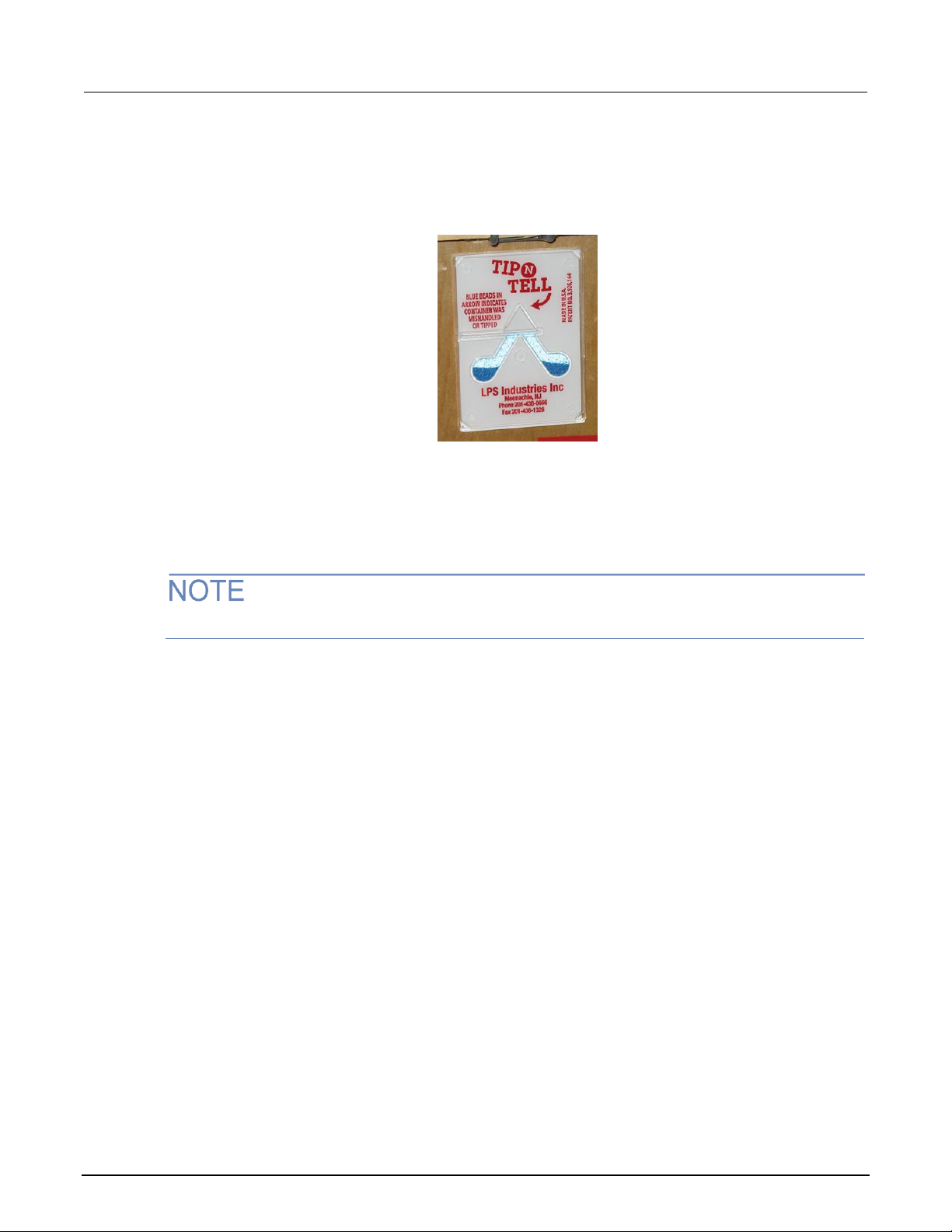

Also, check the "TIP N TELL" indicator to ensure that the crate has not been tipped over (see the

following figure).

Figure 3: S540 crate tipping indicator

Carefully remove all system components from the crate. While unpacking, make sure there is no

component damage. Report any damage to the shipping agent immediately. Please reuse or recycle

packaging materials in accordance with your local requirements.

You need at least two people to unpack and move the S540 system cabinet.

S540-924-01 Rev. D / January 2019

Page 16

S540 Power Semiconductor Test System Administrative Guide Section 2: S540 site preparation and installation

2-5

To unpack the system components:

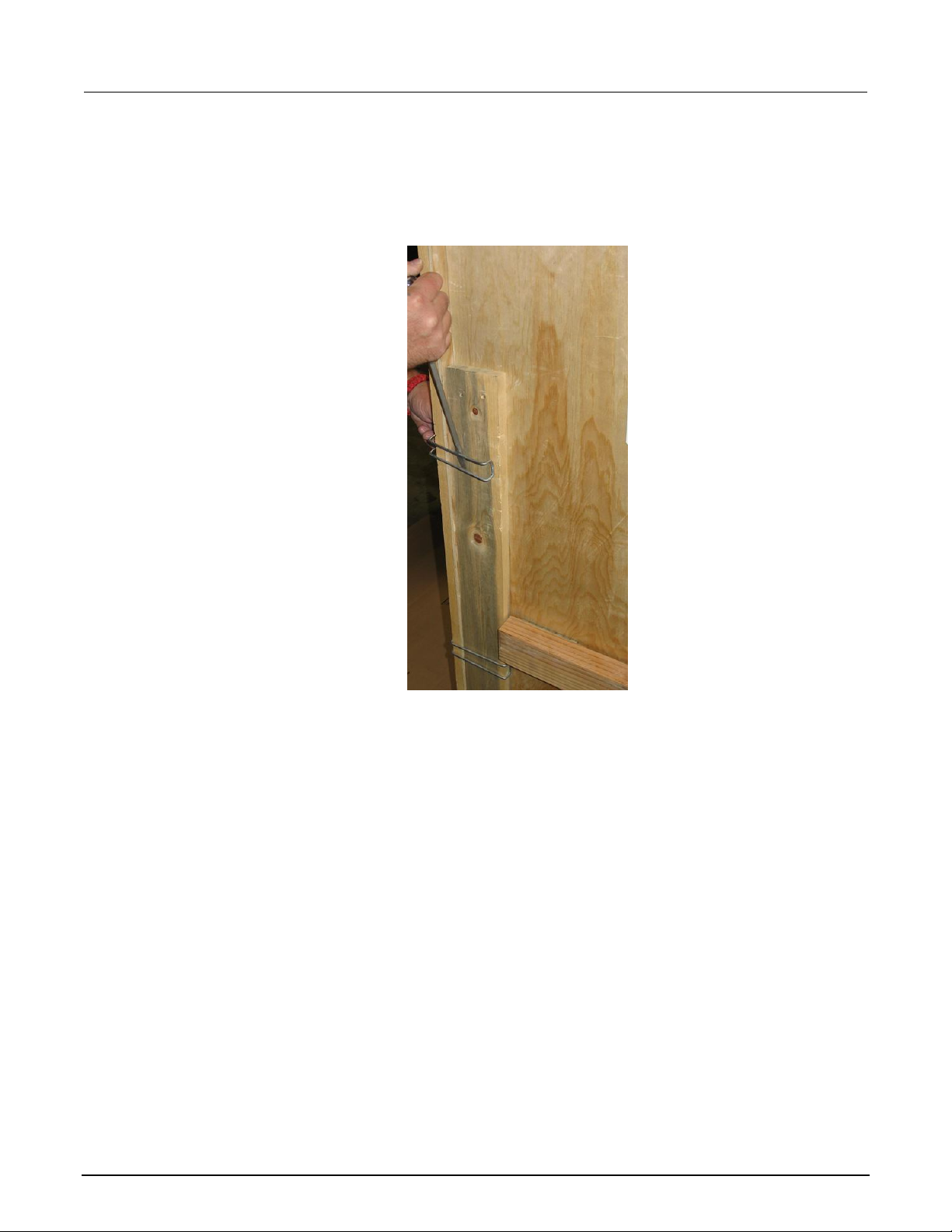

1. Remove the crate clamps from the crate using a standard screwdriver.

Figure 4: Removing the crate clamps

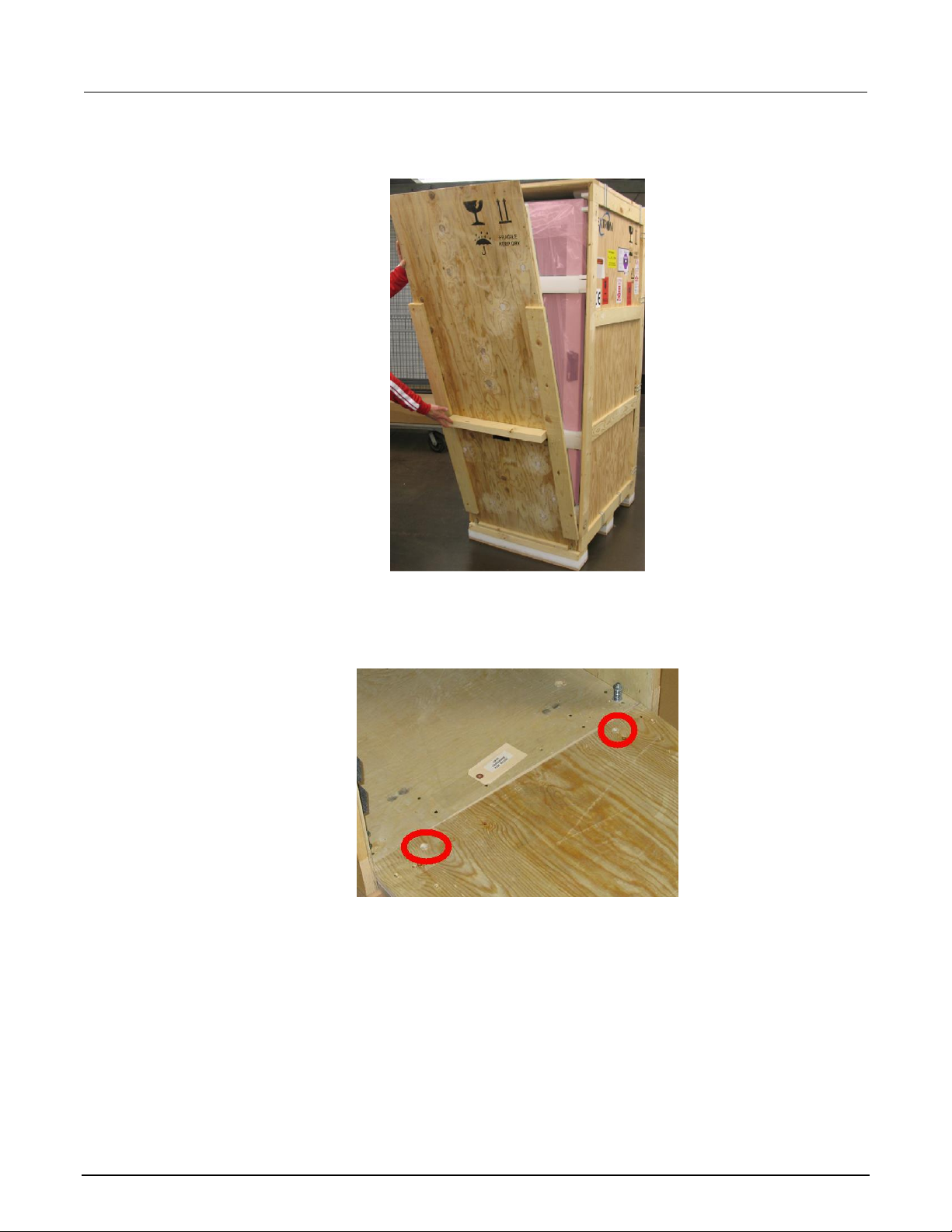

2. Open the front of the crate. The front is identified by the wooden ramp support attached across

the panel (see the following figure).

3. Make sure the ramp support is pulled away from the crate. It is held in place with hook and loop

fasteners (such as Velcro®).

S540-924-01 Rev. D / January 2019

Page 17

Section 2: S540 site preparation and installation S540 Power Semiconductor Test System Administrative Guide

2-6

Figure 5: Opening the front of the crate

4. Attach the ramp using the two bolts that are attached to the bottom front of the crate.

Figure 6: Front of the crate with ramp down

S540-924-01 Rev. D / January 2019

Page 18

S540 Power Semiconductor Test System Administrative Guide Section 2: S540 site preparation and installation

2-7

5. Remove the padding from the front of the S540 system cabinet.

Figure 7: Removing the padding

6. Remove the crate clamps and slide the outer box cover off the crate.

Figure 8: Sliding the outer box off the crate

S540-924-01 Rev. D / January 2019

Page 19

Section 2: S540 site preparation and installation S540 Power Semiconductor Test System Administrative Guide

2-8

7. Make sure that you retract the leveling feet on the bottom of the system (next to the casters) to

put weight on the casters and prepare the system to be rolled down the ramp.

Figure 9: Leveling feet

S540-924-01 Rev. D / January 2019

Page 20

S540 Power Semiconductor Test System Administrative Guide Section 2: S540 site preparation and installation

2-9

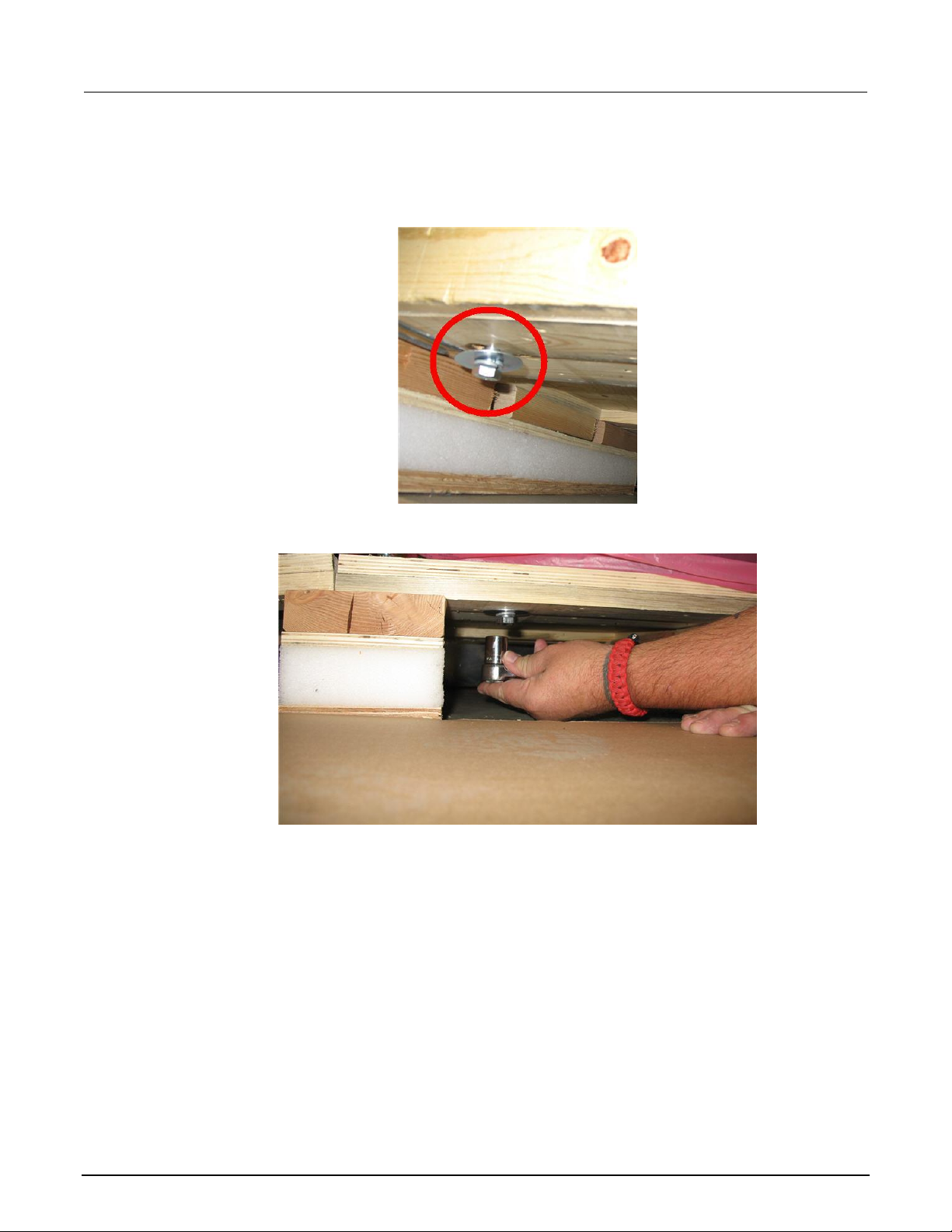

8. Remove the four bolts from the bottom of the crate that are attached to the bottom of the S540

system cabinet using a 19 mm socket head on a socket wrench.

Figure 10: System bolted to the crate

Figure 11: Removing the bolts from the crate

S540-924-01 Rev. D / January 2019

Page 21

Section 2: S540 site preparation and installation S540 Power Semiconductor Test System Administrative Guide

2-10

9. Save the hardware (the four bolts and washers) that you remove from the bottom of the crate.

Figure 12: System crate hardware

10. Unlock the two casters that are on the front of the S540 system cabinet by moving the locks up.

Figure 13: System caster brakes

S540-924-01 Rev. D / January 2019

Page 22

S540 Power Semiconductor Test System Administrative Guide Section 2: S540 site preparation and installation

2-11

11. With two people, slide the S540 system cabinet down the ramp.

Figure 14: Rolling the system down the ramp

12. Remove the tape from the packing material using scissors, taking care not to scratch the S540

system cabinet.

Figure 15: Cutting the wrap off the system

13. Move the S540 system cabinet to its final destination.

The system cabinet is shipped from the factory with all of the instruments installed. Most equipment

connections and wiring of instruments in the system cabinet was done at the factory.

S540-924-01 Rev. D / January 2019

Page 23

Section 2: S540 site preparation and installation S540 Power Semiconductor Test System Administrative Guide

2-12

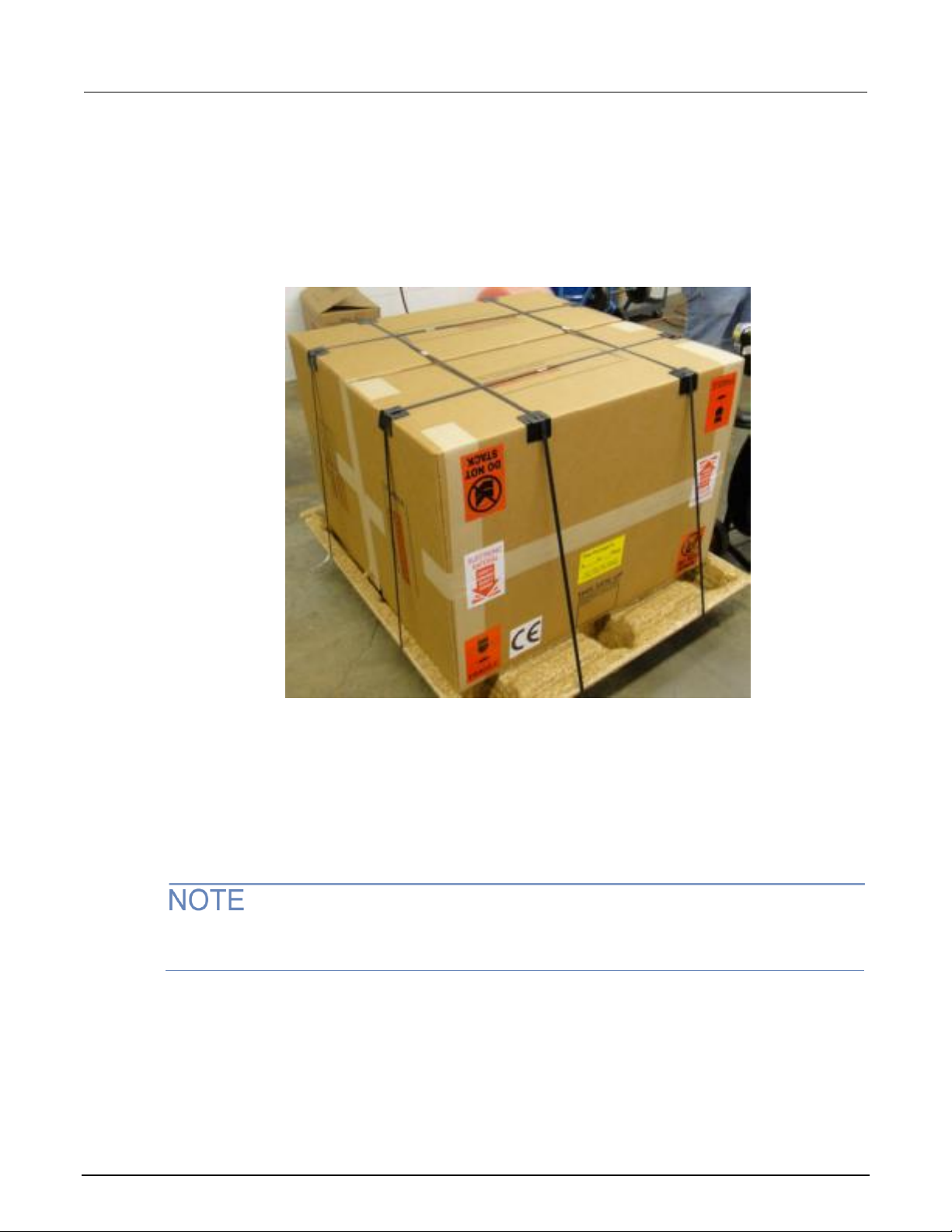

Unpacking the S540 system accessories

The accessories are shipped in a separate box or in multiple boxes, depending on how many

accessories are ordered.

Figure 16: S540 system accessories

The accessories box contains a computer monitor, keyboard, and mouse. It also includes required

installation hardware, USB extension cables, cable support arm, connectors for the keyboard and

mouse, and any other accessories that may have been ordered with the system (for example, probe

card adapter, cables to connect to the test fixture or probe card adapter, or advanced seismic

securement kit). You will also find all of the documentation that is shipped with your order. Please

reuse or recycle packaging materials in accordance with your local requirements.

The following figures are examples of system accessories that may be included in your shipment.

What you receive may be different depending on your system configuration.

S540-924-01 Rev. D / January 2019

Page 24

S540 Power Semiconductor Test System Administrative Guide Section 2: S540 site preparation and installation

2-13

Figure 17: Typical system accessories

Figure 18: Monitor arm accessory

S540-924-01 Rev. D / January 2019

Page 25

Section 2: S540 site preparation and installation S540 Power Semiconductor Test System Administrative Guide

2-14

Figure 19: Keyboard tray and arm accessory

Figure 20: Cable support arm accessory

S540-924-01 Rev. D / January 2019

Page 26

S540 Power Semiconductor Test System Administrative Guide Section 2: S540 site preparation and installation

2-15

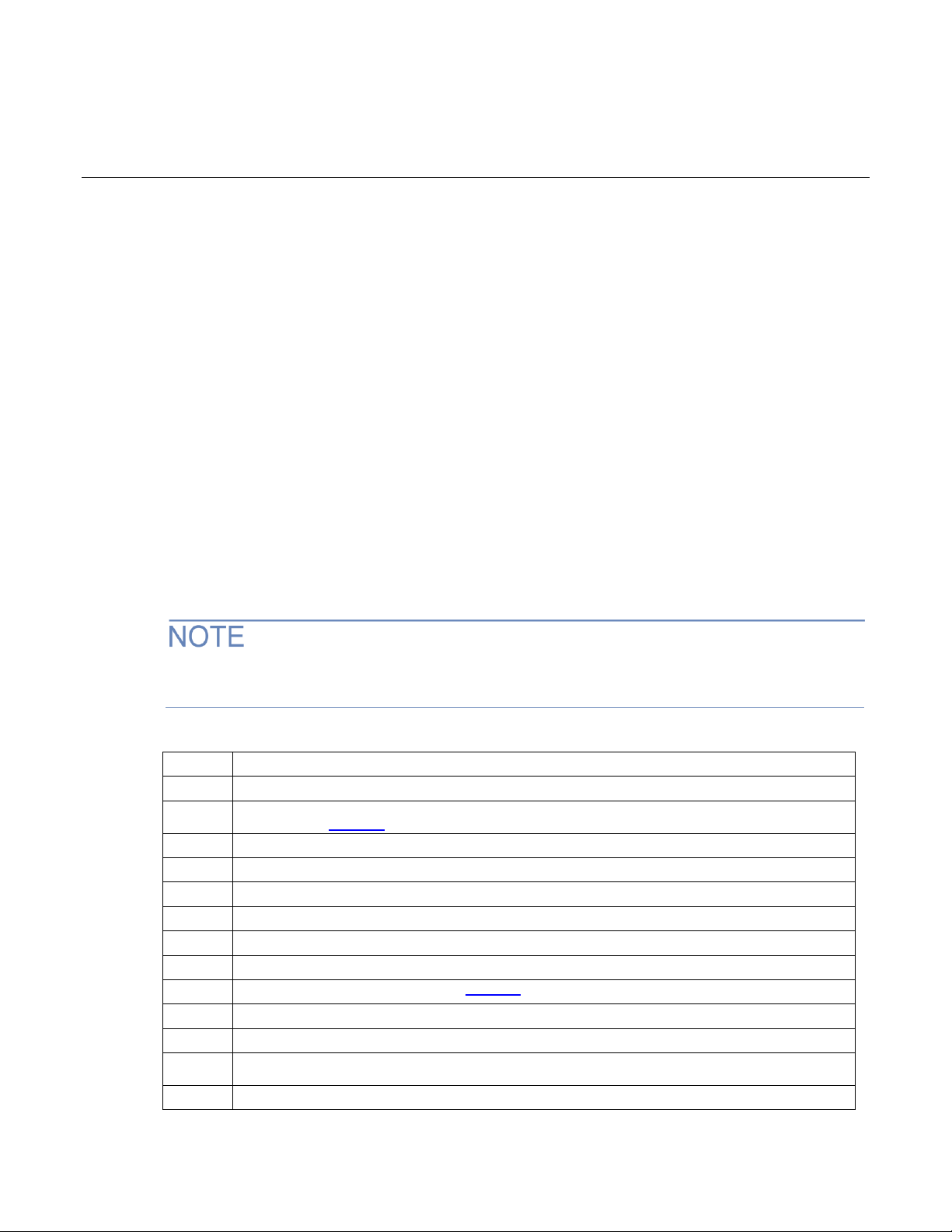

Chuck cables for optional probe card adapters

Model

Quantity

Description

CA-63-12

2

12 ft three-lug triaxial cables

237-TRX-T

1

Three-slot male to dual three-lug female triaxial tee adapter

237-BNC-TRX

1

High-voltage two-slot BNC to three-lug female triaxial adapter

A set of chuck cables is included with the optional 9140A-PCA probe card adapter. Model numbers of

cables vary based on the prober you are using. For example, the Keithley Field Service Engineer

(FSE) will install the cables shown in the following table for Tel P8 probers.

If a different cable termination scheme is required, a customer-supplied solution can be used.

Optional probe card adapter vacuum requirement

9140A-PCA probe card adapter requirement: A 50.80 cm (20 in.) Hg (which is the same as 40.73 PSI)

vacuum supply, with a hose connection of 0.64 cm (1/4 in.) outside diameter and 0.32 cm (1/8 in.)

inside diameter.

For detailed information about the 9140A-PCA probe card adapter, see the 9140A-PCA Probe Card

Adapter Instruction Manual (part number 9140A-901-01). This manual is available for download at

tek.com/keithley.

Keithley field service engineer installation tasks

The Keithley field service engineer (FSE) will perform the following tasks:

Unpack the system components and accessories.

Attach the keyboard arm and monitor arm to the system.

Install the keyboard and the mouse on the keyboard arm, and the monitor on the monitor arm.

Install the cable support arm to the system.

Install the probe card assembly (PCA) (if ordered) on the back of the system cabinet, and the

60190-PCA (probe card assembly) to the correct prober plate (customer-supplied from the prober

company). The prober plate is attached to the prober.

Plug in the system to your power facilities (supplied by your facilities department at the final

location for the S540 system cabinet) and power up the entire cabinet.

Verify communications of all instruments and with the properly configured prober.

Perform diagnostics and system verification tests of the entire S540 system, to include the

60190-PCA (if ordered).

Record all the information on the System Installation Form.

S540-924-01 Rev. D / January 2019

Page 27

Section 2: S540 site preparation and installation S540 Power Semiconductor Test System Administrative Guide

2-16

Example Series 500 System Installation Form

Figure 21: Example Series 500 System Installation Form page 1

S540-924-01 Rev. D / January 2019

Page 28

S540 Power Semiconductor Test System Administrative Guide Section 2: S540 site preparation and installation

2-17

Figure 22: Example Series 500 System Installation Form page 2

S540-924-01 Rev. D / January 2019

Page 29

Section 2: S540 site preparation and installation S540 Power Semiconductor Test System Administrative Guide

2-18

Figure 23: Example Series 500 System Installation Form page 3

S540-924-01 Rev. D / January 2019

Page 30

S540 Power Semiconductor Test System Administrative Guide Section 2: S540 site preparation and installation

2-19

Power and operating conditions

Number

Description

1

20 A, 125 V American

2

15 A, 125 V American

3

16 A, 250 V Eurostyle cord

The following topics contain information about power and operating environment conditions.

Supplied power cords

Keithley Instruments provides power cords that match the power requirements of the system. The

following figure and table describe these cords.

Figure 24: Supplied power cables

If power cords with different cord ends are needed, you must provide those cords.

Line power requirements

Nominal input line voltage: 100 VAC, 115 VAC, 220 VAC, 240 VAC (50 Hz, 60 Hz)

Short-circuit current rating: 5 kA

Power consumption: Rated at 2.4 kVA for the 2 kW power distribution unit (PDU)

Heat generation: Quiescent heat of 1720 BTU (1815 kJ) to maximum heat of 8191 BTU (8642 kJ)

S540-924-01 Rev. D / January 2019

Page 31

Section 2: S540 site preparation and installation S540 Power Semiconductor Test System Administrative Guide

2-20

Severe personal injury or death due to electric shock or electrocution or equipment damage

may occur if you do not have the correct circuit amperage.

S540 systems that are configured to operate between 100 VAC and 120 VAC must use a 20 A

circuit; systems that are configured to operate between 200 VAC and 240 VAC must use a

15 A circuit.

System power dissipation

The total power dissipated by the S540 depends on the type and number of instruments in the test

system. The power distribution unit (PDU) limits the incoming power to these instruments.

Though the PDU ensures electrical safety and compliance to the required standards, it does not

prevent the system from overheating.

When a Series 2600B or 2657A instrument detects an excessive heat condition, the instrument turns

the output off to minimize power dissipation. This safeguard prevents damage to individual Series

2600B and 2657A instruments, but may result in test instability. For instance, if you continuously

source more than 1 A from all the source-measure units (SMUs) for more than 100 seconds, it may

trigger a temperature error in one or more of the Series 2600B or 2657A instruments. However, an

average output of less than 1 A for an indefinite period will not cause a temperature error.

For additional information about the Keithley Instruments Series 2600B and 2657A SourceMeter®

instruments, refer to the documentation at tek.com/keithley.

Operating environment conditions

To ensure operation within specifications, the S540 must be operated inside of the following

environmental conditions.

Temperature: 23 °C ±5 °C

Operating humidity: 30% to 60% relative humidity, noncondensing, after a two-hour warm up time

Vibration: High ambient vibration levels may require isolation pads or the repositioning of equipment

Air quality: The S540 system is compatible for use in a Class 10 clean room

Audible system noise: Decibel level is 65 dBA in optimal environmental conditions

Airflow: The S540 system is configured for top to bottom airflow

Altitude: Less than 2000 m (6,561 feet) above sea level

S540-924-01 Rev. D / January 2019

Page 32

S540 Power Semiconductor Test System Administrative Guide Section 2: S540 site preparation and installation

2-21

Noise interference: To prevent electrical noise from interfering with measurements, the ambient AC

magnetic field must not exceed 2 × 10-3 G (2 × 10-7 T):

Avoid locating the S540 next to plasma etchers, large motors, magnets, RF transmitters,

equipment with flash lamps, and other potential sources of interference

Position equipment to avoid routing signal and power cables near sources of electrical noise

Triaxial connector handling and avoiding contamination

Keep source-measure triaxial cable connectors (if applicable) clean and free of any foreign

contaminants. Do not touch the connector pins of the triaxial connectors. Contamination can cause

current leakage in the source-measure signal paths to the device under test (DUT), which can

significantly degrade the test results.

Do not touch any connector pins or the areas adjacent to the electrical contacts of the triaxial

connectors; contamination will degrade the performance of the test system.

Cleaning: Use lint-free swabs moistened with methanol or isopropyl alcohol to clean contaminated

connectors and then blow-dry them with nitrogen gas. After blowing dry, wait several minutes before

using.

Lockout and tagout

For maximum safety while power is applied, always perform a lockout and tagout procedure. Remove

power from the entire test system and discharge capacitors before connecting or disconnecting

cables or any instrument, including the device under test. When you perform lockout and tagout

procedures, make sure that you read all warning labels on the cabinet and instruments (see the

following figure).

Figure 25: Hazardous warning label

S540-924-01 Rev. D / January 2019

Page 33

Section 2: S540 site preparation and installation S540 Power Semiconductor Test System Administrative Guide

2-22

Severe personal injury or death due to electric shock or electrocution may result if power is

not removed before working inside the cabinet. Always perform the lockout and tagout

procedure before opening the system cabinet. Also, never turn on the system until all

connections and safety grounds are installed.

To remove system power:

You must shut down the software and remove all power from the computer and the system (see Shut

down using ACS (on page 3-5) or Shut down using KTE (on page 3-6)).

Before proceeding, you must make sure the power indicator on the front door is not

illuminated. See the following figure for an example of what the indicator looks like when

illuminated.

Figure 26: Indicator showing system power is still on

1. Place the breaker for the power distribution unit (PDU) in the OFF position. The PDU is at the

back of the cabinet below the rear door. See the figure in Power distribution unit connections and

power distribution basics (on page 4-10) for a simplified drawing of the PDU.

2. If you are working in the system cabinet, disconnect the system cabinet line cord from the AC line

power receptacles.

3. Verify that all power has been removed and discharged from the system cabinet by switching the

main power switch (on the front door of the cabinet) to the ON position and verify that the green

light does not illuminate. If the light does not come on, the power is off. Turn the main power

switch back to the OFF position.

4. With the PDU breaker in the OFF position, lockout and tagout the system source power

connection by locking a padlock through the hasp that surrounds the PDU breaker.

S540-924-01 Rev. D / January 2019

Page 34

S540 Power Semiconductor Test System Administrative Guide Section 2: S540 site preparation and installation

2-23

Installation and connections

The following installation and connection procedures should be performed by trained site

installers who are familiar with the associated physical and electrical hazards. Also, you

should never turn on the system until all connections and safety grounds are installed.

Position the system cabinet

The system cabinet contains the controller and instrumentation for the test system. The cabinet is on

casters, which allows you to easily roll it on a hard floor surface. The two steering casters in the rear

are swivel type, and the two casters at the front are in fixed positions.

To position the system cabinet:

1. Carefully roll the system cabinet to its location next to the prober, allowing a minimum distance of

15 cm (6 in.) up to a maximum distance of 122 cm (48 in.). Allow approximately 60 cm (23.5 in.)

(nominal) of clearance between the cabinet and other instrumentation.

2. Lock the casters by pushing down on the caster-locking mechanisms near the front-bottom of the

cabinet.

3. Adjust the height of the four legs so that the weight of the cabinet is on the legs and not on the

casters. Adjust the legs so that the cabinet is level and does not move (see Physically securing

the system (on page 2-27)).

System securement is required for safety of the S540 system and for personnel. You must

bolt the legs adjacent to the four casters to the floor. See Physically securing the system (on

page 2-27) for details.

S540-924-01 Rev. D / January 2019

Page 35

Section 2: S540 site preparation and installation S540 Power Semiconductor Test System Administrative Guide

2-24

Cable harness routing

The S540 has a dual-door rear portal for output leads. Cables can be routed from the cable harness

at the rear portal to either the right or left of the cabinet.

Figure 27: S540 cabinet rear doors and cable portal

You can mount cable support arms on either side of the cabinet to suspend cables off the floor and

prevent a tripping hazard.

Floor plan

The following floor plan information is for the system cabinet only. Be sure to place the cabinet a

minimum distance of 15 cm (6 in.) up to a maximum distance of 122 cm (48 in.) from the prober.

Refer to the documentation for the prober or other test-fixture equipment to determine its floor space

requirements.

S540-924-01 Rev. D / January 2019

Page 36

S540 Power Semiconductor Test System Administrative Guide Section 2: S540 site preparation and installation

2-25

The system cabinet requires a floor space of approximately 1.2 m × 2.1 m (4 ft × 7 ft), plus additional

room for service personnel access from the front and back of the cabinet. The following figures show

a top view of the floor plan and the typical S540 system cabinet weight distribution and center of

gravity. System cabinet size and weight (on page 2-26) lists the dimensions and weight of the system

cabinet.

See the figure on the following page for floor plan specifications.

Figure 28: S540 floor plan, top view

S540-924-01 Rev. D / January 2019

Page 37

Section 2: S540 site preparation and installation S540 Power Semiconductor Test System Administrative Guide

2-26

Figure 29: S540 weight distribution and center of gravity

System cabinet size and weight

Size (width × depth × height)

Weight

Minimum configuration

Maximum configuration

600 mm × 918 mm × 1905 mm

(23.63 in. × 36.13 in. × 75.00 in.)

195.05 kg

(430 lb)

396.89 kg

(875 lb)

Front feet

Left

51.83 kg

(114.25 lb)

Front feet

Left

105.46 kg

(232.50 lb)

Right

51.83 kg

(114.25 lb)

Right

105.46 kg

(232.50 lb)

Rear feet

Left

45.70 kg

(100.75 lb)

Rear feet

Left

92.98 kg

(205 lb)

Right

45.70 kg

(100.75 lb)

Right

92.98 kg

(205 lb)

System cabinet size and weight

The size and weight specifications for the system cabinet are listed in the following table. See Floor

plan (on page 2-24) for details about designing a floor plan for the system cabinet.

S540-924-01 Rev. D / January 2019

Page 38

S540 Power Semiconductor Test System Administrative Guide Section 2: S540 site preparation and installation

2-27

Physically securing the system

You must bolt the S540 system cabinet to the floor for safety purposes and to ensure the cabinet will

not tip over.

The following figure shows the restraint brackets and bolt installation dimensions for the system

cabinet.

Figure 30: S540 system securement dimensions

S540-924-01 Rev. D / January 2019

Page 39

Section 2: S540 site preparation and installation S540 Power Semiconductor Test System Administrative Guide

2-28

The following figure shows how a floor-mounting bracket is installed. Keithley part numbers are

included for the required hardware.

Figure 31: S540 system cabinet floor mount

S540-924-01 Rev. D / January 2019

Page 40

S540 Power Semiconductor Test System Administrative Guide Section 2: S540 site preparation and installation

2-29

The following figure shows a label on the keyboard tray that indicates a tip-over hazard. The

maximum weight capacity for the keyboard tray is 12 kg (25 lb).

Figure 32: S540 tip-over hazard warning label on keyboard tray

Optional advanced seismic securement

The S540 system can be ordered with an advanced seismic fastening option that has been tested

and certified to the standards stated in IEC 61587-2 Ed. 2.0 Mechanical structures for electronic

equipment — Tests for IEC 60917 and 60297 Part 2: Seismic tests for cabinets and racks.

If your system has this option, use the following installation instructions.

To install advanced seismic securement:

You must supply the washers (flat and lock), threaded insert anchors, and mounting bolts that attach

the mounting brackets to the floor (16 of each). The bolts should be at least grade-five bolts.

S540-924-01 Rev. D / January 2019

Page 41

Section 2: S540 site preparation and installation S540 Power Semiconductor Test System Administrative Guide

2-30

1. Position the cabinet where needed on a smooth, level floor.

2. Place the floor mounting brackets at the corners and make sure you have enough room for

proper placement.

3. To properly place the mounting brackets, lift the cabinet by the leveling legs.

Lifting the cabinet allows the holes in the mounting brackets to line up with the holes in the lower

frame of the cabinet.

4. Temporarily attach the mounting brackets to each corner with the provided screws.

The following figure shows the restraint brackets and bolt installation for the system cabinet.

Figure 33: S540 seismic restraints

5. Mark the position of the mounting holes to the floor with a marker.

6. Remove the mounting brackets and also mark the location of the cabinet leveling legs.

7. Lower the cabinet and move as needed for drilling and installing the customer-supplied floor

anchors.

S540-924-01 Rev. D / January 2019

Page 42

S540 Power Semiconductor Test System Administrative Guide Section 2: S540 site preparation and installation

2-31

Anchors should have a minimum pullout rating of 450 kg (1000 lb) each. Install 16 anchors for

maximum protection.

8. Return the cabinet to marked locations on the floor and use the leveling legs to lift the cabinet to

the proper height.

9. Attach the mounting brackets to the corners with the mounting hardware provided (16 screws and

washers; 25 ft lb torque required).

10. Fasten brackets to the floor with user-supplied washers and grade-five (or higher) bolts.

The following figure shows how a floor-mounting bracket is installed.

Figure 34: S540 advanced cabinet floor mount

S540-924-01 Rev. D / January 2019

Page 43

In this section:

Introduction .............................................................................. 3-1

Initial equipment startup ........................................................... 3-1

System startup ......................................................................... 3-2

Before starting system software ............................................... 3-3

Start the KTE software ............................................................. 3-4

Start the ACS software ............................................................. 3-5

Shut down using ACS .............................................................. 3-5

Shut down using KTE ............................................................... 3-6

Emergency OFF button ............................................................ 3-6

Safety interlocks ....................................................................... 3-7

LO patch panel ....................................................................... 3-11

Prober safety .......................................................................... 3-11

Network information ............................................................... 3-12

Introduction

Section 3

Equipment startup

All of the instruments in the equipment rack are connected to one power distribution unit (PDU), which

is in the back of the cabinet.

Initial equipment startup

To begin equipment startup:

1. Check that all power cords for the system cabinet are connected to AC power.

Follow the instructions in the following topics to start up your system and software.

Make sure that the circuit breaker on the power distribution unit (PDU) is in the ON position.

Page 44

Section 3: Equipment startup S540 Power Semiconductor Test System Administrative Guide

3-2

Figure 35: S540 power distribution unit (PDU) circuit breaker

2. Press the power/standby button on the computer and monitor.

3. Set the power button on the front door of the system cabinet to the ON position.

Figure 36: S540 power ON switch

System startup

To start up the system:

1. Make sure that the power switch on the power distribution unit (PDU) is set to ON.

2. Set the power button on the front door of the system cabinet to the ON position.

3. If the computer has not started to boot, open the front cabinet door and press the power/standby

switch on the host computer.

4. Wait for all of the instruments to power up.

5. Log onto your computer.

S540-924-01 Rev. D / January 2019

Page 45

S540 Power Semiconductor Test System Administrative Guide Section 3: Equipment startup

3-3

Before starting system software

You must make sure that all of the instruments are connected with the appropriate interface cable

and a TSP-Link® connection between any Series 2600B/2657A or DMM7510 instruments.

Assign GPIB or TCP/IP addresses (as appropriate) and node numbers to the hardware and

instruments.

To avoid instrument errors, make sure that all of the instruments in the system are completely

powered up and have finished self-testing before starting the system software.

The S540 system includes the following system software option:

Keithley Test Environment (KTE)

For more information about the KTE software setup procedures, refer to the KTE S530/S535/S540

Release Notes document (part number PA-1036).

Using Telnet

Telnet is not enabled by default on the S540 system; you must to enable it to use it.

To enable Telnet:

1. From the command prompt (as root user), type su and the root password.

2. Type gedit /etc/xinetd.d/telnet to open the Telnet server configuration file.

3. In the opened file, change the line that says disable = yes to disable = no (see the following

figure).

Figure 37: Enabling Telnet

S540-924-01 Rev. D / January 2019

Page 46

Section 3: Equipment startup S540 Power Semiconductor Test System Administrative Guide

3-4

4. Save and close the file.

5. At the command prompt (as root user), type the following:

service xinetd start

chk config telnet on

chk config xinetd on

Start the KTE software

To start the KTE software, first start the instrument controller (IC) process. To start the IC process, log

on to the computer and enter the following command:

run_ic.pl

The IC process must be started manually after you log on.

The first time the IC process is started after a new KTE software installation, all instruments in the

TSP-Link® network are initialized, which may take a few minutes. A status message is displayed on

the TSP master instrument (Model 2450) during this process.

After the initial software installation, run_ic.pl initializes only the TSP-Link master instrument, and

the other TSP instruments in the system execute the appropriate TSP script without delay.

IC process log messages

The run_ic.pl script sends any output messages from the IC process to the

$KILOG/ic_<QMO>_YYYYMMDD_HHMM.log file, where:

<QMO> is the QMO number of the tester.

YYYYMMDD_HHMM is the date and time when the IC process was started.

The IC process by default only outputs DEBUG and ERROR messages. You can use the

KI_TRACE_LEVEL environment variable to define the minimum level of messages to display. Valid

values of this variable are: TRACE, DEBUG, and ERROR. After changing the environment variable, the

IC process must be restarted by executing $KIHOME/IC/bin/run_ic.pl.

Stopping the IC process

To stop the IC process, enter the following command:

$KIHOME/IC/bin/stop_ic.pl

S540-924-01 Rev. D / January 2019

Page 47

S540 Power Semiconductor Test System Administrative Guide Section 3: Equipment startup

3-5

Start the ACS software

To start the ACS software, log on to the computer and double-click the ACS icon.

For more information about the ACS software setup procedures, refer to the Automated

Characterization Suite (ACS) Reference Manual (part number ACS-901-01).

Shut down using ACS

To shut down using the Automated Characterization Suite (ACS) software:

You must have administrator rights in the ACS software to shut down the S540 system.

1. Double-click the Shutdown icon on the computer desktop.

2. In the dialog box that opens, click Yes that you want to shut down the S540 tester.

The message in the following figure opens after you click Yes to shut down the S540. You must wait

until the 4200A-SCS and the system computer shut down before you press the power button on the

system cabinet. It may take several minutes for the system to shut down.

Figure 38: Shut down the S540

3. Once the ACS host computer has shut down, press the power button on the front door of the

system cabinet.

S540-924-01 Rev. D / January 2019

Page 48

Section 3: Equipment startup S540 Power Semiconductor Test System Administrative Guide

3-6

Shut down using KTE

To shut down using the Keithley Test Environment (KTE) software:

1. Close all KTE programs.

2. In the LINUX® terminal, type the following command:

sudo $KIBIN/shutdown_s530.pl

3. Enter the requested password.

4. Wait for the system computer to stop.

5. Turn off power to the cabinet.

Emergency OFF button

An EMERGENCY OFF (EMO) button is on the system cabinet front door (see the following figure). If

you push the EMERGENCY OFF button, it removes power to all of the system instruments except the

host computer.

Figure 39: EMERGENCY OFF button

The EMO TRIPPED indicator light (on the cabinet door) turns on when the system has undergone an

emergency shutdown.

Emergency shutdown procedure

Press the red EMERGENCY OFF button on the front of the system cabinet. The instruments power

down and the red EMO TRIPPED indicator illuminates.

The red indicator also illuminates when the system recovers from a sudden power loss.

S540-924-01 Rev. D / January 2019

Page 49

S540 Power Semiconductor Test System Administrative Guide Section 3: Equipment startup

3-7

Recovering from an emergency shutdown

To recover after an emergency shutdown:

1. Verify that the hazardous condition or emergency situation is no longer present.

2. Rotate the EMERGENCY OFF button to release it.

3. Toggle the power switch from ON to OFF, and then back to ON again. All of the system

instruments should power up.

4. Open the front cabinet door and press the power/standby switch on the host computer.

5. Call run_ic.pl to reinitialize the instrumentation.

Figure 40: S540 front-panel controls and indicators

Safety interlocks

Failure to make sure that the safety interlock and safety shields and guards are properly

installed and arranged as indicated will put personnel in severe danger. Severe personal

injury or death due to electric shock or electrocution may result.

For the safety interlock to function properly, the device under test (DUT) interlock sensor

must be installed near the DUT connections and the interlock magnet must be installed on

the safety shield. It must be set up so that when the magnet is near the switch (interlock

closed) the operator cannot touch voltage-carrying conductors. If not properly installed, it will

render the interlock inoperative and place personnel at severe risk.

For operator safety, the S540 has interlocks on both the front and back cabinet doors and at the DUT.

Also, the optional probe card adapter (PCA) has interlocks that provide protection for connections to a

prober.

S540-924-01 Rev. D / January 2019

Page 50

Section 3: Equipment startup S540 Power Semiconductor Test System Administrative Guide

3-8

If you open a cabinet door or open the DUT interlock while instruments are sourcing, the interlock

activates and disconnects the hazardous voltage from the source-measure instruments, stopping any

tests in progress.

An indicator on the front door of the S540 cabinet illuminates, and the KTE software immediately

notifies you of the interlock activation.

Figure 41: Interlock indicator

Once the interlock has been activated, you must clear the cause of the interlock activation.

To clear the interlock activation:

1. Follow the instructions on the computer.

2. Make sure the front and rear doors are closed.

3. Make sure the DUT interlock is properly set for safe operation.

4. Close the DUT safety shield.

5. The software must recover before you can continue normal operation. You may need to rerun

your tests.

S540-924-01 Rev. D / January 2019

Page 51

S540 Power Semiconductor Test System Administrative Guide Section 3: Equipment startup

3-9

Additional probe card adapter safety interlock cable

The Model 174-7047-XX Safety Interlock Cable provides additional protection from electric shock at

the Keithley probe card adapter (PCA). The cable attaches to the prober top plate and the PCA so

that if you unlatch the top plate of the prober and lift it up to change a probe card or take off the PCA,

the interlock is tripped.

Figure 42: Model 174-7047-XX Safety Interlock Cable

The Model 174-7037-XX cable can be used with customer-supplied PCA solutions.

Figure 43: Model 174-7037-XX interlock cable

The Model 174-7047-XX cable interfaces with your prober interlock through a relay contact. A

shorted prober contact engages the interlock circuit. An open contact interrupts the interlock, turning

off hazardous voltage.

S540-924-01 Rev. D / January 2019

Page 52

Section 3: Equipment startup S540 Power Semiconductor Test System Administrative Guide

3-10

9140A-PCA interlock connections for S540 systems

The following diagram shows the interlock connections to the optional 9140A-PCA Probe Card

Adapter.

Figure 44: 9140A-PCA interlock block diagram for S540 systems

For additional information about the 9140A-PCA, see the 9140A-PCA Probe Card Adapter Instruction

Manual (part number 9140A-901-01). This manual is available for download at tek.com/keithley.

S540-924-01 Rev. D / January 2019

Page 53

S540 Power Semiconductor Test System Administrative Guide Section 3: Equipment startup

3-11

LO patch panel

The S540 must have a single, direct connection between instrument lows and protective earth (safety

ground). The S500-LOPATCH-3KV panel provides this common LO connection and protective earth

(safety ground) reference.

The LO patch panel provides:

Figure 45: S500-LOPATCH-3KV

A common reference point for all the instrument low-side connections

In 4-wire systems, a common connection for the sense low terminals of the source-measure units

(SMUs)

Connections from low to sense low using a 100 kΩ resistor to enable autosensing

Prober safety

Hazardous voltages may be present on the probe card adapter, even after you disengage the

interlock. Cables can retain charges after the interlock is disengaged, exposing you to live

voltages that, if contacted, may cause personal injury or death.

Never attempt to touch or change a probe card when tests are running. You must be

absolutely certain that all tests have stopped before making contact with anything in the

vicinity of the probe card adapter. Also, never run tests without a probe card installed.

S540-924-01 Rev. D / January 2019

Page 54

Section 3: Equipment startup S540 Power Semiconductor Test System Administrative Guide

3-12

Network information

The network connections for the system computer include:

System controller network interface: Ethernet port (10, 100, or 1000 Base-T capable using RJ-45)

Supplied cables: One ethernet crossover cable (connects the computer to the tester)

One 10Base-T patch cable (connects to your network)

IP address is specified by you

When setting up the computer for the S540 system, do not change the computer name. Software

licenses are tied to the computer name. If you change the computer name, the Keithley Interactive

Test Tool (KITT), Keithley Test Execution Engine (KTXE), and other Keithley Test Environment

(KTE) tools will not work.

S540-924-01 Rev. D / January 2019

Page 55

In this section:

Hardware replacement ............................................................. 4-1

Handling and cleaning precautions .......................................... 4-2

Electrical hazard tasks ............................................................. 4-3

Instrument removal and installation .......................................... 4-4

Power distribution and emergency off ...................................... 4-8

Data hub license .................................................................... 4-13

Editing the icconfig_<QMO>.ini file ........................................ 4-13

Using NPLCs to adjust speed and accuracy .......................... 4-14

Decommissioning an S540 test system ................................. 4-16

Hardware replacement

Section 4

Maintenance

The information in this section is intended only for qualified service personnel, as described

in Safety precautions (on page 1-1). Because some of these procedures may cause exposure

to hazardous voltages that could result in personal injury or death, service personnel must

wear personal protective equipment (PPE) suitable for voltages greater than 40 VAC. Do not

attempt to perform these procedures unless you are qualified to do so.

This section contains information about removal and installation of system cabinet components, and

instructions for replacing components determined to be faulty.

Page 56

Section 4: Maintenance S540 Power Semiconductor Test System Administrative Guide

4-2

Handling and cleaning precautions

Always grasp cards by the side edges and shields to avoid contamination that will degrade

the performance of the components. Do not touch the connectors, the board surfaces, or

components. On plugs and receptacles, do not touch areas adjacent to the electrical

contacts.

Take care when handling or servicing to prevent possible contamination in high-impedance areas,

which could degrade performance. Take the following precautions when servicing any system

component:

Do not store or operate the system in an environment where dust could settle on the components.

Use dry nitrogen gas to clean dust off the components, if necessary.

Handle cards only by the side edges and shields.

Do not touch any board surfaces, components, or connectors.

Do not touch areas adjacent to electrical contacts.

Wear clean-room approved gloves when servicing any component.

If necessary, make solder repairs on a circuit board using lead-free solder. Remove the solder

from the work areas when the repair is complete. Use pure water and clean cotton swabs or a

clean, soft brush to remove the solder. Take care not to spread the solder to other areas of the

components. Once the solder is removed, use a swab moistened with methanol or isopropyl

alcohol to wipe only the repaired area, and then blow-dry the board with dry nitrogen gas.

After cleaning, place the components in a 50 °C low-humidity environment for several minutes

before use.

S540-924-01 Rev. D / January 2019

Page 57

S540 Power Semiconductor Test System Administrative Guide Section 4: Maintenance

4-3

Special handling of static-sensitive devices

System components can be damaged by electrostatic discharge (ESD). Wear a ground strap

and attach the clip lead to the grounding bar in the test head or the system cabinet frame

before working on the system. Assume all parts are static sensitive.

High-impedance devices are subject to possible static discharge damage because of the

high-impedance levels involved. When handling such devices, assume all parts are static sensitive:

Static-sensitive components should be transported and handled only in containers designed to

prevent or dissipate static buildup. Typically, these components are received in anti-static

containers made of plastic or foam. Keep these parts in their original containers until ready for

installation or use.

Remove the components from their protective containers only at a properly grounded workstation.

Also, ground yourself with an appropriate wrist strap while working with these components.

Handle the connectors only by their bodies. Do not touch the boards, pins, or terminals.

Any printed circuit board into which the device is to be inserted must first be grounded to the

bench or table.

Use only anti-static type desoldering tools and grounded-tip soldering irons.

Electrical hazard tasks

Definitions of electrical hazard tasks (as defined in the SEMI S2-0715a standard) are listed in this

section. For S540 systems, Type 2 electrical hazard tasks are typically performed.

For additional information about diagnostics, troubleshooting, or maintenance of specific Keithley

instruments, refer to the documentation for that instrument for details before attempting to repair it.

You can download manuals for related instruments at tek.com/keithley.

S540-924-01 Rev. D / January 2019

Page 58

Section 4: Maintenance S540 Power Semiconductor Test System Administrative Guide

4-4

Types of electrical hazard tasks

Live circuit

type

Description

1

Equipment is fully de-energized.

2

Equipment is energized. Energized circuits are covered or insulated.

SEMI S2-0715a standard, NOTE 41: Type 2 work includes tasks where

the energized circuits are or can be measured by placing probes through

suitable openings in the covers or insulators.

3

Equipment is energized. Energized circuits are exposed and inadvertent

contact with uninsulated energized parts is possible. Potential exposures

are no greater than 30 V

RMS

, 42.4 V

peak

, 60 VDC, or 240 VA in dry

locations.

4

Equipment is energized. Energized circuits are exposed and inadvertent

contact with uninsulated energized parts is possible. Potential exposures

are greater than 30 V

RMS

, 42.4 V

peak

, 60 VDC, or 240 VA in dry locations.

Potential exposures to radio-frequency currents, whether induced or via

contact, exceed the limits in SEMI S2, Appendix 3, Table A3-1.

Repair and replacement

Keithley Instruments offers a fee-based service agreement with all S540 systems. Under this

agreement, a field service engineer will either repair or replace equipment. For more information

about this service agreement, contact Keithley Instruments at 1-800-935-5595.

For additional information about specific parts, operations, and maintenance of Keithley instruments,

refer to the documentation for the instrument for details before attempting to replace or repair any

equipment. You can download manuals for related instruments at tek.com/keithley.

Instrument removal and installation

The following topics describe the process for removing or installing instruments in the system, and

any special precautions that must be taken.

Remove system power

Severe personal injury or death due to electrical shock or electrocution may result if power is

not removed before moving, removing, or installing equipment. Do not attempt to perform

these procedures unless you are qualified to do so and are wearing personal protective

equipment (PPE) suitable for voltages greater than 40 VAC.

Make sure the system and instruments that are being installed, moved, or removed are turned