Page 1

INSTRUCTION MANUAL

MODEL 153

MICROVOLT-AMMETER

@COPYRIGHT 1974

J+ZEITHLEY INSTRUMENTS. INC.

Page 2

CONTENTS

MODEL 153

SECTION

SPfTCIFICATIONS __-_-_____---__________________--

GENERAL DESCRIPTION _____--______-______----

1.

(-,pE~TION _______-__---______---------------

2.

APPLICATIONS __-______-__-_______-----------

3.

CIRCUIT DESCRIPTION ___-_______________-----

4.

SERVICING __-_____-___________-------------

5.

C&IBuTION _--_________--________--__-_---

6.

ACCESSORIES -_--___________--_______________

7.

REpuCpygjLE PARTS -------------------------

8.

SCHpJ.fATIC _____-_______-__-------------------

PAGE

iv

3

12

13

17

23

33

37

45

1174

Page 3

MODEL 153

ILLLlSTRATIO!&

ILLUSTRATIONS

'i . Vo . .

Title

1 Model 153 Front Panel. ______________-_-_-_------------------2

Front pane1 Controls. -______----_---___--_----------------------

3 Rear panel Terminals. --___----_________--_____---------------_4 Thermal Sink Construction. _--___-_______-_____------------------

5 Using Model 153 with 4-Terminal Connections. ----_--------__-----

6

Null Circuit and Leeds and Northrup K3 Potentiometer. ----------7 Diagram Showing Currents in Solid State Circuits. --------------8 Circuit for Semiconductor Resistivity Measurements. ----- -------9 Model 153 Block Diagram. ____-___-___________________________

10 Wave Form at Junction of Diodes D301 and 0302. ----------------11

Wave Form at Junction of Resistor R302 and Capacitor C302B.

12 Wave Form at -13 Volt Supply. __--____________---_---------------13 Divider Connection for Multivibrator Frequency Adjustment. ------14 Wave Form of Multivibrator Output. --------------------------

15

lb

17

Wave Form for Tuned Multivibrator Output Across Resistor R121. ---

Wave Form for Input Modulator ElOl.

----------------------------

Demodulator Wave Form for Full-Scale Input on l-Volt Range.

18 Typical Model 153 Drift Chart. _____-_-_____-___-__----------19

20 Model 153 Inter&,=. __-_______--______-___----------------------21

22

23

24

25

26

27

28

29

30

31

32

33

Model 153 Interior. ----__--------_-_--------------------------

Capacitor, Tube, Battery, and Modulator Locations on PC-lob. -----

Resistor Locations on Printed Circuit Board PC-lob. ---- - ----- --

Component Locations for Printed Circuit Board PC-107.

_--_____Component Locations on Model 153 Rear Chassis Panel. ---- ----- -Component Locations on Range Switch Sl.

component Locations on Range Switch Sl.

-_------__------------_____-______-_-___-_---

Component Locations for Model 153 Power Supply and Multivibrator.

Keithley Instruments Model 1531 Gripping Probe. -_--_---_-e-s-Keithley Instruments Model 1532 Test Leads. ----___-----------Keithley Instruments Model 1533 Mating Connector. -------------Model 1483 Low-Thermal Connection Kit. _____-______________---Keithley Instruments Model 6012 Triaxial-to-Coaxial Adapter. _---Exploded View of Model 4005 Rack Mounting

Kit. ___-_____-____----

------

-----

Pap*

7

4

5

10

11

1:

12

12

13

16

18

18

20

20

20

20

21

25

26

27

28

29

30

30

31

31

32

33

33

33

34

34

35

1174

iii

Page 4

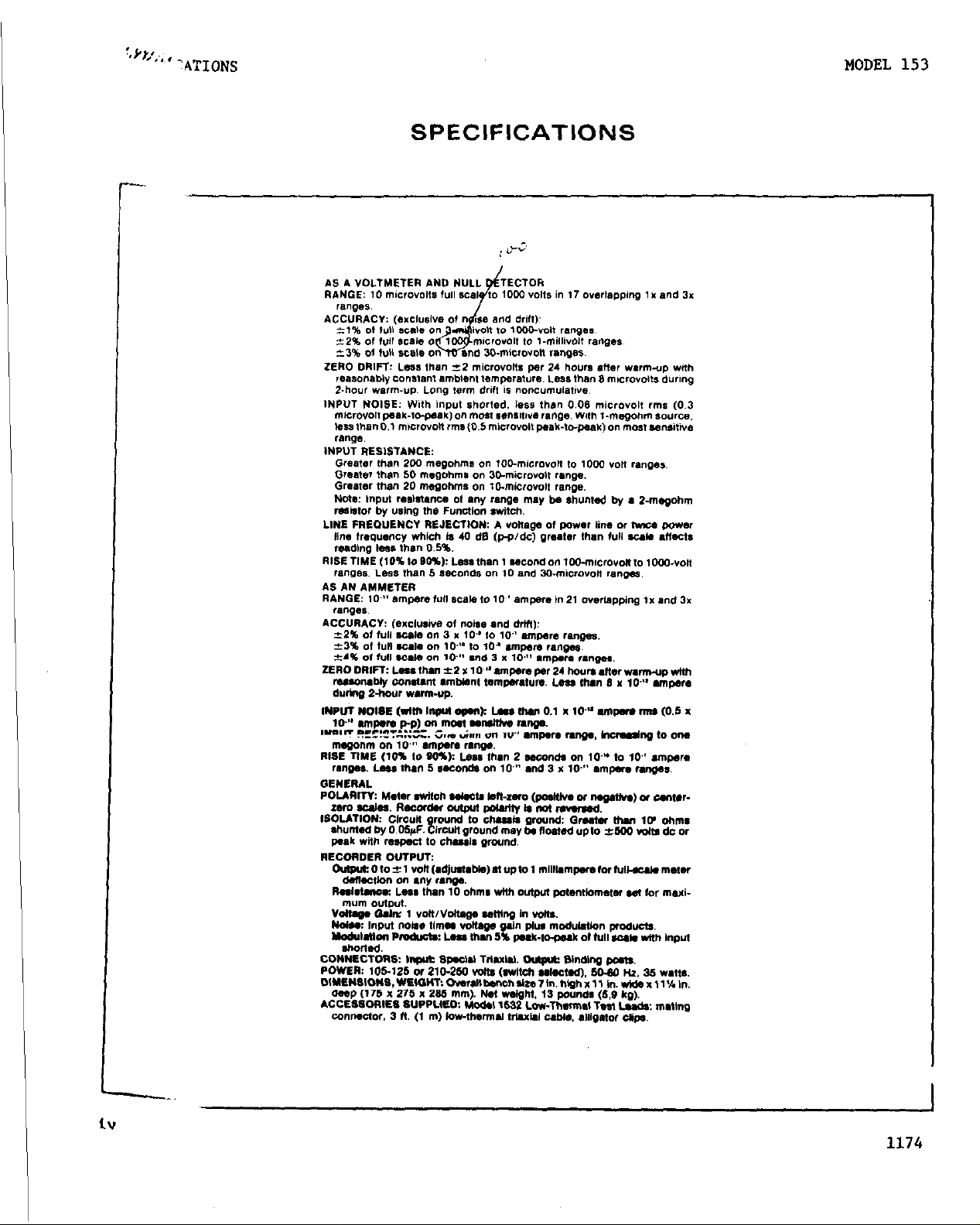

SPECIFICATIONS

MODEL 153

Page 5

KEITHLEY INSTRUMENTS.

INSTRUCTION MANUAL

CHANGE NOTICE

MODEL 153 MICROVOLT-AMMETER

INTRODUCTION: Since Keithley Instruments is continually improving pro-

duct performance and reliability, it is often necessary to make changes

to Instruction Manuals to reflect these improvements. Also, errors in

Instruction Manuals occasionally occur that require changes. Sometimes,

due to printing lead time and shipping requirements, we can't get these

changes immediately into printed Manuals. The following new change in-

formation is supplied as a supplement to this Manual in order to provide

the user with the latest improvements and corrections in the shortest

possible time.

to a Manual to minimize user error.

cated

Page 41, Replaceable Parts, Resistors should read as follows:

R172

R173

Pages 38 s 39, Replaceable Parts, Diodes, should read as follows:

D303

D304

in italics.

9.9kn O.l%, 1/3w w

100 n

Rectifier, l.OA, 8OOV lN4006

Rectifier, l.OA, 6OOV IN4006

Many users will transfer this change information directly

All changes or additions are indi-

O-l%, 1/3w w

15909

15909 1250-100R

1250-9.9KR

R-110-9.9??

R-110-100

MOT RF-38

MOT RF-38

I LN c.

22

22

27

27

Page 6

MODEL 153

GENERAL DESCRIPTIO1i

SECTION 1.

l-l. GENIZAL.

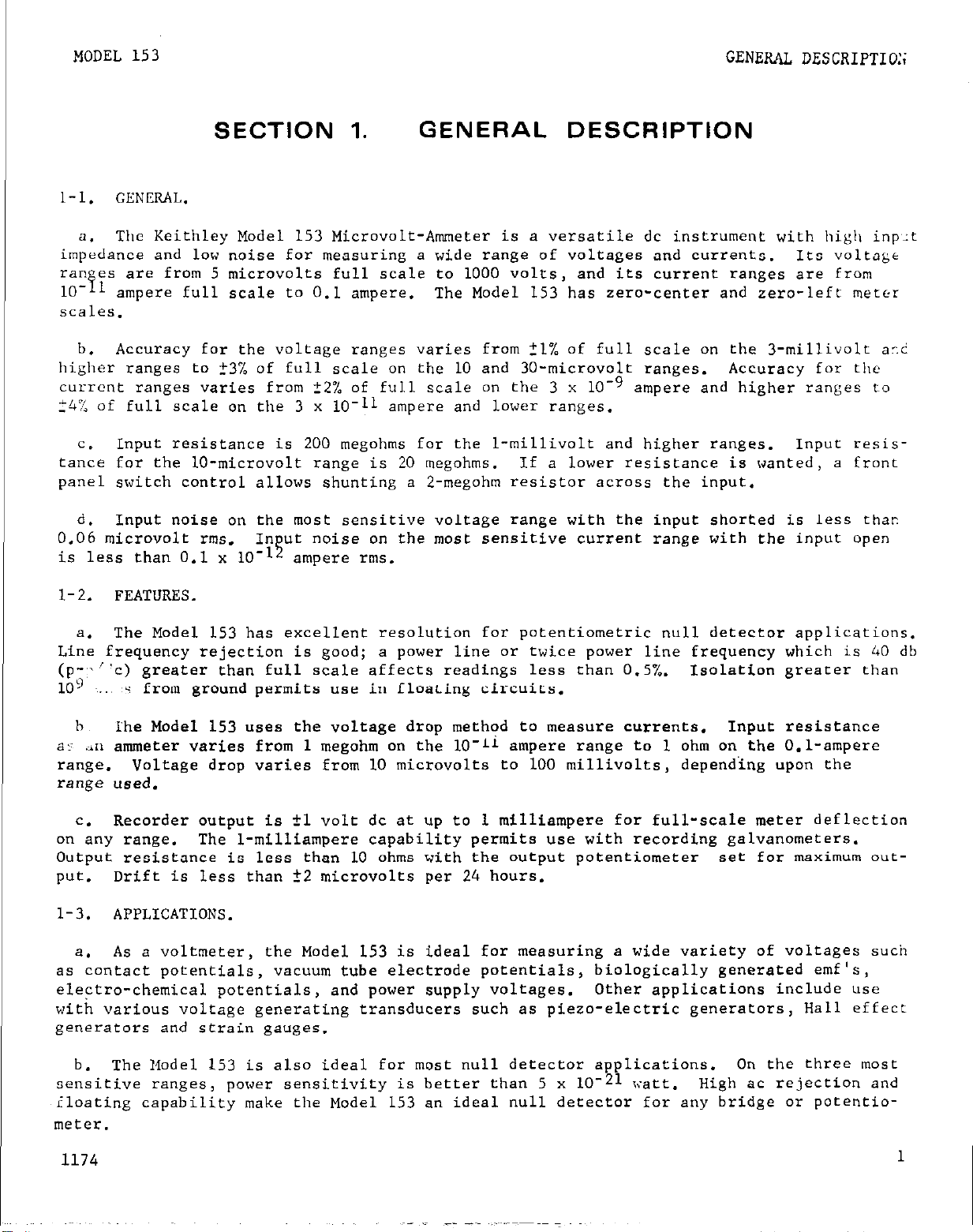

The Keithley Model 153 Microvolt-Ammeter is a versatile dc instrument with high inp,:t

a.

impedance and low noise for measuring a wide range of voltages and currents.

ranyes are from 5 microvolts full scale to 1000 volts, and its current ranges are from

?l

lo-

scales.

higher ranges to ?3% of full scale on the 10 and 30-microvolt ranges.

current ranges varies from +2% of full scale on the 3 x 10v9

24% of full scale on the 3 x lo-11 ampere and lower ranges.

tance for the lo-microvolt range is 20 megohms. If a lower resistance is wanted, a front

panel switch control allows shunting a 2-megohm resistor across the input.

0.06 microvolt rms. In ut noise on the most sensitive current range with the input open

is less than 0.1 x lo-

ampere full scale to 0.1 ampere.

Accuracy for the voltage ranges varies from 21% of full scale on the 3-millivolt a-.?

b.

Input resistance is 200 megohms for the l-millivolt and higher ranges. Input resis-

c.

Input noise on the most sensitive voltage range with the input shorted is less thar.

d.

13

ampere rms.

GENERAL DESCRIPTION

Its voltage

The Model 153 has zero-center and zero-left meter

Accuracy for tjle

ampere and higher ranges to

1-2.

Line frequency rejection is good; a power line or twice power line frequency which is 40 db

(p-:~“c) greater than full scale affects readings less than 0.5%. Isolation greater than

10') -..,~s from ground permits use in floating circuits.

a:: .in ammeter varies from 1 megohm on the lo-L1 ampere range to 1 ohm on the O.l-ampere

range. Voltage drop varies from 10 microvolts to 100 millivolts, depending upon the

range used.

on any range. The l-milliampere capability permits use with recording galvanometers.

Output resistance is less than 10 ohms with the output potentiometer set for maximum out-

put.

l-3. APPLICATIONS.

as contact potentials, vacuum tube electrode potentials,

electro-chemical potentials, and power supply voltages.

with various voltage generating transducers such as piezo-electric generators, Hall effect

generators and strain gauges.

FEATURES.

The Model 153 has excellent resolution for potentiometric null detector applications.

a.

h

The Model 153 uses the voltage drop method to measure currents.

Recorder output is fl volt dc at up to 1 milliampere for full-scale meter deflection

=.

Drift is less than +2 microvolts per 24 hours.

As a voltmeter, the Model 153 is ideal for measuring a wide variety of voltages such

a.

biologically generated emf's,

Other applications include use

Input resistance

The Model 153 is also ideal for most null detector applications.

b.

sensitive ranges, power sensitivity is better than 5 x lo-21 wtt.

~iloating capability make the Model 153 an ideal null detector for any bridge or potentio-

meter.

1174

On the three most

High ac rejection and

1

Page 7

I

GENERAL DESCRIPTION

MODEL 153

2

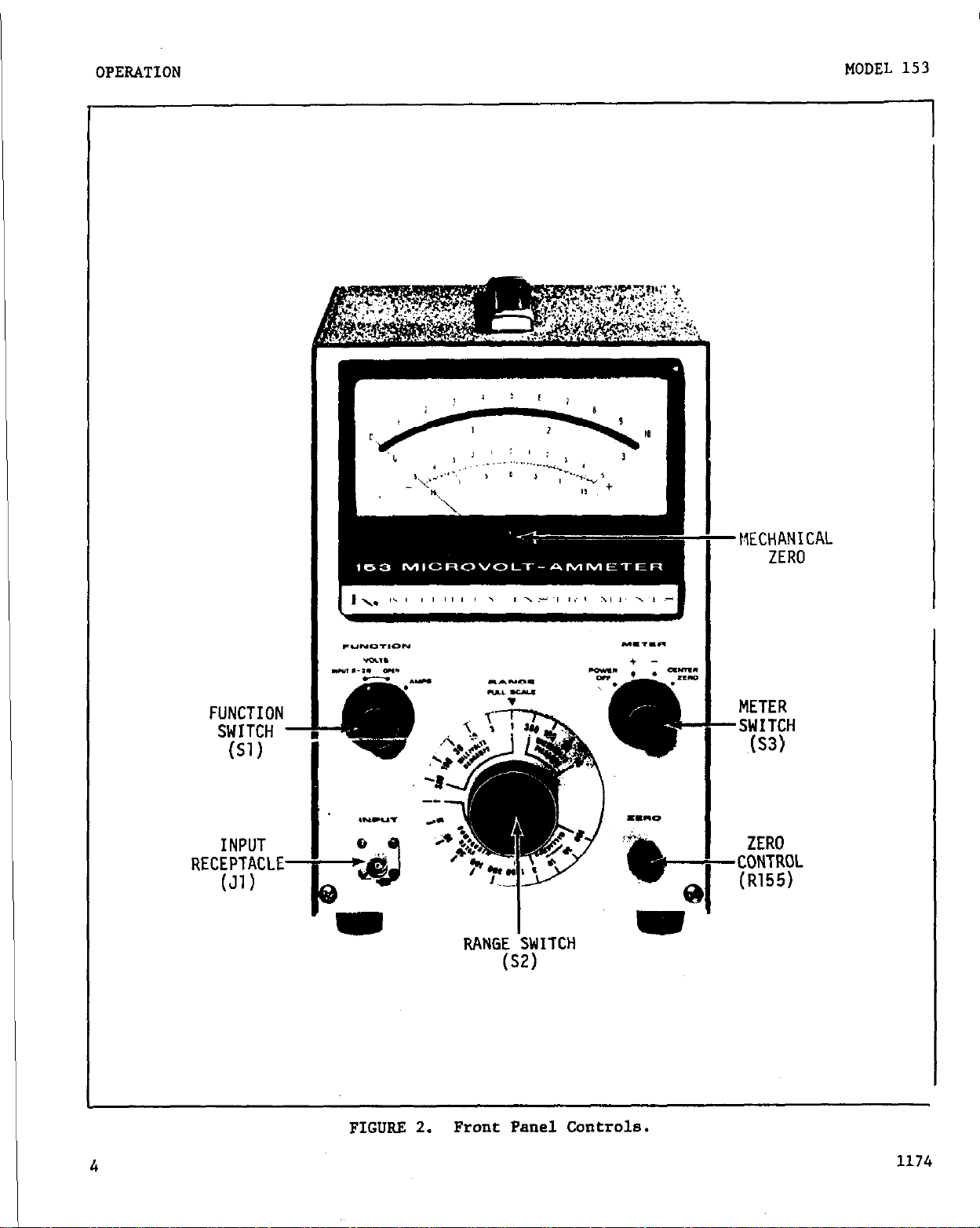

FIGURE 1,

Model 153 Front Panel.

1174

Page 8

MODEL 153

OPERATION

SECTION 2. OPERATION

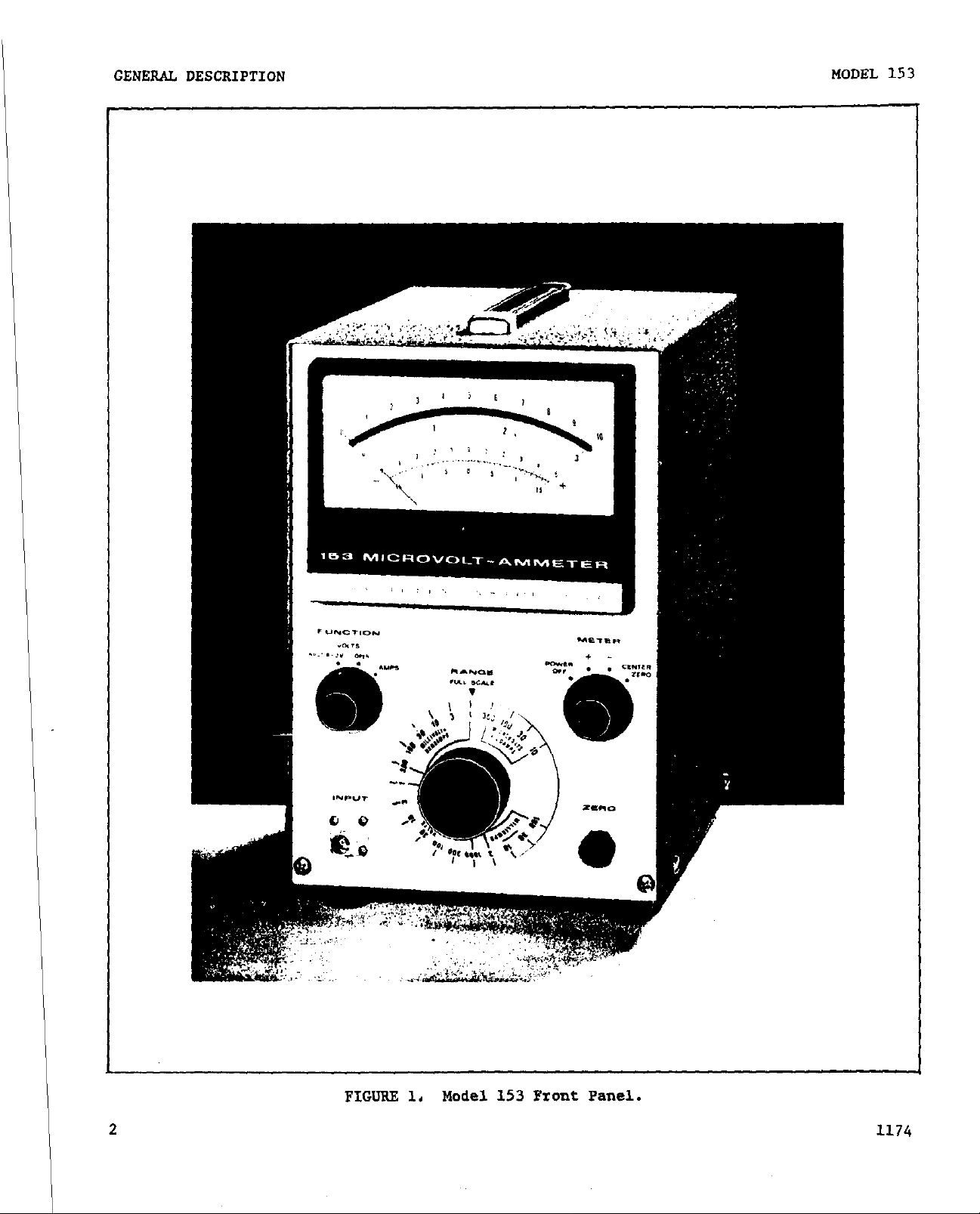

2-1. FRONT PANEL CONTROLS AND TERNINALS.

a. METER Switch. The METER Switch has four positions. POWER OFF shuts off the in-

strument; this also short circuits the meter,

ment.

for center zero operation (lower meter scales).

b.

and one for current inputs. In the VOLTS INPUT R-2M position,

proximately 2 megohms.

mum for the range being used.

tions as an ammeter.

c.

one of 17 voltage and 21 current ranges.

to full-scale deflection for the range selected with the RANGE Switch.

METER + and METER - determine meter polarity.

FUNCTION Switch. The FUNCTION Switch has three positions, two for voltage inputs

In the VOLTS R-OPEN position, input resistance is at the maxi-

(See Table 1.) In the AMPS position, the Model 153 func-

RANGE Switch. The RANGE Switch selects the full-scale instrument sensitivity for

allowing accurate mechanical zero adjust-

CENTER ZERO sets the instrument

input resistance is ap-

The 10 or 3 of the top meter scale corresponds

d. ZERO Control.

20 microvolts,

higher ranges use a 1OOO:l divider,

range.

e. INPUT Receptacle. The INPUT Receptacle is a Teflon-insulated Triaxial type con-

nector. Its center terminal is the circuit high; the inner shield is circuit low (circuit ground); the outer shield is chassis ground.

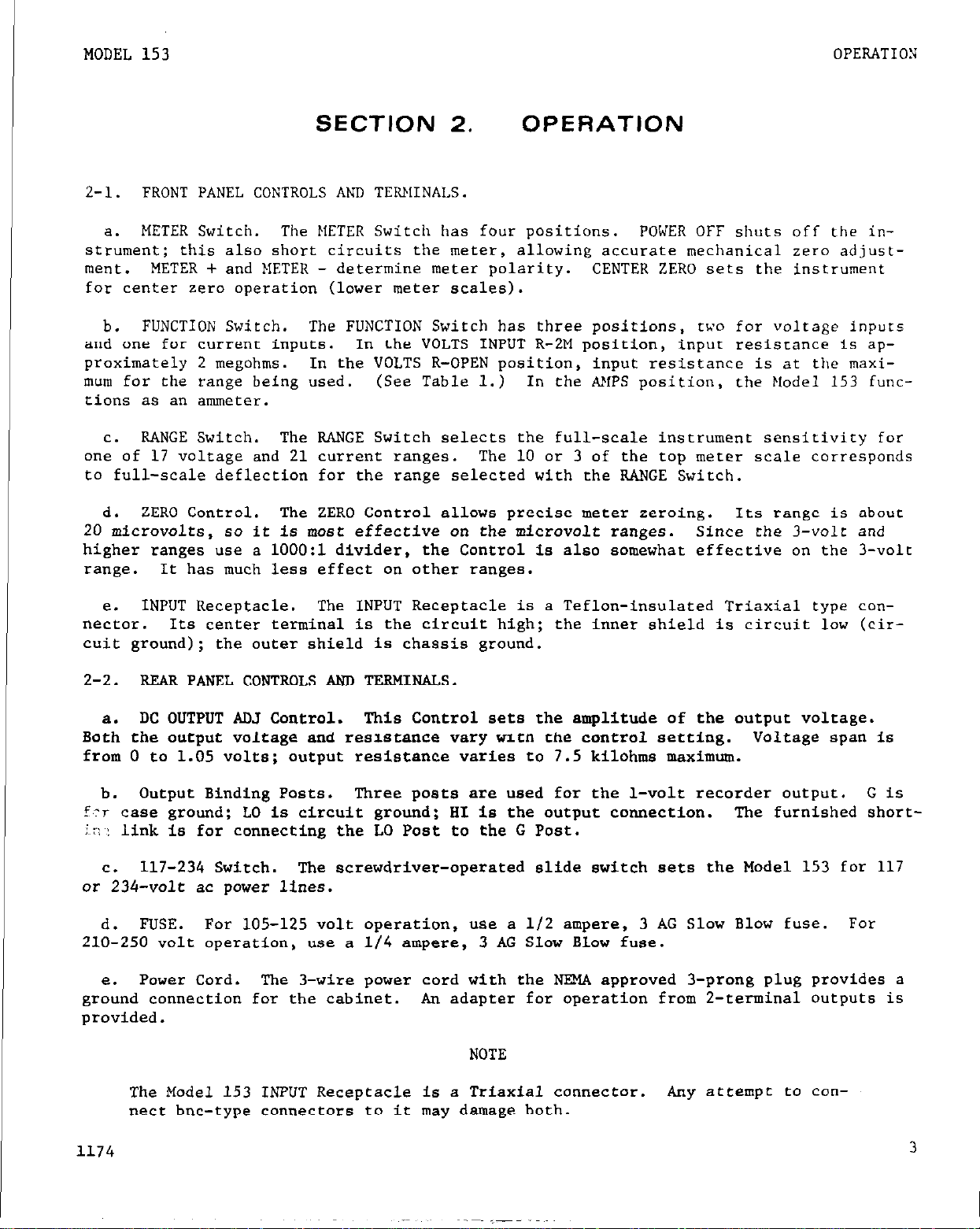

2-2.

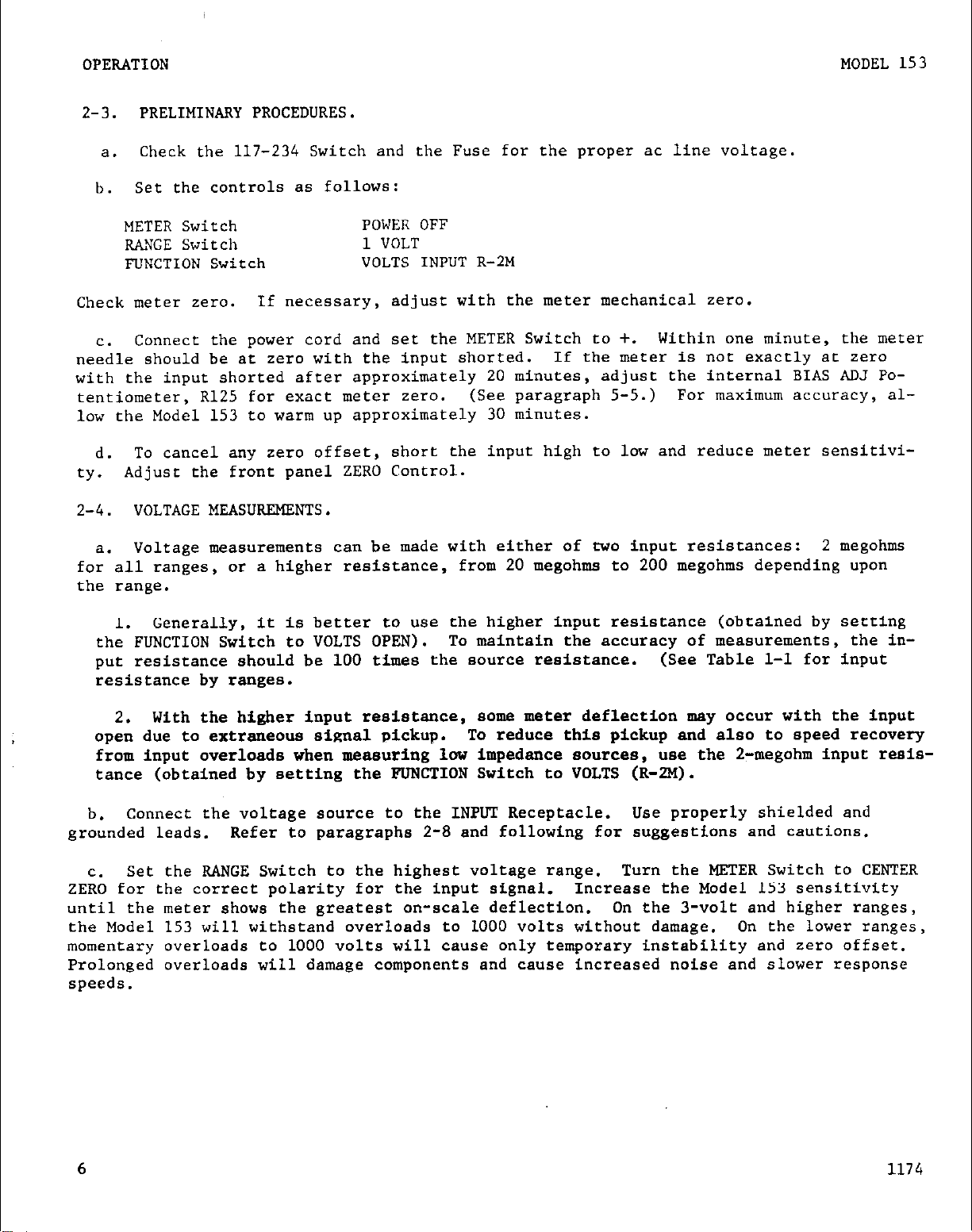

a. DC OUTPUT ADJ Control.

Both the output

from 0 to 1.05 volts; output resistance varies to 7.5 kilohme maximum.

b. Output Binding Posts.

f;r case ground; LO is circuit ground; HI is the output connection.

!-:: link is for connecting the LO Post to the G Post.

C. 117-234 Switch. The screwdriver-operated slide switch sets the Model 153 for 117

or 234-volt ac power lines.

d.

210-250 volt operation, use a l/4 ampere, 3 AG Slow Blow fuse.

It has much less effect on other ranges.

REAR PANEL CONTROLS AND TERMINALS.

FUSE. For 105-125 volt operation, use a l/2 ampere, 3 AG Slow Blow fuse.

so it is most effective on the microvolt ranges. Since the II-volt and

voltage

The ZERO Control allows precise meter zeroing. Its range is about

the Control is also somewhat effective on the 3-volt

This Control sets the amplitude of the output voltage.

and reszstance vary wxtn the control setting. Voltage span is

Three posts are used for the l-volt recorder output. G is

The furnished short-

For

e. Power Cord. The 3-wire power cord with the NEMA approved 3-prong plug provides a

ground connection for the cabinet. An adapter for operation from 2-terminal outputs is

provided.

NOTE

The Model 153 INPUT Receptacle is a Triaxial connector.

nect bnc-type connectors to it may damage both.

1174

Any attempt to con-

3

Page 9

OPERATION

MODEL 153

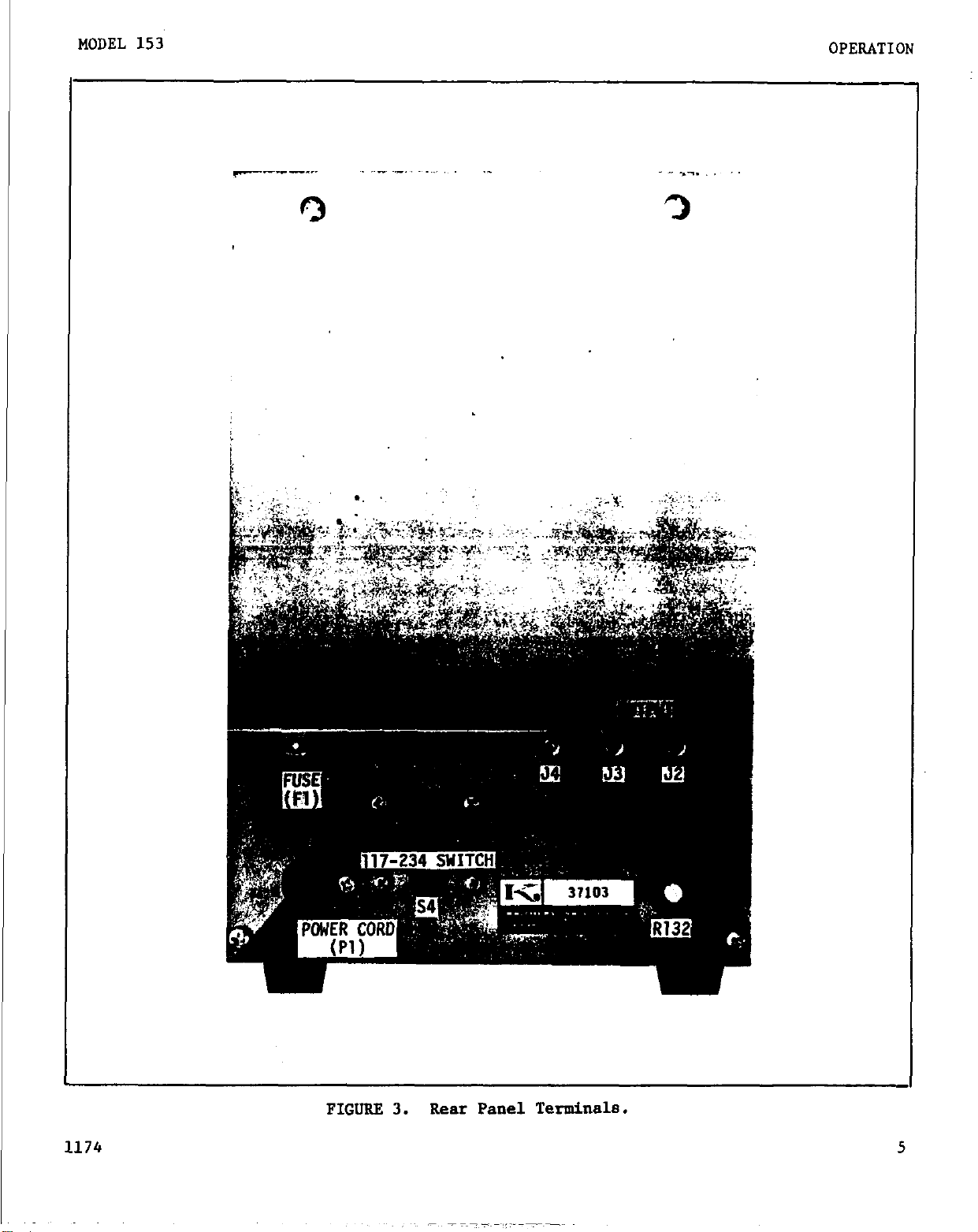

FUNCTION

SWITCH -

(S1)

INPUT

RECEPTACLE-

(Jl)

-MECHANICAL

ZERO

METER

-SWITCH

.(S3)

ZERO

-CONTROL

(R155)

I I

RANGE SWITCH

(S2)

FIGURE 2.

Front Panel Controls.

Page 10

I

MODEL 153

OPERATION

- ..-. ,.

3

FIGURE 3.

Rear Panel Terminals.

Page 11

OPERATION MODEL 153

2-3. PRELIMINARY PROCEDURES.

Check the 117-234 Switch and the Fuse for the proper ac line voltage.

a.

Set the controls as follows:

b.

METER Switch

POWER OFF

RANGE Switch 1 VOLT

FUNCTION Switch

Check meter zero.

Connect the power cord and set the METER Switch to +.

C.

If necessary,

needle should be at zero with the input shorted.

VOLTS INPUT R-2M

adjust with the meter mechanical zero.

If the meter is not exactly at zero

with the input shorted after approximately 20 minutes,

tentiometer, R125 for exact meter zero.

(See paragraph 5-5.) For maximum accuracy, al-

low the Model 153 to warm up approximately 30 minutes.

To cancel any zero offset,

d.

Adjust the front panel ZERO Control.

ty.

2-4.

for all ranges,

VOLTAGE MEASUREMENTS.

Voltage measurements can be made with either of two input resistances:

a.

or a higher resistance, from 20 megohms to 200 megohms depending upon

short the input high to low and reduce

the range.

Generally, it is better to use the higher input resistance (obtained by setting

1.

the FUNCTION Switch to VOLTS OPEN).

To maintain the accuracy of measurements, the input resistance should be 100 times the source resistance.

resistance by ranges.

Within one minute, the

meter

adjust the internal BIAS ADJ Po-

meter

sensitivi-

2 megohms

(See Table l-l for input

With the higher input resistance,

2.

open due to extraneous sisal pickup.

soma meter deflection may occur with the input

To reduce this pickup and also to speed recovery

from input overloads when measuring low impedance sources, use the 2:megohm input resistance (obtained by setting the FIJNCTION Switch to VOLTS (R-2M).

Connect the voltage source to the INPDT Receptacle. Use properly shielded and

b.

grounded leads. Refer to paragraphs 2-8 and following for suggestions and cautions.

Set the RANGE Switch to the highest voltage range. Turn the METER Switch to CENTER

c.

ZERO for the correct polarity for the input signal. Increase the Model 153 sensitivity

until the meter shows the greatest on-scale deflection.

On the 3-volt and higher ranges,

the Model 153 will withstand overloads to 1000 volts without damage. On the lower ranges,

momentary overloads to 1000 volts will cause only temporary instability and zero offset.

Prolonged overloads will damage components and cause increased noise and slower response

speeds.

I

6

1174

Page 12

MODEL 153

OPERATION

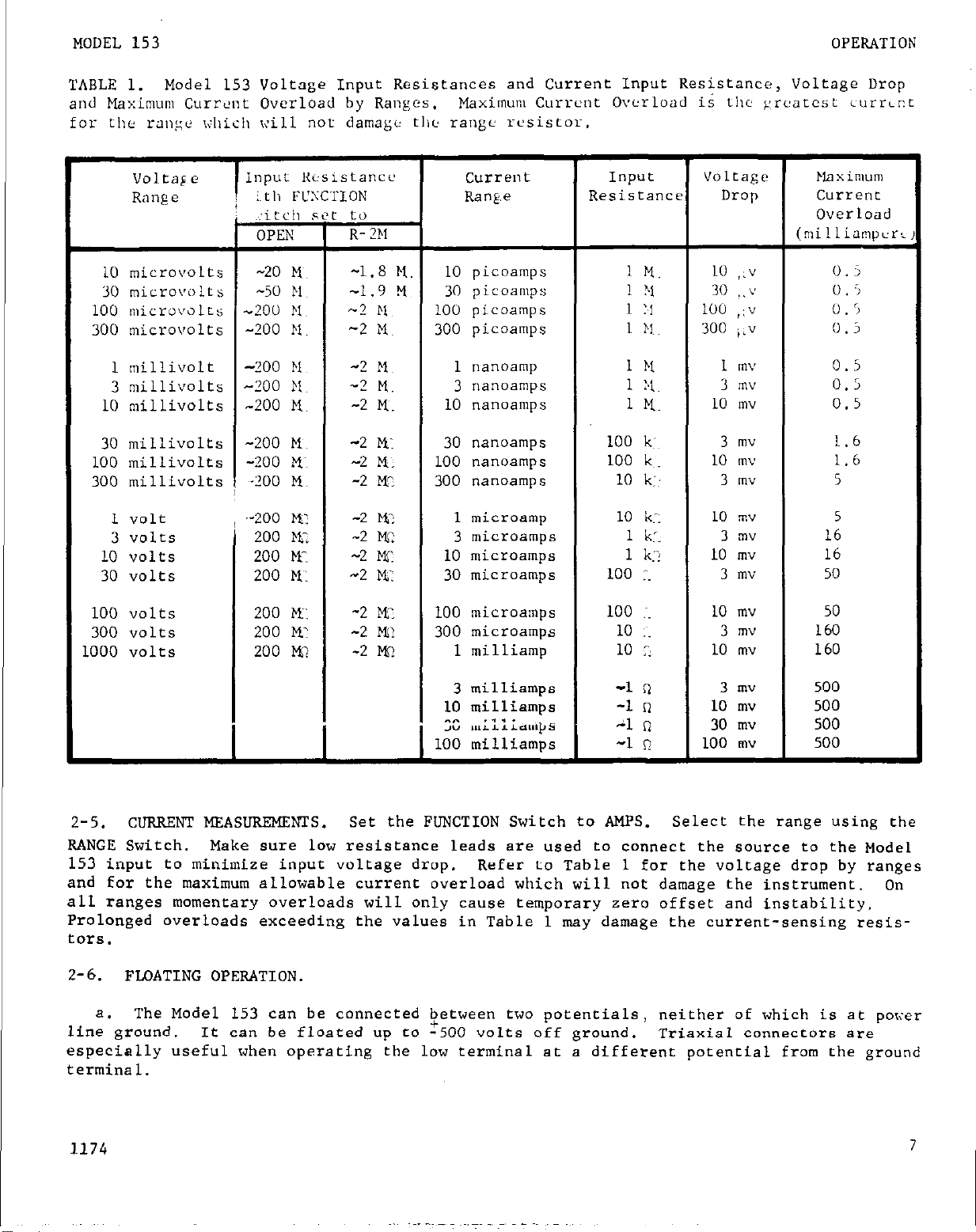

TABLE 1.

and Maximum Current Overload by Ranges.

Model 153 Voltage Input Resistances and Current Input Resistance, Voltage Drop

Maximum Current Overload is tllc p,r~'atcst curr~p.t

for the ralli;e xliich will not damage tliti range resistor.

vo1tag e

Range

Inpur Rcsistancc current Input

:~tll FLTC'rION

Renfie

Resistance

Voltage

Drop GUI-rent

..:itcll sft to

OPEN

R-211

10 microvolts -20 Mu -1.8 M. 10 picoamps 1 M. 10

,I"

(milliampcr:

30 micro\~i,lts -50 M -1.9 x 30 picoamps 1 ?1 30 ,.v 0 . i

100 microi~olts -200 hl~ -2 El 100 picoamps 1 T.1 100 ,:v 0.5

300 microvolts -200 )I. -2 Mu 300 picoamps 1 bl, 300 ;i" 0 . 5

1 millivolt -200 M -2 M 1 nanoamp 1 hl 1 m\ 0.5

3 millivolts -200 K -2 M. 3 nanoamps 1 x 3 rn" 0.5

10 millivolts -200 M. -2 M. 10 nanoamps 1 Mu 10 mv 0.5

30 millivolts -200 Mu -2 MY 30 nanoamps 100 k:~ 3 mv 1.6

100 millivolts -200 Mu -2 M. 100 nanoamps 100 k~. 10 mv 1.6

300 millivolts -700 Mu -2 M' 300 nanoamps 10 k:: 3 mv 5

1 volt

-200

i

M:

-2 M? 1 microamp 10 k:. 10 mv 5

3 volts 200 MT -2 MC 3 microamps 1 kl. 3 rn" 16

10 volts 200 M: -2 MS 10 microamps 1 k:: 10 mv 16

30 volts 200 Mu: -2 I-Ii: 30 microamps 100 1. 3 mv 50

Maximum

Overload

0.5

100 volts 200 M: -2 w 100 microamps 100 :. 10 mv 50

300 volts 200 M1 -2 Ml? 300 microamps 10 1. 3 mv 160

1000 volts 200 M? -2 I% 1 milliamp 10 7. 10 mv 160

3 milliamps -1 n 3 mv 500

10 milliamps -1 R 10 mv 500

X rnil.~icatupS 21 R 30 mv 500

100 milliamps -1 r! 100 mv 500

2-5. CURRENT MEASUREMENTS.

Set the FUNCTION Switch to AMPS. Select the range using the

RANGE Switch. Make sure low resistance leads are used to connect the source to the Model

153 input to minimize input voltage drop.

Refer to Table 1 for the voltage drop by ranges

and for the maximum allowable current overload which will not damage the instrument. On

all ranges momentary overloads will only cause temporary zero offset end instability.

Prolonged overloads exceeding the values in Table 1 may damage the current-sensing resistars.

2-6.

line ground,

FMATING OPERATION

a. The Model 153 can be connected Qetween two potentials,

It

can be floated up to -500 volts off ground.

neither of which is at powr

Triaxial connectors are

especially useful when operating the low terminal at a different potential from the ground

terminal.

1174

7

Page 13

OPERATING INSTRUCTIONS

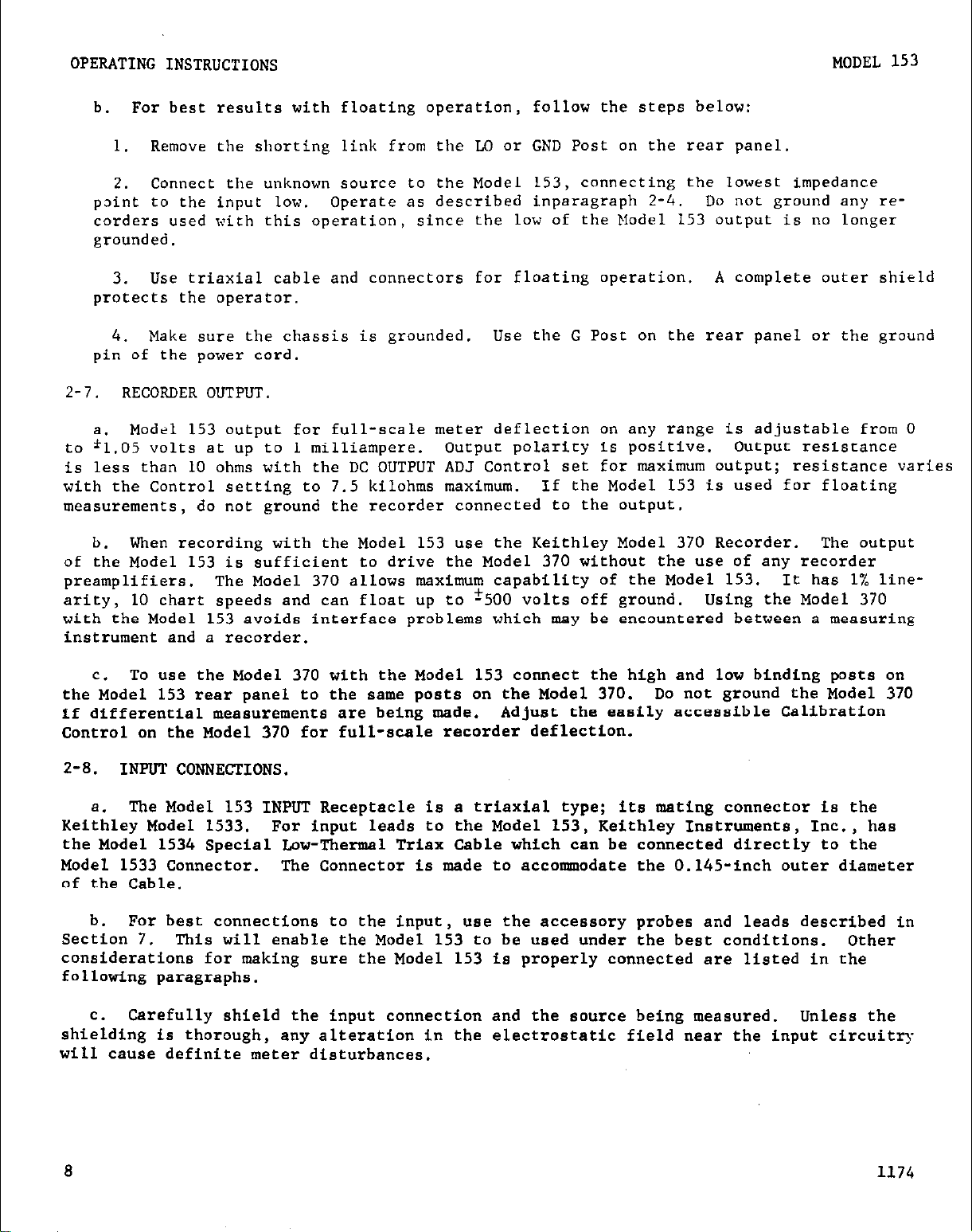

For best results with floating operation, follow the steps below:

b.

Remove the shorting link from the LO or GND Post on the rear panel.

1.

Connect the unknown source to the Model 153, connecting the lowest impedance

2.

paint to the input low.

corders used with this operation,

grounded.

Operate as described inparagraph 2-4.

since the low of the Model 153 output is no longer

MODEL 153

Do not ground any re-

Use triaxial cable and connectors for floating operation.

3.

A complete outer shield

protects the operator.

4. Make sure the chassis is grounded.

Use the G Post on the rear panel or the ground

pin of the power cord.

2-7. RECORDER OUTPUT.

Model 153 output for full-scale meter deflection on any range is adjustable from 0

a.

to *1.05 volts at up to 1 milliampere.

Output polarity is positive. Output resistance

is less than 10 ohms with the DC OUTPUT ADJ Control set for maximum output; resistance varies

with the Control setting to 7.5 kilohms maximum.

If the Model 153 is used for floating

measurements, do not ground the recorder connected to the output.

When recording with the Model 153 "se the Keithley Model 370 Recorder. The output

b.

of the Model 153 is sufficient to drive the Model 370 without the "se of any recorder

preamplifiers. The Model 370 allows maximum capability of the Model 153.

It has 1% line-

arity, 10 chart speeds and can float up to ?500 volts off ground. Using the Model 370

with the Model 153 avoids interface problems which may be encountered between a measuring

instrument and a recorder.

To "se the Model 370 with the Model 153 connect the high and low binding posts on

c.

the Model 153 rear panel to the sama posts on the Model 370.

if differential measurements are being made.

Adjust the easily accessible Calibration

Do not ground the Model 370

Control on the Model 370 for full-scale recorder deflection.

2-8.

INPUT CONNECTIONS.

a. The Model 153 INPUT Receptacle is a triaxial type; its mating connector is the

Keithley Model 1533.

For input leads to the Model 153, Keithley Instruments, Inc., has

the Model 1534 Special Low-Thermal Triax Cable which can be connected directly to the

Model 1533 Connector.

The Connector is made to acconrmodate the 0.145-inch outer diameter

of the Cable.

b. For best connections to the input,

Section 7.

This will enable the Model 153 to be used under the best conditions.

use the accessory probes and leads described in

Other

considerations for making sure the Model 153 is properly connected are listed in the

following paragraphs.

c.

Carefully shield the input connection and the source being measured.

shielding is thorough,

any alteration in the electrostatic field near the input circuitry

Unless the

will cause definite meter disturbances.

8

1174

Page 14

MODEL 153

OPERATING INSTRUCTIOXS

d. Use high resistance,

low-noise materials - such as Teflon (recommended), polyethy-

lene or polystyrene - for insulation. The insulation leakage resistance of leads shx*Jld

be greater than 500 megohms to maintain the Model 153 input resistance.

age reduces the accuracy of readings from high impedance sources.

the cable must also be high:

tween shields.

The Model 1534 Cable meets these requirements.

1000 volts center conductor to inner shield; 500 volts be-

Voltage breai:d3jm of

Triasial cables used

Excessive lea;:-

should be a low-noise type which employ a graphite or other conductive coating brt!ieen

the dielectric and the surrounding shield braid.

e. Any change in the capacitance of the measuring circuit to ground will cause extran-

eous disturbances.

For instance, cable flexture changes the cable capacitance and thus

affects meter readings. Make the measuring setup as rigid as possible and tie down connec-

ting cables to prevent their movement. If a continuous vibration is present, it may appear at the output as a sinusoidal signal and other precautions may be necessary to iso-

late the instrument and the connecting cable from the vibration.

f. For low impedance measurements, unshielded leads and the Model 6012 Adapter ma)

be used.

Since the circuit low and ground are connected with the Adapter, do not

use

it

for off-ground measurements.

NOTE

Keithley Instruments, Inc., has several booklets available on low voltage measurements and low current high resistance measurements. A list is available from

Keithley Instruments, Inc., or its representative.

2-V. ACCURACY CONSIDERATIONS. For sensitive measurements - 100 millivolts and below -

other considerations besides the instrument affect accuracy.

Effects not noticeable when

working with higher voltages are very important with microvolt signals. The Model 153

only reads the signal received at its input; therefore,

it is important that this signal

be properly transmitted from the source. The following paragraphs indicate factors which

affect accuracy: thermal emf's,

2-10.

THERMAL EMF'S.

Thermal emf's (thermo-electric potentials) are generated by thermal gradients be-

a.

tween any two junctions of dissimilar metals.

shielding and circuit connections.

These can be significatn compared to the

signals which the Model 153 can measure.

Thermal emf's can cause the following problems:

b.

Metal instability or zero offset much higher than normal.

1.

Note, though, the

Model 153 may have some offset (paragraph 2-3).

Meter is very sensitive to ambient temperature

2.

VariStiOnS.

ing the circuit, by putting a heat source near the circuit,

instability,

corresponding to heating and air conditioning systems or changes in sun-

or by a regular pattern of

This is seen by touch-

light.

1174

9

Page 15

OPERATING INSTRUCTIONS

To minimize the drift caused by thermal emf's, use the same metal or metals having

c.

low thermo-electric powers in the input circuit.

have thermo-electric

ture difference of

emf of 2.5 microvolts.

owers within about *0.25 wv/'C of copper.

1

C between one of these metals and copper will generate a thermal

10

At the other extreme, germanium has a thermo-electric power of

Gold, silver and low-thermal solder

This means even a tempera'-

about 320 uv/°C, and silicon will develop about 420 pv/oC against copper.

handbooks contain tables of thermo-electric powers of materials.

circuit is of copper, the best juntion is copper to copper.

However, copper oxide in the

Since the Model 153 input

MODEL 153

Standard physical

junction or differences in processing of two pieces of copper can cause thermal emf's Of up

to 0.2 microvolt oer oC.

The Model 1483 Kit contains all necessary equipment to make

low-thermal joints. See Section

7.

very

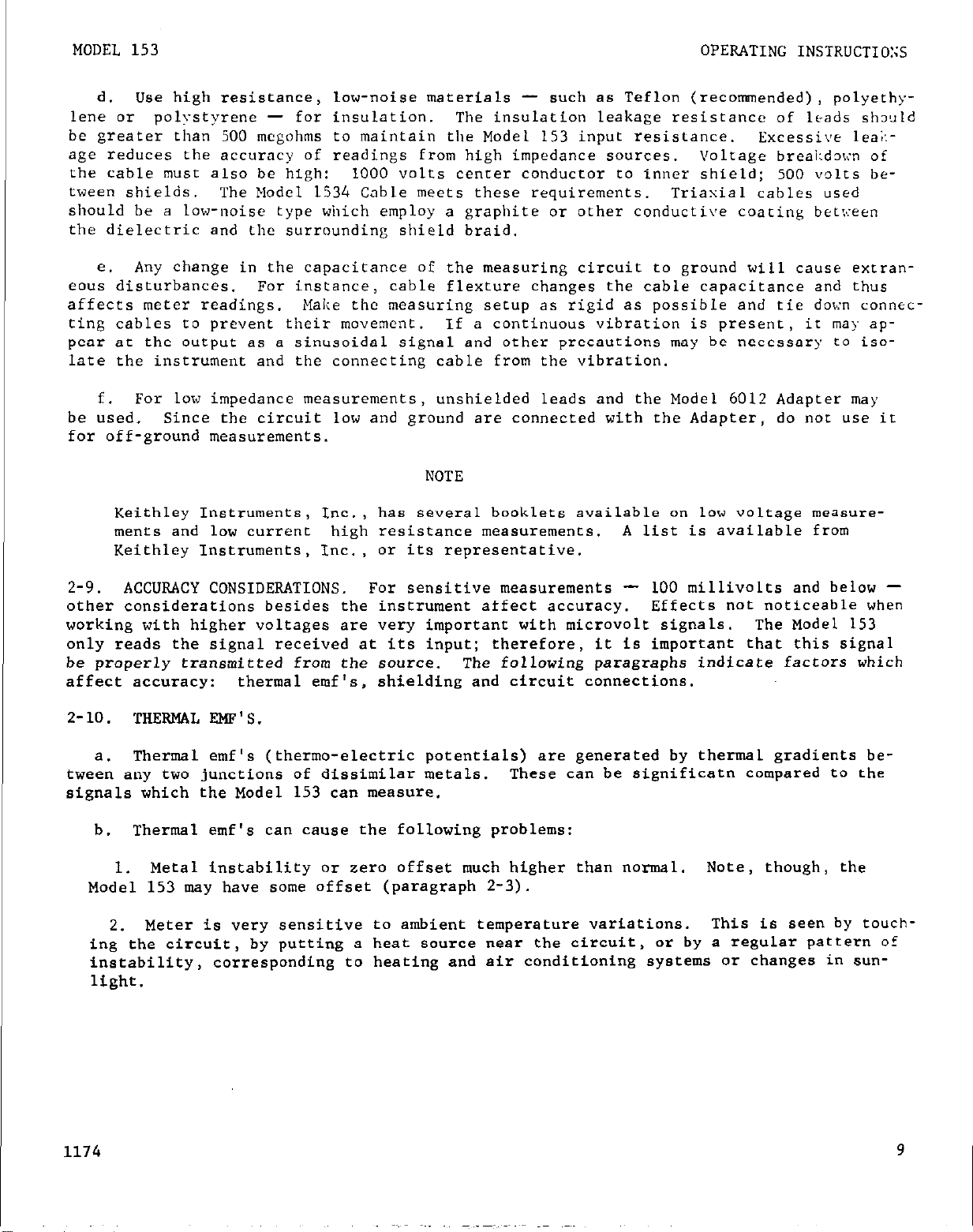

d. Maintaining constant temperatures

F?pf ~~5~%~~~~~~:~~~~~d~~~~~~~~ Es

and similar sources which vary temperature.

Minimize thermal gradients by-placing all

junctions physically close on a large heat

sink.

with a non-metallic abrasive such as Scotch

Brite before making a connection. Crimp to-

gether the ends of each copper wire; bolt

the lugs for each connection point together;

mount all stacks of lugs on a thick metal

plate having high thermal conductivity.

Thermal conductivity between the junctions

and the heat sink can be kept at a high

level by using mica washers or high conduc-

tivity ceramics for electrical insulation.

the effects of thermal emf's. Use only

cadmium-tin low-thermal solder (Model conductivity.

1503), such as supplied in the Model 1483

Kit, for soldered connections. Unlike

metals controlled oil bath or a good heat sink is used.

the thermoelectric power of the materials in the junction and the temperature difference

between the junctions.

Thoroughly clean all copper leads

Several other techniques will reduce

e.

including regular solder

FIGURE 4.

Thermal Sink Construction.

Connect leads or lugs as close as possible.

Separate only with insulation of high heat

- may be used and low thermal emf's obtained if a wellThermal voltages may be calculated from

2-11. SHIELDING.

Generally, the Model 153 is insensitive to ac voltages superimposed upon a dc signal

a.

at the input terminals.

signal can cause erroneous readings.

apparatus in the measurement circuit together and ground at one point.

However, ac voltages which are very large compared with the dc

Usually it is sufficient to connect the cases of all

This provides a

"tree" configuration, which minimize ground loops. Also floating the instrument (para-

graph 2-6) will minimize ground loops.

The connnon point at which all shields are connect-

ed should be as near as possible to the circuit low of the Model 153 at its input.

Improper shielding can cause the Model 153 to react in one or more of the following

b.

ways :

10

1174

Page 16

MODEL 153 OPERATING INSTRUCTIONS

Meter jitter or instability,

1.

High offset (dc bias).

2.

tion between the LO and GND Posts may affect the amount of offset.

3. Slow response time. sluggish action and/or inconsistent reading between ranges.

from 10% to 20% of full scale.

Reversing the power cord polarity or removing the connec-

c. To minimize pickup, keep the circuit away from ac sources.

possible.

The voltage induced due to a magnetic flux is proportional to the area of the loop.

fore, minimize loop areas in the shield connections as well as the input circuitry.

nect the shield at only one point. Run all wires in the circuit along the same path, so

the loop area is only the small difference in position of two adjacent rcires.

d. To reduce the effect of magnetic fields, use magnetic shielding. Where high ac magnetic fields are present, it may be necessary to magnetically shield the measuring circuit, the unknown emf circuit or auxiliary equipment in the circuit.

is available from several companies in the from of plates, foil or cable.

e. The Model 153 line frequency rejection refers to the total ac voltage appearing at

the input terminals. Therefore, in null detector applications,

of the ripple in the working standard and the unknown source.

standards having high ac ripple components will significantly reduce the amount of ac

voltage which may be tolerated in the unknown.

2-12.

a. When measuring in the microvolt region,

will have on the potential being measured.

significant, now become important.

of approximately 10 milliohms per foot.

of this wire will cause a voltage drop of five microvolts.

microvolt would mean using a wire an inch long.

Connect all shields together at the low side of the input or at the LO Post.

CIRCUIT CONNECTIONS.

consider the effect the physical connections

Voltage drops,

For example No. 20 AWG copper wire has a resistance

A 1-milliapere current through a 6-inch length

which in most circuits are in-

To reduce this drop below 1

Shield as carefully as

There con-

Magnetic shielding

it is affected by the sum

Because of this, working

Four-terminal ,,....,,:;,.., _.A.. “ZL,..

b.

be used to eliminate this error. Refer

to Figure 5.

If a small unwanted voltage drop is

c.

constant,

nullify the voltage.

d.

the measuring system fluctuate, they will

develop fluctuating voltages which will

appear as noise or drift in the system,

2-13. OPERATING FROM SOURCE OTHER THAN 117 VOLT.

use a screwdriver to change the 117-234 Switch on the back panel (Figure 3).

the fuse from 0.5 ampere to 0.25 ampere.

1174

the ZERO Control may be used to

If the currents or resistances in

FIGURE 5.

Connections,

If the ac power source is 234 volts,

No other adjustment is necessary.

Using Model 153 with 4-Terminal

Change

11

Page 17

APPLICATIONS

MODEL 153

SECTION 3.

3-l.

tims. These are

applications as demonstrations of techniques for using the Model 153.

3-2.

ful for measuring small signals from high source resistances.

can accurately measure a lo-millivolt signal through a l-megohm source.

The Model 153 is connected between the unknown and the potentiometer rather than across

the null detector terminals because shunts in the potentiometer reduce power sensitivity.

3-3.

wide range. For example,

drain current about 10-4

about 10-3 ampere.

lox voltage circuitry is undisturbed because the Model 153 has a very low input voltage drop

GESEFUL.

NULL DETECTOR.

The Model 153 is ideal for most null detector applications.

a.

Figure 6 shows a typical null circuit using the Leeds and Northrup K3 potentiometer.

b.

AMMETER. Solid-state circuit design often requires an ammeter with an extremely

This Section contains descriptions and diagrams of some Model 153 applica-

just

samples,

in the circuit of Figure 7, gate current is about lo-11

ampere, base current about 3 x 10-6

The Model 153 measures these currents easily and accurately.

and they do not exhaust all possible uses.

APPLICATIONS

ampere, and emitter current

Refer to these

It is particularly use-

For instance,

the Model 153

ampere,

The

FIGURE 6. Null Circuit Using Model 153 an

Leeds and Northrup K3 Potentiometer,

3-4. VOLTMEP.ER. Measuring microvolts

through megohm source resistance - a prime

requisite in semiconductor resistivity "easurements - is a simple task for the Model

153.

semiconductor resistivity measuring system.

Four sharp probes contact th? surface of a

semiconductor wafer or ingot.

rent is applied through the outer two probes,

while the inner two pick up the voltage

drop.

current,

probes.

12

Figure 8 illustrates a typical 4-point

Known cur-

Resistivity is then computed fro"

voltage drop and spacing between

FIGURE 7.

Solid State Circuits.

Diagram Showing Currents in

/

1

:GURE 8. Circuit Using Model 153 for

Semiconductor Resistivity Measurements.

I

1174

Page 18

MODEL 153

CIRCUIT DESCRIPTIOS

SECTION 4.

4-1. GE:;EF!AL.

The Keith1

a.

and demodulator

whole loop.

Signals below 1 volt are applied directly to the input filter; those above 1 volt

b.

arc attenuated 1OOO:l with a resistive divider.

input filter which attenuates undesireable ac signals.

4 cps.

feedback voltage.

the tuned ac amplifier,

nal is filtered and used to drive the output, meter and feedback.

=.

tor through which the input current flows.

range determines the current sensitivity.

The filtered dc signal enters the photo-modulator,

The Model 153 operates as an ammeter by measuring the voltage drop across a resis-

.ev Model 153 Microvolt-Ammeter consists of a photo-modulator, ac amplifier,

system followed by a dc cathode follower.

The difference or 'error signal is modulated at 4*3 cps, amplified by

and synchronously demodulated to regain dc.

Circuit designations refer to schematic diagram 1777111.

CIRCUIT DESCRIPTION

Feedback is applied to the

All signals pass through the low-pass

The filter has a 3 db cutoff at

where it is compared to the

The resistor used and the instrument voltage

NOTE

The demodulated sig-

4-2. INPUT CIRCUIT.

The setting of the FUNCTION Switch,

15::

put terminal, and the input resistance is approximately two megohms for all ranges.

ting the Switch to OPEN increases the input resistance of each range to that shown in Table

1.

by resistors R134 and R135.

resistance, but a synthetic resistance obtained by using high feedback factors.

tive divider, consisting of resistors R134 to R137.

ac signals from the voltage being measured.

and R104 and capacitors ClOl, Cl02 and ClO3.

I

With the Switch set to VOLTS INPUT R-2M, resistor R133 is connected to the high in-

For the 3-voit ano nq+nrr ranges,

For the lower ranges the input resistance is not a fixed

For the 3-volt and higher ranges,

b.

The input signal is then filtered by the low pass input filter to remove unwanted

=.

52, determines the input resistance of the Model

set-

~nr input r~rsistance is 200 megohms, as determined

the input signal is attenuated 1OOO:l by a resis-

The filter consists of resistors R102, R103

1174

FIGURE 9.

Model 153 Block Diagram.

Page 19

CIRCUIT DESCRIPTION

Resistor R102 and neon lamp GLlOl in the input circuit provide overload protection

d.

for lhe voltmeter.

The input also includes a system for increasing the speed of measurr-

MODEL 153 MCROVOLT-AMMETER

mats from high source impedances by driving capacitor Cl02 from the feedback signal.

The dc input signal is converted to an ac signal by photo-modulators El01 and ELO?.

c.

The

piloto-modulators are specially designed for high input resistance and low offset.

Lucite rods are used to conduct the light from lamps ElOlB and ElOZB to the cells to reduce the drive signal through them.

The input filter and photo-modulator are housed in a separate compartment to shield

f.

and insulate these circuits.

4-3.

AMPLIFIERS.

The ac signal from the photo-modulator is amplified by a 5-stage ac amplifier and

a.

demodulated to dc.

Tke ac amplifier uses low-noise design with fixed bias and low plate voltage on the

b.

first tk‘o amplifier stages, VlOlA and V102A.

The fourth amplifier stage uses a frequency

selective twin-T filter tuned to the carrier frequency to reduce noise and to reduce the

modulation products and beats associated with the modulating action.

Resistors R145 to

R153 are selected with the RANGE Switch and are used in the circuit to vary the amplifier

gain as the ranges are changed.

This maintains an approximately constant feedback factor

on all but the most sensitive ranges.

The output of the ac amplifier is applied to photo-modulator El03 and converted to

=.

The signal is filtered by capacitor Cl20 and resistors R126 and R128 to R130 to re-

dc.

duce the carrier signal appearing on the output.,

4-4.

CATHODE FOLLOWER.

V103B, an impedance transformer which provides a l-volt, l-milliampere output.

The filtered dc signal is applied to the cathode follower, tube

The output

also supplies the recorder output, meter and feedback network.

4-5. FEEDBACK NETWORK.

The feedback network, constructed of accurate stable resistors, controls the input

a.

sensitivity of the instrument.

Special precautions have been taken to keep any thermal

emf's generated to a minimum.

The feedback network is connected between the output of tube V103B and the photo-

b.

modulator, E102A. Setting the RANGE Switch, Sl, selects the feedback resistor, R131,

R158 and R164 to R173, used for the particular range.

4-6.

AMMI?J?ER OPERATION.

When the FUNCTION Switch is set to AMPS, one of resistors R138

to R144 is connected across the input. The particular resistor depends upon the range

being used.

The voltage drop across the resistor, which varies from 10 microvolts to 100

millivolts, is then measured by the Model 153, and read directly in amperes.

4-7.

MULTIVIBRATOR. The multivibrator is a twin-triode tube, V201; which use.8 highly

stable resistors and capacitors in the frequency determining circuits. Potentiometer

R210 adjusts the multivibrator frequency to exactly that of the frequency selective ampli-

fier. The multivibrator is used to drive the neon lamps in the photo-modulators.

.

Page 20

MODEL 153 MICROVOLT-AMMETER

1

CIRCUIT DESCRIPXOS

4-8.

POWER SUPPLY. The power supply uses a highly shielded transformer, Tl, to obtai?

good line isolation for floating operation. A separate winding with rectifiers supplies

a dc voltage for the first amplifier tube filament to reduce amplifier noise.

supply output is regulated by tubes V302 and V301 and zoner diode D305.

regulated outputs, t257,

+150 volts and -13 volts.

An unregulated -306 volts is also

There are three

The poxr

furnished to the multivibrator.

1174

15

Page 21

I

SERVICING

MODEL 153 MICROVOLT-AMMETER

1"str"me"t

<ewlett-Packard Model 200CD Oscillator,

j cps to 600

<eithley Instruments Model 241 Regulated

iigh Voltage Supply, 0 to 1000 volts.

10.05%

<eithley Instruments Model 260 Nanovolt

3ource,

to 1 volt, '0.25%

<eithley Instruments Model 261 Picoampere

Source,

ta 10-4 ampere, +0.25X

Keithley Instruments Model 370 Recorder

Keithley Instruments Model 6lOB Electro-

neter

Tektronix Type 504 Oscilloscope; dc to 450

5 mv/cm sensitivity

kc,

kc, ~2%

10-6 to 10-3 volt

10-11 to 10-7

ampere, f0.5"/.; 10-7

) ?0.5%, 10-3

Use

Low frequency rejection

Source for calibrating high voltage

t-a"geS

Source for calibrating low voltage ran.ses

Source for calibrating current ranges

Record stability

General circuit testing

Check wave forms

rektronix Type P6006 Probe; lo-megohm input impedance, 1O:l attenuation ratio

22-megohm shielded resistor

200~megohm shielded resistor

I ’

Divider:

coupling capacitor <Fib;;; 13).

;rid-modulated tube tester

TABLE 2.

instruments or their equivalent.

22 MR and 1 kR with 1000 pf, 15 v

Equipment Recommended for Model 153 Troubleshooting and Calibration.

Use with oscilloscope

Open circuit zero adjustment

Input impedance check

Multivibrator frequency adjustment

Test tubes

Use these

I

16

1174

Page 22

MODEL 153 MICROVOLT-AMMETER

SECTION 5. SERVICING

SERVICISC

5-l.

Model 153.

usefulness of the instrument.

5-2. SERVICING SCHEDULE.

mal care required of high-quality electronic equipment.

under ordinary use except the bias batteries or,

of the bias batteries is approximately two years.

5-3.

components in the Model 153. Replace components only as necessary; use only reliable replacements chich meet the specifications. Replace those items listed for Keithley manufacture (80164) only with components supplied by Keithley Instruments, Inc., or its representative.

5-4.

15;:

2 lists equipment recommended for troubleshooting.

cated or repaired, contact Keithley Instruments, Inc., or its representative.

placing tubes will clear up the difficulty. All tubes can be readily tested on a grid-

GENERAL. Section 5 contains tile maintenance and troubleshooting procedures for the

Follow these procedures as closely as possible to maintain the accuracy and

The Model 153 needs little periodic maintenance beyond the nor-

No part should need replacement

occasionally, a vacuum tube.

PARTS REPLACEMENT.

Tube VlOl is aged;

TROUBLESHOOTING.

Thz following procedures are for repairing troubles which might occur in the Model

Use these procedures to troubleshoot and use only specified replacement parts.

Before proceeding with the troubleshooting, check the vacuum tubes. Normally, re-

b.

The Replaceable Parts List in Section 8 describes the electrical

replace only with a Keithley part.

If the trouble cannot be readily lo-

The life

Table

Replaced Tube

VlOl

V102 and V201 slow or sluggish re-

v103

V301 and V302

TABLE 3.

above adjustments might be necessary.

Possible Adjustments for Replaced Tubes,. After a faulty tube is replaced, the

Check for

noise

meter accuracy

sponse on 10 and 30-pv adjustment

ranges

meter accuracy

correct bias

meter accuracy

correct bias

zero center meter

i3CCU?Z.?CY

Adjustment

replace tube

meter adjustment

multivibrator frequency 5-6

meter adjustment

bias adjustment 5-5

meter adjustment 6-3

bias adjustment 5-5

zero center meter adjust-

ment

Refer to paragraph 5-4.

Paragraph

Reference

,

6-3

6-3

6-3

1174

17

Page 23

I

SERVICING

MODEL 153 MICROVOLT-AMMETER

modulated tube tester for usual operation,

best way to test a tube.

procedures. Replacing tubes does not necessitate complete recalibration of the instrument.

Refer to Table 3 for adjustments which might be necessary.

Table 4 contains the more common troubles which might occur.

c.

cated in the Table do not clear up the trouble, make a point-by-point check of the circuits. Start by rechecking the power supply for proper operating voltages:

+150 volts,

within the power supply.

The schematic diagram 17771H, found in Section 8,

d.

points.

shorted.

Refer to the circuit description in Section 4 to find the more crucial components and to

determine their function in the circuit.

and -13 volts.

For these values,

The Model 153 controls are set:

METER Switch

FUNCTION Switch

RANGE Switch

If replacing a tube does not correct the trouble, continue the

Figures 10 to 12 show typical ripple at three test points

Use the Oscilloscope to obtain the patterns.

measured tiith the Model 6lOB to ilO%, the Model 153 input is

However,

substituting known good tubes is the

If the repairs indi-

+275 volts,

contains the voltages at selected

+

VOLTS R-2M

1 VOLT

FIGURE 10. Wave Form at Junction of Diodes

D301 and D302 (Figure 27). Vertical setting

is 1 volt/cm; horizontal, 2 milliseconds/cm.

Output is approximately t4UU volts dc.

5-5.

ground by connecting point T. P. (Figure 21) to ground.

the METER Switch to f; and the FUNCTION Switch to INPDT R-2M.

tiometer, R125 (Figure 20), for a zero meter reading.

ground;

5-6.

BIAS ADJUSTMENT. Check the mechanical meter zero. Short pin 1 of tube V103 to

adjust for exact meter zero.

MULTIVIBRATOR FREQUENCY ADJUSTMENT.

Remove tubes VlOl and V103 (Figure 21).

a.

FIGURE 11. Wave Form at Junction of Resistor R302 (Figure 27) and Capacitor C302B

(Figure 19).

volts/cm; horizontal, 2 milliseconds/cm.

Output is approximately +12 volts dc.

FIGURE 12 (Left). Wave Form at -13 Volt

SUPPlY.

horizontal, 5 milliseconds/cm.

Turn the METER Switch to + and the FUNCTION

Vertical setting is 20 millivolts/cm;

Set the RANGE Switch to 1 VOLT;

Remove the short between T. P. and

Vertical setting is 5 milli-

Adjust the BIAS ADJ Poten-

18

1174

Page 24

MODEL 153 MICROVOLT-AMMETER

Difficulty Probable Cause Solution

SERVICING

Instrument inaccurate on

all ranges

Instrument inaccurate on ATTENUATOR Potentiometer R137

3-volt and higher ranges

Excessive zero drift Input filter capacitors polar-

METER CAL Potentiometer R176

out of adjustment

out of adjustment

ized from excessive overload

Battery BlOl or B102 faulty

Adjust per paragraph 6-

Adjust per paragraph 6-.

Let sit for a few hours

on 3 to

lOO-mv range

Check; replace if fault!

VlOl, v102 or v103 faulty Check; replace if fault]

Check; replace if fault!

Slow or sluggish response

on all ranges

Diode D103 faulty

MULTIVIBRATOR Potentiometer Adjust per paragraph 5-t

R210 out of adjustment

Excessive zero drift and MIJLTIVIBPATOR Potentiometer Adjust per paragraph 5-c

slow sluggish response

Excessive noise on most

R210 out of adjustment

Battery BlOl or Bl02 faulty

Check; replace if fault)

sensitive voltage ranges

Excessive overload damaged Check; replace if fault)

resistor R102

Tube VlOl or V103 faulty Check; replace if faulty

Diode D103 faulty Check; replace if faulty

Constant offset on all ran- Meter mechanical zero out of Set METER Switch to POWE

ges with input s:i;zt;?

..lI....c--^rC

- - _) - _ _.- _ . . BIAS Potentiometer R125 out of

OFF; edjust

Adjust per paragraph 5-5

adjustment

%eter off zero on zero ZERO CENTER Potentiometer R177 Adjust per paragraph 6-3

:enter scale out of adjustment

Zero shift with changing OPEN CIRCUIT ZERO Potentiometer Adjust per paragraph 6-5

source resistance on more R160 out of adjustment

sensitive ranges

%cessive ac line frequency

interference

Large ac fields present Change location or im-

prove shielding

Battery BlOl faulty Check; replace if faulty

Heater-to-cathode leakage in Check; replace if tube

VIOI, vm.? or VI03

is faulty

1174

TABLE 4.

Excessive power supply ripple

Model

153 Troubleshooting Chart.

Check per paragraph 5-4

19

Page 25

SERVICING

MODEL 153 MICROVOLT-AMMETER

FIGURE 13.

brator Frequency Adustment.

Divider Connection for Multivi-

Connect the

divider to either pin 1 or 6 of V201 and to

pin 2 of V102A. Use l%, l/2 watt, deposi-

FIGURE 14.

put.

Oscilloscope was attached to pin 1 of

tube V201A (Figure 19). Vertical setting

is 100 volts/cm; horizontal, 5 msecicm.

Wave Form of Multivibrator Out-

ted carbon resistors and a 15-volt capacitor for the divider.

SWITCH to INPUT R-2M.

Use the Model 610B to check pin 7 of tube VlOl for approximately

-1.23 volts +lO%.

Place the resistor divider from either plate of tube V201 (Figure 19) to ground.

b.

See Figure 13. Connect the output of the divider to the grid of tube V102A (Figure 21).

Monitor the output across resistor R121 (Figure 22) with the Type P6006 Probe.

C. Set the RANGE Switch to 30 MILLIVOLTS.

Adjust the MULTIVIBRATOR FREQUENCY ADJ Poten-

tiometer, R210 (Figure 27), to obtain the largest signal across resistor Rl21, approxi-

mately 6.5 to 7.5 volts peak-to-peak (650 to 750 millivolts with divider Probe).

14 shows typical wave form at the multivibrator output.

across R121 (junction of R121 and C117).

signal to swing through maximum,

change the value of resistor R208 (Figure 27) to center

If tuning potentiometer R210 does not cause the

Figure 15 shows typical waveform

Figure

the potentiometer adjustment.

FIGURE 15. Wave

tor Output

Across Resistor R1.21 (Figure 22).

Form

for Tuned Multivibra-

Vertical setting is 1 volt/cm; horizontal,

2 milliseconds/cm.

FIGURE 16.

ElOl.

Wave

The output is monitored at pin 2 of

VlOl with a 1O:l divider probe. Oscillo-

scope IS dc coupled.

20 millivolts/cm; horizontal, 2 milliseconds/cm.

Form for Input Modulator

Vertical setting is

20 1174

Page 26

MODEL 153 MICROVOLT-AMMETER SERVICING

TUtJc Gain

VlOlA 10

VlOlB 10

V102A 20-30

V102B 25-35

FIGURE

Demodulator Wave Form for Full-

17.

Scale Input on l-Volt Range. The signal is

V103A 30-35

monitored at the junctions of capacitor

C113, resistor R126 and modulator E103A.

TABLE 5. Approximate Amplifier Gains by

stages.

5-7.

network to ground; see paragraph 5-8b.

INPUT MODULATOR CHECK.

Remove the divider of Figure 13; remove tube VlOl (Figure 21).

a.

Set the RANGE Switch to 1 VOLT. Use the

Model 260 Nanovolt Source to apply a +l volt input signal to the Model 153.

Vertical setting is 2 volts/cm; horizontal,

2 milliseconds/cm.

Short the feedback

Use the Type

P6006 Probe with the Oscilloscope to monitor the signal at pin 2 of tube VlOl (Figure 21).

A typical wave form is show" in Figure 16 for a properly functioning modulator El01 (Fig-

ure

23).

The wave should be a minimum of

700

millivolts

peak-to-peak average value (70

millivolts using the 1O:l Probe).

Replace all tubes and shields; allow the instrument to stabilize for

b.

5-8.

amplifier gain for each range.

and the constant _oain f~rrnrr IV-P ohz=cbc=cl

GAIN ADJUSTMENT.

a. The

Model 153

maintains a" approximately co"Uta"t feedback factor by changing the

In the gain adjustment,

the feedback network is shorted

a

few

minutes.

Short the feedback network on the Model 153 by connecting the rear,deck of the

b.

RANGE Switch, Sl (Figure 19),

to the circuit low terminal of the INPUT Receptacle.

Set

the METER Switch to +, the EIJNCTION Switch to OPEN, and the RANGE Switch to 30 MILLIVOLTS.

Apply a" input signal to the Model 153, using the Model 260, sufficient to obtain a full-

scale meter reading; normally this will be between 300 and 400 microvolts. Set the METER

Switch to - and repeat this procedure.

essary to drive the meter to full scale.

Average the value,of the two input voltages "ec-

If the average is between 300 and 430 microvolts,

the loop gain of the Model 153 amplifier is between 100 and 70. If the average is less

than 300 microvolts, add resistor, RllO (Figure 22), to decrease the gain. If the average

is greater than 430 microvolts, the gain is too low.

If the gain is too low,

c.

either the efficiency of modulator El01 (Figure 23) is too

low or the gain of a particular amplifier stage is too low. Normally, the modulator ef-

fiency should be greater than 70%.

on the l-volt range is shown in Figure 17.

5-9. NOISE.

Set the Model 153 RANGE Switch to 10 MICROVOLTS and short its input. Meter

noise must be less than 3 minor divisions,

Switch to AMPS. Shield the input and check meter noise.

For a l-volt input signal, the demodulator wave form

Typical stage gains are show in Table 5.

exclusive of any thermal drift. Set the FUNCTION

It should be less than 5 minor

divisions, exclusive of any thermal drift.

1174

21

Page 27

SERVICING

5-10. AC REJECTION CHECK.

MODEL 153 MICROVOLT-AMMETER

60-cps Rejection:

a.

Operate the Model 153 from a 60-cps power line.

tor to apply a lo-volt peak-to-peak,

60-cps signal to the Model 153 input. Set the Model

Use the Oscilla-

153 RANGE Switch to 100 MILLIVOLTS, and the METER Switch to ZERO CENTER. Turn down the

Oscillator output amplitude and make sure the Model 153 is properly zeroed.

There should

be less than 0.5% change in the meter needle deflection from no signal to full signal.

Disregard any transient swings while applying the signal.

50-cps Reiection:

b.

Operate the Model 153 from a 50-cps power line.

Follow the in-

structions given for the 60-cps rejection check in the preceding sub-paragraph.

22

1174

Page 28

I

MODEL 153 MICROVOLT-AMMETER

CALIBRATION

SECTldN 6. CALIBRATION

6-1. GENERAL,

The following procedures are recommended for calibrating the Model 153.

a.

equipment recommended in Table 2.

If proper facilities are not available or if difficulty

is encountered, contact Keithley Instruments, Inc.,

factory calibration.

or its representative to arrange for

Use the

The following procedures are covered:

b.

meter and attenuator adjustments, open circuit zero adjustment, verification of voltage and current range calibrations, rise time and

drift verifications, and input impedance check.

If the Model 153 is not within specifications after the calibration, follow the

c.

troubleshooting procedures or contact Keithley Instruments,

6-2. CALIBRATION SCHEDULE.

Calibrate the Model 153 yearly.

Inc., or its representative.

This normally means perfor-

ming the bias adjustment (paragraph 5-5), meter adjustment (paragraph 6-3), attenuator

adjustment (paragraph 6-4), and open-circuit zero adjustment (paragraph 6-5). The other

verifications need be done only if desired.

6-3.

If necessary, adjust the BIAS ADJ Potentiometer, R125 (Figure 20).

METER ADJLISTMENIY.

a. After a 30-minute warm-up,

check the Model 153 for zero reading on the l-volt range.

See paragraph 5-5.

Connect the Model 260 Nanovolt Source to the Model 153 INPUT Receptacle. Set the

b.

controls as follows:

METER Switch

FlTNC’?TCIN !-hi trh,

RANGE Switch

+

INPUI R-2M

1 VOLT

Control

Bias adjust

Circuit

Desig.

R125

Fig.

Ref.

20

Refer to

Paragraph

Attenuator adjust R137 20 6-4

Open circuit Zero R160 20 6-5

Meter Calibration R176 20 6-3

Center Zero adjust

Multi-vibrator frequency adjust

TABLE 6.

Model 153 Internal ,Controls.

R177 20 6-3

R210 27

The Table lists all internal controls, the figure

picturing the location and the paragraph describing the adjustment.

5-5

5-6

l

Page 29

CALIBRATION

MODEL 153 MICROVOLT-AMMETER

Set the Model 260 to apply +l volt.

20.5%.

scale deflection. This adjusts the meter for all voltage ranges below 1 volt.

c.

Control on the rear panel for a l-volt output il%.

d.

METER Switch to CENTER ZERO; keep the FUNCTION and RANGE Switches as in sub-paragraph b.

The meter needle should be at zero on the bottom scale.

ZERO ADJ Potentiometer, R177 (Figure 20) for zero meter deflection on the bottom scale.

6-4. ATTENUATOR ADJUSTMENT.

Receptacle.

Set the Model 241 to apply +lO volts.

iO.S%.

full-scale deflection.

If necessary, adjust the METER CAL Potentiometer, R176 (Figure 20), for a full-

Using the same settings and input as in the previous step, adjust the OUTPUT ADJ

Remove the input signal from the Model 153 and short the input terminals.

Connect the Model 241 Voltage Supply to the Model 153 INPUT

Set the Model 153 controls as follows:

METER Switch

FUNCTION Switch

RANGE Switch

If necessary, adjust the ATTENUATOR ADJ Potentiometer, R137 (Figure 20), for a

This adjusts the meter for all voltage ranges 3 volts and higher.

The Model 153 meter should read full scale, 1 volt

Set the

If necessary, adjust the CENTER

+

INPUT R-2M

10 VOLTS

The Model 153 should read full scale, 10 volts

NOTE

Before making this adjustment, warm up the Model 153 for at least two hours and

make sure its drift is within specifications (paragraph 6-9.)

6-5.

Shunt the input with a 22-megohm shielded resistor between the high (center terminal) and

low (inner shield) of the INPUT Receptacle.

meter using the front panel ZERO Control.

the OPEN CIRCUIT ZERO Potentiometer, R160 (Figure 20), for a zero meter reading.

the FUNCTION Switch to AMPS position and recheck for meter zero.

6-6. VERIFICATION OF VOLTAGE CALIBRATION.

positive and negative polarity. Calibrate the lo-microvolt to l-volt ranges before

calibrating the higher ranges. Make sura potentiometer R125 is adjusted (paragraph 5-5).

input.

put signal for the lo-microvolt range; 30-microvolt input signal for the 30-microvolt

range, etc.),

for the lOO-microvolt to l-millivolt ranges, within -f1.5%; for the 3-millivolt to l-volt

ranges, within -fO.5%.

Check for both positive and negative polarity.

tiometer, R176 (Figure 20), until all ranges meet specifications.

adjusted for any subsequent range, repeat the calibration for each previous range until

all ranges,are within the required accuracy.

OPEN CIRCUIT ZERO ADJUSTMENT.

Calibrate the voltage ranges for a full-scale meter deflection on all ranges, both

a.

For the ranges from 10 microvolts to 1 volt, connect the Model 260 to the Model 153

b.

For each range,

For the 10 and 30-microvolt ranges, the Model 153 should read within +2.5%;

set the Model 260 for a full-scale input (i. e., lo-microvolt in-

On the zero-left scale, 1% is equivalent to one minor division.

Set the Model 153 RANGE Switch to 30 MICROVOLTS.

Set the FUNCTION Switch to AMPS; zero the

Switch the FUNCTION Switch to OPEN and adjust

Return

If necessary, adjust the METER CAL Poten-

If the potentiometer is

For the ranges from 3 to 1000 volts,

c.

Model 153 input.

24

For each range,

connect the Model 241 Voltage Supply KO the

set the Model 241 for a full-scale input.

For all these

1174 ;

Page 30

I

MODEL 153 MICROVOLT-AMMETER

CALIBRATIO::

<~

ranges, the Model 153 should read within 10.5% of full scale.

negative polarity.

for the proper range accuracy. If potentiometer Rl37 is adjusted for any range, repent

the calibration for each range from 3 to 1000 volts until all ranges arc within the req_lred accuracy.

6-7. VERIFICATION OF CURRENT RANGE CALIBRATION.

Connect the Model 261 Picoampere Source to the Model 153.

a.

Model 261 for a full-scale input.

ampere to 100~milliampere ranges;

and i3.5% for the 30 and lo-picoampere ranges.

current source; the Model 261 output is not sufficient for the higher ranges.

The range resistor in the 3 through 100-milliampere positions, Rl44, is selected t3

b.

0

a +a/.,

sistor to circuit low.

6-8. RISE TIME VERIFICATION.

a. Connect the Oscilloscope to the Model 153 OUTPUT,

Model 260 POLARITY Switch from OFF to + or - as required) to the Model 153 input which

will produce 100, 30 or lo-microvolt full-scale readings. The rise time (10% to 90% of

full scale) for a full-scale input signal should be less than 1 second on the loo-micro-

volt range; less than 5 seconds on the 30 and lo-microvolt ranges.

-2% tolerance due to a" approximate 1% effect in the lead resistance from the ri--

If necessary, adjust the ATTENUATOR ADJ Potentiometer, R137 (Figure Xl),

The Model 153 should read within f1.5% for the 3 "an=-

?2.5% for the 1-nanoampere to lOO-picoampere ranges;

For the ranges above 10-4, construct a

Use a step function (turn the

Check for both positive 2nd

For each range, set tht

Apply the step function for the l-millivolt and higher ranges. Note the motion oi

b.

the meter.

tor R127 (Figure 22) to obtain a smooth motion.

6-9. DRIFT VERIFICATION.

with a good low thermal short.

METER Switch to +.

8 microvolts. After two hours,

See Figure 18 for a typical drift run for the Model 153.

6-10. INPW IMPEDANCE CHECK.

153 input.

Apply 1 volt to the resistor with the Model 241 Voltage Supply. The Model 153 must read

at least 50% of full scale.

FIGURE 18.

range at various increasing input shunt resistances between short circuit and 20 megohms.

Noise increases with increase in shunt resistance as Johnson noise' in the shunt add in

quadratare to basic instrument noise.

due to physical changing of the shunts.

If the meter shows uneven travel to full scale, increase the value of resis-

Make sure the Model 153 cover is on and the input is shorted

Connect the Model 153 to the Model 370 Recorder. Turn the

During the first two hours of warm-up, the drift should be less than

the drift should be within f2 microvolts per 24 hours.

Put a 200-megohm shielded resistor in series with the Model

Set the Model 153 RANGE Switch to 1 VOLTS and the FUNCTION Switch to OPEN.

If it does not,

Typical Model 153 Drift Chart.

Transients occuring at points of shunt change are

return the instrument to the factory.

The instrument is set on the

lo-microvolt

I

1174

25

Page 31

CALIBRATION

MODEL 153 MICROVOLT-AMMETER

FIGURE 19.

meter feting left.

26

Model 153 Interior.

Components and assemblies are shown in the view with the

Figure 20 shows the chassis view from the other side.

1174 :

Page 32

I

l-

MODEL 153 MICROVOLT-AMMETER

CALIBRATION

(Fig. 27:

,301

..,,_ ;.A::~

FIGURE 20. Model 153 Interior.

meter facing right.

I

1174

Figure 19 shows the chassis view from the other side.

Components and assemblies are shown in the view with tt

.&A>~~~_. _

.

.“L..~. -. _~

27

Page 33

CALIBRATION

MODEL 153 MICROVOLT-AMMETER

"lOl--;i

--"d.- ..,. -

FIGURE 21.

Capacitor, Tube,

Battery and Modulator Locations on Printed Circuit

Board PC106. Refer to Figure 22 for resistor locations.

28

r

1174 _

Page 34

Page 35

CALIBRATION

MODEL 153 MICROVOLT-AMMETm

cio3

cio4

FIGURE 23 (left).

Component Locations f3r

Printed Circuit Board PClO7.

FIGURE 24 (right).

Component Locations

on Model 153 Rear Chassis Panel.

is from the inside of the instrument.

The view

P

30

Page 36

I

MODEL 153 MICROVOLT-AMMETER

CALIBRATION

I

I

FIGURE 25.

Switch Sl.

1174

Component Locations on Range

R169-

FIGURE 26.

Switch Sl.

IRi66 1

R167 Rl65

Component Locations on Range

RI-64

31

Page 37

I

CALIBRATION

i<rzOV-

3.201-

w ..-

MODEL 153 MICROVOLT-AMMETER

R207'

RZO?-

C303

FIGURE 27.

'1 r,

.i

Y

Component Locations for Model 153 Power Supply and Multivibrator.

I

32

1174

Page 38

MODEL 153 MICROVOLT-AMMFPER

ACCESSORIES

SECTION 7.

7-l.

3-foot triaxial cable,

feature is useful for attaching the Probe at a single point for repeated measurements.

When making low-level measurements,

thermal emf's.

measurements.

Keithley part number for the input cable used on the Probe is SC-22; the number for the

cable on the low lead is SC-32.

7-2.

153 is with the Model 1532 Test Leads supplied with the instrument. The Leads consist

of a mating connector to the Model 153,

designed for repeated measurements. To reduce thermal emf's, the Leads are of all copper

construction and use low-thermal cadmium solder connections.

remnve the alligator clips and attach the lead to a circuit with low-thermal solder (Model

1503) or by a crimp connection.

as Scotch Brite, before making the connecl

MODEL 1531 GRIPPING PROBE (Figure 28).

It is useful for making in-circuit measurements.

Allow the circuit being tested to reach thermal equilibrium before ;n;i.ng

Connect the Probe plug directly to the Model 153 INPLlT Receptacle.

MODEL 1532 TEST LEADS (Figure 29).

Clean the bare wire with a non-metallic abrasive, such

The plug on the Leads mates with th,

:t.

handle the probe body as little as possible to avoid

ACCESSORIES

The Model 1531 has a gripping probe and e

Its gripping

An easy way to make connections to the Model

a 3-foot cable and two alligator clips. It is

For permanent connections,

:iol

eM

For trim" connections. use the Model 1483

1.

od

153 INPirr Receptacle: ,

I.

FIGURE 28.

Gripping Probe.

7-3.

30).

with the Model 153 special triaxial INPUT

Receptacle and to accept the Model 1534

Triax Cable or any other cable with 0.145-

inch outer diameter. FIGURE 30.

7-4,

CABLE.

ciently high to maintain the Model 153's performance specifications.

is 1000 volts center conductor to inner shield; 500 volts between shields. The Cable uses

copper in the signal leads.

with no connectors.

7-5.

used is clean and that it has not been used with regular solder before.

MODEL 1533 MATING CONNECTOR (Figure

The Model 1533 is designed to mate

MODEL 1534 SPECIAL LOW-THERMAL TRIAK

ACCESSORY KITS.

If cadmium solder (Model 1503) is used for a connection,

a.

Keithley Instruments Model 1531

The Model 1534 is 10 feet of low-noise cable which has leakage resistance suffi-

outer diameter of the Cable is 0.145 inch.

FIGURE 29.

T.DL Laida.

I

I

Mating connector.

KeFthley Instruments Model 1532

Keithley Instruments Model 1533

Voltage breakdown

The Cable comes

make sure the soldering iron

Use only rosin

1

I

Page 39

ACCESSORIES

.-..-- ^. . .I”^_ -. .^

LG”Kb JL.

Ploae1 lita, LOw-‘l”ermaL Lonnec-

tion Kit. Refer to Section 8 for contents.

MODEL 153 MICROVOLT-AMMETER

b. Use crimp connections vith copper

wire and lugs ior the best low-thermal

joints. Thcrzml enf's can be reduced to

10 nanovolts or less using the copper vi:_:

sleeves and lugs found in the Model 1483

Loxr-Thermal Connection Kit.

'Tllc Kit con-

tains a crimp tool, shielded cable, an assortment of copper lugs, copper wire, cai-

mium solder and nylon bolts and nuts.

is a complete kit

for making very low the:-

1:

ma1 measuring circuits. The Kit enables

the user of the Model 153 to maintain ther-

mal stability in his own circuit. Sectio::

8 lists the contents of the Kit.

7-6. MODEL 6012 ADAPTER (Figure 32). The

Model 6012 is a triaxial-to-coaxial adapter.

FIGURE 32.

Keithley Instruments Model 6012

Triaxial-to-Coaxial Adapter

floated when used with the Adapter.

Circuit low and chassis ground are connected, and the

It may be used to connect uhf and coaxial

circuits to the Model 153 input. Note, j‘3>1ever,

that the Model 153 should not be

outer shell of the Adapter would be off ground if it were floated.

7-7. RACK MOUNTING (See Figure 33).

The Model 153 is shipped for bench use.

a.

the instrunxnr tz ;mL's u,uu,,L;~I~ w LWZ

To convert the Model 153, remove the four screws at the bottom of each side of the

b.

sctinaard h.LA

The Model 4005 Rack Mounting Kit converts

LV-inch width.

instrument case. Lift off the top cover assembly with the handles; save the four screws.

To remove the feet and tilt bail from the bottom cover assembly,

remove the four screws

and allow it to drop off. Remove the feet and tilt bail and replace the bottom cover using

the same screws.

Item Keithley

(See Fig. 33) Description Part No. Quantity

1

2

3 Filler Panel

-_

__

Cover Assembly

20018B

1

Mounting Panel 19396B 1

19397B 1

Screw, No. IO-3/8, HSS

Kep Nut, No. 10

_-

--

12

8

TABLE 7. Parts List for Keithley Model 4005 Rack Mounting Kit.

34

1174 1

Page 40

MODEL 153~MICFiOVOLT-AMMETER ACCESSORIES

Insert the top cover assembly (1) in place and fasten to the chassis with the fo-r

c.

screws previously removed.

and kep nuts.

the filler panel (3) to the opening in the mounting panel with four #IO screws and

nuts.

0

Fasten the

3

I

0

Attach the mounting panel (2) to the rack with four /ilO sc:+:,:s

Model 153 to the mounting panel with four 810 screws.

Faster

kep

0

0

Q

1174

35

Page 41

Page 42

MODEL 153 MICROVOLT-MER

REPLACEABLE PARIS

SECTION 8.

8-I.

Model 153 and its accessories.

tion,

ber.

8-2.

Part Number,

and those parts coded for Keithley manufacture (80164) must be ordered through Krithle,~

Instruments or its representatives.

Parts List,

ment, Keithley Instruments, Inc.

=w

CbVar

CerD

Comp

CompV

REPLACEABLE PARTS LIST.

a suggested manufacturer, the manufacturer’s part number and the Keithley Part NIX-

The last column indicates the figure picturing the part.

HOW TO ORDER PARTS.

For parts orders, include the instrument’s model and serial number, the Keithle!

a.

the circuit designation and a description of the part.

completely describe the part, its function and its location.

Order parts through your nearest Keithley representative or the Sales Service Depart-

b.

a”pere Mfg.

Carbon Variable Mil No. Military Type Number

Ceramic, Disc

Composition

Composition Variable

The Replaceable Parts List describes the components of t?e

The List gives the circuit designation, the part descrip-

REPLACEABLE PARTS

All structural par-s

In ordering a part not listed in the Replaceable

Manufacturer

MtF Metal Film

MY

n

Mylar

ohm

DCb

EAl

JiUC

EXB

RTT

f

Fig.

hy

k

M or meg mega (106) or megohms wwvar

m milli (10-3)

Deposited Carbon

Electrolytic, Aluminum

Elecrrnlytir~ metal rza9eli

Electrolytic, tubular Ref.

Electrolytic, tantulum

farad

Figure

henry

kilo (103)

TABLE 8.

Abbreviations and Symbols

PMT Metalized paper, phenolic cas

Poly Polystyrene

P

CI

” volt

Var

Gw

wwenc

pica (lo-129

Reference

micro ( 10e6)

Variable

watt

Wirewound

Wirewound encapsulated

Wirewound Variable

,

.

1174

37

Page 43

RE LACEABLE PARTS

P

MODEL 153 MICROVOLT-AMMETER

J.lODEL 153 REPLACEABLE PARTS LIST

(Refer to Schematic Diagram 17771H for circuit designations.)

CAPACITORS

Circuit Mfg.

Desig.

Cl01 0.1 pf

Cl02

Cl03 0.1 pf 100 v

Cl04 .Ol @f

Cl05 .OOl pf 1000 "

Cl06

Cl07 40/40/20 vf

Cl08

Cl09

Cl10

Cl11

Cl12 0.1 pf

Cl13

Cl14

Cl15

Cl16

Cl17 .Ol pf 300 "

Cl18

Cl19 100 pf

Cl20

Value Rating

100 ”

0.1 I.lf

.Ol IJ.f

.047 pf

10 pf

0.1 I.lf

.Ol kf

10 IJ.f

.05 pf

.05 pf 100 v

.l !Jf

0.5 wf

1.0 pf

100 v

500 "

200 v

450/450/50 " Em

200 v

15 v

200 v

1000 v

100 "

15 v

100 "

200 "

400 "

25 v

200 "

'Op=

Poly

Poly

Poly

Poly

CerD

MY

MY

EAl

MY

CerD

MY

EAl

MY

MY

MY

CerT 13050

MY

EAl

MY

Code

80164 C142-O.lM

80164 Cl42-O.lM

80164 Cl42-O.lM

71590

72982 8OlZ5V102P C22-.OOlM

14655

56289

14655

56289

02777

72982

12673

56289

12673

12673

02777

14655

29309

13050

Mfg.

Part No.

CPR-1000.J

WMF-2Sl

TVL3786

WMF-2547

8913159 C93-10M

P-12M C66-O.lM

811Z5V103P C22-.OlM

37-M

89D159

32M

32M

P-12.M

MWlA.Ol@

wMF4P5

JC8100258P C211-100M

107-21

Keithley Fig.

Part No. Ref.

Cl38-.OlM

C66-.OlM

C33-40/40/20M

C66-.047M

Cl05-O.lM

C93-10M

C105-.05M

C105-.05M

C66-O.lM

C61-.OlM

Cl14-0.5M

C66-l.OM

23

23

23

23

21

21 -

19

21

21

21

21

21

21

21

21

21

21

21

21

21

Cl21

Cl22 .05 vf 600 v

c201

c202

c301

C302

c303

c304

c305

circuit

Desig.

D301

D302

D303

100 !Jf '

.Ol pf

.Ol pf

80/40 pf

1000/1000 pf

100 )lf

.OOl pf

.OOl pf

VP=

Silicon

Silicon

Silicon

15 "

400 "

400 "

450/450 v

35 v

15 "

1000 v

1000 v

ETB

My

MY

MY

EMC

aB

ETB

CerD

CerD

Number

lN3256

lN3256

lN3253

DIODES

56289

56289

14655

14655 wMp4Sl

56289

56289

56289

72982

72982

Mfg.

- .

Code

02735 RF-22

02735 W-22

02735 ,xF-20

TE1162

6PS-S50

wMF4Sl

2778

FP =-'ti+/

TE1162

8OlZ5V102P C22-.OOlM

8OlZ5VlO2P C22-.OOlM

Keithley

Part No.

C3-100M

C62-.05M

c114-.olM 27

C114-.OlM

C36-80/40M

r

1' 27

: 27

21

24

27

20

19

27

24

24

Fig.

Ref.

27

38

1174

Page 44

MODEL 153.MICROVOLT-AMMFER

REPLACEABLE PARTS

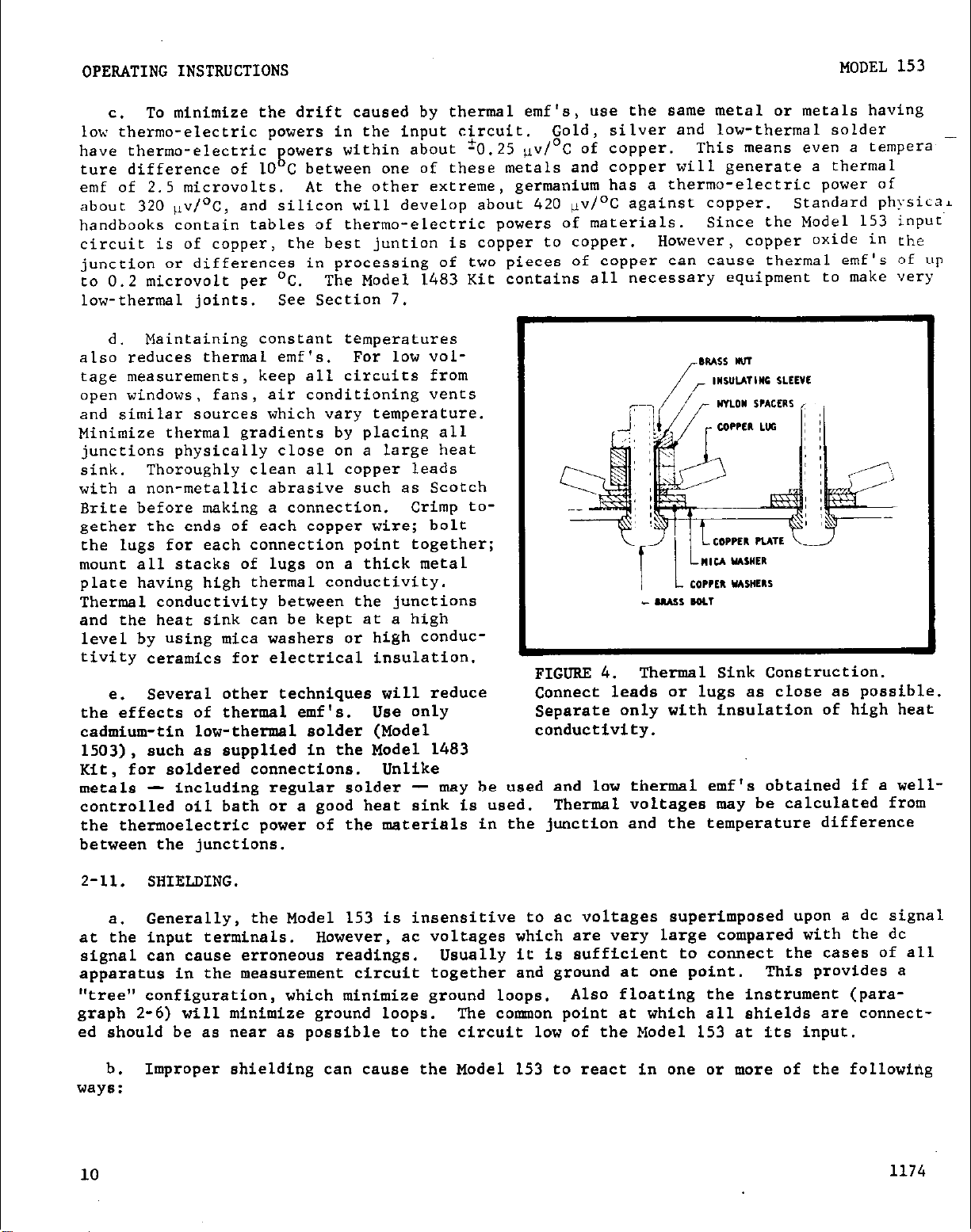

DIODES (Cont'd)

circuit

Desig.

D304

D305

Circuit

Desig.

BlOl

B102

El01

El02

E103A

E103B

Fl(117 v)

Yl(234 v)

-

Type

Silicon

ZlXC??2

Description

Mercury Cell,

Mercury Cell,

Photocell (Mfg. No. cL603C~)

Fuse;

Fuse Holder (Mfg. No. 342012)

slow blow, 0.25 amp (Mfg. Nb: 313.250)

1.35 v (Mfg. No. PX-13)

1.35 v (Mfg. No. PX-13).

NWlbel- Code

lN3253

lN3022A

MISCELLANEOUS PARTS

,mo c+ss

. . . -

Mfg.

02735

04713

Keithley

Part No.

Bs-20. b I

DZ-23

Mfg. Keithley

Code

37942 BA-16

37942 BA-16

75915

75915

Part No.

Fu-4

Fu-17

FH-3

Fig.

Ref.

~ 27

27

Fig.

Ref.

21

21

23

23

3

3

GLlOl

Jl

-

32

53

54

L301

L302

Ml01

Pl

Sl

52

33

Neon Lamp (Mfg. No. NE-2U) 08804

Receptacle, Special, INPUT

Plug, Triaxial, Mate of Jl

Binding Post, DC OUTPUT (Mfg. No. DFZlRC) 50474 BP-11R

Binding Post, LO (Mfg. No. DF2LBC) 58474 BP-11B