Page 1

INSTRUCTION MANUAL

Model 750 Printer

Page 2

WARRANTY

We warrant each of our products to be free from defects in material

and workmanship. Our obligation under this warranty is to repair

or replace any instrument or part thereof which, within a year after

shipment, proves defective upon examination. We will pay local

domestic surface freight costs.

To exercise this warranty, write or ca~ll your local Keithley representative, or contact Keithley headquarters in Cleveland, Ohio.

You will be given prompt assistance and shipping instructions.

REPAIRS AND

CALIBRATION

Keithley Instruments maintains a complete repair and calibration

service as well as a standards laboratory in Cleveland, Ohio.

A Keithley service facility at our Munich, Germany office is

available for our customers throughout Europe. Service in the

United Kingdom can be handled at our office in Reading. Addition-

ally, Keithley representatives in most countries maintain service

and calibration facilities.

To insure prompt repair or recalibration service, please contact

your local field representative or Keithley headquarters directly

before returning the instrument. Estimates for repairs, normal

recalibrations and calibrations traceable to the National Bureau of

Standards are available upon request.

KEITHLEY

The measurement engineers.

Keithley Instruments, Inc., 28775 Aurora Road, Cleveland, Ohio 44139. (216) 248-0400

European Headquarters: Heiglhofstrasse 5, D-8000 Munchen 70 West Germany, (089) 7144065

United Kingdom: 1 Boulton Road, Reading, Berkshire, (0734) 661267

France: 44 Rue Anatole France, F-91121 Palaiseau (01) 014-22-06

Page 3

INSTRUCTION MAYUAL

Model 750 Printer

OCOPYRIGHT 1976, KEITHLEY INSTRUMENTS, INC.

SECOND PRINTING, AUG. 1978, CLEVELAND, OHIO, U.S.A.

DOCUMENT NO. 27965, REVISION CODE AA.

Page 4

INSTRUCTION MANUAL

Model 750 Printer

CONTENTS

Section

Page

CONTENTS

......................................

ii

ILLUSTRATIONS.

................................... iii

SPECIFICATIONS

...................................

iv

1. GENERAL INFORMATION.

.............................. l-l

l-l. INTRODUCTION

............................... l-l

1-2. WARRANTY INFORMATION

........................... l-l

l-3.

CHANGE NOTICE.

.............................. l-l

2.

INITIAL PREPARATION.

.............................. 2-l

2-l. GENERAL..................................2- I

2-2. INSPECTION

................................ 2-l

2-3. PREPARATION FOR USE.

...........................

2-l

2-4.

HOW TO INSTALL ACCESSORY PLUG-IN CARDS

..................

2-l

2-5.

HOW TO INSTALL PRINT PAPER (FAN-FOLD OR ROLL).

..............

2-3

2-6.

HOW TO INSTALL RIBBON.

..........................

2-6

2-J.

HOW TO RACK MOUNT THE MODEL

750.

.....................

Z-J

3.

OPERATING INSTRUCTIONS

.............................

3-l

3-l.

GENERAL ..................................

3-l

3-2.

HOW TO USE FRONT PANEL CONTROLS.

.....................

3-1

3-3.

HOW TO OPERATE THE PRINTER

........................

3-l

3-4.

INTERFACING THROUGH I/O "A".

.......................

3-2

3-5.

INTERFACING THROUGH I/O "6".

.......................

3-5

4.

ACCESSORIES.

..................................

4-l

4-l.

PRINTER INPUT INTERFACES

.........................

4-l

4-2.

MODEL

7503

PRINTER CLOCK

.........................

4-l

4-3.

MODEL

7504

SEQUENCE COUNTER.

.......................

4-1

5.

THEORY OF OPERATION.

..............................

5-l

5-l.

INTRODUCTION

...............................

5-l

5-2.

OVERALL FUNCTIONAL DESCRIPTION

......................

5-l

5-3.

PRINT SEQUENCE DESCRIPTION

........................

5-1

6.

MAINTENANCE.

..................................

6-l

2:::

GENERAL ..................................

6-1

MECHANISM - SIMPLE MAINTENANCE

......................

6-1

6-3.

ELECTRONIC CIRCUITRY

...........................

6-4

7.

REPLACEABLE PARTS.

...............................

7-1

J-1.

GENERAL ..................................

7-1

7-2.

ORDERING INFORMATION

...........................

7-l

7-3.

SCHEMATICS

................................

J-l

APPENDIX A.

MODEL

7503

PRINTER CLOCK.

....................... A-l

APPENDIX B.

MODEL 7504 SEQUENCE COUNTER

......................

B-l

APPENDIX C.

MODEL 7502 PRINTER INPUT INTERFACE.

..................

C-l

APPENDIX D.

CHASSIS REPLACEABLE PARTS

.......................

D-l

APPENDIX E. RACK MOUNTING INSTRUCTIONS.

......................

E-l

APPENDIX F.

COMPONENT LAYOUTS

...........................

F-l

ii

AA

Page 5

INSTRUCTION MANUAL

Model 750 Printer

ILLUSTRATIONS

igure

NO. Title

Page

1 Front and Rear Views of Model 750

.....................

l-2

2

Installation of Accessory Plug-in Cards

..................

2-2

2

How to Open the Front Panel to Access the Mechanism ............

2-4

How to Install Fan-Fold or Roll Paper

...................

2-4

2

View of Paper Feed Mechanism.

.......................

2-5

How to Replace Ribbon

...........................

2-6

;

Timing For External Print Command

..................... 3-4

Timing For Red Print.

...........................

3-4

9

Timing For PIC x 2.

............................ 3-4

10

Top View of Chassis Showing Roll and Fanfold Paper Installed.

.......

3-8

II

Model 7503 Clock.

.............................

4-2

12

Model 7504 Sequence Counter

........................

4-2

13

Simplified Block Diagram.

.........................

5-2

14

Top View of Printer With Cover Removed.

..................

6-3

15

Assembly of Chassis

............................

16

6-5

Mother Board Assembly

...........................

6-5

17

Assembly of Connector Board

........................

6-6

18

Controls and Modifications to Model 7503.

.................

A-2

19

Diagram of Time Set For Model 7503.

....................

A-3

20

Diagram of Model

750/7503

Operation

....................

A-4

21

Component Layout of PC-374.

........................

A-5

22

Block Diagram of Model 7503

...

....................................

: :

A-6

23

Pin Identification for Connector J502 A-8

24

Model 7504 Controls and Connectors.

....................

B-2

25

Diagram of Model

750/7504

Operation

....................

B-3

26

Block Diagram of the Model 7504

......................

B-4

27

Component Layout of Model

7504 (~~-385)

..................

B-6

28

Model 7502 General Purpose Printer Input Interface. ............

C-2

::

Chassis Parts Identification.

.......................

D-2

Handle Assembly For Model 750

.......................

E-2

31

Model 1011 Rack Mounting Kit.

.......................

E-4

;:

Model 1012 Rack Mounting Kit.

.......................

E-6

Model 1015 Rack Mounting Kit.

.......................

E-9

34

Model 1014 Rack Mounting Kit.

.......................

E-l

;z

Model 1016 Rack Mounting Kit.

.......................

E-l

Component Layout, PC-380.

.........................

F-l

Component Layout,

PC-378.

.........................

F-3

Location of Test Points Described in Section 5. .............. F-4

AA

iii

Page 6

INSTRUCTION MANUAL

Model 750 Printer

SPECIFICATIONS

low-to-high transition,

CONTROL OUTPUT: Printer-in-Cycle (PIG); End-of-Print Data

Hold: Manual Print: Print Twice.

iv

AA

Page 7

INSTRUCTION MANUAL

Model 750 Printer

SECTION I.

GENERAL INFORMATION

SECTION 1

l-l.

INTRODUCTION.

The Keithley Model 750 Printer is a medium speed, ink impression,

line printer designed for use with Keithley digital measuring instruments and other

digital instrumentation.

a.

Printing Capabilities.

The tlodel 750 records up to 18 columns of data per line.

Columns 3 through I8 print numeric data,

while columns 1 and 2 of the printer are re-

served for measurement units and contain no numeric characters.

Columns 3, 4, 5 can

print certain measurement units (see Table 3-5 on page 3-7). Columns 6 through IO and 12

through 15 contain a floating decimal point which can be printed to the right of any one

of the numeric data columns,

without deleting numerical data in that umn.

Either

adding machine roll paper (Z-1/4 inch width) or fan-fold paper can bf ;ed.

b. Accessory printer Input Interfaces are available for use with t thley digital mea-

suring instruments. The factory-wired interfaces are plug-to-plug cb,,, atible so 'that

installation is very simple to perform. All data is properly encoded and formatted for

printout of data, decimal point, range, and units of measurement (where available at the

digital output). See ACCESSORIES Section 4 for more detailed information regarding

accessory interfaces for Keithley instruments as well as for general purpose applications.

l-2.

WARRANTY INFORMATION. The warranty is given in the Keithley general catalog. If

there is a need for service, contact your Keithley representative or authorized repair

facility as given in our catalog.

l-3.

CHANGE NOTICE. Improvements or changes to the instruvent not incorporated into the

manual will be explained on separate instruction manual addenda sheets.

CAUTION

Since input Lo can float to 350 volts peak with respect to chassis ground, care

should be exercised when making connections to either I/O "A" or "BP.

Turn off

power to all instruments c0nnectp.d before plug-in cards are installed or removed,

or cable connections are made. If I/O "B" is not used, make certain the cover

plate is installed to prevent the possibility of electrical shock.

AA

l-l

Page 8

SECTION 1

INSTRUCTION MANUAL

Model 750 Printer

PAPER CUTTING BAR

JZOI

J202

POWER INDICATOR

DS301

POWER S3OIA

PAPER FEED S3OlB

RUN S301C

MANUAL PRINT S301

'PRINT INTERVAL

s103/~106

LINE VOLTS SIOI

FUSE FIOI

POWER P105

C

FIGURE I.

Front and Rear Views of Model 750.

l-2

AA

Page 9

INSTRUCTION MANUAL

Model 750 Printer

SECTION 2.

INITIAL PREPARATION

SECTION 2

2-l.

GENERAL.

This section provides information needed for incoming inspection and

preparation for use.

2-2. INSPECTION.

The Model 750 was carefully inspected both mechanically and electri-

cally before shipment. Upon receiving the instrument, check for any obvious damage

which may have occurred during transit.

verify the electrical specifications,

Report any damages to the shipping agent. To

follow the procedures in Section 5.

2-3.

PREPARATION FOR USE.

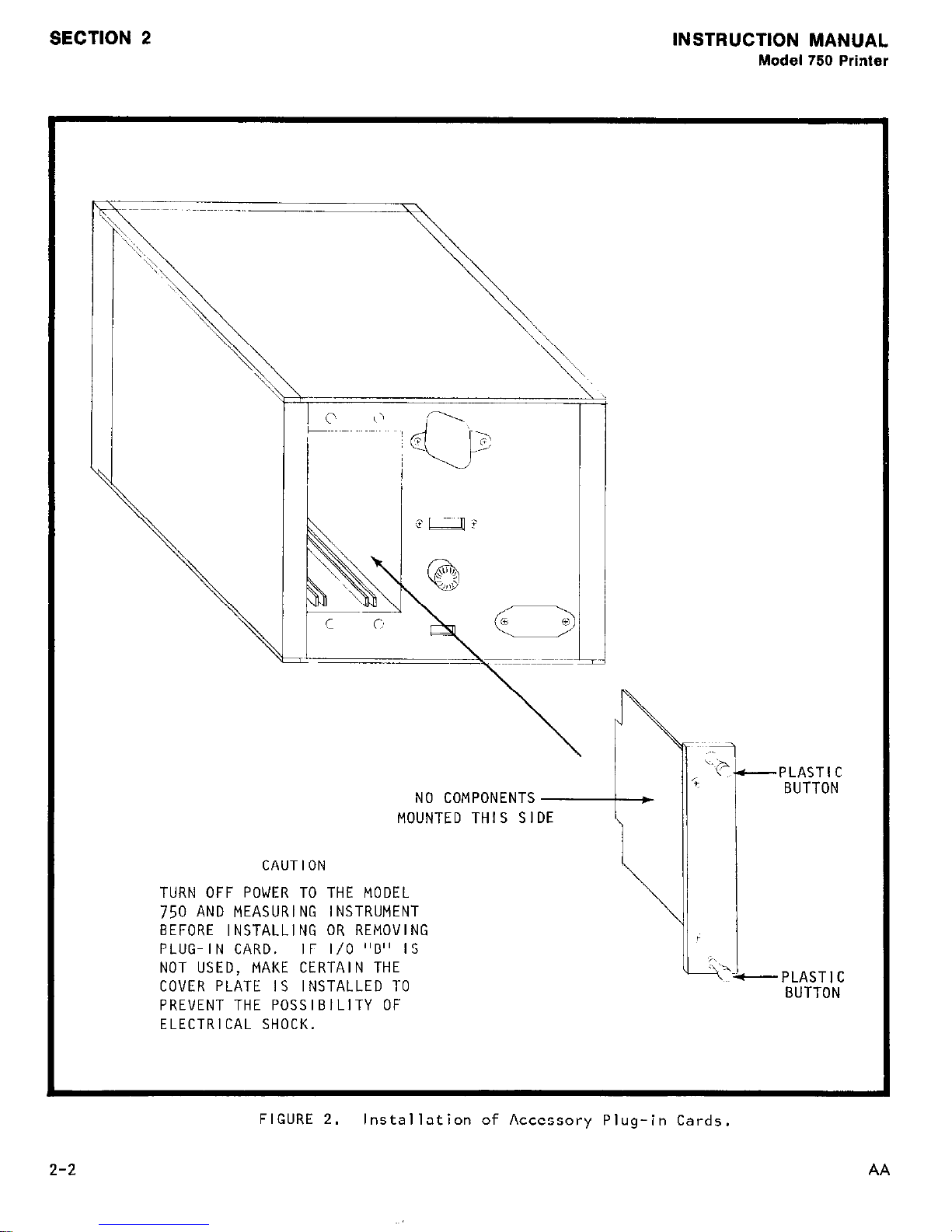

a. How to Set the Line Switch. The rear panel LINE Switch should be set to the

appropriate nominal setting as shown in Table 2-l. For example,

be used is 120 volts,

if the line voltage to

set the LINE Switch to "117".

If the line voltage to be used is

within 105 and llOV, then either range (100 V or 117 V) may be selected.

TABLE 2-l.

Voltage Ranges Useable With Model 750

Range of Voltage Appropriate Setting

Fuse Rating

go - IIOV

I oov

3/4A

105 - l25V

117v

3/4A

200 - 240V 22ov

3/8A

b.

Line Fuse Requirements.

shown in Table 2-l.

The Model 750 uses a 3AB or 3AG Slow-Blow fuse with rating

The line fuse is located on the rear panel as shown in Figure I.

C.

Line Power Connections.

An accessory line cord is furnished with the Model 750.

The 3-wire, 8 foot (244 cm) line cord mates with the rear panel receptacle p]Ol. An

extra line cord can be ordered from Keithley by specifying Keithley Part No. CO-7.

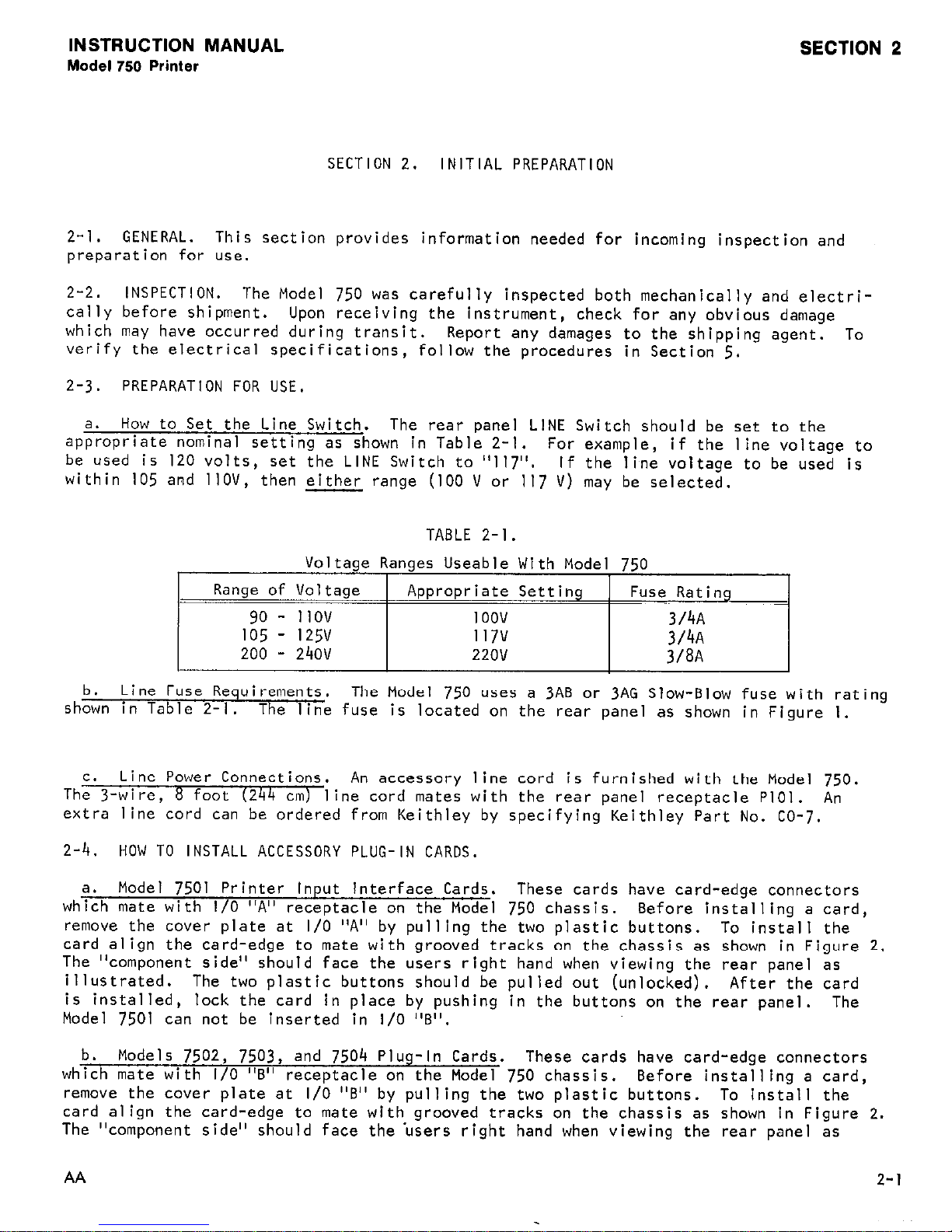

2-4. HOW TO INSTALL ACCESSORY PLUG-IN CARDS.

a. Model 7501 Printer Input Interface Cards.

These cards have card-edge connectors

which mate with I/O "A" receptacle on the Model 750 chassis. Before installinq a card,

remove the cover plate at I/O "A" by pulling the two plastic buttons.

To install the

card align the card-edge to mate with grooved tracks on the chassis as shown in Figure 2.

The "component side"

should face the users right hand when viewing the rear panel as

illustrated. The two plastic buttons should be pulled out (unlocked). After the card

is installed,

lock the card in place by pushing in the buttons on the rear panel. The

Model 7501 can not be inserted in I/O "B".

b.

Models 7502, 7503, and 7504 Plug-In Cards. These cards have card-edge connectors

which mate with I/O "6" receptacle on the Model 750 chassis.

Before installing a card,

remove the cover plate at I/O "B" by pulling the two plastic buttons.

To install the

card align the card-edge to mate with grooved tracks on the chassis as shown in Figure 2.

The "component side"

should face the 'users right hand when viewing the rear panel as

AA

2-1

Page 10

SECTION 2

INSTRUCTION MANUAL

Model 750 Printer

CAUTION

TURN OFF POWER TO THE MODEL

750 AND MEASURING INSTRUMENT

BEFORE INSTALLING OR REMOVING

PLUG-IN CARD. IF I/O "B" IS

NOT USED, MAKE CERTAIN THE

COVER PLATE IS INSTALLED TO

PREVENT THE POSSIBILITY OF

ELECTRICAL SHOCK.

FIGURE 2.

2-2

NO COMPONENTS

MOUNTED THIS SIDE

Installation of Accessory Plug-in Cards.

I t

.\

AA

Page 11

INSTRUCTION MANUAL

Model 750 Printer

SECTION 2

illustrated.

buttons on the rear panel.

7501

cards. The Model 7502 may be installed in either I/O “A” or I/O “B”. Models

and 7504 must be installed in I/O “B” as they will not operate in I/O “A”.

2-5.

tape can be used as a recording medium for the Model

paper is shipped with the printer and is more convenient to install than roll paper.

However,

for installing printer paper. (Extra fan-fold paper may be ordered from Keithley by

specifying Model

a. How to Install Fan-Fold Paper.

shown in Figure 3.

the tray is aligned so that the metal tab is in the front.

ing the tape in the print mechanism.

--

HOW To

I .

Pull out front panel by grasping handle on front panel.

2.

Pull out paper tray.

Place stack of fan-fold paper in pull-out tray as shown in Figure 4.

3.

4. Lift and fold-out the top two layers of paper.

After the card is installed, lock the card in place by pushing in the

I/O “B” has a polarizing pin to prevent insertion of Model

INSTALL PRINT PAPER (FAN-FOLD

the printer will accommodate either paper type.

7505.

See ACCESSORIES section.)

oft

ROLL). Standard

750

2-l/4

Printer.

Use the following procedure

This provides a leader for load-

inch adding machine

A package of fan-fold

Panel swings open as

Be certain

7503

Hold the pack so that the leader is pointing away from the pr’mter and slide the

5.

tray into the tape drawer. When properly installed, the front end of the paper tray

should be just behind the front panel.

6.

Proceed to Paper Feed Instructions in paragraph c.

b.

How to Install Roll-Type Paper.

NOTE

Roll should not exceed Z-3/4 inches in diameter.

I .

Remove the top cover by unscrewing the four Phillips head screws.

2.

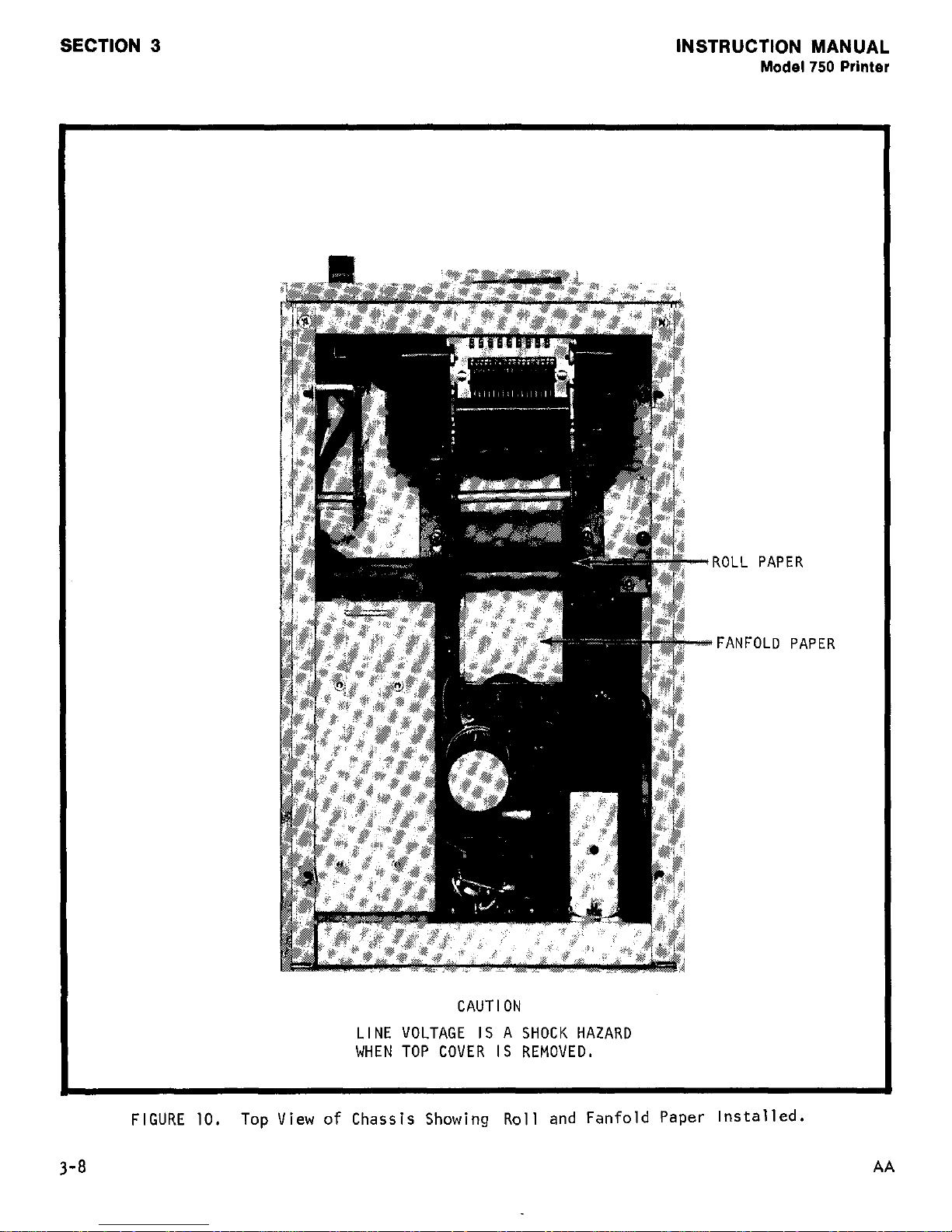

Install the roll paper on the roller pin located as shown in Figure 10

Pull out front panel by grasping handle on front panel.

3.

show in Figure 3.

4.

Grasp the paper roll in one hand and pull out a twelve inch leader.

Point the leader toward the front panel on the printer and, position the paper

5.

rol

I

o that the leader is being pulled off the bottom of the roll.

6.

Slide the paper roll into the roll fixture as shown in Figure 10.

Panel swings open as

Feed the free end of paper under mechanism until it protrudes at the front panel

7.

see

(

‘igure

Replace the top cover.

8.

Proceed to Paper Feed Instructions in paragraph c.

9.

4).

AA

2-3

Page 12

SECTION 2

INSTRUCTION MANUAL

Model 750 Printer

/

+-- -1

PULL OUT AND SLIDE

PANEL TO THE LEFT

'

SO THAT TAB CLEARS

PULL HANDLE

FIGURE

3.

How to Open the Front Panel to Access the Mechanism.

ROLL PAPER

PAPER EXITS

MECHANISM

REAR PANEL

FRONT PANEL

FAN-FOLD PAPER

PAPER TRAY

SIDE VIEW

FIGURE

4.

How to Install Fan-Fold or Roll Paper.

2-4

AA

Page 13

INSTRUCTION MANUAL

Model 750 Printer

SECTION 2

t.

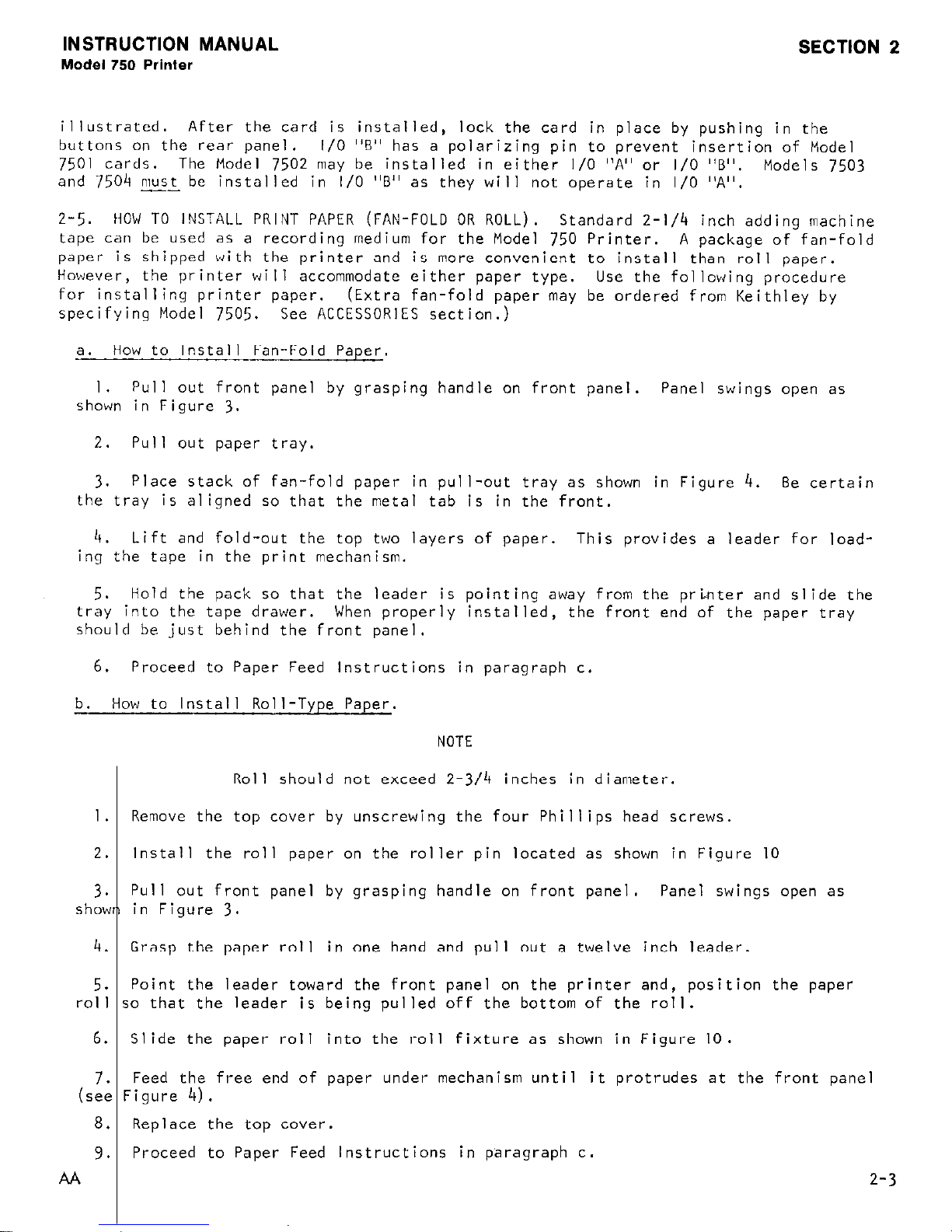

Paper Feed Instructions.

I .

Release the RUN pushbutton to place the Model 750 in "Standby".

2.

Apply power to the instrument by depressing the front panel POWER pushbutton.

3.

Install paper (either fan-fold or roll-type as in preceeding paragraphs).

4.

Locate the arrow on the front of printer mechanism.

5.

Feed paper under the clip,

over the arrow, and into printer mechanism as shown

in Figure

5.

6.

Depress PAPER FEED pushbutton until printer begins to pull paper through mech-

ansim.

7.

As the paper appears at the top of printer, guide the paper under the cutting

bar.

a. Allow about 2 extra inches of paper to feed, then release PAPER FEED button.

9.

Tear off paper flush with cutting bar.

IO. Replace front panel by inserting right side and snapping into place.

Il.

Test for smooth paper advance by depressing PAPER FEED button until a few inches

of paper are advanced.

DE

ITECTIN

LEVER

MET!

SHIEL

FIGURE

5.

View of Paper Feed Mechanisln.

AA

2-5

Page 14

SECTION 2

INSTRUCTION MANUAL

Model 750 Printer

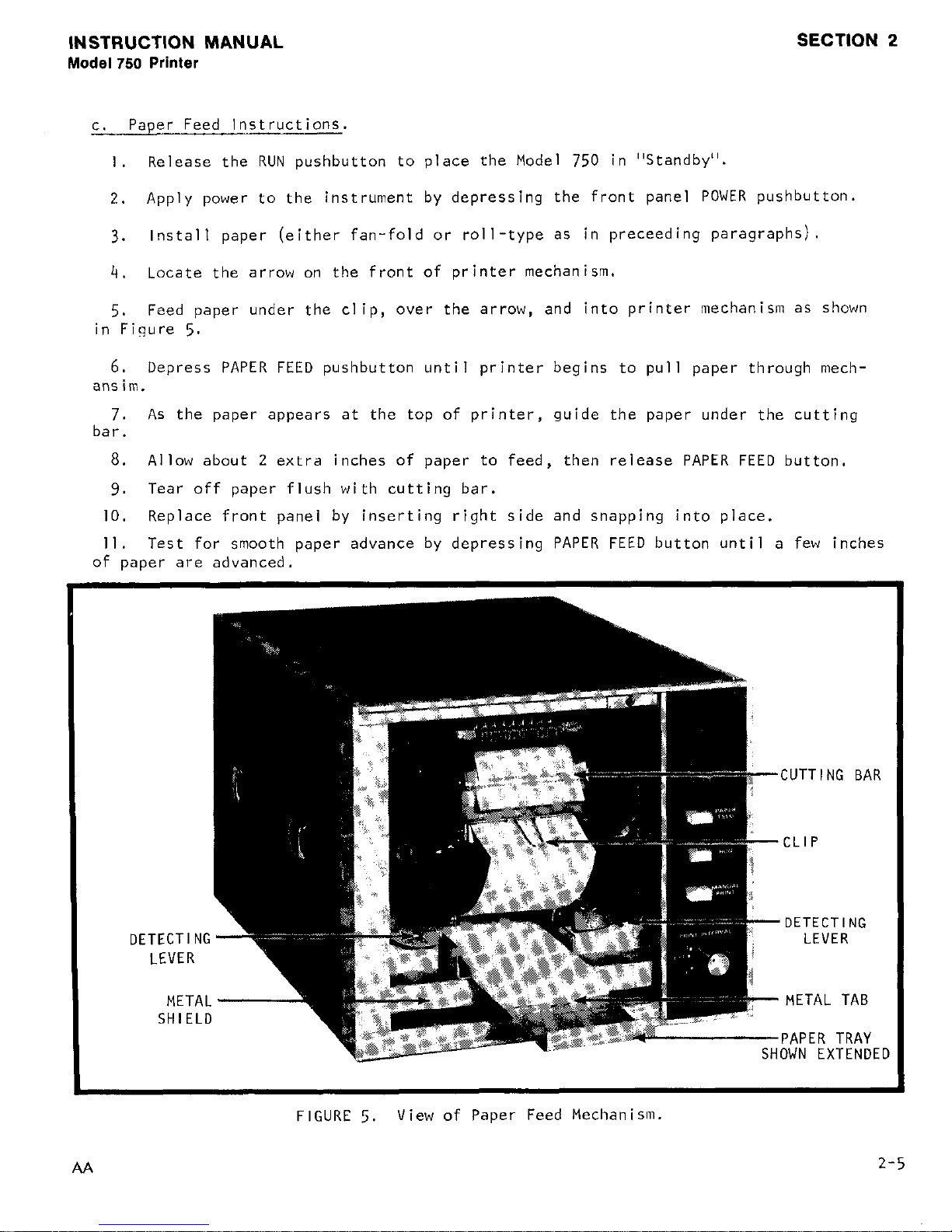

2-6.

HOW TO INSTALL RIBBON.

The Model

750

is shipped with a ribbon installed. Use the

following procedure for replacing a ribbon.

(Extra ribbons may be ordered from Keit!lley

by specifying Model

7506.

See ACCESSORIES section.)

a. Pull out front panel by grasping handle on front panel.

b. On the printer mechanism, locate and push down the Detecting Lever of both spool

shafts (see Figure

5

).

t.

Carefully remove old ribbon spools from shafts.

d.

Remove old ribbon from feed guides and from under hammer.

e.

Separate the new ribbon spools and lay them on a flat surface with their "finger"

side down.

f. Refer to Figure

6

and ensure that the new ribbon is properly threaded on the spools.

9.

On the printer mechanism, locate and push down the Detecting Lever on left hand

spool shaft,

slide the spool onto the shaft making note of the proper threading direc-

tion shown in Figure

6.

h.

Unwind 6 or

8

inches of ribbon from the remaining spool, if necessary, and position

the ribbon over the feed guides as shown in Figure

6.

i. Depress the detecting lever on the empty spool shaft and slip the second spool onto

the shaft. Make sure that there are no twists in the ribbon.

FIGURE 6. How to Replace Ribbon.

2-6

AA

Page 15

INSTRUCTION MANUAL

Model 750 Printer

SECTION 3.

OPERATING INSTRUCTIONS

SECTION 3

3-l. GENERAL.

This section provides information to operate the Model 750 with a variety

of Keithley and other digital measuring instruments.

Information on specific models can

be found in the appropriate Interface manual.

3-2.

HOW TO USE FRONT PANEL CONTROLS.

a. How to Apply Power.

The POWER switch is a "push-push" switch. Depress to apply

power to the instrument.

When the switch is released power is off. The Power Indicator

is lighted when power is on.

b.

How to Feed Paper. The PAPER FEED Switch is a "momentary push" switch.

In the

depressed position it advances papei through the printer mechanism. The switch is used

for loading paper tape or for advancing printed data past the cutting bar.

c.

How to Set Printer to RUN Mode.

The RUN pushbutton is a "push-push" switch.

Depress to allow the printer to be activated by a print command from either of two

sources:

I . Internal print interval.

2.

External Source.

When the switch is released, the printer can be activated only by MANUAL PRINT.

d.

How to Activate the Printer Manually. The MANUAL PRINT Switch is a "momentary

push" switch.

Depress to activate a single line of data. If the switch is depressed

and held in this position, the printer will print data at a rate determined by the PRINT

INTERVAL control. Minimum interval is I second. The external source does not affect

the print interval when MANUAL PRINT is used.

e. How to Set Print Interval. The PRINT INTERVAL control is continuously adjustable

and sets the internal print Interval from a minimum of I ,second'to a maximum of IO

seconds (apprm. The PRINT INTERVAL 'contr,ol also has an EXTERNAL position. In

EXTERNAL the print interval is determined by external print commands.

3-3.

HOW TO OPERATE THE PRINTER.

a. Release POWER Switch (power off).

b. Release RUN Switch (i.e., set to STANDBY mode).

c. Check LINE switch setting as in paragraph

2-3a.

d. Install Model 7501 Printer Input Interface Plug-In Card and/or other accessory

plug-in card as appropriate.

AA

3-l

Page 16

SECTION 3 INSTRUCTION MANUAL

Model 750 Printer

e. Set PRINT INTERVAL control to the appropriate settings.

I.

If an external print interval is to be used, set the PRINT INTERVAL control to

EXT.

2.

If the internal print interval is to be used,

set the PRINT INTERVAL control to

the desired~ position.

f. Connect the line cord.

4.

Depress the POWER Switch.

Power indicator should be lighted.

h. 'Check operation of the Model 750 in STANDBY mode.

(Depress MANUAL PRINT switch

momentarily to cause the Model

750

to print one line.)

i. Depress RUN. This action will cause the Model

750

to initiate printing at inter-

vals determined by the position off the PRINT INTERVAL control.

j.

To halt further printing, release RUN switch.

k. To advance paper through the print mechanism, depress PAPER FEED.

1.

Tear off the printed information by pulling the paper tape along the "cutting bar".

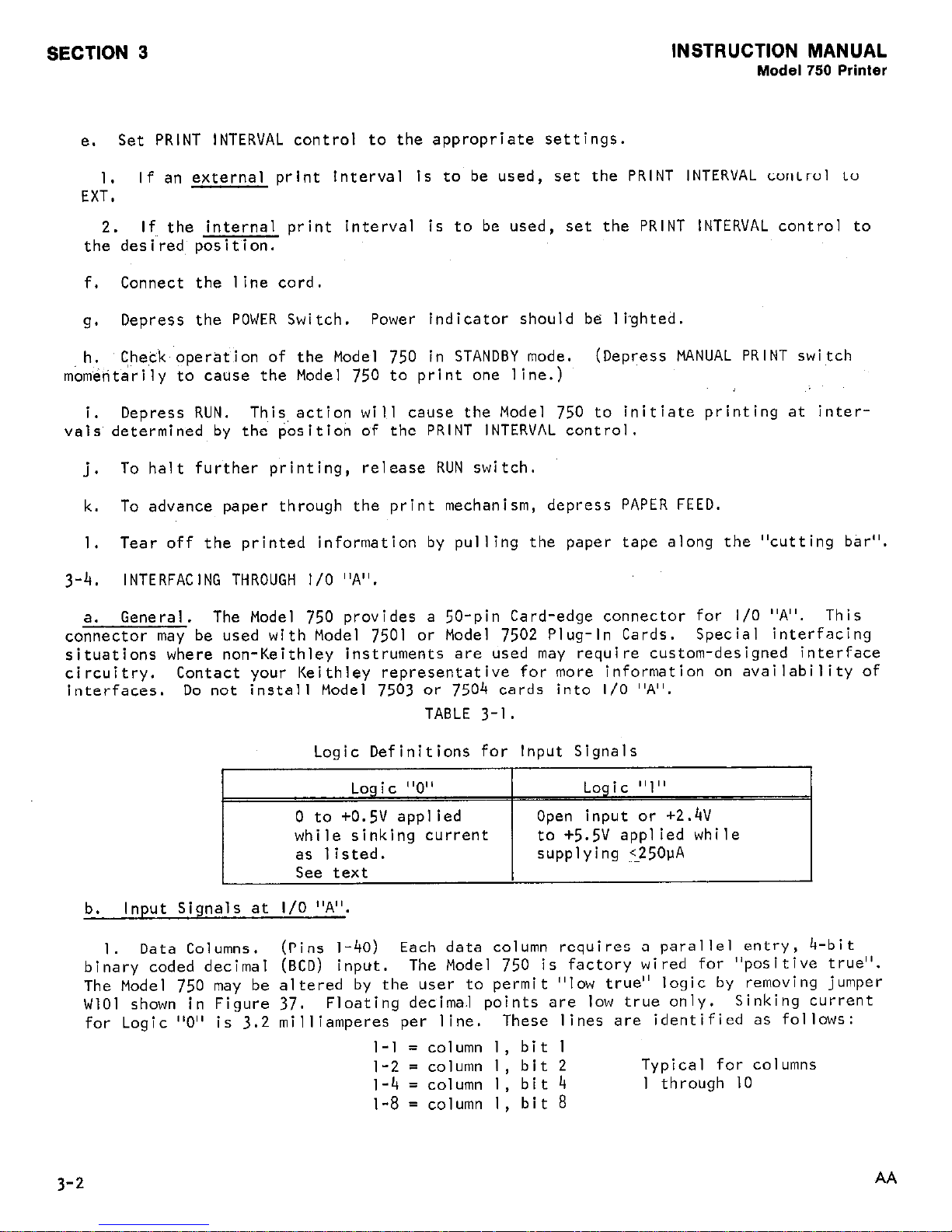

3-4.

INTERFACING THROUGH I/O "A".

a. General. The Model

750

provides a 50-pin Card-edge connector for I/O "A". This

connector may be used with Model

7501

or Model 7502 Plug-In Cards.

Special interfacing

situations where non-Keithley instruments are used may require custom-designed interface

circuitry. Contact your Keithley representative for more information on availability of

interfaces.

Do not install Model

7503

or

7504

cards into I/O "A".

TABLE 3-l.

Logic Definitions for Input Signals

Logic "0"

Logic "1"

0 to +0.5V applied Open input or +2.4V

while sinking current to +5.5V applied while

as listed.

supplying 250pA

See text

b.

Input Signals at I/O "A".

I. Data Columns.

binary coded decimal

The Model 750 may be

WlOl shown in Figure

for Logic

IW’

is

3.2

(Pins l-40) Each data column requires a parallel entry, 4-bit

(BCD) input.

The Model 750 is factory wired for "positive true".

altered by the user to permit "low true" logic by removing jumper

37.

Floating decima.l points are low true only.

Sinking current

milliamperes per line. These lines are identified as follows:

l-l = column I, bit I

l-2 = column I, bit 2

Typical for columns

l-4 = column I, bit 4 I through IO

l-8 = column I, bit 8

3-2

AA

Page 17

INSTRUCTION MANUAL

Model 750 Printer

SECTION 3

2.

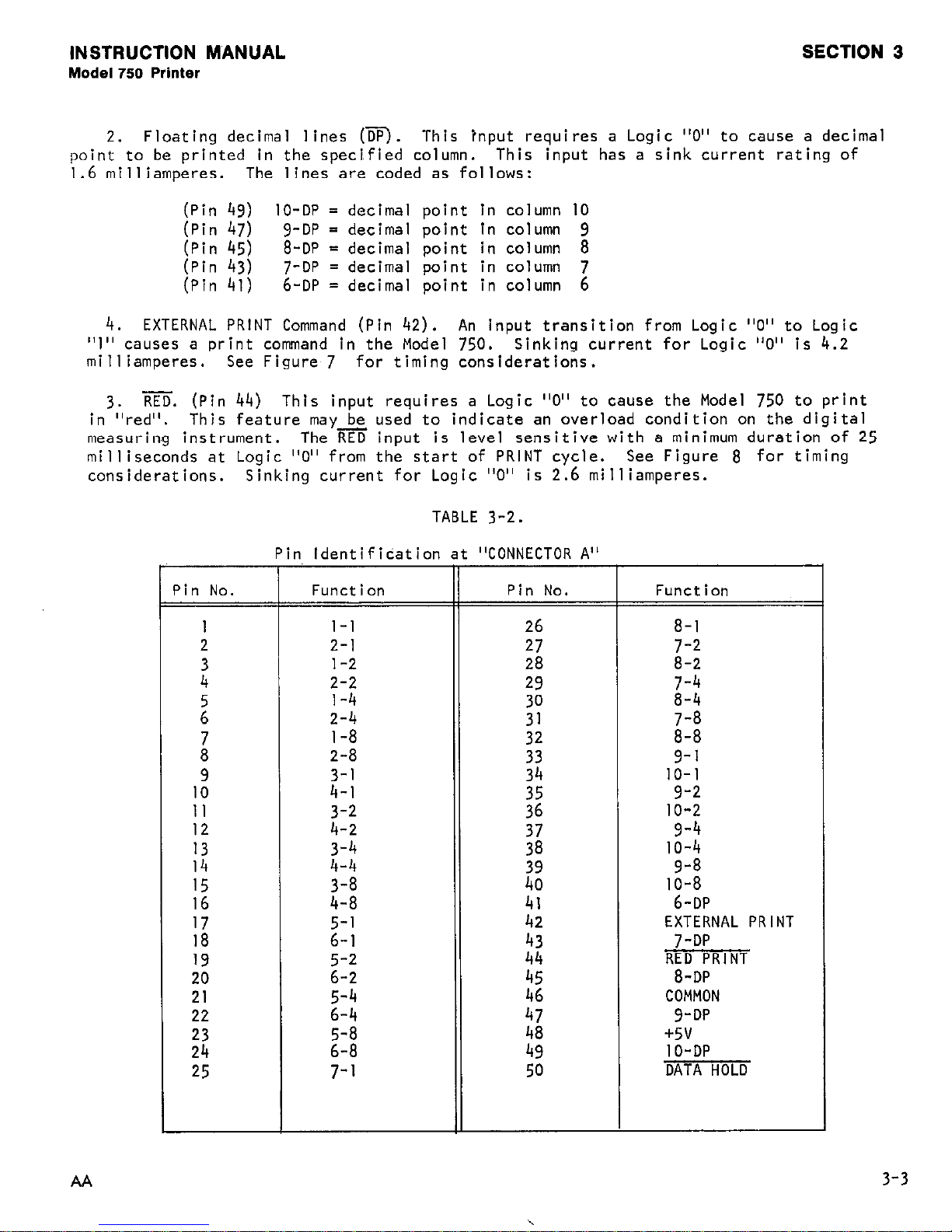

Floating decimal lines (m. This tnput requires a Logic "0" to cause a decimal

point to be printed in the specified column.

This input has a sink current rating of

I.6 milliamperes. The lines are coded as follows:

(Pin 43) IO-DP = decimal point in column IO

(Pin

47)

g-DP = decimal point in column 9

(Pin

45)

8-DP = decimal point in column 8

[;jn z;i

In

7-DP = decimal point in column i

6-DP = decimal point in column

4.

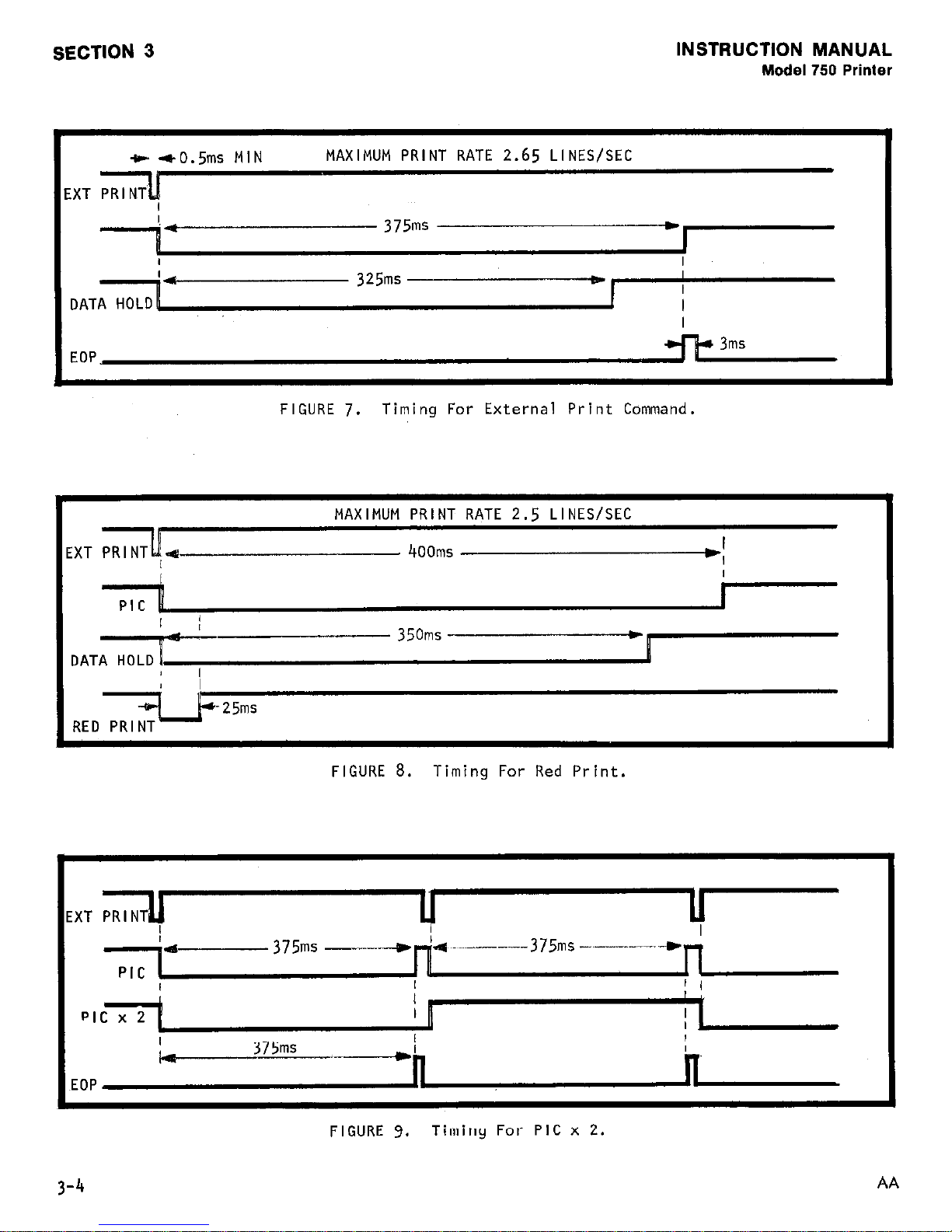

EXTERNAL PRINT Command (Pin 42).

An input transition from Logic "0" to Logic

"I" causes a print command in the Model 750.

Sinking current for Logic "0" is 4.2

milliamperes.

See Figure 7 for timing considerations.

3.

RED. (Pin 44) This input requires a Logic

"0" to cause the Model 750 to print

in "red". This feature may be used to indicate an overload condition on the digital

measurin,g instrument.

The RED input is level sensitive with a minimum duration of 25

milliseconds at Logic "0" from the start of PRINT cycle. See Figure 8 for timing

considerations. Sinking current for Logic "0" is 2.6 milliamperes.

TABLE

3-2.

I

'in No. Function Pin No.

I

2

z

2

is

9

IO

II

:;

I4

15

I6

1;

19

7.0

21

22

2';

25

P

n Identification

l-l

2-l

1-2

2-2

l-4

2-4

l-8

2-8

3-l

4-l

3-2

4-2

2:;

3-8

4-8

2:;

2:;

2:;

2:;

7-I

"CONNECTOR A"

26

27

28

29

;:

2:

47

48

49

50

Function

=

8-l

7-2

8-2

7-4

8-4

7-8

8-8

9-l

IO-I

9-2

IO-2

9-4

IO-4

9-8

10-8

6-DP

EXTERNAL PRINT

7-DP

RED PRINT

8-DP

COMMON

3-DP

+5v

IO-DP

DATA HOLD

AA

3-3

Page 18

SECTION 3

INSTRUCTION MANUAL

Model 750 Printer

e 40.5ms MIN

MAXIMUM PRINT RATE

2.65

LINES/SEC

I

I

- 375ms

I

I

I_

325ms

I

I

DATA HOLD

I

I

I

EOP

FIGURE

7.

Timing For External Print Command.

MAXIMUM PRINT RATE 2.5 LINES/SEC

II

EXT PRINT';- 400ms

w'

I

PIG

DATA+

I

- 350ms

1

I

-25ms

FIGURE 8. Timing For Red Print.

EXT PRINT

u

I

4

I

--~.--375 ms-..- ----.*

I

!

k

375ms

I

EOP

n

FIGURE 9.

Timing For PIC x 2.

AA

Page 19

INSTRUCTION MANUAL

Model 750 Printer

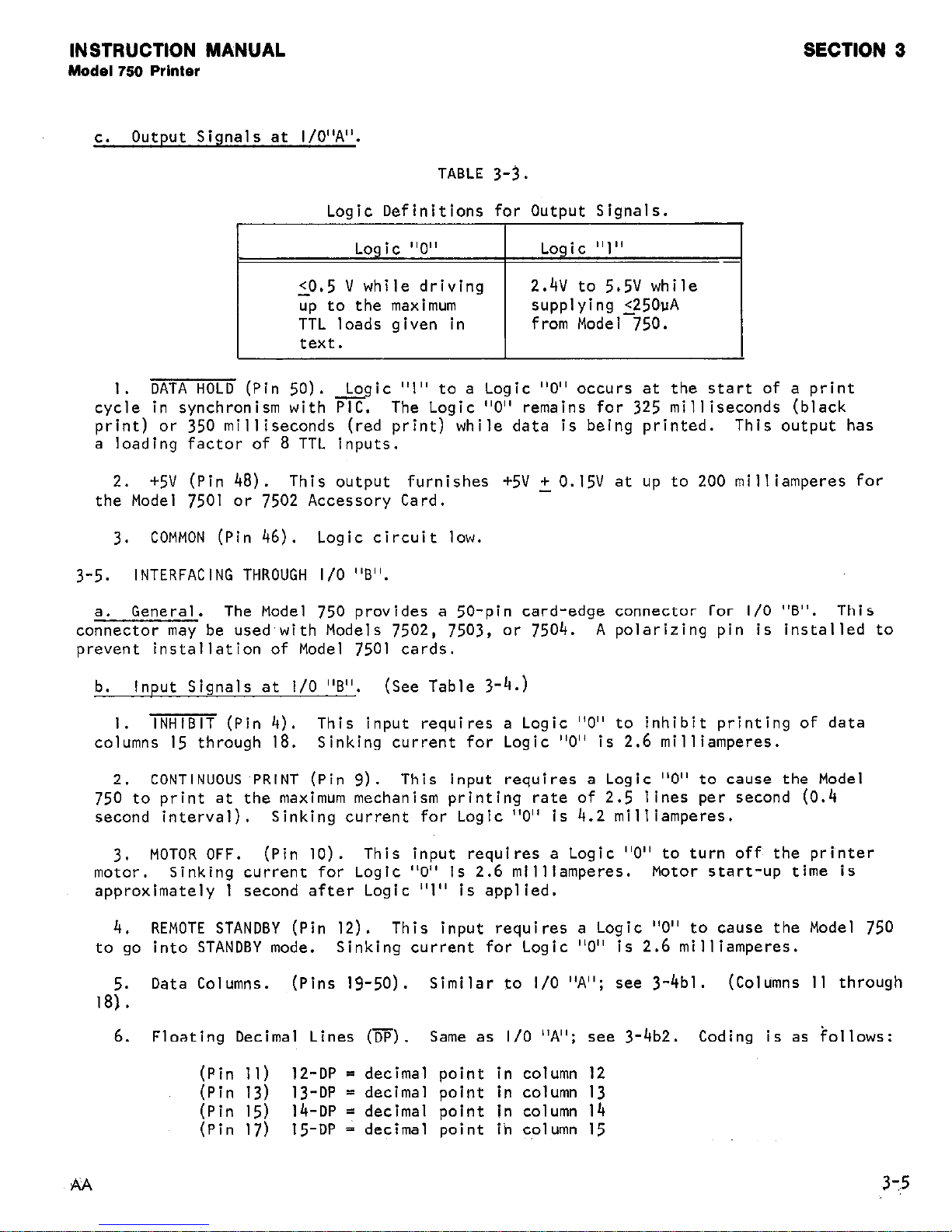

c. Output Signals at I/O"A".

TABLE 3-3.

Logic Definitions for Output Signals.

Logic "0" Logic "1"

-

0.5 V while driving

2.4V to 5.5V while

up to the maximum

supplying 250uA

TTL loads given in

from Model 750.

text.

1.

DATA HOLD (Pin 50). &ic "1" to a Logic "0" occurs at the start of a print

cycle in synchronism with PIC.

The Logic "0" remains for 325 milliseconds (black

print) or 350 milliseconds (red print) while data is being printed. This output has

a loading factor of 8 TTL inputs.

2. +5V (Pin 48). This output furnishes +5V + 0.15V at up to 200 milliamperes for

the Model 7501 or 7502 Accessory Card.

3.

COMMON (Pin 46). Logic circuit low.

3-5.

INTERFACING THROUGH I/O "B".

General. The Model 750 provides a 50-pin card-edge connector for I/O "B". This

co:nector may be used,with Models 7502, 7503, or 7504.

A polarizing pin is installed to

prevent installation of Model 7501 cards.

b. Input Signals at l/O "6". (See Table 3-4.)

I. INHIBIT (Pin 4). This input requires a Logic

"0" to inhibit printing of data

columns 15 through 18.

Sinking current for Logic "0" is 2.6 milliamperes.

CONTINUOUS PRINT (Pin 9)

This input requires a Logic "0" to cause the Model

75i*to print at the maximum mechanism printing rate of 2.5 lines per second (0.4

second interval). Sinking current for Logic "0" is 4.2 milliamperes.

3.

MOTOR OFF. (Pin 10).

This input requires a Logic

"0" to turn off the printer

motor.

Sinking current for Logic "0" is 2.6 milliamperes. Motor start-up time is

approximately 1 second after Logic "1" is applied.

4.

REMOTE STANDBY (Pin 12). This input requires a Logic "0" to cause the Model 750

to go into STANDBY mode.

Sinking current for Logic "0" is 2.6 milliamperes.

18;:

Data Columns. (Pins 19-50).

Similar to I/O "A"; see 3-4bl.

(Columns 11 through

6. Floating Decimal Lines (iiTi). Same as I/O "A"; see 3-4b2. Coding is as follows:

(Pin 11) 12-DP = decimal point in column 12

(Pin 13) 13-DP = decimal point in column 13

(Pin 15) 14-DP = decimal point in column 14

(Pin 17) 15-DP = decimal point ih column 15

Page 20

~EECT~ON 3

INSTRUCTION MANUA~L

Model 750 Prlf%&

C.

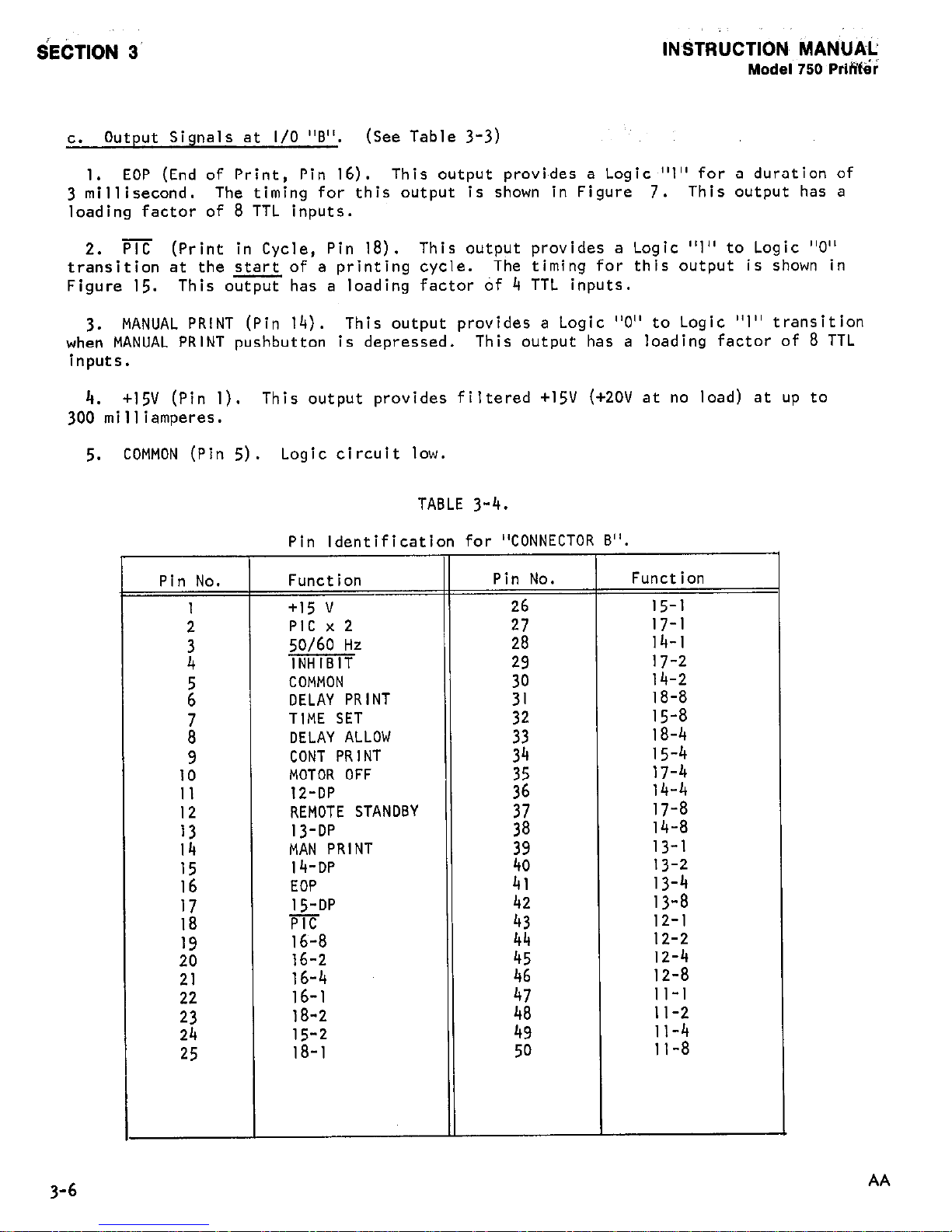

Output Signals at I/O "B".

(See Table 3-3)

1.

EOP (End of Print, Pin 16). This output provides a Logic "1" for a duration of

3 millisecond. The timing for this output is shown in Figure 7.

This output has a

loading factor of 8 TTL inputs.

2.

PIG (Print in Cycle, Pin 18). This output provides a Logic "1" to Logic "0"

transition at the start of a printing cycle. The timing for this output is shown in

Figure 15. This output has a loading factor of 4 TTL inputs.

3.

MANUAL PRINT (Pin 14). This output provides a Logic "0" to Logic "I" transition

when MANUAL PRINT pushbutton is depressed. This output has a loading factor of 8 TTL

inputs.

4.

+15V (Pin 1). This output provides filtered +15V (+2OV at no load) at up to

300 milliamperes.

5.

COMMON (Pin 5).

Logic circuit low.

TABLE 3-4.

Pin

Identification for "CONNECTOR B".

.., .--..-.. .---.-.. .-. ..~...~.~~~~

Pin No. Function

Pin No.

1 +15 v

z

PIG

50/l

mi

i’6

17

18

19

20

21

22

23

24

25

COMMON

DELAY PRINT

TIME SET

DELAY ALLOW

CONT PRINT

MOTOR OFF

12-DP

REMOTE STANDBY

13-DP

MAN PRINT

14-DP

EOP

15-DP

PIG

16-8

16-2

16-4

16-1

18-2

15-2

18-l

:e

14-2

18-8

32

15-8

18-4

15-4

;2

1z:::

;i

;;I;

iz

13-l

13-2

41

13-4

13-8

::

12-l

44

12-2

12-4

12-8

II-1

;i

II-2

49

11-4

50

11-8

3-6

AA

Page 21

INSTRUCTION MANUAL

Model 750 Printer

SECTION 3

d.

Signals Used on Model

7503

Printer Clock.

I.

SO/60 Hz (Pin

3).

This output is connected to the Model 750 power transformer

secondary. It is used exclusively for a timing reference for the Model

750.3.

2.

DELAY PRINT (Pin 6)

3.

TIME SET (Pin 7)

I

Refer to Appendix A

4.

DELAY ALLOW (Pin 8)

5.

PIC x 2 (Pin 2).

This output depends on the setting of the PIC switch (SlO2).

The timing for this output is shown in Figure 8.

TABLE

3-5.

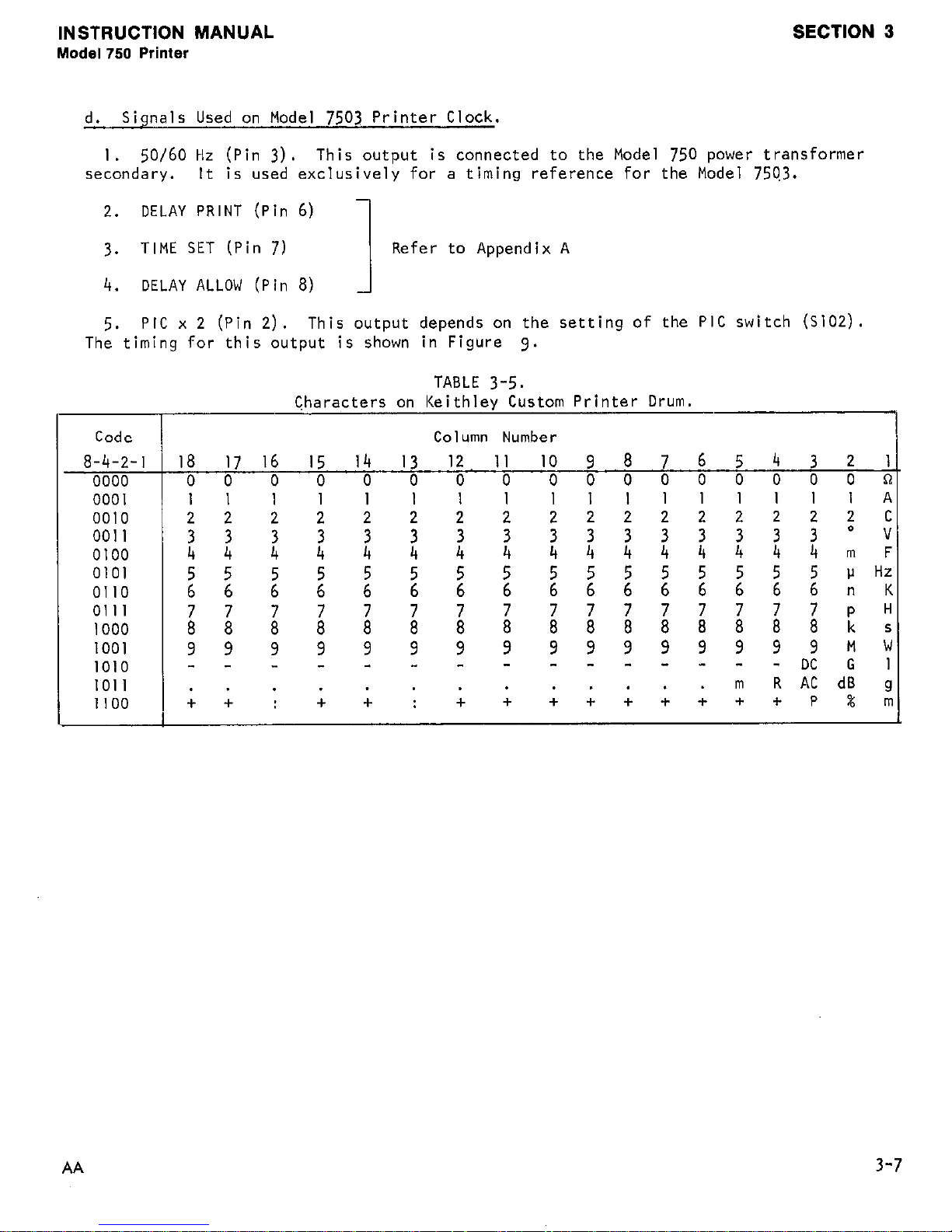

Characters on Keithlev Custom Printer Drum.

Code

I

Column Number

8-4-2-l j 18

17 16 15 14

13 12

11 IO 9

8 7 6 5 4 3 2

1

0000 100 0 0 0 0 0 0 000000000n

0001

0010

0011

0100

0101

0110

0111

1000

1001

1010

1011

1100 (

11 11 11 1 I lllllllllA

22 2 2 2 2 2 2 222222222c

; i z 2 2 2 z z ;;;;;;33-

4 4

m F

2

56

2 2 2 2 ;

5 6 55555555vHz 6 6 6 6 6 6 6 6

n K

ii

i ;: i i ll i ;

7 8 7 8 7 8 7 8 8 7 7 8 7 8 7 8

p k H

s

99 9 9 9 9 9 9

_ _ _ _ - - - -

9 9 9 9 9 9 “,2

- - - - - -

My

G

. . . . . . . . . . . . . m

R AC dB g

++:

+

+ :

+

+ + + + + + + + P % rr

AA

3-7

Page 22

SECTION 3

INSTRUCTION MANUAL

Model 750 Printer

ROL

* FAI

AF

.D

'ER

PAPER

CAUTION

LINE VOLTAGE IS A SHOCK HAZARD

WHEN TOP COVER IS REMOVED.

FIGURE 10.

Top View of Chassis Showing Roll and Fanfold Paper Installed.

Page 23

INSTRUCTION MANUAL

Model 750 Printer

SECTION 4

SECTION 4. ACCESSORIES.

4-l. PRINTER INPUT INTERFACES.

These accessory plug-ins provide interfacing between

the Model 750 and Keithley digital measuring instruments.

TABLE 4-1.

Model

7501-160/1602

Summary of Printer Input Interfaces

Used With Remarks

Mode1 160/1602 Digital Multimeter with digital ) 3-l/2 digits

I

output installed.

Model 164/1602 Digital Multimeter with digital

I

I I

output installed.

I

7501-16OB/l602B Model 1608/1602B Digital Multimeter with digital 3-l/2 digits

outcut installed. I

Model 171/1712 Digital Multimeter with digital

Model 190 Diqital Multimeter. 1 5-l/2 diqits 1

7501-616/6162

I

Model 616 Digital Electrometer

3-l/2 digits

Model 6162 Isolated Outout/Control I

7502

I

General purpose.

I

I

4-2. MODEL 7503 PRINTER CLOCK. This accessory plug in is a real-time digital clock

that prints the time in 24 hour format in the left five columns (14, 15, 16, 17, 18).

The Model 7503 is factory wired to print hours and minutes HH:MM, however it may be rewired in the field to print minutes and seconds MM:SS.

The Model 7503 must be installed

at I/O "B" only.

See Figure 11.

4-3.

MODEL 7504 SEQUENCE COUNTER.

This accessory plug-in is a four digit counter which

numbers successive printer cycles from 0000 to 9999.

Switches on the plug-in board may

be preset for a specific total count.

A Reset pushbutton resets the counter to 0000.

An Inhibit toggle switch inhibits the counter operation. See Figure 12.

AA

4-l

Page 24

SECTION 4

INSTRUCTION MANUAL

Model 750 Printer

FIGURE 11.

Model

7503

Clock.

FIGURE 12.

Model 7504 Sequence Counter.

4-2

Page 25

INSTRUCTION MANUAL

Model 750 Printer

SECTION 5.

THEORY OF OPERATION

SECTION 5

5-l.

INTRODUCTION.

This section of the manual contains an overall functional descr,iption utilizing block diagrams, timing diagrams, and partial schematics, to analyze the

basic operation of the Model 750. For detailed Theory of Operation on the printer head,

refer to SEIKO Model 102 Printer Head Instruction Manual.

This manual is available

from Keithley Instruments.

5-2. OVERALL FUNCTIONAL DESCRIPTION.

a.

The Model 750 is a medium speed, ink impression,

line printer designed as a re-

cording peripheral for "se with digital type instruments.

The printer records up to I8

columns of information at a rate of 2.65 lines per second for black print and 2.5 lines

per second for red print. Each column contains 13 characters plus a space (blank).

A decimal may be printed on the right of the characters in eight of the columns.

Prjnting of the floating decimal is independent of the numerical data presented'to the

column input and therefore, does not delete the column data.

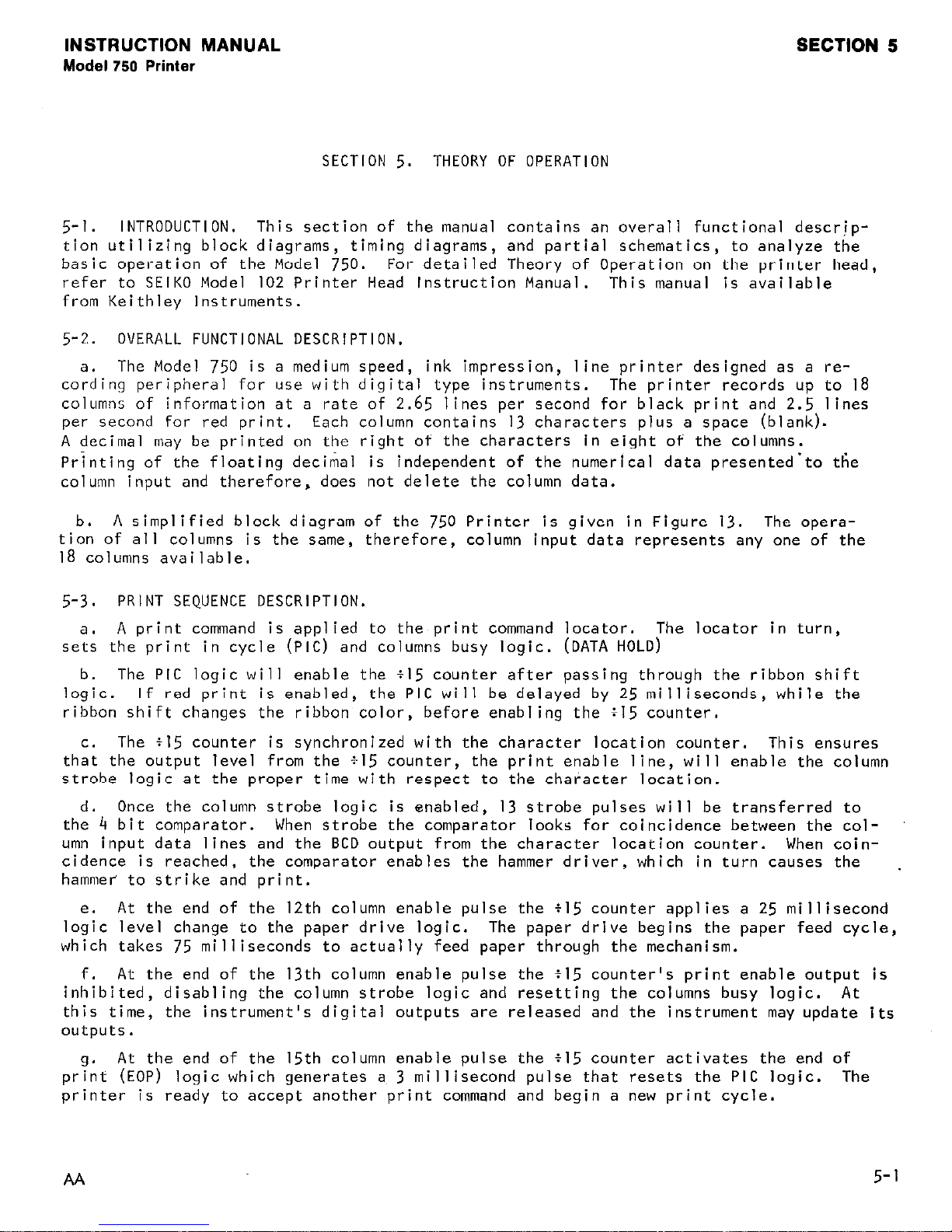

b.

A simplified block diagram of the 750 Printer is given in Figure 13. The opera-

tion of all columns is the same, therefore,

column input data represents any one of the

18 columns available.

5-3.

PRINT SEQUENCE DESCRIPTION.

a. A print command is applied to the print command locator. The locator in turn,

sets the print in cycle (PIG) and columns busy logic. (DATA HOLD)

b. The PIC logic will enable the $15 counter after passing through the ribbon shift

logic. If red print is enabled, the PIC will be delayed by

25

milliseconds, while the

ribbon shift changes the ribbon color,

before enabling the $15 counter.

C.

The +I5 counter is synchronized with the character location counter.

This ensures

that the output level from the $15 counter,

the print enable line, will enable the column

strobe logic at the proper time with respect to the character location.

d.

Once the column strobe logic is enabled, I3 strobe pulses will be transferred to

the 4 bit comparator. When strobe the comparator looks for coincidence between the column input data lines and the BCD output from the character location counter.

When coincidence is reached, the comparator enables the hammer driver, which in turn causes the

hammer to strike and print.

e.

At the end of the 12th column enable pulse the tl5 counter applies a 25 millisecond

logic level change to the paper drive logic.

The paper drive begins the paper feed cycle,

which takes 75 milliseconds to actually feed paper through the mechanism.

f.

At the end of the 13th column enable pulse the ~15 counter's print enable output is

inhibited, disabling the column strobe logic and resetting the columns busy logic. At

this time,

the instrument's digital outputs are released and the instrument may update its

outputs.

9.

At the end of the 15th column enable pulse the $15 counter activates the end of

print (EOP) logic which generates a 3 millisecond pulse that resets the PIC logic. The

printer is ready to accept another print command and begin a new print cycle.

AA

5-1

Page 26

SECTION 5.

INSTRUCTION MANUAL

Model 750 Printer

s+ +

SE

<z

----I

PRINT

RATE

C"NTR"l

I

COLUMN "N"

INPUT DATA

HAMMER

DRIVER

TIMING

MOTOR

PRINTING

J

OFF -

HEAD

RESET

L

I

HAMMER

4

COLUMN

STROBE

PRINT

ENABLE

$13

$15

4

COUNTER

PIG

END OF PRINT END OF PRINT

i

I

I

I 1

I

t

I

4EOP , 1 ,

COLUMNS

I

PRINT

BUSY

I

RED

IN CYCLE

I

A

4

FIGURE

13.

Simplified Block Diagram.

5-2

AA

Page 27

INSTRUCTION MANUAL

Model 750 Printer

SECTION 6.

MAINTENANCE

SECTION 6

6-l. GENERAL. This section contains information necessary to verify performance of the

entire instrument, perform simple maintenance on the printer mechanism, troubleshoot and

repair the control electronics and switching. Extensive maintenance and repair procedures

are available separately in the

Seiko Instruction Manual for the Modei! 102 Printer

Mechanism.

No calibration of electronic circuitry is required.

6-2. MECHANISM - SIMPLE MAINTENANCE PROCEDURES.

a.

Paper Replacement.

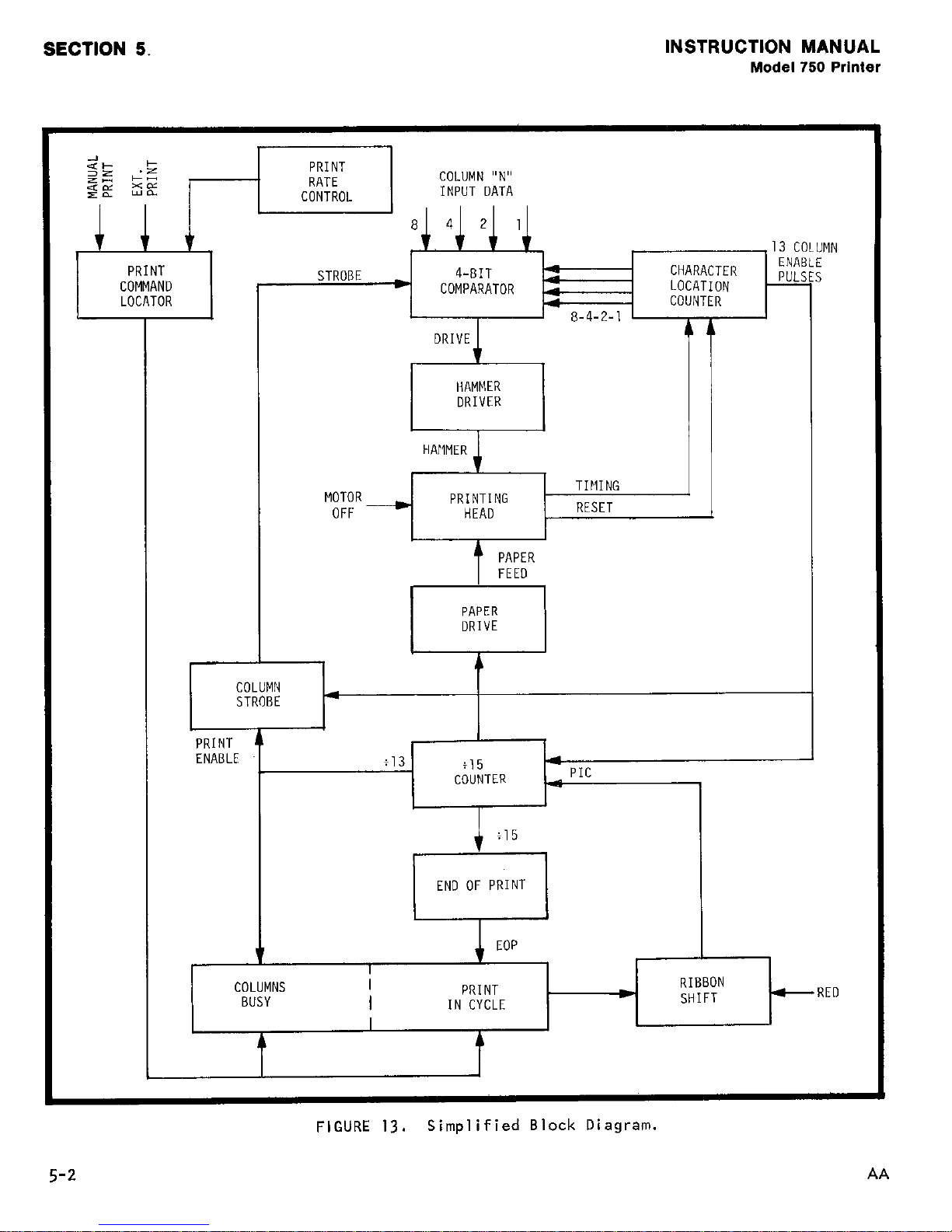

I. How to Install Fan-Fold Paper.

a)

Pull out front panel by grasping handle on front panel. Panel swings open as

shown in Figure 3.

b) Pull out paper tray.

C)

Place stack of fan-fold paper in pull-out tray as shown in Figure 4. Be cer-

tain the tray is aligned so that the metal tab is in the front.

d) Lift and fold-out the top two layers of paper. This provides a leader for

loading the tape in the print mechanism.

4

Hold the pack so that the leader is pointing away from the printer and slide

the tray into the tape drawer.

When properly installed,

tray should be just behind the front panel.

the front end of the paper

f) Proceed to Paper Feed Instructions in paragraph a3.

2. How to Install Roll-Type Paper.

NOTE

Roll should not exceed Z-3/4 inches in diameter.

4

Remove top cover by unscrewing the four Phillips head screws.

b)

Install the roll paper on the roller pin located as shown in Figure IO.

c)

Pull out front panel by grasping handle on front panel.

shown in Figure 3.

Panel swings open as

d) Grasp the paper roll in one hand and pull out a twelve inch leader.

4

Point the leader t&ward the front panel on the printer and, position the paper

roll so that the leader is being pulled off the bottom of the roll.

f) Slide the paper roll into the roll fixture as shown in Figure IO.

g) Feed the free end of paper under mechani.sm. until it protrudes at the front

.panel. (See Figure 4.)

h) Replace the top cover.

i)

Proceed to Paper Feed Instructions in paragriph.a3.

3.

Paper Feed Instructions.

a)

Release the RUN pushbutton to place the Model 750 in "Standby".

AA

6-1

Page 28

SECTION 6

INSTRUCTION MANUAL

Model 750 Printer

b) Apply power to the instrument by depressing the front panel POWER pushbutton.

d

Install paper (either fan-fold or roll-type as in preceeding paragraphs).

d) Locate the arrow on the front of printer mechanism.

e)

Feed paper under the clip, over the arrow, and into printer mechanism as shown

in Figure

5.

f) Depress PAPER FEED pushbutton until printer begins to pull paper through mech-

ansim.

g) As the paper appears at the top of printer,

guide the paper under the cutting

bar.

h) Allow about 2 extra inches of paper to feed,

then release PAPER FEED button.

i) Tear off paper flush with cutting bar.

j) Replace front panel by inserting right side and snapping into place.

k) Test for smooth paper advance by depressing PAPER FEED button until a few

inches of paper are advanced.

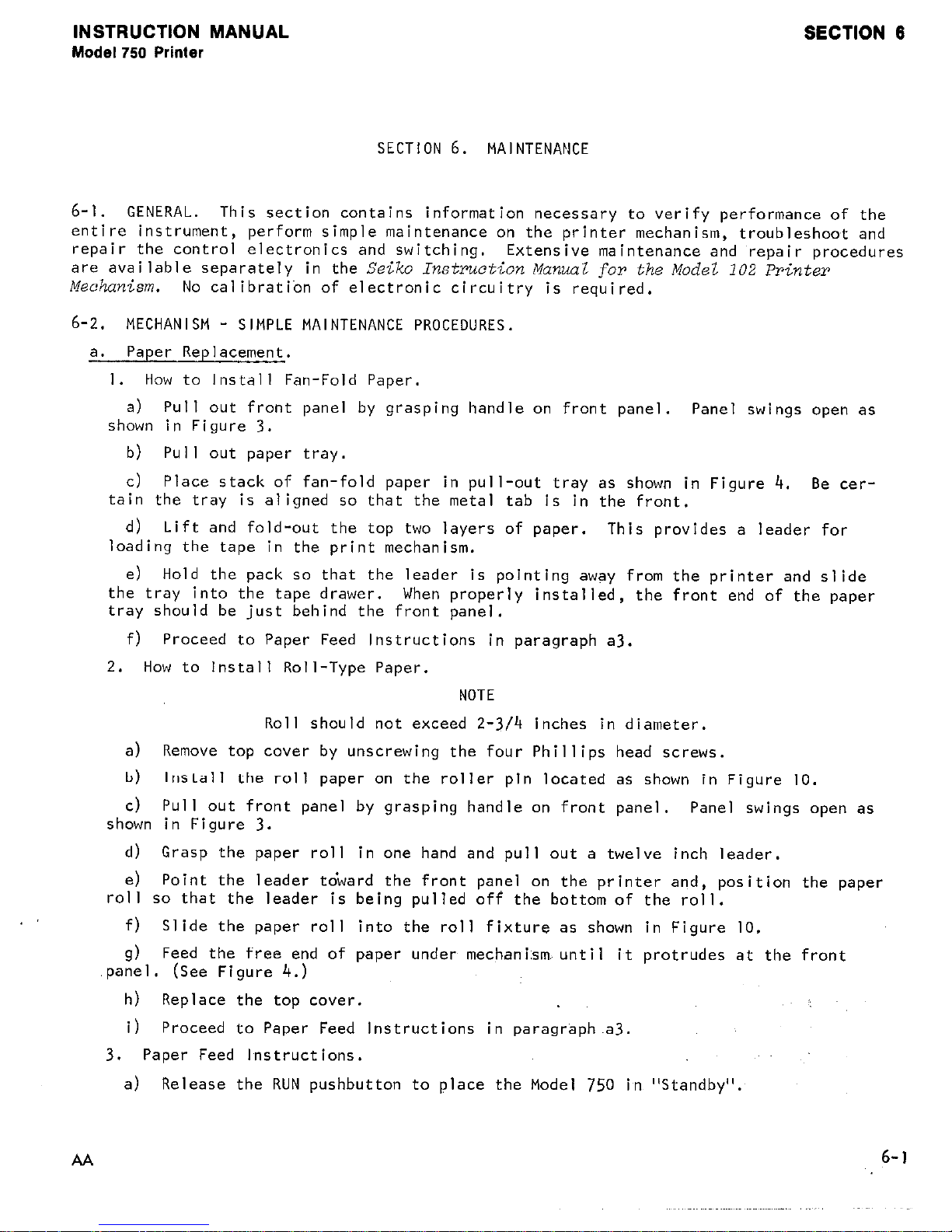

b. Ribbon Replacemerit.

I.

Pull out front panel by grasping handle on front panel.

2.

On the printer mechanism, locate and,push down the Detecting Lever of both spool

shafts (see Figure

5).

3.

Carefully remove old ribbon spools from shafts.

4. Remove old ribbon from feed guides and from under hammer.

5.

Separate the new ribbon spools and lay them on a flat surface with their "finger"

side down.

6.

Refer to Figure 6 and ensure that the new ribbon is properly threaded on the

spools.

7.

On the printer mechanism, locate and push down the Detecting Lever on left hand

spool shaft,

slide the spool onto the shaft making note of the proper threading direc-

tion shown in Figure 6.

a.

Unwind 6 or 0 inches of ribbon from the remaining spool, if necessary, and posi-

tion the ribbon over the feed guides as shown in Figure 6.

9.

Depress the detecting lever on the empty spool shaft and slip the second spool

onto the shaft.

Make sure that there are no twists in the ribbon.

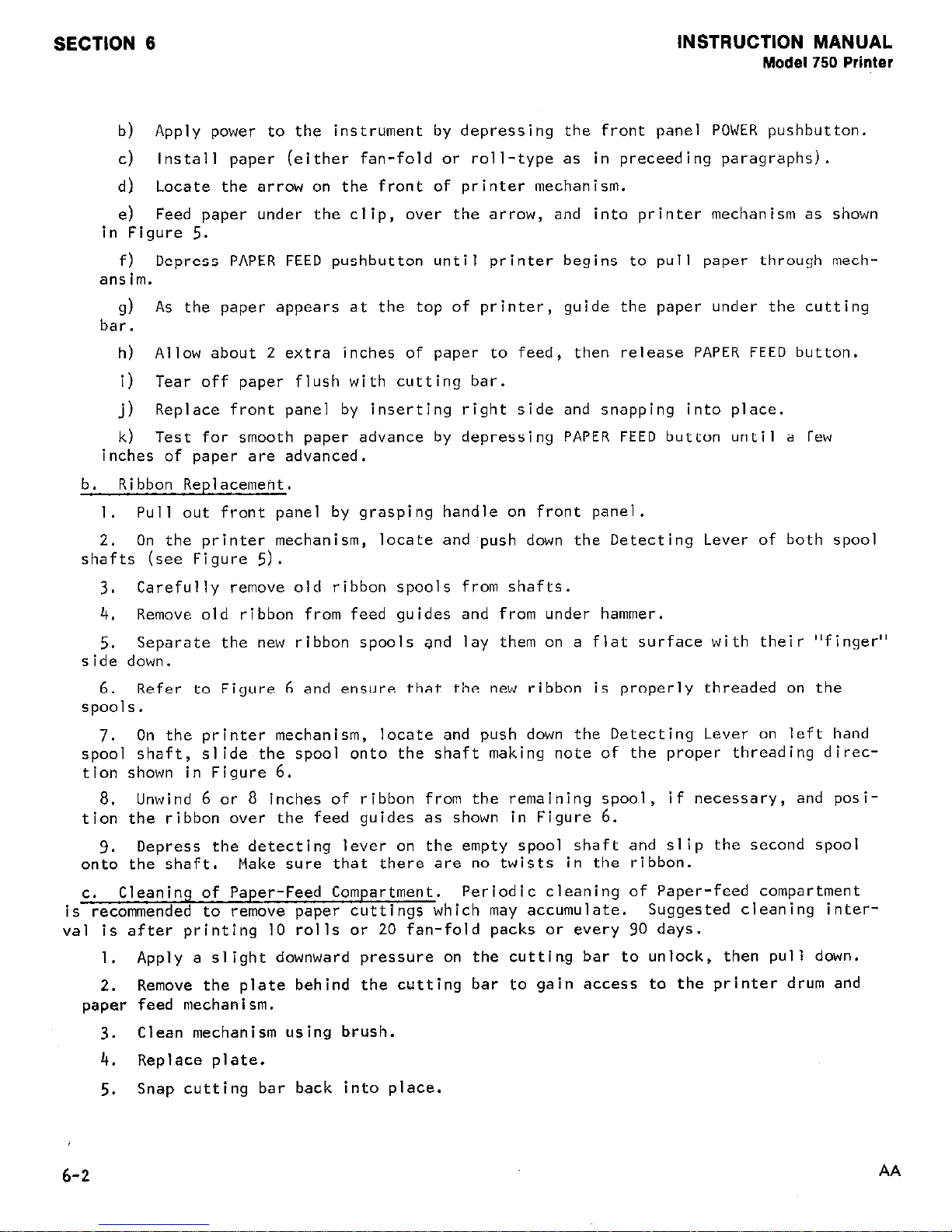

c. Cleaning of Paper-Feed Compartment.

Periodic cleaning of Paper-feed compartment

is recommended to remove paper cuttings which may accumulate.

Suggested cleaning inter-

val is after printing 10 rolls or 20 fan-fold packs or every 90 days.

I.

Apply a slight downward pressure on the cutting bar to unlock, then pull down.

2.

Remove the plate behind the cutting bar to gain access to the printer drum and

paper feed mechanism.

3.

Clean mechanism using brush.

4. Replace plate.

5.

Snap cutting bar back into place.

6-2

AA

Page 29

INSTRUCTION MANUAL

Model 750 Printer

SECTION 6

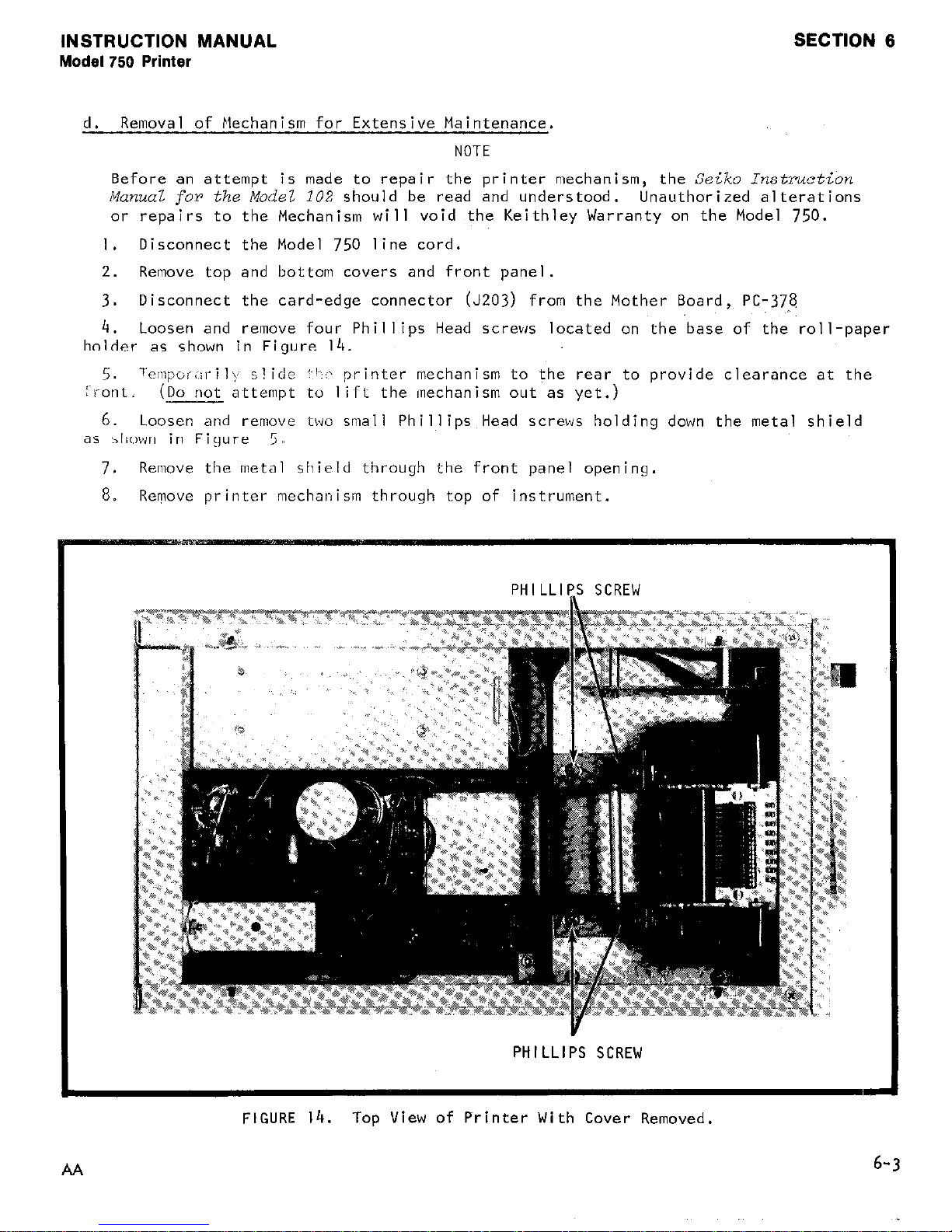

d. Removal of Mechanism for Extensive Maintenance.

NOTE

Before an attempt is made to repair the printer mechanism, the

Seiko Instruction

Manual,

for

the Mode2

102 should be read and understood. Unauthorized alterations

or repairs to the Mechanism will void the Keithley Warranty on the Model 750.

I.

Disconnect the Model 750 line cord.

2. Remove top and bottom covers and front panel.

3.

Disconnect the card-edge connector (J203) from the Mother Board, PC-378

4.

Loosen and remove four Phillips Head screws located on the base of the roll-paper

holder as shown in Figure I4

i-,-&t. (D

TempoiI,iril\. s!ide :~I-~(- printer mechanism to the rear to provide clearance at the

o not attemp't to Ii~Tt the (mechanism out as yet.)

6. Loosen and remove tbwo small Phillips Head screws holding down the metal shield

as il?own in Figure

5 /,

7.

Remove the metal shield through the front panel opening.

8.

Remove printer mechanism through top of instrument.

PHILLIP_S SCREW

PHILLIPS SCREW

FIGURE 14.

Top View of Printer With Cover Removed.

6-3

Page 30

SECTION 6

e.

Cleaning of Mechanism.

INSTRUCTION MANUAL

Model 750 Printer

Use a small brush, vacuum cleaning device,

I.

and paper particles from the hammers, springs, and solenoid ratchets.

2. Use alcohol to remove grease from metal parts of the mechanism.

CAUTkON

Care should be taken if other solvents are used on the plastic parts, since solvents

such.as tri-chloroethylene and ketone may cause damage.

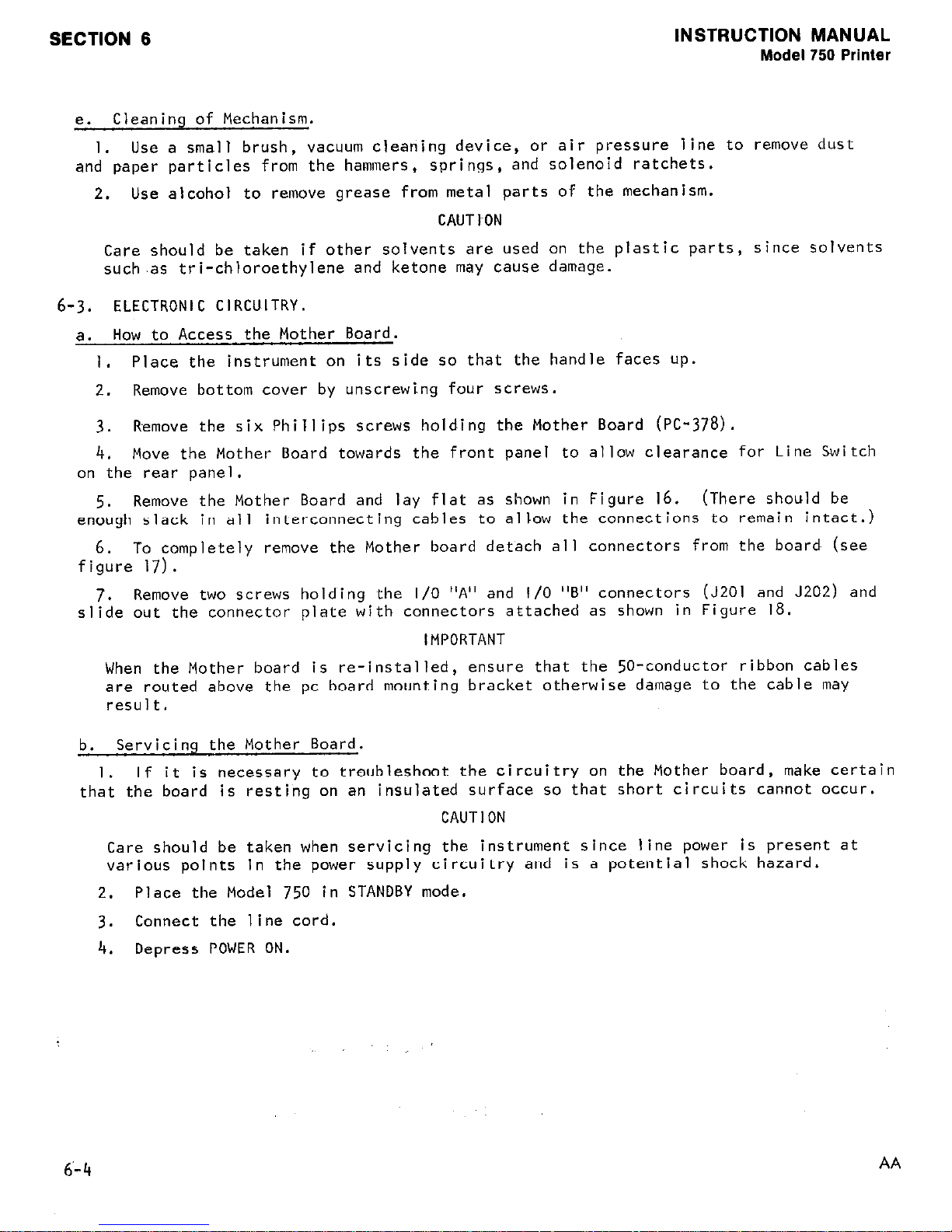

6-3. ELECTRONIC CIRCUITRY.

a. How to Access the Mother Board.

1. Place the instrument on its side so that the handle faces up.

Remove bottom cover by unscrewing four screws.

2.

Remove the six Phillips screws holding the Mother Board (PC-37~8).

3.

4. Move the Mother Board towards the front panel to allow clearance for Line Switch

on the rear panel.

Remove the Mother Board and lay flat as shown in Figure 16.

5.

enough slack in all interconnecting cables to allow the connections to remain intact.)

6.

To completely remove the Mother board detach all connectors from the board (see

figure 17).

Remove two screws hold~ing the I/O "A" and l/O "5" connectors (JZOI and J202) and

7.

slide out the connector plate with connectors attached as shown in Figure 18.

or air pressure line to remove dust

(There should be

IMPORTANT

When the Mother board is re-installed, ensure that the 50-conductor ribbon cables

are routed above the pc board mounting bracket otherwise damage to the cable may

result.

b. Servicing the Mother Board.

If it is necessary to troubleshoot the circuitry on the Mother board, make certain

I.

that the board is resting on an insulated surface so that short circuits cannot occur.

CAUTION

Care should be taken when servicing the instrument since line power is present at

various points in the power supply circuitry and is a potential shock hazard.

Place the Model 750 in STANDBY mode.

2.

Connect the line cord.

3.

4. Depress POWER ON.

6’-4

AA

Page 31

INSTRUCTION MANUAL

Model750 Printer

SECTION 6

AA

FIGURE

J106

J'04~ioJ~~ J103

FIGURE 16.

Assembly of Chassis.

15.

Q

'

Mother Board Assembly.

6-5

Page 32

SECTION 6

INSTRUCTION MANUAL

Model 750 Printer

PHILLIP

FIGURE

17.

Assembly of Connector Board.

C.

Troubleshooting Procedures.

The following information is designed to aid in lo-

cating problems within the electronic circuitry.

Extensive repairs should be performed

only by authorized factory repair facilities.

I.

Set the Line Voltage switch to the appropriate position.

2. Check the fuse for proper rating.

3.

Set the Model

750

to STANDBY mode.

4.

Partially remove the Mother board as described in paragraph

6-3a.

5.

Connect the line cord.

6.

Depress POWER ON.

7.

Set Print Interval control to EXT.

8.

Follow the troubleshooting procedure given in Table

6-2.

NOTE

Test point A should be used as a common reference point for all measurements.

6-6

AA

Page 33

INSTRUCTION MANUAL

Model 750 Printer

SECTION 6

TABLE

6-1.

Recommended Test Equipment

1

Item Description

Specification Mfr. Model

A

Digital Multimeter O.lV - 1OOOV DC, CO.l%

KI

168

B Oscilloscope

DC coupled, 100 1.1s sweep

Tektronix

560

TABLE

6-2.

Troubleshooting Guide For Model 750 Circuitry.

_TROUBLE CHECK

OPERATION

RESULT PROBLEM

lot Printing Test Point B STANDBY

+15v

Rectifiers open

Test Point C STANDBY

+5v

Regulator faulty

Test Point D STANDBY

5ms low going pulse Rate Control UlO2

.Is interval faulty

Test Point E DEPRESS E. HOLD IOms low going pulse

UlO4 or U103 faulty

MANUAL PRINT

1s interval

Test Point F STANDBY

.3ms low going pulse Reset or Timing Pulse

375ms interval shaper circuit faulty

Test Point G STANDBY

18ms high, Ims low

Ul13 faulty, timing

pulse train

pulse shaper circuit

faulty

Test Poing H DEPRESS PRINT Above Pulse Train for U122 faulty

375ms

Test Point J DEPRESS PRINT 375ms low going

If held lo EOP generat-

(PIG)

lC?"C?l

or faulty.

If held

high Ulll faulty

Test Point K DEPRESS PRINT 3ms

low

going pulse

EOP generator faulty

(EOP)

.Is interval

(UlO8, Ul25,

or

Ul24)

Test Point L DEPRESS PRINT Pulse train 32.5ms

~120 or ~116 faulty

Test Point M DEPRESS PRINT Pulse train 325ms

UIIO or Ul20 faulty

Test Point N DEPRESS PRINT Pulse train 325ms

u118 faulty

lo Paper

Test Point P DEPRESS FEED

25ms low pulse IOOms u119 faulty

'eed

time interval

DEPRESS PRINT 25ms low pulse Is

~106, ~116 or U124

interval faulty

NOTE

Test point locations can be found

in Figure 38 in Appendix F.

AA

6-7

Page 34

SECTION 6

INSTRUCTION MANUAL

Model

750 Printer

CAUTION

To

ensure the integrity of the chassis to earth ground connection only a Keithley

part number CO-7 line cord should be used for replacement.

If a different line cord

is used ensure that the wiring polarity is the same as shown in the following dia-

gram.

NEMA

5-15p

WHiTE

WHITE

6-8

AA

Page 35

INSTRUCTION MANUAL

Model 750 Printer

SECTION 7.

REPLACEABLE PARTS

SECTION 7

7-l.

GENERAL. This section contains information for ordering replacement parts. The

parts list is arranged in alphabetical order of their Circuit Designations.

7-2.

ORDERING INFORMATION.

To place an order or to obtain information concerning

replacement parts,

contact your Keithley representative or the factory. See the inside

front cover of the catalog for addresses. When ordering,

include the following informa-

tion.

a.

Instrument Model Number

b. Instrument Serial Number

C.

Part Description

d. Circuit Designation (if applicable)

e.

Keithley Part Number

7-3.

SCHEMATICS.

a. No. 27226E:

Logic and Power Supply (~~-378).

Describes the printer controls,

logic, and power supply.

b.

No. 27227E: Multiplex/Driver circuit (PC-378).

Describes the printer driver cir-

cuits and the I/O connector pinout.

c. No. 272436:

Describes the pushbutton switching assembly (PC-380).

d.

No. 27245E: 7503 Digital Clock.

Describes accessory Clock plug-in.

e. No. 27246D:

7504 Sequence Counter.

Describes the accessory Sequence Counter.

f.

No. 27244D:

7502 General Purpose Plug-in.

7-4.

REPLACEABLE PARTS LIST.

The following parts list includes the Model 750, 7503,

and 7504.

a. Model 750:

Parts are located on PC-378 and PC-380.

b. Model 7503:

Parts are located on PC-374.

c. Model 7504: Parts are located on ~~-385.

7-1

Page 36

SECTION 7

CAPACITORS

Schematic 27226E, Logic and Power Supply (PC-378)

Circuit Mfr. Mfr. Keithley

Desig. Description Code Desig. Part No.

Cl01

Cl02

Cl03

Cl04

Cl05

1.0 pF, 2OV, ETT.

5.6 pF, 2OV, IO%, ETT

1.0 pF, 2OV, IO%, ETT

10 ,,F, 2OV, IO%, ETT. .....

3300 pF, 5OOV, 20%, CerD.

.......

.....

.....

...

COMPI TSDl20105A C-204-l.OM

COMPI

COMPI

COMPI

ERIE 801-25~0-332~ C-22-3300P

TD502056620

TSDl20105A C-204-l.OM

TSD120105A C-204-IOM

INSTRUCTION MANUAL

C-l79-5.6M

Model 750 Printer

Qty .

3

1

. .

. .

2

cl06

Cl07

cl08

Cl09

Cl10

Clll

Cl12

Cl13

Cl14

Cl15

cl16

Cl17

cl18

Cl19

Cl20

Cl21

Cl22

Cl23

Cl24

Cl25

Cl26

Cl27

cl28

Cl29

Cl30

Cl31

22 I-IF, 2OV, ETT

10 UF, 2OV, IO%, ETT.

0.01 pF, Ibv, CerD.

0.01 ~JF, l6~, CerD.

IO uF, 2OV, lo%, ETT.

I.0 uF, 16v, CerD

4.7 uF, 2OV, ETT.

0.047 uF, 25OV, MtF

0.047 pF, 25OV, MtF

0.047 uF, 250V;MtF

0.047 ~.IF, 25OV, MtF

2.2 uF, 2OV, ETT.

0.047 I.IF, 25OV, MtF

0.1 uF, 16v, CerD

0.047 nF, 25OV, MtF

1000 lip, 25v, EMC

780 uF, 3OV, EAL.

1.0 nF, 35V, ETT.

IO I-IF, 2OV, IO%, ETT.

3300 pF, 5OOV, 20%, CerD.

I.0 pF, 5OV, CerF

0.01 uF. 16~. CerD.

0.01 uF,

0.01 liF,

0.01 IJF,

0.01 pF,

,

6~; CerD. .....

6v, CerD. .....

6v, CerD. .....

6v, CerD. .....

........

.....

......

......

.....

.......

.......

......

......

......

......

.......

......

.......

......

.......

.......

.......

.....

.......

......

...

COMPI

COMPI TSDl20106A C-204-IOM

CENLB ~~16-104 C-238-O.OlM

CENLB

COMPI

CENLB TSDl20105A C-204-l.OM

COMPI

AMPRX

AMPRX

AMPRX

AMPRX

COMPI

AMPRX

CENLB ~~16-104 C-238-O.lM

AMPRX

AMPRX

GE

KEMET

COMPI TSDl20106A

ERIE

ERIE

CENLB u1<16-104

CENLB u1<16-lo4

: CENLB u1<16-104

. CENLB ~~16-104

. CENLB u1<16-lo4

TD12022620

~~16-104

TSDl20106A C-204-IOM

TDI-20-475-20

C280AE/P47K C-l78-0.047M

C280AE/P47K

C280AE/P47K C-l78-0.047M

C280AE/P47K

TDI-20-225-20

C280AE/P47K C-178-0.047M

C280AE/P47K C-l78-.047M

ETl20X025A03 C-160-IOOOM

86~-148~ C-263-7800M

KlE35

801-~5~0-332~

8131050651-105~

C-179-22M

C-238-O.OlM

C-l79-4.7M

C-l78-0.047M

C-l78-0.047M

C-l79-2.2M

C-170-l.OM

C-204-IOM

C-22-3300P

C-237-l.OM

C-238-O.OlM

~-238-0.01~

C-238-O.OlM

C-238-O.OlM

C-238-O.OlM

I

2

35

. .

I

. .

z

. *

. .

. *

1

. .

. .

. .

I

I

I

I

. .

I

. .

. .

. .

. .

. .

Cl32

Cl33

Cl34

Cl35

Cl36

Cl37

Cl38

7-2

0.01 nF, 1 6v, CerD. .....

0.01 uF, 1 6v, CerD. .....

0.01 pF, l6v, CerD. . . . . . . . CENLB u1<16-lo4

0.01 uF,

0.01 pF, 6v, CerD. .....

0.01 pF, 6v, CerD. .....

0.01 pF, I~V, CerD. .....

6v, CerD. .....

CENLB ~~16-104

CENLB u1(16-lo4

CENLB ~~16-104

CENLB u1<16-lo4

CENLB ~~16-104

CENLB ~~16-104

C-238-O.OlM

C-238-O.OlM

C-238-O.OlM

C-238-O.OlM

C-238-O.OlM

C-238-O.OlM

~-238-0.01~

. .

. .

. .

. .

. *

. .

. .

AA

Page 37

INSTRUCTION MANUAL

Model 750 Printer

SECTION 7

CAPACITORS

Schematic 27227E, Multiplex/Driver Circuit (~~-278)

Circuit

Mfr. Mfr. Keithley

Desig. Description

Code

Desig. Part No.

Qtv.

c201

c202

C203

~204

C205

C206

~207

CL?08

czog

CZIO

c211

c212

c213

C214

c215

1~216

C217

~218

c21g

c220

C221

0.01 liF, l6~, CerD. . . . .

0.01 uF, l6v, CerD. . . . .

0.01 uF, l6v, CerD. . . . .

0.01 pF, I~v, CerD. , . . .

0.01 pF, I~v, CerD. . . . .

0.01 JJF, I~v, CerD. . . . .

0.01 uF, l6v, CerD. . . . .

0.01 ~.IF, I~v, CerD. . . . .

0.01 uF, I~V, CerD. . . . .

0.01 uF, I~V, CerD. . . . .

0.01 uF, I~V, CerD. . . . .

0.01 I-IF, I~V, CerD. . . . .

0.01 ~.IF, I~v, CerD. . . . .

0.01 IJF, I~v, CerD. . . . .

0.01 !JF, I~v, CerD. . . . .

0.01 uF, I~v, CerD. . . . .

0.01 uF, 16~, CerD. . . . .

0.01 !JF, I~v, CerD. . . . .

0.01 I-IF, I~v, CerD. . . . .

0.01 uF, I~v, CerD. . . . .

0.01 uF, I~v, CerD. . . . .

Schematic 27226E?

. . CENLB ~~16-104

CENLB ~~16-104

: : CENLB 1~~16-104

CENLB u1<16-lo4

: : CENLB ~~16-104

CENLB ~~16-104

: : CENLB ~~16-104

CENLB Ul<l6-104

: : CENLB ~~16-104

. .

CENLB ~~16-104

CENLB ~~16-104

: : CENLB ~16-104

. . CENLB ~~16-104

cENLB ~~16-104

: : CENLB ~~16-104

. .

CENLB ~~16-104

. . CENLB ~~16-104

. .

CENLB UK16-104

. . CENLB ~~16-104

CENLB ~~16-104

: : CENLB ~~16-104

DIODES

Logic & Power Supply

C-238-O.OlM

C-238-O.OlM

C-238-O.OlM

C-238-O.OlM

C-238-O.OlM

C-238-O.OlM

C-238-O.OlM

C-238-O.OlM

C-238-O.OlM

C-238-O.OlM

C-238-O.OlM

C-238-O.OlM

C-238-O.OlM

C-238-O.OlM

C-238-O.OlM

C-238-O.OlM

C-238-O.OlM

C-238-O.OlM

C-238-O.OlM

C-238-O.OlM

C-238-O.OlM

(PC-378)

. .

. .

. .

. .

. *

. .

* .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

* .

. .

. .

Circuit Mfr.

Mfr. Keithley

Desig.

Description

Code Desig. Part No.

Qty .

CRIOI Rectifier, 6A, 1OOV ....... MOT

MR751

RF-42

CR102 Rectifier, 6A, IOOV ....... MOT

MR751

RF-42 ..

CR103 Rectifier, 6A, IOOV ....... MOT

MR751

RF-42

..

CR104 Rectifier, 6A, 1OOV ....... MOT

MR751

RF-42

..

CR105 Rectifier, l.OA, 800~ ...... MOT 1~4006 RF-38

CR106 Rectifier, 75mA, 75V. ...... TEXAS IN914

RF-28

CR107 Rectifier, 75mA, 75V. ...... TEXAS IN914

RF-28 . .

CR108

Rectifier, 75mA, 75V. ...... TEXAS IN914 RF-28 ..

CR109

Rectifier, 75mA, 75V. ...... TEXAS IN914

RF-28

..

CRIIO

Rectifier, 75mA, 75V. ...... TEXAS IN914

RF-28

..

CRlll Rectifier, 75mA, 75V. ...... TEXAS IN914

RF-28 . .

CR112 Rectifier, 75mA, 75V. ...... TEXAS IN914

RF-28

..

CRII3 Rectifier, 75mA, 75V. ...... TEXAS IN914

RF-28

..

CR114 Rectifier, 75mA, 75V. ...... TEXAS IN914

RF-28 ..

FUSES

Circuit

Mfr. Mfr. Keithley

Desig. Description

Code

Desig.

Part No.

Qty .

FIOI (220V) Fuse, Slo-Blo, 3/8A, 250V FUSE MDL-3/8A

FU-I8 I

--

.(lOO-117V) Fuse, Slo-Blo, 3/4A,

250~. ............. FUSE MDL-3/4A

FU-19

1

AA

7-3

Page 38

SECTION 7

INSTRUCTION MANUAL

Model 750 Printer

CONNECTORS

Schematic 27226E, Logic E Power Supply (PC-378)

Circuit Mfr. Mfr. Keithley

Desig. Description

Code

Desig. Part No.

Qty .

JIOI 5-pins. . . . . . . . . . . . . . . . MOLEX 2139-5 CS-287-5 I

J102 It-pins. . . . . . . . . . . . . . . . MOLEX 2139-4

CS-287-4

I

JlO3 3-pins. . , . . . . . . . . . . . . . MOLEX 2139-3 ~5-287-3

I

PlOl S-pin , . , . . . . . . . . . . . . . MOLEX A-23pl-5A

~~-288-5 I

PI02

4-pin . . . . . . . . . . . . . . . . MOLEX A-23vl-4A

~~-288-4

2

PI03 3-pin + . . , . . . . . . . . . . . . MOLEX A-23vl-3A cs-288-3

I

PI04 4-pin . . . , , . . . . . . . . , . . MOLEX A-23vl-4A CS-288-4

. *

PI05 Power Receptacle. , . . . . , . . . . S-C EAC-301 CS-254 I

~106 2-pin . . . . . . . . . . . . . . . . MOLEX A-23vl-2A

CS-288-2

I

CONNECTORS

Schematic 27227E, Multiplex/Driver Circuit (~~-378)

Circuit Mfr.

Mfr. Keithley

Desig. Description

Code Desig.

Part No.

Qtv.

J201

J202

J203

J3Ol

J302

P2Ol

P202

P203

Cable . . . . . . . . . . . . . . . . . KI --

750-24B(set of 2) I

Cable................KI --

__

Part of printer mechanism . . . . . . --

--

__

4-pin . . . . . . . . . . . . . . . . MOLEX 2139-4

cs-287-4

I

2-pin . . . , , , . . . . . . . . . . MOLEX 2139-2 CS-275

I

Not Used. . . . . . . . . . . . . . . -- --

__

Not Used. . . . . . . . . . . . . . . --

--

__

Part of ~~-378. , . . . . . ., . . . . -- --

-_

TRANSISTORS

Schematic 27226E, Logic & Power Supply (~~-378)

Circuit Mfr.

Mfr. Keithley

Desig.

Description

Code Desig. Part No.

Qtv.

QIOI NPN Silicon, TO-92 Case . . . . . . . FAIR

2N3903

TG-49

3

Q102

NPN Silicon, TO-92 Case . . . . . . . FAIR

2N3903

TG-49 . .

QlO3

NPN Silicon, TO-92 Case . . . . . . . FAIR

2N3903

TG-49 . .

Q104 NPN Silicon, TO-5 Case. . . . . . . . RCA

40317

TG-43

3

Q105

NPN Silicon, TO-5 Case. . . . . . . . RCA

40317

TG-43 . .

Qlo6

I

QlO7

I

QlO8

1

I

NPN, TO-92 Case . . . . . . . . . . . MOT

2N3904

TG-47

NPN, TO-92 Case . . . . . . . . . . . MOT

2~5089 TG-62

6109

NPN, Power Type, TO-220 Case. . . . . MOT

2N5190

TG-IO8

NPN Silicon, TO-5 Case. . . . . . . . RCA

40317

TG-43

TRANSISTORS

Circuit

Schematic 27227E, Multiplex/Driver Circuit (~~-378)

Mfr. Mfr.

Keithley

Desig.

Description

Code

Desig. Part No.

QV.

Q201 PNP, Power Type, Plastic Case TO-220

4OW, 4A . . . . . . . . . . . . . . MOT

2N5193

TG-107 I

Q202

Transistor NPN, TO-92 Case. . . . . . MOT

2N3904

TG-47

I

Q3Ol

Transistor, NPN, Case TO-106. . . . . FAIR

2N3565

K-39

I

7-4

AA

Page 39

INSTRUCTION MANUAL

Model 750 Printer

SECTION 7

RESISTORS

Schematic 27226(3, Logic & Power Supply (PC-3781

Circuit Mfr.

Mfr. Keithley

Desig. Description Code

Desig. Part No.

Qtv .

RIO1

RI02

RI03

RI04

RI05

RI06

RI07

RI08

RlOY

RllO

RI11

RI12

RI13

RI14

RI15

RI16

RI17

RI18

RI19

RI20

RI21

RI22

RI23

~124

RI25

RI26

RI27

RI28

RI29

RI30

R13l

RI32

RI33

RI34

RI35

RI36

RI37

RI38

RI39

RI40

RI41

RI42

RI43

RI44

RI45

AA

4.7k0, IO%, 0.25W, Comp

4.7kfi, IO%, 0.25W, Comp

8.2kn, IO%, 0.25W, Comp

4.7kn, IO%, 0.25W, Comp

4.7kn, IO%, 0.25W, Comp

4.7kn, IO%, 0.25W, Comp

4.7kn, IO%, 0.25W, Comp

4.7kn, lo%, O.25W, Comp

26lkR, I%, 1/8w, MtF. .

845Q, 1%; 1/8w, MtF . .

4.7kn, IO%, 0.25W, Comp

4.7ka, IO%, O.25W, Comp

4.7kn, IO%, 0.25W, Comp

4.7kn, IO%, 0.25W, Comp

4.7kn, IO%, 0.25W, Comp

4.7kn, IO%, 0.25W, Comp

4.7kn, IO%, 0.25W, Comp

4.7kQ, IO%, 0.25W, Comp

8.2kn, IO%, 0.25W, Comp

4.7k0, IO%, 0.25W, Comp

4.7k0, IO%, 0.25W, Comp

4.7kn, IO%, 0.25W, Comp

4.7k0, IO%, 0.25W, Comp

Ika, IO%, 0.25W, Comp .

loon, lo%, 0.25w, Comp.

l2kR, IO%, 0.25W, Comp.

4.7kn, IO%, 0.25W, Comp

22kn, IO%, O.25W, Comp.

lOOka, IO%, 0.25W, Comp

1500, IO%, O.l2W, Comp.

4.7kn, IO%, 0.25W, Comp

4.7kn, IO%, 0.25W, Comp

1800, IO%, 0.25W, Comp.

1800, IO%, 0.25W, Comp.

l5On, IO%, O.l2W, Comp.

....... A-B

....... A-B

....... A-B

* . * . * . . A-B

....... A-B

.......

A-B

. . * . * * . A-B

....... A-B

....... IRC

....... IRC

....... A-B

. * . * * . . A-B

....... A-B

....... A-B

....... A-B

.......

A-B

....... A-B

........

A-B

....... A-B

.......

A-B

.......

A-B

.......

A-B

.......

A-B

....... A-B

....... A-B

....... A-B

....... A-B

....... A-B

.......

A-B

....... A-B

....... A-B

.......

A-B

....... A-B

....... A-B

....... A-B

-- .......

.......

A-B

Not Used. .......

3.Ykn, IO%, 0.25W, Comp

18.2kn, IO%, 0.25W, Comp. ......

A-B

4.7ka, IO%, 0.25W, Comp .......

A-B

4.7kn, IO%, 0.25W, Comp

.......

A-B

4.7kn, IO%, 0.25W, Comp .......

A-B

4.7kn, IO%, O.25W, Comp .......

A-B

1.2kn, IO%, 0.25w, camp .......

A-B

4.7kn, IO%, 0.25W, Comp .......

A-B

4.7kn, IO%, 0.25W, Comp .......

A-B

CB-472-10%

CB-472-108

CB-822-10%

CB-472-10%

CB-472-10%

CB-472-10%

CB-472-10%

CB-472-10%

CEA-TO-261K

CEA-TO-100

CB-472-10%

CB-472-10%

CB-472-10%

CB-472-10%

CB-472-IO%

CB-472-10%

CB-472-10%

CB-472-10%

CB-822-10%

CB-472-10%

CB-472-10%

CB-472-10%

CB-472-10%

CB-lO2-10%

CB-IOI-10%

CB-l23-10%

CB-472-10%

CB-223-10%

CB-lO4-10%

BB-l5l-10%

CB-472-10%

CB-472-10%

cB-181-10%

CB-l8l-10%

BB-l5l-10%

--

R-76-4.jK

R-76-4.7K

R-76-8.2K

R-76-4.7K

R-76-4.7K

R-76-4.7K

R-76-4.7K

R-76-4.7K

R-88-261K

~-88-845

R-76-4.7K

R-76-4.7K

R-76-4.7K

R-76-4.71<

R-76-4.7K

R-76-4.7K

R-76-4.7K

R-76-4.7K

R-76-8.2K

R-76-4.7K

R-76-4.7K

R-76-4.7K

R-76-4.7K

R-76-IK

R-76-100

R-76-12K

R-76-4.7K

R-76-2X

R-76-IOOK

R-143-150

R-j6-4.7K

R-76-4.7K

~-76-180

~-76-180

R-143-150

--

CB-392-10% R-76-3.YK

CEA-TO-l8.2K R-88-18.2K

CB-472-10% R-76-4.7K

CB-472-10% R-76-4.7K

CB-472-IO%

R-76-4.7K

CB-472-10% R-76-4.7K

CB-l22-10% R-76-l.2K

CB-472-10%

R-76-4.7K

CB-472-10% R-76-4.71(

40

. .

2

. .

. .

. .

. .

. .

I

I

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

2

I

. .

. .

2

I

2

.a

. .

2

. *

. .

1

. .

. .

. .

. .

. .

5

. .

. .

7-5

Page 40

SECTION 7 INSTRUCTION MANUAL

Model 750 Printer

RESISTORS (Cont'd)

Circuit

Mfr.

Mfr. Keithley

Desig. Description Code

Desig.

Part No.

Qty .

~146

R147

RI48

RI49

RI50

RI51

RI52

RI53

RI54

RI55

Rl56.

RI57

RI58

RI59

RI60

RI61

~162

RI63

~164

RI65

RI66

RI67

R168

RI69

RI70

RI71

RI72

RI73

RI74

4.7kn, lo%, 0.25w, camp .......

A-B

4.7kQ, IO%, 0.25W, Comp

....... A-B

82k0, lo%, 0.25W, Comp.

....... A-B

22kn, IO%, O.25W, Comp.

....... A-B

IOkn, IO%, 0.25W, Camp,.

....... A-B

4.7kn, IO%, 0.25W, Comp .......

A-B

4.7kn, IO%, 0.25W, Comp .......

A-B

l.2kn, IO%, 0.25W, Comp

.......

A-B

l.2kn, IO%, O.25W, Comp .......

A-B

l.2kn, IO%, O.Z5W, Comp .......

A-B

l.2kn, IO%, 0.25W, Comp .......

A-B

IkQ, lo%, 0.25w, Comp ........

A-B

~4.7k0, IO%, 0.25W, Comp .......

A-B

470, 5%, 5W, WW ...........

DALE

2.5~0, 30%, 0.25w, vet-.

.......

CTS

4.7k0, IO%, O.25W, Comp

.......

A-B

4,7ka, IO%, O.25W, Comp .......

A-B

4.7kn, IO%, O.25W, Comp

.......

A-B

lOk0, IO%, O.25W, Comp. .......

A-B

4.7ka, IO%, 0.25W, Comp

....... A-B

l5On, IO%, 0.25W, Comp. .......

A-B

IOka, IO%, 0.25W, Comp. .......

A-B

4.7ka, IO%, O.i5W, Comp .......

A-B

4.7kn, IO%, 0.25W, Comp ........

A-B

4.7kn, IO%, 0.25W, Comp .......

A-B

l.5n, 5%, IOW, WW ..........

OHM

I5On, 5%, 5W, WW. ..........

DALE

330~2,

lo%, 0.25w, Comp. .......

A-B

3300,

IO%, 0.25W, Comp.

....... A-B

CB-472-10%

CB-472-10%

CB-823-10%

CB-223-10%

CB-103-10%

CB-472-10%

CB-472-10%

CB-122-10%

CB-l22-IO%

CB-l22-10%

CB-l22-10%

CB-102-10%

CB-472-10%

RS-5-47$7

VF-T450

CB-472-IO%

CB-472-IO%

CB-472-10%

CB-103-10%

CB-472-10%

CB-l51-10%

CB-lO3-IO%

CB~-472-10%

CB-472-10%

CB-472-10%

FR-IO-l.5n

RS-5-l5Ofi

CB-33l-10%

CB-33l-10%

R-76-4.7K

R-76-4.7K ::

~-76-821~

1

R-76-22K

. .

R-76-IOK

3

R-76-4.7K

. *

R-76-4.7K

. .

R-76-l.2K

. .

R-76-1.2K

. .

R-76-l.2K

. .

R-76-1.2K

. .

R-76-1K

. .

R-76-4.7K

. .

R-4A-47 I

RP-II2 I

R-76-4.7K . .

R-76-4.7K . .

R-76-4.7K . .

R-76-IOK

. .

R-76-4.71<

. .

R-76-150 I

R-76-IOK

. .

R-76-4.71(

. .

R-76-4.7K

R-76-4.7K ::

R-5-1.5 1

R-4A-150

I

R-76-330 2

R-76-330

. .

RESISTORS

Schematic 27227E, Multiplex/Driver Circuit (PC-378)

Circuit

Mfr.

Mfr.

Keithley

Desig.

Description

Code

Desig.

Part No.

QV.

R20l

2.7kQ ,

IO%, 0.25W, Camp. . . . . . . A-B CB-272-10%

R-76-2.7K I

R202

560~2,

lo?, IW Comp . .

R203

IOKR, 10%, I/&W, Comp . : : 1 : : : :

A-B GB-XXX-IO%

R-2-560 I

A-B CB-103-10%

R-76-IOK

R204'

IOKs?, IO%, 1/4W, Comp . . . . . . . . A-B

CB-103-108

R-76-IOK

R205,

IOKQ, IO%, 1/4W, Comp , . . . . . . . A-B

CB-lO3-10%

R-76-IOK

R206

IOKQ, IO%, 1/4W, Camp.. . . .

Thick Film l4-Pin DIP . : 1 : : . . .

A-B

CB-lO3-10%

R-76-IOK

R207

BEC 899-I-R-2K

TF-l9-IOK

R2.08

Thick Film I4-Pin DIP . . . . . . . . BEC

899-l-R-2K

TF-IV-IOK

R209

Thick Film I4-Pin DIP . . . . . . . . BEC 899-I-R-2K TF-IV-IOK

RZIO Thick Film Ill-Pin DIP . . . . . . . . BEC

899-I-R-2K TF-IV-IOK

R2ll

Thick Film 14-Pin DIP . . . . . . . . BEC

899-I-R-2K TF-l9-IOK

R212 Thick Film I4-Pin DIP . . . . . . . . BEC 899-I-R-2K _TF-IV-IOK

R30l

6800,

IO%, l/2W, Comp . . . . . . . . A-B EB-XXX-IO%

R-l-680

I

R302 22Kn, l.O%, l/4W, Comp . . . . . . . . A-B

CB-IOO-10%

R-76-22K I

7-6

AB

Page 41

SECTION 7

INSTRUCTION MANUAL

Model 750 Printer

SWITCHES

Circuit

Mfr.

Mfr.

Keithley

Desig.

Description

Code Desig.

Part No. Qty.

SIOI

Slide Switch . . . . . . . . . . , . . . .

S-C

110-1139

SW-273

SlO2

Switch

,,

Slide, DPDT. . , . . . . , . . . . C-W

GG350PCDPDT SW-318 1

SlO3

Switch (Part of Rl60). . . . , I . , . . . --

--

_-

s301

Pushbutton type, 2 pole DT . . . . . . .

. CENLB PB-20

SW-383

I

TRANSFORMER

Circuit

Mfr. Mfr.

Desig.

Keithley

Description

Code Desig.

Part No.

Qtv.

TIOI

Power type . . . . . . . . . . . . . . . . KI

--

TR-160

I

INTEGRATED CIRCUITS

Schematic 27226E, Logic E Power Supply (PC-378)

Circuit

Mfr.

Mfr.

Keithley

Desig.

Description Code Desig.

Part No.

QW.

UIOI

UlO2

UlO3

VI04

UlO5

~106

UlO7

~108

UIOV

VII0

Ulll

Ull2

Ull3

Ull4

Ull5

~116

Ull7

~118

UIIY

Ul20

Ul2l

Ul22

VI23

U124

U125

AB