Page 1

INSTRUCTION MANUAL

MODEL 15OB

MICROVOLT AMMETER

Page 2

WARRANTY

We warrant each of our products to be free

from defects in material and workmanship. Our

obligation under this warranty is to repair or

replace any instrument or part thereof (except

tubes and batteries) which, within a year after

shipment, proves defective upon examination.

We,will pay domestic surface freight costs.

To exercise this warranty, call your local

field representative or the Cleveland factory,

DDD 216-248-0400. You will be given assist-

ance and shipping instructions.

REPAIRS AND RECALIBRATION

Keithley instruments maintains a complete re-

pair service and standards laboratory in Cleve-

land, and has an authorized field repair facility

in Los Angeles.

To insure prompt repair or recalibration serv-

ice, please contact your local field representative or the plant directly before returning the

instrument.

Estimates for repairs, normal recalibrations,

and calibrations traceable to the National Bureau of Standards are available upon request.

Page 3

MODEL 150B MICROVOLT AMMETER

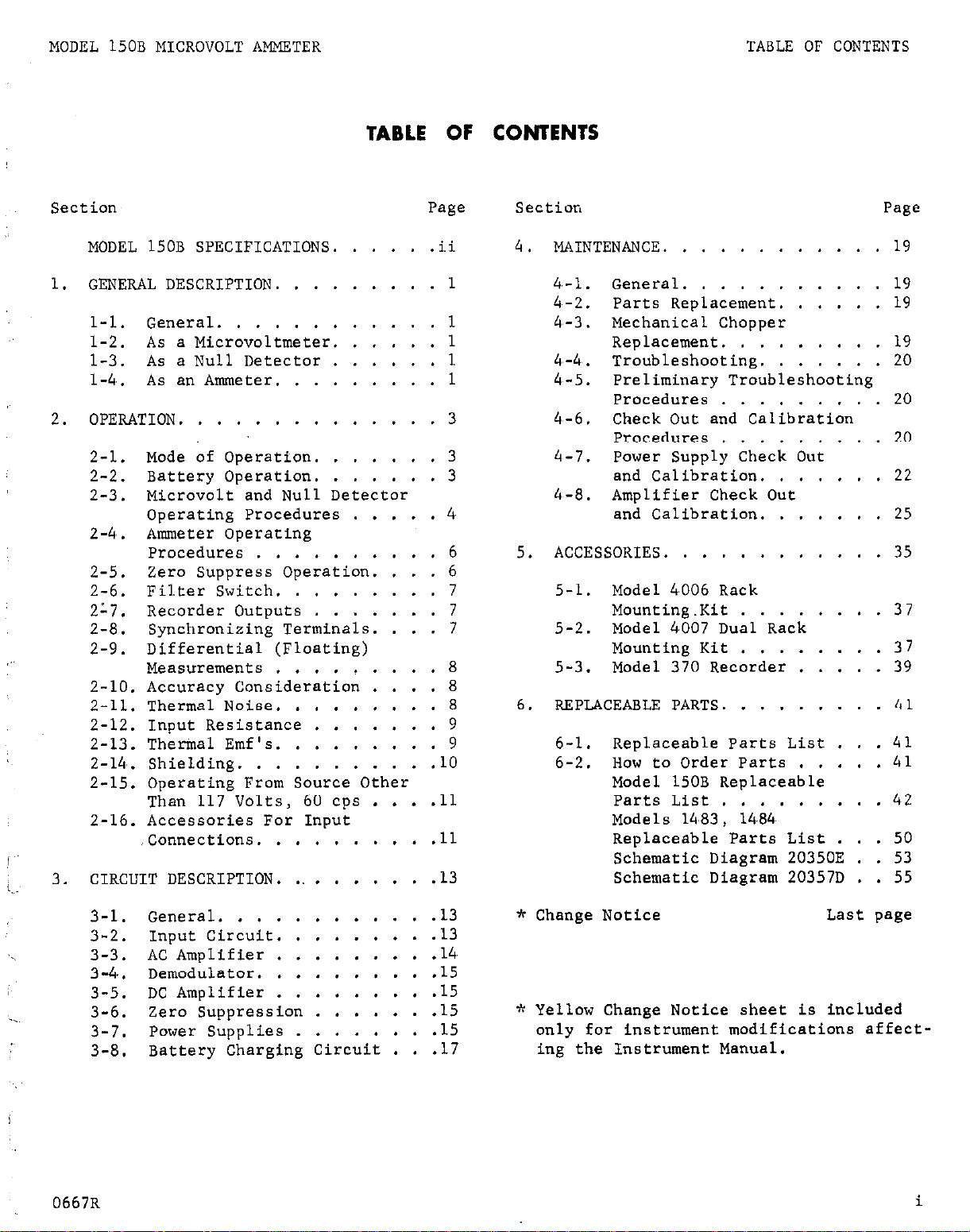

TABLE OF CONTENTS

TABLE OF

Section

MODEL 150B SPECIFICATIONS. .... .ii 4. MAINTENANCE. . . . . . . . . . . 19

1. GENERAL DESCRIPTION. ........

l-1.

l-2. As a Microvoltmeter. ..... 1

l-3.

l-4 .. As an Ammeter. ........ 1

2. OPERATION. ............. 3

2-1.

2-2.

2-3.

2-4,.

2-5.

2-6.

2e7.

2-8.

2-9.

2-10.

2-11.

2-12.

2-13.

Z-14,.

2-15.

2-16.

CIRCUIT DESCRIPTION. ., . . . . . . .13

3.

General. ...........

As a Null Detector ...... 1

Mode of Operation. . . . . .

Battery Operation. . . . . .

Microvolt and Null Detector

Operating Procedures . . . .

Ammeter Operating

Procedures . . . . . . . . .

Zero Suppress Operation. . .

Filter Switch. . . . . . . .

Recorder Outputs . . . . . .

Synchronizing Terminals. . .

Differential (Floating)

Measurements . . , . F . . .

Accuracy Consideration . . .

Thermal Noise. . . . . . . .

Input Resistance . . . . . .

Therinal Emf's. . . . . . . .

Shielding. . . . . . . . . .

Operating From Source Other

Than 117 Volts, 60 cps . . .

Accessories For Input

Connections. . . . . . . . .

Page

.3

.3

. 4,

.6

.6

: 7

.7

.8

.8

: 9

. 9

.lO

.ll

.ll

CONTENTS

1

1

7

0

Section

4,-l.

4-2.

4,-3. Mechanical Chopper

4,-4,. Troubleshooting. . . . . . . 20

4-5.

4,-6. Check Out and Calibration

4-7.

4,-a. Amplifier Check Out

ACCESSORIES. . . . . . . . . . . . 35

5.

5-l.

5-2. Model 4007 Dual Rack

5-3.

6. REPLACEABLE PARTS. . . . . . . . . 41

6-l.

6-2. How to Order Parts . . . . . 41

General. . . . . . . . . . . 19

Parts Replacement. . . . . . 19

Replacement. . . . . . . . . 19

Preliminary Troubleshooting

Procedures . . . . . . . . . 20

Procedures . . . . . . . . . 20

Power Supply Check Out

and Calibration. . . . . . . 22

and Calibration. . . . . . . 25

Model 4,006 Rack

Mounting.Kit . . . . . . . . 37

Mounting Kit . . . . . . . . 37

Model 370 Recorder . . . . . 39

Replaceable Parts List . , . 41

Model 150B Replaceable

Parts List . . . . . . . . . 42

Models 14,83, 14.84

Replaceable Parts List . . . 50

Schematic Diagram 20350E . . 53

Schematic Diagram 20357D . . 55

Page

3-1. General. . . . .

3-2.

3-3.

3-4..

3-5.

3-6.

3-7.

3-8.

0667R

Input Circuit. .

AC Amplifier . . .....

Demodulator. . . ... * ..

DC Amplifier . .

Zero Suppression .....

Power Supplies . .....

Battery Charging

, ......

.......

......

Circuit .. .17

13

13

. .14.

.15

.15

. .15

. .15

* Change Notice Last page

* Yellow Change Notice sheet is included

only for instrument modFfications affect-

ing the Instrument Manual.

i

Page 4

GENERAL DESCRIPTION

MODEL 150B MICROVOLT AMMETER

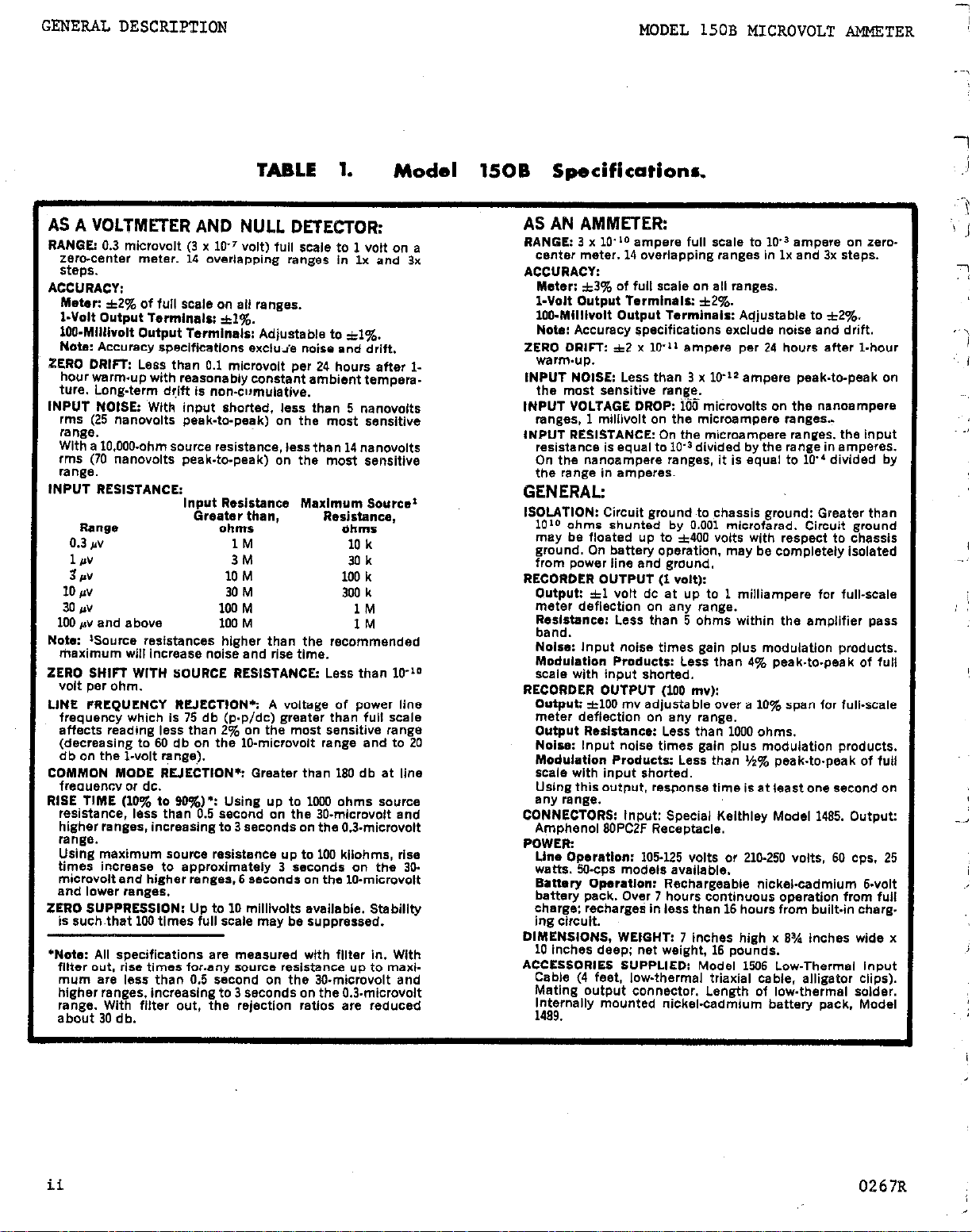

TABLE 1.

Model 1SOB Specifications.

AS A VOLTMETER AND NULL DETECTOR:

RANGE: 0.3 microvolt (3 x 10-’ volt) full scale to 1 volt on a

Zero-centw meter. 14 overlapping ranges in Ix and 3x

steps.

ACCURACY:

Meter:

*2g Of full scale on all ranges.

I-Volt Output Terminals: *I%.

100.Millivolt Output Terminals: Adjustable to ~1%.

Note: Accuracy specifications excluie noise and drift.

ZERO DRIFT: Less than 0.1 microvolt per 24 hours after I-

hour warmup with reasonably constant ambient tempera.

ture. Long-term d!ift is ncwcumulatlve.

INPUT NOISE: ‘With input shorted, less than 5 nanovolts

rms (25 nanovolts peak-to-peak) on the most sensitive

range.

With a 10,000.ohm source resistance. lessthan 14 nanovolts

rms (70 nanovalts peak-to-peak) on the most sensitive

range.

INPUT RESISTANCE:

Range

0.3 IN 1M

1 P”

3,

10 pv 30 M

30 IN 100 M

100 #v and above 100 M

Note: ‘Source resistances higher than the recommended

maximum will increase noise and rise time.

ZERO SHIFf WITH SOURCE RESISTANCE: Less than

volt

per ohm.

LINE FREQUENCY RUECTION’: A voltage of power line

frequency which is 75 db (p.p/dc) greater than full scale

affects reading less than 2% on the most sensitive range

(decreasing to 60 db on the 10.microvolt range and to 20

db on the l-volt range).

COMMON MODE RLIECTIDN*: Greater than

frequencv or dc.

RISE TIME (10% to 90?&)? Using up to 1wO ohms source

reSistanCe, less than 0.5 second on the 30.mlcravolt and

higher ranges. increasing to 3 seconds on the 0.3.microvolt

range.

Using maximum source resistence up to 100 kllohms, rise

times increase to approximately 3 seconds on the 30.

microvolt and higher ranges. 6 seconds on the lo-microvolt

and lower ranges.

ZERO SUPPRESSION: Up to 10 millivolts available. Stability

is such.that

‘Note: All specifications are measured with filter in. With

filter out. rise times forany source resistance up to maxi.

mum are less than 0.5 second on the 30.microvolt and

higher ranges. increasing to 3 seconds on the 0.3.microvolt

range. With filter out, the rejection ratios are reduced

about 30 db.

Input Resistance Maximum Source*

Greater than,

ohms

3M

10

M

100

times full scale may be suppressed.

Resistance,

Ohms

10 k

30 k

100 k

300 k

1M

IM

180

db at line

1o-‘o

AS AN AMMETER:

RANGE: 3 x lOLo ampere full scale to

center meter. 14 overlapping ranges In lx and 3x steps.

ACCURACY:

Meter: a3% Of full Scale on ali ranges.

I-Volt Output Terminals: *2%.

100.Mllllvolt Output Terminals: Adjustable to +2q6.

Note: Accuracy specifications exclude noise and drift.

ZERO DRIFT A2

werm.up.

INPUT NOBE: Less than 3 x 10’12 ampere peak.to-peak on

the most sensitive ran,~e,

INPUT VOLTAGE DROP: 100 microvolts on the nsnoampere

renges, 1 millivolt on the microampere ranges..

INPUT RESISTANCE: On the microampere ranges. the input

resistance is equal to lo” divided by the range in

On the nanoampere ranges, it is equal to

the range in

x lo’”

amperes~

ampere per 24 hours after

1W3

empere on zero.

lo”

divided by

l.hour

amperes.

GENERAL:

ISOLATION: Circuit ground ,to chassis ground: Greater than

1O’O ohms shunted by 0.001 microfarad. Circuit ground

may be floated up to ~400 volts with respect to chassis

ground. On battery operation. may be completely isolated

from power line end ground.

RECORDER OUTPUT (1 volt):

Output: ztl Volt dc et up to 1 milliampere for full-scale

meter deflection on eny range.

Resistance: Less than 5 ohms within the amolifiar oass

band. band.

Noise: Input noise times gain plus modulation products. Noise: Input noise times gain plus modulation products.

Modulation Products: Less than 4% peak.to-peak of full Modulation Products: Less than 4% peak.to-peak of full

Scale with input shorted. Scale with input shorted.

RECORDER OUTPUT

Output: ztlO0 mv adj;stabi;&er a

meter deflection on eny range.

Output Rsslstancs: Less than 1000 ohms.

Noise: Input noise times gain plus modulation products.

Modulation Products: Less than ‘/z% peak.to.peak of full

scale with input shorted.

Using this output, response time is at least one second on

any IB”B.3.

CONNECTORS: Input: Special Kelthley Model 1485. Output:

Amphenol BOPCZF Receptacle.

POWER:

Line Dperatlon: 105125 volts or 210.250 volts, 60 ops. 25

watts. 50.cps mode18 available.

Battery Operation: Rechargeable nickel-cadmium &volt

battery pack. Ov?r 7 hours continuous operation from full

charge: recharges in less than

ing circuit.

DIMENSIONS. WEIGH(T: 7 inches high x 8% inches wide x

10

inches deep; net weight, 16 pounds.

ACCESSORIES SUPPLIED: Model

Cable (4 feet, low-thermal triaxial cable, alligator clips).

Mating output connector. Length of lowthermal solder.

Internally mounted nickel.cadmium battery pack. Model

1499.

1100

1100

mv): RECORDER OUTPUT

mv):

10%

spa” for full-scale

16

hours from built.in charg.

1506

Low.Therma, Input

ii

0267R

Page 5

MODEL 150B MICROVOLT AMMETER

GENERAL DESCRIPTION

SECTION 1.

l-l.

instrument which measures voltages from 0.3 microvolt to 1 volt and currents from 0.3

nanoampere

with either battery or line power operation.

l-2.

thermopile and thermocouple potentials, Hall effect, contact resistances, biologically

generated emf's, electrochemical potentials and strain guages emf's.

sistance and loti zero shift; excellent zero stability;

and common mode rejection; battery operation; zero suppression;

circuitry;

ment accuracy even from high resistance sources; is ideal for long-term measurements; de-

tects dc signals in the presence of large ac voltages and is virtually insensitive to nc

or dc voltages applied between circuit and chassis ground;

for improved isolation; measures small changes in dc signals: reduces temperature and shielding problems; provides outputs where either filtering is needed or fast response or greater

output power is needed.

GENERAL.

AS A MICROVOLTMETER.

a. The Model 150B is ideal as a microvoltmeter for measuring semiconductor resistivity,

b. The Model 15OB has input noise less than 25 na,novolts peak-to-peak; high input re-

c. With these features, the Model 150B permits excellent resolution; maintains measure-

The Keithley Model 150B Microvolt Ammeter is an extremely sensitive

to

1 milliampere. It can be used as a voltmeter, null detector or an ammeter

two available outputs.

GENERAL DESCRIPTION

very high line-frequency rejection

special low-thermal input

disconnects from power lines

l-3. AS A NULL DETECTOR.

As a null detector the Model 15OB is excellent for use in ratio measurements and in

a.

potentiometer and bridge circuits.

b. The Microvolt Ammeter's outstanding features as a null detector are:

solution; high line frequency and cormnon mode rejection; isolation from chassis ground to

input terminals; battery operation; high input resistance; floating capability; low zero

shift;

C.

usable resolution of most potentiometers and bridges; may be simply connected to the terminals of a null circuit; is very insensitive to commnn mode voltages developed in the

null circuit; can be used in most potentiometer and bridge circuits without off-null load-

ing; accurately detects a null regardless of the setting on most potentiometers and bridges;

compensates for thermal emf's generated in the null circuit.

1-4. AS AN AMMETER.

It is useful for making low voltage drop,

output of radiation detectors,

.._

b.

low zero drift for measuring long-term current; excellent floating capabilities for measuring ungrounded sources;

zercl suppression.

Because

a. The Model 150B has general use in research,

The instrument has low voltage drop for measuring currents in very low-voltage circuits;

of these features the Model 150B has resolution comparable to the maximum

design and production test facilities.

in-circuit measurements as well as measuring the

phototubes and other current generating transducers.

and low input noise,giving excellent resolution.

very good re-

'.

0667R

1

Page 6

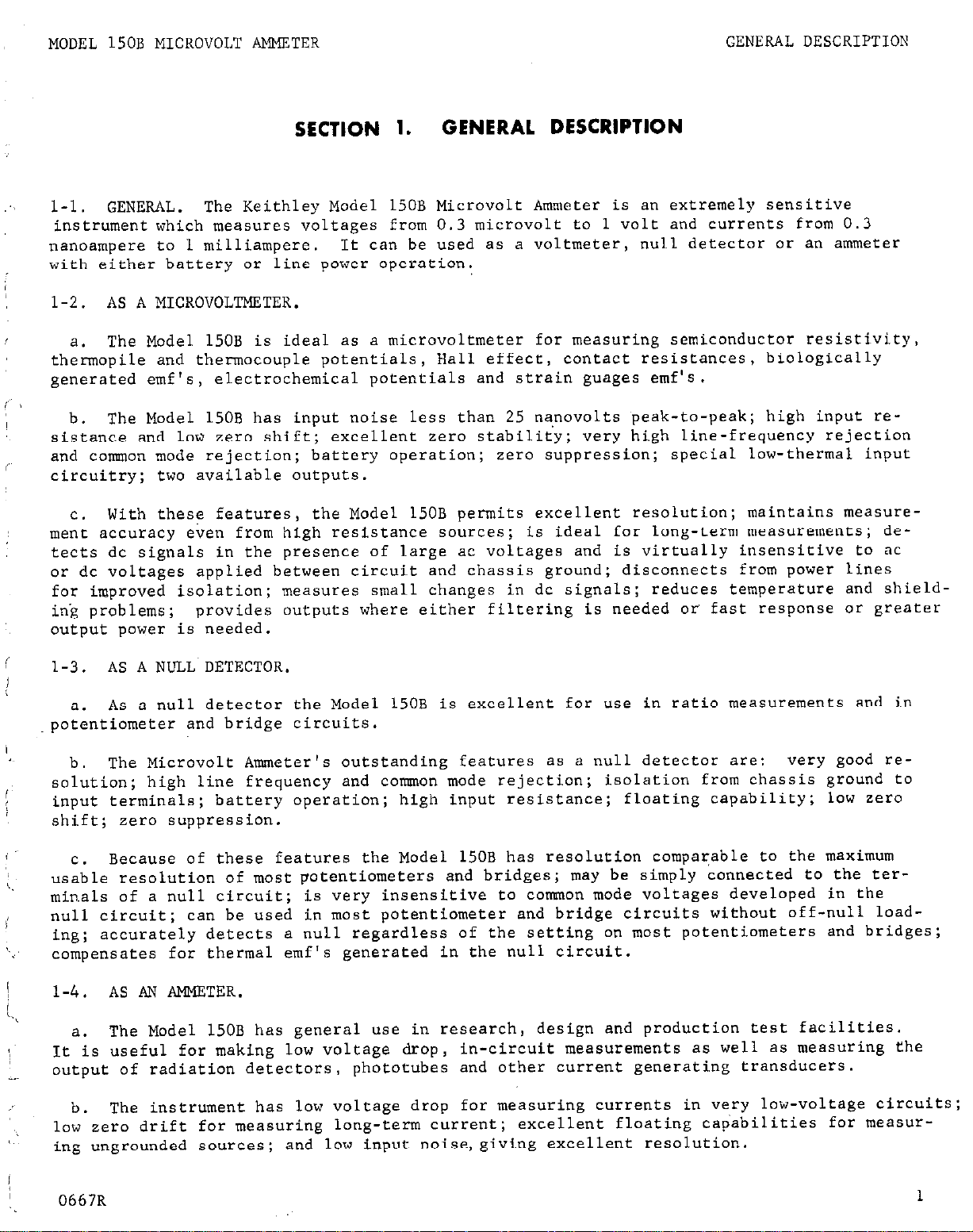

OPERATION MODEL 150B MICROVOLT AMMETER

Control

JEER SUPPLY Switch

4NGE Swi.tch

UNCTION Switch

ERO SUPPRESS Controls Determines the amount of zero suppression

LLTER Switch Connects or disconnects a lfne frequency filter

gPLIT Receptacle Connection for input cable 2-16

TABLE 2.

indicates the paragraph which contains instructions on the use of the control.

Model 150B Front Panel Controls.

Control

Controls mode of operation for power supply

Se.lects the full scale voltage or current which

is to be measured

Determines whether the Model 150B measures voltage or 2-3,2-

current;

at the input

Functional Description

selects input resistance on voltage ranges.

The table briefely describes each control, and

Functional Descriotion Par.

Par.

2-1,2-

2-3,2-

2-5

2-6

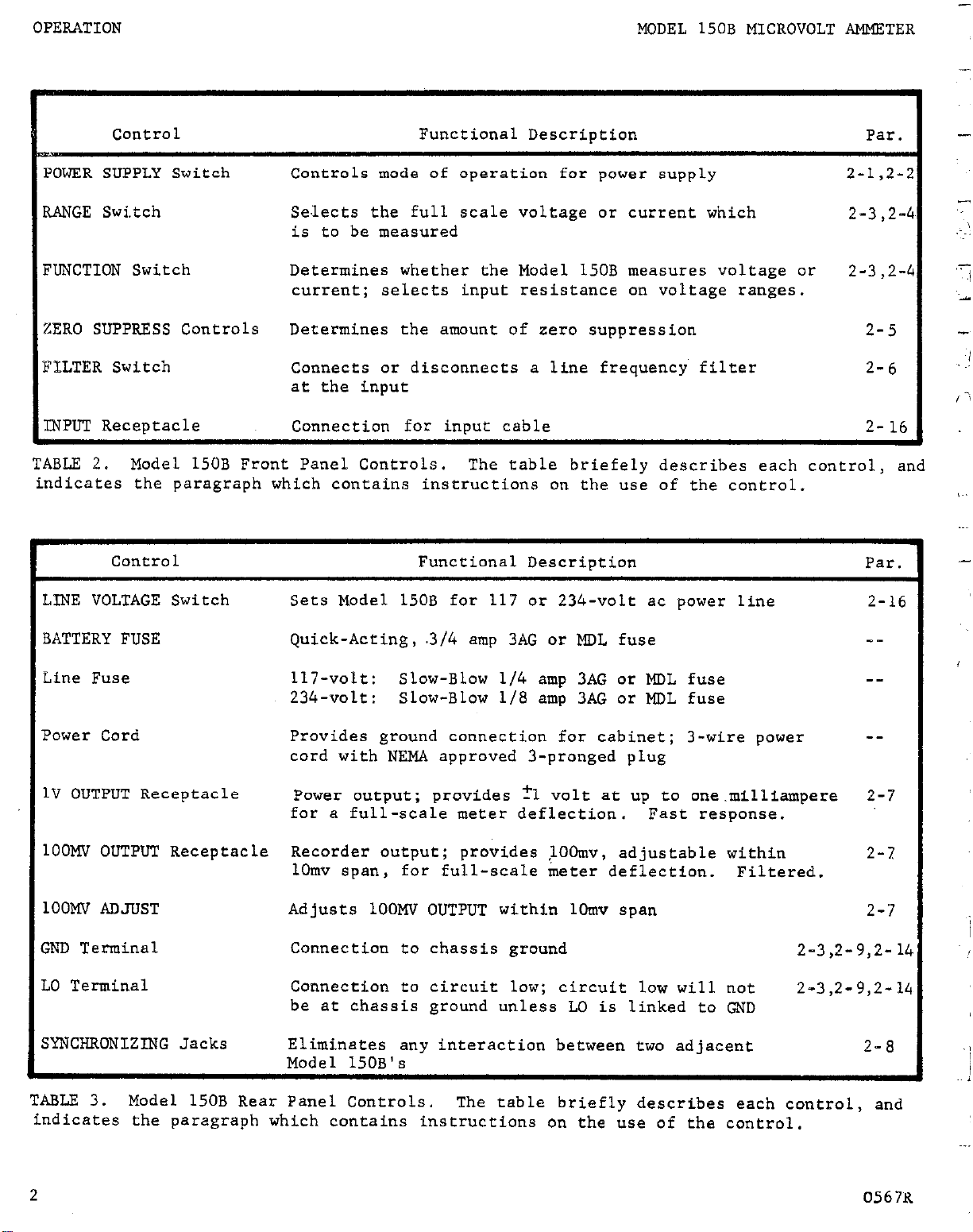

LINE VOLTAGE Switch

BATTERY FUSE

Line Fuse

Power Cord

1V OUTPUT Receptacle

1OOMV OUTPUT Receptacle

1OOMV ADJUST

GND Terminal

LO Terminal

SYNCHRONIZING Jacks

Sets Model 150B for 117 or 234-volt ac power line

Quick-Acting, .3/4 amp 3AG or MDL fuse

117-volt: Slow-Blow l/4 amp 3AG or MDL fuse

234-volt: Slow-Blow l/8 amp 3AG or MDL fuse

Provides ground connection for cabinet; 3-wire power

cord with NEMA approved 3-pronged plug

Power output; provides ?l volt at up to one.milliampere

for a full-scale meter deflection.

Recorder output; provides >OOmv, adjustable within

1Omv span, for full-scale meter deflection. Filtered.

Adjusts 1OOMV OUTPUT within 1Omv span

Connection to chassis ground

Connection to circuit low; circuit low will not

be at chassis ground unless LO is linked to GND

Eliminates any interaction between two ad~jacent

Fast response.

2-16

__

--

--

2-7

2-7

2-7

2-3,2-9,2-14

2-3,2-9,2-14

2-8

TABLE 3.

indicates the paragraph which contains instructions on the use of the control.

2

Model 150B Rear Panel Controls.

The table briefly describes each control, and

0567K

Page 7

MODEL 150B MICROVOLT AMMETER

OPERATION

SECTION 2.

2-l.

and the red dot cannot be seen through the switch knob.

in the AC position, or from its battery with the Switch in BATTERY position.

sition the red dot can be seen.

battery operation, however, if the ac power line will create ground loop or isolation prob-

lems.

is'disconnected; it is greater than 101" ohms shunted by .OOl microfarad with the power

cord connected.

8 cps) which may appear at the output for certain low-level measurements. (See paragraph

2-14,.)

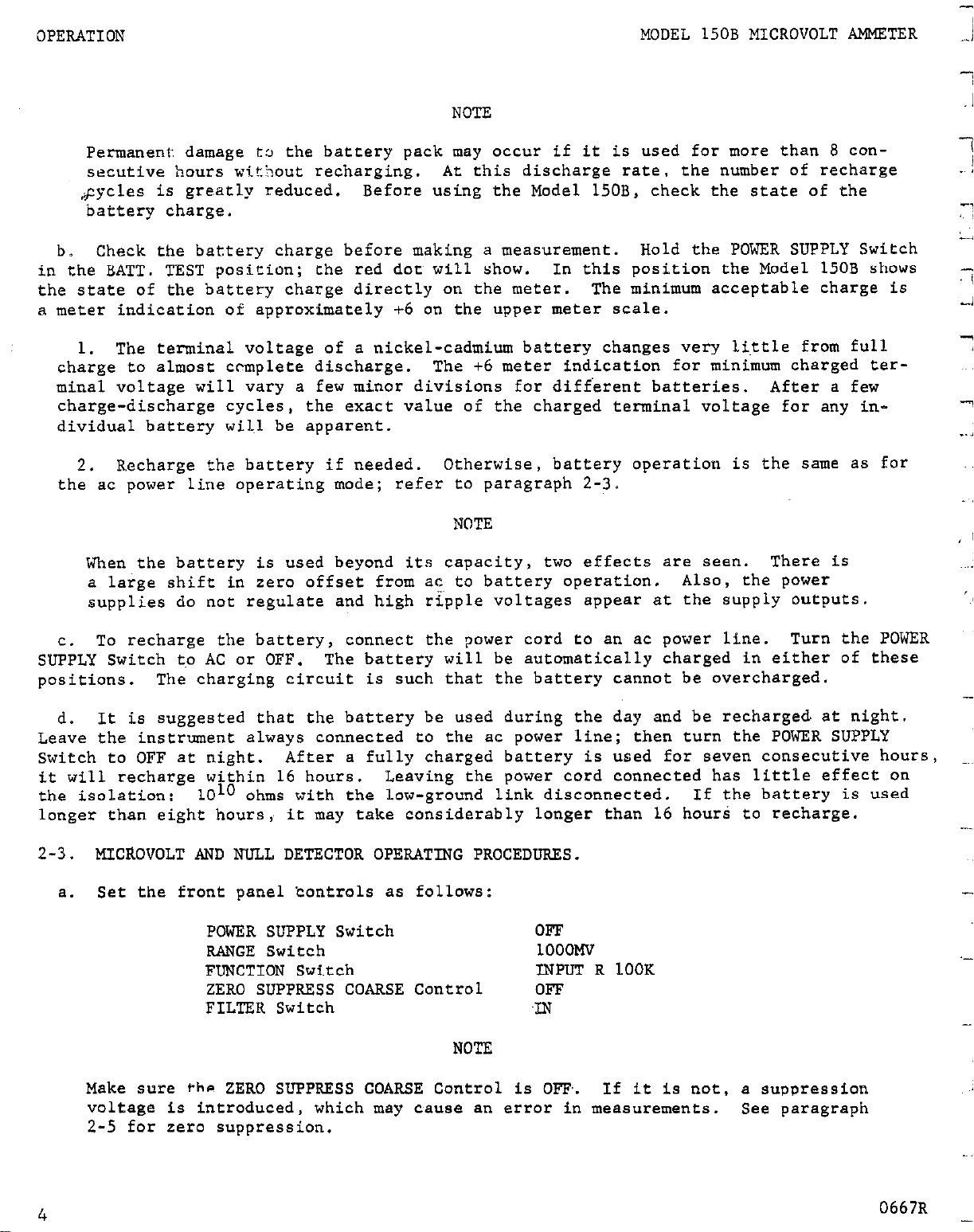

2-2.

MODE OF OPERATION,

a. When the POWER SUPPLY Switch is in the OFF position, the Model 150B will

b. The Model 150B operates either from an ac power line when the POWER SUPPLY Switch is

For most uses the instrument functions well from ac. use

Isolation from low to ground is complete for battery operation when the power cord

Also, battery operation is useful to reduce modulation products (usually

Before using the battery operation,

battery operation can damage the battery pack and lead to inaccurate measurements.

BATTERY OPERATION.

thoroughly read paragraph 2-2.

OPERATION

not operate,

In either po-

NOTE

Improper

The Model 150B is supplied with a rechargeable 6-volt,

battery pack. Do not use the battery more than seven consncutive hours without recharging.

4, ampere-hour nickel-cadmium

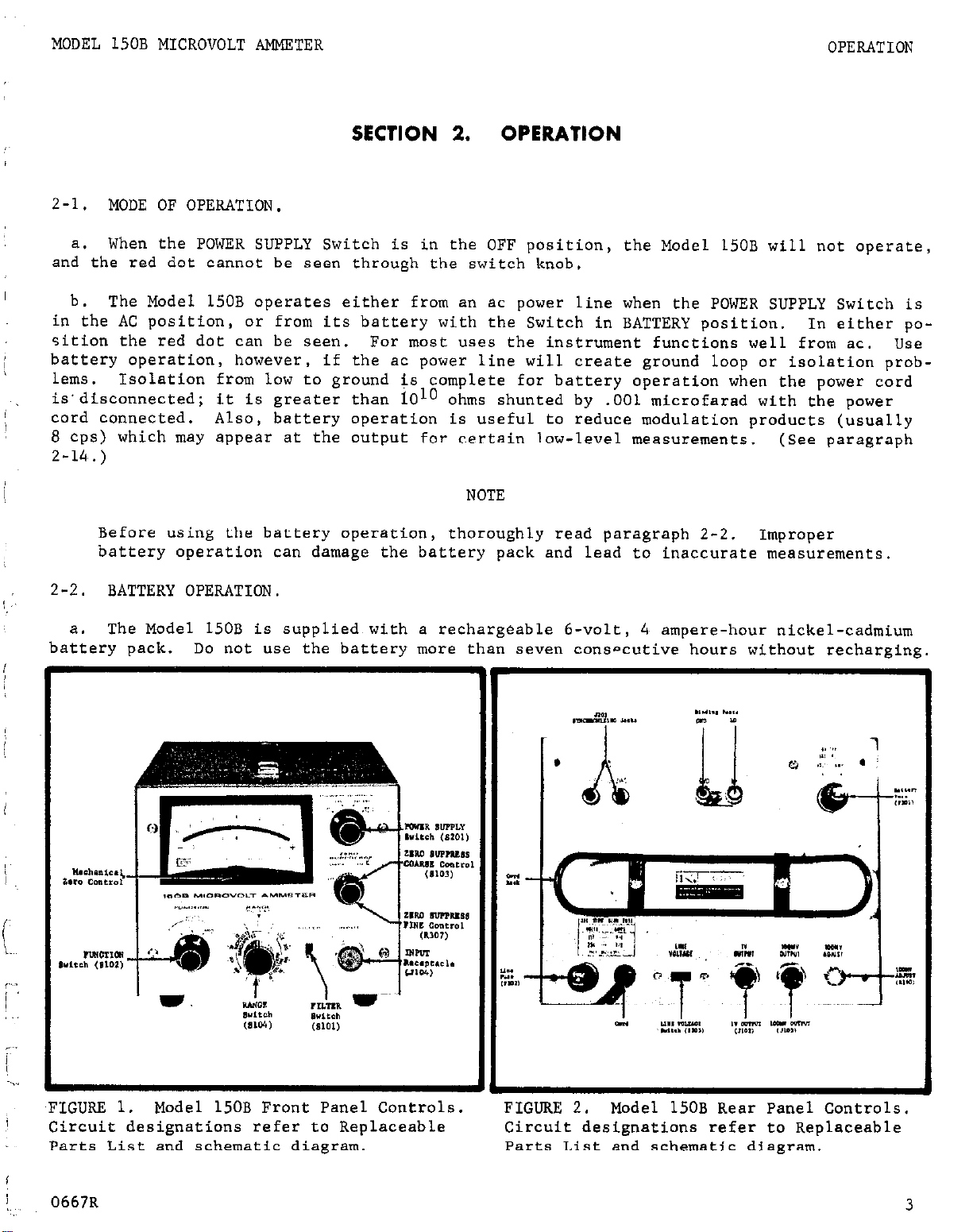

,FIGURE 1.

Circuit designations refer to Replaceable

Parts List and schematic diagram.

0667R

Model 150B Front Panel Controls.

FIGURE 2.

Circuit designations refer to Replaceable

Parts List and schematic diagram.

Model 150B Rear Panel Controls.

3

Page 8

OPERATION

..~

-.,

-.

MODEL 150B MICROVOLT AMMETER

NOTE

Permanent damage to the battery pack may occur if it is used for

secutive hours witbout recharging.

gycles is greatly reduced.

Before using the Model 150B, check the state of the

At this discharge rate, the number of recharge

more

than 8 con-

battery charge.

Check the battery charge before making a measurement. Hold the POWER SUPPLY Switch

b.

in the BATT. TEST position; the red dot will show.

the state of the battery charge directly on the meter.

In this position the Model 150B shows

The minimum acceptable charge is

a meter indication of approximately +6 on the upper meter scale.

Tine terminal voltage of a nickel-cadmium battery changes very little from full

1.

charge to almost crmplete discharge.

minal voltage will vary a few minor divisions for different batteries.

The +6 meter indication for minimum charged ter-

After a few

charge-discharge cycles, the exact value of the charged terminal voltage for any in-

dividual battery wil.1 be apparent.

Recharge the battery if needed.

2.

Otherwise, battery operation is the same as for

the ac power line operating mode; refer to paragraph 2-3.

NOTE

When the battery is used beyond its capacity, two effects are seen.

a large shift in zero offset from ac to battery operation.

Also,

There is

the power

supplies do not regulate and high ripple voltages appear at the supply outputs.

C. To recharge the battery,

SUPPLY Switch t,o AC or OFF.

connect the power cord to an ac power line.

The battery will be automatically charged in either of these

Turn the POWER

positions. The charging circuit is such that the battery cannot be overcharged.

d. It is suggested that the battery be used during the day and be recharge& at night.

Leave the instrument always connected to the ac power line; then turn the POWER SUPPLY

Switch to OFF at night.

After a fully charged

it will recharge within 16 hours.

Leaving the power cord connected has little effect on

battery is used icor

the isolation: loLo ohms with the low-ground link disconnected.

longer than eight hours,

2-3.

MICROVOLT AND NULL DETECTOR OPERATING PROCEDURES.

it may take considerably longer than 16 hours to recharge.

_ .

seven

ConseCutiVe Hours,

If the battery is used

a. Set the front panel 'controls as follows:

POWER SUPPLY Switch

RANGE Switch

FUNCTION Switch

OFF

1oooMV

INPUT R lOOK

ZERO SUPPRESS COARSE Control OFF

FILTER Switch

-IN

NOTE

Make sure rha ZERO SUPPRESS COARSE Control is OFF.

voltage is introduced,

which may cause an error in measurements.

If it is not, a suppression

See paragraph

2-5 for zero suppression.

.-

-

4

0667R

Page 9

MODEL 150B MICROVOLT AElMETER

b. Check the voltage shown on the rear panel LINE VOLTAGE Switch; connect the Model

150B to the ac power line. The battery will now be charging.

If the circuit low is to be at ground, put the low-ground link between the LO and GND

c.

terminals on the rear panel. The ground terminal (GND) is connected to the chassis and the

third wire of the power cord. The low terminal (LO) is connected to circuit ground and the

low side of the INPUT Connector.

OPERATION

d. Turn the POWER SUPPLY~Switch to the desired mode of operation, AC or BATTERY.

moat stable operation, allow the Model 150B to warm up for 1 hour.

Connect the unknown voltage to the INPUT Receptacle using a Model 1506 or 1507 Low-

e.

Thermal Input Cable.

f. Set the FUNCTION Switch to INPUT R OPEN if high input resistance is desired.

position the Model 150B input resistance varies bv range (See Table 4,). If the input is

left completely open circuit,

onds.

ings as the input circuit is opened.

age with 100 kilohms shunting the INPUT Terminals.

g.

shows the greatest on-scale deflection.

specified for the range being used. (See Table 4). If the maximum is exceeded, the

Model 150B may not perform within its specifications.

circuit's thermal construction.

to the Model 15OB INPUT Receptacle, offset should be less than 0.5 microvolt.

Set the FUNCTION Switch to INPUT R 1OOK if it is desired to maintain on-scale read-

Increase the sensitivity of the Model 150B with the RANGE Switch until the meter

Check the source resistance to make sure'that it is within the maximum value

1.

Zero offsets with the ZERO SUPPRESS Controls off will vary with the quality of the

2.

(See paragraph 2-16)

the meter mav drift off scale on any range within a few sec-

In this position the Microvolt Ammeter measures volt-

When a Model 1488 Low-Thermal Shorting Plug is connected

For

In this

-~

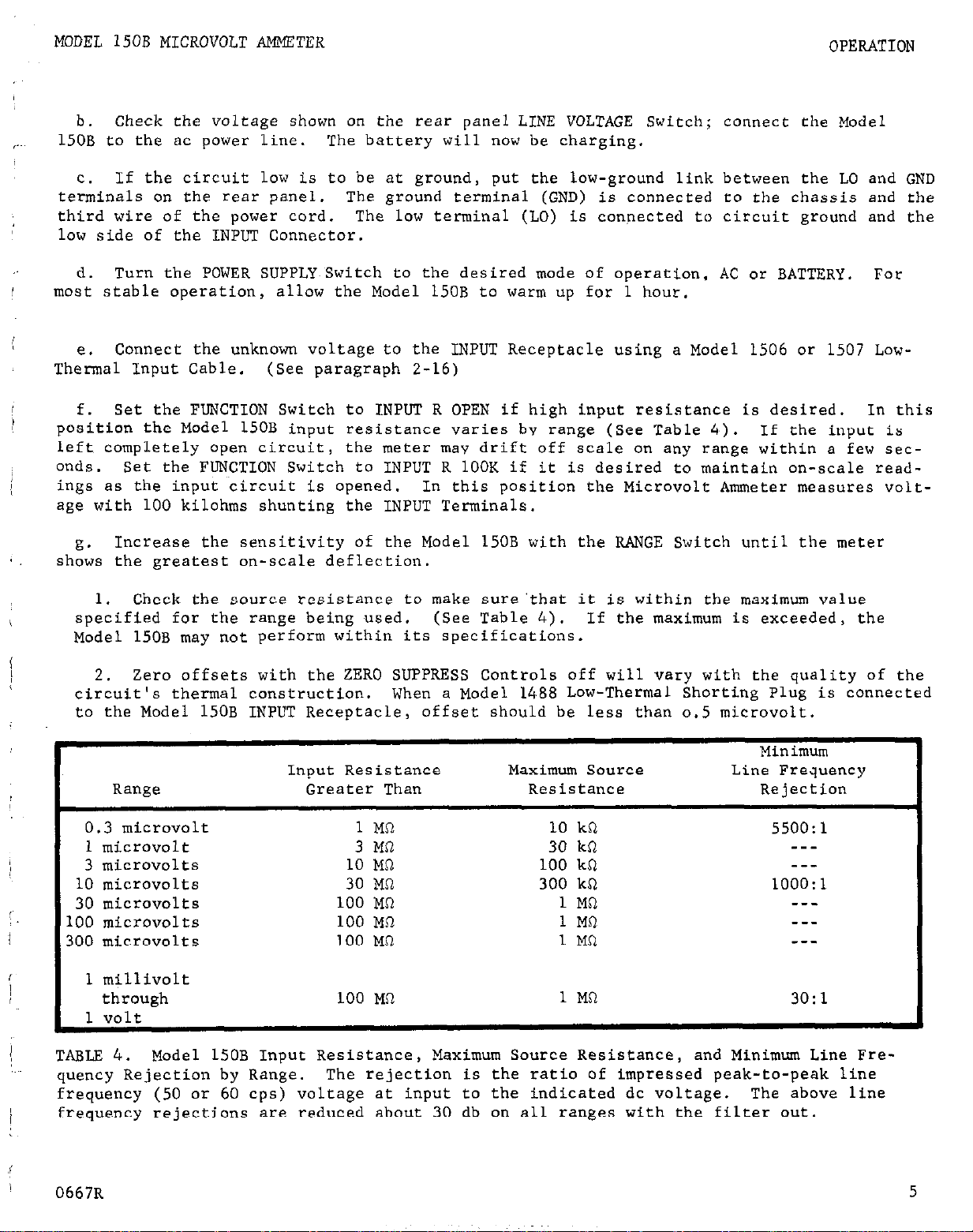

Input Resistance

Range

0.3 microvolt

1 microvolt

3 microvolts

10 microvolts

30 microvolts

100 microvolts

300 microvolt8

1 millivolt

I

through 100 MR

TABLE 4.

quency Rejection by Range.

frequency (50 or 60 cps) voltage at input to the indicated dc voltage. The above line

frequency rejections are reduced about 30 db on all ranges with the filter out.

0667R

Model 150B Input Resistance, Maximum Source Resistance, and Minimum Line Fre-

Greater Than Resistance Rejection

1 Ma 10 kQ 55OO:l

3 Ma 30 kR ---

10 MQ 100 kR --30 Ma 300 kR 1OOO:l

00 MO 1 Ma ---

1

00 MR 1 MR ---

1

00 MO 1 MR ---

1

The rejection is the ratio of impressed peak-to-peak line

Maximum Source

1 MR

Minimum

Line Frequency

3O:l

5

Page 10

-

OPERATION

__;

I

Shifts in source resistance may also affect the zero offset, if the source resis-

3.

tance approaches the maximum value given in Table 4.

source resistances less than 10% of the maximum value.

MODEL 150B MICROVOLT AMMETER

This effect is negligible for

h. At low levels,

leads and the circuit under test.

spurious emf's may be generated simply by conta.ct between the input

These may be compensated for by the zero suppression

circuit. If possible, always leave the instrument connected, Andy adjust the zero after

estabLishing a zero reference in the apparatus under test.

For example, in bridge measure-

ments, disconnect the bridge, exciting voltage, or with a phototube, shield the tube from,

light.

2-4.

AMMETER OPERATING PROCEDURES.

the range using the RANGE Switch.

Set the FUNCTION Switch to the AMPS position.

Make sure low resistance leads are used to connect the

source to the Model 150B input to minimize input voltage drop.

rent overload on any range is 100 mii'liamperes.

put voltage drop is exceeded (see specifications),

If this is exceeded,

the current-sensing resistor may be dam-

The maximum allowable cur-

or if the maximum in-

Select

aged. The Model 150B rise time (10% to 90%) as an ammeter is less than 1 second on the 3nanoampere and higher ranges, increasing to 3 seconds on the 0.3-nanoampere range.

2-5.

ZERO SUPPRESS OPERATION.

a. Purpose:

The zero suppression circuit cancels any constant voltage in order to use

a more sensitive range to observe a superimposed signal. Stability is such that up to

100 times full scale may be suppressed. For example,

the Model 150B can measure changes

of less than one microvolt in a lOO-microvolt steady signal on its l-microvolt range.

b. Suppression Voltages Available:

one of four maximum values. (Refer to Table 5).

The COARSE Control sets the suppression voltage to

The FINE Control continuously adjusts the

voltage between the positive and negative value of COARSE Control setting. For example, if

the COARSE Control is at 3 for a maximum suppression voltage of l 1.2 mv, the FINE Control

adjustment span is from -1.2 mv to +1.2 mv.

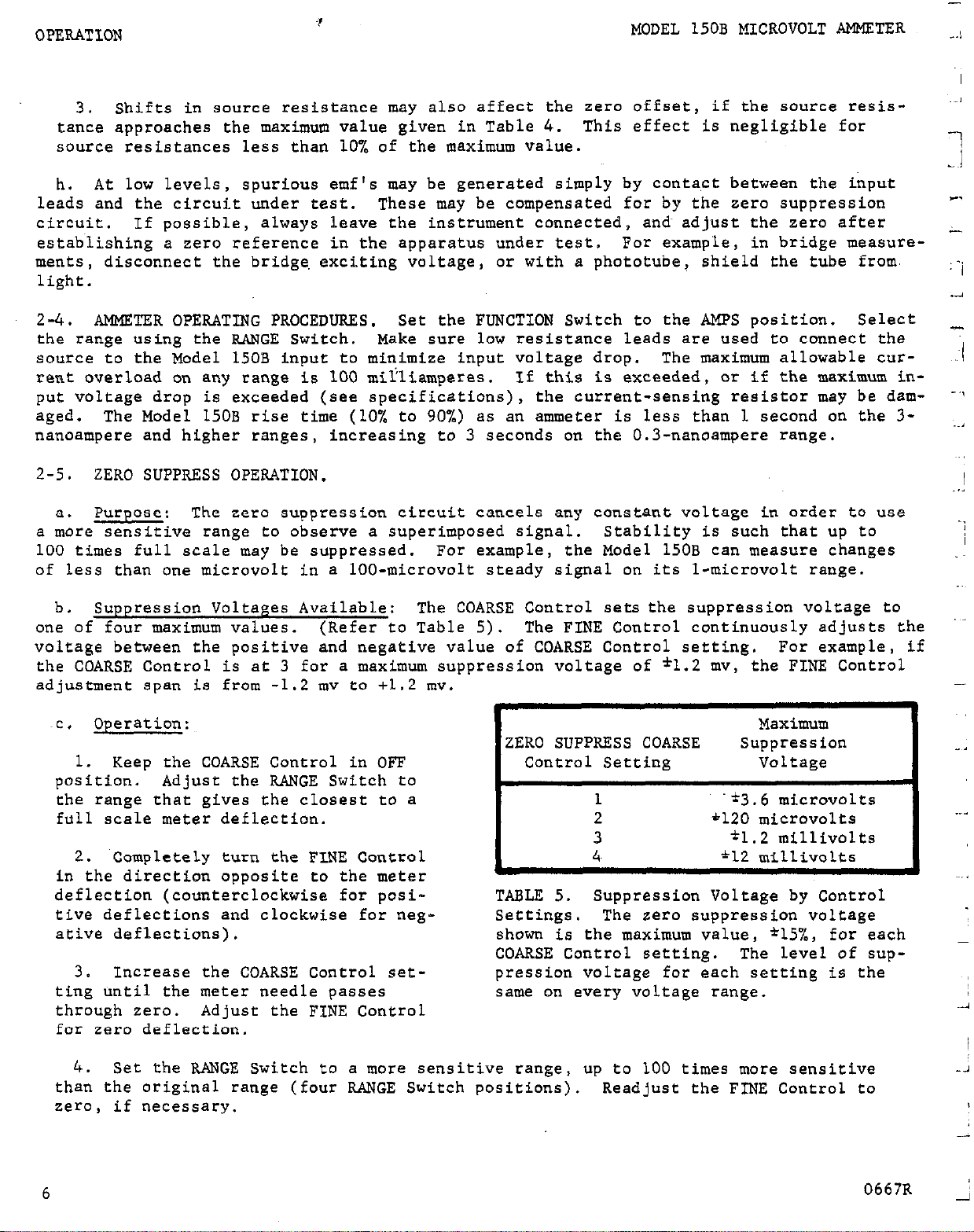

Operation:

~C.

Maximum

ZERO SUPPRESS COARSE Suppression

1.

Keep the COARSE Control in OFF

position.

Adjust the RANGE Switch to

the range that gives the closest to a

full scale meter deflection.

Control Setting Voltage

1

2

.*3.6 microvolts

*120 microvolts

3 t1.2 millivolts

2.

Completely turn the FINE Control

4.

*12 millivolts

in the direction opposite to the meter

deflection (counterclockwise for positive deflections and clockwise for negative deflections).

TABLE 5.

Settings. The zero suppression voltage

shown is the maximum value, *15%, for each

Suppression Voltage by Control

COARSE Control setting. The Level of sup-

3.

Increase the COARSE Control set-

ting until the meter needle passes

pression voltage for each setting is the

same on every voltage range.

through sero. Adjust the FINE Control

for zero deflection.

..,

-,

I

-

4.

Set the RANGE Switch to a more sensitive range,

than the original range (four RANGE Switch positions).

zero, if necessary.

6

up to 100 times more sensitive

Readjust the FINE Control to

-J

0667R _;

Page 11

MODEL 150B MICROVOLT AMMETER

OPERATION

2-6.

FILTER SWITCH.

The input filter is adjusted at the factory for 60 cps line frequency, unless 50 cps

a.

is indicated on the rear panel of the Model 150B.

b. When the FILTER Switch is at the IN position, a line frequency (Twin-Tee) filter is

used at the INPUT. With the Switch at the IN position a higher level (about 3~0 db) of 60

cps

can be tolerated at the INPUT without affecting the accuracy or the sensitivity of the

Model 150B.

Nomally ,

it is best to leave the FILTER Switch at the IN position for all

cases except where the source resistance exceeds 300 kilohms.

c. The filter has a 5-microfarad capacitor.

capacitor is in use and produces an RC time constant.

ohms or greater,

the rise time of the Model 150B is affected by the RC time constant and

When the FILTER Switch is set to IN, this

For a source resistance of 300 kil-

increases above that given in the specifications.

With the Switch set to OUT, the capacitor is not in use.

d.

If rise time is important,

set the FILTER Switch to~the OUT position for source resistances greater than 300 kilohms.

HOWeVer, with the filter out, the line frequency rejection is reduced 30 db on all ranges.

2-7. RECORDER OUTPUTS.

The Model 150B has two'recorder outputs; fl volt at up to 1 mil-

liampere and a filtered *lOO millivolts.

The *l volt, 1 milliampere output is accurate to i-l% of full scale. Output resis-

a.

tance is less than 5 ohms within the amplifier pass band.

eithef battery or ac operation.

I'f the Model 150B is used for differential measurements,

This output may be used during

do not ground the recorder connected to the output.

When recording with the 1 volt 1 milliampere output, the Keithley Model 370 Recorder

1.

offers complete compatability with the Model 150B.

This output is sufficient to drive

the Model 370 without the use of any recorder preamplifiers. The Model 370 allows maxi-

mum capability of the Model 150B.

to 1500 volts off ground.

Using the Model 370 with the Model 150B avoids interface

It has 1% linearity, 10 chart speeds and can float up

problems which may be encountered between a measuring instrument and a recorder.

The Model 370 is very easy to use with the Model 150B.

2.

All that is necessary is

connecting the two units and adjusting an easily accessible control for full-scale recorder deflection.

on the Model 150B.

an 8 cps beat may appear..

The furnished Model 3701 Input Cable mates with the output connector

On the most sensitive ranges of the Model 150B, under some conditions,

This condition can be eliminated by mounting a lOO-microfarad

capacitor across pins 14. and 17 in the back of the Model 370 Recorder.

The other recorder output is ilO0 millivolts.

b.

with servo balance recorders.

The 1OOMV ADJUST, which is a screwdriver adjust potentiom-

eter on the rear panel of the Model 150B,

millivolt span.

The resistance of this recorder output is less than 1000 ohms.

is used to adjust the 1OOMV output over a lo-

This output can be used in conjunction

The 1OOMV

output Receptacle is filtered to provide less than l/2% peak-to-peak ac voltages in the

output signal.

may be used during either ac or battery operation.

The rise time will be no less than 1 second on any range. This output

If the Model 150B is used for differ-

ential measurements, do not ground the recorder connected to the output.

2-8. SYNCHRONIZING TERMINALS.

When two or more Model 150Bs are close together,

due to the slight difference in their chopper frequencies.

All Model 150Bs have nearly the same chopper frequency.

a beat may develop between the instruments

To eliminate this interaction,

0667R

7

Page 12

OPERATION

/

I

MODEL 150B MICROVOLT AMMETER

7

.,

use the two synchronizing terminals on the rear panel of the instrument.

synchronize the chopper, frequencies.

No polarity is necessary; just connect leads from the

These terminals ~'

terminals of one Model 150B to the same terminals on an adjacent Model 150B.

2-9. DIFFERENTIAI. (FLOATING) MEASUREMENTS.

a. The Model 150B will measure the difference between two voltages, neither~ of which is

at power line ground.

It can be floated up to *400 volts off ground.

CAUTION

The instantaneous voltage between circuit low and case ground must not exceed *400

volts at any time.

If the power cord is unplugged,

case may be at any voltage.

For best results in making differential measurements, follow the steps below:

b.

The front panel controls are electrically conne,cted to the case.

and the off-ground voltage exce'eds *400 volts, the

Use necessary safety precautions.

-

1. Remove the link from the LO terminal on the rear panel.

Connect the source to the input.

2.

Make ,measurements as described in- paragraph 2-3.

The zero suppress controls may be used for differential measurements.

If power line frequency pickup is a problem, use battery operation.

3.

-

When recording from the Model 150B with the LO to GND link removed, be sure to

4.

-use a recorder which also has LO isolated from GND by a high imp&dance, and is also

capable of withstanding the necessary voltage with respect to ground.

The Keithley

Model 370 Recorder meets these requirements.

Z-10.

ACCURACY CONSIDERATIONS.

other considerations besides the instrument affect accuracy.

working with higher voltages are very important with microvolt signals.

For sensitive measurements - 10 millivolts and below -

Effects not noticeable when

The Model 150B

reads only the signal received at its input; therefore, it is important that this signal

be properly transmitted from the source. The following paragraphs indicate factors which

affect accuracy:

thermal noise,

input resistance, thermal emf's, shielding and circuit

connections.

2-11. THEIU@L NOISE.

a. The lower limit in measuring small potentials occurs when the Johnson noise, or

thermal agitation, becomes evident. The amount of noise present in the source is shown

in the following equations.

Thermal noise in any ideal resistance can be determined from the Johnson

1.

noise equation:

E2

rms

- 4kTRF Equation 1

where E,, is the rms noise voltage developed across the voltage source;

T is the temperature in degrees Kelvin;

R is the source resistance in ohms;

F is the amplifier bandwidth in cps;

k is the Boltzmann constant (1.38 x 10mz3 joules/OK).

8

0667R

Page 13

MODEL 150B MICROVOLT AMMETER OPERATION

For an ideal resistance at room temperature (300°K), equation 1 simplifies to

Erms

2. Peak-to-peak meter indications are of more interest than the rms value.

mentally, the peak-to-peak Johnson noise is about five times the rms value.

temperature, equation 2 becomes

EPP

where Epp is peak-to-peak noise voltage developed across the voltage source.

3. The Model 150B bandwidth, F, can be estimated from the response speed, tr, by:

F = 0.35/t, Equation 4

The response speed varies with the range used and the source resistance. On the l-

microvolt range when the source resistance is less than 33 kilohms, for example, the

bandwidth is greater than .07 cps.

ation is 6 seconds, so the .07-cps bandwidth is a minimum value.

b. In general,

tars, and equations 2 and 3 are nearly correct. If the source resistance is composed of

other materials, it may be necessary to include other terms in the equations to account

for flicker, l/f, and current noise over and above the thermal noise.

c. As seen in equations 2 and 3, the noise of even low resistance values becomes significant in the microvolt region. The noise in non-ideal resistors is even greater. Therefore, keep the source resistance as low as possible. Other effects of very high source

resistance are decreased response speed and added pickup of extraneous voltages.

good wirewound or low-noise metal-film resistors approximate ideal resis-

= 1.29 x 10-l' (R F)1/2

= 6.4,s x 10-l' (R F)l/2

The maximum specified response speed for this situ-

Equation 2

Experi-

At room

Equation 3

Z-12.

obtained using high feedback factors. When the source resistance exceeds the amplifier's

physical input resistance - amplifier input resistance without feedback - the feedback

is partially destroyed.

exceed the maximum source resistance listed in Table 4,.

but noise, offsets, slow response and instability may result. On the most sensitive ranges,

the maximum specified source resistance is consistent with Johnson noise considerations.

2-13.

a. Thermal emf's (thermo-electric potentials) are generated by thermal gradients be-

tween any two junctions of dissimilar metals. These can be large compared to the signals

which the Model 150B can measure.

b.

Model 150B can have some offset (paragraph 2-3).

touching the circuit, by putting a heat source near the circuit, or by a regular pattern

of instability,

INPUT RESISTANCE.

THERMAL EMF'S.

Thermal emf's can cause the following problems:

Meter instability or zero offset much higher than expected.

1.

Meter is very sensitive to ambient temperature differences.

2.

corresponding to heating and air conditioning systems or changes in sun-

light.

The Model 150B is a feedback amplifier; its input resistance is

Then the instrument may not operate properly. Normally, do not

Higher resistances can be used,

Note, though, the

This is seen by

9

Page 14

OPERATION

To minimize the drift caused by thermal emf's, use the same metal or metals having

C.

MODEL 150B MICROVOLT AMMETER

the same thermo-electric powers in the input circuit. Gold, silver and low-thermal solder

have a thermo-electric power within about to.25 pv/“C of copper. This means a temperature

inbalance of l°C between these metals would generate a thermal,emf of about 0.25 microvolt.

At the other extreme, germanium has a thermoelectric power of about 320 nv/oC, and silicon

will develop about 420 nvv/'C against copper. Standard physical handbooks contain tables

of thermoelectric powers of materials. Since the Model 150B input circuit is made of pure

copper, the best junction is copper to copper. However, copper oxide in the junction will

cause thermal emf's on the order of 100 nanovolts per oC or less. Also, differences in

processing of two pieces of copper can cause thermal emf's of up to 0.2 microvolt per "C.

The Model 1483 Kit contains all necessary equipment to make very low thermal copper crimp

joints.

d.

temperatures.

lar sources which vary temperature.

See paragraph 2-16.

Besides using similar metals, thermal emf's can be reduced by maintaining constant

Keep all circuits from open windows, fans,

air conditioning vents and simi-

Minimize thermal gradients by placing all junctions

physically close on a large heat sink. Thoroughly c,lean all copper leads before making a

connection.

Crimp together the ends of each copper wire; bolt the lugs for each connectior

point together; mount all stacks of lugs on a thick metal plate having high thermal conductivity. Thermal conductivity between the junctions and the heat sink can be kept at a high

level by using mica washers or high conductivity ceramics for electrical insulation.

e. Several other techniques will reduce the effects of thermal emf's. Use the zero suppression circuit to buckout constant voltages.

cadmium-tin low-thermal solder, such as supplied in the Model

If connections must be soldered, use only

1483 Kit.

If cadmium solder

is used for connections, make sure the soldering iron used is clean and that it has not

been used with regular solder before. Use only Rosin solder flux.

all cadmium,-soldered joints together to reduce thermal emf's.

Unlike metals - including

If possible, heat sink

regular solder - may be used and low thermal emf's obtained if a well-controlled oil bath

or a good heat sink is used.

Thermal voltages may be calculated from the thermoelectric

power of the materials in the junction and the possible temperature difference between the

junctions.

2-14.

a. Due to its narrow bandwidth and filtering,

voltages superimposed upon a dc signal at the input terminals.

SHIELDING.

the Model 150B is quite insensitive to ac

However,

ac voltages which

are large compared with the dc signal - thousands of times greater on the more sensitive

ranges - may drive the Model 150B ac amplifier into saturation, increasing the noise and

erroneously producing a dc output at the demodulator. Therefore,

the circuit should be

shielded and the shield connected to the Microvolt Ammeter ground, particularly for low-

level sources.

Improper shielding can cause the Model 150B to react in one or more of the following

b.

ways:

Needle jitter or instability,

1.

from 10% to 20% of full scale.

2. High offset (dc bias). Changing the power cord polarity or the connection between

the LO and GND terminals may affect the amount of offset.

3. Slow response time, sluggish action and/or inconsistent readings between ranges.

c. To minimize pickup, keep the voltage source and the Microvolt Ammeter away from

strong ac magnetic sources.

Connect all shields together at the low side of the input or

10

0467R

Page 15

MODEL 150B MICROVOLT AMMETER

OPERATION

at the LO terminal.

of the loop.

Therefore, minimize loop areas in the shield connections as well as the in-

The voltage induced due to magnetic flux is proportional to the area

put circuitry. Connect the shield at only one point. Run all wires in the circuit along

the same path,

so the loop area is only the small difference in position of two adjacent

wires.

Strong third harmonic magnetic fields - 180 cps for 60-cps units - may create an

d.

8-cps beat at the Microvolt Ammeter output and meter. To reduce this effect, turn off all

possible nearby sources, such as heavy-duty transformers. Remove the Model 150B and the

measuring circuit as far as possible from the magnetic field. If removal does not greatly

reduce the beat, magnetic as well as electrostatic shielding around the circuit may be

necessary. The ratio of the 8-cps amplitude to the dc output level may be reduced by

nearly 1 decade using the 1OOmv filtered output.

2-15.

OPERATING FROM SOURCE OTHER THAh' 117 VOLTS, 60 CPS.

If the ac power source is 234 volts, use a screwdriver to change the Line Voltage

a.

Switch on the back panel, Change the fuse from l/8 ampere to l/16 ampere. Use only 250-

volt MDL fuses. No other adjustment is necessary.

The Model 150B can operate satisfactorily from 60 or 50-cps sources, but the best ac

b.

reiection is achieved when the filteris set for the line freauencv.

For 50-CDS ac Dower

sources, change the two resistors in the input filter R14~7 and R14~8 (Figure 18). use

Keithley part Rl32-1273 (R147 and R14,8)

for 50 cps. Some units are, per special

order, modified at the factory for 50-cps ac

power sources. The filter in these cases is

adjusted for SO-cps,

and this fact is indi-

cated on the re.ar panel of the Model 150B.

2-16.

ACCESSORIES FOR INPUT CONNECTIONS.

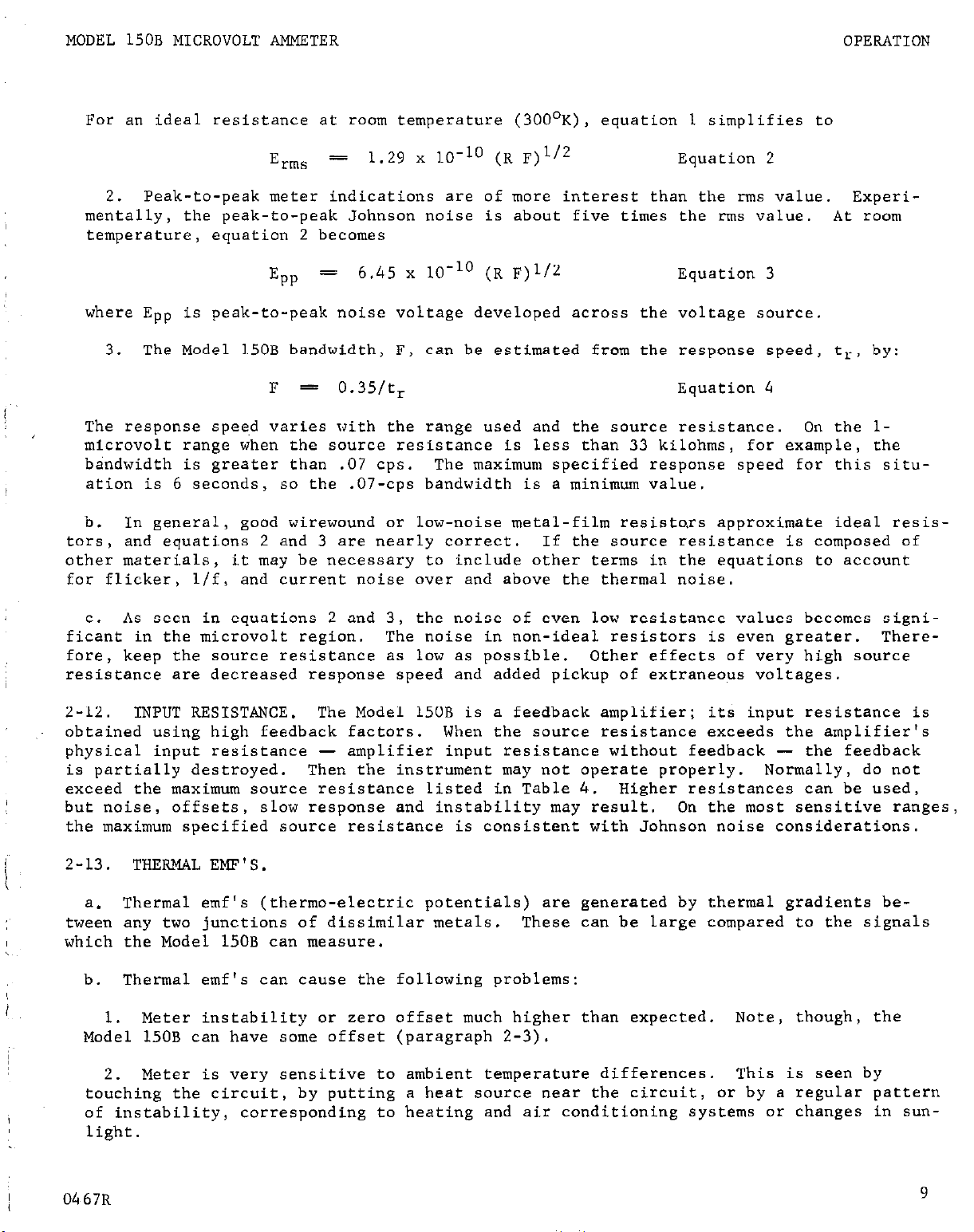

The easiest way to connect the volt-

a.

age source to the Model 150B input is with

the Model 1506 Input Cable supplied with

the instrument.

ary setups, for measurements at several

points, and when fast connections are needed.

Use the Cable for tempor-

FIGURE 3.

Cable.

Model 1506 Low-Thermal Input

The Model.1506, which has alligator clips,

connects directly to the INPUT Receptacle.

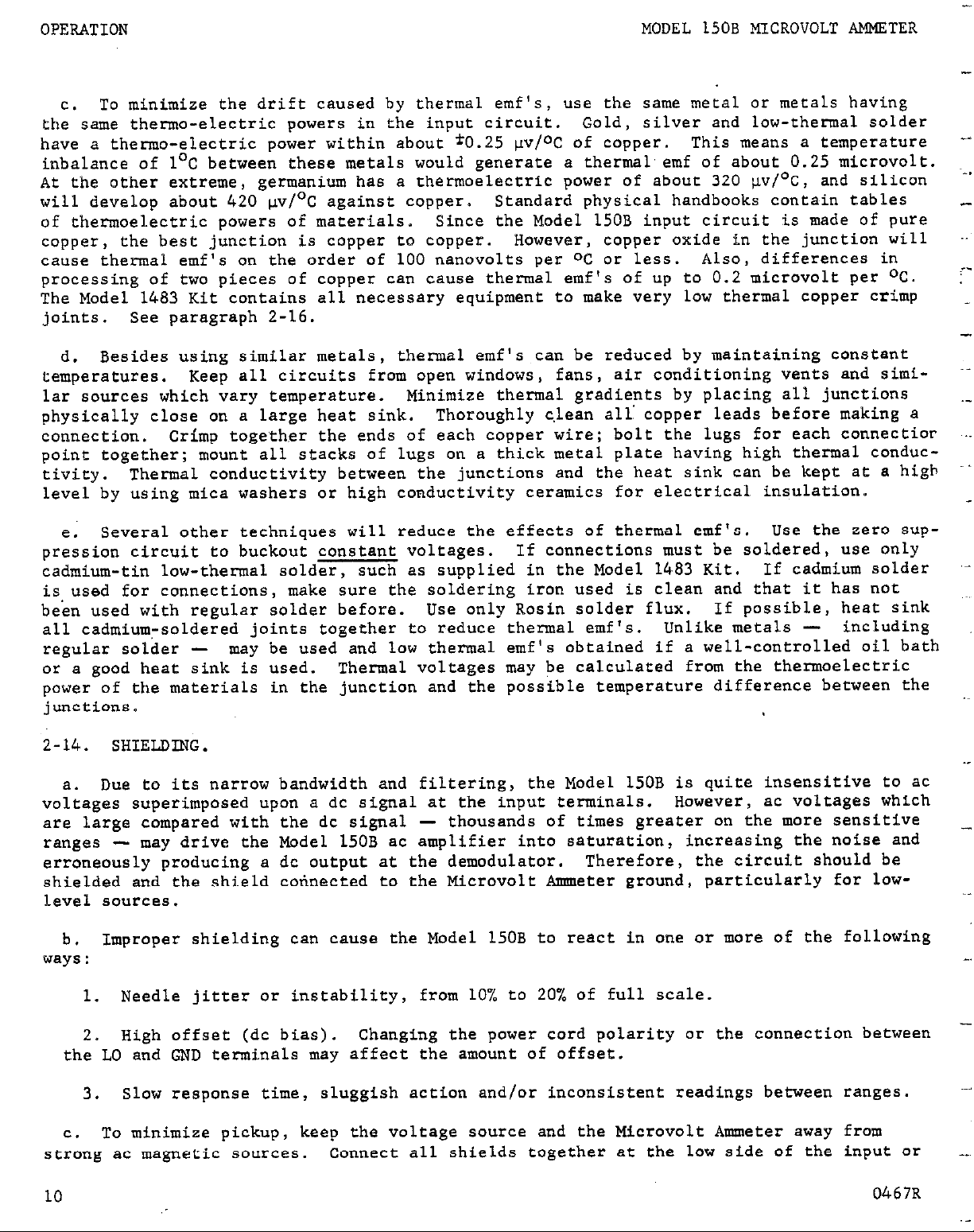

Where more permanent setups are needed,

b.

use the Model 1507 Input Cable. It is

similar to the Model 1506, except it has spade lugs instead of alligator clips.

Use crimp connections with copper wire and lugs for the best low-thermal joints.

C.

The Model 14,83 Low-Thermal Connection Kit contains a crimp tool, shielded cable, an assort-

ment of copper lugs, copper wire,

cadmium solder and nylon bolts and nuts. It is *

com-

plete kit for making very low-thermal measuring circuits. The Kit enables the user of

the Model 150B to maintain the high thermal stability of the Microvolt Ammeter in his

own circuit.

0667R

11

Page 16

OPERATION

The Model 1486 male low-thermal input

d.

connector is for connecting custom-made

circuits to the Model 150B.

e. Other available accessories are:

The Model 1484 Refill Kit, which contains

replacement parts for the Model 1483; The

Model 1485 female low-thermal input con-

nector to use with the Model 1486 for

building shielded low-thermal circuits;

Model 1488 Low-Thermal Shorting Plug, which

is helpful in testing the Model 150B; Model

1489, which is a replacement nickel-cadmium

battery pack.

Model 1481 or Model 1482 Input Cable,

f.

supplied with the Keithley Models 147 and

148, may be-used with the Model 150B. The

shielding in these cables, however, is not

as good as the shielding in the Models 1506

and 1507 Input Cables.

Shielding problems

occur with the Models 1481 and 1482 Cables

at source resistances greater than 10

kilohms.

WODEL 150B MICROVOLT AMMETER

FIGDRE 4.

Model 1483 Low-Thermal

Connections Kit..

12

0667R

-

Page 17

MODEL 1508 MICROVOLT AMMETER

CIRCUIT DESCRIPTION

SECTION 3. CIRCUIT DESCRIPTION

3-1. GENERAL.

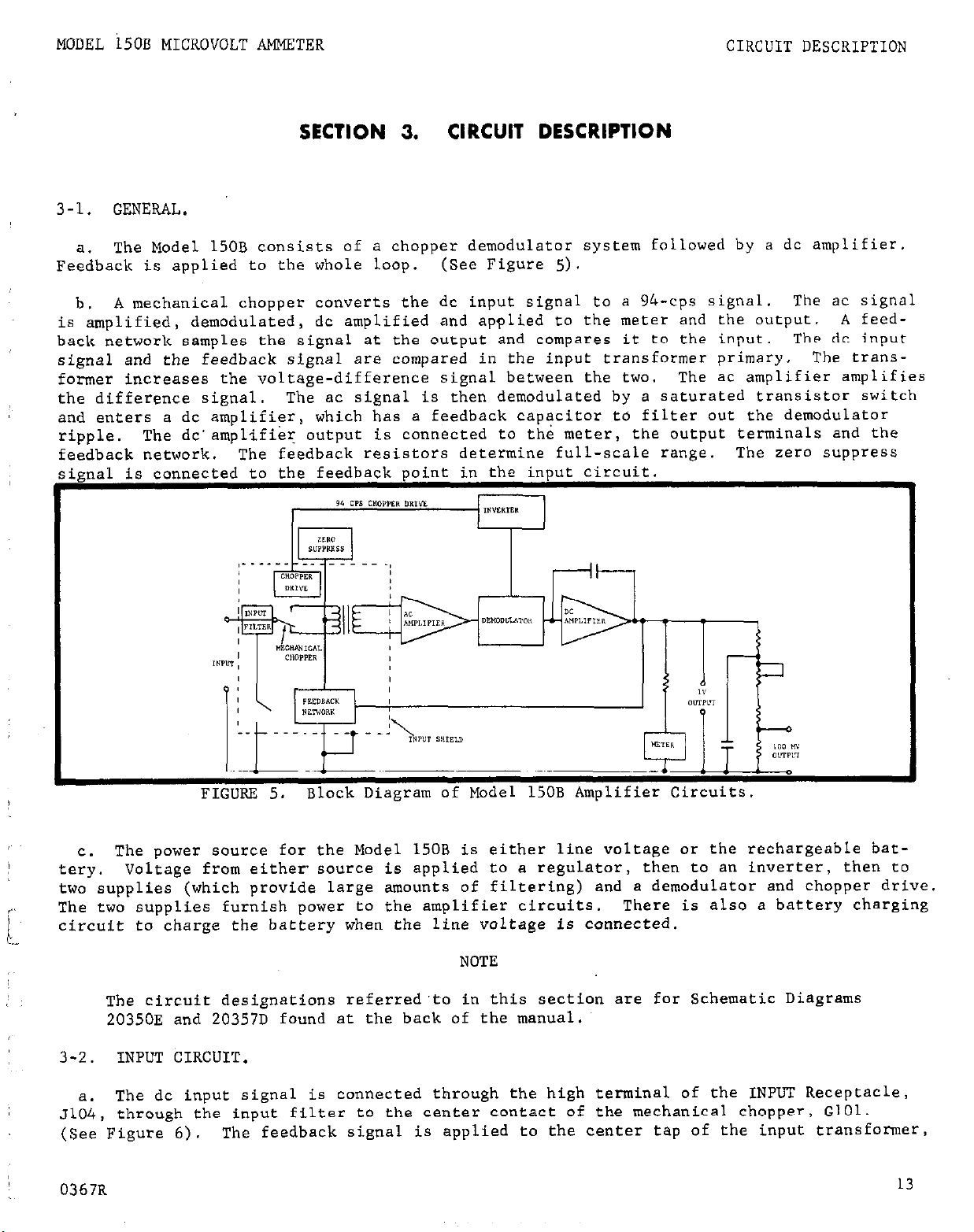

The Model 150B consists of a chopper demodulator system followed by a dc amplifier.

a.

Feedback is applied to the whole loop. (See Figure 5).

A mechanical chopper converts the dc input signal to a 94-cps signal. The ac signal

b.

is amplified, demodulated,

back network samples the signal at the output and compares it to the input.

dc amplified and applied to the meter and the output.

The dc input

signal and the feedback signal are compared in the input transformer primary.

former increases the voltage-difference signal between the two.

the difference signal.

The ac signal is then demodulated by a saturated transistor switch

The ac amplifier amplifies

and enters a dc amplifier, which has a feedback capacitor td filter out the demodulator

ripple.

feedback network.

The dc’amplifier output is connected to the meter, the output terminals and the

The feedback resistors determine full-scale range.

The zero suppress

signal is connected to the feedback point in the input circuit.

A feed-

The trans-

94 CPS CIIOPPTR DRIrn

I

I 1

FIGURE 5.

f

I

Block Diagram of Model 150B Amplifier Circuits.

LNMRTER

I I1 I

c. The power source for the Model 150B is either line voltage or the rechargeable bat-

tery .

Voltage from either’ source is applied to a regulator, then to an inverter, then to

two supplies (which provide large amounts of filtering) and a demodulator and chopper drive.

The two supplies furnish power to the amplifier circuits. There is also a battery charging

circuit to charge the battery when the line voltage is connected.

NOTE

The circuit designations referred~to in this section are for Schematic Diagrams

203503 and 20357D found at the back of the manual.’

3-2. INPUT CIRCUIT.

The dc input signal is connected through the high terminal of the INPUT Receptacle,

a.

5104, through the input filter to the center contact of the mechanical chopper, GlOl.

(see Figure 6).

The feedback signal is applied to the center tap of the input transformer,

03678

13

Page 18

CIRCUIT DESCRIPTION

._

~~_

MODEL 150B MICROVOLT AMMETER

Input

Chopper

. ”

Transformer

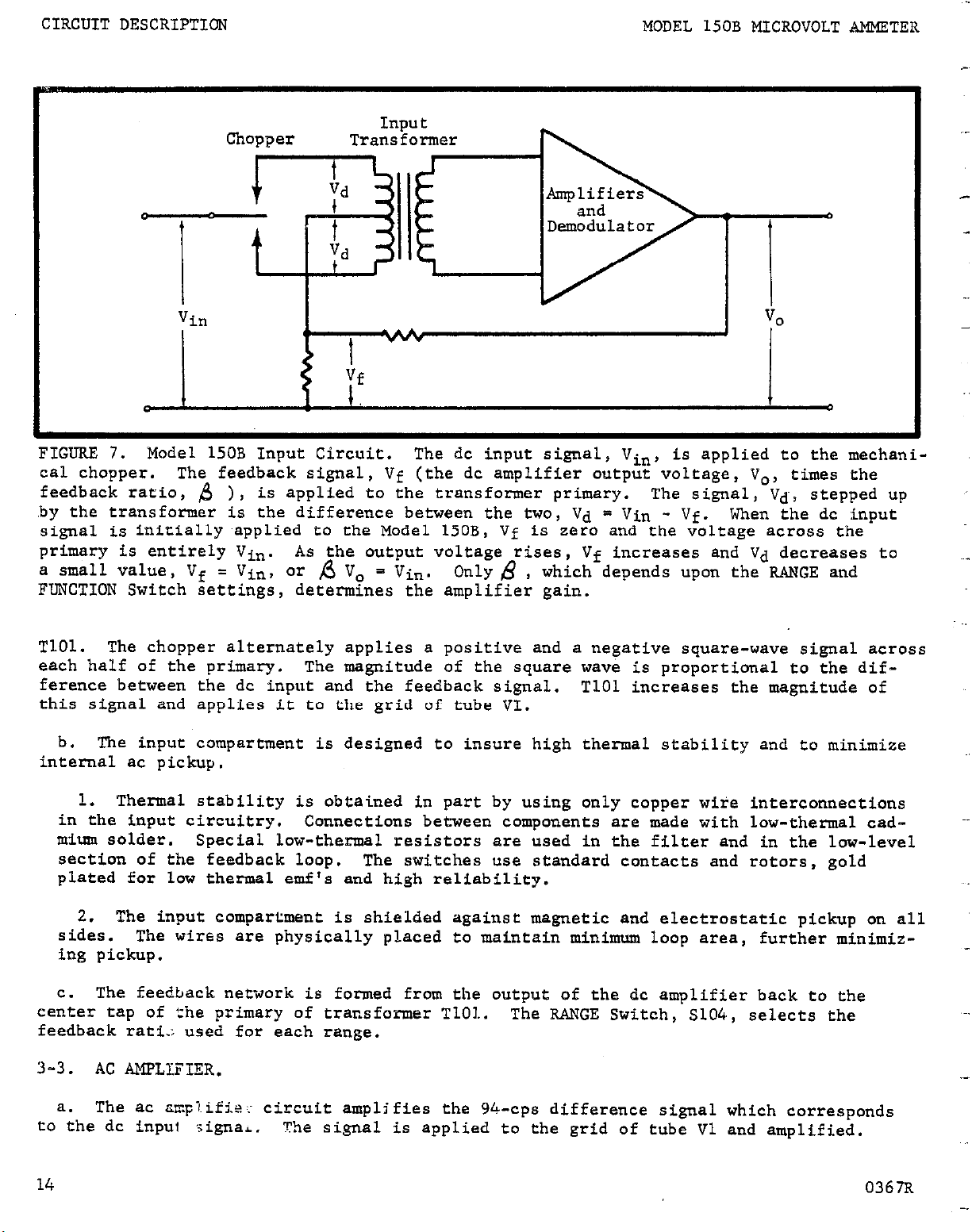

FIGURE 7. Model 150B Input Circuit. The dc input signal, Vin, is applied to the mechani-

cal chopper.

The feedback signal, Vf (the dc amplifier output voltage, Vo, times &he

feedback ratio, b ), is applied to the transformer primary. The signal, Vd~> stepped up

by the transformer is the difference between the two, Vd = Vin - Vf. When the dc input

signal is initially .applied to the Model 150B,

primary is entirely vin. As the output voltage rises,

a small value, vf = fin. or 4 V, = vin.

Vf is zero and the voltage across the

Vf increases and vd decreases to

Only L? I

which depends upon the RANGE and

FUNCTION Switch settings, determines the amplifier gain.

T101. The chopper alternately applies a positive and a negative square-wave signal across

each half of the primary. The magnitude of the square wave is proportional to the dif-

ference between the dc input and the feedback signal.

TlOl increases the magnitude of

this signal and applies it to the grid of tube VI.

b. The input compartment is designed to insure high thermal stability and to minimize

internal ac pickup.

1. Thermal stability is obtained in part by using only copper wire interconnections

in the input circuitry. Connections between components are made with low-thermal cad=.

mium solder.

section of the feedback loop.

Special low-thermal resistors are used in the filter and in the low-level

The switches "se standard contacts and rotors, gold

plated for low thermal emf's and high reliability.

The input compartment is shielded against magnetic and electrostatic pickup on all

2.

sides.

The wires are physically placed to maintain minimum loop area, further minimiz-

ing pickup.

C.

The feedback network is formed from the output of the dc amplifier back to the

center tap of the primary of transformer TlOl.

The RANGE Switch, S104, selects the

feedback rati.: used for each range.

3-3.

AC AMPLIFIER.

a. The ac ampiifi;?:: circuit amplifies the 94-cps difference signal which

to

the dc inpui signa,.

The signal is applied to the grid of tube Vl and amplified.

14

corresponds

0367R

Page 19

MODEL 150B MICROVOLT AMMETER

CIRCUIT DESCRIPTION

Transistor QlOl acts as a cc~nstant current source for tube Vl, with field effect transistor

Q102 providing a high impedance level following the first stage. Transistor Q103 is for

impedance matching.

justs the gain to compensate for beta variations.

by transistors QlO4 through Q107.

Potentiometer R112, between the Q103 emitter and the QlO4 base, ad-

The difference signal is then amplified

Transistors 9106 and Ql07 also form a full wave signal

for demodulation.

The tube type of Vl and the bias of Vl with transistors QlOl and Q102 are selected

b.

for low-noise operation at 94, cps.

quency to be amplified by the first stage is selected to be 94 cps (TT ADJ Controls,

A narrow bandwidth around 94 cps is provided. The fre-

Poten-

tiometers R140 and R143) by a notch filterin a feedback loop around the first stages.

3-4. DEMODULATOR.

switch demodulator.

with ripple component.

wave rectified signal.

Transistors QlO6 and QlO9 in inverted configuration form a transistor

They convert the 94,-cps wave from the ac amplifier into a dc voltage

Resistors Rl.27 and Rl28 sum the voltages from each to form a fullThe secondary of the inverter transformer, T201, furnishes a

square-wave drive for the demodulator.

3-5. DC AMPLIFIER.

a. The demodulator signal is amplified by two low-drift,

QllO and Qlll,

in differential configuration to compensate for temperature drift.

high gain silicon transistors,

Silicon

transistors Qll2 and Q113 form the second amplifier stage. Total gain is about 500.

Diode D102 limits the output current,

A feedback loop with capacitors Cl09 and Cl20 around the dc amplifier acts as an

b.

integrator, filtering the ripple component of the demodulated waveform.

capacity,

which is approximately the value of Cl09 and Cl.20 times the dc amplifier gain,

protecting output transistor 9114.

The effective

and the feedback factor (or open-loop gain) of the entire amplifier, Vl to Q114, determine

the response speed of the system.

The capacitive feedback also reduces the noise in the

amplifier outside the system bandpass.

3-6. ZERO SUPPRESSION.

The zero suppress circuit provides a regulated voltage from the

power supplies to buckout steady background potentials in the input signal. The lo-turn FINE

Control, potentiometer R307, is connected between -12 and +12 volt outputs. The rotor of

potentiometer R307 is connected to a resistive divider R187, R301, R302 and R303 in the

COARSE Switch which further divides the voltage. The suppression voltage is applied direct-

ly to the feedback resistor, RT65, whic'h acts as another divider in conjunction with R149.

3-7. POWER SUPPLIES (See Figure 7.)

The power supply for the Model 150B consists of a

regulated supply which operates from the power transformer or a rechargeable battery.

The output of this regulator feeds an inverter, two highly filtered supplies with outputs

of +12, -12 volts and a drive circuit for the chopper and demodulator. These power all

the other Model 150B circuits.

The line power, battery and battery charging circuits are controlled through the

a.

POWER SUPPLY Switch, S201.

When the switch is in AC, the battery is charged and the power

supply operates from the power transformer, T202. When the switch is in OFF, the battery

charges; all other circuits are off.

When the switch is in BATTERY, the power supply

operates from the battery; the power transformer is disconnected at its primary windings.

The regulated supply is prefiltered with a large capacitor, C211. The supply con-

b.

sists of a series regulator with a darlington pass arrangement made up of Q218, Q212 and

Q214.

Any variation across the output is referenced by resistors R234 and R238 with zener

0467R

15

Page 20

CIRCUIT DESCRIPTION

MODEL 150B 'MICROVOLT AMMETER

FIGURE 7. Block Diagram of Model 150B Power Supplies.

diode D211 and compensated for by the amplifier consisting of Q215, Q216 and Q217.

The

output of the supply is adjustable around -5 voLts.

Voltage from the regulated supply is applied to the inverter circuit.

Transistors

92:; and Q202 form a switching network to supply a square-wave voltage to transformer

T201.

The switching frequency is 94 cps,

T201 has a saturable ferrite core.

The inverter circuit supplies voltages to the two

the same as the carrier frequency. Transformer

regulated supplies and the chopper demodulator circuit.

The +12 volt supply is a highly filtered voltage taken from the secondary windings

d.

of the inverter transformer, T201. Diodes D201 and D202 furl wave rectify the signal

from the transformer.

lington configuration,

supply output.

A current limiting circuit, transistor Q205, protects the pass transistor

This signal is filtered by the RC filter, R204 and C203.

A Dar-

transistors Q203 and Q204, maintains the low-ripple voltage at the

if the output of the supply is shorted.

The -12 volt supply operates in 9 similar manner to the +12 volt supply.

e.

One secondary of the inverter transformer drives transistors Q209 and Q2LO through

f.

a phase compensating network made up of resistors R220 through R224 and capacitor C210.

This phase compensation network compensates for the chopper phase shift.

Transistors

Q209 and Q210 are alternately cut off and driven into saturation, forming a square wave

drive to the demodulator.

ary of the inverter transformer that is used to drive the demodulator.

The drive for the chopper is taken from one-half of the second-

Capacitor C213

"rounds off" the square wave to produce a more acceptable chopper drive wave form.

-..

.-

-

Page 21

MODEL 150B MICROVOLT AMMFTER

CIRCUIT DESCRIPTION

3-8.

BATTERY CHARGING CIRCIIIT.

a. The battery circuit operates when the POWER SUPPLY Switch, 5201, is in the AC or

OFF position.

b. A charging currant from transistor T20.. is applied to the battery through a half

wave rectifier and a series resistor, RZ28. A fuse is incorporated in this circuit to

protect the instrument and the battery.

Note, however,

that the battery can be damaged

if it is used far beyond its capacity. A polarity reversal of a crll may occur, causing

heavy circulating currents within the battery.

,..

1266~ 17

Page 22

MAINTENANCE MODEL

I.508

._

MICROVOLT AMMETER

.,.

,-

Instrument

Hewlett-Packard Model 200 CD

Oscillator, 5 cps to 600 kc,

*2% accuracy.

Hewlett-Packard Model 5512A

Electronic Counter, 300-kc counting

rate, 10.1% accuracy.

Keithley Instruments 1488

Low-Thermal Shorting Plug.

Keithley Instruments Model 1507

Input Cable.

Keithley Instruments Model 260

Nanovolt Source.

Keithley Instruments Model 261

Picoampere Source.

Keithley Instruments Model 370

Recorder.

Use

TT adjust and Filter adjust

calibration.

Minitor oscillator frequency.

Short Model 150B INPUT Receptacle.

Connecting cable for Model 260 and

Model 150B.

Signal source for calibrating Model

150B.

Signal source for calibrating Model

150B.

Monitor drift.

,_.

7

<~_

.-

.-

_.

.-

Keithley Instruments Model 6lOB

Check plate voltage of tube VI.

Electrometer.

Keithley Instruments Model 662

Check voltage at output terminals.

Guarded DC Differential Voltmeter,

l

O.Ol% to 1 millivolt.

RCA Model WV98B Senior Voltohmyst,

Check dc voltages throughout circuit.

11 MD input resistance, *3% accuracy,

0 to 1500 volts dc.

Tektronix Type 503 Oscilloscope, dc Check wave forms for troubleshooting

to 450 kc.

TABLE 6.

Equipment Recormsended for Troubleshooting and Calibrating the Model 150B. Use

and calibration.

these instruments or their equivalents.

18 0667R

Page 23

MODEL 150B MICROVOLT AMMETER

SECTION 4.

4-l. GENERAL.

Section 4 contains the maintenance,

a.

the Model 150B.

to maintain the instrument's specifications.

The Model 150B requires no periodic maintenance beyond the normal care required of

b.

high-quality electronic equipment.

cipal maintenance is an occasional chopper replacement. (See paragraph 4-3.) Occasional

verification of meter calibration (paragraph 4-7) should show any need for

4-2.

Microvolt Ammeter.

ments which meet the specifications.

the components listed in Table 7.

List are purchased only from Keithley Instruments or its distribtitors.

4-3. MECHANICAL CHOPPER REPLACEMENT.

PARTS REPLACEMENT,

a. The Replaceable Parts List in Section 6 describes the electrical components of the

It is recommended these procedures be followed as closely as possible

Components operate well below maximum ratings. Prin-

Replace components only as necessary, and use only reliable replace-

The Model 150B uses no special critical parts except

Make sure parts coded 80164 in the Replaceable Parts

MAINTENANCE

troubleshooting and calibration procedures for

adjustment.

The mechanical chopper is designed for long life.

a.

it will eventually wear and become noisy.

~em0~1 Procedures.

b.

Disconnect the chopper drive coil at connector 5105 (Figure 11).

1.

the chopper lugs from the studs mounted on the bottom of the input compartment.

Remove the four mounting screws from the bottom of the input compartment. Remove

2.

the old chopper.

Replacement Procedures.

c.

Mount the chopper with the four furnished screws.

1.

!

Battery pack assembly

Mechanical chopper assembly and input connector

assembly (See paragraph 4.-3.) GlOl & J105

Input transformer assembly

Dress the leads and draw the lugs down on the studs.

2.

component Desig.

At this point, replacement is necessary.

However, since it is mechanical,

Carefully remove

Circuit

BT201

TlOl

Keithley

Part No.

Model 1489

20139B

20137B

.

.

TABLE 7.

the proper lead length.

0667R

Model 150B Pre-assembled Components.

These parts have lugs crimped on them and

Use only Keithley parts for replacement.

19

Page 24

MAINTENANCE

MODEL 150B MICROVOLT AMMETER

Connect

3.

4. Check the instrument for proper operation.

the chopper drive coil at connector JlO5.

Follow paragraph 4-8, subparagraph b,

steps 1, 2 and 3.

4-4.

TROUBLESHOOTING.

The following procedures give instructions for repairing troubles which might occur

a.

in the Model 150B. Use these procedures to troubleshoot and use only specified replacement

parts.

readily Located or repaired,

b.

checking out the power supply and amplifier circuits.

Table 6 lists equipment recomsrended for troubleshooting._ If the trouble cannot be

contact Kqithley Instruments or your Keithley field engineer.

Paragraphs 4-6, 4-7 and 4-8 give step-by-step procedures for troubleshooting and

Follow these in the order given.

Tables 9 and 12 are troubleshooting tables for these circuits. Also refer to Section 3 to

find the more crucial components and to determine their function. The Schematic Diagrams,

203503, and 20357D, contain the voltages at certain points in the circuit, measured with

a Model WV98B Voltohmyst.

NOTE

Before troubleshooting inside the Model 150B, check the external circuits (paragraph 4-5). Always check out the power supply circuit before touching the ampli-

fier circuits.

The amplifier circuits often appear faulty only because of a de-

fect in the power supply.

.-

.-

4-5.

PRELIMINARY TROUBLESHOOTING PROCEDURES.

a. Before troubleshooting, check the outside circuits to the Model 150B. Isolate the

Microvolt Aaraeter from all external effects:

1.

Disconnect all outside circuits from the INPUT and OUTPUT Receptacles, and CND

and LO terminals.

Connect a low-thermal short across the INPUT Receptacle.

2.

The best connector is a

Model 1488 Low-Thermal Shorting Plug. The next best is a Model 1506 Input Cable with

the clips connected together or the Model 1507 Input Cable with the .lugs connected to-

gether. Keep the cable as far as possible from ac sources, and avoid a loop where the

alligator clips or lugs are connected.

3. Set the ZERO SUPPRESS COARSE Control to OFF.

b.

If the battery charge is acceptable (paragraph 2-2), set the POWER SUPPLY Switch to

BATTERY.

Disconnect the power cord from the power Line. Battery operation eliminates

many ground-Loop connection problems with the test equipment.

c.

If ac operation is used, check the Line Voltage Switch for correct position and the

Fuse for correct rating.

4-6.

CHECK OUT AND CALIBRATION PROCEDURES.

a. TO ascertain whether the Model 15OB is operating

of the voltage ranges and current ranges,

20

properly, perform a-~ accuracy check

0667R

Page 25

MODEL 150B MICROVOLT AMMETER

MAINTENANCE

1. To check the accuracy of the voltage ranges,

2-3.

150B using the 1507 Input Cable.

a nine-tenths full-scale signal with the Model 260 (i.e.

the 10 microvolt range; 27 microvolt signal for the ~Omicrovolt range, etc.). Check

each range for both positive and negative polarity. The meter accuracy of the Model 150B

is specified to be f2% of full scale exclusive of noise and drift.

2-4,. Use the Model 261 as the current source and connect the Model 261 to the Model 150B

using the 1507 Input Cable.

nine-tenths full-scale signal with the Model 261 (i.e.

10 nanoampere range; 27 nanoampere input signal on-tKe 30 nanoampere range, etc.),

each range for both positive and negative polarity.

is specified to be “3% of full scale exclusive of noise and drift.

calibration (paragraph.4,-7~).

to be within specification, check the indicated resistors in Table 11.

b. The following procedures give the steps to check out and calibrate the Model 150B

circuits.

shooting table.

Table 6.

Use the Model 260 as the voltage source and connect the Model 260 to the Model

Check each voltage range on the Model 1508 by applying

2. To check the accuracy of the current ranges,

Check each current range on the Model 150B by applying a

3. If any range. fails to be within specifications, check to see if the meter is in

If the meter is in calibration and any range still fails

If a circuit fails to check out at any point, refer to the circuit’s trouble-

Continue as Long as the points check out. Use the equipment listed in

follow the procedures of paragraph

9 microvolt input signal for

follow the procedures of paragraph

9 nanoampere input signal for the

Check

The meter accuracy of the Model 150B

c. Procedures are given for the power supply and amplifier circuits.

principal adjustments to bring the instrument within specifications.

d. If the Model 150B is not within specifications after performing these checks and

calibrations, return the unit to Keithley Instruments for further checkout, or follow the

troubleshooting procedures to find the fault.

I

VL Bias adjust

Gain control

TT adjust

Filter adjust

Meter Cal.

Frequency adjust

Current Coma. adiust

TABLE 8.

picturing the location,

Make sure the power supply circuit is operating correctly before checking the

amplifiers.

taken out of ourder,

Control

Model L50B Internal Controls.

All circuits depend upon properly functioning power supplies. If

Circuit

Desig.

R107 LO 4-7, 4,-8

R112 15 4-8

Rl4,O and R14,3 15 4-8

~14,6 18 4-8

R193 17 4-7

R235 13 4-7

R304, 10 4-7

The table lists all the controls, the figure

and the paragraph describing the adjustment.

NOTE

the resulting adjustment may be faulty.

Fig.

Ref.

These cover the

Refer to

Paragraph

0667~

21

Page 26

MAINTENANCE

-

MODEL 150B MICROVOLT AMMETER

TROUBLE

No voltage.at the blat'

and white wire attache1

to la$t pin before

strdon S103 (point G

Fix. 10).

Irregular wave form at

pin 8 or 9 (Fig. 8).

Incorrect 1-12 volt

supply voltage, or

ligh ripp,le on this

SUPPlY.

PROBABLE CAUSE

k

Blown fuse.

i

II209 or D210 open.

Regulator circuit not

functioning nomally.

I

Check for shorted transformer T202

or wiring;

I

Check components; replace if faulty

I

Refer to Section 3 to determine the

components in the regulator circuit.

SOLUTION

then replace fuse.

Check these components and replace

if faulty.

Defective Q203 and/or

Check components; replace if faulty.

Q204

Defective C203 and/or

Check components;

replace if faulty.

c204

-5 volt regulator

Change the value of R204; increase the

not supplying enough value if the t12 output is low; devoltage to inverter

for 94 cps.

crease it (not below 3.9 kR) if the +l

output is high.

Incorrect -12 volt

supply voltage, or

Defective Q207 and/or

Q208

Check components;

replace if faulty.

ligh ripple on this

'upply.

Defective

c209

-5 volt regulator not

Check and/or

components;

replace if faulty.

I

Change the value of R219; increase the

supplying enough volt- value if the -12 output is low; deage to inverter for

94 cps.

w.3 9.

4-9.

Troubleshooting Table for

Power

SUPP

POWER SUPPLY CHECK OUT AND CALIBRATION.

‘1Y.

a. All circuits depend upon the -5 volt regulated supply.

crease it (not below 3.9 kR) if the -1

output is high.

This supply drives the in-

verter transformer which, in turn, supplies the -12 and cl2 volt outputs.

-5 volt supply must be operating correctly before further checks are made.

suppLy fails to check out at any point, refer to Table 9.

After clearing the trouble,

continue the check.

Therefore, the

If the power

Procedures for Checking Regulated Power Supplies.

b.

Connect the Model 1488 Low-Thermal Shorting Plug to the INPUT.

1.

controls as follows:

22

Set the Model 150B -

0667R

:

Page 27

MODEL 150B MICROVOLT AMMETER

POWER SUPPLY Switch OFF

RANGE Switch 1 MICROVOLT

FUNCTION Switch INPUT R OPEN

ZERO SUPPRESS COARSE Control OFF

Line Voltage Switch Set to line voltage

FILTER Switch

Turn the FREQ ADJ Potentiometer, R235 (Figure 13) and Vl BIAS Potentiometer, R107

2.

(Figure 10) completely counterclockwise.

This ensures that the tube in the first stage

IN

and the chopper will not be damaged.

Plug in the power cord.

3.

4,. Measure the voltage at the red wire on the POWER SUPPLY Switch front deck. It

should be -11 volts dc *2 vdc.

MAINTENANCE

Turn the POWER SUPPLY Switch to AC.

5.

Use the Type 503 Oscilloscope to check the

wave form at pin 8 or 9 of connector 5201 on the bottom of PC-120 (Figure 11). Wave

form should look like Figure 8.

The dc voltage at pin 8 or 9 should be -5 volts *0.3 vdc.

a)

This voltage will be

present at pin 8 or,9 if the chopper frequency is 94 cps.

b) Check the chopper frequency by connecting the Type 503 Oscilloscope differential-

ly at pins A and D on connector X05 (Figure 11).

with the Model 5512A Electronic Counter set at 94 cps.

Measure the oscillator frequency

Connect the oscillator to the

horizontal channel of the Type 503 Oscilloscope and obtain a lissajous pattern. The

wave form of the chopper drive should resemble that in Figure 9.

FIGLJRE 8.

Correct -5v Regulated Supply

Wave Form at Pin 8 or 9 of Connector 5201.

See paragraph 4-7.

Form was obtained on

the 1 pv range with the FILTER Switch set

The

to IN.

scale is 0,2v/cm verticle, 2

msec/cm horizontal.

0667R

FIGURE 9.

at Pins A and D of 5105.

Correct Chopper Drive Wave Form

See paragraph

4-7. Form was obtained on the 1 NV range

with the FILTER Switch set to IN.

The

scale is 5v/cm vertical, 2 mseclcm horizontal.

23

Page 28

MAINTENANCE

T

~'

..,

._

..~

Measure the signal levels and ripple with respect to low of the +12 and -12 volt

6.

supplies. Table 10 gives the values.

MODEL 150B MICROVOLT AMMETER

a) To measure the +12 volt supply,

connector 5201, Figure 11.

b) To measure the-12 volt supply,

connector 5201, Figure 11.

c) To find the ripple on the supplies connect the Type 503 Oscilloscope to pin 19

or 6. The ripple should be less than 2 mv peak-to-peak.

Regulated

Power

SUPPlY

+12 volt pin 19, 5201 11 to 12.5 1;5 850 *lOO

-12 volt p'in 6, 5201 11 to 12.5 2.0 460 *70

TABLE 10.

c. Meter Noise Check.

Model 15OB input with the Model 1488 Shorting Plug or some other suitable device.

the meter noise.

not, then possible sources of noise are transistor QlOl, tube Vl, the chopper, power sup-

PlY,

and cadmium solder joints.

Signal Level, Maximum Ripple and Resistance for Regulated Power Supplies.

Test Point, Signal Level;

Figure 11 Volts dc

Set the Model 150B RANGE Switch to 0.3 MICROVOLT.

The meter noise should be less than 25 nanovolts peak-to-peak.

connect the Model WV98B Voltmeter at pin 19 of

connect the Model WV98B Voltmeter ta pin 6 of

Maximum Ripple, Resistance

Millivolts to Ground,

Peak-to-Peak

Ohms

Short the

Check

If it is

-

d. Meter Calibration.

Set the Model 150B front panel controls as follows:

1.

POWER SUPPLY Switch

RANGE Switch 100 MICROVOLTS

FUNCTION Switch

ZERO SUPPRESS COARSE Control OFF

ZERO SUPPRESS FINE Control

FILTER Switch IN

2. Short the Model 150B input with the Keithley Model 1488 Shorting Plug or s~ome

other suitable device.

Zero the meter with the Mechanical Zero Control.

3.

4. Turn the POWER SUPPLY Switch to ON and set the ZERO SUPPRESS Control to position 2.

5. Adjust the Model 15OB 1V Output to within fO.l% of full scale as read on the

Keithley Model 662 Differential Voltmeter.

6. Adjust the Meter Calibration potentiometer (Rl93, Figure 17) for a reading of 10

on the Model 150B meter scale.

OFF

VOLTS (either position)

Approximately-centered

24

e.

Current Compensation Calibration.

0667R

Page 29

MODEL 150B MICROVOLT AMMETER

1. Set the Model 150B front panel controls as follows:

MAINTENANCE

POWER SUPPLY Switch

OFF

RANGE Switch 10 MICROVOLTS

FUNCTION Switch

ZERO SUPPRESS COARSE Control

VOLTS, INPUT R 1OOK

OFF

ZERO SUPPRESS FINE Control Approximately centered

FILTER Switch

IN

2. Short the Model 150B input with the Keithley Model 1488 Shorting Plug or some

other suitable device.

Turn the POWER SUPPLY Switch to ON,

3.

Allow the Model 150B to warm up for 10

minutes and reach thermal equilibrium.

4. Zero the Model 150B using the ZERO SUPPRESS Controls.

Remove the short from the input.

5.

Adjust the Current Compensation Adjust (R304,, Figure 10) for null. A few tenths

6.

of a microvolt instability is to be expected.$

4-8. AMPLIFIER CHECK OUT AND CALIBRATION.

The check cut and calibration of the amplifier circuits is divided into these parts:

a.

operational check, gain calibration,

dtift verification.

The operational check does not have to be followed by gain calibration.

Use this to check the Model 150B operation.

point,

refer to Table 12. After clearing the trouble, continue the check.

TT Adjust calibration, Filter Adjust calibration and

If the amplifiers fail to check out at any

NOTE

If

Check the power supply circuits before adjusting the amplifiers.

changes are made,

Operational Check Procedures.

b.

Connect the Model 14,88 Low-Thermal Shorting Plug to the INPUT RECEPTACLE.

1.

the amplifier circuit may need recalibration.

extensive

Set the

front panel controls as follows:

POWER SUPPLY Switch AC

RANGE Switch 1 MICROVOLT

FUNCTION switch

INPUT R OPEN

ZERO SUPPRESS COARSE Control OFF

ZERO SUPPRESS FINE Control

FILTER Switch

On the l-microvolt range, the meter offset should be less than 0.5 microvolt (50%

2.

of full scale).

Connect the Model 610B Electrometer to'the plate of tube Vl (point E, Figure 11).

3.

It may be higher if the shorting plug (Model 1488) is not used.

Adjust the Vl BIAS Potentiometer (R107,

*0.1 volt.

the Vl BIAS Potentiometer,

If the plate voltage is high and cannot be adjusted down to 7 volts with

then decrease the value of resistor R102;

Figure 10) until the Model 610B reads 7 volts

Approximately centered

IN

If the plate vol-

tage is low and cannot be adjusted up to 7 volts with the Vl BIAS Potentiometer, then

0667R

25

Page 30

MAINTENANCE

_-

MODEL 150B MICROVOLT AMMETER

increase the value of

Remove the Model 1488 Siwrting Plug and leave the Model 150B input open. Set the

4.

FUNCTION Switch to ;I?;PUT R 100%.

1v OUTPUT.

Set the oscilloscope amplifier to dc coupling, 0.2 volt/cm, time base to 1

second/cm. Set the Model .!5OB LO the 3-microvolt range.

Control to 1 and adjust the

reli3tor

X102. Disconnect the Model 610B.

Connect the Type 503 Oscilloscope to the Model 15OB

Set the ZERO SUPPRESS COARSE