Page 1

MetraBus User’s Guide

Keithley Instruments, Inc.

28775 Aurora Road, Cleveland, OH 44139

Technical Support: I-888-KEITHLEY

Monday -Friday 8:00 a.m. to 5:OO p.m. (EST)

Fax: (440) 248-6168

httD://www.keithlev.com

Revision F - July, 1994

Pari Number: 62470

Page 2

The information contained in this manual is believed to be accurate and reliable. However, Keithley

Instruments, Inc., assumes no responsibility for its use or for any infringements of patents or other

rights

of third parties that may result from ik use. No license is granted by implication or otherwise

under any patent

righk

of Keithley Instruments, Inc.

KEITHLEY INSTRUMENTS, INC., SHALL NOT BE LIABLE FOR ANY SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES RELATED TO THE USE OF THIS

PRODUCT. THIS PRODUCT IS NOT DESIGNED WITH COMPONENTS OF A LEVEL OF

RELIABILITY SUITABLE FOR USE IN LIFE SUPPORT OR CRITICAL APPLICATIONS.

Refer to your Keithley hWrumenk license agreement and Conditions of Sale document for specific

warranty and liability information.

MetraByte is a trademark of Keithley hMru.menk, Lnc. AU other brand and product names are

&ademarks or registered trademarks of their respective companies.

@Copyright Keithley Instruments, Inc.

1991,1992,

1993,1994

Au rights reserved. Reproduction or adaptation of any part of this doctunentation beyond that

permitted by Section 117 of the 1976 United States Copyright Act without pem&zion of the Copyright

owner is unlawful.

Keithley MetraByte Division

Keithley

Instruments, Inc.

440 Myles Standish Blvd., Taunton, h4A 02780

TEL 508/880-3000 * FAX 5081880-0179

Page 3

Contents

CHAPTER 1

i::

- INTRODUCTION

General Overview.

The MetraBus Cable

..................................

..................................

MetraBus Boards

:::

2

1:7

Mounting & Connection.

MetraBus Addressing

Programming

Additional Notes

............................ : : : : : : : : : : : : : : : : : : : II-3

.................................

.....................................

....................................

CHAPTER 2 - THE CONTROLLER BOARDS

Part 2A: MDB-64 Driver Board

2A.1

2A.2

2A.3

2A.4

2A.5

2A.6

2A.7

2A.8

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . : I??-;

Features

Specificat’ions : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : . 2A-2

Setting The Base Address Switch . . . . . . . . . . . . . . . . . . . . . . . . . . 2A-2

Installing The MDB-64 Fuse (Fi) . . . . . . . . . . . . . . . . . . . . . . . . . . 2A-3

Installing The MDB-64 Driver Card

The MDB-64 MetraBus Connector. : : : : : : : : : : : : : : : : : : : : : : : : . 2A-4

Programming The MDB-64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2A-4

Part 2B: MID-64 Driver Board

28.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . , . . . . . . . . .28-l

2B.2

28.3

Features

Specificat’ions : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : .2B-2

Setting The Base Address Switch . . . . . _ . . . . . .

z-i

2B:6

2B.7

2B.8

Use 0-t The Auxiliary Supply . . . . . . . . . . . . . . . : : : : : : : : : : : : . . .2B-3

Installing The Mid-64 Drier Card . . . , . . . . . . . . . . . . . . . . . . . . . . 28-3

The MID-64 MetraBus Connector . . . , . . . . . . . . . . . . . , , . . . . . . . 2B-4

Programming The MID-64 . . . . . . . . . . . . . . . . . . . . . . . . , . . . . . 2B-5

,1-l

l-l

1-2

.I-4

.I-4

l-6

. 2A-3

. 2B-2

. . 2B-2

Part 2C: pCMDB-64 Driver Board

2c.1 General

2c.2

2C.3

2C.4

2c.5

Specifications 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Use Of An Auxiliary Power Supply. . . . .

System Configuration. . . . . . . . , . ; .

Programming . . . . . . . . . . . . . . . .

1 1 1 1 1 1 1 1 1

1 1 1

. . . . . . . . .

. . .

. . . . . . . . .

. . .

. . . . . . . . .

. . .

1 1 1 1 1 1

. . . . . .

. . . . . .

. . , . . .

1 1

. . .2C-2

. . .2C-2

. . .2C-7

Part 2D: REhh-64 Driver Board

2D.I General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2D-1

2D.2 Features. . . . . . . . . . . . . . . . . . . . . . . . , . . . . . . . . . . . . . . .2D-2

2D.3

g$;E;tions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . : : :X$-g

2D.4

2D.5

2D.6

2D.7

2D.8

Connectors’ : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : . * 2D-5

Use of An Auxiliary Power Supply . . . . . . . . . . . . . . . . . . . . . . . . : : zLD-77

Installation Of The REM-64. . . . . .

Programming The REM-64 To Control ‘M’etraBus : : : : : : : : : : : : : : : : . . 2D-8

. . .

- Ill -

.2c-1

.2C-1

Page 4

Contents

CHAPTER

3

- THE POWER SUPPLY

Part 3A: PWR-ZVPWR-100 Boards

3A.1

3A.2

3A.4

3A.3

3A.5

3A.6

General, , . . . . .

Features

Specifications’ : : 1 1 1 1 1 1 1 1

Installing The PWR-55/PWR-100

Use of Other Power

TheMTAP- . . . . Supplies . . . . . . .

Part 38: MBUS-PWR Boards

3B.1

3B.2

3B.3

3B.4

3B.5

3B.6

38.7

CHAPTER 4 -

General........................,.............:.

Features

Specifications’ 1 1 1 1 1 1 1 1 1

Installation .

Use of Output Ground Jumper

The MATP-1

The MBUS-PWk ‘cbnnkdtdrs :

. . . . . .

MDI-16/M%-16 SOLID STATE SWITCHING I/O SYSTEM

General, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . , . . . . . . 4-1

Features

Specifications 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Using An Auxiliary Supply . . . . . . . , . . . . . . . . . . . . . . . . . . . .

Configuring The MSS-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . : : . 4-2

Installing The MDI-16

BOARDS

. . . . . . .

. .

.

.

. . .

. .

1 1 1 1

.

. . .

1 1 1

. .

. . . . . . .

1 1 1 1 1 1 1 1

: : : : : : : :

: : : : : : : :

. . . .

. .

. . .

1 1 1 1 1

1 1 1

. . . .

. . .

. .

. . . . . . . . . .

1 1 1 1

: : : :

1 1 1 1 1 1

: : : : : :

: : : : : : : : : :

. . . . . .

: 1 1 1 1

. . . . . .

. .

1 1 1

. . .

. . .

1 1 1

. .

. . . . . . . . . 3A-2

1 1 1 1 1 1 1 1 1 38-2

: : : : : : : : : 3B-3

: : : : : : : : : 3B-3

3A-1

3A-1

3A-2

3A-2

3A-3

3B-1

3B-2

3B-3

3B-3

;::

. 4-2

CHAPTER 5 -

THE RELAY BOARDS

Part 5A: MEM-8 Electromechanical Relay I/O System

5A.l

5A.2

5A.3

5A.4

5A.5

5A.6

Part

58: MEM-32/A

58.1

5B.2

5B.3

5B.4

5B.5

5B.6

5B.7

5B.8

General. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications . . . . . . . . . , . . . . . . _ . . : ’ ’ ’ ’ * ’ . ’ ’ * *

Using An Auxiliary Power Supply

Setting The MEM-8 Board Address : : : : : : : I- : : ’ * ’ . ’ . . ’ ’ ’ ’ ’ ’ * :

Programming The MEM-8 . . . . . . . . . . . . . . . : : : : : : : : : : : : : : . 5A-4

Use of Alternative Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-5

& MEM-32/W Electromechanical Relay System

General. . . . . . . . . . . . . . . . . . . .

Features

Specifications’ 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Using An Auxiliary Power Supply

Setting The MEM-32 Board Address : : : :

Typical Output Connections . . . . _ . . . .

Programming The MEM-32 . .

Using Compiled Or Assembled ian&&-% ’

_. . . . . . . . . . . . . . . . . . “I._

....................

....................

....................

....................

....................

....................

....................

....................

SA-1

!iA-3

SA-3

5A-3

5B-1

58-2

5B-2

E-33

58-4

5B-4

5B-7

- iv -

Page 5

Contents

Part 5C: MSSR-32 Solid State Switching I/O Module

5C.l

5c.2

E-i

5c:5

5C.6

Part 5D: MCPT-8X8 Cross-Point, Matrix Relay Board

5D.l

5D.2

5D.3

5D.4

5D.5

5D.6

5D.7

CHAPTER 6 - THE LOGIC LEVEL l/O BOARDS

Part 6A: MIO-32 Isolated Digital Output Board

6A.l

6A.2

6A.3

6A.4

6A.5

6A.6

6A.7

6A.8

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SC-1

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SC-2

Specifications

Use Of An AuxkySuppiy: : : : : : : : : : : : : : : : : : : : : : : : : : : : . .5C-2

Configuring The MSSR-32 . . . . , . . . . .

Installing The MSSR-32 . . . . . . . . . . . : : : : : : : : : : : : : : : : : : : : 5C-3

General

Specifications : -1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Use Of An Auxrlrary Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . .5D-3

Jumpers And Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5D-3

Resistor Termination Networks. .

Installing The MCPT-8X8. , . . . : : : : : : : : : : : : : : : : : : : : : : : : : : 5D-4

Programming The MCPT-8X8 . . . . . . . . . . . . . . . . . . . . . . . . . . . .5D-4

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6A-1

Features

Specifications 1 1 1 1 1 1 1: 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1: 1 1

Using An Auxiliary Power Supply

Installing The MIO-32. . . . . . . : : :

Typical Output Connections

Programming TheMIO-32 . : : : : : : : : : : : : : : : : : : : : : : : : : : : : .

Using Compiled Or Assembled Languages . . . . . . . . . . . . . . . . . . . . . 6A-7

. . SC-2

5c-3

. .5D-1

. .5D-2

5D-4

. 6A-2

. 6A-2

6A-3

:

: : : : : : : : : : : : : : : : : : : : : : 6A-3

. 6A-4

6A-5

Part 6B: MII-32 Isolated Digital Input Board

6B.1

6B.2

68.3

6B.4

6B.5

6B.6

6B.7

6B.8

6B.9

General

Features

Specifications

........................................

............

......... 1 1 1 1 1 1 1 1: 1 1 1 1 1 1 1 1 1 1 1 1: 1 1 1 1 1 1

Using An Auxiliary Power Supply

Installing The MI!-32

...

.... : : : : : : : : : : : : : : : : : : : : : : : : :

Configuring The Mll-32 For Non-standard Inputs

Typical Input Connections

Programming The Mll-32. : : : : : : : : : : : : : : : : : : : : : : : : : : : : :

Using Compiled Or Assembled Languages

..................

.....................

6B-1

6B-2

6B-2

6B-3

:

68-3

654

6B-4

:

6B-5

6B-7

-V-

Page 6

Contents

CHAPTER 7 - MCN-8 COUNTER/TIMER BOARD

;::

2

T-56

7:7

7.8

7.9

CHAPTER 8 - THE ANALOG I/O BOARDS

Part 8A: MAO-8 Analog Output Board

8A.l

8A.2

8A.3

8A.4

8A.5

8A.6

8A.7

8A.8

Part 88: MAO-12 Analog Output Board

8B.l General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8B-1

8B.2 Features

8B.3 Specifications : : : 1 : : 1 : : : : : : : : : : : : : : : : : : : : : : : : : : : : . 8B-2

8B.4

8B.5

8B.6 Programming The MAO-1 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8B-5

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Features

Specification’s* * : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : 1 : : : . . 7-2

Use Of An Auxiliary Supply . . , . . . . . . . . . . . . . . . . . . . . . . . . . . , 7-3

Installing The MCN-8

Cascading The MCN-8’Coun’ters : : : : : : : : : : : : : : : : : : : : : : : : : : . 7-4

Typical Input Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Programming The MCN-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Using Compiled Or Assembled Languages . . . . . . . . . . . . . . . . . . . . . 7-8

General.

Features

Specificatiork’.~ : : : : : : : : : : : : : : : : : : : : : : : : : : : : 1 : : : : : . 8A-2

Use Of An Auxrlrary Power Supply

Installing The MAO-8

ProgrammingTheMAd-~::::::::::::::::::::::::::::

Calibration And Adjustment Of The MAO-8

Serviceable Parts ..... .. ..

Use Of An Auxiliary Power Supply . . . . . . . . . . . . . . . , . . . . . . , . . 88-3

Installing The MAO-1 2 , . . . . . . . . . . , . . . . . . . . . , . . . . . . . . . . 8B-3

.......................................

.......................

......................

......................

. . 7-2

. 7-3

$A-1

. 8A-2

: : 883-z

. . 8A:6

.;;;; ;

. 8B-2

Part 8C: MAI- Analog Input Board

8C.l General. . . .

8C.2

8C.3

8C.4

8C.5

8C.6 Typical Input Connections . . . . . . . s . , . . . . . . . . . . . .

8C.7

8C.8

8C.9

E4 :

8C:12

SC.13 Gain Selection Via Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8C-7

8C.14

3

Features . . . : : : : : : : : : : : : : : : : : : 1 : : : : : : : : : : : : : : : : : 8C-2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8C-2

Using An Auxiliary Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . 8C-3

Installing The MAI-I 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8C-3

Input Signal Attenuation . . . . . . . . . . . . . . . . . , . . . . . : : : : : : : i 883-z

Measuring Signals Greater Than +I 0 VDC . . . . . . . . . . . . . . . . . .

Measuring Signals Smaller Than +I .25 VDC . . . . . . . . . . . . . . . . . : : . 8&

Measuring Current With The MAI- 6 . . . . . . . . . . . . . . . . . . . . . . . . 8C-6

Auto Convert Mode Of Operation . . . . , . . . . . . . . . . . : . . . . . . . . . 8C-6

A/D Resolution Via Hardware . . . , . . . . , . . . . . . , . . . . . . . . , . . . 8C-7

Programming The MAI- 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . , 8C-8

Using Compiled Or Assembled Languages

Calibration Procedure For MAI- . , . . . : : : : : : : : : : : : : : : : : : : : 8C-13

- vi-

8C-1

8C-4

8C-12

Page 7

Contents

Part 8D: MTHERM-20 Thermocouple Input Board

8D.l

8D.2

8D.3

8D.4

8D.5

8D.6

8D.7

8D.8

CHAPTER 9 - THE UTILITY BOARDS

Part 9A: MBB-32 Prototype/Breadboard

9A.1 General . . . , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9A-1

9A.2

9A.3

9A.4 Installing The MBB-32

9A.5

9A.6

9A.7

9A.8

Part 9B: MDG-1 Diagnostic Board

9B.1

98.2

98.3

9B.4

General General

Functional bescnptidn’ 1 : : : : : : : 1 : : : : : : : : : : : : : : : : : : : : : : Functional bescnptidn’ 1 : :

Features Features

Specifications 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 Specifications 1 1 1 1 1 1 1 1

Installing The MTHERM-20.

Installing The MTHERM-20. . . . . . . . . . . . . .

Programming The MTHERM-20

Programming The MTHERM-20 .

Other Memory Locations . . . . . . . . . . . . . . . . . . . . . . . . . . _ . . . Other Memory Locations

Calibration Procedure. . . . . . . . . . . . . . . . . . . . . , . . . . . . . . . . Calibration Procedure.

Features . . , . . . . . . . . . . . . .

Specifications . . . . . . . . . . . . . : : : : : : : : : : : : : : : : : : : : : : : : 9A-2

MBB-32 l/O Connections : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : 9A-3

The Read/Write

Programming The MBB-32. . . .

Possible Uses For The MBB-32 . : : : : : : : : : : : : : : : : : : : : : : : : : : 9A-6

General . . . . . . . . . . . . . . . . . . . , . . . . . . . . . . . . . . . . . . . . ;JI;

Features. . . . . . . . . . . . . . . .

Installing The MDG-1 . _ , . . . . . . : : : : : : : : : : : : : : : : : : : : : : : : 98-2

Example Program. . . . . . . . . . . . ~ . . . . . . . . . . . . . . . . . . . . . .9B-2

Status Lines. . . . . . . . . . . . . . . . . . . . , . . . . . . . .

. . .

. . . .

:

: : : : 1

1

1 1 1 1 1

. .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . .

. . . . .

: : : : : : : : : : :

1 1 1 1 1 1 1 1 1 1 1

.

. . . .

. . . . . :

. . . . . . . . . . .

. . . . . . . . . . .

: : : :

: : : : :

1 1 1 1 1

: : :

. . . . .

, . . . .

: : :

: : : : : :

1 1 1 1 1 1

. . _ . . .

. . . . . .

: : : :

. 8D-1

. 8D-2

. 8D-2

, 8D-2

_ 8D-3

: FE

8D-;o

9A-2

9A-2

9A-3

9A-4

CHAPTER10 - FACTORYRETURNS

APPENDIX

Appendix A - Serial Communications Tutorial

Appendix B - Configuration Worksheets

- vii -

Page 8

a

a

a

. . .

- VIII -

Page 9

Chapter 1

INTRODUCTION

1.1

GENERAL

The MetraBus system provides a low-cost means of connecting real-world I/O devices to a

computer. The system is available in two configurations: (1) tightly coupled to an IBM PC bus

system or (2) remotely operated through RS-232/422 serial communications from any

computer.

Under the supervision of a PC, MetraBus digital, analog, and counter-timer measurement, and

control interfaces can control cost-effective industrial I/O systems. Each MetraBus system can

measure and control hundreds of analog, digital, and counter/timer I/O points. Several

MetraBus systems can simultaneously control thousand of I/O points.

MetraBus fills the gap between I/O plug-in boards and dedicated industrial controllers. Plugin boards and a personal computer are finding applications in process measurement and

control applications and product test stations. However, the large number of date I/O points

required, the proximity of the sensors to the control room combined Gith a finite number of

expansion slots available in a personal computer often require versatile systems that are

flexible, provide for enhanced expansion capability and are inexpensive. The MetraBus family

of industrial data acquisition products retains the close link of the personal computer to a data

acquisition system while offering extreme flexibility at a price that rivals many plug-in I/O

boards.

Key MetraBus features include:

1.2

l

Low cost I/O

l

Ease of programming

l

Simple packaging and interconnection

l

Reliability

l

100% personal computer compatible

l

Local, high speed interfaces

l

Remote capability, up to 1.2 km from computer

THE METRABUS

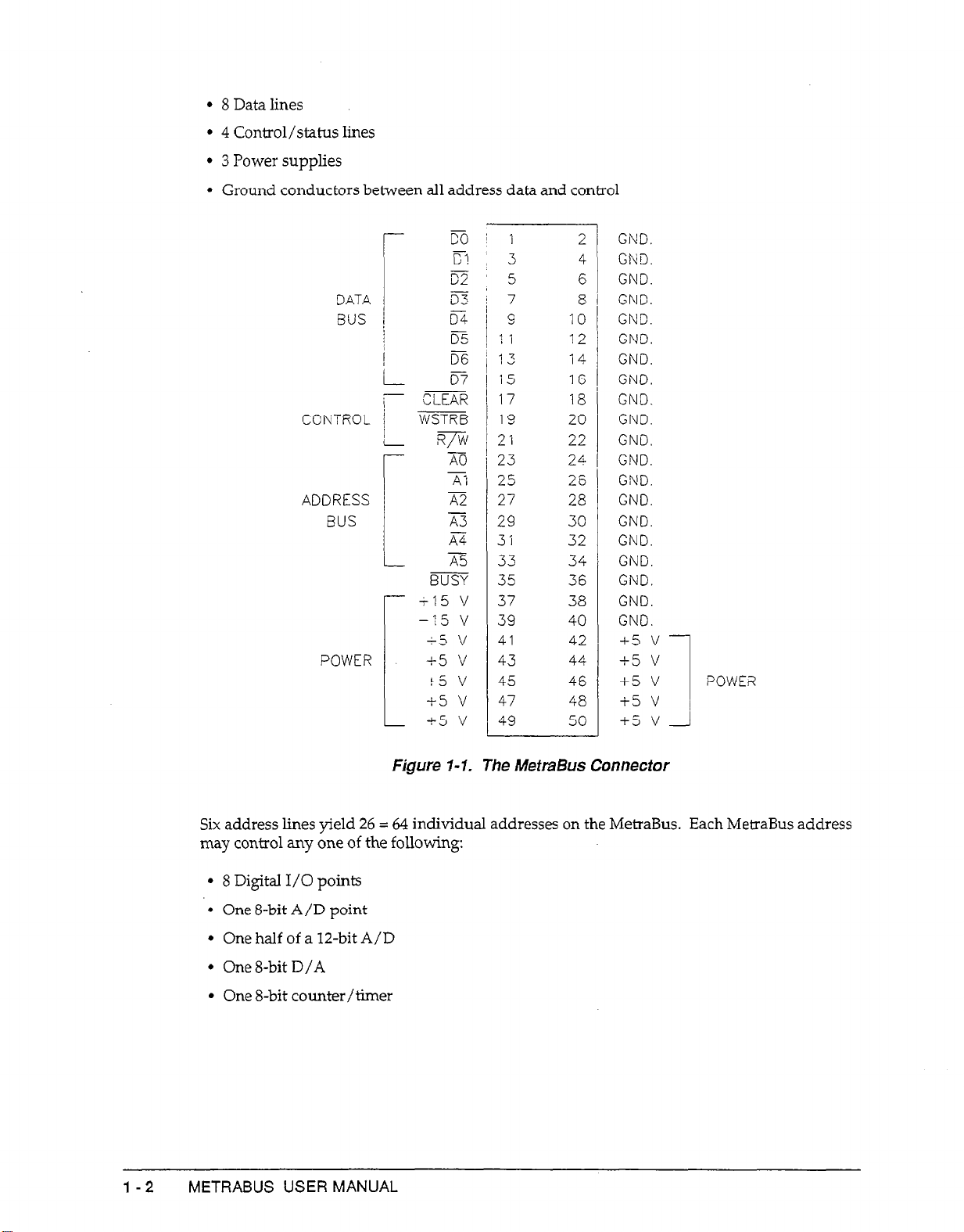

The MetraBus system is an extension of the computer bus to real world measurement and

control devices. All MetraBus I/O boards share the 5O-conductor cable illustrated in Figure l-

1. The MetraBus cable consists of:

l

6 Address lines

INTRODUCTION I- 1

Page 10

l

8 Datalines

l

4

Control/status lines

l

3 Power supplies

l

Ground conductors between all address data and control

-

-

r

CONTROL j WSTRB

ADDRESS x-2

BUS

!

i

co

c?

-

c2

07

CLEAR

R/W

AO

A:

A3

K-4

A5

BUSY

+15 v

-

15 v

+5 ‘d

POWER

+-5 v

t5 v

+5 v

15 v

-

1

3

5

7

9 10

11

13 14

15 16

17

13 20

21 22

23

25 26

27

29 30

3:

33 34

35 36

37 38

39

41

43

45

47 48

49 50

12

18

24

28

32

40

42

44

46

7

GND.

2

4

GND.

GND.

6

8

GND.

GND.

GND.

GND.

GND.

GND.

GND.

GND.

GND.

GND.

GND.

GND.

GND.

GND.

GND.

GND.

GND.

+5 v

+5 v

+5 v

i5 v

-i5 v

POWE?

I

l-2

Figure 1-l. The MetmBus Connector

Six address lines yield 26 = 64 individual addresses on the MetraBus. Each MetraBus address

may control any one of the following:

* 8

Digital I/O points

* One 8-bit A/D point

* One half of a la-bit A/D

* One 8-bit D/A

l

One 8-bit counter/timer

METRASUS USER MANUAL

Page 11

1.3 AVAILABLE METRABUS BOARDS

MetraBus I/O boards are controlled by the PC through one of the MetraBus controller/driver

cards. These I/O Boards are as follows:

l

pCMDB-64: PS/2 compatible MetraBus controller board

l

MDB-64: IBM PC compatible MetraBus controller board

l

MID-64: IBM PC compatible controller card with full optical isolation between PC and

MetraBus.

REM-64: Remote MetraBus controller. Communication via RS-232/422 serial. Multidrop

up 16 REM-64 per computer serial port.

l

INTMDB-64: Intelligent MetraBus controller board. This board is described in a separate

manual.

Both local and remote MetraBus systems control the same family of signal acquisition and

control boards. The boards and their various functions are as follows:

l

MID-16/M%-%: 16 solid-state relays

. MEM-8: 8 electromechanical relays

l

MEM-32: 32 electromechanical relays

l

MIO-32: 32-channel, optically isolated TTL output

l

MII-32: 32-channe1, optically isolated TT’L input

l

MAI-16: Wchannel, 12-bit A/D

l

MAO-8: &channel, 8-bit D/A

l

MAO-12: 12-Channel, 12-bit A/D

l

MCN-8: 8 Channel, &bit counter timer

l

MJ3B32: 32-bit prototype board with four fully decoded addresses

l

MDG-1: Diagnostic/training board with LEDs

l

MBUS-PWR: MetraBus power supply

l

MSSR-32:

l

MCPT-8X8: Cross-point relay board

l

MTHERM-20: 20-channel thermocouple

l

MTAP-1: Power supply tap board

32-channel,

solid-state reIay board

1.4 PACKAGING & INTERCONNECTION

All MetraBus I/O boards are 19” rack mountable using either the RMT-02 housing, a standard

NEMA cabinet, or any 7” x 6”~ 2” enclosure. A 50-way, 0.05” spacing ribbon cable connects the

MetraBus controller/driver card to the I/O boards. This MetraBus cable operates at lengths

of up to 100’. Connectors are standard, 50-pin insulation-displacement type; their parallel

architecture allows placement at any point along the MetraBus cable.

INTRODUCTION 1 -3

Page 12

1.5 CONCEPTUAL VIEW OF METRABUS

MetraBus is an extension of the PC I/O control address space. The MetraBus controller card

implements three control functions, as follows:

* An address Ppinter

l

A data input/output path

l

A reset/clear line

An I/O OUT command from the PC sets the address pointer to a MetraBus I/O board at its

address. Data may then move to or from the selected I/O boards. A RESET/CLEAR may

come from the PC at any time, clearing all I/O boards and resetting the address pointer to

zero.

1.6 PROGRAMMING METRABUS

MetraBus is programmable from any PC-usable language having INPUT and OUTPUT

commands capable of manipulating the I/O bus. Examples of such languages are:

l c

l

BASICA

l

Microsoft PASCAL

l

Assembly

l

GWBASIC

l

TURBO PASCAL

In addition, the REM-64 MetraBus controller allows connection of a MetraBus’system to any

computer with an Rs-232/RS-422 interface. A REM-64 can be controlled from any language

capable of writing and reading the computer’s serial ports.

Programming the MetraBus is a two-step procedure: (1) set the address pointer then (2) read

or write the data. The following discussion wiIl use the variables DATAIO, ADRPTR, and

MRESET in order to help clarify MetraBus progr amming technique. These variables are

generally set at the beginning of your programs for ease of manipulation as follows:

lODATA = 768

20ADRPTR = 769

30MRESET = 770

4OOU-T ADRJ?TR, 01

‘Declare MetraBus data I/O path

'Declare address pointer location

'MetraBus reset location

'Set the address pointer to address #l

5OOUT DATAIO,45 'Write data 45 to address 1

Set the MetraBus address pointer by issuing a single comman d to the MetraBus controller

board. Once set, the address pointer is latched and need not be reset until a different address

is required.

l-4

Writing and reading data from a MetraBus I/O board is transparent once the address pointer

is set. Issuing an OUT command will write data to the targeted I/O board. Likewise, issuing

an INP command will retrieve data from the I/O board via the data I/O path.

OTJT ADRPTR,Ol 'Set address to 1

40

500UT DATAIO,45 'Write data 45 to address 1

6OVAL

= INP(DATAI0) 'Read back data from 1

The MetraBus controller board and all attached MetraBus I/O boards may be reset by writing

to the reset address. Here is an example in BASIC:

METRABUS USER MANUAL

Page 13

40 OUT

MRESET, 00 ‘Clear the MetraBus

Examples of all MetraBus programming features are available on the MetraBus diskettes.

MDB-64 vs. REM-64 Programming

Direct bus plug-in controller boards (MDB-64 and MID-64) program differently than the

REM-64 MetraBus serial controller board. Commands to the MDB-64 and MID-64 are direct

statements to an I/O port. For example, in BASIC:

40 OUT ADRPTR, 01

5OOUT DATAIO, 44

REM-64 co

mmands are writes to a COMl or COM2 serial port. The REM-64 has an on-board

m&!roprccessor which interprets

‘Set address pointer to #l

‘Write data 44 to board #l

co

mmands from the personal computir. The REM-64 issues

commands to the I/O boards (via the MetraBus cable) identical to those issued by an MDB-64

or MID-64. For example, in BASIC:

10 PRINT #l,"B" ; 1 'Activate REM-64 #l

20

PRINT #1, "A" ; 4

30

PRINT #l, "W" ; 44 ‘Write data “44” to I/O board #l

'Set address pointer to MetraBus address 4

Since the MDB-64 and REM-64 use different hardware connections, programs for the MDB-64

are not compatible with those for the REM-64.

Programming l/O Boards

MetraBus I/O boards fall into three major categories:

l

Digital in and out

l

Analog in and out

l

Counter/timer

Digital MetraBus I/O boards program with byte wide (8 bits) write and read commands.

Driving a single digital line high or reading the status of a single line requires one bit.

Therefore, 8 lines (or bits) are controlled when writing to or reading from the digital I/O

boards.

Data to a MetraBus digital ouQut board is latchtid and may be read back from the board. This

data readable feature is usable when manipulating the I/O lines, thus making digita

programming easy.

Analog output boards are controlled as an g-byte port, one byte per channel. The analog

equivalent of the &bit data is output by the DAC on the MetraBus analog output board.

Analog input for the MetraBus is full-featured, allowing user control of application specific

parameters. Prior to reading A/D data from a MetraBus MAI-16, the range channel and type

(12-bit or 8-bit) must be set. An A/D conversion is triggered by software only.

INTRODUCTION

I- 5

Page 14

I

The MCN-8 counter/ timer board has two functions available from software: clear counter

and read counter. Writing to a counter will clear it while reading a counter will retrieve the

current count in the register.

.7

SUMMARY

The remainder of this manual covers the individual MetraBus controller boards and I/O

function boards. The electrical interfacing and programming aspects of each board are

explained.

All explanations and example programs are as if the I/O board is under the control of an

MDB-64. The MIX-64 is a complete and simple implementation of the MetraBus concept.

The MID-64 and REM-64 embody additional features, and are treated in this manual with

programming examples for each.

The lNTMDI3-64 is an intelligent stand-alone driver/controller board for the MetraBus, It is

usable as a dedicated, low-cost controller, or as a satellite controller monitored/controkd by

a larger host computer. This board is described in the INTMDB-64 user’s manual.

Schematics for the MetraBus are available in the MetraBus schematic package.

I-6 METRAHJS USER MANUAL

Page 15

Chapter 2: The Controller Boards

2A.l GENERAL

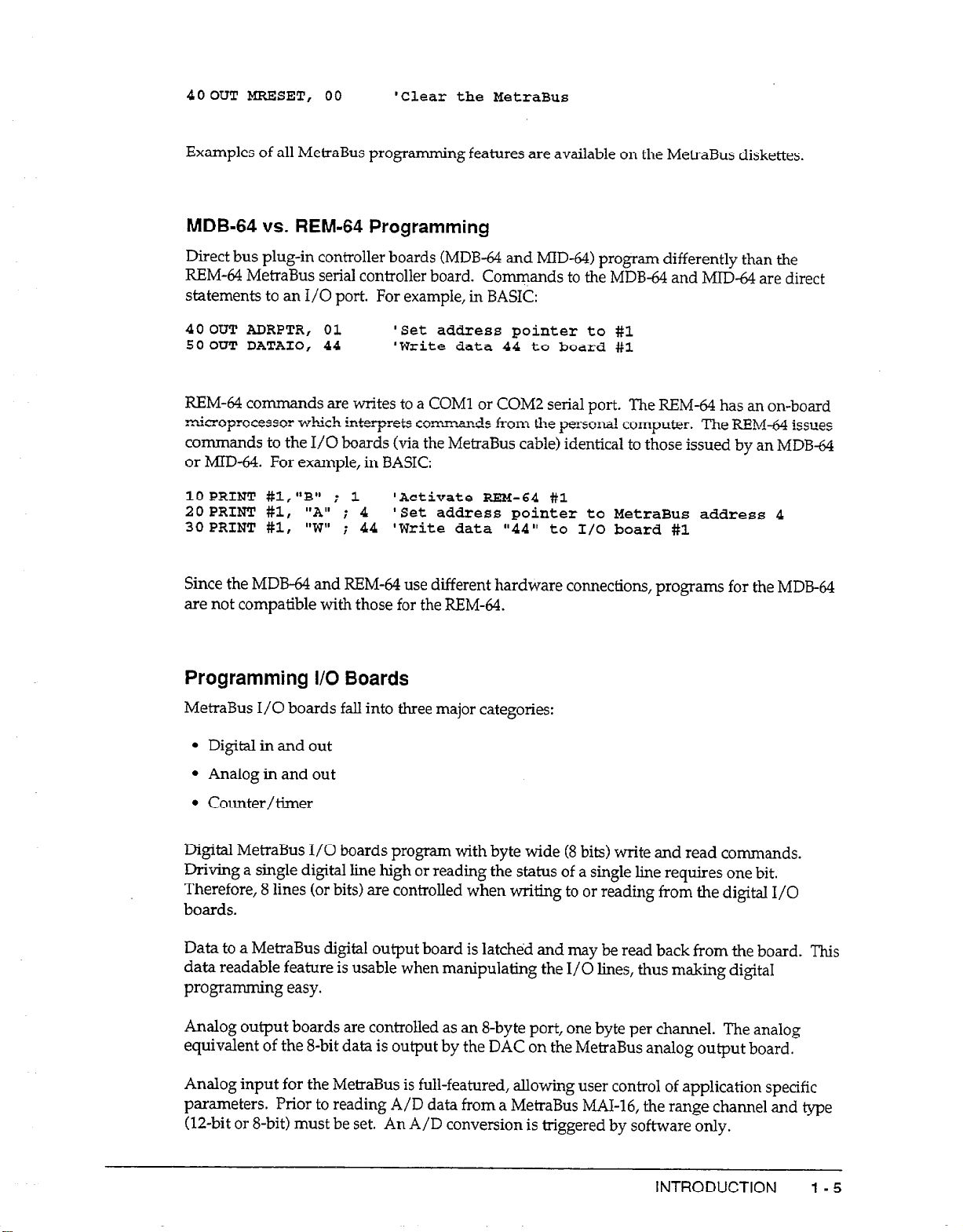

The MDB-64 driver board is the functional heart of the MetraBus system. This board

supervises all I/O operations between the computer and MetraBus I/O boards within your

system. Since the MBD-64 generates all necessary control signals, it controls system-level data

transfer. Because of its design, a single MDB-64 is capable of addressing up to 64 MetraBus

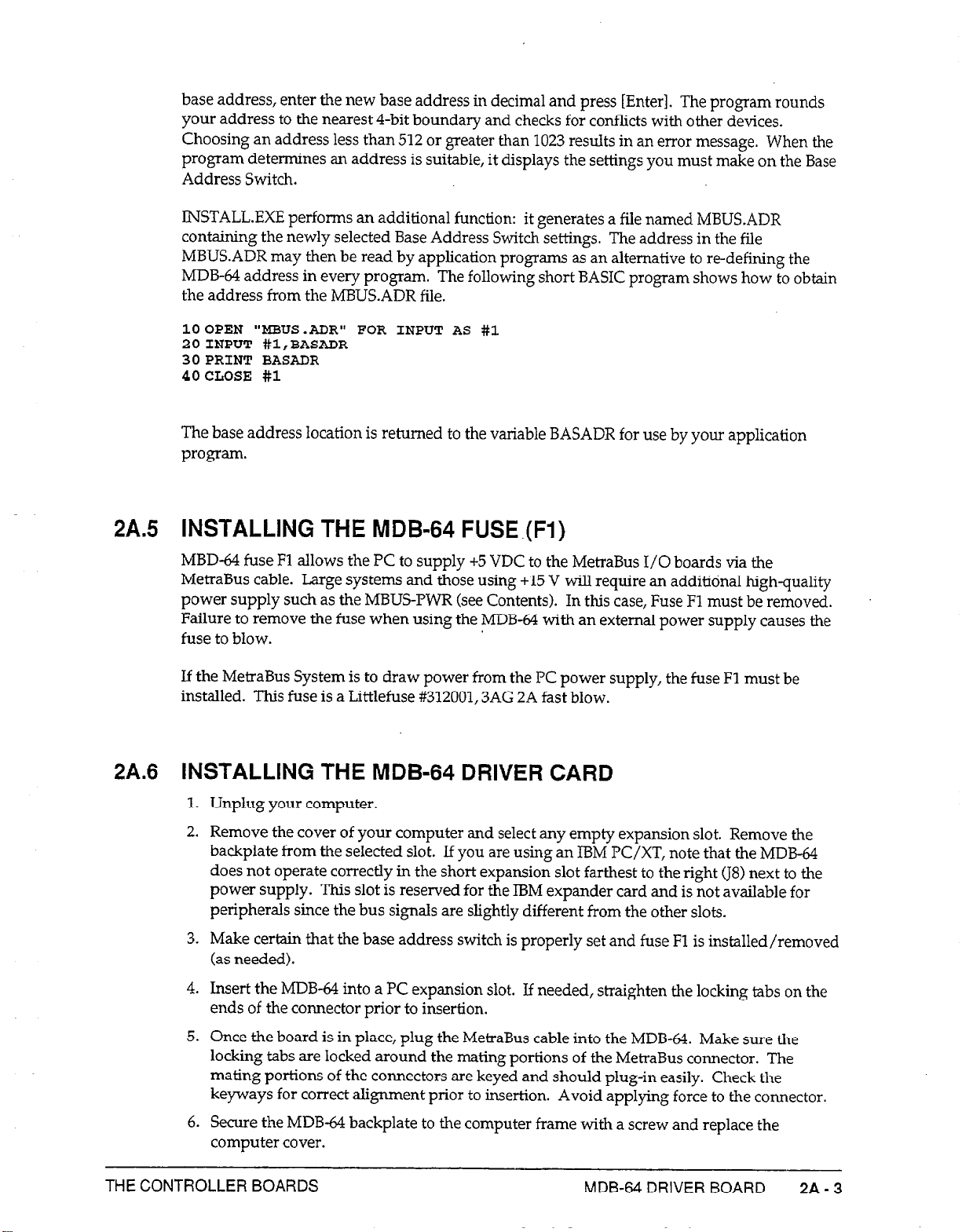

I/O boards. Figure 2A-1 is a functional block diagram of the MDB-64.

I

I I

,

COMPUTER

EXPANSION

BUS

L-------------------------_--_-______---------------,

MDB-64 DRIVER BOARD

MFI’RABUS

ADDRESS

DECODE - AND

LOGIC

BASE

AOORESS

SWITCH

TIMING

CONTROL - DRIVER/ -

SIGNAL

LOGIC

METRABUS

CABLE

RECEIVER I

Part 2A

I

I

I

I

I

I

I

I

I

I

METRABUS

CABLE

The MDB-64 is a ‘half-slot” board that installs in any PC expansion slot. A 50-pin connector

extends through the rear of the computer and connects to the MetraBus cable. Functionally,

MetraBus has a parallel-bus architecture with the MetraBus cable carrying all data, address,

and control signals, as well as distributing power to the MetraBus I/O boards. Ground

conductors are interleaved between all signal lines to reduce system noise. The MDB-64

allows MetraBus cable lengths of up to 100 feet.

The MetraBus industrial data acquisition and control interface allows higher speed, greater

accuracy, and total autonomous operation to otherwise slow and troublesome applications.

A.2 FEATURES

l

Interfaces with IBM PC/XT, PC AT or other bus-compatible computers.

l

Allows placement of MetraBus I/O boards at up to 100 feet from the computer.

l

Compatible with many off-the-shelf software packages.

l

Controls up to 512 digital I/O lines.

l

Controls up to 256 (8 or U.-bit) A/D.

Figure 2A-1. MDB-64 Functional Block Diagram

l

Controls up to 64 @-bit) DACs.

THE CONTROLLER BOARDS

MDB-64 DRIVER BOARD 2A-1

Page 16

l

Extremely cost effective.

l

Adapts to your changing requirements.

2A.3 SPECIFICATIONS

Number of addressable MetraBus 64

ports:

Maximum MetraBus data transfer 80 kbytes/s

rate:

Maximum drivable cable length: 100 feet at full speed

200 feet at reduced speed

MetraBus cable type:

MetraBus connector:

Power required:

50 conductor ribbon cable

3M 3425-4050

-+ 5

V: 250 rr~4

typical, 325 n-4 maximum

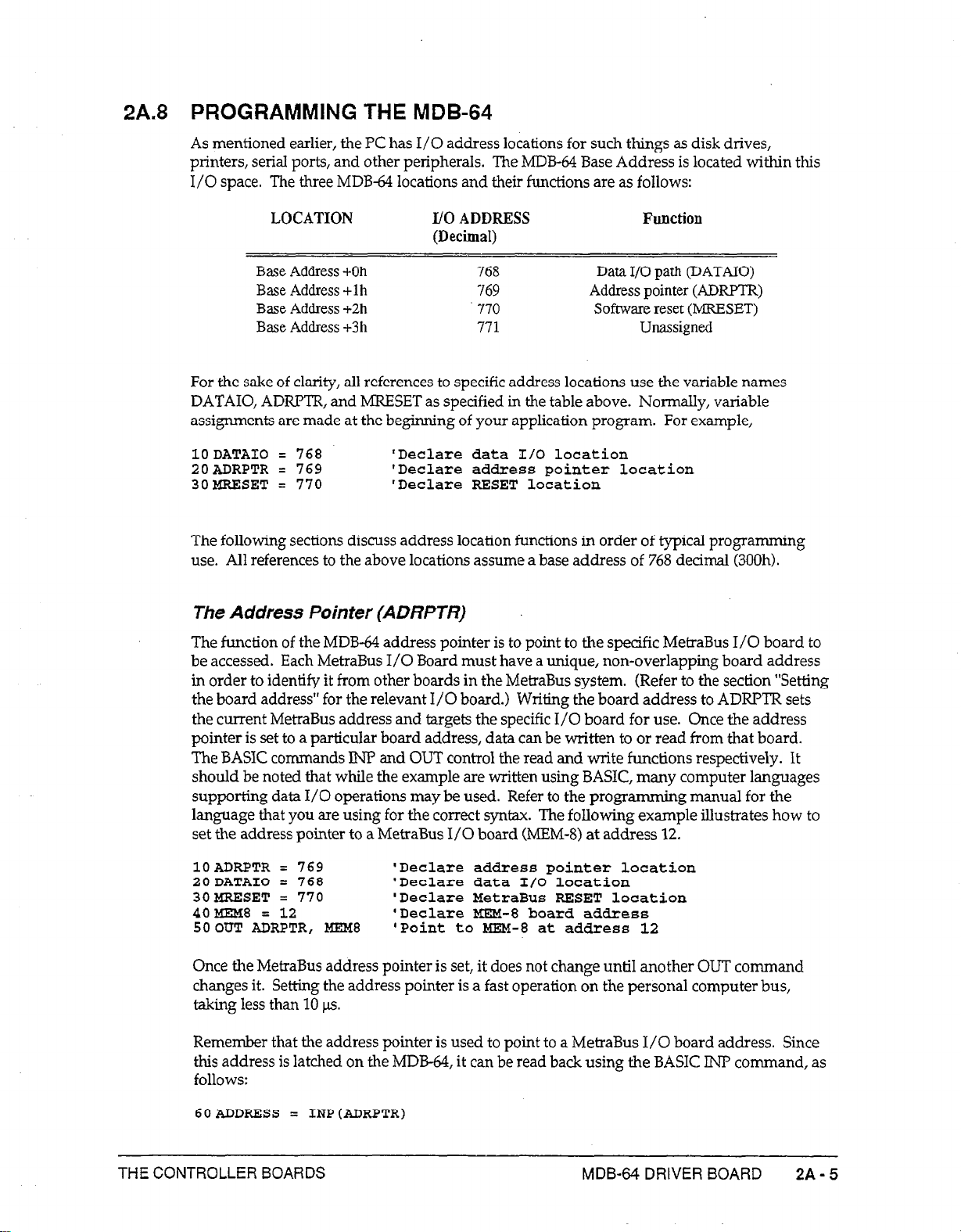

2A.4 SE’TJING THE BASE ADDRESS SWITCH

The MD13-64 uses four consecutive locations in the PC I/O address space. This address space

extends from decimal 512 to 1023.

for 768 (3OOh), as shown in Figure 2A-2.

-2

The MDB-64 base address switch is preset by the factory

ADDRESS

ADDRESS UNE VALUES:

LINE DECIWL HEX

512

200

256 100

Figure ZA-2. Defautt Base Address Switch SettiRgs.

If I/O address 768 (300h) is occupied by another device, you must reset the base address

switch. Refer to your PC manual for available addresses in the I/O space.

Once you have selected an address, change the base address switch accordingly. For

assistance with the settings, use the INSTALLEXE program provided on your MetraBus

diskette.

NOTE: Setting the base address to a location used by another device

may cause erratic operation or PC system failure.

To run the INSTALLEXE program, change to the appropriate directory and at the DOS

prompt, and type

INSTALL

2A-2 METRABUS USER MANUAL

Switch settings indicate o voluc o!

512 i 256 = 768 Dccimoi

(768 decimal, 300h)

followed by [Enter]. When the program asks for the desired

Page 17

base address, enter the new base address in decimal and press [Enter]. The program rounds

your address to the nearest 4-bit boundary and checks for conflicts with other devices.

Choosing an address less than 512 or greater than 1023 results in an error message. When the

program determines an address is suitable, it displays the settings you must make on the Base

Address Switch.

INSTALL.EXE performs an additional function: it generates a file named MBUS.ADR

containing the newly selected Base Address Switch settings. The address in the file

MBUS.ADR may then be read by application programs as an alternative to m-defining the

MDB-64 address in every program. The following short BASIC program shows how to obtain

the address from the MBUSADR file.

lOOPEN "KBUS.ADR" FOR INPUT AS #l

20

INPUT #~,BASADR

30 PRINT BASADR

40

CLOSE #l

The base address location is returned to the variable BASADR for use by your application

program.

2A.5 INSTALLING THE MDB-64 FUSE.(Fl)

MBD-64 fuse Fl allows the PC to supply +5 VDC to the MetraBus I/O boards via the

MetraBus cable. Large systems and those using +15 V will require an additional high-quality

power supply such as the MBUS-PWR (see Contents).

Failure to remove the fuse when using the MDB-44 with an external power supply causes the

fuse to blow.

If the MetraBus System is to draw power from the PC power supply, the fuse Fl must be

installed. This fuse is a Littlefuse #312001,3AG 2A fast blow.

In this case, Fuse Fl must be removed.

2A.6 INSTALLING THE MDB-64 DRIVER CARD

1. Unplug your computer.

Remove the cover of your computer and select any empty expansion slot. Remove the

2.

backplate from the selected slot. If you are using an IBM PC/XT, note that the MDB-64

does

not

operate correctly in the short expansion slot farthest to the right (I8) next to the

power supply. This slot is reserved for the IBM expander card and is not available for

peripherals since the bus signals are slightly different from the other slots.

Make certain that the base address switch is properly set and fuse Fl is installed/removed

3.

(as needed).

Lnsert the MDB-64 into a PC expansion slot. If needed, straighten the locking tabs on the

4.

ends of the connector prior to insertion.

Once the board is in place, plug the MeiraBus cable into the MDB-64. Make sure the

5.

locking tabs are locked around the mating portions of the MetraBus connector. The

mating portions of the connectors are keyed and should plug-in easily. Check the

keyways for correct alignment prior to insertion, Avoid applying force to the connector.

Secure the MDB-64 backplate to the computer frame with a screw and replace the

6.

computer cover.

THE CONTROLLER BOARDS

MDB-64 DRIVER BOARD 2A-3

Page 18

NOTE: The MDB-64 is shipped with two resistor networks. These

termination resistors are to be installed in sockets RN1 and RN2 on the

last MetraBus I/O board in your system. These resistor networks are

used to minimize signal reflection due to long MetraBus cable lengths.

They are optional, however, and have little effect for cables of 50 feet or

less.

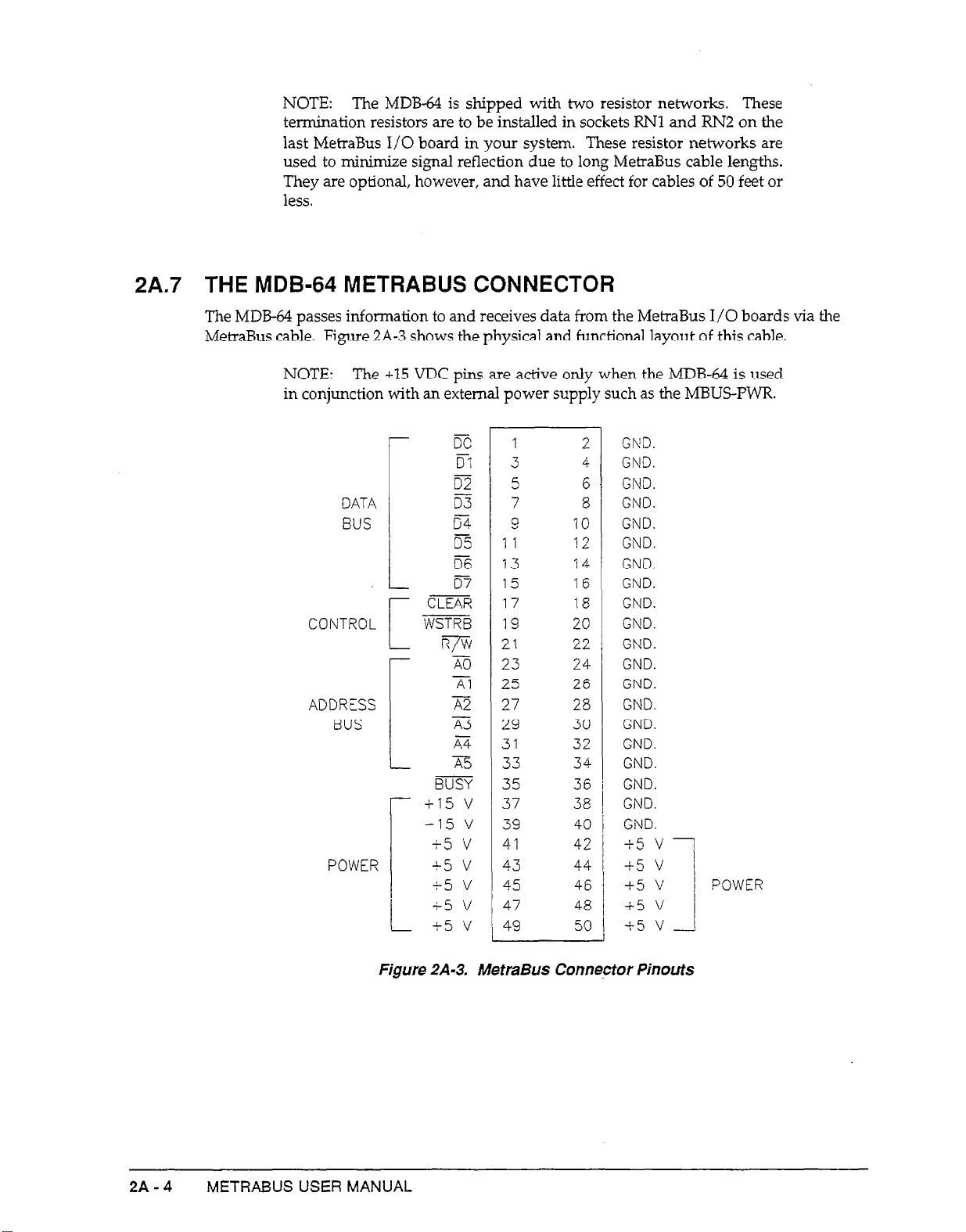

2A.7 THE MDB-64 METRABUS CONNECTOR

The MDB-64 passes information to and receives data from the MetraBus I/O boards via the

MetraBus cable. Figure ZA-3 shows the physical and functional layout of this cable.

NOTE: The +15 VDC pins are active only when the MDB-64 is used

in conjunction with an external power supply such as the MBUS-PWR.

DATA

BUS

POWER

BUSY

+15 v

-15 v

+5 v

+5 v

+5 v

+5 v

L t5v

1

3

5 6

7

9 10

1 1

13

15 16

17

19 20

21 22

23 24

25 26

27 28

29

31

33

35 36

37

39 40

41

43

45 46

47 48

49 50

12

14

18

30

32

34

38

42

44

GND.

2

4

GND.

GND.

GND.

8

GND.

GND.

GND.

GND.

GND.

GND.

GND.

GND.

GND.

GND.

GND.

GND.

GND.

GND.

GND.

GND.

+5 v

i-5 v

+5 v

-1-5 v

i-5 v

POWER

2A-4

Figure ZA-3. MetraBus Connector Pinouts

METRABUS USER MANUAL

Page 19

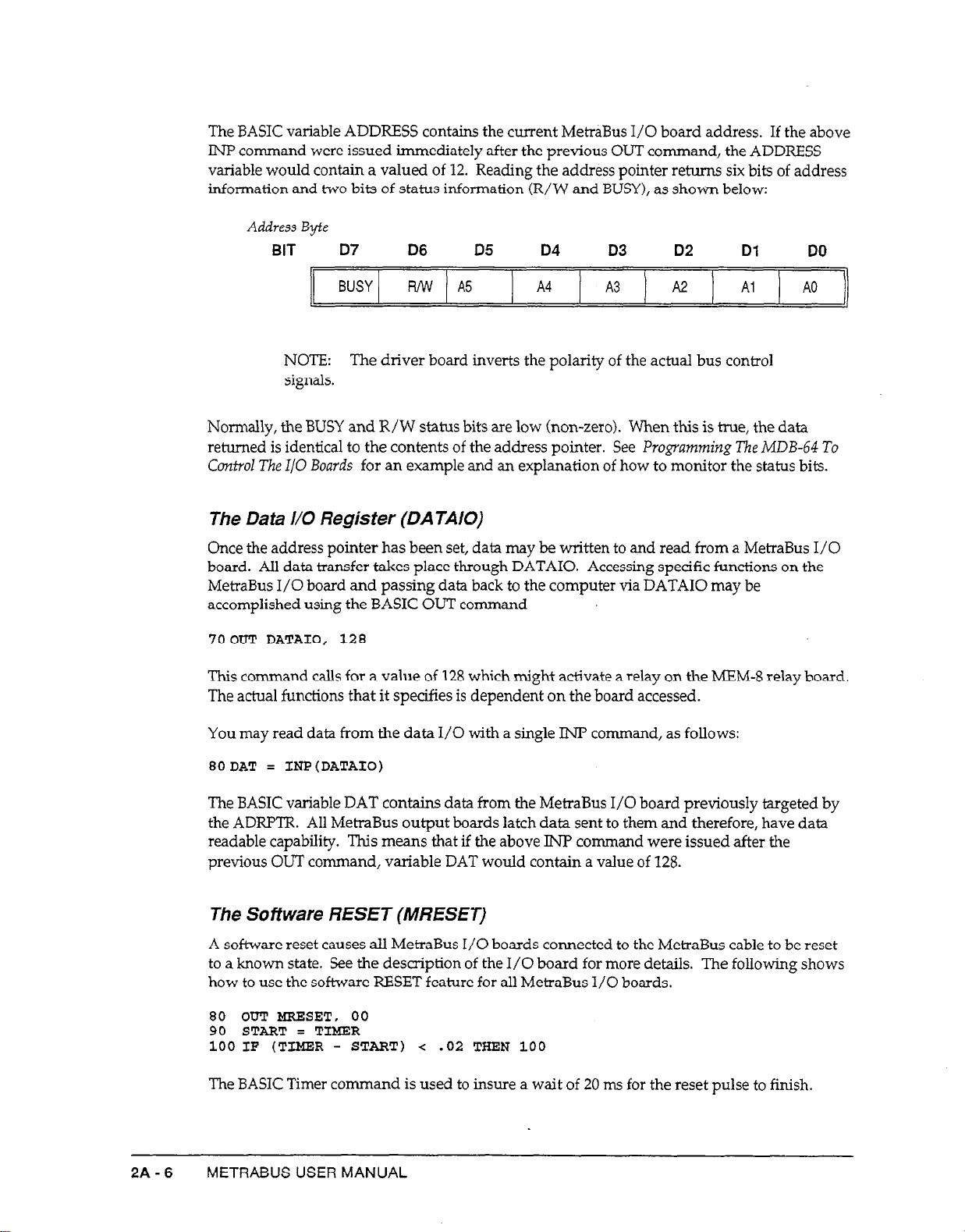

2A.8 PROGRAMMING THE MDB-64

As mentioned earlier, the PC has I/O address locations for such things as disk drives,

printers, serial ports, and other peripherals. The MDB-64 Base Address is located within this

I/O space. The three MDB-64 locations and their functions are as follows:

LOCATION I/O ADDRESS

(Decimal)

Base Address +-Oh

Base Address +lh

Base Address +2h

Base Address +3 h

768 Data I/O path (DATAIO)

769

‘770 Software reset (PRESET)

771 Unassigne4l

Address pointer (ADRPTR)

Function

For the sake of clarity, all references to specific address locations use the variable names

DATAIO, ADRFTR, and MRESET as specified in the table above. Normally, variable

assignments are made at the beginning of your application program. For example,

ZODATAEO = 768 'Declare data I/O location

20ADRPTR = 769 'Declare addxess pointer location

30WSET = 770 'Declare RESET location

The following sections discuss address location

use. All references to the above locations assume a base address of 768 decimal

The Address Pointer

(ADRPTR)

functions

in order of typical programming

(300h).

The function of the MDB-64 address pointer is to point to the specific MetraBus I/O board to

be accessed. Each MetraBus I/O Board must

in order to identify it from other boards in the MeiraBus system.

have

a unique, non-overlapping board address

(Refer to the section “Setting

the board address” for the relevant I/O board.) Writing the board address to ADFUYIR sets

the current MetraBus address and targets the specific I/O board for use. Once the address

pointer is set to a particular board address, data can be written to or read from that board.

The BASIC commands IN? and OUT control the read and write functions respectively. It

should be noted that while the example are

written

using BASIC, many computer languages

supporting data I/O operations may be used. Refer to the programming manual for the

language that you are using for the correct syntax. The following example illustrates how to

set the address pointer to a MetraBus I/O board (MEM-8) at address 12.

10ADRPTR = 769

2QDATAIO = 76%

30MRELSET = 770

4OMBf8 = 12

5OOUT ADRPTR, MEM8 'Point to HEM-8 at address 12

Once the MetraBus address pointer is set, it does not change until another OUT command

changes it. Setting the address pointer is a fast operation on the personal computer bus,

taking less than 10 p.

Remember

that

the address pointer is used to point to a MetraBus I/O board address. Since

this address is latched on the MDB-64, it can be read back using the BASIC INP command, as

follows:

60ADDREXS = INP(ADRPTR)

THE CONTROLLER BOARDS

'Declare address pointer location

'Declare data I/O location

'Declare HetraBus RESET location

‘Declare m-8 board address

MDB-64 DRIVER BOARD

ZA-5

Page 20

The BASIC variable ADDRESS contains the current MetraBus I/O board address. If the above

INP command were issued immediately after the previous OUT command, the ADDRESS

variable would contain a valued of 12. Reading the address pointer returns six bits of address

information and two bits of status information (R/W and BUSY), as shown below:

Address Byte

BIT D7

D6

D5

D4 D3 D2

Dl

DO

BUSY R/w A.5

A4

A3

A2

Al A0

NOTE: The driver board inverts the polarity of the actual bus control

signals.

Normally, the BUSY and R/W status bits are low (non-zero). When this is true, the data

returned is identical to the contents of the address pointer. See Programming The MDB-64 7’0

Covttiol The I/O Boar& for an example and an explanation of how to monitor the status bits.

The Data l/O Register (DATAIO)

Once the address pointer has been set, data may be written to and read from a MetraBus I/O

board. All data transfer takes place through DATAIO. Accessing specific functions on the

MetraBus I/O board and passing data back to the computer via DATA10 may be

accomplished using the BASIC OUT command

70 OUT DATAIO, 128

This command calls for a value of 128 which might activate a relay on the MEM-8 relay board.

The actual functions that it specifies is dependent on the board accessed.

You may read data from the data I/O with a single IN7 command, as follows:

EODAT = INP(DATAI0)

The BASIC variable DAT

contains

the ADRPTR. All MetraBus output boards latch data sent to them and therefore, have data

readable capability. This means that if the above IN? command were issued after the

previous OUT command, variable DAT would contain a value of 128.

The Sofiware RESET (MRESET)

A software reset causes alI MetraBus I/O boards connected to the MetraBus cable to be reset

to a known state. See the description of the I/O board for more details. The following shows

how to use the software RESET feature for all MetraBus I/O boards.

80 OUT HRZSET, 00

90 START = TIMER

100 IF (TIZGR - START) < .02 THEN 100

The BASIC Timer command is used to insure a wait of 20 ms for the reset pulse to finish.

214-6 METRABUS USER MANUAL

data from the MetraBus I/O board previously targeted by

Page 21

Notes On The Use Of Compiled Or Assembled Languages

Execution speeds with compiled and assembled languages may call for precautions. As

mentioned earlier, when reading the currently latched MetraBus I/O address, the lowest six

bits contain address information while the two most significant bits carry status information.

Prior to any BASIC Inp or Out command, check the status bits (R/W and Busy). The

following example shows the proper status checks.

DATA10 = 768

10

ADRPTR = 769

20

MRESET = 770

30

MA116 = 8

40

OUT MRESET, 00

50

60 START = TIMR

IF (TIKER - START) <

70

IF (INPUDRPTR) AND 192)

80

90 OUT ADRPTR, HAI16+2

IF (INP(ADFU?TR) AND 192)

100

OUT DATAIO, 18

110

IF (INP(ADRPTR) AND 192)

120

130 OUT ADRPTR, HAI16+1

140 IF (INP(ADRPTR) AND 192) THEN 140

150 AIN = INP(DATAI0)

.02 THEN 70

THEN 80

THEN 100

THEN 120

'Declare I/O location

'Declare address pointer location

'Declafe MetraBus RESET location

'Declare MAI- board address

'Input Time

'Wait 20 ms

'Check status

'Point to

'Check status

'Set gain to +5 V range on than 2

'Check status

'Point to result of conversion

'Check status

'Return result to computer

g-bit

A/D resolution

Programming The MDB-64 To Control The l/O Boards

As described above, the three MDB-64 I/O locations have quite distinct

of execution generally follows a consistent pattern when programming any MetraBus I/O

board. The following examples illustrate programming techniques used with both digital and

analog

I/O Boards. For prograrnmin

g information on a specific board, refer to the board

description.

Digital l/O Boards

functions.

Their order

Digital I/O boards are the easiest to control. Data can be written to DATAIO

setting the address pointer. Digital output boards typically have several &bit ports. In the

following example, a digital output board (MIO-32) is at board address 0 and the MDB-64 is at

computer I/O Address 768 decimal (3OOh).

lODATA = 768

20ADRPTR = 769

3OMRESET = 770

40MI032 = 0 'Declare MIO-32 board address

5OOUT

ADRPTR, MI032

6OOUT DATAIO, 255

Lines 10 through 40 declare the locations of the MetraBus DATAIO, ADRF’TR, and

MRESET functions, as well as declare the MIO-32 board address. Line 50 sets the address

pointer to the MIO-32 digital output board. Line 60 outputs a value of 255 to the MIO-32,

setting all outputs high.

THE CONTROLLER BOARDS

'Declare data

'Declare

address pointer location

I/O

location

'Declare MetraBus REXXT location

'Point to MIO-32

at

address 0

'Output bit pattern 1111 1111

MDB-64 DRIVER BOARD

soon

after

the

2A-7

Page 22

Digital input board (Mu-32) programmin

g is similar to that for digital output boards. Digital

input boards typically have several B-bit ports. After the address pointer has been set, data

can be read from the DATAIO, as follows:

lODATA = 768 'Declare Data I/O Location

20ADRPTR = 769 'Declare Address Pointer Location

30MRBSET = 770 'Declare MetraBus RESET Location

40MII32 = 4 'Declare MII-32 Board Address

5OOUT ADRPTR, MI132 'Point to MII-32 at Address 4

60DATIN = INP(DATAI0) 'Get data from DATA10

Lines 10 through 40 declare the locations of the MetraBus DATAIO, ADKPTR, and

the

MRESET functions, as well as declare the MU-32 board address. Line 50 sets the address

pointer to the MIl-32 digital input board. Line 60 reads the contents of one of the four &bit

ports on the m-32 and stores the result in the BASIC variable DATIN.

Analog I/O Boards

Analog output boards (MAO-8) use one MetraBus I/O address per channel. Setting the

Address Pointer to the appropriate address and writing data to the DATAIO will produce an

analog output. The following example shows how to set the address pointer and output a

voltage.

lODATA = 768

20ADRPTR = 769

30MRESET = 770

4OMAO8 = 8

5OOUT ADRPTR, MAO8

6OOUT DATAIO, 255

7OOUT DATAIO, 0

8OOUT ADRPTR, MA116

Lines 10 through 40 declare the locations of the MetiaBus DATAIO, ADRPTR, and the

MRXSET functions, as well as declare the MAO-8 board address. Line 50 sets the address

pointer to channel 0 of the MAO-8 board. Line 60 outputs the highest voltage possible for its

selected range.

'Declare Data I/O Location

'Declare Address Pointer Location

'Declare MetraBus RESET Location

'Declare MAO-8 Board Address

'Point to HAO-8 at Address 8

'Output Pull Range Voltage

'Start A/D Conversion

'Select the MSB's address

Analog Input boards (MAI-16) require additional steps, however, in order to set the gain and

resolution for the desired channel prior to taking data. Assume an MAI- board has been set

at Board Address 8.

lODATA = 768 'Declare Data I/O Location

20ADRPTR = 769 'Declare Address Pointer Location

30MRESET = 770

35MAI16 = 8

4OOUT ADRPTR, KAI16+2'Point to 8-bit A/D resolution

SOOUT DATIO,18 'Set gain to + 5 V

6OCUT ADRPTR, MAI16+1'Point to result of conversion

90AIN = INP(DATAI0) 'Return result to computer

Lines 10 through 35 declare the locations of the MetraBus DATAIO, ADRPTR, and the

MXESET functions, as well as declare the MN-16 board address.

Line 40 selects the gain/channel selection mode for the board at address 8 (see MN-16

description for full explanation).

2A-a METRABUS USER MANUAL

'Declare MetraBus RESET Location

'Declare MAI- Board Address

range

on channel 2

Page 23

Line 50 sets the gain to + 5V full scale range on channel 2.

Line 60 points to the B-bit conversion mode for the board and channel previously selected.

Line 70 starts the A/D conversion process.

Line 80 points to the results of the A/D conversion.

Line 90 returns the result to the computer and stores the data in the variable AJN.

THE CONTROLLER BOARDS

MDB-64 DRIVER BOARD 2A-9

Page 24

cl

P

2A-10 METRABUS USER MANUAL

Page 25

Chapter 2: The Controller Boards

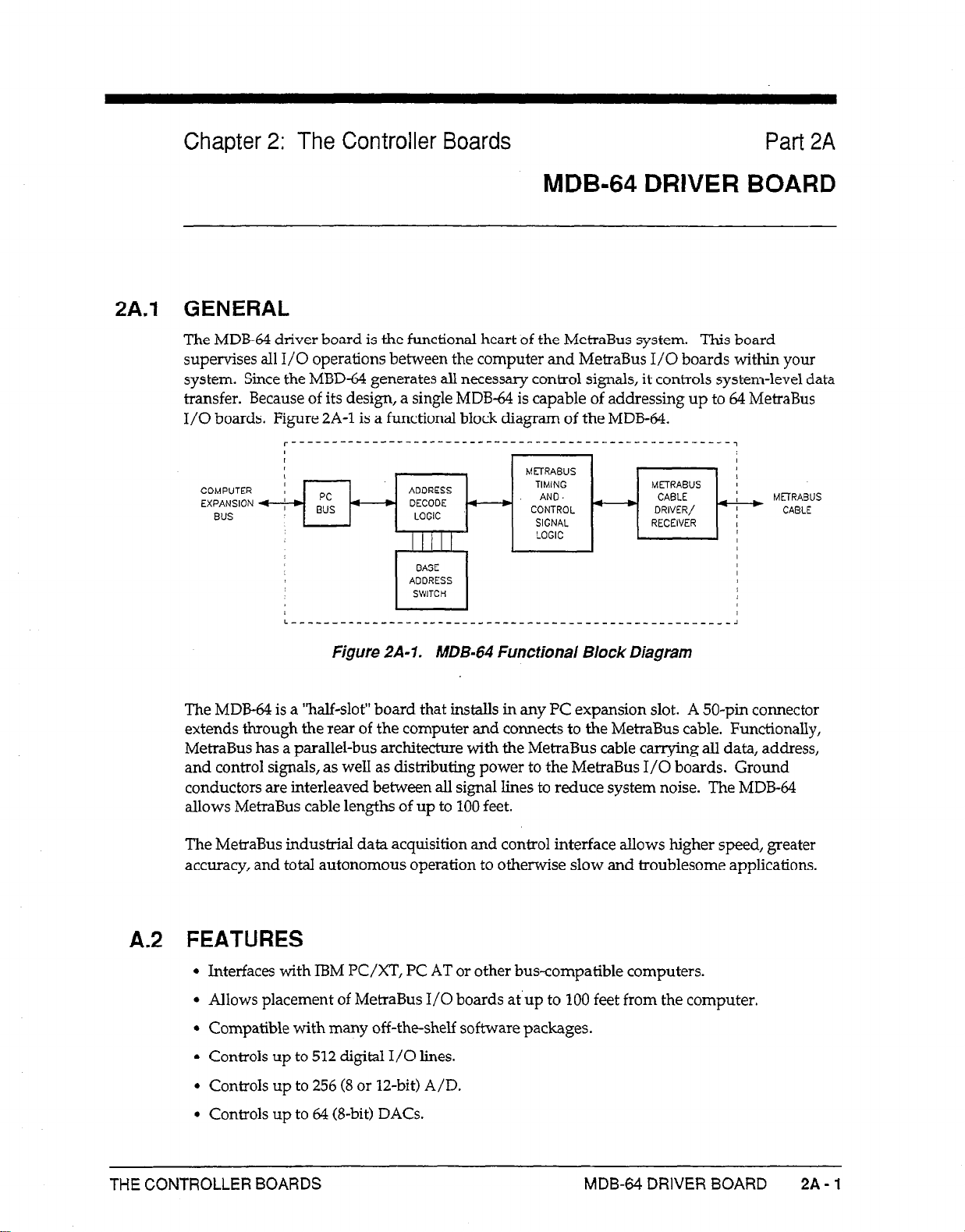

2B.l GENERAL

Part 2B

MID-64 DRIVER BOARD

The MID-64 driver board optically isolates the computer bus from

acquisition and control

computer and MetraBus I/O boards within your

system.

The MID-64 supervises all I/O operations between the

system.

All necessary control signals are

the

MetraBus data

generated within the MID-64, so you don’t have to worry about system level data transfer.

Because of its design, a single MID-64 is capable of addressing up to 64 MetraBus I/O boards.

The MID-64 contains an on-board, programmable counter/timer capable of periodic

system

interrupt generation. This allows the MetraBus operation in a foreground/background mode

emulating many common multitasking environments. A functional block diagram of the

MlD-64 is provided in Figure 2B-1.

r--------------------------------------------------------------------~

METfZABUS

COMPUTER :

EXPANSION -

BUS

PC

I BUS -

ADDRESS

OECOOE -

LOGIC

BASE

ADDRESS

WITCH

TIMING MEmABuS !

AND

CONTROL - ISOLAlORS DRIER/ ?-+ CABLE

SIGNAL RECEIVER 1

LOGIC

CABLE ’ Mmus

Figure 2B-1. MID-64 Functional Block Diagram

When installed, a 50-pin connector extends out the rear of the computer and connects to the

MetraBus cable. Functionally, the MetraBus has a parallel bus architecture with the MetraBus

cable carrying all data, address, and control signals, as well as distributing power to the

MetraBus I/O boards. Ground conductors are interleaved between all signal lines to increase

system noise immunity. The MID-64 has been designed to allow MetraBus cable lengths of up

to loo feet.

The MetraBus industrial data acquisition and control interface, in conjunction with your

present computer, allows higher speed, greater accuracy, and total autonomous operation to

previously slow, troublesome, applications.

THE CONTROLLER BOARDS

MID-64 DRIVER BOARD

2B-1

Page 26

2B.2 FEATURES

l

Connects with IBM PC/XT, PC AT, or other bus compatible computers.

l

Allows placement of MetraBus I/O at up to 100 feet from the PC.

l

Full optical isolation to 500 Volts.

l

Fully compatible with software written for the MDB-64 driver board.

l

Interrupt generation capability.

l

Controls up to 512 digital I/O lines.

l

Controls up to 256 (8 or 12-bit) A/D.

l

Controls of 64 @-bit) DACs.

l

Controls up to 64 counter/timers.

l

Extremely cost effective.

l

Adapts to your changing requirements.

28.3 SPECIFICATIONS

Number of Addressable MetraBus

64

Ports:

2B.4

Maximum MetraBus Data TrmR;yz

80 kbytes/s

Maximum Drivable Cable Length: 100 feet at full speed

200 feet at reduced speed

+ 5

Power Required:

PC to MetraBus Isolation:

V: 250 mA typical, 325 rnA maximum

500 volts (minimum)

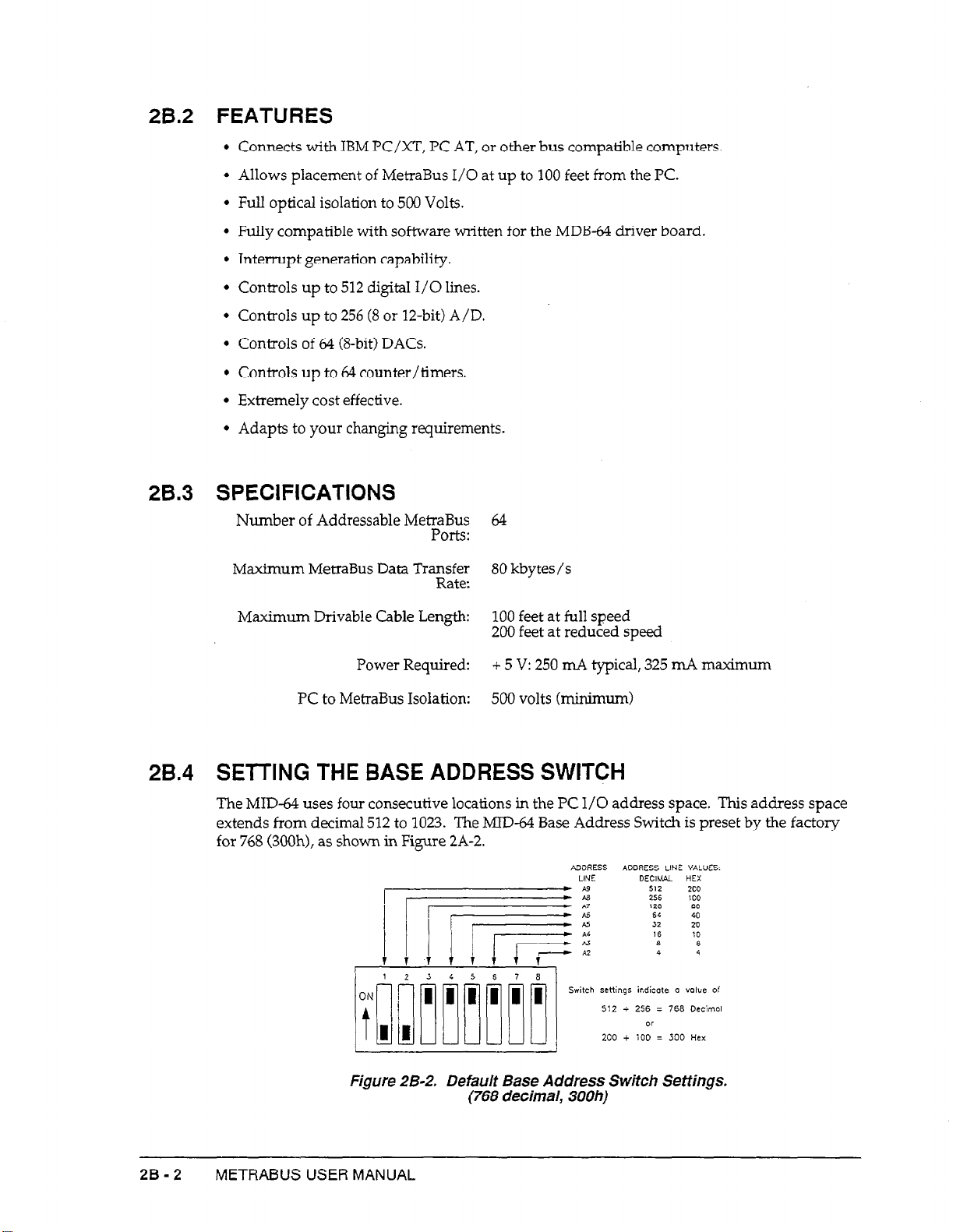

SETTING THE BASE ADDRESS SWITCH

The MID-64 uses four consecutive locations in the PC I/O address space. This address space

extends from decimal 512 to 1023. The MID-64 Base Address Switch is preset by the factory

for 768 (3OOh), as shown in Figure 2A-2.

ADDRESS

LINE

qs iedicote 0 value o!

i 256 = 766 Decimal

or

+ iOD = 300 Hex

Figure 2B-2. Default Base Address Switch Settings.

2B-2 METRABUS USER MANUAL

(768 decimal, 300h)

Page 27

If I/O address 768 (300h) is occupied by another device, you must reset the base address

switch. Refer to your PC manual for available addresses in the I/O space.

Once you have selected an address, change the base address switch accordingly. For

assistance with the settings, use the INSTALLEXE program provided on your MetraBus

diskette.

NOTE:

may cause erratic operation or PC system failure.

To run the INSTALL.EXE program, change to the appropriate directory and at the DOS

prompt, and type INSTALL followed by [Enter]. When the program asks for the desired

base address, enter the new base address in decimal and press [Enter]. The program will

round your address to the nearest 4-bit boundary and check for conflicts with other devices.

Choosing an address less than 512 or greater than 1023 results in an error message. When the

program determines an address is suitable, it displays the settings you must make on the base

address switch.

INSTALL.EXE also generates a file named MBUSADR containing the newly selected base

address switch settings. The address in the file &!fHJS.ADR may then be read by application

programs as an alternative to redefining the MID-64 address in every program. The

following short BASIC program shows how to obtain the address from the MBUS.ADR file.

1OOPKN "MBUS.ADR" FOR INPUT AS #1

20 INPUT #l,BASADR

30PRINT BASADR

40

CLOSE #l

The base address location is returned to the variable BASADR for use by your application

program.

Setting the base Aadress to a location used by another device

2B.5 USE OF THE AUXILIARY POWER SUPPLY

An auxiliary power supply such as the MBUS-Pm is required for operation of the MID-64,

since it does not distribute power from the computer’s supply. See the chapters of this

manual dealing with the MBUS-PWR for specifications and installation instructions.

2B.6 INSTALLING THE MID-64 DRIVER CARD

1. Unplug your computer.

2. Remove the cover of your computer and select any empty expansion slot. Remove the

back-plate from the selected slot.

3. Make certain that the base address switch is properly set.

4. Insert the MID-64 into the expansion slot. It may help to straighten the locking tabs on the

ends of the connector prior to insertion.

THE CONTROLLER BOARDS MID-64 DRIVER BOARD 28-3

Page 28

5. Once the board has been inserted, plug the MetraBus cable into the MID-64. Make sure

that the locking tabs are locked around the mating portions of the MetraBus connector.

The mating portions of the connectors are keyed and should plug-in easily.

Check the

keyways for correct alignment prior to insertion. Avoid applying force to the connector.

6. Secure the MID-64 back-plate to the computer frame with a screw and replace the

computer cover.

NOTE:

The MID-64 is shipped with two resistor nehvorks.

termination resistors are to be installed in sockets RN1 and RN2 on the

last MetraBus I/O board in your system. These resistor networks are

used to minimize signal reflection due to long MetraBus cable lengths.

They are optional, however, and have little effect for cables of 50 feet or

less.

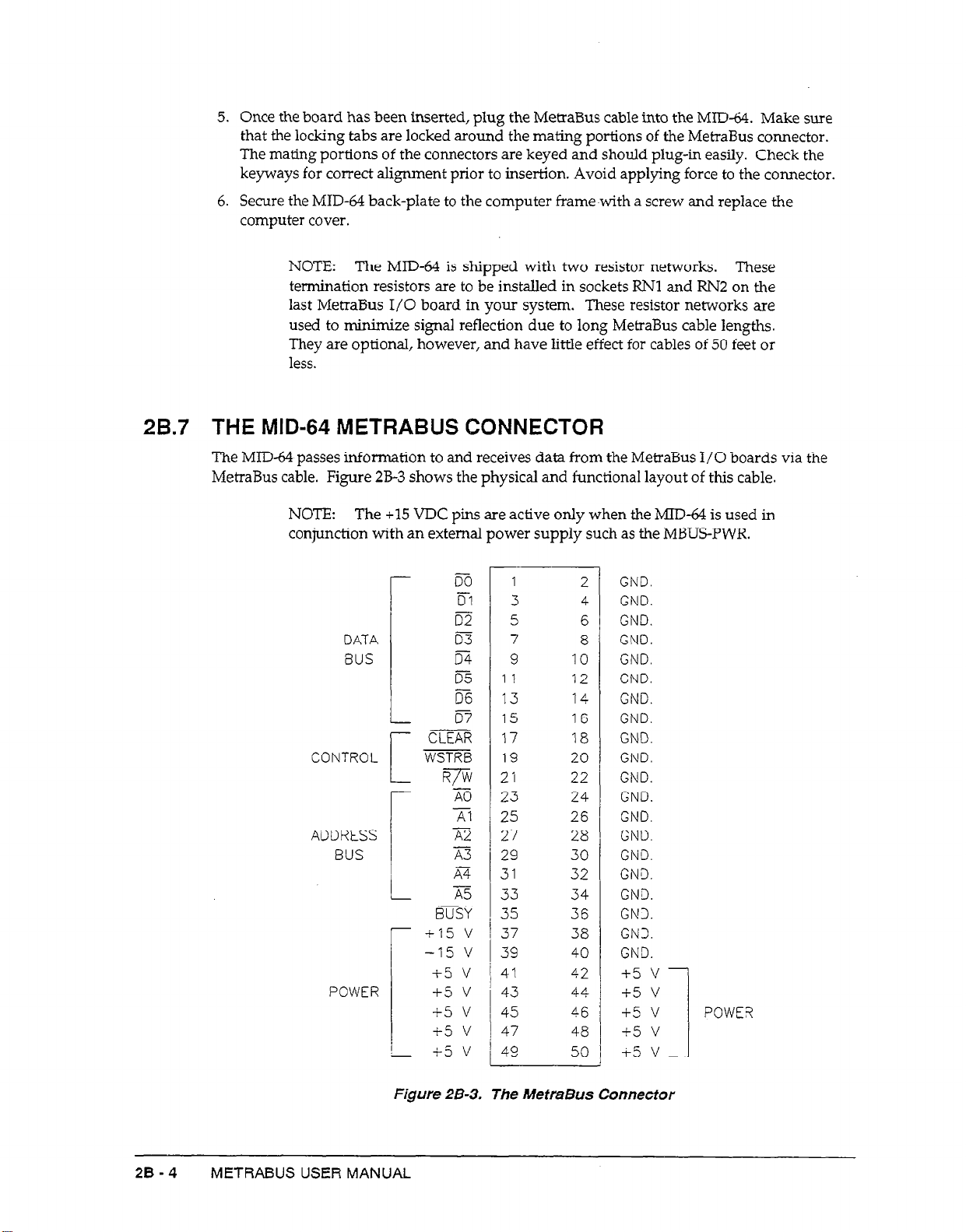

2B.7 THE MID-64 METRABUS CONNECTOR

The MID-64 passes information to and receives data from the MetraBus I/O boards via the

MetraBus cable. Figure 2B-3 shows the physical and functional layout of this cable.

The

+15

NOTE:

conjunction with an external power supply such as the MBUS-PWR.

DATA m

BUS

CONTROL

ADDRESS /

BUS

POWER +5 v

VDC pins are active only when the MID-64 is used in

r

L

C

r

i

r

i

m

D-1

m

m

iz

tie

m

CLEAR

WSTRB

%

-iii

A2

23

XT

A5

BUSY

+I5 v

-15 v

i5 v

+.5 v

+5 v

+5 v

1

3

5

7

9 IO

1 1

13 14

15

17

19

2 1 22

23

25 26

27 28

29 30

31

33 34

35

37

39 40

4’1

43 44

45

47

49

12

16

18

20

24

32

36

38

42

46

48

50

2

4

6

8

GND.

GND.

GND.

GND.

GND.

GND.

GND.

GND.

GND.

GND.

GND.

GND.

GND.

GND.

GND.

GND.

GND.

GN3.

GN3.

GND.

+5 v

+5 v

+5 v

+5 v

+5 v

These

POWER

I

28-4

Figure 28-3. The MetraBus Connector

METRABUS USER MANUAL

Page 29

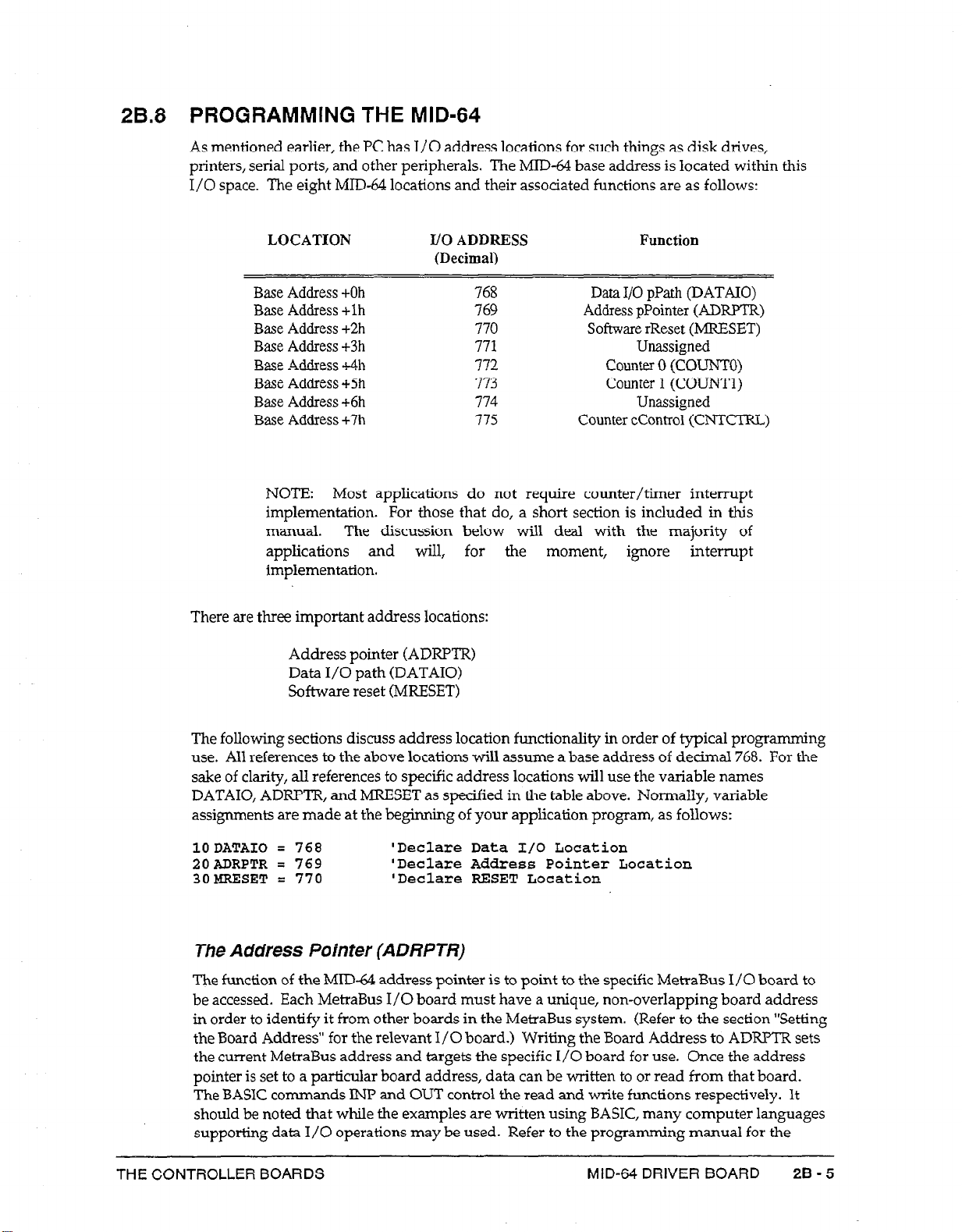

2B.8 PROGRAMMING THE MID-64

As mentioned earlier, the PC has I/O address locations for such things as disk drives,

printers, serial ports, and other peripherals. The MID-64 base address is located within this

I/O space. The eight MID-64 locations and their associated functions are as follows:

LOCATION

I/O ADDRESS

(DecimaI)

Base Address +Oh

Base Address +lh

Base Address

+2h

Base Address +3h

Base -4~Uress 4h

Base Address +5h

Base Address +6h

Base Address +7h

768

769

770

771

772

773

774

775

NOTE: Most applications do not require counter/timer interrupt

implementation.

For those that do, a short section is included in this

manual. The discussion below will deal with the majority of

applications and wiIl, for the moment, ignore interrupt

implementation.

There are three important address locations:

Address pointer (ADRF’TR)

Data I/O path (DATAIO)

Software reset (MRESET)

Function

Data I/O pPath (DATAIO)

Address pPointer (ADRXR)

Software rReset (MRESET)

Unassigned

counter 0 (COUNTO)

Counter 1 (COTJNTI)

Unassigned

Counter cContro1 (CNTCTRL)

The following sections discuss address location functionality in order of typical programming

use. All references to the above locations will assume a base address of decimal 768. For the

sake of clarity, all references to specific address locations will use the variable names

DATAIO, ADRPTR, and MRESET as specified in the table above. Normally, variable

assignments are made at the beginning of your application program, as follows:

1ODATAIO = 768 'Declare Data I/O Location

20ADRPTR = 769 ‘Declare Address Pointer Location

30MRESET = 770

The Address Pointer (ADRPTR)

The function of the MID-64 address pointer is to point to the specific MetraBus I/O board to

be accessed. Each MetraBus I/O board must have a unique, non-overlapping board address

in order to identify it from other boards in the MetraBus system. (Refer to the section “Setting

the Board Address” for the relevant I/O board.) Writing the Board Address to ADRPTR sets

the current MetraBus address and targets the specific I/O board for use. Once the address

pointer is set to a particular board address, data can be written to or read from that board.

The BASIC commands INP and OUT control the read and write functions respectively. It

should be noted that while the examples are written using BASIC, many computer languages

supporting data I/O operations may be used. Refer to the programming manual for the

THE CONTROLLER BOARDS

‘Declare RELSET Location

MID-64 DRIVER BOARD

28-5

Page 30

language that you are using for the correct syntax. The following example illustrates how to

set ADRF’TR to address 12 for a MEM-8 board:

10 ADRPTR = 769

20DATAI0 = 768

30MRESET = 770

40MEMB = 22 ‘Declare MEN-8 board address

50

OUT ADRPTR, KEN8

'Declare address pointer location

'Declare data I/O location

'Declare MetraBus RESET location

'Point to MELM-8 at address 12

Once the MetraBus address pointer is set, it does not change until another OUT command

changes it.

Setting the Address pointer is a fast operation on the personal computer bus,

taking less than 10 microseconds. Since this address is latched on the MID-&, it can be read

back using the BASIC INF’ command, for example:

60

ADDRESS = INPCADRPTR)

The BASIC variable ADDRESS contains the address of the MetraBus I/O board currently

targeted. If the above INP co

mmand is issued soon after the previous OUT command, the

ADDRESS variable would contain a value of 12. Reading the address pointer returns 6 bits of

address information and two bits of status information (R/W and BUSY), as follows:

Address Byte

BIT D7 D6 D5 D4

BUSY Pu’W A5

A4

D3 D2 Dl

A3

A2 Al A0

DO

NOTE: The driver board inverts the polarity of the actual

signals.

bus control

Normally, the BUSY and R/W status bits will be low (non-zero>. When this is true, the data

returned is identical to the contents of the address bus. See Programming The MID-64 To

Control The I/O Boards for an example and an expknation of how to monitor the status bits.

The Data I/O Register (DATA/O)

Once the address pointer has been set, data may be written to and read from a targeted

MetraBus I/O board. All data transfer takes place through DATAIO. Accessing specific

functions on the MetraBus I/O board and passing data back to the computer via DATA10

may be accomplished using the BASIC OUT command:

7OOUT DATAIO, 128

This command outputs a value of 128 which might activate a relay on the

The actual functions that it specifies is dependent on the board accessed.

Data

can be read from the

80DAT

= INP (DATAIO)

Data I/O with a single lNP con-man

d, as follows:

The BASIC variable DAT wiIl contain data from the MetraBus I/O board previously targeted

by the ADRM’R. All MetraBus output boards latch data sent to them and therefore, have data

MEM-8

relay

board.

2B-6 METRABUS USER MANUAL

Page 31

readback capability. This means that if the above INP command were issued after the

previous OUT command, variable DAT would contain a value of 128.

The Software RESET (MRESET)

A software reset causes all MetraBus I/O boards connected to the MetraBus cable to be reset

to a known state. See the description of the I/O board for more details. The following shows

how to use the software RESET feature for al1 MetraBus I/O boards.

OUT MRESET, 00

80

90 START = TIMER

IF (TIMF,R - START) < .3 THEN 100

100

The BASIC Timer command is used to insure a wait of 300 ms for the reset pulse to finish.

Notes On The Use Of Compiled Or Assembled Languages

The execution speed of compiled and assembledIanguages calls for precautions. As

mentioned earlier, when reading the currently latched MetraBus I/O address, the lowest six

bits contain address information while the two Most Significant Bits carry status information.

Prior to any BASIC Inp or Out command, you should check the status bits (R/W and Busy).

The following example shows the proper status checks.

DATA10 = 768

10

ADRPTR = 769

20

MRESET = 770

30

MA116 = 8

40

OUT MRESET, 00

50

60 START = TIMER

IF (TIMER - START)

70

80 IF (INJ?(ADRPl'R) AND

90 OUT ADRPTR, MAI16+2

100 IF (INP(ADRPTR) AND

OUT

110

120 IF (INP(ADRmR) AND

130 OUT ADRPTR, MA116+1

140 IF (INP(ADRPTR) AND

150 AIN = INP(DATAI0)

DATAIO, 18

<

.3 THEN 70

192) TEEN 80 'Check status

192) TW3N 100

192) TWEN 120

192) THEN 140

'Declare I/O location

'Declare address pointer location

'Declare MetraBus RESET location

'Declare MAI- board address

'Input Time

'Wait 300 ms

'Point to B-bit A/D resolution

'Check status

'Set gain to +5 V range on than 2

'Check status

'Point to result of conversion

'Check status

.'Return result to computer

Programming The MID-64 To Control The I/O Boards

As described above, the eight MID-64 I/O locations have distinct functions. Their order of

execution generally follows a consistent pattern when programming any MetraBus I/O board.

The following examples illustrate programmin

Analog I/O Boards. Detailed programmin g information on a specific board, refer to the board

description.

Digital I/O Boards

Digital I/O boards are the easiest to control. Data can be written to DATAIO soon after

setting the Address Pointer. Digital output boards typically have several 8-bit ports. In the

following example, a digital output board (MIO-32) is at board address 0 and the MID-64 is at

computer I/O Address 768 decimal GOOh).

g techniques used with both Digital and

THE CONTROLLER BOARDS MID-64 DRIVER BOARD

28-7

Page 32

IODATAIO = 768 'Declare Data I/O Location

20ADRPTR = 769 'Declare Address Pointer Location

30MRESET = 770 'Declare MetraBus RESET Location

40MI032 = 0 'Declare MIO-32 Board Address

50 OUT ADRPTR, MI032

60OUT DATAIO, 255

'Point to MIO-32 at Address 0

'Output bit pattern 1111 1111

Lines 10 through 40 declare the locations of the MetraBus DATAIO, ADRPTR, and the

MRESET functions, as well as declare the MIO-32 board address. Line 50 sets the address

pointer to the MIO-32 digital output board. Line 60 outputs a value of 255 to the MIO-32,

setting all outputs

high.

Digiti input board programming is similar to that for digital output boards. Digital input

boards (MII-32) typically have several &bit ports. After the address pointer has been set, data

can be read from the DATAIO, for example:

1ODATAIO = 768

20ADRPTR = 769

30HRESET = 770

4OMII32 = 4

5OOUT ADRPTR, MI132

'Declare Data I/O Location

'Declare Address Pointer Location

'Declare MetraBus RESET Location

'Declare MII-32 Board Address

'Point to MII-32 at Address 4

60 DATIN = INP(DATAI0) 'Get data from DATAIO

Lines 10 through 40 declare the locations of the MetraBus DATAIO, ADRPTR, and the

MFZSET dictions, as well as declare the MI-32 board address. Line 50 sets the address

pointer to the MII-32 digital input board. Line 60 reads the contents of one of the four &bit

ports on the m-32 and stores the result in the BASIC variable DATIN.

Analog l/O Boards

Analog output boards (MAO-8) use one MetraBus I/O address per channel. Setting the

address pointer to the appropriate address and writing data to the DATAIO will produce

analog output. The following example shows how to set the address pointer and output a

voltage.

lODATA = 768

ZOADRPTR = 769

30MRESET = 770

4OMAO8 = 8

5OOUT ADRPTR, MAO8

600UT DATAIO, 255 'Output Full Range Voltage

'Declare Data I/O Location

'Declare Address Pointer Location

'Declare MetraBus

RESET

Location

'Declare MAO-8 Board Address

'Point to MAO-8 at Address 8

an

28-8

Lines 10 through 40 declare the locations of the MetraBus DATAIO, ADRPTR, and the

MR.ESET functions, as well as declare the MAO-8 board address. Line 50 sets the address

pointer to channel 0 of the MAO-8 board. Line 60 outputs the highest voltage possible for its

selected range.

Analog input boards (MAI-16) require additional steps, however, in order to set the gain and

resolution for the desired channel prior to taking data. Assume an MAI- board has been set

at Board Address 8.

10DATAIO = 768 'Declare Data I/O Location

20ADRPTR = 769 'Declare Address Pointer Location

30MRESET = 770 'Declare MetraBus RESET Location

35MAIl6 = 8 'Declare MAI- Board Address

4OOuT ADRPTR, MAI16+2'Point to 8-bit A/D resolution

METRABUS USER MANUAL

Page 33

500UT DATI0,18 'Set gain to + 5 V range on channel 2

600UT ADRPTR, MAI16+1'Point to result

90AIN

= INP(DATAI0) 'Return result

of conversion

to computer

Lines 10 through 35 declare the locations of the MetraBus DATAIO, ADRPTR, and the

MFCESET functions, as well as declare the MAI- board address.

Line 40 selects

the

gain/channel selection mode for the board at address 8 (see MAI-

description for full explanation).

Line 50 sets the gain to + 5V full scale range on channel 2.

Line 60 points to the &bit conversion mode for the board and channel previously selected

Line 70 starts the A/D conversion process.

Line 80 points to the results of

the

A/D conversion.

Line 90 returns the result to the computer and stores the data in the variable AIN,

Interrupt Generation Via The 8254 Counter/Timers

The following discussion is for MetraBus users familiar with the 8254 and its associated

registers as well as IBM PC interrupts and interrupt service routines. See the 8254 Data Sheet

for further information.

For this discussion, we will simply show how to generate the interrupt. It is left to the user to

actually implement interrupt functionality. There are several good books dealing with IBM

PC interrupts and

information, such as: Inside the IBM PC by Peter Norton and Assembler for

PC-XT by Peter Abel.

how to service

them as well as vector tables and related interrupt

the

IBM PC and

The MID-64 has an INTEL 8254 programmable interval timer I.C. in conjunction with a 6 MHz

clock. The output from these counters may be connected to the PC bus. The counter can be

programmed to generate periodic interrupts for any of the IBM PC interrupt levels 2 through

7. This allows an interrupt service routine to be controlling the MetraBus in the background

while the computer is doing some other function in the foreground.

Timing is accomplished as follows:

the output of counter 0 is cascaded to the input of counter

1 creating a 32-bit counter (this provides a maximum interrupt time of once every 11.9

seconds). The output from counter 1 is brought to the interrupt jumpers on the MID-&l.

There are typically 6 interrupt levels number 2 through 7, (level 1 is reserved). Level 2

highest priority if more than one peripheral is requesting interrupt service at the same time.

To enable an interrupt request (IRQ), simply connect the counter output to the computer bus

by placing the IXQ level jumper on the desired level. Then, write the desired control word to

the 8254 control register. Next, point to counter 0 and/or counter 1 via the ADRPTR and

write a data word (clock multiplier) to the high and low byte registers of the 8254. This sets

up the tuner. Writing to the base address +7 starts the timer.

THE CONTROLLER BOARDS MID-64 DRIVER BOARD

has the

26-9

Page 34

cl

28-10 METRABUS USER MANUAL

Page 35

Chapter 2: The Controller Boards

2C.l GENERAL

The pCMDB-64 MetraBus controller board allows you to integrate your IBM PC System 2

(PS/2) computer (models 50 through 80) with a MetraBus industrial data acquisition and

control system. The MetraBus system is a low-cost solution for slow, troublesome data

acquisition applications.

The pCMDB-64 Board supervises all I/O operations between the PS/2 and the.MetraBus I/O

boards in your system (refer to Chapter 1 for a list of compatible boards). One pCMDB-64

board controls up to 64 external MetraBus I/O boards. The lKMDB-64 is capable of

controlling up to 512 Digital I/O lines, 256 (8 or 12 bit) A/D lines, and 64 (8 bit) D/A lines.

All timing and control signals are generated from the pCMDE-64.

The lKMDB-64 is easily programmable using any of the following languages: C, BASICA,

Microsoft Pascal, TURBO PASCAL, Assembly, or GWBASIC. A Utility Disk, containing

sample programs, is provided with the @vIDB-64 to aid in creating custom programs.

Part 2C

pCMDB-64 DRIVER BOARD

2C.2 SPECIFICATIONS

Physical

MetraBus Cable Type: 50-Conductor Ribbon cable.

MetraBus Connector:

Environmental

Operating Temperature: +32 to +158” F (0 to +70” C)

Storage Temperature: -104 to +212” F t-40” to +lOO” C)

Humidity: 0 to 95%, non-condensing

Size:

Weight: 18 ounces (509.40 g.)

11.50” L x 3.47’ H (29.17 cm L x 8.61 cm H)

3M 3425-6050

THE CONTROLLER BOARDS

pCMDB-64 DRIVER BOARD

2c-1

Page 36

2C.3 USE OF AN AUXILIARY POWER SUPPLY

If you have more than one MCPT-8x8 or other MetraBus I/O boards installed in your

MetraBus system or do not wish to use the PC +5 V power, an auxiliary power supply may be

required. Refer to the MBUSPWR sections for more information.

2C.4 SYSTEM CONFIGURATION

The jKMDB-64 design is in accordance with the IBM PS/2 POS (Programmable Option Select)

rules and there are no user jumpers or switches.

registered with IBM. If you need a special ID number for O.E.M. applications, contact our

technical support department as instructed in Instrz~tions For FLZC~~~ Rams .

If you are familiar with installing peripheral boards in your PS/2, you may want to skim over

most of this section. It is important, however, that you read the section Configuring the

System . The system configuration procedure differs slightly from typical ones.

If you have never installed a peripheral board in your PS/2, you might find it helpful to have

your PS/2 User’s Guide handy.

Installing The Board

The Board Identifier Number (602Bh) is

Before installing the pCMDI3-64, be sure that you have created a working diskette containing

the @602b.ADF file and the contents of the IBM PS/2 Reference Disk (provided with your

computer). This section provides general instructions for installing the pCMDB-64 Board. For

more detailed information regarding installation of peripheral boards, refer to the Installing

options section of the IBM Personal System/2 Model XX Quick Reference provided with your

computer.

WARNING

DO NOT ATTEMPT TO INSERT OR REMOVE ANY ADAPTER

BOARD WITH THE COMPUTER POWER ON, OR YOU RISK

DAMAGING YOUR COMPUTER!

IBM PS/2 Model 50

To

install the pCMDB-64 Board,

1. Turn off power to the PS/2 and to all attached options.

2. Unplug the power cords of the PS/2 and all attached options from the electrical outlets.

Note where all the cables and cords are attached to the rear of the system unit, and

disconnect.

3. Make certain the cover lock is unlocked.