Page 1

Page 2

K&~l~y~in&iwnt~, II&. ~i&&t$@i~ &oduct to b+&&om detects

Kelthley~in&&nts, Inc. ~&arrantSth~s product to befree from defects

fin metertal~ Andy workmanship~ for~e~period of 1 year from date of ship- fin metertal~ Andy workmanship~ for~e~period of 1 year from date of ship-

~~ menb During.the warranty period;~~tia~@;~at our option, either repair ~~ menb During.the warranty period;~~tia~~ill;~at our option, either repair

,~~ ,~~ ~. or ~replatie any~ product that proves~to be defective; :~ ~. or ~replatie any~ product that proves~to be defective; :~

~~ To~exercise this warranty, ~write~or $811 ~your lo&Kehhley~mpreesnt-:

~~~ ~~ ~~~ ~~

~~ ~~ ~~ ~~

.~ ~~ ~~~ .~ ~~ ~~~

~~ To~exercise this warranty, ~write~or $811 ~your

ative, ,or contacts Keithley headquarters in Cleveland, ohlti.~You~will~be ative, ,or contacts Keithley headquarters in Cleveland, ohlti.~You~will~be

given prompt assistance and return instructions, Send:the instrument; given prompt assistance and return instructions, Send:the instrument;

~‘~ transportation prepaid; to the indir+sd service f&lii~ jIegairs @l be ~‘~ transportation prepaid; to the indir+sd service f&lii~ jIegairs @l be

~rnade~ land the~~instrument returned,~ transpotitiort prepeid.~ R~epaired ~rnade~ land the~~instrument returned,~ transpotitiort prepeid.~ R~epaired

products~are~vyarrsnted fork the:bMance of the origin8~warianty period, products~are~vyarrsnted fork the:bMance of the origin8~warianty period,

~~ ~~ or at least 90 ~days. or at least 90 ~days.

:

LIMITATION~~OF~WARAANTV~~

:

LIMITATION~~OF~WARAANTV~~

This warranty does not epply~to ~defectsresulting~ from unauthorized This warranty does not epply~to ~defectsresulting~ from unauthorized

mpdification or misuse oft any product or part. This warmnty al&o does mpdification or misuse oft any product or part. This warmnty al&o does

~~ not spply to~fuses; batter@, or damage from ~battery leakege~~ ~~ ~~ not spply to~fuses; batter@, or damage from ~battery leakege~~ ~~

This werranty is in lieu,of all other &rranties, expra$ed or implied, in- This werranty is in lieu,of all other &rranties, expra$ed or implied, in-

dluding~ any implied ~warranty of :merchentability nor f%ne& -for a par; dluding~ any implied ~warranty of :merchentability nor f%ne& -for a par;

ticularuse; Keithley Instruments, ~lnti. shall not bs IiabMfor any indirect, ticularuse; Keithley Instruments, ~lnti. shall not bs IiabMfor any indirect,

special nor coosequential~damsges. ~~~ ~~~~ special nor coosequential~damsges. ~~~ ~~~~

;’ ~~~

;S~~~EM~E,N~T~OF~CAL1BRATION

;S~~~EM~E,N~T~OF~CAL1BRATION

l6&Keithiey~~p~epresent-:

~~ ~~

Ran ~: : ~~ ;’ ~~~

Ran ~: : ~~

~~~ This ~itiStrument~ has, been~ inspected land t&tedin~ crCcOrdance v&h ~~~ This ~itiStrument~ has, been~ inspected land t&tedin~ crCcOrdance v&h

specifications bublishedby Keithley instruments, fin& ~~ specifications bublishedby Keithley Instruments, fin& ~~

: The~at%uracy and calibration~of this instrument am traceable to the ~~ : The~at%uracy and calibration~of this instrument am traceable to the ~~

~Nationat ~Bureau of Standards through equipment which is cal~@reted at ~Nationat ~Bureau of Standards through equipment which is cal~@reted at

,~ fWrned ~Jnterv& by comparisqn to ,~ertlfii Standards maintained in

,~ @anned ~Jntery&ls~ by comparisqti !a ,~et$fii standafds nMin@nad in

the Laboratories of :Keithley lnstruments;~ Inc. the Laboratories of :Keithley Instruments;~ Inc.

Page 3

INSTRUCTION MANUAL

Model 148

Nanovoltmeter

COPYRIGHT 1974, Keithley Instruments, Inc.

PRINTED JAN. 1979, CLEVELAND, OHIO U. S. A.

DOCUMENT #29029

Page 4

CONTENTS

Page 5

MOOEI, 148

ILlsJSTRATIONS

ILLUSTRATIONS

FIG. TITLE PACE

la Front Panel ................................

lb Front Panel With Model 1481 Input Cable

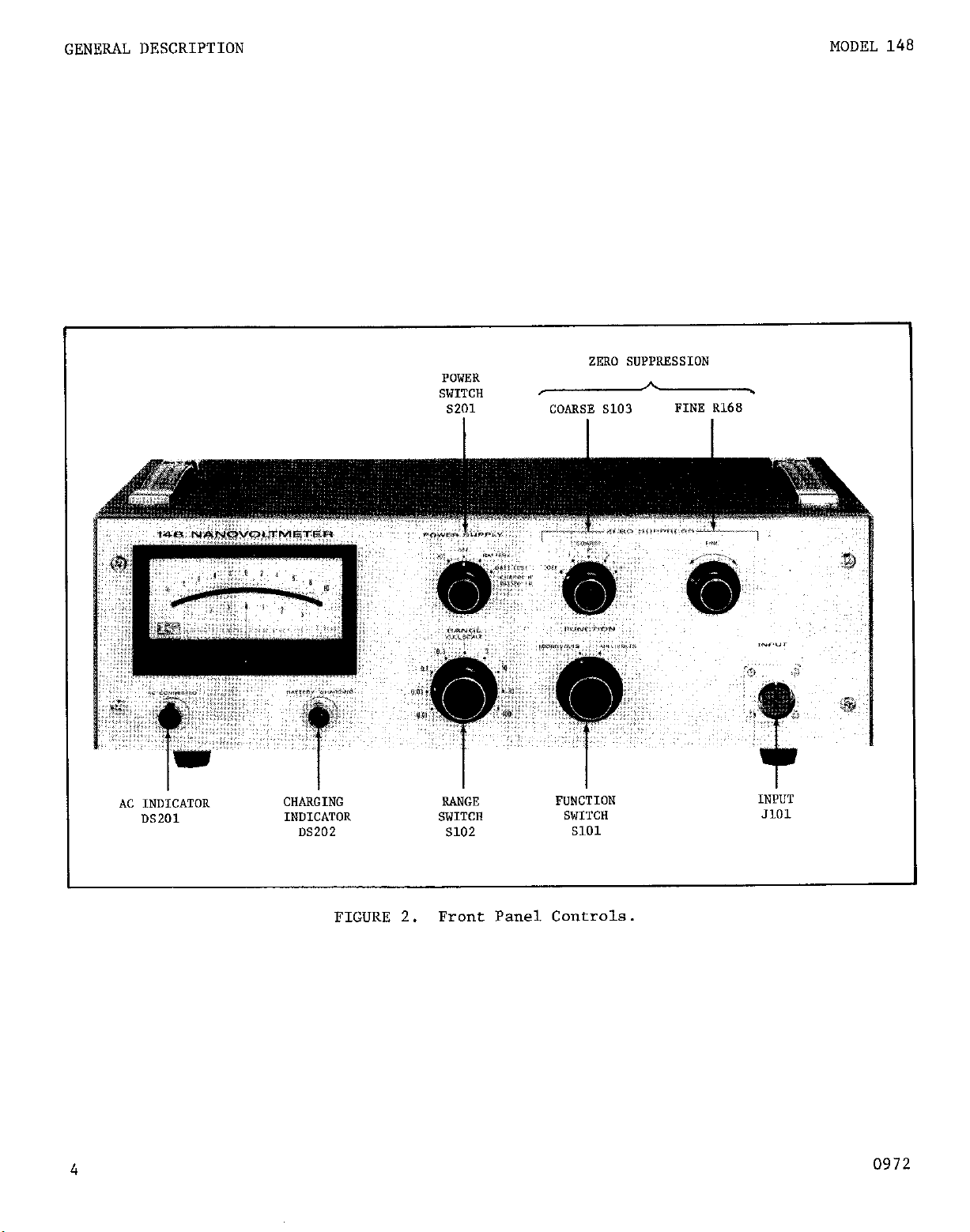

2

Front Panel Conrrole. ...........................

3 Rear Panel Conerols and Connections

4

Model 1481 Low-Thermal Input Cable.

5 Made! 1483 Low-Thermal Connection Kit

6 Normal Wave Form at Demodulator with Input Sbor’ted.

7 Wave Format Demodulator Sham with Some Pickup.

8

Wave Format Demodulator when Amplifier is Saturated

9 “sing Model 148 with 4-Terminal Connections

10 Exploded “few far Rack Mounting

11 Block Diagram of Model 148 Amplifier Circuits

12

13 Block Diagram of Model 148 Power Supplies

14 Model 148 Input Compartment

15 Correct Wave Form in dc-to-dc Inverter.

16 correct wave Form at Point F in Oscillator circuit.

17 Improper wave Form af point F in Oscillator Circuit

18 NOf Used.

19 Nof Used. .................................

20 Top View of Model 148 massis

21 Bottom View of Model 148 Chassis.

22 Transistor Locations on Printed Circuit 76.

23 Capacitor and Diode Locations on Printed Circuit 76

24

25 Resistor and Test Point Locations on Printed Circuit 76

26

27 Component Locations on Printed Circ”it 74, Top Face

28 Resistor and Test Point Locationa on Printed Circuit 75

29 Capacitor and Transistor Locations on Printed Circuit 75.

30

31 Resistor LOcationS on RANOE SWitCh (5102)

Model 148 Input Circuit

.................................

Resistor Locations on Printed Circuit 76.

Resistor and Test Point Locations on Printed Circuit 74. Bottom Face.

Resistor Locations on RANGE Switch (S102)

.......................... 20

...................... 18

........................ 26

....................... 38

.................. 3

.................... 6

.................... 10

............ : ...... 10

............ 15

.............. 15

............ IS

................ 17

............... 19

................. 23

.................. 31

............ 32

............ 32

..................... 39

................ 40

............ 40

................. 41

............ 42

................. 44

................. 44

--

--

.......... 41

.......... 4,

.........

... 42

43

1

4

0375

Page 6

SPECIFICATIONS

MODEL 148

SPECIFICATIONS

iv

0375

Page 7

MODEL 148

GENERAL DESCRIPTION

SECTION 1.

GENERAL DESCRIPTION

l-l. GENERAL.

The Keithley Model 148 Nanovoltmeter conveniently measures dc potentials

a.

from 10 nanovolts (10 x 10-g

volts) to 100 millivolts full scale. It makes

accurate and sensitive measurements without painstaking methods often previously

required.

Meter accuracy is 2% of full scale on all ranges.

than 1 nanovolt peak-to-peak on the lo-nanovolt range.

than 10 nanovolts per 24 hours after warm-up.

On the three most sensitive

Zero drift is less

Noise is less

ranges, line-frequency rejection is greater than 1OOO:l.

For reliable and versatile use,

b.

design, except for the first two input stages.

the Nanovoltmeter is of solid-state

It has high line isolation

and battery or line operation.

0972

FIGURE la. Front panel.

Page 8

GENERAL DESCRIPTION

MODEL 148

1-2.

ing many grounding problems.

FEATURES.

Battery operation permits complete isolation from power line, eliminat-

a.

Battery operation also allows flexibility and

convenience in use. The Model 148 automatically recharges the battery if

needed when the ac power cord is connected.

The Nanovoltmeter has a 21 volt at 1 milliampere output at full-scale

b.

meter deflections for driving a recorder or oscilloscope.

Accuracy is 1% of

full scale for output.

c. A zero suppression circuit permits measuring small changes in a larger

dc signal.

l-3. APPLICATIONS.

The Model 148 Nanovoltmeter measures very small dc potentials or

a.

small changes in dc potentials from low impedance sources. These are found

in fundamental or applied research, laboratory standards work, cryogenic

experiments and instrument development for space research.

It can also

serve as an amplifier in these uses.

Typics.1 uses include measuring small temperature differences and

b.

small temperature changes indicated by thermocouple outputs, small changes

in conductance,

outputs used in narrowband spectrum analysis.

the thermoelectric power of metals,

making Bolometer

super conductivity in the lo-6 ohm range, and thermopile

Other uses are determining

conducting Hall effect studies, and

measurements.

Also, the Model 148 is suited for use with

potentiometers, ratio sets and resistance bridges, including Wenner, Wheatst

and Kelvin Double bridges. It can be used to make 4-terminal resistance

measurements.

2

0972

Page 9

MODEL 148 GENERAL DESCRIPTION

0972

FIGURE lb.

Front Panel With Model 1481 Input Cable.

3

Page 10

GENERAL DESCRIPTION

ZERO s”PPmssIoN

POWER

SWITCH

5201 COARSE 5103

MODEL 148

*

FINE R168

4

FIGURE 2. Front Panel Controls.

0972

Page 11

MODEL 148 NANOVOLTMETER

OPERATION

SECTION 2.

.2-l. FRONT PANEL CONTROLS.

a. AC CONNECTED Lamp.

The Lamp is lit whenever the unit is connected to

(See Figure 2.)

OPERATION

the ac line and the POWER SUPPLY Switch is in the AC or OFF position.

NOTE

The AC CONNECTED Lamp indicates only that the instrument

is connected to the ac power line; it does not indicate

that the Nanovoltmeter is operating.

Also, when the

POWER SUPPLY Switch is turned from AC to OFF, a difference

in Lamp brightness is normal.

BATTERY CHARGING Lamp. When lit,

b.

charging.

not lit,

POWER SUPPLY Switch.

c.

The charge current determines its brightness.

then the battery is charged.

The Switch controls the mode of operation for

this Lamp indicates the battery is

If the lamp is

the power supply.

AC position:

1.

The battery will be charged if needed; then,

The Nanovoltmeter will operate from the ac power lint.

the BATTERY CHARGING Lamp

will light.

OFF position: The Model 148 is not operating.

2.

will be charged,

BATTERY position:

3.

if needed and if the power cord is connected.

The Nanovoltmeter is operated from its battery.

The ac power line is internally disconnected;

However )

the AC CONNECTED Lamp is off;

tk! battery

the battery cannot be charged.

BATT.TEST position:

4.

When the POWER SUPPLY Switch is held in this

position, the Model 148 shows the state of the battery charge directly

on its meter. All circuits within the instrument are the same as for

battery operation except at the meter terminals.

Switch Settin

TABLE 1.

Indicating Lamps and POWER SUPPLY Switch Settings.

The table shows the relationship between the front panel

lamps,

the power cord and the POWER SUPPLY Switch setting.

Page 12

OPERATION

MODEL 148 NANOVOLTKETER

RANGE Switch.

d.

The RANGE Switch selects the full-scale meter sensitivity

(either microvolts or millivolts) for one of nine ranges, from 0.01 to 100.

FUNCTION Switch.

e.

The FUNCTION Switch selects the function - MICROVOLTS

or MILLIVOLTS - which is to be measured.

ZERO SUPPRESS Controls.

f.

The COARSE Control disconnects the suppression circuit (in OFF position)

1.

or selects one of four suppression voltages in decade steps.

The FINE Control is a continuously variable adjustment for the suppression

2.

voltage set by the COARSE Control.

Two controls determine the amount of zero suppression.

Refer to Table 3.

It adjusts the range between the positive

and negative values of the maximum voltage set by the COARSE Control.

INPUT Receptacle.

g.

The INPUT Receptacle is of a special low-thermal design.

Use only the Models 1481, 1482 and 1486 for mating connectors.

5103:

FIGURE 3. Model 148 Rear Panel Controls and Connections.

refer to Replaceable Parts List and schematic diagrams.

2-2.

REAR PANEL CONTROLS AND CONNECTIONS.

Line Voltage Switch. The screwdriver-operated slide switch sets the

a.

Model 148 for 117 or 234~volt ac power lines.

Fuse.

b.

For 117~volt operation,

1.

For 234volt operation, use only a MDL Slow-Blow l/16-ampere fuse.

2.

Power Cord. The 3-wire power cord with the NEMA approved 3-prong plug

c.

provides a ground connection for the cabinet.

use a 3 AG or MDL Slow-Blow l/8-ampere fuse.

An adapter for operation from

2-terminal outlets is provided.

WER

RD

Circuit designations

6

0464

Page 13

MODEL 148 NANOVOLTMETER

A note above the power cord shows the ac power line frequency

for which the rejection filter is adjusted.

will work at any line frequency from 50 to 1000 cps, but ac

rejection is best at the indicated frequency.

OPERATION

The instrument

DEMODULATOR TEST.

d.

A phone jack provides access to the demodulator for

test purposes.

e.

OUTPUT.

The OUTPUT Receptacle provides fl volt at one milliampere for

a full-scale meter deflection on any range.

GND and LO Terminals. The ground terminal (GND) is connected to the chassis

f.

and the third wire of the power cord. The low terminal is connected to

circuit ground and the low side of the input connection.

2-3.

or from its battery. For most uses,

operation, however,

problems.

MODE OF OPERATION. The Model 148 operates either from an ac power line

it functions well from ac. Use battery

if the ac power line will create ground loop or isolation

Isolation from low to ground is complete for battery operation

when the power cord is disconnected; it is greater than 10' ohms with the power

cord connected. Also use battery operation to reduce the 8-cps ripple which

may appear at the output with the input shorted in ac operation.

See

paragraph Z-13.

NOTE

Before using the battery operation, thoroughly read paragraph 2-4.

Inproper

to

inaccurate

battery

measurements.

operation can damage the

battery

pack and lead

2-4. BATTERY OPERATION.

The Model 148 is supplied w;th a rechargeable 6-volt, 4 ampere-hour

a.

nickel-cadmium battery pack. Re<,c~mmended:

than eight consecutive hours without recharging.

rate /

the battery should last about 1000 recharge cycles.

Do not use the battery more

At this discharge

NOTE

Permanent damage to the battery pack occurs if it is used

for more than 14 consecutive hours without recharging.

At this discharge rate, the recharge cycles are greatly

reduced.

Before using the Model 148, check the state

of the battery charge.

Check the battery charge before making a measurement. Hold the

b.

POWER SUPPLY Switch in the BATT. TEST position.

The minimum acceptable

charge is a meter indication of +8; full charge is shown by the BATTERY

CHARGING Lamp not being lit.

Recharge if needed. Otherwise,

battery operation is the same as for the ac power line operating mode;

refer to paragraph 2-5.

1067'

7

Page 14

OPERATION

MODEL 148 NANOVOLTMETER

NOTE

When the battery is used beyond its capacity, two effects

are seen.

There is a shift in zero offset from ac to

battery operation. Also, the power supplies do not regulate and high ripple voltages appear at the supply outputs.

(See paragraph 4-7.)

To recharge the battery,

c.

come-t the power cord to an ac power line.

the POWER SUPPLY Switch to AC or OFF.

The BATTERY CHARGING lamp will light. The

Turn

battery will be charged only if needed, and the circuit automatically prevents

it from being overcharged.

It is suggested that the battery be used during the day and be recharged

d.

at night.

Leave the instrument always connected to the ac power line; then

turn the POWER SUPPLY Switch to OFF at night, After a fully charged battery

is used for eight consecutive hours, it will recharge within 14 hours.

the power cord connected has little effect on the isolation:

109 ohms with

Leaving

the POWER SUPPLY Switch in BATTERY position and the low-ground link disconnected.

2-5. OPERATING PROCEDURES,

Set the front panel controls as follows:

a.

POWER SUPPLY Switch OFF

FUNCTION Switch MILLIVOLTS

RANGE Switch 100

ZERO SUPPRESS COARSE Control OFF

NOTE

Make sure the ZERO SUPPRESS COARSE Control is OFF. If it is not,

a suppression voltage is introduced, causing an error in measurements.

Connect the unknown voltage source to the INPUT Receptacle.

b.

Refer to

paragraph 2-6 for suggestions.

Check the voltage shown on the rear panel Line Voltage Switch; connect the

c.

Model 148 to the ac power line. Make sure the frequency shown above the power

cord is the frequency of the ac power line. At this point, the AC CONNECTED Lamp

will light, as will the BATTERY CHARGING Lamp if the battery is being charged. If

the circuit low is to be at ground, put the low-ground link between the LO and

GND terminals on the rear panel.

Turn the POWER SUPPLY Switch to the desired mode of operation, AC or BATTERY.

d.

Increase the sensitivity of the Model 148 until the

e.

meter

shows the greatest

on-scale deflection.

Check the source resistance to make sure it is within the maximum value

1.

specified for the range being used. (See Table 2.) If the maximum resistance

is exceeded, the Model 148 may not be within its specifications.

1067

Page 15

MODEL 148 NANOVOLTMETER OPERATION

Zero offsets with the Zero Suppress Controls off will vary with the

2.

quality of the circuit's thermal construction. See paragraph 2-14.

a Model 1486 with a copper-wire short is on the Model 148 INPUT Receptacle,

offset should be less than 0.2 microvolt.

Shifts in source resistance also affect the zero offset, if the

3.

source resistance approaches the maximum value given in Table 2.

effect is negligible for source resistances less than 10% of the

maxiwm value.

If the input is left completely open-circuit, the meter will drift

4.

off scale on any range.

Refer to Table 4 if problems exist during the measurement.

5.

Minimum

Input Resistance Maximum Source Line Frequent

Range Greater Than Resistance Rejection

when

This

0.01 microvolt

0.03 microvolt

0.1 microvolt

0.3 microvolt

1 microvolt

3 microvolts

.O microvolts 300 kll

i0 microvolts 300 kn

10 microvolts 300 krl

0.01 millivolt

0.03 millivolt

0.1 millivolt

0.3 millivolt

1 millivolt

3 millivolts

.O millivolts

IO millivolts

10 millivolts

TABLE 2. Model 148 Input Resistance, Maximum Source Resistance,

and Minimum Line Frequency Rejection by Range.

the ratio of impressed peak-to-peak line frequency (50 or 60 cps)

voltage at input to the indicated dc voltage.

1 kcl

3 kcl 30 n

10 kn

30 kn

100 lcrl

300 kn 3 kc1

1 I%,2

1lQ

l?Sl 10 kn

1 Ma.

1Kl

3Kl

5 Ml

5 I%1

5 Nl

10 n

100 n

300 11

1 lu?

3 kn

3&l

3kn

10 kn

10 kcl

10 kn

10 kn

30 m

50 Icn

50 k!J 5:l

50 kn

The rejection is

3OOO:l

1OOO:l

1OOO:l

5OO:l

5OO:l

1OO:l

decreasing

to

5O:l

100: 1

5O:l

2O:l

2O:l

2O:l

1O:l

1O:l

5:l

Three millivolt and microvolt ranges overlap: 0.01, 0.03 and 0.1

f.

millivolts and 10, 30 and 100 microvolts.

source resistance is high or if large 60-cps fields are present.

volt ranges are more convenient to use if subsequent measurements require more

sensitive ranges.

frequency rejection by range.

At low levels,

g.

between the input leads and the circuit under test.

leave the instrument connected, and adjust the zero after establishing

a zero reference in the apparatus under test.

1067

Refer to Table 2 for maximum source resistance and line

spurious emf's may be generated simply by contact

use the millivolt ranges when the

The micro-

If possible, always

For example,

in bridge measurements,

9

Page 16

MODEL 148 NANOVOLTMETER

disconnect the bridge exciting voltage; or with a phototube, shield the tube

from light.

2-6. ACCESSORIES FOR INPUT CONNECTIONS.

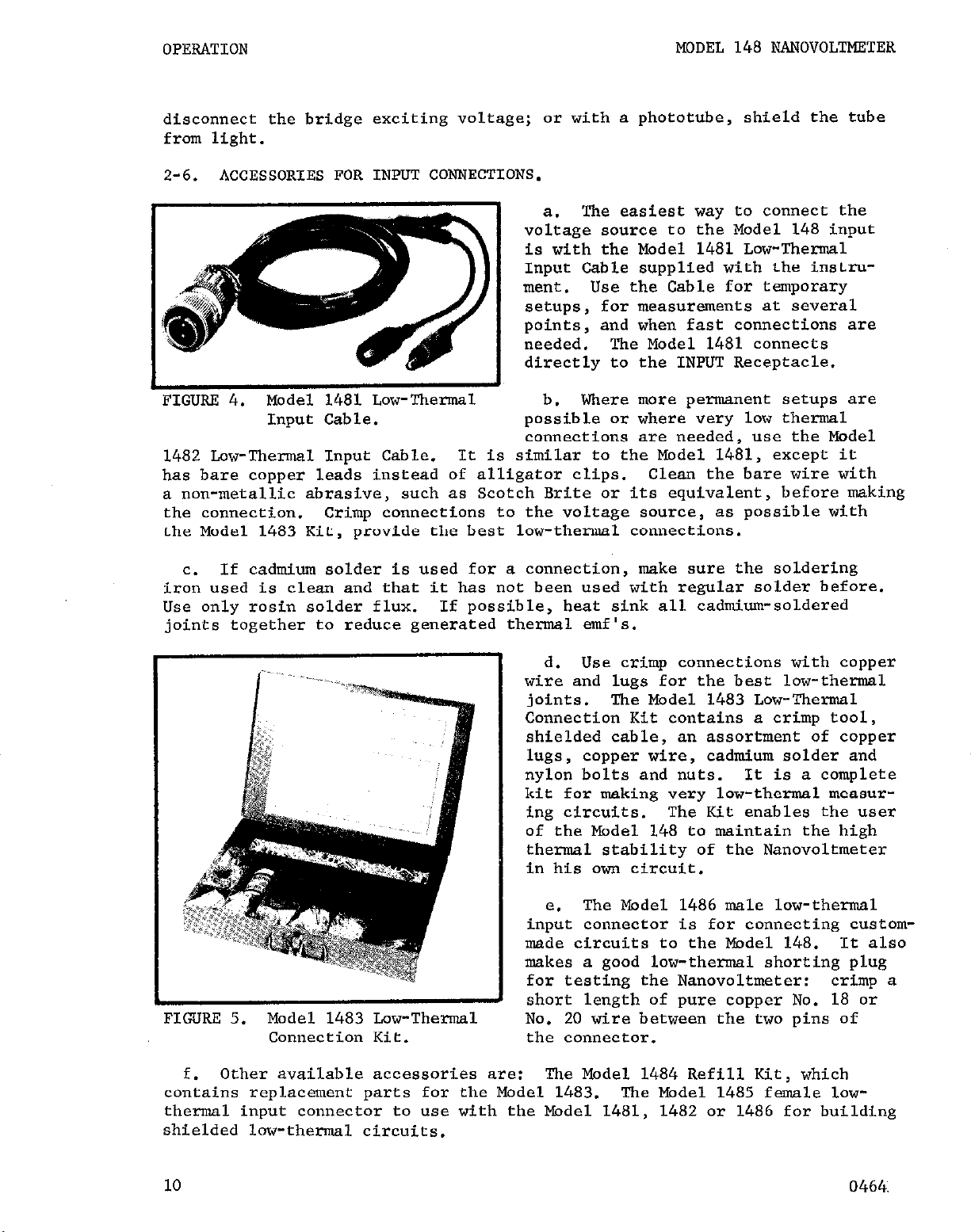

a. The easiest way to connect the

voltage source to the Model 148 input

is with the Model 1481 Low-Thermal

Input Cable supplied with the instru-

ment.

Use the Cable for temporary

setups, for measurements at several

points, and when fast connections are

needed. The Model 1481 connects

directly to the INPUT Receptacle.

I

FIGURF: 4.

Model 1481 Low-Thermal

Input Cable.

possible or where very low thermal

Where more permanent setups are

b.

connections are needed, use the Model

1482 Low-Thermal Input Cable. It is similar to the Model 1481, except it

has bare copper leads instead of alligator clips.

Clean the bare wire with

a non-metallic abrasive, such as Scotch Brite or its equivalent, before making

the connection. Crimp connections to the voltage source, as possible with

the Model 1483 Kit, provide the best low-thermal connections.

If cadmium solder is used for a connection, make sure the soldering

C.

iron used is clean and that it has not been used with regular solder before.

Use only rosin solder flux.

If possible, heat sink all cadmium-soldered

joints together to reduce generated thermal emf's.

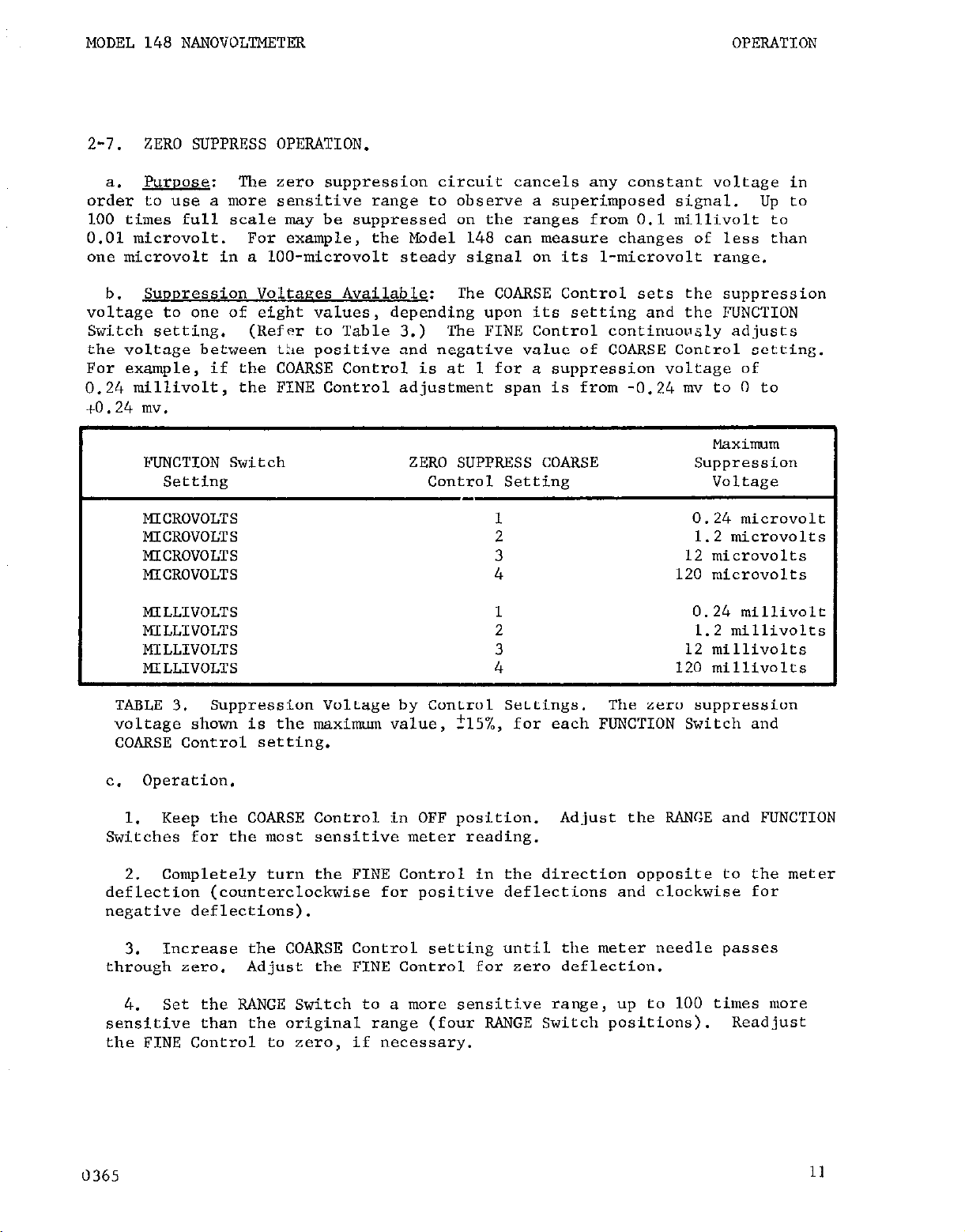

Use crimp connections with copper

d.

wire and lugs for the best low-thermal

joints.

The Model 1483 Low-Thermal

Connection Kit contains a crimp tool,

shielded cable, an assortment of copper

lugs,

copper wire, cadmium solder and

nylon bolts and nuts. It is a complete

kit for making very low-thermal measur-

ing circuits. The Kit enables the user

of the Model 148 to maintain the high

thermal stability of the Nanovoltmeter

in his own circuit.

The Model 1486 male low-thermal

e.

input connector is for connecting custommade circuits to the Model 148. It also

makes a good low-thermal shorting plug

for testing the Nanovoltmeter: crimp a

short length of pure copper No. 18 or

'IGURE 5. Model 1483 Low-Thermal

Connection Kit.

No. 20 wire between the two pins of

the connector.

Other available accessories are:

f.

contains replacement parts for the Model 1483.

The Model 1484 Refill Kit, which

The Model 1485 female low-

thermal input connector to use with the Model 1481, 1482 or 1486 for building

shielded low-thermal circuits.

10

0464.

Page 17

MODEL 148 NANOVOLTMETER

2-7. ZERO SUPPRESS OPERATION.

OPERATION

Purpose:

a.

order to use a more sensitive range to observe a superimposed signal.

100 times full scale may be suppressed on the ranges from 0.1 millivolt to

0.01 microvolt. For example, the Model 148 can measure changes of less than

one microvolt in a lOO-microvolt steady signal on its l-microvolt range.

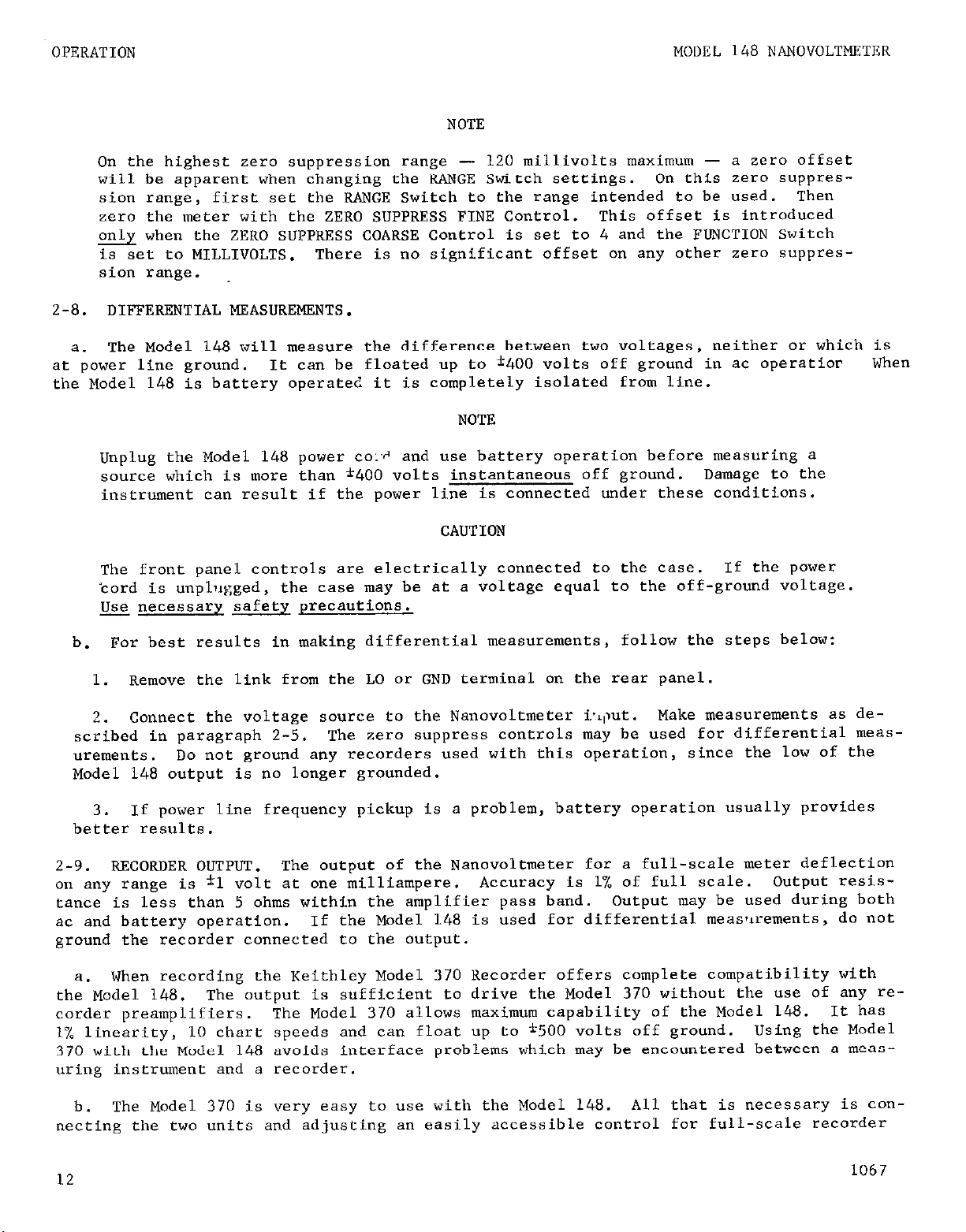

Suupression Voltaxes Available: The COARSE Control sets the suppression

b.

voltage to one of eight values, depending upon its setting and the FUNCTION

Switch setting. (Refer to Table 3.) The FINE Control continuously adjusts

the voltage between tile positive and negative value of COARSE Control setting.

For example, if the COARSE Control is at 1 for a suppression voltage of

0.24 millivolt,

+0.24 mv.

FUNCTION Switch

Setting

MICROVOLTS

MICROVOLTS

MICROVOLTS

MICROVOLTS

MILLIVOLTS 1 0.24 millivolt

MILLIVOLTS 2 1.2 millivolts

MILLIVOLTS 3 12 millivolts

MILLIVOLTS 4 120 millivolts

The zero suppression circuit cancels any constant voltage in

up to

the FINE Control adjustment span is from -0.24 mv to 0 to

Maximum

ZERO SUPPRESS COARSE

Control Setting

1

2

3

4

Suppression

Voltage

0.24 microvolt

1.2 microvolt6

12 microvolt6

120 microvolt6

TABLE 3.

voltage shown is the maximum value, ?15%, for each FUNCTION Switch and

COARSE Control setting.

c. Operation,

Keep the COARSE Control in OFF position.

1.

Switches for the most sensitive meter reading.

Completely turn the FINE Control in the direction opposite to the meter

2.

deflection (counterclockwise for positive deflections and clockwise for

negative deflections).

Increase the COARSE Control setting until the meter needle passes

3.

through zero.

Set the RANGE Switch to a more sensitive range, up to 100 times more

4.

sensitive than the original range (four RANGE Switch positions).

the FINE Control to zero, if necessary.

Suppression Voltage by Control Settings. The zero suppression

Adjust the RANGE and FUNCTION

Adjust the FINE Control for zero deflection.

Readjust

0365

11

Page 18

OPERATION

MODEL 148 NANOVOLTMETER

NOTE

On the highest zero suppression range - 120 millivolts maximum - a zero offset

will be apparent when changing the RANGE Switch settings. On this zero suppres-

sion range, first set the RANGE Switch to the range intended to be used. Then

zero the meter with the ZERO SUPPRESS FINE Control. This offset is introduced

only when the ZERO SUPPRESS COARSE Control is set to 4 and the FUNCTION Switch

is set to MILLIVOLTS. There is no significant offset on any other zero supprss-

sion range.

2-8. DIFFERENTIAL MEASUREMENTS.

The Model 148 will measure the difference between two voltages, neither or which is

a.

at power line ground. It can be floated up to 1-400 volts off ground in ac operatior

the Model 148 is battery operated it is completely isolated from line.

Unplug the Model 148 power co? and use battery operation before measuring a

source which is more than f400 volts instantaneous off ground.

Damage to the

instrument can result if the power line is connected under these conditions.

When

CAUTION

The front panel controls are electrically connected to the case.

"cord is unplugged,

Use necessary safety precautions.

For best results in making differential measurements, follow the steps below:

b.

Remove the link from the LO or GND terminal on the rear panel.

1.

Connect the voltage source to the Nanovoltmeter i,L,wt.

2.

scribed in paragraph 2-5.

urements.

Do not ground any recorders used with this operation, since the low of the

the case may be at a voltage equal to the off-ground voltage.

Make measurements as de-

The zero suppress controls may be used for differential meas-

If the power

Model 148 output is no longer grounded.

3. If power line frequency pickup is a problem, battery operation usually provides

better results.

2-9. RECORDER OUTPUT.

on any range is *l volt at one milliampere.

tance is less than 5 ohms within the amplifier pass band.

ac and battery operation.

The output of the Nanovoltmeter for a full-scale meter deflection

Accuracy is 1% of full scale. Output resis-

Output may be used during both

If the Model 148 is used for differential meas?xements, do not

ground the recorder connected to the output.

When recording the Keithley Model 370 Recorder offers complete compatibility with

a.

the Model 148. The output is sufficient to drive the Model 370 without the use of any re-

corder preamplifiers. The Model 370 allows maximum capability of the Model 148.

1% linearity, 10 chart speeds and can float up to *500 volts off ground.

Using the Model

It has

370 with the Model 148 avoids interface problems which may be encountered between a meas-

uring instrument and a recorder.

The Model 370 is very easy to use with the Model 148. All that is necessary is con-

b.

necting the two units and adjusting an easily accessible control for full-scale recorder

12

1067

Page 19

MODEL 148 NANOVOLTMETER

OPERATION

L

Trouble (seen on meter)

Change in offset between ac

Possible Cause

Low Battery

Refer to

paragraph 2-4

and battery operation

Very slow response time

High source resistance paragraph 2-12

Improper shielding paragraph 2-13

Excessive drift

I I

Thermal emfs

paragraph 2-14

I

Improper connection to input paragraph 2-15

Excessive noise or needle

instability

High source resistance paragraphs 2-11,2-l

improper shielding paragraph 2-13

Improper connection to input

paragraph 2-15

Thermal emfs paragraph 2-14

Excessive temperature sensitivity Thermal emfs

paragraph 2-14

presence of large, constant zero suppress Controls on paragraph 2-5

signal Thermal emfs paragraph 2-14

Improper connection to input paragraph 2-15

Excessive 8-cps beat at output

or meter magnetic shielding

I

TABLE 4.

Troubleshooting Operating Procedures. *he Table gives some possible sources of

Improper location or poor

I

paragraph 2-13

I

errors while using the Model 148 and refers to instructions to correct the situation.

deflection. The furnished Model 3701 Input Cable mates with the output connector on the

Model 148. On the most sensitive ranges of the Model 148, under some conditions, a" 8-

cps beat may appear. This condition can be eliminated by mounting a 100~microfarad capac-

itor across pins 14 and 17 in the back of the Model 370 Recorder.

2-10.

ACCURACY CONSIDERATIONS.

For sensitive measurements - 10 millivolts and below -

other considerations beside the voltmeter affect accuracy. The Model 148 reads only the

signal received at its input; therefore, it is important that this signal be properly

transmitted from trle source. The following paragraphs indicate factors which affect ac-

CllrWy: thermal noise, loading, shielding, thermal emfs and circuit connections.

Table

4 also offers a quick reference to correct troubles which may occur.

2-11 THERMAL NOISE.

The lower limit in measuring small potentials occurs when the Johnson noise, or

a.

thermal agitation, becomes evident. The amount of noise present in the source is show" in

the following equations.

1. The thermal noise in any ideal resistance can be determined from the Johnson noise,

equation:

-As

=4kTRF Eq. 1

where Er,, is the rms noise voltage developed across the voltage source;

T is the temperature in degrees Kelvin;

1067

13

Page 20

OPERATION MODEL 148 NANOVOI~'~ETEl?

R is the source resistance in ohms;

F is the amplifier bandwidth in cps;

k is the Boltzmann constant (1.38 x lo-23 joules/OK).

For an ideal resistance at room temperature (300°K), equation 1 simplifies to

rms = 1.29 x lo-lo (R F)112

Peak-to-peak meter indications are of more interest than the rms value.

2.

mentally,

E

the peak-to-peak Johnson noise is about five times the rms value.

Eq. 2

Experi-

At room

temperature, equation 2 becomes

= 6.45 x lo-10 (R F)li2

EPP

Eq. 3

where Epp is the peak-to-peak noise voltage developed across the voltage source.

The Model 148 bandwidth, F,

3.

can be estimated from the response speed, tr, by:

F = 0.35/tr Eq. 4

The response speed varies with the range used and the source resistance.

On the O.l-

microvolt range when the source resistance is less than 10 ohms, for example, the bandwidth is greater that 0.7-cps.

The maximum specified response speed for this situation

is 0.5 second, so the 0.7-cps bandwidth is a minimum value.

As an example, determine the Johnson noise of a lo-ohm ideal resistor. Measured

4-

with the Model 148 on the 0.1~microvolt range and using equation 3, this becomes

17.1 x lo-10 volts peak-to-peak or 1.71 nanovolts peak-to-peak minimum.

In general, good wirewound or low-noise metal-film resistors approximate ideal resis-

b.

tors,

and equations 2 and 3 are nearly correct. If the source resistance is.composed of

other materials, it may be necessary to include other terms in the equations to account

for flicker, l/f, and current noise over and above the thermal noise.

c. As seen in equations 2 and 3,

ficant in the microvolt region.

fore, keep the source resistance as low as possible.

the noise of even low resistance values becomes signi-

The noise in non-ideal resistors is even greater. There-

Other effects of high source resis-

tances are decreased response speed and added pickup of extraneous voltages.

2-12. INPUT RESISTANCE.

is obtained by using high feedback factors.

The Model 148 is a feedback amplifier, and its input resistance

When the source resistance exceeds its physi-

cal input resistance - the amplifier without feedback - the feedback is partially de-

stroyed.

higher resistances may be used, but noise, offset,

result.

Normally, do not exceed the maximum source resistance specified in Table 2;

slow response time and instability may

On the most sensitive ranges,

the maximum source resistance is consistent with

Johnson noise considerations.

Z-13. SHIELDING.

Due to its narrow bandwidth, the Model 148 is somewhat insensitive to ac voltages

a.

superimposed upon a dc signal at the input terminals.

However,

ac voltages which are

large compared with the dc signal may drive the Model 148 ac amplifier into saturation,

erroneously producing a dc output

at

the demodulator.

Therefore, shield the circuit to

the Nanovoltmeter input, particularly for low-level sources.

14

1067

Page 21

MODEL 148 NANOVOLTMETER OPERATION

Improper shielding can cause the Model 148 to react in one or more of

b.

the following ways:

Needle jitter or instability, from 10% to 20% of full scale.

1.

High offset (dc bias). Changing the power cord polarity or the

2.

connection between the LO and GND terminals may affect the amount of offset.

Slow response time, sluggish action and/or inconsistent readings

3.

between ranges.

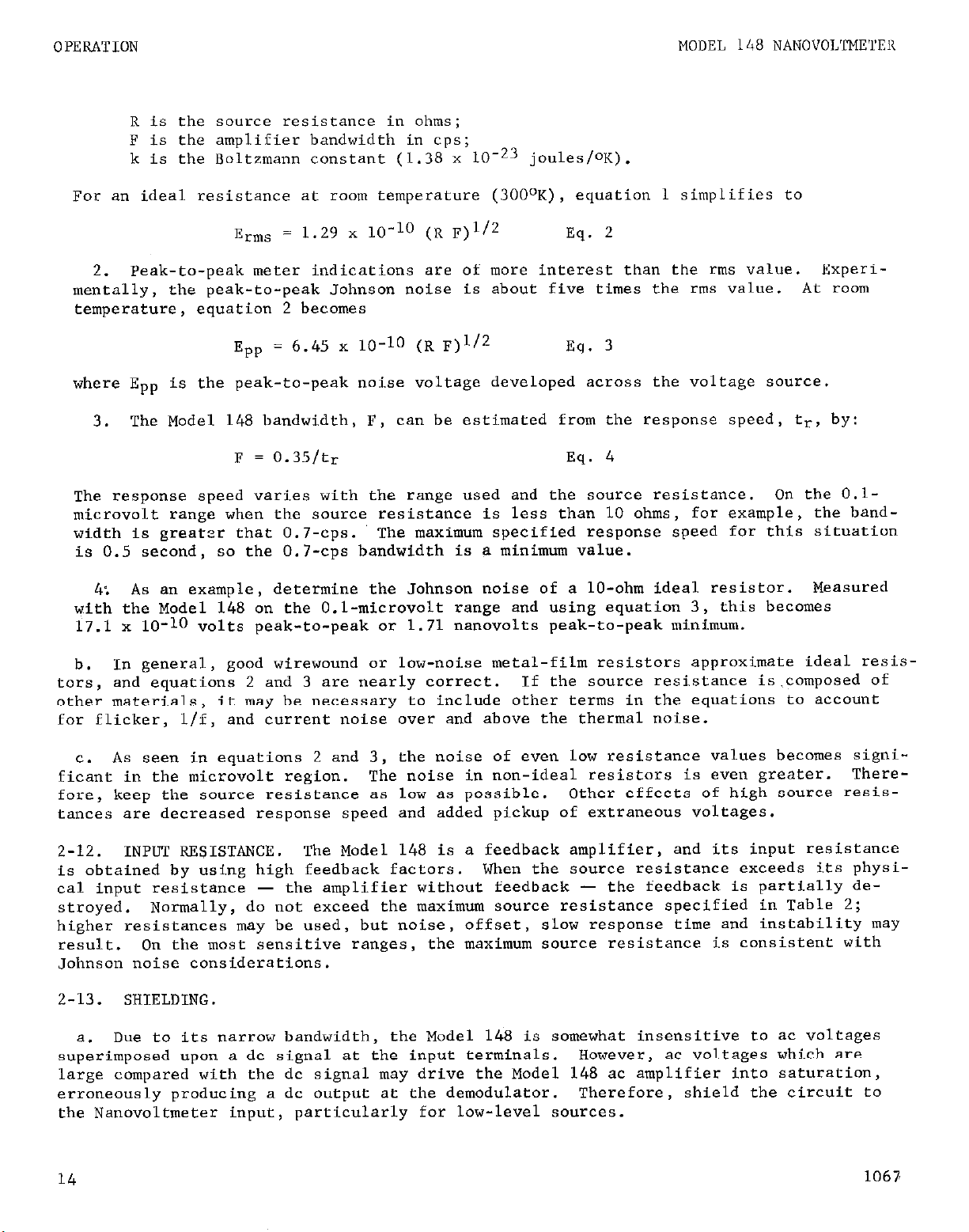

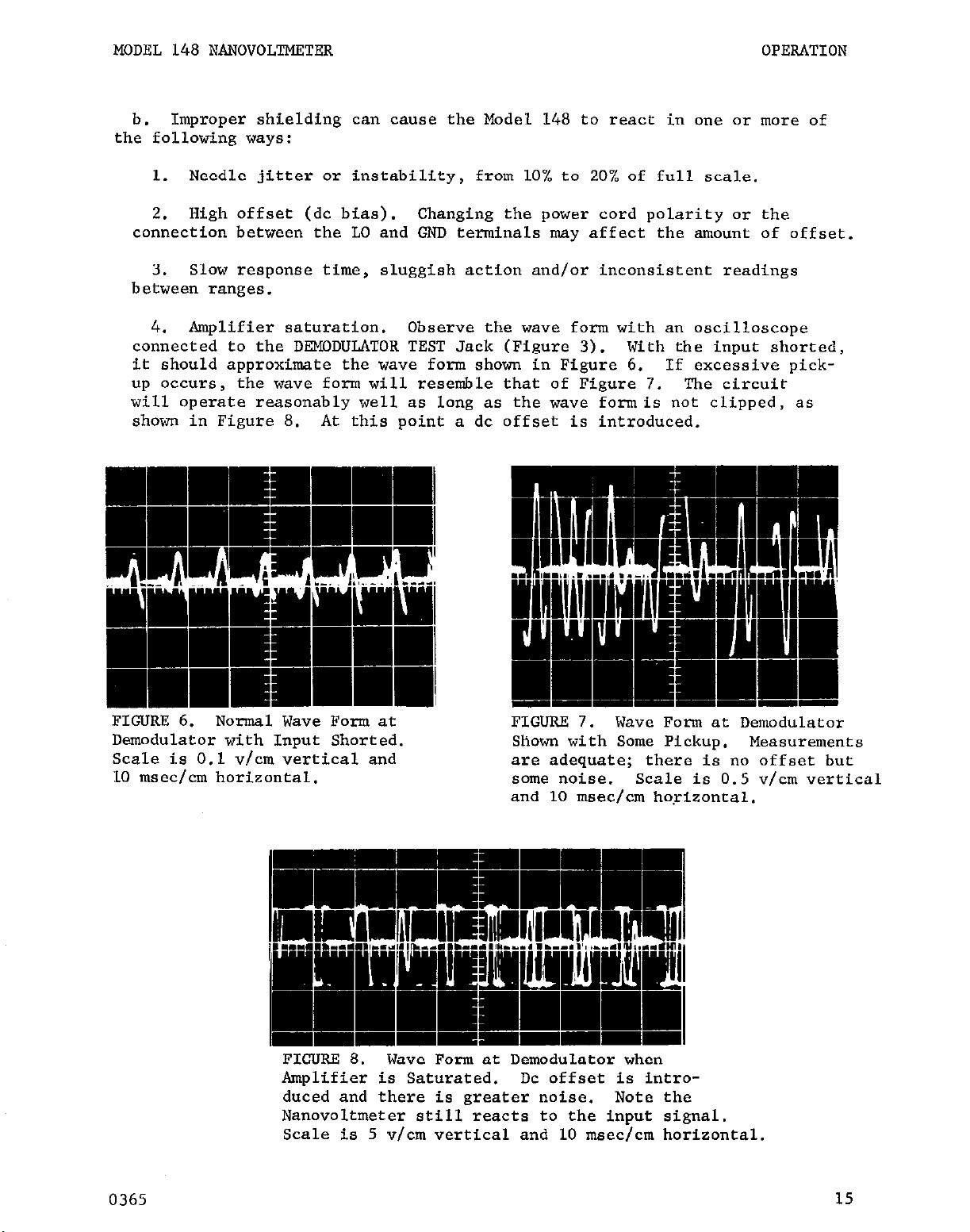

Amplifier saturation.

4.

Observe the wave form with an oscilloscope

connected to the DEMODULATOR TEST Jack (Figure 3). With the input shorted,

it should approximate the wave form shown in Figure 6. If excessive pickup occurs, the wave form will resemble that of Figure 7. The circuit

will operate reasonably well as long as the wave formis not clipped, as

shown in Figure 8.

---

FIGURE 6.

Normal Wave Form at

Demodulator with Input Shorted.

Scale is 0.1 v/cm vertical and

10 msec/cm horizontal.

At this point a dc offset is introduced.

FIGURE 7.

Wave Form at Demodulator

Shown with Some Pickup.

are adequate;

some noise.

there is no offset but

Scale is 0.5 v/cm vertical

Measurements

and 10 msec/cm ho,rizontal.

0365

FIGURE 8. Wave Form at Demodulator when

Amplifier is Saturated. DC offset is intro-

duced and there is greater noise. Note the

Nanovoltmeter still reacts to the input signal,

Scale is 5 v/cm vertical and 10 msecfcm horizontal.

15

Page 22

OPERATION

To minimize pickup, keep the voltage source and the Nanovoltmeter away

c.

from ac sources.

at the low side of the input or at the LO terminal.

magnetic flux is proportional to the area of the loop.

areas in the shield connections as well as the input circuitry.

at only one point. Run all wires in the circuit along the same path, so the

loop area is only the small difference in position of two adjacent wires.

Shield as carefully as possible.

MODEL 148 NANOVOLTMETER

Connect all shields together

The voltage induced due to a

Therefore, minimize loop

Connect the shield

Strong third harmonic magnetic fields

d.

create an 8-cps beat at the Nanovoltmeter output and meter.

effect, turn off all possible nearby sources,

Remove the Model 148 and the measuring circuit as far as possible from the

magnetic field.

as electrostatic shielding around the circuit may be necessary.

tion concerning your particular shielding problem,

1322 North Elston Street, Chicago, Illinois.

Shielding is preferable to input filters.

e.

add noise (see Johnson noise equation),

tracted from the maximum source resistance in Table 2.

filters tend to create loop instabilities with the Nanovoltmeter.

across the input, however,

be used to filter ac components in some cases.

2-14.

velop an emf if there is a temperature difference between the metals.

may be seen by blowing on one junction and checking the meter indication.

b. Thermal emf's can cause the following problems:

THERMAL EMF'S.

Junctions between two dissimilar metals form a thermocouple and will de-

a.

Meter instability or zero offset much higher than expected. Note,

1.

though, the Model 148 can have some offset (paragraph Z-5).

If removal does not greatly reduce the beat, magnetic as well

is less likely to cause loop instabilities, and it may

- 180 cps for ho-cps units - may

To reduce this

such as heavy-duty transformers.

For informa-

contact Perfection Mica Corp.,

Resistive-capacitive filters

and the resistance value must be sub-

Inductive-capacitive

Capacity alone

This effect

Meter is very sensitive to ambient temperature differences.

2.

seen by touching the circuit, by putting a heat source near the circuit, or

by a regular pattern of instability, corresponding to heating and air con-

ditioning systems or changes in sunlight.

To minimize the drift caused by thermal emf's, use metals having the same

c.

thermoelectric powers in the input circuit.

have a thermoelectric power within about i0.25 pv/"C of copper. This means a

temperature unbalance of l°C between these metals would generate a thermal emf

of about 0.25 microvolt.

power of about 320 IJ-v/'C,

copper.

of materials. Since the Model 148 input circuit is made of pure copper, use

metals with nearly the same thermoelectric power.

to copper; however,

mal emf on the order of a few nanovolts per OC.

all necessary equipment to make very low-thermal copper crimp joints.

16

Standard physical handbooks contain tables of thermoelectric powers

slight amounts of copper oxide will cause a very slight ther-

At the other extreme, germanium has a thermoelectric

and silicon will develop about 420 pv/OC against

Gold, silver and low-thermal solder

The best junction is copper

The Model 1483 Kit contains

This is

0375

Page 23

MODEL 148 NANOVOLTMETER

OPERATION

Several other techniques will reduce the effects of thermal emf's.

d.

the zero suppression circuit to buckout constant voltages.

from "pen windows, fans,

temperatures.

solder,

such as supplied in the Model 1483 Kit.

If connections must be soldered, use only cadmium-tin low-thermal

air conditioning vents and similar sources which vary

Unl.ike metals - including

Keep all circuits

USC?

regular solder - may be used and low thermal cmf's obtained if a well-controlled

oil bath or a good heat sink is used.

Thermal voltages may be calculated Cram

the thermoelectric power of the materials in the junction and the possible

temperature difference between the junctions.

2-15. CIRCUIT CONNECTIONS.

When measuring in the microvolt and nanovolt regions, consider the effect

a.

the physical connections will have on the potential being measured. IR drops,

which in most circuits are insignificant, now become important.

For example!,

No. 20 AWG copper wire has a resistance of approximately 10 milliohms per

foot.

produce five microvolts.

A l-milliampere current through a b-inch length of this wire will

To reduce this drop to 0.5 nanovolt would mean

using a wire 0.0006 inch long.

. Four-terminal connections can

, ,

often be used to eliminate this error.

Refer to Figure

If

an

9.

unwanted IR drop is con-

j ;it the zero suppress may be used

to nullify the voltage.

~ 1 M":::d:48 1

d. '

If the currents or resistances

I

/

FIGURE 9.

Using Model 148 with

4-Terminal Connections.

in the measuring system fluctuate,

they will develop fluctuating voltages

which will appear as noise or drict

in the system.

2-16. OPERATING FROM SOURCE OTHER THAN 117 VOLT, 60 CPS.

If the ac power source is 234 volts,

a.

Line Voltage Switch on the back panel (Figure 3.)

l/8 ampere to l/16 ampere.

Use only 250-volt MDL fuses. No other adjust-

use a screwdriver to change the

Change the fuse from

ment is necessary.

For 50-cps ac power sources,

b.

Cl03 and C104.

The Model 148 can operate satisfactorily from 60 or 50-cps

change the sideband filter capacitors,

sources, but the best ac rejection is achieved when the filter is set for

the lint frequency.

(C104) for 50 cps.

Use Keithley part C105-.109M (ClO3) and C45-.0155M

Refer to Figure 23 for component location.

2-17. RACK MOUNTING. (See Figure 10.)

The Model 148 is shipped for bench use with four feet and a tilt-bail.

a.

'The Model 4002 Rack Mounting Kit converts the instrument to rack mounting

to the standard EIA (RETMA) 19-inch width.

To convert the Model 148, remove the four screws at the bottom of

b.

each side of the instrument case.

Lift off the top cover assembly with the

17

Page 24

OPERATION

MODEL 148 NANOVOLTMETER

handles; save the four screws.

cover assembly, turn the two screws near the back.

will release the cover and allow it to drop off.

bail and replace the cover (2).

c. Attach the pair of rack angles (3)

previously

;he chassis with the two pawl-type fasteners at the rear. Store the top cover

with handles, feet and tilt-bail for future use.

Item

I

k

See Fir. 10)

1

2

3

4 screw, Slotted, lo-32 UNC-2x1/4 (Supplied

5

removed. Insert the top cover assembly (1) in place and fasten to

Cover Assembly

Cover Assembly, Bottom (Supplied with

Model 148) 17695B

Angle, Rack

with Model 148)

Front Panel (Supplied with Model

TABLE 5.

Parts List for Moi

To remove the feet and tilt bail from the bottom

The two pawl-type fasteners

Remove the feet and the tilt

o the cabinet with the four screws (4)

t

Keithley

Description Part No: Quantity

17162C 1

1

14624B 2

--- 4

148) --- 1

1 4002 Rack Mounting Kit.

,r. __--...

Z COVER ASSEMBLY

4

ACOVER ASSEMBLY

18

FIGURE 10.

Exploded View for Rack Mounting.

0464:

Page 25

MODEL 148 NANOVOLTMETER CIRCUIT DESCRIPTION

SECTION 3.

CIRCUIT DESCRIPTION

3-1. GENERAL.

The Model 148 consists of a chopper demodulator system followed by a

a.

dc amplifier.

Feedback is applied to the whole loop. (See Figure 11.)

b. A mechanical chopper converts the dc input signal to a 94-cps signal

'The ac signal is amplified, demodulated, dc amplified and applied co the

meter.

it to the input.

A feedback network samples the signal at the output and compares

The dc input signal and the feedback signal are compared

in the input transformer primary. The transformer increases the voltagedifference signal between the two. The ac amplifier amplifies the difference signal; line-frequency sidebands of the 94-cps signal are filtered

out. The a~ signal is then demodulated by a saturated transistor switch

and enters a dc amplifier, which has a feedback capacitor to filter out

the demodulator ripple. The dc amplifier output is connected to the

meter, the output terminals and the feedback network. The feedback

resistors determine full-scale range. The zero suppress signal is connected to the feedback point in the input circuit.

FIGURE 11. Block Diagram of Model 148 Amplifier Circuits.

The power source for the Model 148 is either line voltage or the

c.

rechargeable battery. Voltage from either source is applied to a dc-todc inverter and then to three highly regulated supplies. The three

supplies furnish power to the oscillator and the amplifier circuits.

There

is also a battery charging circuit to charge the battery when it is necess-

ary and when the line voltage is connected.

NOTE

The circuit designations referred to in this section are

for Schematic Diagrams 17351F, 17352D and 17353D found

at the back of the manual.

0464

19

Page 26

CIRCUIT DESCRIPTION

MODEL 148 NANOVOLTMETER

3-2.

INPUT CIRCUIT.

The dc input signal is connected through the high terminal of the INPUT

a.

Receptacle, JlOl, to the center contact of the mechanical chopper, GlOl.

(See Figure 12.) The feedback signal is applied to the center tap of the input

transformer, TlOl. .The chopper alternately applies a positive and a negative

square-wave signal across each half of the primary. The magnitude of the square

wave is proportional to the difference between the dc input and the feedback

signals.

TlOl steps up this signal and applies it to the grid of tube Vl.

Chopper

1

0

L

t

"in

VO

FIGURE 12. Model 148 Input Circuit.

The dc input signal, Vin, is

applied to the mechanical chopper. The feedback signal, Vf (the dc

amplifier output voltage, Vo,

applied to the transformer primary. The signal, Vd,

transformer is

the

difference between the two, Vd = Vin - Vf, When

times the feedback ratio,,@ ), is

stepped up by the

the dc input signal is initially applied to the Model 148, Vf is zero

and the voltage across the primary is entirely Vin.

voltage rises, Vf increases and Vd

decreases to a small value.

As the output

Vf = Vinj OrgV, = Vin. Only beta, which depends upon the RANGE and

FUNCTION Switch settings, determines the amplifier gain.

The input compartment is designed to insure high thermal stability and

b.

to minimize internal ac pickup.

Thermal stability is obtained in part by using only copper wire in the

1.

input circuitry. The input transformer primary and the mechanical chopper leads

are pure copper.

the mechanical strength without creating large thermal emf's.

portion of the FUNCTION Switch uses pure copper pins and rotor.

to components are made with pure copper crimp lugs.

The input connector is 99.5% copper; the impurities add to

The low voltage

All connections

Connections between

components are made by bolting the lugs together - not soldering - to reduce

thermal emf's.

The input compartment is doubly shielded against magnetic and electrostatic

2.

pickup on all sides. The wires are physically placed to maintain minimum loop

area, further minimizing pickup.

20

0464

Page 27

MODEL 148 NANOVOLTMETER

The feedback network is formed from the output of the dc amplifier bacl;

c.

to the center tap of the primary of transformer TlOl.

selects the feedback ratio used for each range.

3-3. AC AMPLIFIER.

The ac amplifier circuit amplifies the 94-cps difference signal which

a.

corresponds to the dc input signal. The signal is applied to the grid of

Vl and further amplified by tube V2.

provides a high impedance load for V2.

transistors 44 and Q6. Potentiometer R109, between the Q3 emitter and Q4

base, adjusts the gain to compensate for beta variations.

each stage has some local degeneration.

matching. The difference signal is amplified by transistors (27 and 98,

which also form a full-wave signal for demodulation.

A series high-Q filter from the plate of V2 to circuit ground provides

b.

notch rejection at the power-line frequency sidebands.

pacitors Cl03 and Cl04 depend upon the power-line frequency.

high Q of the inductor,

for 60-cps power lines and 44 cps and 144 cps for 50-cps power lines.

ac amplifier's 94-cps gain and phase characteristics are affected very

little.

the filter forms sharp notches at 34 cps and 154 cps

A low-noise silicon transistor, Q3,

The signal is then ampl~ificd by

Transistor 95 is for impedance

CIRCUIT DESCRIPTION

The RANGE Switch, SlO2:

In addition,

The values of ca-

Due to the

ThC

The tube type and bias point of Vl are selected for low-noise oper-

c.

ation at 94 cps. The high-Q tuned circuit in the plate of Vl has a good

signal-to-noise ratio, and it provides a narrow bandwidth around 94 cps.

The tuned circuit's Q is lowered on the higher ranges for amplifier stability.

3-4. DKMODULATOR.

switch demodulator.

into a dc voltage with ripple component. Resistors R123 and R124 sum the

voltages from each to form a full-wave rectified signal. Jack 5102 allows

access to observe the waveform. The 94-cps oscillator furnishes a square-

wave drive for the demodulator.

3-5. DC AMPLIFIER.

The demodulator signal is amplified by two low-drift, high-gain

silicon transistors, Qll

pensate for temperature drift. Transistors Q13 and Q14 form the second amp-

lifier stage.

- transistors Q15 and Ql6 in pnp-npn configuration - draws little current

at zero output. Diodes DlOl and D102 limit the output current, protecting Ql5 and Q16.

b. A feedback loop with capacitor Cl15 around the dc amplifier acts as

an integrator, filtering the ripple component of the demodulated waveform.

The effective capacity, which is approximately the value of Cl15 times

the dc amplifier gain,

the response speed of the system. The capacitive feedback also lessens

the noise in the amplifier outside the system bandpass.

Total gain is about 500.

Q9 and QlO in inverted configuration form a transistor

They convert the 94-cps wave from the ac amplifier

and 912, in differential configuration to com-

The emitter follower output stage

and the feedback factor (or open-loop gain) determine

0464

21

Page 28

CIRCUIT DESCRIPTION

MODEL 148 NANOVOLTMETER

3-6. OSCILLATOR.

phase-shift network for a 94-cps signal,

a transistor switch and phase compensation network for the square-wave demodu-

lator drive.

a. The phase-shift network consists of capacitors C301 through C303, resistors

R319 through R321, and the combined resistance of R303 and R318, which bias

transistor Q17. The input impedance of the emitter follower, 917, has little

loading effect on the effective value of this last resistance. Transistor Q18

compensates for signal losses in the phase-shift network.

adjusts the signal frequency.

miniature tube, Raytheon CK6418, provides variable degeneration to maintain a sine

wave output to the next stage.

From the phase-shift network, the signal is amplified and used to drive

b.

the chopper. Transistor Q19 matches the impedance of transistor 920 to the

phase-shift network. Potentiometer R313 adjusts the signal amplitude.

transistor Q20, the signal is applied to the primary of transformer T301,

which drives the class B stage, transistors 922 and 923. After amplification

the sine-wave signal is applied to the mechanical chopper, GlOl. Transistor

921 develops the bias voltage for the class B stage, providing ambient temperature compensation for the chopper-drive signal amplitude.

transformers T301 and T302 supply dc current for the class B stage.

The chopper drive signal is also applied to the primary of transformer

T3;;.

ting network,

for the chopper phase shift.

cut off to form a square-wave drive for the demodulator, transistors Q9 and QlO.

The transformer drives transistors Q24 and Q25 through a phase-compensa-

The oscillator circuit, stable to 0.1 cps, has three parts:

an amplifier to drive the chopper, and

Potentiometer R319

Resistor R322, the filament of a low-power sub-

From

The center taps of

resistors R308 to R310, R323 and capacitor C309, which compensates

The transistors alternate between saturation and

3-7.

from the power supplies to buckout steady background potentials in the input

signal. The lo-turn FINE Control, potentiometer R168, is connected between

-12 and +12 volt outputs.

Switch, S103, further divide the voltage.

in the MILLIVOLTS position,

primary of transformer TlOl.

ition,

copper resistor R137A, and a copper resistor R141. Using copper resistors for

the lowest voltage points shunted by evenohm resistors provides thermal and re-

sistive stability.

3-8. POWER SUPPLIES (See Figure 13.) The power supply for the Model 148 is

powered by an unregulated supply from the line voltage or rechargeable battery.

Either source feeds a dc-to-dc inverter and three highly regulated supplies

with outputs of +12, -12, and +1.2 volts.

circuits.

through the POWER SUPPLY Switch, S201.

is charged if necessary and the power supply uses line voltage.

is in OFF, the battery charging circuit will operate if necessary; all other

circuits are off.

battery;

ZERO SUPPRESSION.

the suppress voltage is divided by an evenohm, 0.25% resistor, R140,

a. The line voltage, battery and battery charging circuit are controlled

When the switch is in BATTERY, the power supply usas the

the other two circuits can not operate.

The zero suppress circuit provides a regulated voltage

The resistors R165 to R167 and R172 in the COARSE

When the FUNCTION switch, SlOl, is

the suppress voltage is applied directly to the

When the FUNCTION Switch is in MICROVOLTS pos-

These power all the other Model 148

When the switch is in AC, the battery

When the switch

22

0464

Page 29

MODEL 148 NANOVOLTMETER

CIRCUIT DESCRIPTION

FIGURE 13. Block Diagram of Model 148 Power Supplies.

The unregulated supply consists of a full-wave rectifier, diodes

b.

D212 and D213, and a dropping resistor, R232. The AC CONNECTED Lamp,

DS201, is in series with resistor R226, which is connected directly

across this supply. For battery operation the primary of transformer

T201 is disconnected.

Voltage from the unregulated supply or the battery is applied to the

c.

dc-to-dc inverter circuit. Transistors 428 and Q29 form a switching network

to supply an interrupted voltage to transformer T202.

quency is about 2 kc, well away from the carrier frequency.

has a saturable ferrite core.

The inverter circuit supplies voltages to

The switching fre-

Transformer T202

the three regulated supplies, which are basically the same series regulator

design.

For the +12 volt supply, diodes D206 and D207 full-wave rectify the

d.

signal from transformer T202.

Q30.

The output of Q30 is divided by resistors R208 and R209 and compared

to the zener diode reference, D205.

The signal is applied to the pass transistor,

Transistors Q34 and Q33 amplify any

potential difference and apply a signal t,o the base of transistor 932.

Diodes D204 and D205 fix the emitter voltage of 432; therefore, the

collector voltage of Q33 directly determines the current through Q32,

which comes from the -12 volt supply.

The current drop through resistor

R216 determines the voltage at the base of transistor Q31, and therefore

.the output voltage through the base-emitter junction.

Diode D203 limits

0464

23

Page 30

CIRCUIT DESCRIPTION

MODEL 148 NANOVOLTMETER

the base-to-emitter voltage of the 430 and 931 combination, thus also limit- *

ing the current which it will pass. Diode D203 protects the pass transistor, Q30,

if output of the supply is shorted,

For the -12 volt regulated supply,

e.

the signal from transformer T202.

Q35.

The output of Q35 is divided by resistors R217 and R218, thereby compar-

The signal is applied to the pass transistor,

diodes D210 and D211 full-wave rectify

ing it to the +12 volt supply, using ground as a reference. Transistors 938

and 939 amplify any potential difference and apply a signal to transistor Q37.

Transistors Q35 and Q36 form a Darlington combination, and work similarly to

that in the ,112 volt supply. The differences are that the -12 volt supply draws

a higher current than the +12 volt supply, and therefore uses two diodes,

D208 and D209, to protect the pass transistor. The negative "bootstrap"

current supply is from a filter, resistor R225 and capacitor C210.

The +1.2 volt supply operates in the same manner as the 1~12 volt supply

f.

with these differences. The output of the pass transistor, Q40, is compared to

the output of the t12 volt supply divided down one tenth. The operating voltages

for the comparator stage, 443 and 444, are obtained from the -h2 and -12 volt

supplies.

Except for the comparator stage, npn transistors are used.

3-9. BATTERY CHARGING CIRCUIT.

The battery charging circuit operates when the POWER SUPPLY Switch, 5201,

a.

is in AC or OFF position, and only when the battery needs charging.

The battery voltage is compared to a reference by two cascaded transistors,

b.

926 and Q27. When it is low, a charging current from transformer T201 is applied

to the battery through the BATTERY CHARGING lamp, DS202, transistor 927 and diode

D216. The reference is zener diode D214; the reference voltage is adjusted by

potentiometer R228. The difference between the battery and the reference poten-

tials determines the magnitude of the charge current through Q27. A silicon

diode, 0216, prevents the battery from being run down because of leakage currents

through Q27,

a germanium power transistor.

Diode D215 limits the base-to-

emitter voltage of the Q26 and Q27 combination, so no more than 400 milliamperes

(the rated maximum charge current of the battery) can flow in the circuit.

This circuit protects the battery. It decreases the charging current to

c.

a trickle-charge rate as the battery terminal voltage approaches the reference

voltage. It also limits the charge current if the battery was used beyond its

ampere-hour capacity, Note, however, that the battery can be damaged if it is

used far beyond its capacity. A polarity reversal of a cell may occur, causing

heavy circulating currents within the battery.

24

0464,

Page 31

MODEL 148 NANOVOLTMETER

MAINTENANCE

SECTION 4.

4-1. GENERAL.

Section 4 contains the maintenance, troubleshooting and c.libratzon pro-

a.

cedures for the Model 148.

closely as possible to maintain the instrument's specifications.

The Model 148 requires no periodic maintenance beyond the normal care

b.

required of high-quality electronic equipment. Components operate well below

maximum ratings. Principal maintenance is an occasional chopper replacement.

(See paragraph 4-3.) Occasional verification of meter calibration should show

any need for adjustment.

4-2.

ponents of the Nanovoltmeter.

only reliable replacements which meet the specifications. The Model 148 uses

no special critical parts except for resistor R322, which is a subminiature

tube filament,

80164 in the Replaceable Parts List are purchased only from Keithley Instruments

or its distributors.

PARTS REPLACEMENT.

The Replaceable Parts List in Section 5 describes the electrical com-

a.

and the components listed in Table 6.

It is recommended these procedures be followed as

Replace components only as necessary, and use

MAINTENANCE

Make sure parts coded

The physical location of components in the input compartment is critical.

b.

Place replacement parts in the exact position shown in Figure 14. Circuit

loops will introduce extraneous ac signals; see paragraph 2-13. The order of

the copper lugs on the insulated posts greatly affects offiset and noise in tllc

Model 148. Tag or record the number on each lead as it is removed.

in reverse sequence.

them. When replacing these parts,

such as Scotch-Brite found in the Model 1483 Kit, or its equivalent.

the procedures necessary for good low-thermal connections.

Battery pack assembly

Mechanical chopper assembly (See paragraph 4-3.) GlOl

Input connector assembly JlOl

Copper feedback resistor assembly

Evanohm resistor assembly R139

Evanohm resistor assembly R140

Evanohm resistor assembly

Function switch plate assembly

Input transformer assembly

TABLE 6.

crimped on them and the proper lead length.

for replacements; follow instructions given in paragraph 4.-Z.

Model 14,8 Pre-assembled Components.

Table 6 lists components which have lugs crimped on

clean the lug with a non-metallic abrasive,

Circuit

ComDonent

Desig.

BA201

R137

R14.1

SlOl

TlOl

These parts have lugs

Use only Keithley parts

Replace

Follow

Keithley

Part No.

Model 148'

17689A

17638A

17627A

17635A

17636A

17637A

16883A

17623B

1266

25

Page 32

MAINTENANCE

MODEL 148 NANOVOLTMETER

FIGURE 14.

Model 148 Input Compartment.

If replacing, duplicate location and order of leads on posts.

Note exact physical location of parts.

Figure 21 gives

circuit designations.

4-3.

mechanical, it will eventually wear and become noisy.

MECHANICAL CHOPPER REPWXMKNTS.

a. The mechanical chopper

is

designed for long life. However, since it is

At this point, replace-

ment is necessary.

Removal Procedures.

b.

Disconnect the chopper drive coil at connector 5302 (Figure 20).

1.

Carefully remove the three thumb screws in the input compartment and the

three chopper lead lugs.

Carefully slide the degaussing coil, L302 (Figure 20), from the chopper

2.

body; remove the old chopper.

Replacement Procedures.

c.

Slide the degaussing coil, L302, over the new chopper body from the bottom.

1.

Orient so that the cut-out in the coil fits over the chopper drive lead.

2. Mount the chopper and coil in the input compartment.

Dress leads as

shown in Figure 14.

26

0365

Page 33

MODEL 148 NANOVOLTMETER

MAINTENANCE

Check the instrument for proper operation.

3.

subparagraph b, steps 1, 2 and 3.

Degaussing Coil Adjustment Procedures.

d.

With the input shorted,

1.

a signal through the Model 148. Use a differential input to the Type 503

Oscilloscope (-i- and - inputs) to observe the wave form between the emitters

of transistors Q9 and QlO (Points P and Q, Figure 25).

The wave form amplitude varies as the degaussing coil is moved along

2.

the chopper body. Potentiometer R301 (Figure 21) determines the effect of

the coil on the wave form. Adjust both the coil and the potentiometer for

minimum amplitude. Reverse the red and black leads to the degaussing coil

if necessary.

An 8-cps beat at points P and Q may be present. Use battery opera-

3.

tion to reduce the beat; refer to paragraph 2-3.

4-4.

might occur in the Model 148.

only specified replacement parts.

troubleshooting.

tact Keithley Instruments or its representatives. Paragraph 2-17 describes

how to remove the Nanovoltmeter cover.

TROUBLESHOOTING.

The following procedures give instructions for repairing troubles which

a.

If the trouble cannot be readily located or repaired, con-

use the ZERO SUPPRESS Controls to generate

Use these procedures to troubleshoot and use

Table 7 lists equipment recommended for

Follow paragraph 4-9,

Paragraphs 4-6, 4-7 and 4-8 give step-by-step procedures for trouble-

b.

shooting and checking out the power supply,

Follow these in the order given.

tables for these circuits.

components and to determine their function.

17352D and 17353D, contain the voltages at certain points in the circuit.

Before troubleshooting inside the Model 148, check the

external circuits (paragraph 4-5). Always check out the

power supply and the oscillator circuits before touching

the amplifier circuits.

pear faulty only because of a defect in the power supply

or oscillator circuits.

4-5. PRELIMINARY TROUBLESHOOTING PROCEDURES.

Before troubleshooting,

a.

Isolate the Nanovoltmeter from all external effects:

Disconnect all outside circuits from the INPUT and OUTPUT Recep-

1.

tacles,

and GND and LO terminals.

Also refer to Section 3 to find the more crucial

Tables 9,

NOTE

The amplifier circuits often ap-

check the outside circuits to the Model 148.

oscillator and amplifier circuits.

10 and 12 are troubleshooting

The Schematic Diagrams, 17351F,

0972

27

Page 34

MAINTENANCE

MODEL 148 NANOVOLTMETER

Use

Monitor oscillator frequency.

Keithley Model 662 Cuardrd DC Differen-

tial Voltmeter

RCA Model WV98113 Sunior Vol.tohmyst, 11 m

input resistance,

.!3-;< accuracy, 0 to 1500

Check voltage at output term-

inals.

Check dc voltages through-

out circuits.

volts dc.

Tektronix Typ? 503 Oscilloscope, dc to

450 kc.

'CABL,C 7.

Equipent

Recommended for Troubleshooting and Calibrating

Check wave forms for troubleshooting and calibrating.

then Model 148. 'USC. these instruments or their equivalents.

Connrci. ii low-therraal short across the INPUT Receptacle.

2.

The best

connector ins a I%&1 1486 male low-thermal connector with a short length

of pure CUI)~:~I: No. 18 or No. 20 wire rimped between the two pins.

The

next best is a Hodcl 1481 Low-Thermal Input Cable with the clips connected

together‘

!0xr) the cable as far as possible from ac sources, and avoid a

loop where i:h,~: alligator clips are connected.

Set t.lh,. Z'KRD SUPPRESS COARSE Control to OFF.

3.

1f hac:~~-~:~~~~ operation is trouble free, set the POWER SUPPLY Switch to

b.

BATTERY.

li!sconnect the power cord from the power line. Battery operation

eliminates maoy ground-loop connection problems with the test equipment.

lf a<. opc?ration is used, check the Line Voltage Switch for correct

c.

position and hire Fuse for correct rating.

NOTE

Often; after checking out according to paragraph 4-5, the Model 148

wj.11 ilunction normally, This points to problems in the circuits

outs:iGt the Nanovoltmeter. Refer to Table 4 to check the external

circuit.

4-6.

Model 148

CHECK WI' AND CALIBRATION PROCEDURES.

The following procedures give the steps

a.

circuits.

If a circuit fails to check out at any point, refer to

to

check out and calibrate the

the circuit's troubleshooting table. Continue as long as the points check

out. Use the equipment listed in Table 7.

Procedures

b.

are given for the power supply, oscillator and amplifier

circuits. These clover the principal adjustments to bring the instrument

within speclficntions.

28

1067

Page 35

MODEL 148 NANOVOLTMETER MhINTENANCE

If the Model 148 is not within specifications after performing these

C.

checks and calibrations, return the unit to Keithley Instruments for further

checkout, or follow the troubleshooting procedures to find the fault.

NOTE

Make sure the power supply and oscillator circuits arc

operating correctly before checking the amplifiers. All

circuits depend upon properly functioning power supplies.

If taken out of order. the resulting adjustment may be

faulty.

4-7.

POWER SUPPLY CHECK OUT AND CALIBRATION.

a. All circuits depend upon the power supplies. Therefore, the ~+12,

-12 and +1.2 volt outputs mst be operating correctly before further

checks are made. If the power supply fails to check out at any point,

refer to Table 9. After clearing the trouble, continue the check.

Procedures for CheckFng Regulated Power Supplies.

b.

Set

Connect the low-thermal shorting plug to the INPUT.

1.

the

Model 148 controls as follows:

POWER SUPPLY Switch OFF

RANGE Switch

100

FUNCTION Switch MILLIVOLTS

ZERO SUPPRESS COARSE Control OFF

Line Voltage Switch Set to line voltage

Plug in the power cord. The AC CONNECTED Lamp should light.

2.

Measure the voltage at the Yellow-White wire on the POWER SUPPLY

3.

Switch front deck (Point A, Figure 20). It should be -18 volts dc ,2 vdc.

4. Turn the POWER SUPPLY Switch to AC. Use the oscilloscope to check

the wave form at point E (Figure 26) in the dc-to-dc inverter. Wave form

should resemble that in Figure 15.

Measure the signal levels and ripple with respect to low of the

5.

three regulated supplies. Table 8 gives the values.

Regulated

Power

SUPPlY

Test Point,

Signal Level,

Figure 21 Volts dc

Maximum Ripple, Resistance

Millivolts

Peak-to-Peak

+12 volt B 11.6 to 12.8 0.3

-12 volt C

cl.2 volt D

TABLE 8.

Signal Level, Maximum Ripple and Resistance for Regulated Power Supplies.

11.9 to 13.1

1.16 to 1.28

2.0

0.2

9664

to Ground,

Ohms

850 2100

460 + 70

20!~ 3

29

Page 36

MAINTENANCE

MODEL 148 NANOVOLTMETER

TROUBLE

No voltage at point Blown fuse.

A (Fig. 20)

Irregular wave form Overloaded regulators

at point E (Fig. 26)

Incorrect voltage at Defective D205, Q33,

points B, C and D

(Fig. 21)

Incorrect voltage Shorted Vl or V2

only at point D filaments

(Fig. 21)

High ripple at

points B, C and D

(Fig. 21)

PROBABLE CAUSE SOLUTION

D212, D213 or R232

OpelI.

Q29

Q34, 438 (0~. 439)s

D204, D212

Defective Q43 or Q44

Defective oscillator

Defective D204, D212,

D205, 433, 434, Q38

or Q39.

Check for shorted transformer

T201 or wiring;

Check components; replace if

faulty.

Check resistances at power supply

faulty.

Check components; replace if

faulty.

Check Vl and V2 filament.

Check components; replace if

faulty.

See paragraph 4-8.

Check components; replace if

faulty.

then replace fuse.

High ripple only at Defective Q43 and/or

point D (Fig. 21)

Unable to adjust for Defective D214, R227,

-8.2v at

(Fig. 26)

High ripple at B, Low battery voltage.

C and D (Fig. 21)

on battery operation only.

TABLE 9.

c.

Connect the Nanovoltmeter to the ac power line. Put the POWER SUPPLY Switch

in AC position.

Adjust potentiometer R228 (Figure 27) for this value.

point G

Troubleshooting Table for Power Supply and Battery Charging Circuits.

Procedures for Charger Circuit.

Disconnect the battery pack;

1.

Set the charger bias voltage to -8.1 volts dc at point G, Figure 26.

2.

444.

R228, R229 or 426.

do not let the terminals touch the chassis.

Check components; replace if

faulty.

Check components; replace if

faulty.

Charge battery (paragraph 2-4).

30

0664

Page 37

MODEL 148 NANOVOLTMETER

MAINTEXANCE

FIGURE 15.

1nverter.

Correct Wave Form in dc-to-dc

Point E, Figure 26, was monitored.

Scale is 5 v/cm vertical, 0.2 msec/cm horizontal.

Connect the battery; make sure the polarity is correct (red to red).

3.

The positive side of the battery is ground. The BATTERY CHARGING Lamp

should light,

showing the charging circuits work. The lamp brightness

directly indicates the charge current - the brighter the light, the

greater the current.

After connecting the battery pack,

4.

the bias voltage may change.

This is normal and no readjustment is required.

4-8. OSCILLATOR CHECK OUT AND CALIBRATION.

The oscillator circuit drives the demodulator and the chopper. If

a.

the power supplies check out, continue on the oscillator.

fails to check out at any point, refer to Table 10.

After clearing the

If the oscillator

trouble, continue to check.

Procedures.

b.

connect the Type 503 Oscilloscope and the Model 5512A Electronic

1.

Counter to point F (Figure 21).

Set the oscillator frequency to 94 cps to.1 cps with potentiometer

2.

R319 (Figure 28).

Set

3.

the oscillator signal amplitude to 15.4 volts peak-to-peak

kO.2 v peak-to-peak, measured on the oscilloscope.

tiometer R313 (Figure 28).

Check the wave form at point F.

4.

It should be essentially sinusoidal,

as in Figure 16.

0664

Adjust with poten-

31

Page 38

MAINTENANCE

If transistors 42.1, 922 or Q23 are replaced, it my be necessary to

change resistor R307.

bias for 422 and 423.

If it does not but resembles Figure 17, use a 15-kilohm resistor

16.

for R307.

MODEL 148 NANOVOLTMETER

NOTE

A 27-kilohm resistor should provide the proper

The wave form at point F should resemble Figure

Fl

in Oscillator Circui:t.

Scale is 2 v/cm &rtIcal,

2 msec/cm horizontal.

FIGURE 17.

Improper Wave Forms at Point F (Figure 21) in Oscillator Circuit.

Wave A indicates the wrong bias; wave B is distorted. Scale for both is 2 v/cm

vertical, 2 mseclcm horizontal.

32

0664

Page 39

MODEL 148 NANOVOLTMETER MAINTENANCE

TROUBLE PROBABLE CAUSE

SOLUTION