Page 1

Model 7158 low Current

Scanner Card

Instruction Manual

Contains Operating and Servicing Information

Page 2

Page 3

Model 7158 Low Current Scanner Card

Instruction Manual

0 1987, Keithley Instruments, Inc.

Test Instrumentation Group

All rights reserved.

Cleveland, Ohio, U.S.A.

June 1990, Second Printing

Document Number: 7158-901-01 Rev. B

Page 4

SAFETY PRECAUTIONS

The following safety precautions should be observed before using this

product and any associated instrumentation. Although 6ome instruments

and accessories would normally be used with non-hazardous voltages,

there are situations where hazardous conditions may be present.

This product is intended for use by qualified personnel who recognize

shock hazards and are familiar with the safety precautions required to

avoid possible injury. Read the operating information carefully before using the product.

Exercise extreme caution when a shock hazard is present. Lethal voltage

may be present on cable connector jacks or test fixtures. The American

National Standards Institute (ANSI) states that a shock hazard exists

when voltage levels greater than 30V RMS, 42.4V peak, or 60VDC are

present. A good safety practice is to expect that hazardous voltage is

present in any unknown circuit before measuring.

Before operating an instrument, make sure the line cord is connected to a

properly grounded power receptacle. Inspect the connecting cables, test

leads, and jumpers for possible wear, cracks, or breaks before each we.

For maximum safety, do not touch the product, test cables, or any other

instruments while power is applied to the circuit under test. ALWAYS remove power from the entire test system and discharge any capacitors be-

fore: connecting or disconnecting cables or jumpers, installing or

removing switching cards, or making internal changes, such as installing

or removing jumpers.

Do not touch any object that could provide a current path to the common

side of the circuit under test or power line (earth) ground. Always make

measurements with dry hands while standing on a dry, insulated surface

capable of withstanding the voltage being measured.

Do not exceed the maximum signal levels of the instruments and awesseries, as defined in the specifications and operating information, and as

shown on the instrument or test fixture rear panel, or switching card.

Do not connect switching cards directly to unlimited power circuits. They

are intended to be used with impedance limited sources. NEVER connect

switching cards directly to AC main. When connecting sources to switching cards, install protective devices to limit fault current and voltage to

the card.

Page 5

When fuses are used in a product, replace with same type and rating for

continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied

to the device under test. Safe operation requires the use of a lid interlock.

If a @ screw is present on the test fixture, connect it to safety earth

ground using #18 AWG or larger wire.

The

more may be present on the terminals. Refer to the product manual for detailed operating information.

Instrumentation and accessories should not be connected to humans

Maintenance should be performed by qualified service personnel. Before

performing any maintenance, disconnect the line cord and all test cables.

symbol on an instrument or accessory indicates that 1OOOV or

f

Page 6

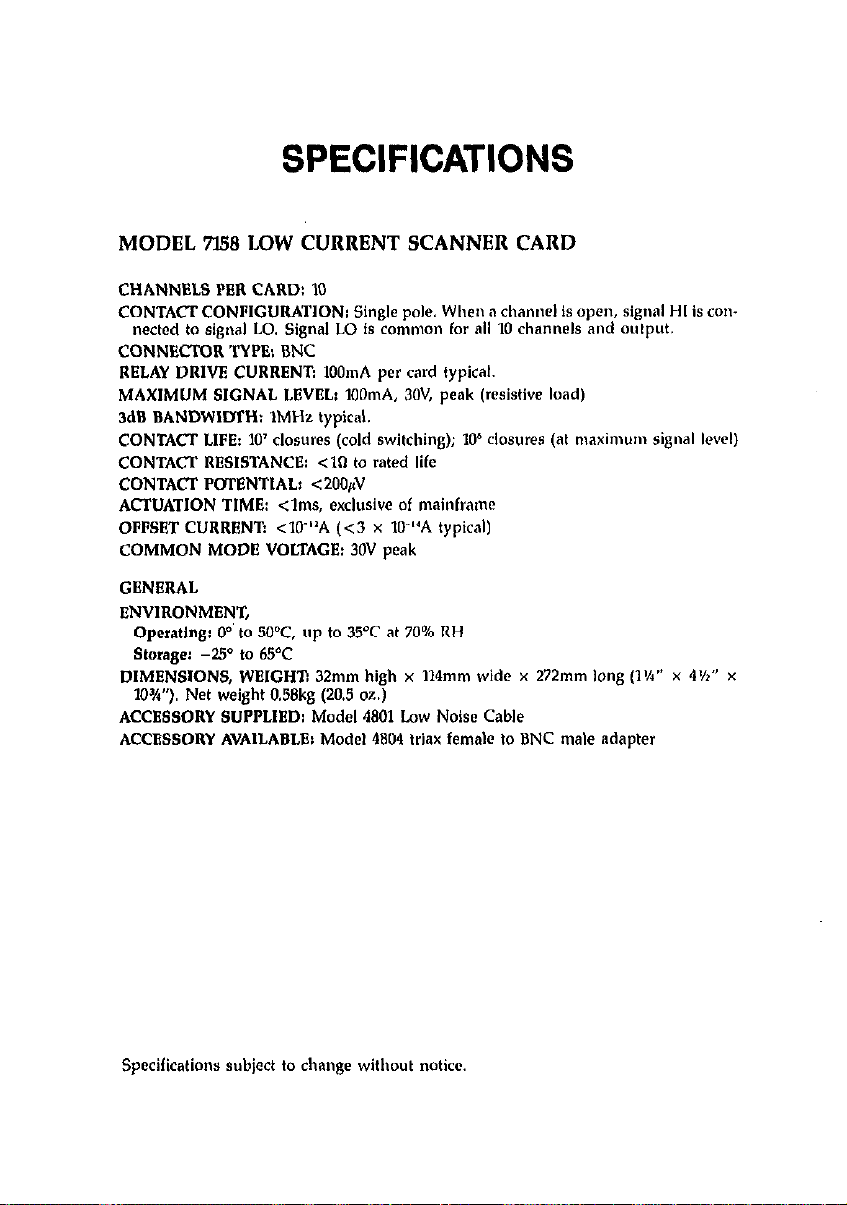

SPECIFICATIONS

MODEL 7158 LOW CURRENT SCANNER CARD

CHANNBLS PER CARD: 10

CONTACT CONFIGURATION: Single pole. When a channel is open, sign81 HI is con-

nected to signal LO. Signal LO is common for ail 10 channels and aulput.

CONNIXTOR TYPE; BNC

RELAY DRIVE CURRENT: lOOmA per card typical.

MAXIMUM SIGNAL LEVEL; lOOmA, 3OV, peak (resistive load)

368 BANDWImHz lM& typical.

CONTACT LIFE: 10’ closures (cold switching); 10’ closures (at maximum signal level)

CONTACT RESISTANCE: <Xl to rated life

CONTACT POTBNTIALr <20,&V

ACTUATION TIME: <Ims, exclusive of mainframe

OPPSET CURReNT: <10’“A (<3 x 10-laA typical)

COMMON MODR VOLTAGE: 3OV peak

GENRRAL

ENVIRONMENT,

Operating: 8’ to 50°C, up to 35’C at 70% RH

storage: -2.5” to 65°C

DIMENSIONS, WEIGHI! 32mm high x 114mm wide x 272mm long (1%” x 4%” x

10%“). Net weight 0.5gkg (20.5 oz.)

ACCBSSORY SUPPLIED; Model 4801 Low Noise Cable

ACCBSSORY AVAILABLG; Model 4804 t&x female to BNC male adapter

Specifications subject to change without notice.

Page 7

TABLE OF CONTENTS

SECTION 1 - GENERAL INFORMATION

1.1

1.2

1.3

1.4

I.5

I.6

Introduction.

warrant\~ Information

Manual.Addenda ....................................

Safety Symbols and Terms ...........................

Unpackmg and lnspectlon ............................

Specifications ........................................

........................................ 1

................................ 1

SECTION 2 - OPERATION

2.1 Introduction .........................................

2.2 Safety Precautions ...................................

2.2.1 High Impedance Considerations

2.2.2 Static Precautions ..................................

2.3 Connections and Cabling .............................

2.4 Installation and Removal .............................

2.5 Operation ..........................................

2.5.1

2.52 Operation Notes ..................................

2.6

Scanner Control of the Channels

Applications. .......................................

.................... 5

................... 11

SECTION 3 - SERVICING INFORMATION

3. I

3.2

3.3

3.4

3.5

3.6

Introduction ........................................

Handling and Cleaning .............................

Relay Replacement ..................................

Recommended Test Equipment

Offset Current Test .................................

Contact Resistance Test ..............................

....................... W

2

2

2

3

5

5

6

6

8

10

18

18

25

25

26

W

29

SECTION 4 - REPLACEABLE PARTS

4.1

4.2

4.3

4.4

4.5

introduction ........................................

Parts Lists .........................................

Ordering Information ...............................

Factory Service .....................................

Component Layout and Schematic Diagram

33

33

33

35

........... 35

Page 8

LIST OF TABLES

SECTION 2 - OPERATION

2-l

2-2

2-3

2-4

2-5

2-6

2-7

Example Channel Assignments in 2-P& Mode. 12

Example Channel Assignments in l-Pole Mode 13

Example Channel Assignments in Matrix (O-Pole)

Mode 14

Scanner Control of Model 7158 4-Pole Mode 15

Scanner Control of Model 7l58 2-Pole Mode 15

Scanner Control of Model 7l58 l-Pole Mode. 16

Scanner Control of Model 7158 Matrix (O-Pole) Mode. 17

SECTION 3 - SERVICING INFORMATION

3-l

Recommended Test Equipment, 27

SECTION 4 - REPLACEABLE PARTS

4-l

4-2

Model 7l58 Electrical Parts. 34

Model 7158 Mechanical Parts 35

iii/iv

Page 9

LIST OF ILLUSTRATIONS

SECTION 2 - OPERATION

2-l Multi-Card Connection. 7

2-2 Installing Card in Model 705, 9

2-3 Installing Card in Model 706.. 10

2-4 Model 7l58 Simplified Schematic, 11

2-5 Capacitor Leakage Schematic 20

2-6

2-7 Measuring Leakages with One

Capacitor Leakage Instrument Setu

Car 23

x ““”

SECTION 3 - SERVICING INFORMATION

., 21

3-l

3-2

3-3 Contact Resistance 31

Offset Current 28

Coax Pigtail Preparation. 30

SECTION 4 - REPLACEABLE PARTS

4-l Model 7l58 Component Layout 36

4-2

Model 7l58 Schematic Diagram 37

v/vi

Page 10

SECTION 1

GENERAL INFORMATION

1.1 INTRODUCTION

The Model 7l58 Low Current Scanner Card has ten channels of paired

single-pole single-throw (SET), normally open (NO) relays. The card

will switch any one of ten signals to one output, or switch one signal

to any one of ten outputs.

Signal HI is connected to signal LO (analog ground) when the scanner

mainframe channel is open, and to output HI when the channel is closed. Signal LO is common to all ten channels and the output. An additional relay isolates all circuitry on the card from the output when no

channel is closed.

Features of the scanner card include:

l Low offset current error (<IpA specified, <30fA typical)

l Switching of AC or DC signals up to lOOmA.

l BNC input and output connectors.

l Two outputs for daisy-chaining of Model 7158 cards.

l Configurable for low current or low voltage switching.

The Model 7l58 is field-installable in the Models 705 and 706 scanner

mainframes.

1.2 WARRANTY INFORMATION

Warranty information is stated on the inside front cover of this manual.

If there is a need for service, contact the Keithley representative or

authorized repair facility in your area. Check the back cover for addresses. The service form supplied at the end of the manual should

be used to provide the service facility with information concerning any

difficulty.

1

Page 11

1.3 MANUAL ADDENDA

Product improvements or changes to this manual will be explained on

an addendum included with the manual. It is recommended that this

information be incorporated immediately into the appropriate ptaces

in the manual.

If an additional instruction manual is required, order the manual

package (Keithley Part Number 7158-901-00). The manual package includes an instruction manual and all pertinent addenda.

1.4 SAFETY SYMBOLS AND TERMS

The symbol A on the card denotes that the user should refer to the

operating instructions.

The WARNING used in this manual explains dangers that could result

in personal injury or death.

The CAUTION used in this manual explains hazards that could damage

the card.

1.5 UNPACKING AND INSPECTION

The Model 7158 was inspected both electrically and mechanically before

shipment. Upon receiving the Model 7l58, unpack all items from the

shippin carton and check for any obvious damage that may have oc-

curred 6: urmg transit. Report any damage to the shipping agent. Re-

tain and use the original packaging materials in case reshipment is

necessary. The following items are shipped with every Model 7158:

Model 7158 Low Current Scanner Card

Model 7l58 Instruction Manual

Model 4801 Low Noise Coax Cable (48 in., supplied accessory)

2

Page 12

The following item is an optional accessory:

Model 4804 Triax (F) to BNC (M) Adapter

1.6 SPECIFICATIONS

Detailed specifications of the Model 7158 precede the Table of Contents

of this manual.

314

Page 13

SECTION 2

OPERATION

2.1 INTRODUCTION

This section contains an operation overview, safety information, connections and cabling information, an installation procedure, operating

instructions, and an application for the card.

2.2 SAFETY PRECAUTIONS

WARNING

Maintain inputs and outputs withln 30V peak of earth

ground. lMn off all power and discharge stored energy in

external cimultry before making or breaklng connections.

1. The maximum signal level is lOOmA peak (30V compliance).

2. Make sure the scanner mainframes are grounded through an earth

grounded receptacle before operation.

3. Inspect all connections for wear and defects such as cracks and exposed wires.

2.2.1 High Impedance Considerations

Because of the high impedance circuits on the card, be careful when

handling it to avoid contamination from such foreign materials as body

oils. Such contamination can substantially lower leakage resistance,

degrading performance.

Handle the card only by the edges. If you remove the relay covers, be

careful not to touch board surfaces or exposed parts.

Page 14

To avoid dirt build-up over a period of time, operate the scanner and

scanner card only in a clean environment. If contamination is suspected,

the card should be carefully cleaned using the procedure given in

paragraph 3.2.

2.2.2 Static Precautions

The card’s IC chips are static-sensitive and can be damaged by static

discharge, rendering the card partially or completely inoperative. For

that reason, be careful not to touch exposed areas of the circuit board

if static is thought to be a problem,

CAUTION

Static discharge to exposed circuits can damage the card

and might invalidate the warranty.

2.3 CONNECTIONS AND CABLING

Signal input and output connections are made with BNC connectors

on the card. The locations for each channel input and the outputs are

indicated on the relay covers. The two output connectors permit multiple Model 7158 cards to be connected together. For example, a 20.channel

scanner system can be connected as shown in Figure 2-l.

In addition to card-to-card connections, the Model 4801 low noise cable

can be used for scanner-to-scanner connections when daisy-chaining

up to five scanner mainframes.

CAUTION CAUTION

Keithley’s Model 7058 low current scanner card has trlax Kelthley’s Model 7058 low current scanner card has trlax

connectors, Be careful not to interchange trlax and BNC connectors, Be careful not to interchange trlax and BNC

connectors to avold damaging them. connectors to avold damaging them.

Caps are provided for all connectors. Unused connectors should be capped to prevent contamination of the insulators, which could degrade

performance.

Page 15

The supplied low noise coax cable has a conductive lubricant (graphite)

to minimize the error current caused by friction between cable insulators

and conductors. This becomes a consideration when measuring current levels in the picoamp range. Since cable flexing due to vibration

and cable expansion and contraction due to temperature fluctuation

cause friction, the signal cables should be fastened to a rigid surface

and not subject to temperature changes. (The temperature changes nor-

mally experienced in laboratory environments are not a problem).

Figure 2-1. Multi-Card Connection

Page 16

2.4 INSTALLATION AND REMOVAL

The procedures to install the Model 7l58 in the Model 705 or 706 Scanners are similar except for the card orientation. See Figure 2-2 for a

Model 705 and Figure 2-3 for a Model 706.

WARNING

Turn off the scanner mainframe and disconnect the power

cord before installing or removing scanner cards.

CAUTION

Leave the Model 7158 In Its anti-static bag until ready for

cabling snd installing to avoid possible static damage.

Once the card is cabled, insert it card edge first into the scanner mainframe by aligning it with the grooves in the appropriate slot. Make sure

it is proper1 seated into the mainframe connector. Push the locking

tabs forwar 1( to the center of the card to lock it in.

To remove a card, first turn off the mainframe and all other equipment

connected to the card. Unfasten the locking tabs on the card by pulling the tabs outward. Grasp the end of the card and carefully pull it

out of the mainframe.

Page 17

I

J

Figure 2-2. Installing Card in Model 705

9

Page 18

Figure 2-3. lnstalllng Card In Model 706

2.5 OPERATION

As shown in Figure 24 for current switching, each channel on the

Model 7158 has a pair of single-pole single-thmw (SKI), normally open

(NO) relays. ‘Ihe relay pair switches signal HI between signal IQ (analog

ground) and output HI. Signal LO (outside shell of the BNC) is common to all channels and outputs in the system.

An additional relay isolates all circuitry on the card from the outputs

when no channel is closed. That is, the isolation relay is open when

all channels are open, and it is closed when any channel is closed,

10

Page 19

The card is designed for scanning current sources: when a channel is

not selected, a current path is maintained through its signal HI to LO

relay. This protects sensitive devices under test from spikes when

switching an ammeter in and out of each circuit.

The Model 7158 can also be configured for voltage switching (schematic

shown in Figure 2-48). This configuration is made possible by remov-

ing the socketed driver chips (Ul and U2) for the channel HI to LO

relay coils. (These chips are static sensitive. See paragraph 3.2 for handl-

ing precautions)

A. Current Swltchlng

6

8. Voltage Switching

Flgure 2-4. Model 7166 Slmpllfled Schematic

- -

11

Page 20

2.5.1 Scanner Control of the Channels

Since the Model 7158 is a lo-channel card, set the scanner to the 2-pole

mode when using theMode 7158 by itself or when intermixing with

other lo-channel cards (such as Models 7056,705& 7OC”, 7066, and 7067).

In the 2-pole mode, each scanner channel controls one channel on one

lo-channel card.

As an example, consider the combination of a Model 7158 and Model

7059. ‘table 2-l shows the scanner and card channel assignments for

a master scanner.

Table 2-l. Example Channel Assignments In 2.Pole Mode

.~.

Card 1 - Model 7158

10 channels

Scanner

Ch. No. Ch. No.

7158 Scanner

Card 2

- Model 7059

10 channels

7059

Ch. No. Ch. No.

001

002

003

004

005

006

007

008

009 9

010 10

The Model 7l58 can be mtxed with cards other than lo-channel cards,

but there are complications when changing the pole mode to support

a mix of card types. When using a Model 7l58 in combination with a

20.channel card, such as the Model 7064, set the scanner to l-pole mode.

In this mode, each scanner channel controls one channel on one

20-channel card. The effect on the Model 7l58 channel assignmen% is

shown in Table 2-2.

1 011

2 012

3 073

ii 014

015

6 016

7 017

8

018

019

020 lo”

1

2

3

4

5

,6

7

8

Page 21

NOTE

In the l-pole scanner mode, close one channel at a time when

using the Model 7158. Otherwise, other channels are closed on

the card and show up on the mainframe display. For example,

close channels 2 and 5, channels 1 and 6 also close.

Table 2-2. Example Channel Asslgnments In l-Pole Mode

Card 1 - Model 7158

r

10 ch; WlS

Scanner

Ch. No. Ch. No.

001

002

003

004

005

006

0”:

009

010

011

012

013

014

015

016

017

018

019

020

7158

3

:

5

5

6

6

7

7

i

;

10

10

I

Card 2

20

Scanner

Ch. No.

021

022

023

024

025

026

027

028

029

030

031

032

033

034

035

036

037

038

039

040

de1 7064

lnels

7064

Ch. No.

1

2

3

4

:

i

9

10

11

12

13

14

15

16

17

:i

20

Next, consider a mix of a lo-channel card

card (Model 7064), and a matrix card (Mode 7052) in a Model 706 scanner mainframe. Since a matrix card is present, the scanner is set to

matrix (O-pole) mode. The scanner crosspoints and card channel

assignments for a master scanner are shown in Table 2-3.

Model 7l58), a 20-channel

\

Page 22

Table 2-3. Example Channel Assignments in Matrix

(O-Pole Mode)

lard 1 - Model ‘7l.V

10 cha

l”“l

els

t c

7158

:h. No.

:

3

4

5

;

8

9

10

706

:rosspoi”l

001,l

002,l

003,l

004,l

005,l

001,2

002.2

003,2

004,2

005.2

Card 2 - Model 7064

20 chal

706

Crosspoints

006.1 007.3

006.1 006,3

007,l 0073

007,l 006,3

008.1 ow,3

008,l 0063

009,l 007,3

009,l 006,3

010.1 007,3

010.1 006,3

006.2 007,3

006,2 006,3

007,2 007,3

00x2 006,3

008,2 0073

008,2 006,3

009,2 007.3

009,2 006,3

010,2 007,3

010.2 006,3

R”l

els

:h. No.

i (

7064

:

3

t

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

kd 3 - h

Colum”!

706

Zrosspoinl

011.1

011,2

011,3

011,4

012,l

012,2

ol2,3

ol2,4

013.1

ol3.2

013.3

013.4

014,l

014.2

014,3

014,4

015.1

015,2

015,3

015,4

Id 7052

, 4 rows

___~

7052

:ohmn,

Row

__~

;*;

113

1.4

2,1

E

214

3.1

3.2

3.3

3.4

4.1

4.2

4,3

4,4

t:

;,3

5,4

When using 20.channel cards in matrix mode, two crosspoints must

be closed for each of the card channels.

in general, the rules for choosing different scanner pole modes are:

matrix (O-pole) - If a matrix card is present.

l-pole - If a 20-channel card is present, but no matrix card.

2-p& - If a lo-channel card is present, but no 20-channel or matrix

cards.

14

Page 23

4.pole - If 4-pole switching is desired with two 2-pole, IO-channel cards.

Tables 2-4 through 2-7 list the scanner channels that conhol Model 7158

channels for all scanner pole configurations.

Table 2-4. Scanner Control of Model 7158 cl-Pole Mode

Scanner

Card No.

1

s

4

2

i

9

10

Table 2-5. Scanner Control of Model 7158 2-Pole Mode

Card No.

1

:

4

5

6

7

8

lo”

Channel No.

01-10

01-10

11-20

11-20

21-30

21-30

31-40

31-40

41-50

41-50

Scanner

Channel No.

01-10

11-20

21-30

31-40

41-50

51-60

61-70

71-80

81.90

91.100

I

7158

Channel No.

l-10

l-10

l-10

l-10

l-10

l-10

l-10

l-10

l-10

l-10

7158

Channel No.

l-10

l-10

l-10

l-10

l-10

l-10

l-10

l-10

l-10

l-10

Scanner

705, 706

705, 706

706

706

706

706

706

706

706

706

Scanner

705, 706

705, 706

706

706

706

706

706

706

706

706

15

Page 24

Table 2-6. Scanner Control of Model 7158 l-Pole Mode

__-

Card 1

Scanner

Ch. No.

Card 2

Scanner

Ch. No.

Card 3

Scanner

Ch. No.

Card 4

Scanner

Ch. No.

Card 5

Scanner

Ch. No.

7258

Ch. No.

01, 02

03, 04

05, 06

07, 08

09, 10

ii32

15: 16

17, 18

19, 20

705, 706

Card 6

Scanner

Ch. No.

101, 102

103, 104

105, 106

107. 108

109, 110

111, 1x2

113, 114

115, 116

117, 118

119, 120

706

21, 22

23, 24

25, 26

27, 28

29, 30

31, 32

33, 34

35, 36

37, 38

39, 40

705, 706

Card 7

Scanner

Ch. No.

121, 122

123, 124

125, 126

127, 128

129,130

131, 132

133,134

135,136

137’ 138

139, 140

706

41, 42

43, 44

45, 46

47, 48

49, 50

51, 52

53, 54

55, 56

57, 58

59, 60

706

Card 8

Scanner

Ch. No.

141, 142

143, 144

145, 146

147. 148

149, 150

151, 152

153, 154

155, 156

157, 158

159, 160

706

61, 62

63, 64

65, 66

6% 68

69, 70

71, 72

73, 74

75, 76

77, 78

79, 80

706

Card 9

Ch. No.

161, 162

163, 164

165, 166

167, 168

169, 170

171, 172

173, 174

175, 176

177, 178

179, 180

706

81, 82

83, 84

85, 86

87, 88

89, 90

91, 92

93, 94

95, 96

97, 98

99, 100

706

Card 10

Scanner

Ch. No.

181, 182

183, 184

185, 186

187, 188

189, 190

191, 192

193, 194

195, 196

197, 198

199, 200

706

1

3’

4

5

6

8’

9

10

Chmio

-L-

:

3

4

5

;

8

9

10

Page 25

Table 2-7. Scanner Control of Model 7158 Matrlx (O-Pole) Mode

1 Card 1

7158

Ch. No.

06, 1 11, 1

07. 1

08, 1 13, 1

09, 1

10, 1 15, 1

06, 2 11, 2

07, 2 12, 2

08, 2 13, 2

12. 1

14, 1

:

3

4

5

r+

8

9

10

Card 6

icanner

:h.

26, 1

27, 1

28, 1

29, 1

30, 1

26, 2

27, 2

28, 2

29, 2

3a

706

Card 7

Scanner

Ch. No.

31, ‘1

32, 1

33, 1

34, 1

35, 1

31, 2

32, 2

33, 2

34, 2

35, 2

706

Card 8

kanner

Ch. No.

36, 1

37’ 1

38, 1

39, 1

40, 1

36, 2

37, 2

38, 2

39, 2

40,

706

Card 9

Scanner

Ch. No.

41, 1

42, 1

43, 1

44 1

45, 1

41, 2

42, 2

43, 2

44 2

45, 2

706

Card 10

Scanner

Ch. No.

46, 1

47. 1

4% 1

49, 1

50, 1

46, 2

47, 2

‘Ia 2

49, 2

50, 2

706

I

n.58

:h. No.

1

2

3

4

5

6

7

8

9

10

17

Page 26

2.5.2 Operation Notes

1. Extreme environmental conditions can cause the offset current to

exceed the 1pA specification. If the card has been exposed to high

humidity and/or temperahue (for example during shipping), stabilize

the board within the specified environmental limits for 24 hours.

2. When a channel is opened or closed, there is a charge transfer in

the picocoulomb range. This is because of the mechanical release

or closure of the contacts, the contact to coil capacitance, and the

stray capacitance between signal and relay drive lines. The charge

transfer causes a current pulse. The effect on the signal depends on

the magnitude of the source being measured.

3. Each relay on the Model 7158 draws lOmA. For current switching,

there are either ten or eleven relays energized with any combination

of open and closed channels. The maximum current draw of one

card from the mainframe power supply is 1lOmA. (For voltage switching, there are between zero and eleven relays energized for any

open/closed channel combination.) There are no restrictions on the

maximum number of simultaneous channel closures unless relays

from other card types are energized at the same time.

4. System response is affected by cable capacitance. This should be considered when the sources are connected to the scanner. Use of a feedback ammeter (or an electrometer in the FAST mode) for currents

below 10~‘A is recommended to increase measurement speed and

decrease the effects of cable capacitance.

5. Power Limits - To prevent overheating or damage to the relay contacts, never exceed the signal level specifications of the card. Maximum switched and carry current and voltage levels are lOOmA, 30V.

The card can switch low power AC (typical bandwidth up to lMHz).

Maximum switched and carry current and voltage levels are lOOmA,

3OV, peak (resistive loads).

6. Switching Speed -Relay actuation time is lmsec maximum plus the

mainframe programming time. Maximum relay switching rate is 100

cycles per second (10msec). This is the maximum rate of the scanner mainframe. For extended relay life, use low power or cold switching (turn on sources after the channel is closed).

2.6 APPLICATIONS

The Model 7158 can be used in a variety of applications to switch low

18

Page 27

current levels. Typical appltcations include those where sourcing voltage

and measuring current are required, such as:

l Leakage currents (e.g. capacitor, FET gate)

l PCB test coupons

l Materials research and characterization

l Semiconductor sub-threshold current

Voltage applications include those where the Model 7158 can be used

to switch a single-pole of low voltage sources. (Refer to the application

example that follows.)

When measuring low currents, the following sources of noise current

should be considered:

l Triboelectric currents are caused by friction behveen a conductor and

insulator when a coax cable flexes due to vibration or temperature

fluctuation. To minimize, use low noise cables and tie down to a rigid

surface.

l Piezoelechic currents are caused by mechanical stress to the insulating

materials of connectors. Remove the stress from the insulators and

use material with low piezoelectric effects to minimize.

l Electrochemical effects generate current between PCB conductors due

to contamination of the card surface. To minimize, handle the card

by the edges only and follow the cleaning instructions in paragraph

3.2.

For a specific application, consider measuring capacitor leakage current to calculate insulation resistance. The amount of leakage current

depends on the capacitor dielectric material as well as the applied

voltage. The schematic of Figure 2-5 shows a Model 705517056 card on

the source side, but a Model 7158 could be used in its voltage configmation when the test voltage does not exceed 3OV.

The configuration shown is the direct method of measuring leakage

currents: a feedback type picoammeter in series with the capacitor

under test. This test is fully explained (including controlling software

19

Page 28

and test fixture construction) in Application Note #l20, “Capacitor

Leakage Measurements”,

NOTE

The indirect method, with a voltmeter reading the voltage drop

across a resistor in series with the capacitor, is recommended

for capacitor values above l@ to maintain stability and noise

performance.

The instrument setup is shown in Figure 2-6. For clarity, only four channels are shown. Obviously, all ten channels are available for testing

purposes.

r----

--7-----1

Figure 2-5. Capacitor Leakage Schematic

20

Page 29

Figure 2-6. Capacitor Leakage Instrument Setup

The internal voltage source of a Model 617 electrometer stagger charges

the capacitors when the corresponding channels are closed on a Model

7056 general purpose card. (At this time, the signal HI to Lo relay on

21

Page 30

the Model 7158 is closed, completing the circuit.) Resistor Rl is needed

to limit current in case the capacitor is shorted and it also helps reduce

noise.

After each capacitor is fully charged (usually 10 times RlC), the Model

7I58 channel is programmed to close. This switches in the Model 617

for reading current or resistance (V/I mode).

Once the Model 617 has settled and the measurement is taken, the

Model 7l58 channel is opened and the signal HI to LO relay closes to

shunt the current to ground. Then the Model 7056 channel is opened

to avoid a current surge through the electrometer and resistors Rl and

R2 bleed off the capacitor charge.

With this two-card configuration, the capacitors have equal soak times.

This is important when comparing low leakage levels (picoamps).

Having equivalent soak times is not as critical at higher leakage levels

(e.g. the nanoamp range of tantalum capacitors). In this case, the onecard configuration shown in Figure 2-7 is sufficient. Since the settling

time of the Model 617 is less when measuring higher currents, the channels can be switched faster.

22

Page 31

-- --

------- -------

SHlELDED TEST FIXTURE SHlELDED TEST FIXTURE

Figure 2-7. Maasurlng Leakages wlth One Card Figure 2-7. Maasurlng Leakages wlth One Card

23/24

Page 32

SECTION 3

SERVICING INFORMATION

3.1 INTRODUCTION

‘This section describes tests for verifying the performance of the Model

7158. Perform these tests in an environment of 18’C to 28’C up to 70%

RH.

Because of the low signal levels measured in these tests, the test cables

should be kept as still as possible to help minimize noise.

Recommended maintenance includes inspection of the card and the

card edge connector to ensure good electrical contact.

3.2 HANDLING AND CLEANING

Because of the high impedance of the board, take special care when

handling and using to prevent degradation of performance. Handle the

board by the edges to avoid contaminating it with dirt, body oil, etc.

CMOS and other high-impedance devices are subject to possible static

discharge damage because of the high impedance levels involved. When

handling such devices (indicated by * in the parts list), use the follow-

ing precautions:

1. Such devices should be transported and handled onl in containers

specially designed to prevent or dissipate static bull -up. Typically, ,J

these devices will be received in anti-static containers of plastic or

foam. Keep these parts in their original containers until ready for

installation.

2. Remove the devices from their protective containers only at a

grounded work station. Also, ground yourself with a suita

strap.

roperly

le wrwt

IT

25

Page 33

3. Handle the devices only by the body; do not touch the pins.

4. Any printed circuit board into which the device is to be inserted must

also be grounded to the bench or table.

5. Use only anti-static de-soldering tools and grounded-tip soldering

irons.

Before cleaning the board, remove the front and rear relay covers. Clean

the board with cotton swabs or a soft brush saturated with an uncontaminated solvent, .such as Freon@ TMS or TE. After the solvent has

been applied and is still liquid, blow-dry the board with dry-pumped

nitrogen gas.

3.3 RELAY REPLACEMENT

If you have determined that a relay is defective, use the following procedure to replace it:

1. Remove the screws that secure the appropriate relay cover and remove

the cover.

2. Unsolder the defective relay and clean the card holes with a desoldering tool or wick. Solder in a replacement relay.

3. Clean the card according to the method given in paragraph 3.2 us-

ing localized cleaning only, then reinstall relay covers.

26

Page 34

3.4 RECOMMENDED TEST EQUIPMENT

Table 3-1 lists recommended test equipment for performance verifici

tion. Other test equipment may be substituted if specifications equa

or exceed those stated.

Table 3-l. Recommended Test Equipment

Description

--

Scanner Mainframe

Extender Card

Low Noise Coax Cable

Electrometer

‘l’riax to BNC Adapter

Ohmmeter-DMM

Kelvin Test Leads

~___

Specification

-

-

4 feet long

10.“A sensitivity

<la sensitivity

-

KeithleG 196

Keithley 5806

3.5 OFFSET CURRENT TEST

This test verifies that the offset current for each channel is within

specification.

27

Page 35

1. Set up the equipment as shown in Figure 3-l with caps on all inputs

and the unused output.

2. Insert the card,into the mainframe.

3. Set the electrometer to the 2pA range and zero check.

4. Turn on the mainframe and close channel 1.

5. Zero correct the Model 677 and release its zero check. Note the offset current long enough to allow the switching transients to decay

and the current to stabdize. The current indicated by the electrometer

should be less than lpA, exclusive of noise. Open the channel after

taking the reading.

6. Close the remaining channels one at a time and repeat step 5.

28

Figure 3-1. Offset Current

Page 36

3.6 CONTACT RESISTANCE TEST

This test verifies that the contact resistance of the relays does not ex-

ceed the specification. The procedure is in three parts:

l Setting up equipment.

l Checking contacts of signal HI to LO relays (when channel is open).

l Checking contacts of signal HI to output HI relays in combination

with the isolation relay (when channel is closed).

Setting Up Equipment

1. Turn on the Model 196 DMM and let it warm up (two hours if from

cold-start).

2. Using the following procedure, k repare two BNC male connectors

with coax pigtails as shown in Igore 3-2.

l Use an X-acto” knife to cut and strip 1% inches of outer insula-

tion without cutting the shield.

l With the knife point, unravel the braided shield and twist it off

to the side.

l Strip one inch of insulation off the center conductor.

3. Connect the Model 7158 to the scanner through the Model 7061

Universal Adapter Card, which is used as an extender to allow access to all connectors.

4. Select the 3OOa range on the Model 196. Temporarily short the test

leads and zero the instrument. Leave zero enabled for the duration

of the test.

Checking Signal HI to LO Relays

5. Connect one of the BNC plugs to an input connector on the card.

Connect the Kelvin leads to the coax pigtail as shown in Figure 3-3A.

6. $th all channels open, verify that the contact resistance is less than

7. Verify the resistance of the remaining signal HI to LO relays by just

moving the BNC plug and Kelvin leads to the remaining input connectors and taking readings.

29

Page 37

Flgure 3-2. Coax Plgtalt Preparatlon

Checking Signal HI to Output HI Relays and Isolation Relay

8. Connect one of the BNC plugs to an input connector and the other

BNC plug to an output connector. Connect the Kelvin leads to the

coax pigtails as shown in Figure 3-38.

9. Program the scanner to close the channel being tested. This closes

both the signal HI to output HI relay and the isolation relay for

measuring.

IO. Verify that the contact resistance of the relay combination (signal

HI to LO relay and isolation relay) is less than 1% Open the channel after taking the reading.

30

Page 38

11. Continue with the remaining channels by leaving one BNC plug

on the output connector and moving the other BNC plug and Kelvin

leads to the remaining input connectors. Take readings with the ap-

propriate channel closed.

Flgure 3-3A. Contact Resistance (Slgnal HI to LO Relays)

31

Page 39

Figure 3-38. Contact Resistance (Signal HI to Output HI

Relays)

32

Page 40

SECTION 4

REPLACEABLE PARTS

4.1 INTRODUCTION

This section contains replacement parts information, a component

layout, and a schematic diagram for the Model ?l5g.

4.2 PARTS LISTS

Electrical parts are listed in order of circuit designation in Table 4-l. Table

4-2 summarizes mechanical parts.

4.3 ORDERING INFORMATION

To place a parts order or to obtain information about replacement parts,

contact your Keithley representative or the factory. See the back cover

for addresses. When ordering parts, be sure to include the following

information:

l Scanner card model number (7158)

l Card serial number

l Part description

l Circuit description (if applicable)

l Keithley part number

33

Page 41

Table 4-1. Model 7158 Electrlcal Parts

Circuit

Desig.

Cl

C2-C5

11-112

Kl-K21

RI-RIO

Rll

R12, Rl.3

R14

TE3, TE4,

TE6, TE7,

TEll, TEl

Ul, u2*

u3, u4*

u5*

Sch

Keithley

Description

Capacitor, IOpF, 25V, Aluminum

LOC

-

Al

Part No.

c-314-10

Electrolytic

SW

Capacitor, 0.M 5OV, Ceramic Film

Connector, Coaxial Female

Relay, SI’ST

Resistor, 330kQ, 5%, NW, Carbon

C-237-.1

sev

CS-249

RL70

se” R-76.330k

Composition

Not used

Resistor, 10kfI. 5%. ‘hW, Carbon

82 R-76.1Ok

Composition

Resistor Network, lOkB, 2%, 1.5W,

TF-39

Thick Film

Terminal, Teflon@

sev TE-105-1

IC, Buffer/Line Driver and Receiver, sev IC-520

74HC241

IC, Hex Inverter, 74HC04

sev IC-354

IC, Mnput NAND Gate, 74HCl33 Bl IC-547

Wl

Cable Assembly

Sockets (2) 1

c4 n5a-wo

50-84-20

#18 AWG Bare Buss Wire

X22 AWG Bare Buss Wire

#22 AWG Natural Thinwall Teflon@

Tubing

*These parts are static sensitive. See paragraph 3.2 for handling

precautions.

34

Page 42

Table 4-2. Model 7155 Mechanlcal Parts

Keithley

.!2!F

1

1

1

1

12

5

6

Description

Bracket, Front Connector Mounting

(CHS-CHlO)

Bracket, Rear Connector Mounting

(CHl-CH4, OUTPUT)

Cable Clamp cc-38-4

Cover, Front Relay (CHS-CHlO) 7158-307

Cover, Rear Relay (CHl-CH4, OUTPUT) 7158-304

Protective Cap (for BNC jacks)

#4-40 x 3116 Phillips pan head sems screw (for

bracket mounting)

#6-32 x l/4 Phillips pan head sems screw (for

cover mounting)

Part No.

7158-303

7158-302

CAP-18

4.4 FACTORY SERVICE

If the scanner card is to be returned to Keithley Instruments for repair,

perform the following:

1. Photocopy and complete the service form at the back of this manual

and include it with the card.

2. Carefully pack the card in the original packing carton.

3. Write ATTENTION REPAIR DEPARTMENT on the shipping label.

Note that it is not necessary to return the scanner mainframe with the

card.

4.5 COMPONENT LAYOUT and SCHEMATIC DIAGRAM

Figure 4-l shows a component layout of the Model 7I58. Figure 4-2

shows a schematic diagram of the Model 7l58.

35

Page 43

Page 44

Page 45

Service Form

Page 46

Keithley Instruments, Inc.

Test Instrumentation Group

28775 Aurora Road

Cleveland, Ohio 44139

Printed in the U.S.A.

Loading...

Loading...