Page 1

INSTRUCTION MANUAL

MODEL 149

MILLI-MICROVOLTMETER

Page 2

WARRANTY

We warrant each of our products to be free

from defects in material and workmanship. Our

obligation under this warranty is to repair or

replace any instrument or part thereof which,

within a year after shipment, proves defective

upon examination. We will pay domestic

surface freight costs.

To exercise this warranty, call your local

field representative or the Cleveland factory,

DDD 216-248-0400. You will be given assistance and shipping instructions.

REPAIRS AND RECALIBRATION

Keithley Instruments maintains a complete repair service and standards laboratory in Cleveland, and has an authorized field repair facility

in Los Angeles and in all countries outside the

United States having Keithley field representatives.

To insure prompt repair or recalibration service, please contact your local field representative or the plant directly before returning the

instrument.

Estimates for repairs, normal recalibrations,

and calibrations traceable to the National Bureau of Standards are available upon request.

Page 3

MODEL 149 MILLI-MICROVOLTMETER CONTENTS

TABLE OF CONTENTS

Section Page

INTRODUCTION . l-1

1.

Specifications . 1-2

OPERATION. . 2-1

2.

Operating Controls . . . 2-l

Preliminary Set-Up . 2-l

General Precautions. . . 2-2

Measuring Voltage. . 2-3

Other Applications 2-4

CIRCUIT DESCRIPTION. 3-1

3.

Input Circuit.

AC Amplifier

DC Amplifier . . . . . .

.

3-l

. . 3-l

3-l

Zero Suppression . . . . 3-2

Other Controls .

Power Supply . .

. . . .

. . . .

3-2

3-2

Section

MAINTENANCE. . . . . . . . .

4.

Trouble-Shooting . . . . .

Excessive Output Noise . . . .

Output not Zero with Input

Terminals Shorted . . .

220-Volt Operation . . . . . . .

REPLACEABLE PARTS. . . . 5-l

5.

Replaceable Parts List . .

How to Order Parts . . .

Model 149 Replaceable Parts List

Models 1483, 1484 Replaceable

Parts List. . . . . . . . 5-6

Model 1491 Replaceable Parts List 5-7

Model 1501 Replaceable Parts List 5-7

Model 1502 Replaceable Parts List 5-7

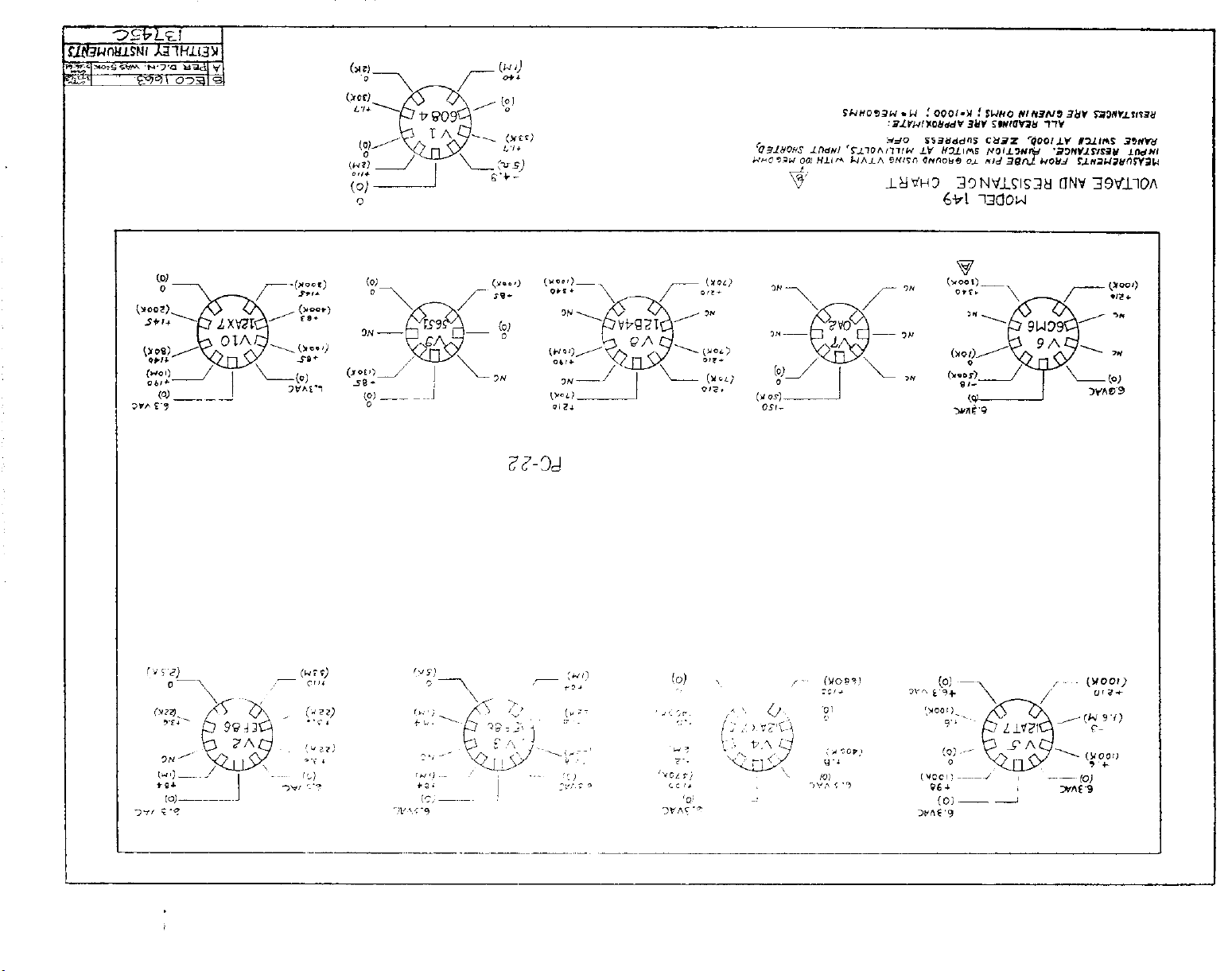

Voltage and Resistance Chart . 5-9

Schematic Diagram. . . . . .

Green Repair and Calibration Form

*

Change Notice . . . . . Last

Page

4- 1

4-l

4- 1

4-2

4-3

5-1

5-l

5-2

5-11

5-13

Page

K

Yellow Change Notice sheet is included only for instrument modifications

affecting the Instruction Manual.

1068R

Page 4

MODEL 149 MILLI-MICROVOLTMETER

INTRODUCTION

SECTION 1. INTRODUCTION

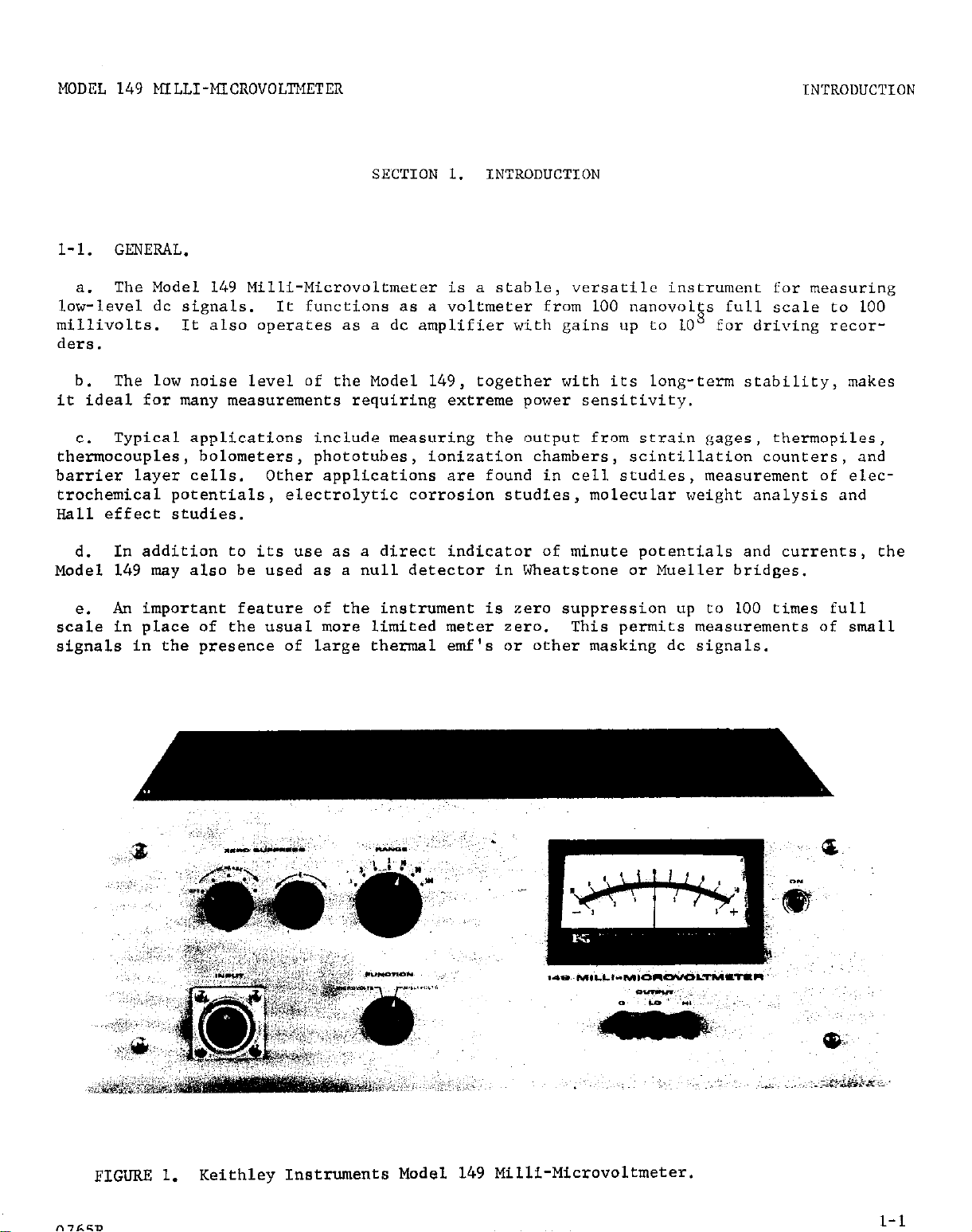

l-l. GENERAL.

The Model 149 Milli-Microvoltmeter is a stable, versatile instrument for measuring

a.

low-level dc signals. It functions as a voltmeter from 100 nanovol s full scale to 100

millivolts.

It also operates as a dc amplifier with gains up to 10 ' for driving recor-

ders.

The low noise level of the Model 149, together with its long-term stability, makes

b.

it ideal for many measurements requiring extreme power sensitivity.

Typical applications include measuring the output from strain gages, thermopilcs,

C.

thermocouples, bolometers, phototubes, ionization chambers, scintillation counters, and

barrier layer cells. Other applications are found in cell studies, measurement of elec-

trochemical potentials, electrolytic corrosion studies, molecular weight analysis and

Hall effect studies.

In addition to its use as a direct indicator of minute potentials and currents, the

d.

Model 149 may also be used as a null detector in Wheatstone or Mueller bridges.

e. An important feature of the instrument is zero suppression up

to

100

times

full

scale in place of the usual more limited meter zero. This permits measurements of small

signals in the presence of large thermal emf's or other masking dc signals.

FIGURE 1.

Keithley Instruments Model 149 Milli-Microvoltmeter.

l-l

Page 5

INTRODUCTION

l-2. SPECIFICATIONS.

RANGE: 0.1 micro"olt (10 x 10-8 volt) full scale to 100 millivolts on zero-center meter.

13 overlapping ranges in lx and 3x steps.

ACCURACY: *2% of full scale on all ranges exclusive of noise and drift.

ZERO DRIFT: Less than 10 nanovolts per hour or less than 30 nanovolts in any *-hour period after approximately Z-hour warm-up with reasonably constant ambient temperature.

Long-term drift is non-cumulative.

INPUT NOISE (with input shorted): Less than 0.6 nanovolt rms (3 nanovolts peak-to-peak)

on most sensitive range.

INPDT CHARACTERISTICS:

MODEL 149 MILLI-MICROVOLTMETER

Input Resistance

Greater than,

m

0.1 P"

0.3 ,I"

1.0 &I"

3.0 ,1"

10.0 1"

30.0 )A"

100 pv and above

Note:l

LINE FREQUENCY REJECTION: Greater than 5O:l on the most sensitive r~ange. (Ratio of impressed peak-to-peak line frequency voltage at input to indicated dc voltage.)

ISOLATION: Circuit ground to chassis ground: Approximately 10'

crofarad.

RISE TIME (10% to 90%):

O.l-microvolt Range:

maximum; 4 seconds using maximum source resistance.

0.3-microvolt to lOO-millivolt Ranges: Less than 1 second when source resistance is

less than 10% of maximum; 2 seconds using maximum source resistance.

Source resistances higher than the recommended maximum will increase noise

and rise time.

Circuit ground may be floated up to *400 volts with respect to chassis ground.

mess than 2 seconds when source resistance is less than 10% of

ohms

10 k

30 k

100 k

300 k

1M

3M

10 M

Maximum Source1

Resistance,

ohms

100

300

lk

3k

10 k

30 k

30 k

ohms shunted by 0.05 mi-

-

ZERO SUPPRESSION: Up to at least 1 millivolt on the microvolt ranges and up to at least

10 millivolts on the millivolt ranges. Stability is such that 100 times full scale may

be suppressed.

RECORDER OUTPUT:

output: *lO volts dc at up to 5 milliamperes for full-scale meter deflection.

Resistance:

Gain:

1-2 1167R

Range setting in volts

Less than 10 ohms within the amplifier pass band,

10 volts

Page 6

MODEL 149 MILLI-MICROVOLTMETER

INTRODUCTION

Noise:

Modulation Products:

CONNECTORS:

Input noise times gain plus modulation products.

Less than 2% peak-to-peak of full scale with input shorted.

Input:

Special connector.

Front Output: Binding posts.

Rear Output:

Amphenol 80-PC2F.

POWER:

105-125 or 210-250 volts, 60 cps, 50 watts.

DIMENSIONS, WEIGHT:

7 inches high x 19 inches wide x 13 inches deep; net weight, 24 pounds.

SO-cps models available.

ACCESSORIES SUPPLIED: Model 1501 Low Thermal Input Cable with alligator clips; mating

output connector; length of low-thermal solder.*

-'t The solder is screwed to the right side of the copper input chassis, located inside the

Model 149.

Remove the top cover to reach the solder.

1-3

Page 7

MDDEL 149 KLLI-MICROVOLB

2-1

OPERATION

SECTION 2 - OPERATION

A.

OPERATING CONTROLS

The controls of the Model 149 are simple and conveniently

placed.

Their functions are as follows:

ON-OFF switch is located to the right of the panel

meter.

FUNCTION switch selects the function which Is to be

used:

MilliVOltS, Or

!dCrOVOltB.

2AN'm switch selects the full scale multiplier of

the function selected by the FUNCTION switch.

ZERC SUPPiWSS controls consists of the ZERO RANGE

switch which selects the coa.188 range of suppressing voltage in discreet steps and the ZERO

SET potentiometer which gives continuously

variable fine control Including settings through

TieI-0.

PRELIMINARY SET-UP

B.

Connect the instrument to the power line. Unless otherwise

marked the unit may be used on 117 volt, 60 cps line.

vert to 220-volt operation,

refer to the

MAIN'lXK4NC!E

To con-

section.

A three-wire line cord is furnished, which grounds the cabinet.

If a three-wire receptable is not available, use the two-pin

adapter furnished, and ground the third lead to an external

ground.

Set controls *a followa:

Function:

Range :

Millivolts

100

zero suppress: OFF

Input:

Short the input leads together.

Page 8

OPE3ATION

C.

GENERAL PRECAUTIONS

1.

sistance SpeCifiCatYiOg the maximum source resistance for use with

each voltage range is specified.

with source resistance up to ten times greater than those specified,

however, the measurement will suffer from a considerable decrease in

speed of response,

left completely open-circuited,

scale on any range.

Shielding - Since the instrument operates with a modulator

2.

frequency of 120 cps,

up unless it is large enough to overload the amplifier. The pickup

may be a source of difficulty when using the amplifier with high

impedances on ~the more sensitive voltage ranges. In these cases it

is desirable to shield the leads and the sources as completely as

possible. In some cases a simple low-pass filter at the input to

eliminate frequencies of about 1 cps and above will be helpful.

No use is made of an input filter in this instrument since any input

series impedance due to the filter will increase the input noise and

the thermal drift. When operating above ground, the case of the instrument must be grounded.

Source Resistance -

and measuring accuracy.

it is not generally sensitive to 60 cps pick-

KNEL

1n

Section luncler the Input Re-

149

MILLI-MICROVOL-R

Reasonable operation is possible

If the instrument is

the meter will generally drift off

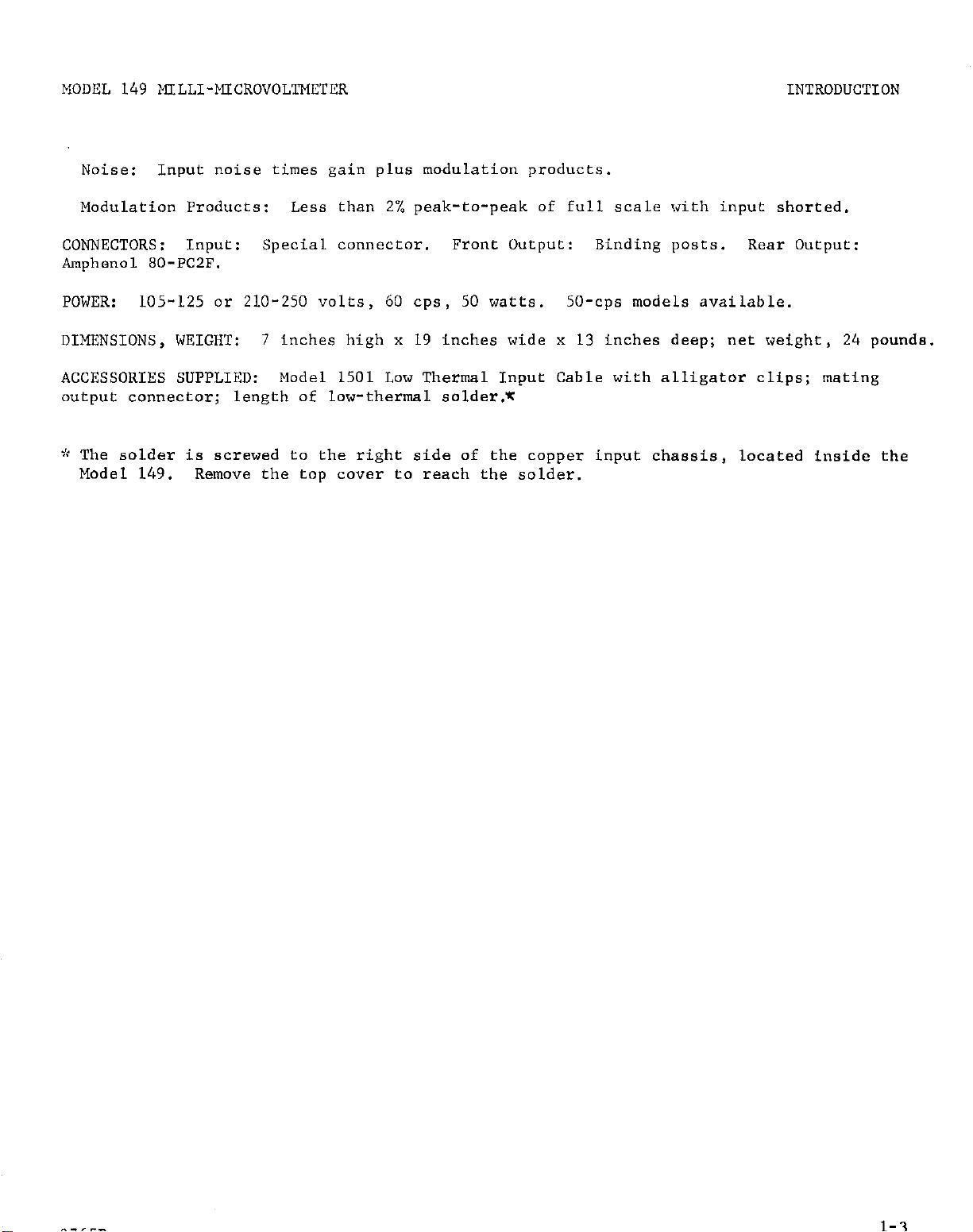

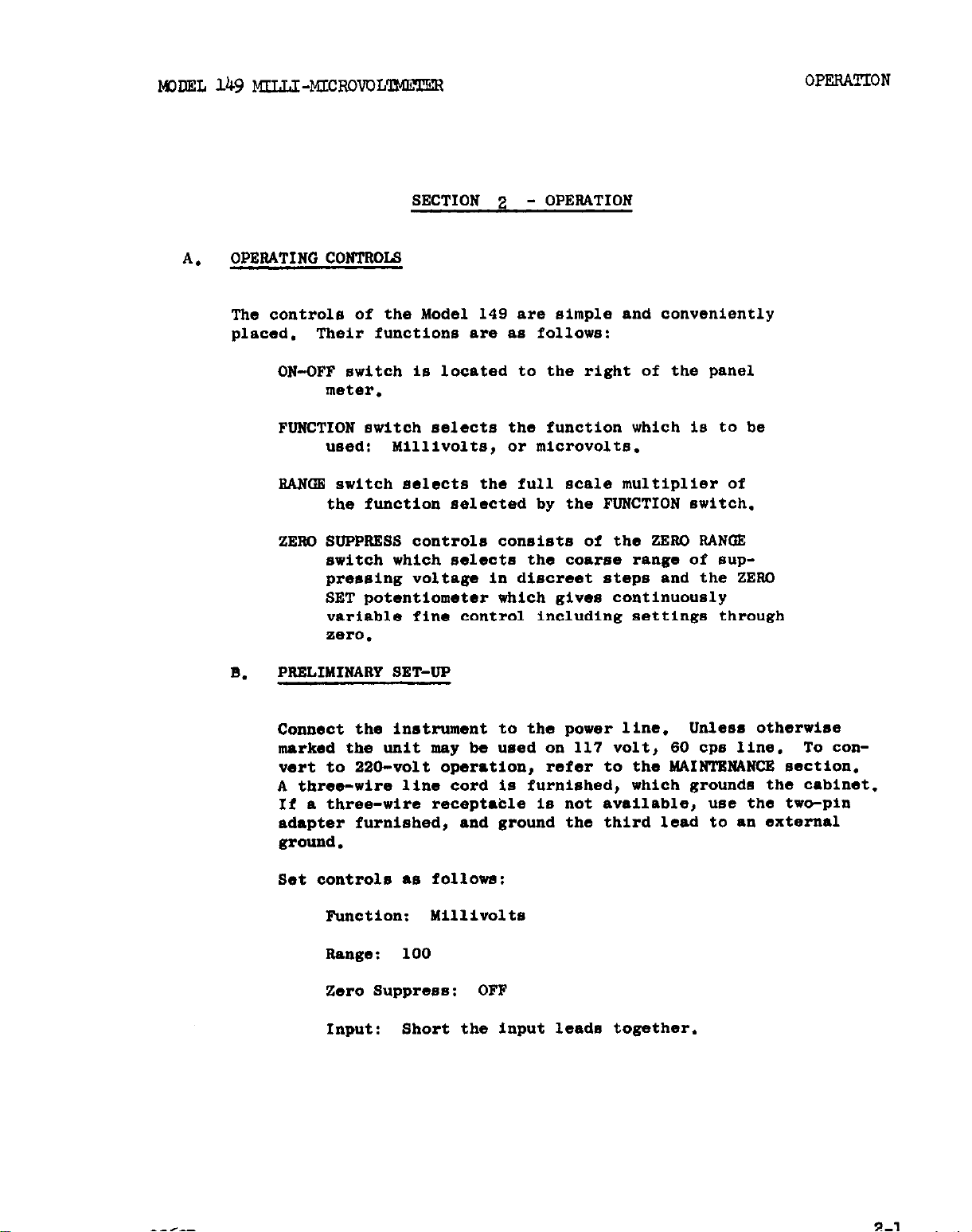

3.

the output of the AC amplifier at the point of the demodulator is

provided at the rear of the instrument. It is labeled DEMOD. OUTPUT.

If an inability to make consistent readings persists, it is possible

to check for the presence of excessive pick-up by observing the

wave-form at this point.

be approximately as shown in figure 2. If

served it will look as shown in figure

reasonably well as long as the wave-form

in figure 4.

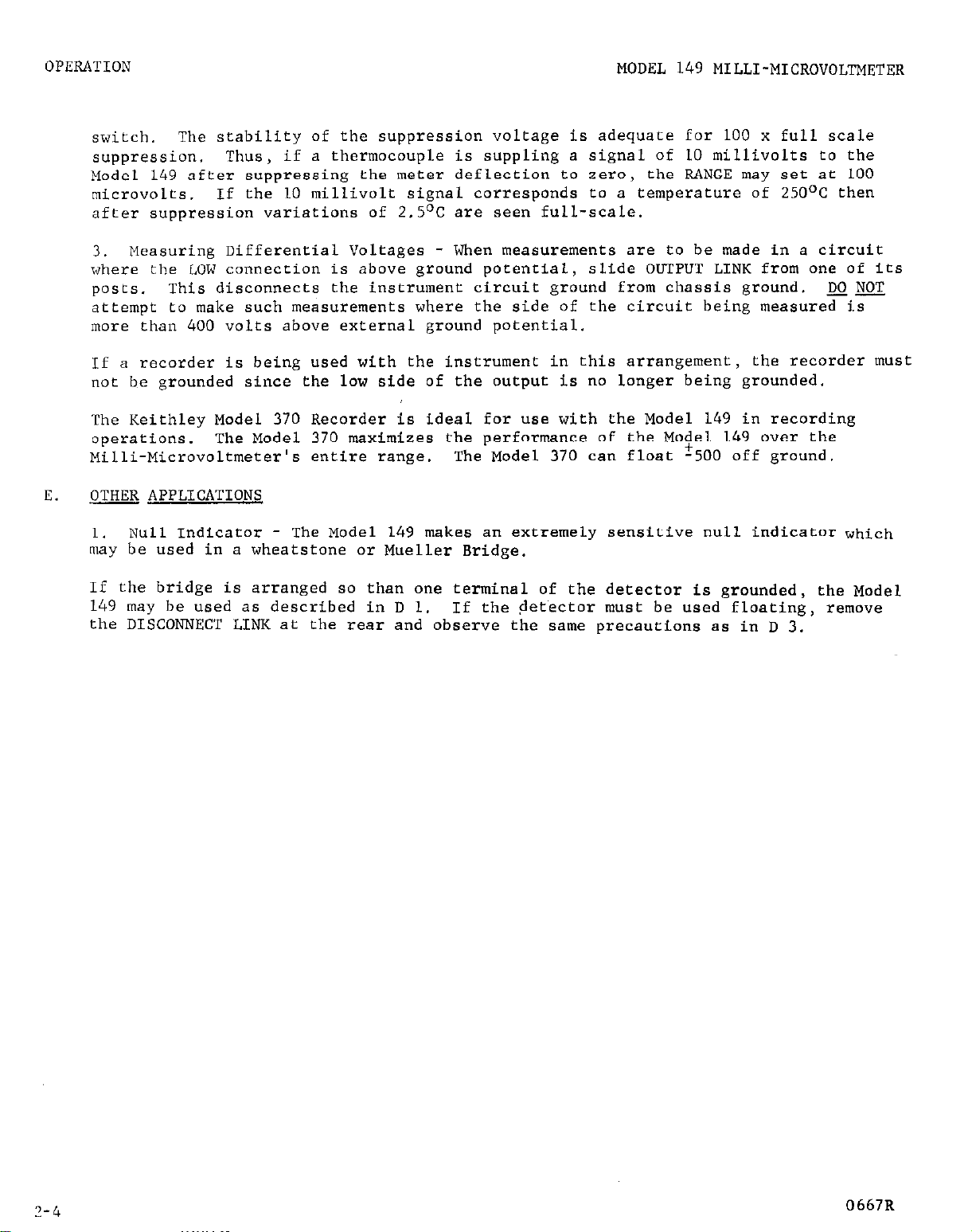

Determination of Excessive AC Pickup - A terminal attached to

With the input shorted the picture should

excessive

3.

The circuit will operate

does

not clip as shown

At this point the operation will be erratic.

pickup is ob-

--I.-

lo v P-P

t

FIOUIlE2

c

40 v P-P

t

Page 9

MODEL 149 MILLI-MICROVOLl'METI

Thermal EMF - Extreme precautions have been taken in the input

4.

circuit to minimize thermal EMF's so the residual RMF is usually less

than 0.5 uv.

The material used in the input circuit is pure copper.

Any other metal will generate a thermocouple potential.

particularly troublesome. Where thermal W's are a problem, soldering

should be done with the cadmium-tin solder supplied with the instrument.

Input Noise - The noise at the input is a function of input

5.

resistance and is approximately given by

E = 1.29 x 10-loum

OPERATION

FIGURE 4

Lead solder is

where E is the RMS noise, and R is the source resistaixe. It is assumed

that the bandwidth of the instrument is about 1 cps and the temperature

is 80° F.

If noise is observed, calculate the theoretical noise and

compare results. Also bear in mind that only wire-wound resistors

approach the ideal resistor. However, if Evanohm or Manganin resistors

are used,

a considerable thermal EMF of the resistor material against

copper will be observed.

Checking the Zero Point - At low levels, spurious W's may be

6.

generated

under test.

simply by contact between the input leads and the terminals

If possible,

always leave the instrument connected and

adjust the zero after establishing a zero reference in the apparatus

under test. For example, in bridge measurements, disconnect the bridge

exciting voltage;

Overloads - The current applied to the input circuit should be less

7.

than one milliampere dc steady state,

or with a phototube, shield the tube from light.

10 milliamperes dc short-term.

When the FUNCTION switch is on the MILLIVOLTS position, the off-scale

impedance can be as low as 1000 ohms.

On the MICROVOLTS position, it may

approach one ohm.

MEASURING VOLTAGE

D.

Direct Voltage Measurements - Place the FUNCTION switch at MILLIVOLTS

1.

or MICROVOLTS as necessary for the measurement to be taken.

Then turn

the RANGE switch to more sensitive ranges until the meter gives a usable

deflection,

Measuring Voltage Variations

2.

- To observe small variations in a large

steady signal, first set the FUNCTION and RANGE switches as described in

D 1.

the meter deflection to zero.

Then operate the ZERO SUPPRESS switch and potentiometer to reduce

Increase the meter sensitivity with the range

0667R

2-3

Page 10

OPERATION

MODEL 149 MILLI-MICROVOLTMETER

switch.

suppression.

Model 149 after suppressing the meter deflection to zero, the RANGE may set at 100

microvolts.

after suppression variations of 2.5OC are seen full-scale.

3. Measuring Differential Voltages - When measurements are to be made in a circuit

where the LOW connection is above ground potential,

posts.

attempt to make such measurements where the side of the circuit being measured is

more than 400 volts above external ground potential.

If a recorder is being used with the instrument in this arrangement, the recorder must

not be grounded since the low side of the output is no longer being grounded.

The Keithley Model 370 Recorder is ideal for use with the Model 149 in recording

operations.

Milli-Microvoltmeter's entire range.

E. QTJEJ APPLICATIONS

Null Indicator - The Model 149 makes an extremely sensitive null indicator which

1.

may be used in a wheatstone or Mueller Bridge.

If the bridge is arranged so than one terminal of the detector is grounded, the Model

149 may be used as described in D 1.

the DISCONNECT LINK at the rear and observe the same precautions as in D 3.

The stability of the suppression voltage is adequate for 100 x full scale

Thus,

If the 10 millivolt signal corresponds to a temperature of 250°C then

This disconnects the instrument circuit ground from chassis ground.

The Model 370 maximizes the performance of the Mo$el 149 over the

if a thermocouple is suppling a signal of 10 millivolts to the

slide OUTPUT LINK from one of its

The Model 370 can float -500 off ground.

If the aet~ector must be used floating, remove

NOT DO

7-4

0667R

Page 11

MDEL 149 MILIJ-IWROVOLI~

SECTION 3 - CIRCUIT DESCRIPTlON

CIRCUIT DESCFUFTION

The Model 149 is basically

negative feedback to stabilize the gain and increase the input impedance.

A.

B.

Input Circuit

Zero Stability: The effect of thermal EMF's generated in the input

circuitry is reduced to nearly the vanishing point by the we of only

copper in the input circuit. All aoldar points are made with a low

thermal cadmium-tin solder. The chopper and chopper transformer

employ copper leads. All switching in the input circuit is accomplished

with copper switch.

wound of copper wire. The input connector has solid copper,apringloaded contacts.

The input voltage is applied to the moving arm of a 120 cpa mechanical chopper. The feedback voltage is connected to the primary

center tap of the input transformer. Thus,

is applied first acro88 one half of the primary and then, with phase

reversal, to the other half. This full wave error signal is stepped

up 90 to 1 by the inputtransformer and applied to the grid of

VI, 'a 6084 low-noise pentode.

AC Amplifier

In parallel with the plate load resistor of Vl is a relatively high

Q, 120 cps resonant circuit which narrow the bandwidth and reduce8

spurious signals.

a narrow-band

Critical resistors in the input circuit are

chopper amplifier employing

the difference voltage

V2 and V3, EF86 pentodes, further amplify the chopper error signal

which is then demodulated synchronously by silicon diodes Dl through

m.

To obtain the 120 cps demodulator driving signal, use is made of the

ripple frequency from a bridge rectifier circuit operating from the

line voltage.

driver transformer.

lx2 Amplifier

C.

The demodulated signal is applied to the grid of V4.

V6 form the dc amplifier and.output cathode follower which add

further forward gain to the system and supply output power. Feedback around V4,

demodulator filter capacitor Cl13 by about 1000. This yields the

large equivalent capacitance necessary to smooth the demodulated

error signal.

stages outside the pass band of the whole amplifier are effeCtiVely

degenerated.

The ripple is used in the primary of the demodulator

V4, V5, and

V5 and V6 multiplies the effective capacitance of

Because of the feedback, spurious noise in the dc

Page 12

CIRCUIT DESCRIF'l'ION

D.

Zero Suppression

A low-current

using lo-volt zener diodes.

voltage from

propriate dropping resistors to the feedback point to achieve zero

suppression.

ZERO STJF'F'FESS, while switch 53, which determines the portion feed-

aback, is labeled 7LERO SUPPRESS, OFF-INCREASE.

E.

Other Controls

Two controls are set at the factory

quent attention by the user.

R118 is an internal control marked DC AMP BAL. It is used to zero

the DC amplifier, i.e., to set the output voltage to zero when the

demodulator output is zero. This is not very critical since an "nbalance will simply be fed back to the input to produce a small error signal to correct itself. R127 is marked CAL. This is the var-

iable portion of the meter multiplier resistance to allow for meter-

to-meter sensitivity differences.

power Supply

F.

+10 volt supply is derived from the main dc supplies

Potentiometer Rl54,may be set at any

-10 to +lO volts, this voltage is applied through apThe potentiometer is the front panel control marked

and

should require only infre-

A standard half-wave rectifier followed by an R-C filter is used to

supply unregulated B l and B- to the output cathode follower.

The unregulated B- is regulated to -150 volts in V7, OA2, and is

used for the negative returns for the dc amplifier.

Unregulated B+ is fed to the plate of V6, 12B4A, the series tube in

a 225-volt electronic regulator. The output voltage from this reg"later is divided by R510 and R511 and compared to reference tube

V9, a 5651. The difference signal is amplified by cascade amplifier

VIO, a 12AX7,

tube.

lifier,

This

through a decoupling filter (R176, Cl101 to the second end

and

regulated

applied to the grid-cathode circuit of the series

225 volts supplies B+ directly to the dc amp-

third ac amplifier stages, and through another decoupling filter

(R103, C104) to the first ac amplifier stage.

Regulated B+ and B- also supply currents to the 10 volt zoner diodes

which are used for zero suppression.

This gives two-stage regulation

for these very critical voltages.

Zoner DiodeDllZ regulates the filament voltage of Vl to reduce line

transient effects.

Page 13

MODEL 149 KILLI-KKROVOL'lXl!TER

SECTION

Except for occasional tube or chopper replacement, very little rcalntenance is

required by the Modell@. Components are operated well below rating and solid

state devices are employed where possible to achieve long, trouble-free service.

Certain portions of the input circuit are wired using chopper wire and special

cadmium-tin solder. These special joints are painted red. If, for sny reason,

these joints must be unsoldered or re-soldered, USE ONLY CADMIUM-TIN SOLDER

ANDACO~-~PPEDSOLDERINCIRONWMCBIIA9NEVERBWUSEDWITHaaDINARYLEAD

TIN SOLDER. A mall spool of cadmium-tin solder is supplied with each instrument.

What

trouble-shooting the instrumeut, check to see whether it operates correctly with:

If the difficulty persists, the following systematic procedure may be employed

to determine the fault.

may seem to be circuit failure in the milJ.imicrovoltmeter is quite often

found to be an unusuel condition in the entire test set-up. !l!herefore, before

1. All other circuitry disconnected.

2.

Input shorted (with copper leads).

POwer Line voltage and

3.

4

- MAINTENANCE

frequency

correct.

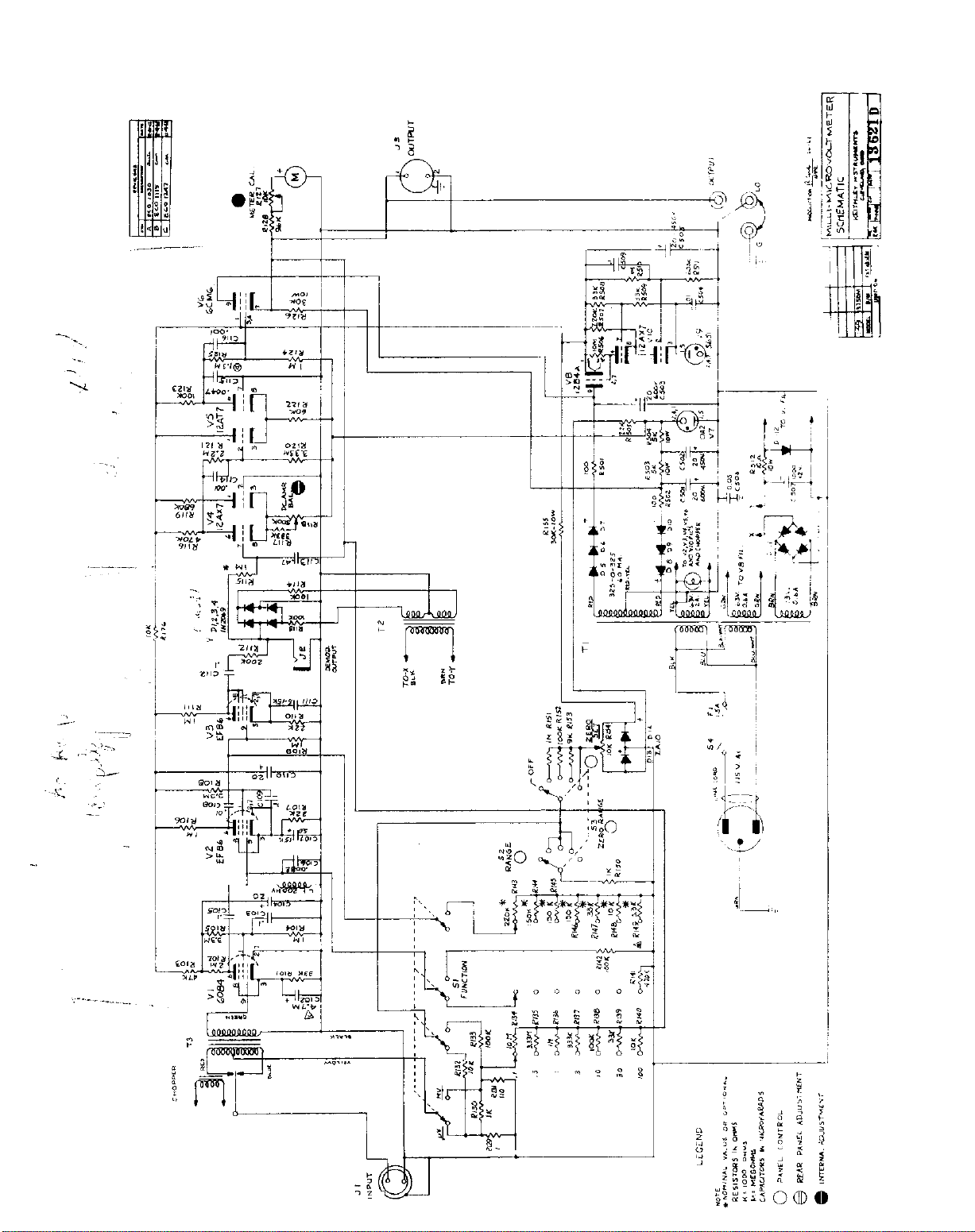

Reference is made to the Schematic Magrsm

Diagram enclosed at the rear of the manuel.

To begin trouble-shooting, short the input terminals, StrapGto I1) with the

link provided. end switch ZERO suppREsS, OFF-INCREASE to OFF. A Zero offset

of v.1 to 0.4 mlcromlt is

E2ZESSIVEOUTFUTNOISE(INiTlTTpIMINAIs SHORTED)

Because of the vary low signal levels involved, noise in the ac amplifier Is

difficult to trace except by the substitution method. Most likely noise sources

are Vlendthe chopper.

being generated in the dc amplifier or power supply. A stage-by-stage search

~shouldrevealthe source.

~mtetal film resistor.

resistors tend to introduce inductive pickup.

To replace the chopper, unplug the cap atthetop. Frcmtha

14.9, removetheplate covering the areaaroundthe chopper base. Unsolder the

chopper leads.

a

correct connection

the chopper frca the top.

Claen out the lead at the input connector; teg the telminsl for

Replace onlywlththe equivalentreeistor. Win-wound

later.

normal.

If noise persists after replacing the chopper, it is

Very often the noise is generated by RlG2, low noise

Unscrewthe choppermunting screws endlift out

13621~,

and the Voltage-Resistance

bottom

of the&o&l

Page 14

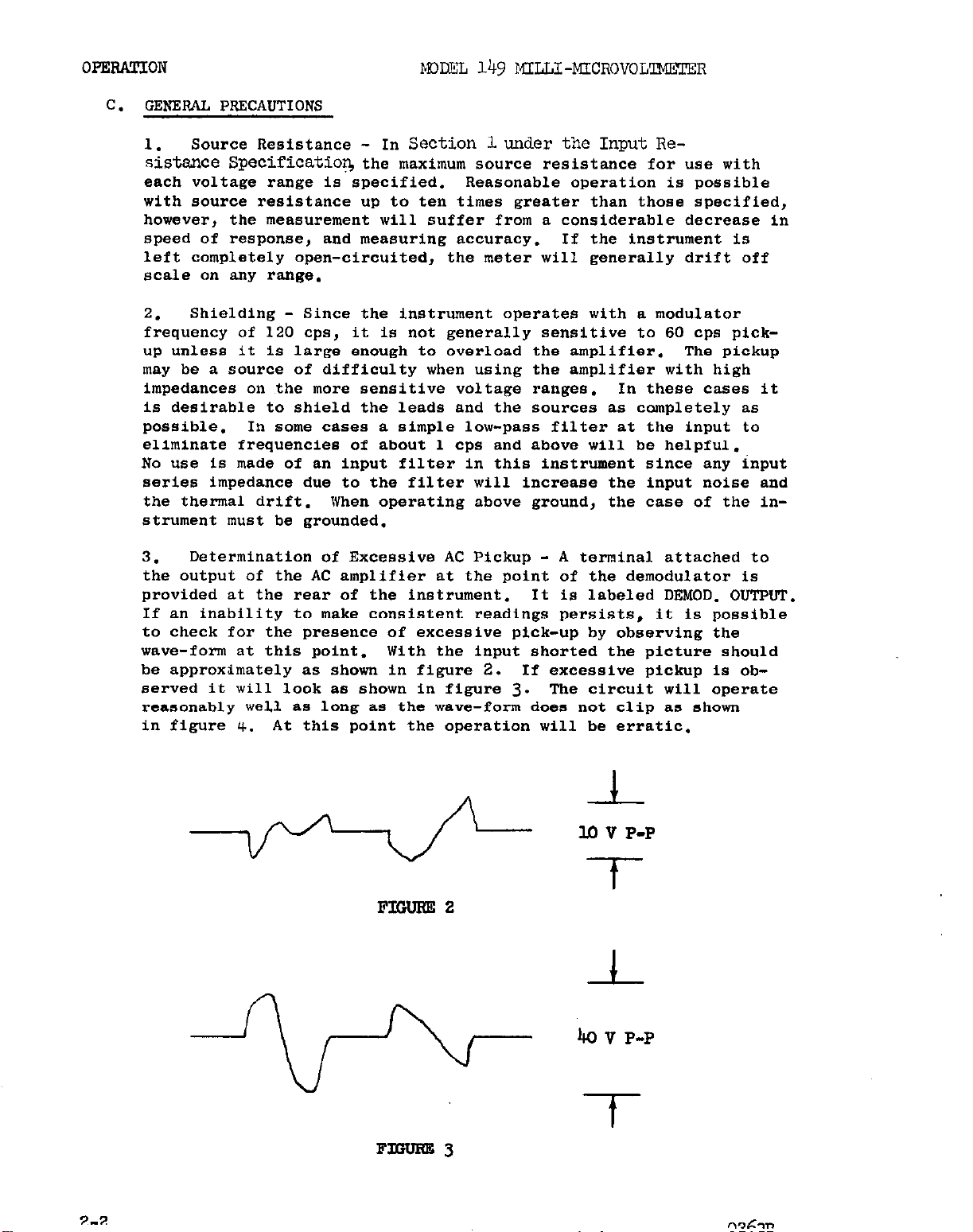

MUNTEWNCE

Insert the new chopper from the

top, putting the wire leads through

the holes. For convenience, place

the No. 2 lead nearest the Model

149 side as shown in Figure

the bottom, secure the chopper with

four No. 4-40 NC-2

proxim&ely 34 In. of teflon tubing

over

other two Gads.

Solder lead No. 2 to the input connector. Insert a shorting bar into

the input connector to push out the

leads enough to facilitate working

on the connection.

lead No. 2 and 2+ in.

screws. Put ap-

5.

over

From

the

M2DEL 149

MIUI-MICRCVOL

NOTEZ

new solid copper tip end low-thermal cadmium solder for all sol&r

connections painted red. This

solder is supplied tith the Model

149.

and mecheacal connections.

Conned lead No. 1 to the red lead

Of trensformer-TR37; connect lead

No. 3 to the blue lead of transformer

m37.

interlock the loops, and solder Do

not cross ortwistthe leads. SliXe

the tubing over the connections.

Twlstshie.l.dleadVaroundchopperleadNo.2asshowninFigure5. Makesure

the end of the shield leed Is free of all-contact.

chopper base.

Use soldering iron with a

Uake sure of goodelectrical

l&k8 loops at the leadends,

Plug in the cap at the top of the chopper.

FIGURR

from the bottom of &Mel 149.

Chopper Replacemnt.

5.

Replacetheplate over the

View

ouTmTNoT2ERo (~0.5mcRo~m)wITRINFuTTwMINnrssRo~

Besurethe?mosuPPmss is

7 of

v4, to glxmld.

control will become very "scratch' but the ad.justment is possible. If this can-

not be done, the dc sqplifler or power supply are at fault. If it ten be set to

zero,

the

trouble n&be

Use the DC AMP RAL control to set the output to Zero. The

set to OFF.

in the ec emplifier or demodulator circuit.

Short the dc amplifier input grid, pin

is

Power

ti -150

the unregulatedB-.

940 volta) a;t the

check the tube pin voltages of VS, Vg, and Vu) to locate the faulty tube or

part.

b. AC Amplifier - Remove the output tube

connectortoground.

ZEIKI SlITandZRRORANUR controls full clockwlse. This puts a large dc error

suppq

on pins 2, 4 or 7 of W.

- B+ should be about

If +225 is not present,

plate pin g

Place the NNCTION switch onMII&IVOLIs, andturnthe

of va.

+225 011 pin 10f va,

If

V7

is not firing, correct the fault in

check for unregulated Dt (about

If the unregulatedB+is all right,

(~6) and

clip pin 1 of the output

and B- should

Page 15

ImDEL 149 PlILLI-MICROVOLI~2XZR

MAINTENANCE

signal across the chopper and input transformer.

for the presence of I20 cps at the primacy of the input trsnsfomers (the

two outside temiuals on the chopper terminal block). Absence of signal

means chopper failure (or much less likely, a shorted or open input transformer).

necessary.

If the I20 cps signal is present, check stage-by-stage throughout the ac

emp.l.ifier, reducing the input signal as desired by backing off the ZERO

FiANGE and/or 2220 SET controls,

d.

Demodulator Circuit -

secondary of the demodulator transformer (at the ends of

The tests outlined above will not suffice to pin-point every fault which

may exist.

In the event that troubles cannot be corrected by these means, or the user

finds it more expedient, the unit may be returned to the factory for repair

and recalibration at a nominal cost.

220-VOLT OPF&lTION

For 220-volt operation the power tramformer primary connections must be changed.

The juktpers connecting black and black-white together and blue and blue-white

should be removed. The blue and black-white leads should be tied together.

Replace the 1.5~ampere fuse (Keithley Part No. W-8) with a 0.75-ampere fuse

(Keithley Part No. m-14).

Listen for audible chopper action and check chopper drive, if

until the failure is discovered.

Check for presence of about 80 volts 2W at the

They should, however, lead to the correction of comon failures.

Use an oscilloscope to check

FLU3

end FtlJ.4).

4-1

Page 16

MODEL 149 MILLI-MICROVOLTMETER

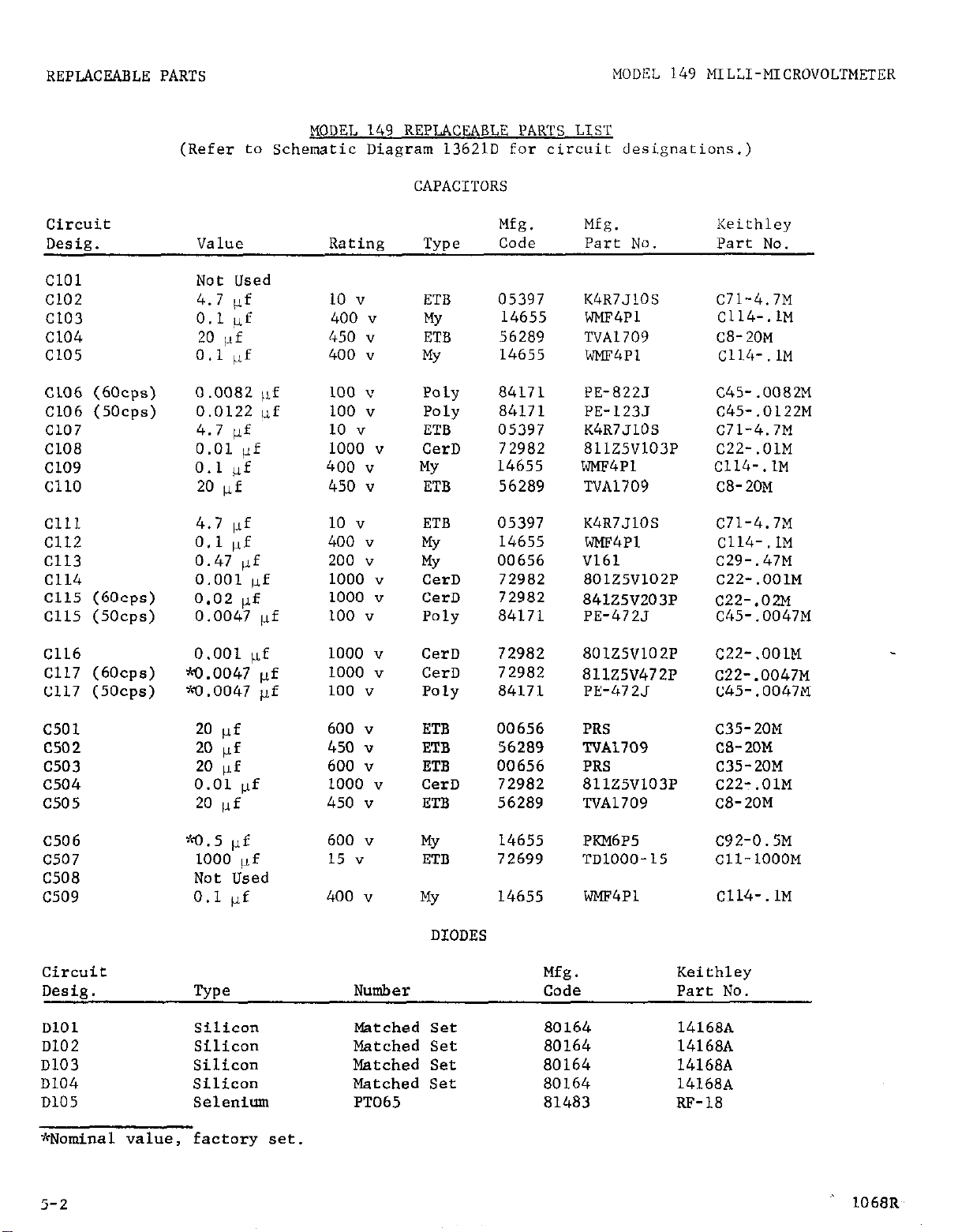

SECTION 5. REPLACEABLE PARTS

REPLACEABLE PARTS

5-1. REPLACEABLE PARTS LIST.

Model 149 and its accessories.

tion,

Number.

contained in Table 3.

5-2.

Part Number,

and those parts coded for Keithley manufacture (80164) must be ordered from Keithley

Instruments, Inc.

describe the part,

ment, Keithley Instruments, Inc.

amp

CbVar

I

CerD

:0lU1

Comp

DCb

ETB

f

hy

a suggested manufacturer,

The name and address of the manufacturers listed in the “Mfg. Code” column are

HOW TO ORDER PARTS.

For parts orders,

a.

the circuit designation and a description of the part.

Order parts through your nearest Keithley distributor or the Sales Service Depart-

b.

include the instrument’s model and serial number, the Keithlcy

In ordering a part not listed in the Replaceable Parts List, completely

its function and its location.

ZXllpere

Carbon Variable

Ceramic, Disc

Commercial

Composition

Deposited Carbon

Electrolytic, tubular

farad

henry

The Replaceable Parts List describes the components of the

The List gives the circuit designation, the part descrip-

the manufacturer’s part number and the Keithley Part

All structural parts

Mfg.

MtF Metal Film

MY

n

P

PM Paper, metal cased

POlY

I-r

”

Var Variable

Manufacturer

Mylar

ohm

pica ( 10-12)

Polvstvrene

. .

micro ( 10m6)

volt

k

M or meg

m milli (10-3)

kilo (103)

mega (106) or megohms

TABLE 2.

w watt

ww Wirewound

wwvar

Abbreviations and Symbols.

Wirewound Variable

5-l

Page 17

REPLACEABLE PARTS

(Refer to Schematic Diagram 13621D for circuit designations.)

MODEL 149 MILLI-MICROVOLTMETER

MODEL 149 REPLACEABLE PARTS LIST

CAPACITORS

Circuit

Desig. Value

Cl01

Cl02

Cl03

Cl04

Cl05

Not Used

4.7 (If

0.1 @f

20 pf

0.1 llf

Cl06 (60~~s) 0.0082 ,rf

Cl06 (50~~s) 0.0122 uf

Cl07 4.7 pf

Cl08 0.01 tlf

Cl09

0.1 I.rf

Cl10 20 uf

Cl11

Cl12

Cl13

Cl14

Cl15 (60~~s)

Cl15 (5Ocps)

Cl16

Cl17 (60~~s)

Cl17 (5Ocps)

4.7 pf

0.1 pf

0.47 ,lf

0.001 ,lf

0.02 If

0.0047 IJ.f

0.001 pf

w.0047 pf

w.0047 pf

Rating

10 v

400 v

450 "

400 v

100 v

100 "

10 "

1000 "

400 I!

450 v

10 "

400 v

200 v

1000 "

1000 "

100 "

1000 "

1000 "

100 "

TYPO

ETB

MY

ETB

MY

Poly

Poly

ETB

CerD

MY

ETB

ETB

MY

MY

CerD

CerD

Poly

CerD

CerD

Poly

Mfg. Mfg.

Keithley

Code Part No. Part No.

05397 K4R7JlOS

14655

wMF4Pl

56289 TVA1709

14655

wMF4Pl

84171 PE-822J

84171 PE-123.l

05397

K4R7JlOS

72982 811Z5V103P

14655

wMF4Pl

56289 TVA1709

05397

14655

K4R7JlOS

wMF4Pl

00656 V161

72982 801Z5V102P

72982

841Z5V203P

84171 PE-472J

72982 801Z5V102P

72982

811Z5V472P

84171 PE-472J

C71-4.7M

C114-.1M

C8-20~

C114-.lM

C45-.0082M

C45-.0122M

C71-4.7M

C22-.OlM

Cl14-.lM

C8-20M

C71-4.7M

Cl14-.lM

C29-.47M

C22-.OOlM

c22-.02M

C45-.0047M

C22-.OOlM

C22-.0047M

C45-.0047M

c501

c502

c503

c504

c505

C506

c507

C508

c509

20 pf

20 pf

20 pf

0.01 IJf

20

jLf

w.5 pf

1000 ,lf

Not Used

0.1 pf

600 v

450 v

600 "

1000 "

450 v

600 v

15 "

400 v

Circuit

Desig.

DlOl

D102

D103

D104

TYPO

SiliCOll

Silicon

Silicon Matched Set 80164

Silicon Matched Set 80164 14168~

Number Code Part No.

Matched Set 80164 14168~

Matched Set 80164

D105 Selenium PT065

~~Nominal value, factory set.

ETB

00656

ETB 56289

ETB

00656

CerD 72982

ETB

MY

ETB

MY

56289

14655

72699 TDLOOO-15

14655

DIODES

PRS

TVA1709

PRS

81125V103P

TVA1709

PI(M6P5

C35-20M

CS-20M

C35-20M

C22:.01M

C8-20M

C92-0.5M

Cll-1000M

wMF4Pl

C114-.lM

Mfg. Keithley

14168A

14168A

81483 RF-18

5-2

1068R

Page 18

MODEL 149 MILLI-MICROVOLTMETER

REPLACEABLE PARTS

DIODES (Cont'd)

Circuit

Desig.

DlO6

D107

Dl08

DlO9

DllO

Dill

Dll2

D113

Dl14

D115

D116

Circuit

Desig. Description

FL (115~)

FL (230~)

TYPO

Selenium

Selenium

Selenium PT065 81483

Selenium PT065 81483

Selenium PT065 81483

Selenium Bridge ClB 81483

ZenC?L- lNl589 81483

Zt?lle?Z lN715 12954

ZeIler

Selenium

Selenium

Fuse, slow blow, 1.5 amp, 3 AG (Mfg. No.

31301.5)

Fuse,

Fuse holder (Mfg. No. 342012)

slow blow, 0.75 amp, 3 AG (Mfg. No.

313.750)

NlXllbf?r Code

PT065 81483

PT065 81483

lN715 12954

PT065

PT065 81483

MISCELLANEOUS PARTS

Mfg.

81483

Keithley

Part No.

RF-18

RF-18

RF-18

RF-18

RF-18

RF-7

DZ-4

DZ-22

DZ-22

RF-18

RF-18

Mfg.

Code

75915 FU-8

75915 m-14

75915 FH-3

Keithley

Part No.

Gl (60~~s)

Gl (50~~s)

Jl

---

52

53

---

_--

--__-

LL

M

---

---

Chopper, Frequency Doubling

Chopper, Frequency Doubling

Receptacle Assembly, INPUT

Plug, Special, Mate of Jl

Jack, Telephone, DEMOD. TEST (Mfg. No. 275)

Receptacle, Microphone, OUTPUT (Mfg. No.

80-PC2F)

Plug, Microphone, Mate of 53 (Mfg. No.

80-MC2M)

Binding Posts (Z), OUTPUT, black (Mfg.

No. DF21BC)

Binding Post, OUTPUT, red (Mfg. No.

DF21RC)

Shorting Link (Mfg. No. 938-L)

Choke, 200 hy

Meter

Meter Lamp (Mfg. No. 323)

Cord Set,

6 feet (Mfg. No. 4638-13)

80164

80164

80164 12450B

80164 13011B

71002 CS-65

02660

02660 cs-33

58474

58474

24655 BP-6

80164

80164

08804

93656

cv-2

cv-3

CS-32

BP-11B

BP-11R

CH-1

ME-14

PL-1

co-5

171/,P

5-3

Page 19

REPLACEABLE PARTS

MODEL 149 MILLI-MICROVOLTMETER

MISCELLANEOUS PARTS (Cont'd)

Circuit

Des@. Description

Cable Clamp (Mfg. No. SR-SP-1)

Sl

---

--s2

Rotary Switch less components, FUNCTION

Switch Assembly with components, Function

Skirted Knob,

Rotary Switch less components, RANGE

Switch Assembly with components, Range

Skirted Knob, Range Switch

s3

Rotary Switch less components, ZERO SUPPRESS,

Range

---

Switch Assembly, Zero Suppress, Range

Skirted Knob,

---

Skirted Knob, Zero Suppress Set Potentiometer

Function Switch

Zero Suppress Range Switch

Mfg.

Code

28520 cc-4

80164 SW-161

80164 13728B

80164

80164 SW-96

80164 13727B

80164 la-10

80164 SW-58

80164

80164 RN-11

80164 KN-17

54 Toggle Switch, DPDT, ON (Mfg. No. 20905-FR) 04009

Tl Transformer, Power 80164

T2 Transformer, Filament

80164 TR-26

T3 Transformer, Chopper 80164

Keithley

Part No.

la-11

13726B

SW-14

TR-36

TR-37

Circuit

Desig. Value Rating

RlOl 33 kn

R102

2Mn

R103 4 7 I~(~?

R104 1 m

R105 3.3 MO

RlO6 1 HT:

R107 22 IC?

R108 3.3 M1

R109 1 It-!

RllO 22 I<<?

Rlll 1 M:

RLl2 200 kc:

R113 100 ki!

R114 100 k:!

Rl15

"1 ti:i

R116 470 kq

R117 333 k?

R118 500 kc:

lO%, l/2 w

0

l/,, 1 w

lO%, l/2 w

l%, l/2 w

lO%, l/2 w

l%, l/2 w

lO%, l/2 w

lO%, l/2 w

l%, 112 w

lO%, l/2 w

I%, l/2 w

l%, l/2 w

l%, l/2 w

l%, l/2 w

l%, l/2 w

l%, l/2 w

l%, l/2 w

10%, 2 w

RESISTORS

Mfg. Mfg.

TYPO

Code Part No.

camp 01121 EB

MtF 07716

Comp

01121 EB Rl-47K

Deb 79727

camp 01121

DCb

79727 CFE-15 R12-1M

camp 01121

camp 01121

MEF R44-2M

CFE-15 Rl2-1M

EB Rl-3.3M

EB Rl-22K

EB Rl-3.3M

Keithley

Part No.

Rl-33K

DCb 79727 CFE-15 R12-1M

camp 01121

DCb

DCb

DCb

DCb

DCb

DCb

DCb

CbVar

79727

79727

79727

79727

79727

79727

79727

01121

EB

CFE-15 Rl2-1M

CFE-15

CFE-15

CFE-15 R12-100K

CFE-15 R12-1M

CFE-15 Ri2-470K

CFE-15

.J RP5-500K

Rl-22K

Rl2-200K

R12-100K

R12-333K

*?jomi.nal value, factory

j-4

set.

1264R

Page 20

MODEL 140 IIILLI-MICROVOLTMETER

REPLACEABLE PARTS

RESISTORS (Cont'd)

Circuit

Desig.

R119

R120

R121

R122

R123

R124

R125

R126

R127

R128

R129

R130

R131

R132

R133

R134

Rl35

Value Rating

680

kn

3.33 m

2. 2 M"

62

k!?

100 kr2

1.3 Mri

1 Mn

30 kfi

10 kn

95.3 kc

12

1 kn

111 ?

10 kR

100 kc

10 m

3.33 m

l%, l/2 w

l%, l/2 w

l%, l/2 w

l%, l/2 w

l%, l/2 w

l%, l/2 w

l%, l/2 w

5%,

lO%, 2 w

l%, 1 w

1%

1%

lf4%, l/3 w

5%

lO%, l/2 "

l%, 112 w

l%, l/2 w

10 w

TYPO

DCb

DCb

DCb

Mfg.

Code Part No.

79727 CFE-15

79727 CFE-15

79727

Mfg.

CFE-15 R12-2.2M

DCb 79727 CFE-15

DCb

79727

CFE-15 Rl2-100K

DCb 79727 CFE-15

Keithley

Part No.

R12-680K

RlZ-3.33M

R12-62K

R12-1.3M

DCb 79727 CFE-15 R12-1M

ww

WWVar

MtF

ww

63743

71450

07716

80164

10F

WP

CEC

R5-30K

RP9-1OK

R94-95.3K

'.*RlE-18-1

Special

ww

80164

'.+cR18-18-1K

Special

wwenc

01686

7010

R105-111

Special

ww

80164

R18-18-10K

Special

camp

DCb

DCb

01121 EB Rl-LOOK

79727 CFE-15 Rl2-1OM

79727 CFE-15 R12-3.33M

RI36

R137

R138

R139

R140

R141

R142

R143

R144

R145

R146

R147

R148

R149

R150

Rl51

Rl52

R153

R154

R155

1Kl

333

k<l

100 kn

33.2

9.9 kn

220 kn

100 kn

II%

100 kn

9 kn

10 kn

30

kn

kn

0.5%, l/2 w

0.5%, l/2 w

0.5%, l/2 w

0.577, l/2 w

0.5%, l/2 w

lO%, l/2 w

lO%, l/2 w

lO%, l/2 w

lO%, l/2 w

lO%, l/2 w

lO%, l/2 "

lO%, l/2 w

lO%, l/2 w

lO%, l/2 w

1%, l/2 w

l%, l/2 w

l%, l/2 w

l%, l/2 w

3%, 5 w

5%,

10 w

MtF

MtF

07716

07716

CEC

CEC

MtF 07716 CEC

MtF

07716

CEC

MtF 07716 CEC

camp

DCb

01121

80164

EB

Special

camp

Comp

Comp

Comp

Comp

01121 EB

01121 EB Rl-150K

01121

EB

01121 EB Rl-150K

01121 EB Rl-33K

camp 01121 EB

Comp

DCb

DCb

DCb 79727

DCb

WWVsr

ww

01121 EB Rl-3.3K

79727 CFE-15 R12-1K

79727 CFE-15

CFE-15

79727 CFE-15

73138 A

63743

10F

R61-1M

R61-333K

R61-100K

R61-33.2K

R61-9.9K

Rl- 220K

R38-

1OOK

RI- 1.5M

Rl-150K

Rl- 3.9K

R12-1M

R12-100K

R12-9K

RP4-

10K

R5-30K

JrNominal vali.le, factory set.

WrR129 and R130 are matched to l/2%.

Order a8 a pair.

Page 21

REPLACEABLE PARTS

RESISTORS (Cont'd)

Circuit Mfg. Mfg.

Desig. Value Rating

R176

R501

R502

R503

R504

R505

R506

R507

R508

R509

R510

R511

R512

10 Ia

too ‘,!

100 R

5 kn

5 kr!

22 kO

10 m

220 ICC

33 kn

33 k0

Ii%

600 kil

10 (2

lO%, l/2 w

lO%, 2 w

lO%, 2 w

5%, 10 w

5%, 10 w

lO%, 2 w

lO%, l/2 w

l%, l/2 w

lO%, 112 w

lO%, l/2 w

lO%, l/2 w

l%, l/2 w

l%, 5 w

TYPO

Code

Comp 01121

Comp 01121

Comp 01121

ww 94310

ww 94310

Comp 01121

camp 01121

DCb 79727

Comp 01121

camp 01121

Comp 01121

Deb 79727

ww 91637

Part No.

IIB

HB

FR-10

FR-10

HB

EB

CFE-15

EB

EB

EB

CFE-15

RS-5

VACWM TUBES

Circuit

Desig.

Number

Mfg.

Code

Keithley

Part No.

Keithley

Part No.

Ill- 1OK

R3-100

R3-100

R5-5K

R5-5K

R3-22K

RI-1OM

R12-220K

Rl-33K

Rl-33K

Rl-1M

Rl2-600K

R4A-10

Vl

v2

v3 ;Ld"kEFB

~:*<6084 80164 ~V-6084/E80~

;+k~t36

6

80164

80164 Ev-EF86/6267

EV-EF86/6267

V4 +&.h 7025 80164 EV-ECC83/7025

v5

V6

~~~lZAT7 80164

EZV-12AT7

>'&6OM6 80164 EV-6CM6

v7 "(,A 2 80164 BV-OA2

V8

v9

12B4A

85599 EZV-12B4A

+'dcCK5651 80164 EV-CK5651

VlO 7025 73445 EV-ECC83/7025

MODELS 1483. 1484 REPLACEABLE PARTS LIST

Description

Mfg.

Keithley

Quantity Code Part No. Kit Model

Used on

Crimp Tool for Copper lugs 1 80164 TL-1 1483

l/8 Nylon Screws 50 80164 --- 1483, 1484

#8 Nylon Hex Nuts 50 80164 ___ 1483, 1484

Copper Bolt-on Lugs 100 80164 17340 A 1483, 1484

Copper Spade Lugs 100 80164 17339 A 1483, 1484

Copper Hook Lugs 100 80164 17336 A 1483, 1484

Copper Splice Tubes 100 80164 17338 A 1483, 1484

Low-Thermal Cadmium-Tin Solder 10 feet 80164 --- 1483, 148b

Copper Alligator Clips (Mfg.

No. 6005) 10 76545 AC-9 1483, 1484

?~w~~Specially aged tubes.

5-6 1267~

Page 22

MODEL 149 MILLI-MICROVOLTMETER

MODELS 1483, 1484 REPLACEABLE PARTS LIST (Cont'd)

REPLACEABLE PARTS

Descriotion

Shielded Cable 10 feet 80164 SC-5 1483, 1484

Insulated 1b2.0 Copper Wire LOO feet 80164 ws- 1 1483, 1484

Non-metalic Abrasive 3 pads 80164

MODEL 1491 REPLACEABLE PARTS LIST

Description

End Frames

Fastener, Thumbscrew

Feet, Rubber

Attaching Parts

Machine Screw, No. 6-32lJNC-2x1/2, Rd Hd, Phillips

Hex Nut, No. 6-32UNC-2 4 Corn1 ---

__________- -

Machine Screw, No. 8-32UNC-2x5/16, Rd Hd, Phillips

Quantity

Mfg.

Code

No. Required

Per Model

2

4

4

4 Corn1 ---

4 Cod ---

Keithley

Part No.

LJ774A

Mfg.

Code Part No.

80164 L312OC

80164 FA-9

80164 FE-2

Used on

Kit Model

1483, 1484

Keithley

BODEI. 1501 REPLACEABLE PARTS LIST

Mfg.

Description

Plug Assembly

CabIe, 48 inches, Vinyl, shielded 86696 SC-5

Alligator Clamps, two (Mfg. No. 6OC5)

MODEL 1502 REPLACEABLE PARTS LIST

Description

Plug Assembly

Cable, 10 feet, Vinyl, shielded 86696 SC-5

DO011 Sylvania Electric Products, Inc.

Buffalo Operations of Sylvania

Electronic Systems

Buffalo, N. Y.

00656 Aerovox Corp.

New Bedford, Mass.

01121 Allen-Bradley Corp.

Milwaukee, Wis.

1

TABLE 3 (Sheet 1).

for Manufacturers, Cataloging Handbook H4-1.)

1264R

Code List of Suggested Manufacturers. (Based on Federal Supply Code

02660 Amphenol-Borg Electronics Corp.

Broadview, Chicago, Illinois

04009 Arrow-Hart and Hegeman Electric Co

Hartford, Corm.

05397 Kemet Co.

Cleveland, Ohio

07716 International Resistance Co.

Burlinnton. Iowa

Code Part No.

80164 1301LB

76545

Mfg.

Code Part No.

80164

Keithley

AC-8

Keithley

L301LB

5-7

Page 23

REPLACEABLE PARTS

MODEL 149 MlLLI-MTCROVOLTMETER

38804

12954

14655

24655

28520

$4655

56289

58474

53743

71002

71450

72982

Lamp Metals and Components

Department G. E. Co.

Clawland, Ohio

Dickson Electronics Corp.

Scottsdale, Ariz.

Cornell-Dubilier Electric Corp.

Newark, N. .J.

General Radio Co.

West Concord. A&ass.

Heyman >ffg. Co.

Kenilworth, ?J. .J.

Ohmite Mfg. Co.

Skokie, ILL.

Sprague Electric Co.

North Adams, Mass.

Superior Electric Co., The

Bristol, Corm.

Ward Leonard Electric Co.

Mount Vernon, N. Y.

Birnbach Radio Co.

New York, N. Y.

CTS Corp.

Elkhart, Ind.

Erie Technological Products, Inc.

Erie, Pa.

75915

76545

79727

80164

81453

81483

83125

83330

84171

85599

86684

Littelfuse, Inc.

Des Plain&, Ill.

Mueller Electric Co.

Cleveland, Ohio

Continental-Wirt Electronics Corp.

Philadelphia, Pa.

Keithley Instruments, Inc.

Cleveland, Ohio

Raytheon Co.

Industrial Components Div.

Industrial Tube Operation

Newton, Mass.

International Rectifier Corp.

EL Segundo, Calif.

General Instrument Corp.

Capacitor Division

Darlington, S. C.

Smith, Herman H., Inc.

Brooklyn, N. Y.

Arco Electronics, Inc.

Great Neck, N. Y.

Tube Department G. E. Co.

Schenectady, New York

RCA Electron Tube Division

of Radio Corp. of America

Harrison, N. 3.

I

73138

Helipot Division of

Beckman Instruments, Inc.

Fullerton, Calif.

73445

Amperex Electronic Co.

Division of North American

Philips Co., Inc.

Hicksville, N. Y.

75042

International Resistance Co.

Philadelphia, Pa.

CABLE 3 (Sheet 2).

Code List of Suggested Manufacturers.

for Manufacturers, Cataloging Handbook H4-1.)

5-8

86606

91637

93656

94310

99942

Radix Wire Co.

Cleveland, Ohio

Dale Electronics, Inc.

Columbus, Nebr.

Electric Cord Co.

Caldwell, N. J.

Tru Ohm Products

Memcor Components Division

Huntington, Ind.

Hoffman Electronics Corp.

Semiconductor Division

EL Monte. Calif.

(Based on Federal Supply Code

1264R

Page 24

Page 25

Behnulry 3, 1965

MlDEL 149 XEU-M

a1-2, Change the firat

After

in any

approdmstely 2-hour warm-up within 0.01 ~crovolt per

&hour period

with

sentence of

relatively constant ambient

pana. Cbanga to the follcwingt

Circuit

DeaiE&

Dl13

WPO

zener

0114 zoner

12954 la

die

nmmfactumr cod41 for M&eon Bloctronica Corp.,

Nladmr

119715

lN715

the SZMILITY Specific;ition

hour or

temperatures.

Mfs.

Keithley

Code Rart No.

12954

12954 m-22

Dz-22

Scottsdale,

to

the folkwing:

0.03 microvolt

Ma.

Page 26

CNANGB NOTICE

April

15, 1965

J&&&& Qangs to the followin?i:

to

1000 "

.02.

Cl15 (60 cpa)

m*

&mge the

value

0.02

&f

of Cl15

Car3

WDET.149 MILY.I-Xt~OLl3f=~

72902

84lZ5V203P

c22-.02M

Page 27

MB Quylo tb

fCratrentuaue

Inpuagraplt 4to road;

4. lltotnml B&trm

thortmt

a Cbango to

AUF's 130 the roaidaal BEC Lo wually leas than 0.5 uv.

-

precoutio~

the follawingr

cfraiit

Do&g.

cl04

Cl10

z:

l?~lItO

z ":

20 ;P

2l.pf

mtbs

450 v

450 v

4sOv

4% v

m* aougo tc rho follow%Dgr

urcdt wt.

aofJ&

v4

VI0

Nther

-7025

-025

code

80164

80164

mg

lsavo been taken in the input circuit to midmlzm

lus

z

Em

56289

56289

56289

56289

TVA1709 ca-20x

ToA c8-20x

TVA1709

TVA1709

K&t&lap

Part

No.

Ew-&xxl33/702s

m-lma3/702s

aurlg~tlunuldmr0f lf4andvxo to’7025

*wspeotallyagod tabu.

Page 28

liuvdmr

3, 1966

lwNLlA9xxL7AI~

PaNo I-2. aut&$o

to

ciroutt

lhrl&

Cl05 0.1 rrf

Cll2

cSo9

value

0.1 pf

0.1 $.4f

the Wlorrkyr

aat-8

4OOV

4OOV

4oov

nv

z

w

146SS

lA6s5

14655

Wi.

part

NXP

NW

NXP

x0.

4Pl

4Pl

4Pl

lWth1.y

POrtlb.

Cllb.ln

Club.ln

ClU-.lx

Page 29

/

~..~~_~.._~~.~~~~ ~.~~_ _._,

r’ ‘~i%inbexr~6 .~..I967 ‘~ ..i.

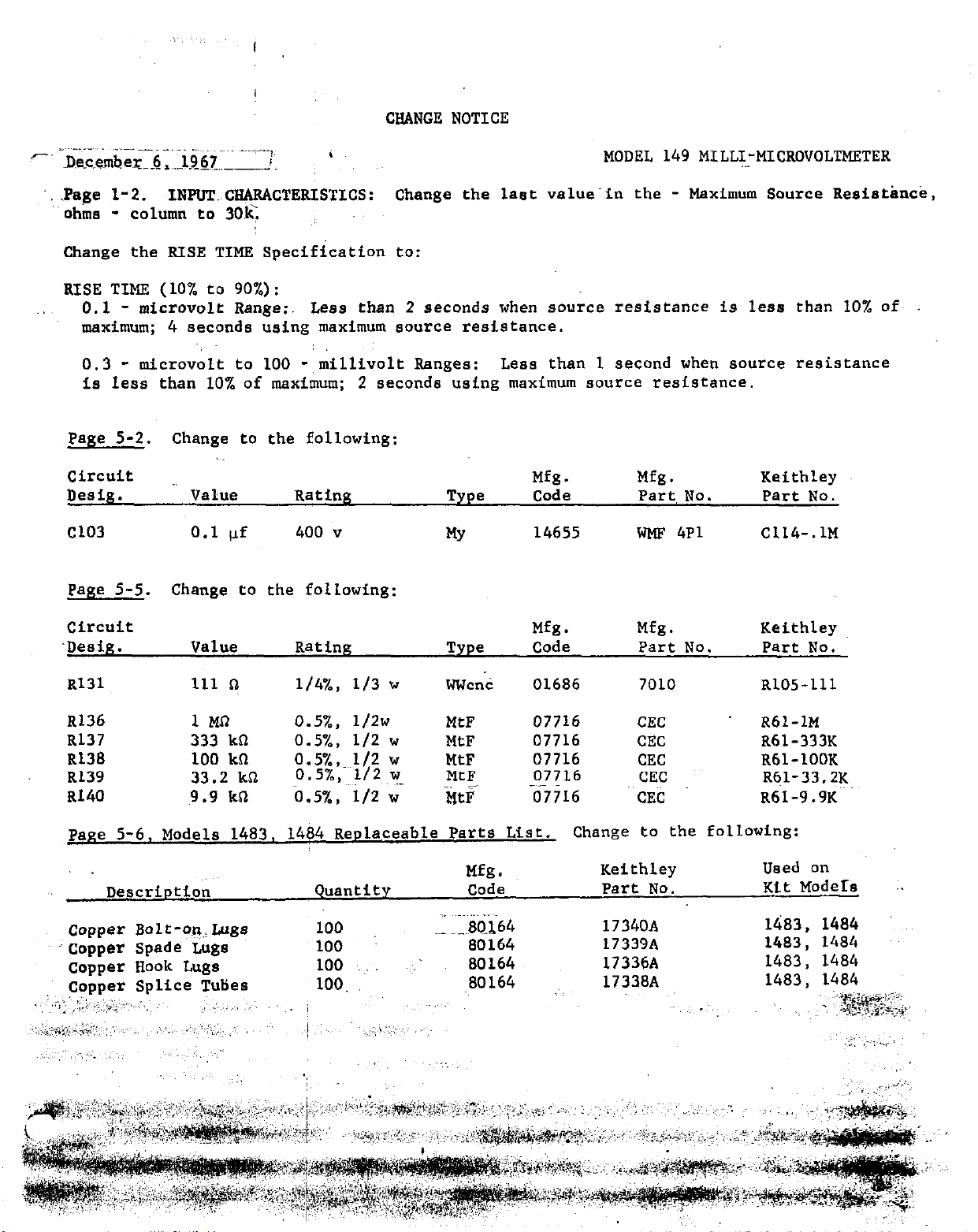

CHANGE NOTICE

MODEL 149 MILLI-MICROVOLTMETER

‘, .Page l-2.

ohms -

INPU’l.~CH@ACTERISTICS:

column to 30,s

Change the last value-in the - Maximum Source Resistance,

Change the RISE TIME Specification to:

RISE TIME (10% to 90%) :

0.1 -

microvolt Range:. Less than 2 seconds when sourceresistance is less than 10% oft

maximum; 4 seconds using maximum source resistance.

- micro& to 100

0.3

- millivolt Ranges:

Less than 1 second when source resistance

is less than 10% of maximum; 2 seconds using maximum source resistance.

Page 5-2. Change to the following:

circuit

Des&. Value

Cl03 0.1 (If

Page 5-5.

Change to the following:

circuit

.Desig.

Value

Rating Type

400 ”

MY

Rating Type Code

Mfg.

code

14655

Mfg.

Mfg.

Part NO.

WMF 4Pl C114-.lM

Mfg.

Part No. Part No.

Keithley

Part NO.

Keithley

R131 111 n

R136

R137

1 MO 0.5%, 1/2w

333 kfl

R138 100 kfl

Rl39 33.2 kfl

R140 9.9 kfl

l/4%, l/3 w

0.5%, l/2 w

0.5%,~ l/2 w

0.5%, l/2~Y ~~, _~

0.5%, ~i/2 w

went 01686

MtF

MtF

MtF

MtF 07716

MtF 07716

Page 5-6, Models 1483, 1484 Replaceable Parts List.

Description

Quantity

._ ~~~... ..~~

Copper Bolt -on,,Lugs

~’ copper Spade Lugs

copper Hook Lugs

Copper Splice Tuties

,,:‘: ,;‘;;,,~ .:!.~;~+ ,., ‘,,~ ~~ ,_, ,,,, ,, ,.,

~‘;i,~..~,:,,*:,~,-.r”,l,‘~, :~ ,, ,;. i ‘~,,~ ,.‘~‘,‘,‘~‘:.; ,,;, :, :

100

100

100 ‘. ~.-

100.

,I~

,;& ::2

.,e-3034

~‘,~ ~,

‘.Y

7010

07716

07716

07716

CEC R61-1M

CEC

CEC

CEC

~~CEti

Change to the following:

Mfg.

Keithley

code Part No.

17340A

80164 17339A

80164

-80164

17336A

17338A

R105-111

R61-333K

R61-100K

R61-33.2K

R61-9.9K’~

Used on

Kit ModeIs

1483. 1484

1483, 1484

1483, 1484

1483, 1484

~. ~?YJ@@y?;,

.~.~.Z~~. i,

,~<T i;l;_~

Page 30

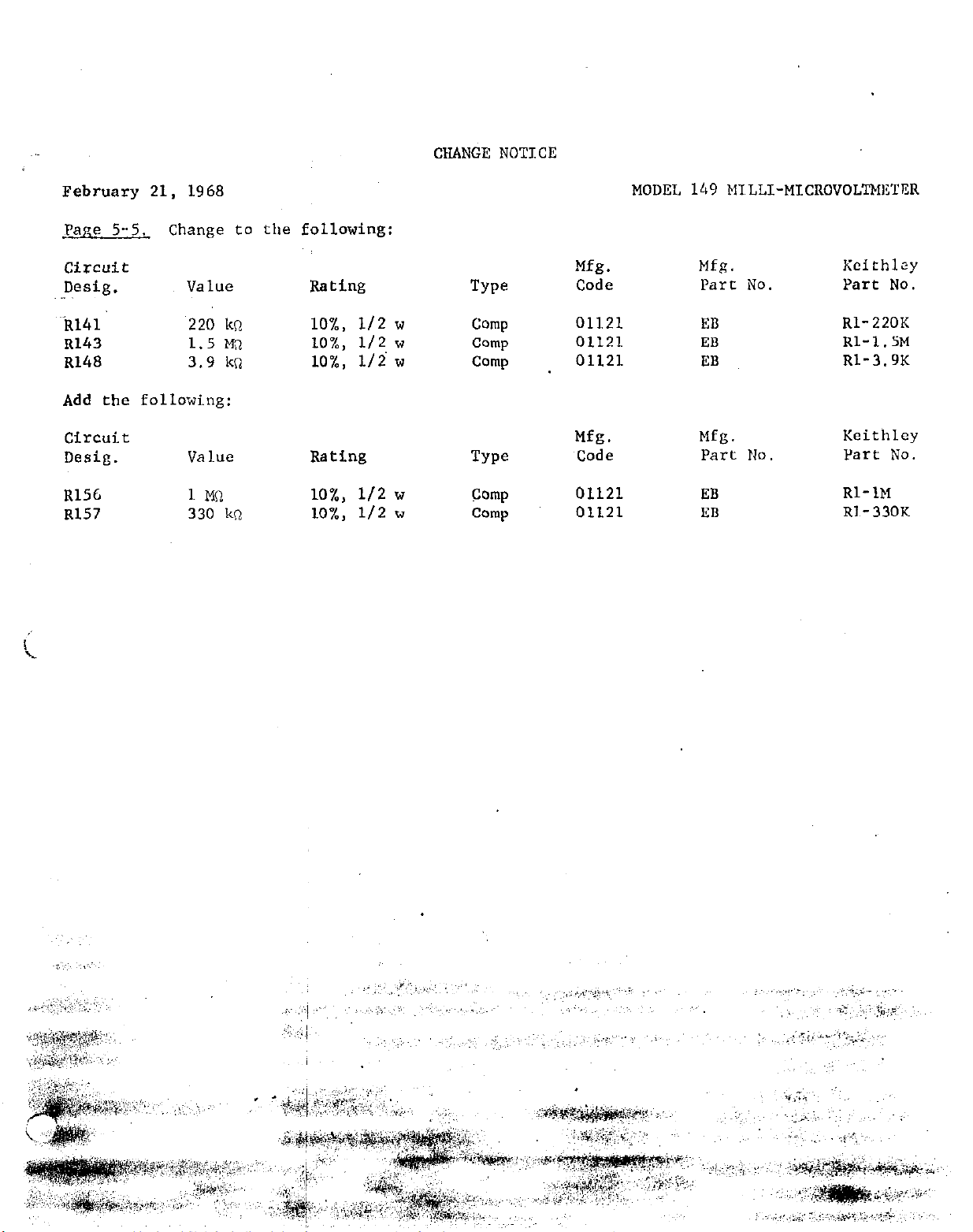

CHANGE NOTICE

February 21, 1968

Pane 5-5.

circuit

twig.

Change to the following:

Value

&41 220 kn

R143

~148

1.5 Ma

3.9 kn

Add the following:

Circuit

Desig.

R156

Rl57

Value

1 MO

330 kn

Rating

lO%, l/2 w

lO%, l/2 w

lO%, l/i w

Rating

lO%, l/2 "

lO%, l/2 w

TYPO

Comp

Camp

Comp

TYPO

Camp

Comp

Mfg.

Code

01121

01121

01121

Mfg.

Code

01121

01121

MODEL 149 MTLLI-MICROVOLTMl3TER

Mfg.

Part No.

EB

ED

EB

Mfg.

Part NO.

EB

EB

Kcithlzy

Part No.

Rl-220K

Rl-l.SM

Rl-3.9K

Keithley

Part No.

Rl-1M

Rl-330K

Page 31

. .

,&$ril 16, 1969

&$;~e s-2

.

Change to the following:

Circuit

Desig

D105

D106

mea

Type

Silicon

Silicon

Silicon

Dl.09 Silicon

.

CNANGE NOTICE

MODEL 149 MILLI-MICROVOLTMETER

Mfg. Keithley

Number

J&J3256

IX3256

IN3256

Ui3256

-.-

Code

Part No.

02735 W-22

02735 RF-12

02735 ' RF-22

02735

RF-22

Page 32

Loading...

Loading...