Page 1

Page 2

Page 3

INSTRUCTION MANUAL

MODEL

NANOVOLT NULL DETECTOR

147

OCOPYRIGHT

PRINTED, APRIL 1977, CLEVELAND, OHIO, U. S. A.

1972,

KEITHLEY INSTRUMENTS, INC.

Page 4

CONTENTS

MODEL 147

CONTENTS

Section

GENERAL DESCRIPTZON---------------------------------------------- 1

1.

OPERATION-------------------------------------------------------- 5

2.

APPLICATIONS----------------------------------------------------- 21

3.

C1I<CUIT DESCRIPTION----------------------------------------------

4.

MhINTENANCE------------------------------------------------------ 31

5.

REPLACEABLE PARTS------------------------------------------------ 51

6.

Page

25

SCHE~T~CS------------------------------------------------__-----__-- 65

0477

ii

Page 5

MODEL 147

igure

NO.

la.

lb.

2.

a:

5.

6.

7.

a.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

ILLUSTMTIONS

ILLUSTNATIONS

Title

FrontPanel..

______-

.............................

Pag:e

1

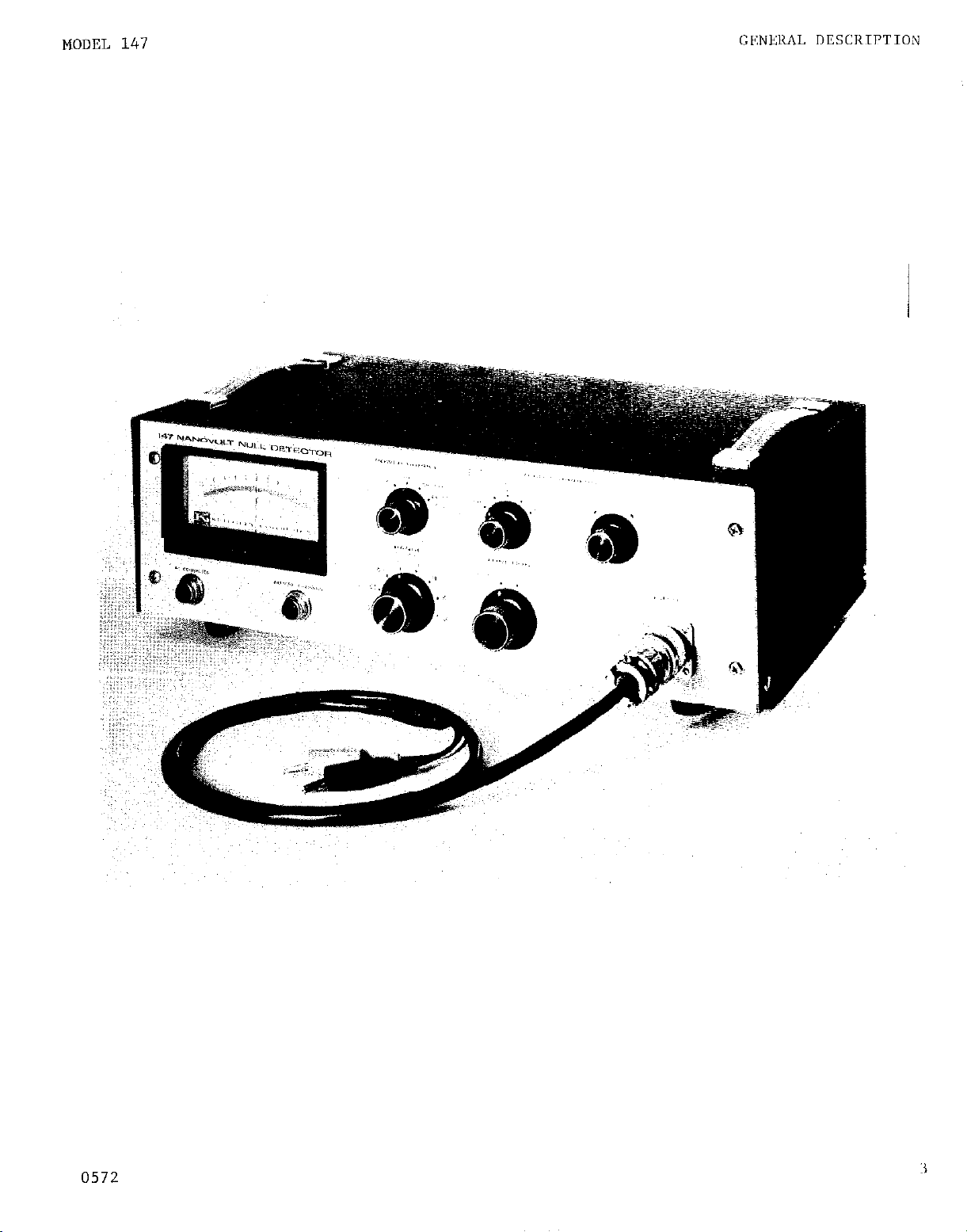

Front Panel with Cable ......................... 3

Front Panel Controls .......................... 4

Model 147 Rear Pmel Controls & Connections. .............. 6

Model 1481 Low-Thermal Input Cable ................... 10

Model 1483 Low-Thermal Connection Kit. ................. 10

Bus System for Model 147 ........................ 12

Thermal Sink Construction.

.......................

15

Normal Wave Form at Demodulator with Input Shorted ........... 17

Wave Form at Demodulator Shown with Some Pickup. ............ 17

Wave Form at Demodulator when Amplifier is Saturated .......... 17

8-cps Filter Circuit for Recorder Output ................ 18

Using Model 147 with 4-Terminal Connections. .............. 18

Exploded View for Rack Mounting .................... 19

Circuit UsingGuildline9144 with Model 147 Null Detector ........ 21

Circuit Using Guildline 4363DL with Model 147 Null Detector. ...... 22

Circuit Using Guildline 9120 with Model 147 Null Detector. ....... 22

Circuit Using Biddle 605001 with Model 147 Null Detector ........ 23

Circuit Using Leeds & Northrup 7556. .................. 23

Circuit Using Model 147 Null Detector with ES1 240, 8OOR and KS 925. .. 24

Block Diagram of Model 147 Amplifier Circuits. ............. 25

Model 1.47 Tnput Circuit. ........................ 26

Diagranl of Power Supplies & Battery Charging Circuit .......... 29

Model 147 Input Compartment. ......................

32

Correct Wave Form in dc-to-dc Inverter ................. 36

Correct Wave Form in Oscillator Circuit. ................ 38

Improper Wave Forms in Oscillator Circuit. ............... 38

Correct Wave Form at Demodulator Test Jack ............... 41

Out-of-Phase Wave Form at Demodulator Test Jack. ............ 41

Top View of Model 147 Chassis ..................... 44

Bottom View of Model 1~47 Chassis .................... 45

Transistor Locations on Printed Circuit 76 ............... 46

Capacitor & Diode Locations on Printed Circuit 76. ........... 46

Resistor Locations on Printed Circuit 76 , ............... 47

Resistor 6 Test Point

Locations

on Printed Circuit 76. ......... 47

Resistor b Test Point Locations on Printed Circuit 74, Bottom Face ... 48

Component Locations on Printed Circuit 74, Top Face. .......... 48

Resistor & Test Point Location on Printed Circuit 75

Capacitor & 'Transistor Locations on Printed Circuit 75

Resistor Locations on RANGE Switch (5102). ...............

..........

.........

49

49

50

Resistor Locations on RANGE Switch (S102). ............... 50

i

0477

iii

Page 6

SPECIFICATIONS

MODEL 147

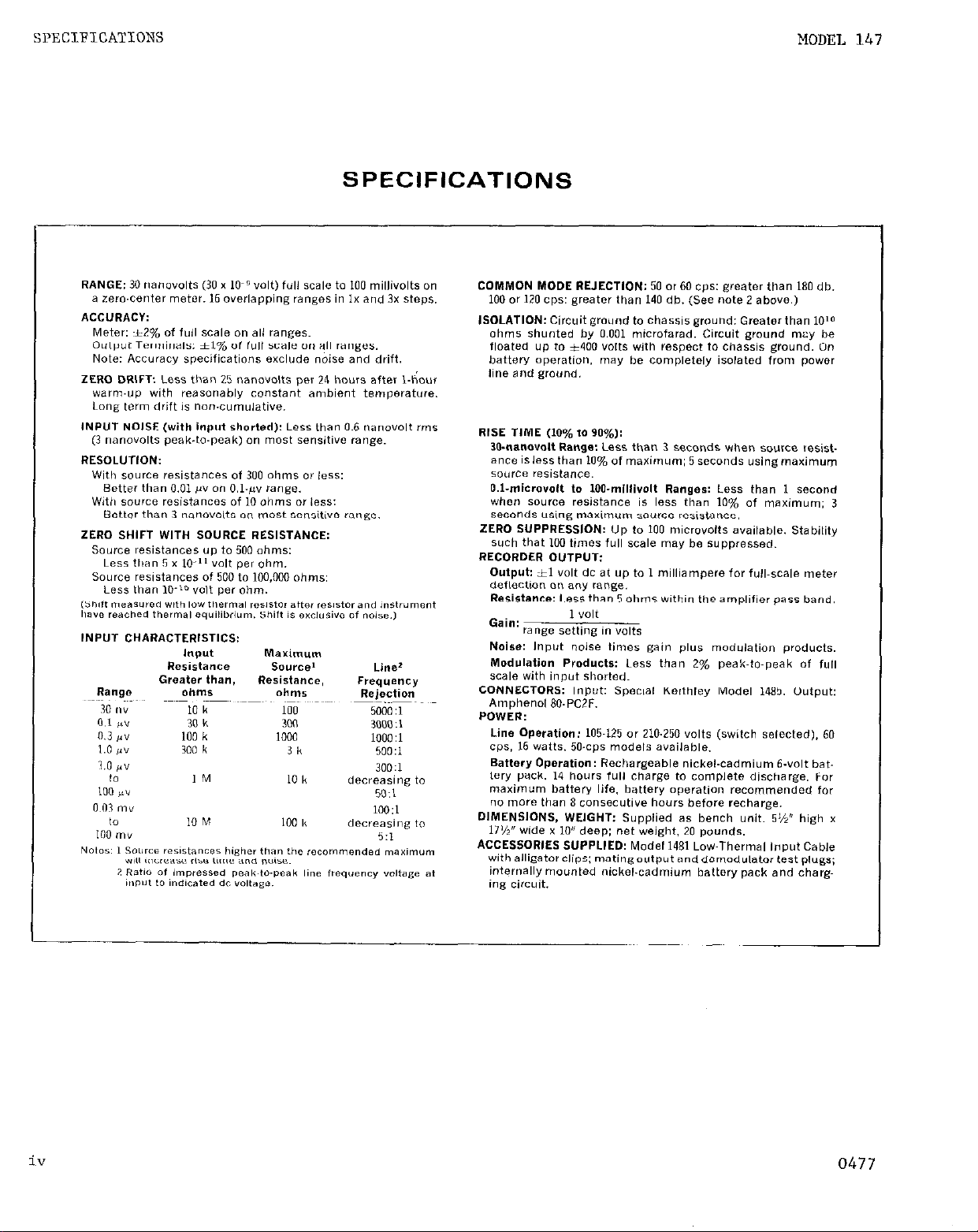

SPECIFICATIONS

iv

0477

Page 7

MODEL 147 NULL DETECTOR

GE:NLSAL DESCRIPTIOX

SECTION 1. GENERAL DESCRIPTION

l-1.

electronic null detector.

x

source resistance and 10 nanovolts with a

a power sensitivity of 3 x lo-21 watt.

GENERAL.

The Keithley Model 147 is designed specificaLly RS a col,vcnicnt self-contained dc

a.

Its sensitivity is 0.6 x LOT3 microvolt per mi.llimrter or 0.03

10-e

microampere per millimeter.

Its resolution is better tllnn 3 nanovolts with a LO-oll:il

300-ohm

source resistance.

This corresponds Lo

Zero shift is less than 15 nanovolts for sourcf

resistance changes from 0 to 300 ohms. Line frequency r~!jcction is better than 5OOO:l 011

its most sensitive range.

The Model 147 has 16 ranges from 30 nanovolts full scale to 1.00 millivolts on a

b.

zero-center meter. Meter accuracy is f2% of full scale on ~11 ranges.

For reliable and versatile use, the Null Detector is of solid-state design, cxccpi

c.

for the first two input stages. It has high line isolation - lOl(J ohms - and battery

or ac power line operation.

0572

FIGUPJ? La.

Front ,>anel,.

I

Page 8

GENERAL DESCRIPTION

MODEL 147

l-2.

grounding problems.

FEATURFS,

Battery operation permits complete isolation from ac power lines, eliminating many

a.

Battery operation also allows flexibility and convenience in use.

The Model 147 automatically recharges the battery if needed when the powercord is connected.

As an electronic null detector,

b.

the Model 147 is immune to mechanical vibrations.

It will also recover from a Z-volt overload on its inost sensitive range in less than 20

seconds.

c. Besides performing as a null detector, the Model 147 can also be used as a 2% direct-

reading nanovoltmeter.

The Null Detector has an output of ;tl volt at up to 1 milliampere for full-scale

d.

meter deflections to drive a recorder or oscilloscope. Output accuracy is ;tl% of full

SCSlS.

e. A zero suppression circuit,

furnishing up to 100 microvolts, permits measuring small

changes in a larger dc signal or compensating for thermal emf's.

l-3.

APPLICATIONS. (Also see Section 3.)

The Model 147 is designed specifically as a null detector. It has sufficient sensi-

a.

tivity to be used in most applications with all commercially available potentiometers, in-

cluding 6-dial models, ratio sets and resistance bridges, including Wenner, Wheatstone and

Kelvin Double Bridges. It can be used to make 4-terminal measurements.

Keithley's Model 147 is more sensitive than the finest galvanometer systems. It is

b.

also immune to mechanical vibrations,

thus eliminating the need for shock-free mountings.

Additional advantages over galvanometer systems'include the ability to recover from 2-volt

overloads in 20 seconds,

much less off-null loading, plus considerably faster speed of

response.

0572

Page 9

MODEL 147

CKNERAL DESCKIPTION

0572

Page 10

GENERAL DESCRIPTION MODEL 147

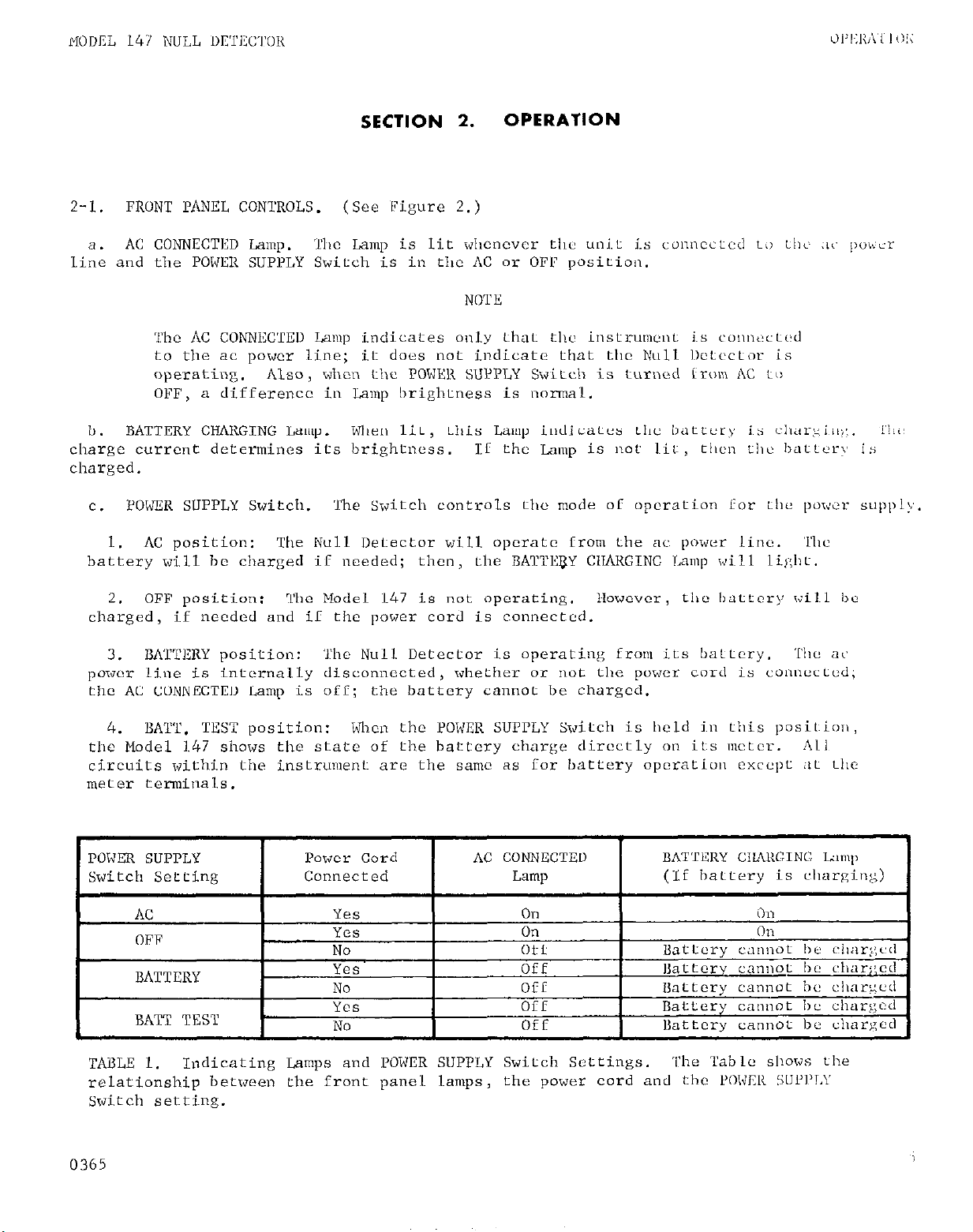

FIGURE 2. Front Panel Controls.

0572

Page 11

MODEL 147 NULL DlXI:C'l'OR

SECTION 2.

2-l.

line and the POWER SUPPLY Switch is in tile AC or OFF position,

charge current determines its brightness.

charged.

FRONT PANEL CONTROLS.

a. AC CONNECTI?D Lamp. l:hc Lamp is lit whcncvcr the unit is connected t0 i.lll xi. pwur

BATTERY CHARGING Lamp. When lit,

b.

POGJIZR SUPPLY Switch.

c.

AC position: The Null Detector will opcratc from the nc power Lint.

1.

battery will be charged if needed; then,

(See Figure 2.)

this Lanq indicates the ibattery ins clrnr:ini:.

Ihe Switch controls tlrc mode of opcratiori for tile powel- suppI!:.

OPERATION

NOTE

If the lamp is noi l~it,

the BATTEQY CIIARGINC Lamp will lil:ht.

tllc" LllC lbilCLtdl.\ ii

'TIIC

p1,:

OFF position:

2.

charged,

3.

power line is internally disconnected, whether or nut tile power cord is coluieclcd;

the AC CONNECTiXD Lamp is off; the battery cannot be charged.

4.

the Model I.47 shows the state of the battery charge directly on its mctcr.

circuits within the instrument are the same as for battery operation exccpl at Lllc

meter terminals.

POWER SUPPLY

Switch Setting Connected

if nccdcd and if the power cord is connected.

BATI'ERY position: The Null Detector is operating from its battery.

BATT. TEST position:

AC

OFF

BATTERY

BATT TEST

The Model 147 is not operating. Howcvcr ,

When the POWER SUPPLY Switch is held in this posil:ioii,

Power Cord AC CONNKTED

I

Yes

YCS

NO

Yes

NO

Yes

NO

Lamp

0”

On Oil

Off

Off

Off

Off

Off

I

tlic battery wil~l lbc

'I‘liC ni'

Al I

BATTERY CIIARGINC La"{'

(If battery is charging)

on

Battery CllnnOt bc cli;lr::c!d

Battfry cannot IbC char;:ed

Battery cannot hc chnr~cd

Battery can,,ot bc cllar~:cd

LIattcry cannot be charged

TABLE 1.

relationship between the front panel lamps,

Switch setting.

0365

Indicating Lamps and POWER SUPPLY Switch Settings.

The Table SllOWS tile

the power cord and the I'Oli'ER SUl'1~'I.Y

Page 12

OPERATION

MODEL 147 NULL DETECTOR

RANGE Switch.

d.

The RANGE Switch selects the full-scale meter sensitivity (either

microvolts or millivolts) for one of eight ranges, from 0.03

FUNCTION Switch.

e.

The FUNCTION Switch selects the function - MICROVOLTS or HILLI-

VOLTS - which is to be measured.

ZERO SUPPRESS Controls.

f.

The COARSE Control disconnects the suppression circuit (in OFF position) or

1.

Two controls determine

the

amount of zero suppression.

selects one of four suppression voltages in decade steps.

The FINE Control is a continuously variable adjustment for the suppression

2.

voltage set by the COARSE Control.

It adjusts the range between the positive and

negative values of the maximum voltage set by the COARSE Control.

INPUT Receptacle. The INPUT Receptacle is of a special low-thermal design.

g.

only the Models 14.81, 1482, 1486 and 1488 for mating connectors.

to

100.

Refer to Table 3.

Use

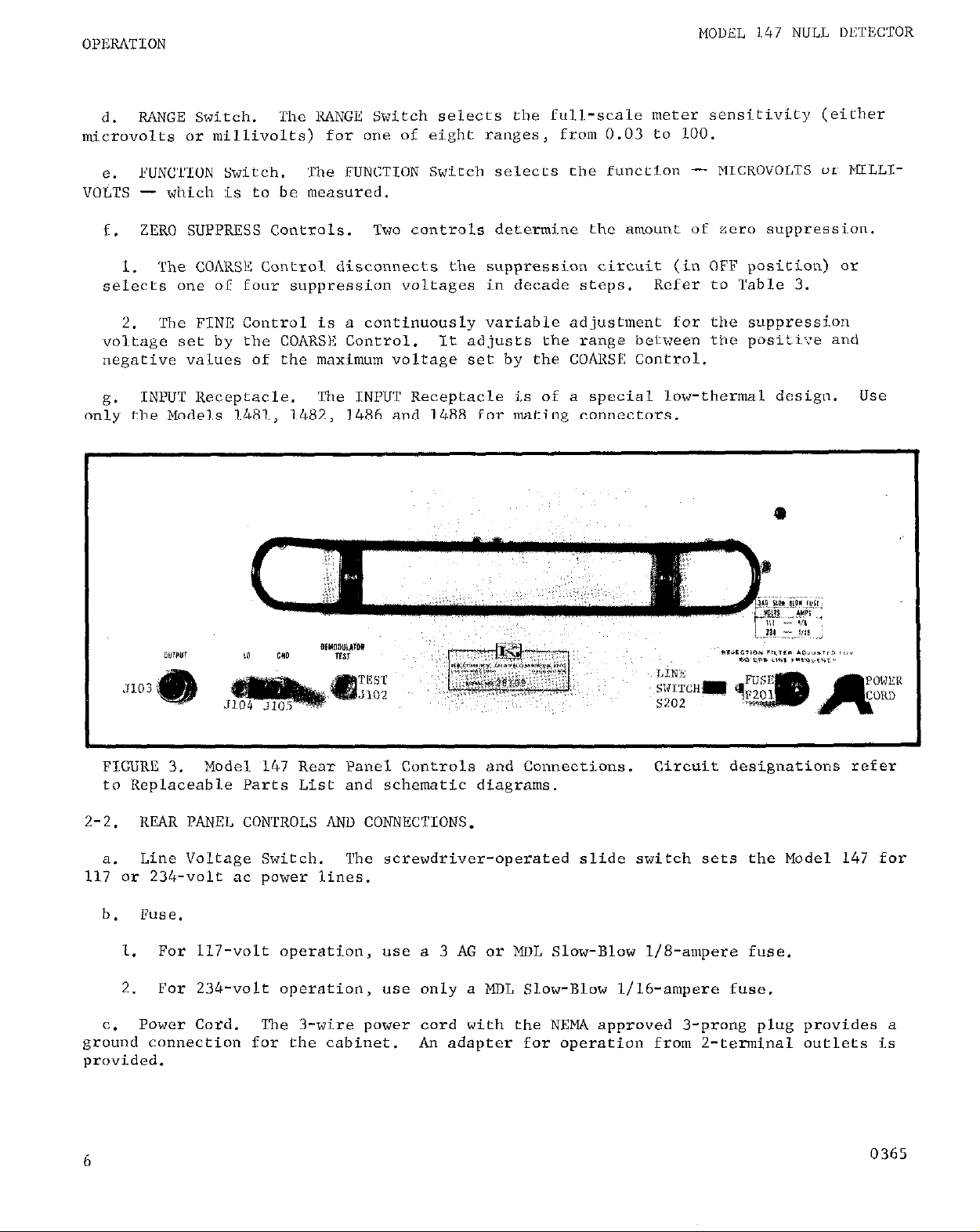

FIGURE 3.

Model 147 Rear Panel Controls and

to Replaceable Parts List and schematic diagrams.

2-2.

RTtiR PANEL CONTROLS AND CONNECTIONS.

Line Voltage Switch. The screwdriver-operated slide switch sets the Model 147 for

a.

117 or 234-volt ac power lines.

Fuse.

b.

For 117-volt operation, use a 3 AG or MDL Slow-Blow l/@ampere fuse.

2.

For 234-volt operation,

2.

Power Cord. The 3-wire power cord with the NEMA approved 3-prong plug provides a

c.

ground connection for the cabinet.

use only a MDL Slow-Blow l/16-ampere fuse.

An adapter for operation from Z-terminal outlets is

provided.

6

Connections.

Circuit designations refer

0365

Page 13

MODEL 1~47 NULL DETCC'TOR

A note above the power cord shows the ac power line i:rcqucncy for

which the rejection filter is ad.justcd. 'The instrument will work

at any line frequency from 50 t" 1000 cps,

at the indicated frequency.

filter circuit.

NOTE

but ac rejection is bcsc

Paragraph 2-18 dcscribcs adjustirl~; lilf

DEMODULATOR TEST Jack.

d.

A phone jack provides access to LllE denl"dLll~ator ior ti.5:

purposes.

f.

OUTPUT.

'The OUTPUT Rcceptaclc provides

iL

volt at

one! mill.iampcrc f:or a

iilll.-scale

meter deflection on any range.

GND and LO Tcrmiasls.

f.

third wire of the power cord.

'The ground terminal. (GND) i.s conncctcd to tllc chassis ;~II)~! ! 1)~.

The low terminal is connected t" circui.t ground and cl!&:

low side of the input connection.

2-3.

MODE 01: OPERATION.

battery. b-or illost "SfS,

the ac power line will create ground loop or isolation problems.

The Model 147 operates cithfr irom an ac power line or irom iis

it functions well from ac. Use battary operation, llo~ifver, i~1~

1solnfi"n irun low to

ground is complete for battery operation when tllc power cord is disconnccl:cd; i,t is

greater than lOlo ohms wit11 the power cord connected.

Al.so use battery operntiiln it>

reduce the 8-cps ripple which may appear at the output with i-11" input shorted in i&c

operation.

See paragraph Z-16.

NOTE

Before using the battery operation, tll"r"ugllly read paragraph 2-4.

Improper battery "pcration can damage the battery pack and lead to

inaccurate measurements.

2-4. UXTERY OPERATION.

The Model 1.47 is supplied with a rcchargcablc h-volt,

ba:tery pack (Model 1489).

Recommended:

secutive hours without recharging.

Do n"t usf the battery more tlliln cigirt COII-

At this discharge rate,

4 ampere-ilour Iliclr~l-~~l(llnilIr!l

the battery sl10u1d last abOUt

1000 recharge cycles.

NOTE

Permanent damage to the battery pack occurs if it is used for more

than 16 consecutive hours without recharging.

rate, the recharge cycles are greatly reduced.

Model 147,

Cheek the battery charge before making a measurement.

b.

in the BATT. TEST position.

check the state of the battery charge.

The minimum acceptable charge is a meter indi.cntion oi ,8;

full. charge is shown by the BATTERY CHARGING Lamp not being lit.

At this discharge

Bflorf usi~ng tile

Hold the POWER SUPl'LY Switch

Recharge il needed.

Otherwise, battery operation is the same as for the ac power line operating mode; rcI:cr

to paragraph 2-5.

0365

Page 14

OPERATION

When the battery is used beyond its capacity, two effects aye seen.

There is a shift in zero offset from ac to battery operation.

the power supplies do not regulate and high ripple voltages appear

at the supply outputs.

MODEL 147 NULL DETECTOR

Also,

(See paragraph 5-8.)

To recharge the battery,

c.

POWER SUPPLY Switch to AC or OFF.

be charged only if needed, and the circuit automatically prevents it from being overcharged.

It is suggested that the battery be used during the day and be recharged at night.

d.

Leave the instrument always connected to the ac power line; then turn the POWEK SUPPLY

Switch to OFF at night. After a fully charged battery is used for eight consecutive

hours ) it will recharge within 16 hours.

effect on the isolation: 1010 ohms with the POWER SUPPLY Switch in BATTERY position and

the shorting link between GND and LO Te?.minals disconnected.

2-5. OPERATING PROCEDURES,

Set the front panel controls as follows:

a.

POWER SUPPLY Switch

FUNCTION Switch

RANGE Switch

ZERO SUPPRESS COARSE Control

Make sure the ZERO SUPPRESS COARSE Control if OFF. If it is not, a

suppression voltage is introduced, causing an error in measurements.

connect the power cord to an ac power line.

The BATTERY CHARGING Lamp will light.

Leaving the power cord connected has little

OFF

MILLIVOLTS

100

OFF

NOTE

Turn the

The battery will

Connect the voltage swrce or null circuit to the INPUT Receptacle.

b.

graph 2-6 for suggestions.

Check the voltage shown on the rear panel Line Voltage Switch; connect the Model 147

c.

to the ac pcwer line. Make sure the frequency shown above the power cord is the frequency

of the ac power line. At this point, the AC CONNECTED Lamp will light, asp will the

BATTERY CHARGING Lamp if the battery is being charged. If the circuit low is to be at

ground, put the shorting link between the LO and GND posts on the rear panel.

Turn the POWER SUPPLY Switch to the desired mode of operation, AC or BATTERY.

d.

Increase the Model 147 sensitivity until the meter shows the greatest on-scale de-

e.

flection.

1. Check the source resistance to make sure it is within the maximum value specified

for the range being used.

sitive ranges is exceeded, the Model 147 may not measure within its specifications.

2. Zero offsets seen when the Zero Suppress Controls are off will vary with the

quality of the circuit's thermal construction,

Shorting Plug is connected to the Model 147 INPUT Receptacle, offset should be less

than 0.3 microvolt.

8

(See Table 2.)

If the maximum resistance for the more sen-

See paragraph Z-14. When a Model 1488

Refer tO para-

046613

Page 15

Page 16

OP1:llATION MODEL I,47 NULL I1lYl'ECTOR

Make sure the signal is greater than Johnson noise in the source resistance (par-

1, ,

agraph 2-12 ).

2. Use materials which generate a low thermal emL (paragraph 2-14).

3. Mini.mize temperature changes and thermal gradients (paragraph Z-14).

4 Reduce magnetically induced signals by proper shielding and minimizing experimen-

tal layout area (paragraph 2-15).

5. Eliminate ground loops through proper grounding and connection to the signal cir-

cuit (paragraph 2-16).

2-6.

14~7 input is with the Model 1481 Low-Thermal Input Cable,

mcnt Use tile Cable for temporary setups,

for measurements at several points, and

when fast connections are needed.

del 148~1 connects directly to the INPUT

1~eceptacl.e.

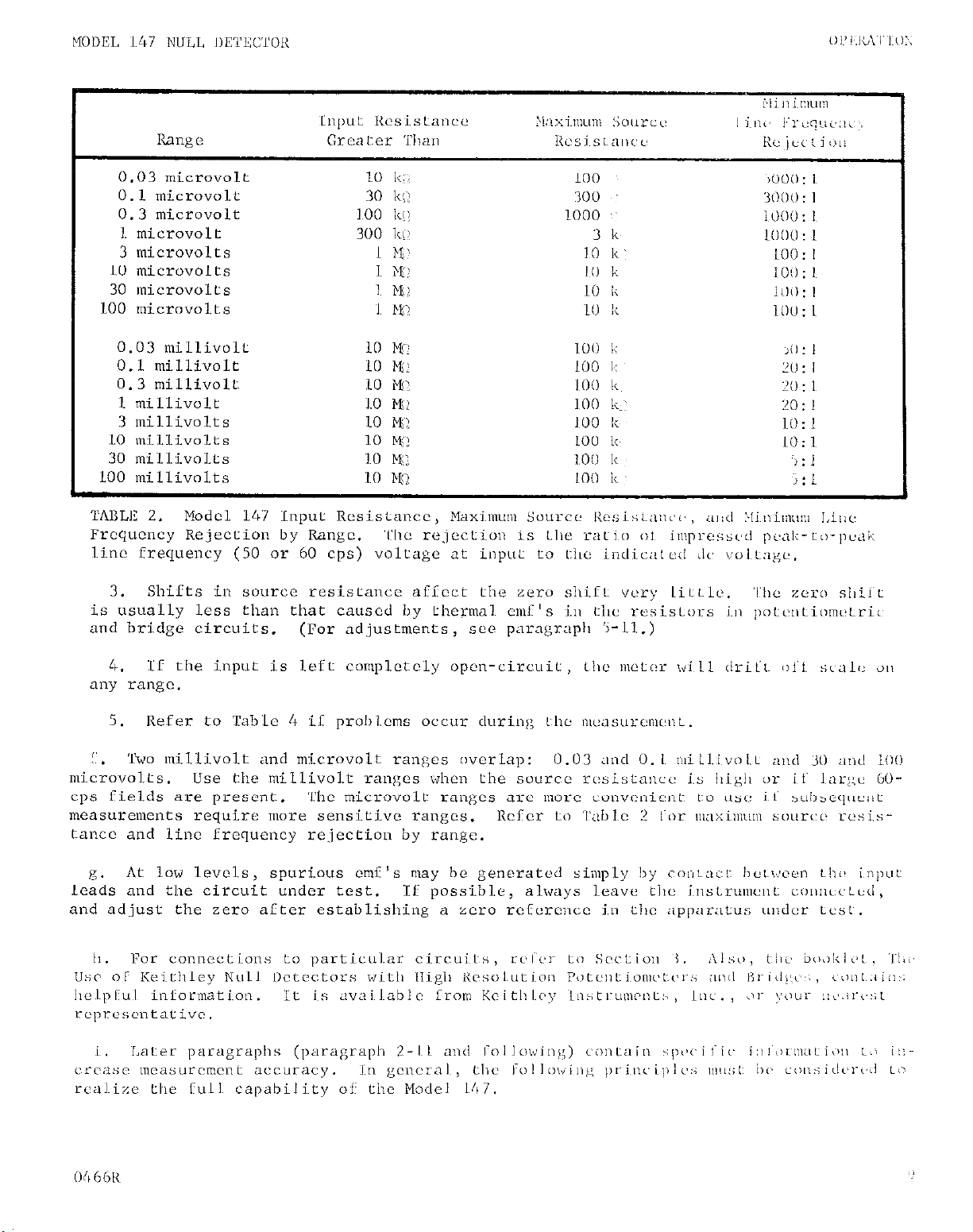

sible or where very Sow thermal connections FIGUKC 4. Model 1481 Low-Thermal Input

arc needed, use the Model 1482 Low-Thermal Cable.

Input Cable.

1481 ,

stead of nl,ligator clips. Clean the bare

wire! width a non-metallic abrasive, such as

Scotch Isrite, before making the connection.

illc> Model 1483 Kit, is best.

iron used is clean and that it has not been used with regular solder before.

LOW-THEIMAL INPUT CONNECTIONS.

a Tlie easiest connection to the Model

supplied with the instru-

The Mo-

b. Where more permanent setups are pos-

'The Model 11+82 Low-Thermal Input

It is similar to the Model

except it leas bare copper leads in- leads instead of alligator clips.

('. Si cadmium solder (Model 1503) is used for a connection, make sure the soldering

Cable is similar except it has bare copper

Making crimp connections, as possible with

USC only

rosin solder flux. If possible, heat sink

all cadmium-soldered joints together to reduce generated thermal emf's.

techniques will keep thermal emf's below

0.1 microvolt.

Careful

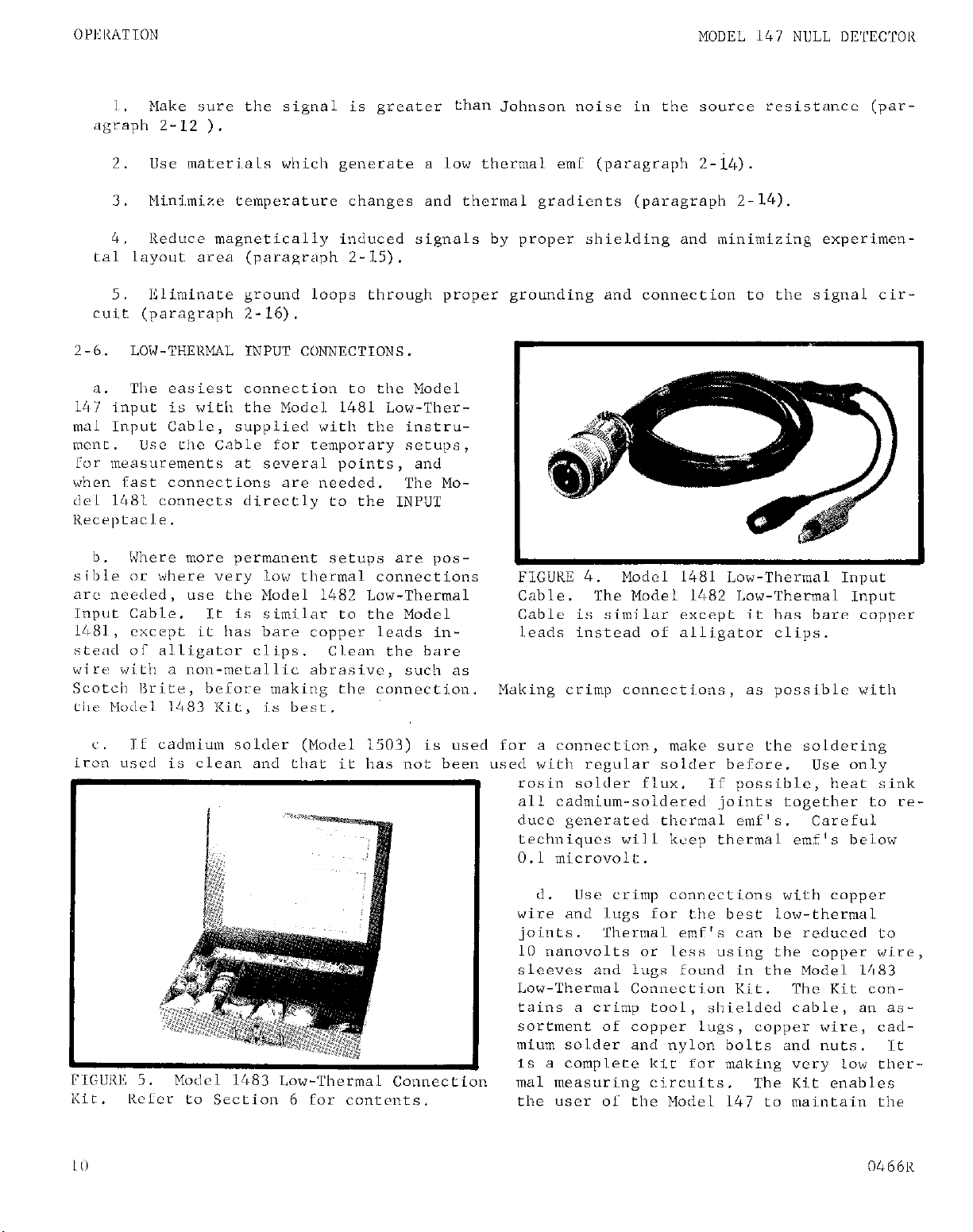

I'LCUIW 5 .

K in t .

lieTcr to Section 6 for contents.

Model 1483 Low-Thermal Connecti

d. Use crimp connections with copper

wire and lugs for the best low-thermal

joints.

10 nanovolts or less using the copper wire,

sleeves and Lugs found in the Model 1483

Low-Thermal Connection Kit.

tains a crimp tool, shielded cable, an assortment of copper lugs, copper wire, cad-

mium solder and nylon bolts and nuts.

is a complete kit for making very low ther-

mal measuring circuits.

the user 011 the Model 147 to maintain the

Thermal emf's can be reduced to

The Kit con-

It

The Kit enables

0466K

Page 17

Page 18

OPERATION

MODEL 14,7 NULL DETECTOR

2-8.

line ground.

2-9.

range is $1 volt at 1 milliampere.

less than 5 ohms within the amplifier pass band.. Output may be used during both ac and

battery operation. If the Model 147 is used for differential measurements, do not ground

the recorder connected to the output.

FMATING OPERATION.

The Model 147 can be connected between two potentials,

a.

It can be floated up to ?4,00 volts off ground.

CAUTION

The front panel controls are electrically connected to the case.

power cord is unplugged,

ground voltage. use necessary e precautions.

For best results with floating operation, follow the steps below:

b.

Remove the shorting link from the LO or GND Post on the rear panel.

1.

Connect the input circuit to the Null Detector.

2.

2-5.

wfth this operation, since the low of the Model 14,7 output is no longer grounded.

better results.

The zero suppress controls may also be used.

If power line frequency pickup is a problem,

3.

KECORDER OUTPUT.

-

The Null Detector output for a full-scale meter deflection on any

the case may be at a voltage equal

Do not ground any recorders used

battery operation usually provides

Accuracy is ?I% of full scale. Output resistance is

neither of which is at power

If the

to

the off-

Operate as described in paragraph

Model 147

P

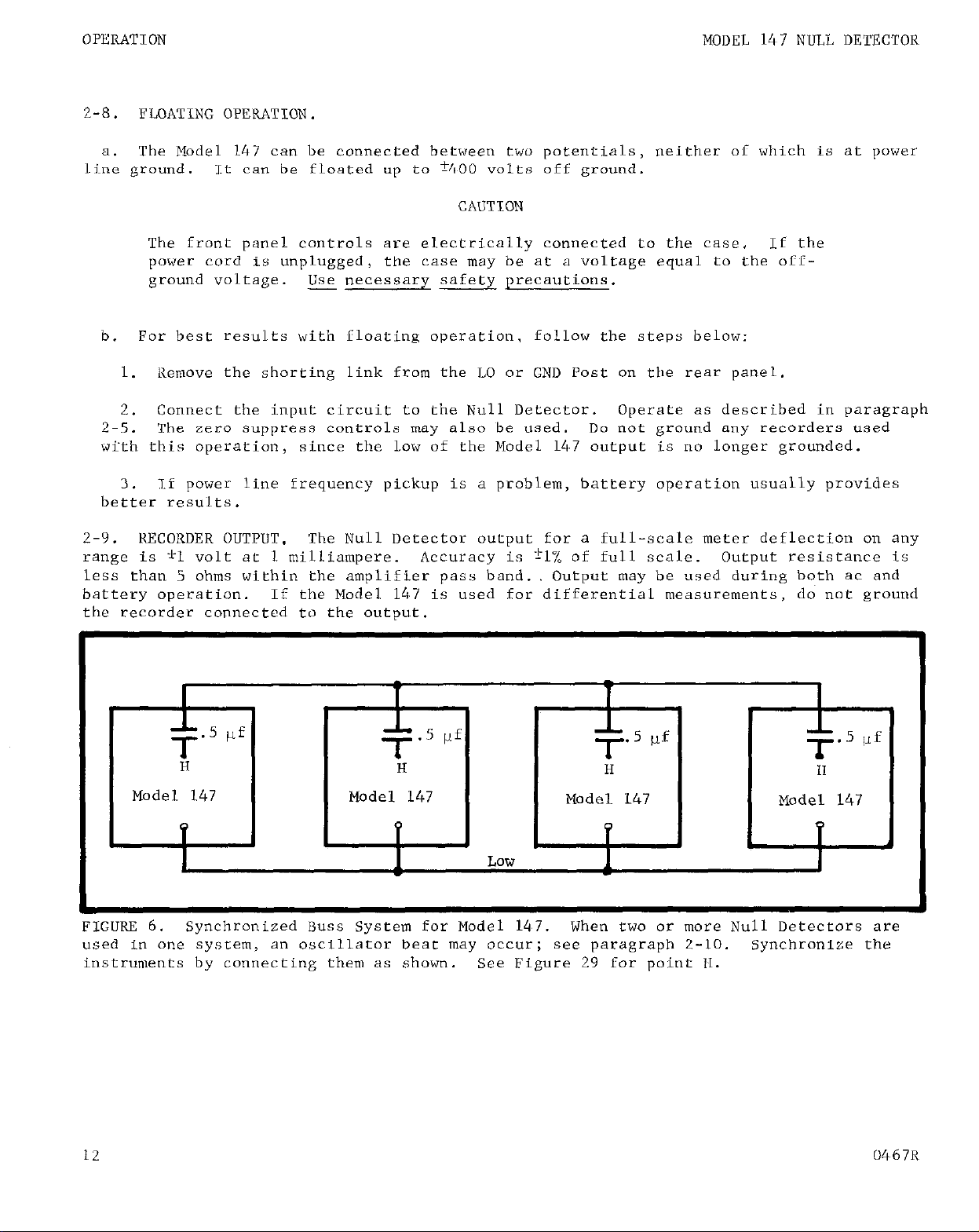

FlGURF 6. Synchronized Buss System for Model 14,7.

used in one system, an oscillator beat may occur; see paragraph 2-10.

instruments by connecting them as shown.

12

Model 147

V

Model 147 Model 147

v

LOW

When two or m"re Null Detectors are

See Figure 29 for point II.

b

4

Synchronize the

P

4

1

04,67R

Page 19

MODEL 1.47 NULL DETECTOR

2-10. USING MOIW THAN ONE MODEL 147 IN A SYSTEM.

The Model 1.47 oscillator is adjusted for a nominal freqnency ol 94 cps. ,,Oi.!i~VC~1 ~

a.

slight variations in frcqucncy do occur between models.

tectors in one system,

an oscillator beat may occur.

Wl,en using two or ,morc Xill I ill

Synchronizing oscillators

b.

"ents together at the collector of transistor (219 (Figure 29, Ipoint II), using iii: O.'i"icro.farad myl.ar capacitor.

At times the system is suc11 that the Null Detector lows may not bc conncctc~! di~-~~~t-

c.

ly together.

instruments. A IlO-volt,

farad isolation capacitor in seri~es with iboth pri~mary and secondary wi~ndin~s o! C!IE i~~:i,i::former.

For several Null Detectors connected together, l,sc a synct,r"ni~zcil bliss :;ysli'T!, :iii

d.

shown in Figure 6.

2-11.

other considerations beside tile instrument affect accuracy.

working with higher voltages are very important with mi~crovolt signals.

reads only the signal received at its input; tllcrciorc, it is i~mportant tllat this signal

be properly transmitted from the source.

affect accuracy: thermaI noise

connections.

ACCURACY CONSIDERATIONS. For sensitive measurcmcnts -

Then,

'Table 4 also offers a quick rcfcrence to correct troubles wllich may occ11r.

use a 1:l transformer havi~ng a fairly higil impedance between tllc Cvil

low power isolation transformer works wit.

prevents an objectionable beat. Connect tllc! cwc in:,t iii-

USC n 0..5-:nicr<v

10 mi~llivolts and bt~1lbi.x -

i:l:Ifcts not Iroticcnblc ,.i'!len

Tl,c, ~lodel vi 7

The fol,i~owing paragraphs indi~cate iactor xiii c:.

, input resistance, thermal emi's,

shi~cldilll: iin<l (. il(.l.: *

1. The thermal noi~sc in any ideal resistance can bc dctarmi~ned Srom tiic Joi~nson !~rlis~'

equation:

EZ",, =

where Erms is the rms noise voltage developed across the voltage source;

T is tile temperature in degrees Kelvin;

R is the source resistance in ohms;

F is the ampl~ificr bandwidth in cps;

k is the Boltzmann constant (1.38 x 10e23 joules / OK).

yor an ideal resistance at room temperature (3OO*K), equation 1 simplilics to

Ii,",

Peak-to-peak meter indi.cations are of "ore interest than tlrc rms vaiuc.

2.

mentally,

temperature, equation 2 becomes

where 13

0477

the peak-to-peak Johnson noi.se is about live times the rms value. At r<10111

EPP

is the peak-to-peak noise voltage developed across tile voltag" source.

PP

4 I< T 11 I; 1:q I

= 1.29 x lo-lo (RF)1'2 xi,

i:xpcri -

= 6.45 x 10-l' (RF)"' I:<,

Page 20

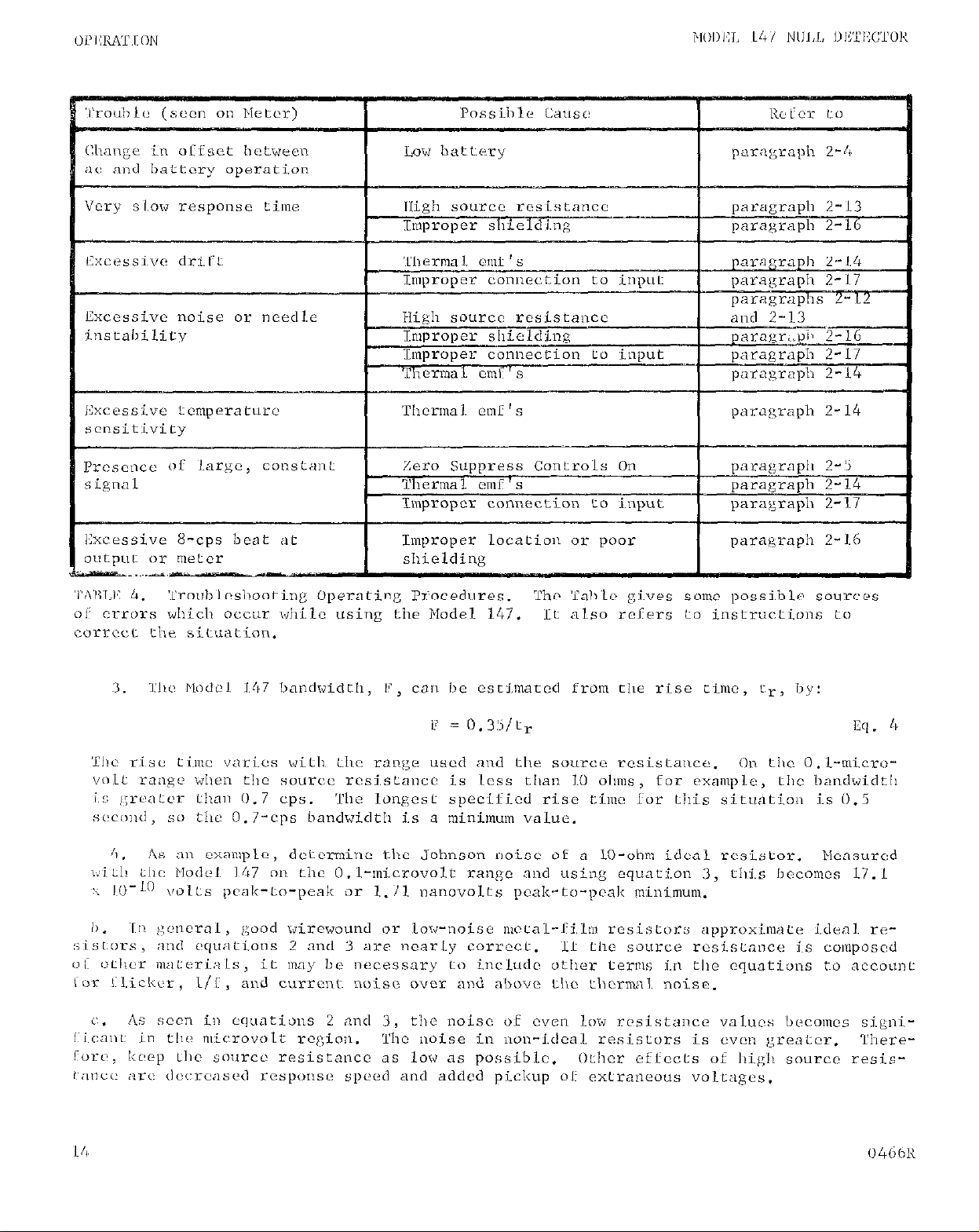

Very slow response time

Page 21

MODEL 147 NULL DETECTOR

2-13. INPUT RESISTANCE.

obtained using high feedback factors.

physical input resistance is partially destroyed.

exceed the maximum source resistance listed in Table 2.

but noise, offsets,

ranges, the maximum specified source resistance is consistent with Johnson noise considcrations.

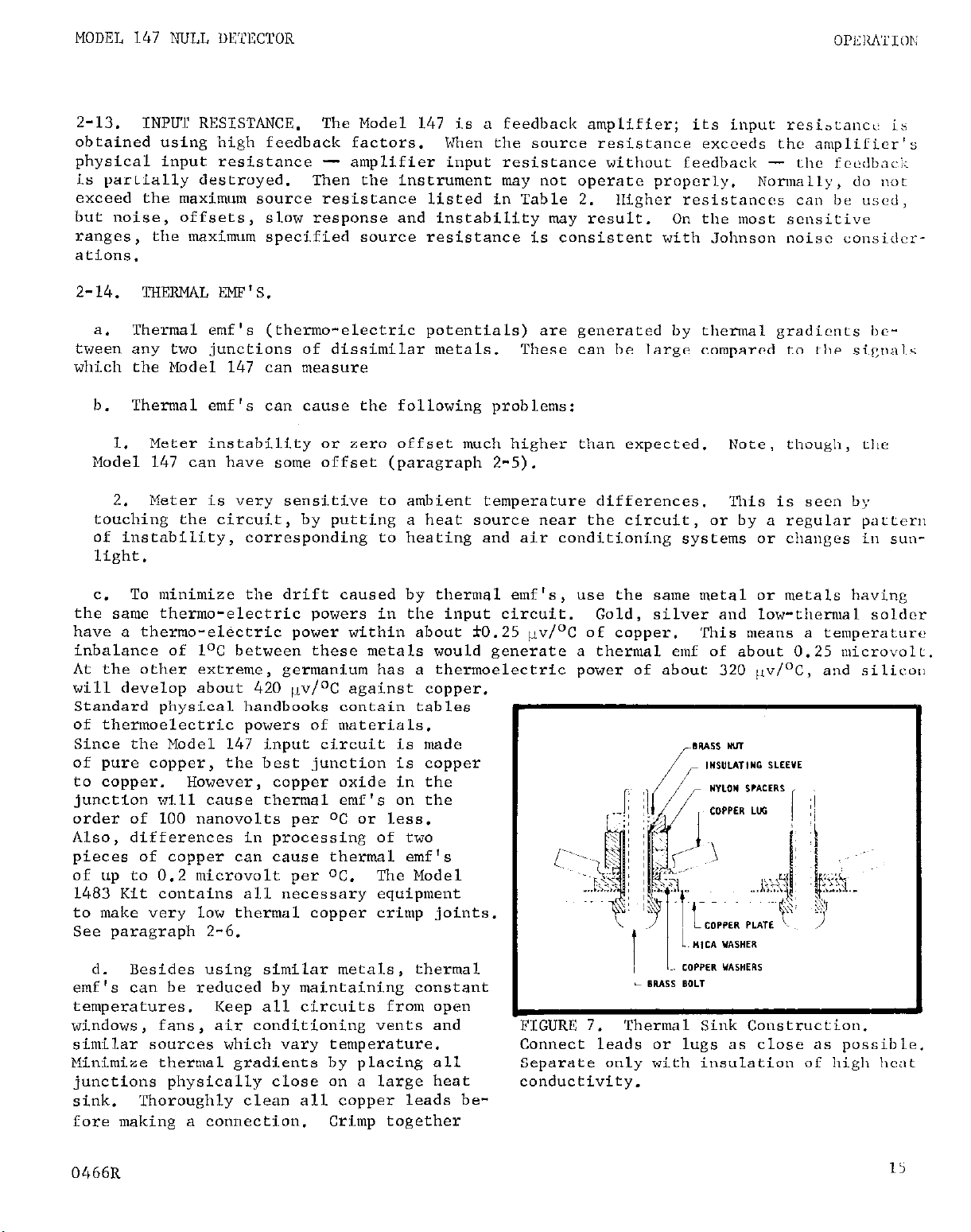

2-14.

a.

tween any two junctions of dissimilar metals.

which the Model 147 can measure

b.

Model 147 can have some offset (paragraph 2-5).

touching the circuit, by putting a heat source near the circuit, or by a regular piliter,,

of instability,

light,

THERMAL EMF'S.

Thermal emf's (thermo-electric potentials) are generated by thermal gradients Ihe-

Thermal emf's can cause the following problems:

Meter instability or zero offset much higher than expected.

1.

Meter is very sensitive to ambient temperature differences.

2.

slow response and instability may result.

corresponding to heating and air conditioning systems or changes in sun-

The Model 147 is a feedback amplifier;

When the source resistance exceeds the amplifier's

amplifier input resistance without feedback - the fecdbacl;

Then the instrument may not operate properly.

Iligher resistances can be used,

These can be large compared to the si!;nals

its input resia:nnc<. is

Normally, do not

On the most sensitive

Note, thougll, the

T%is is seen by

To minimize the drift caused by thermal emf's,

c.

the same thermo-electric powers in the input circuit.

have o thermo-electric power within about f0.25 ,rv/oC of copper.

inbalance of 1oC between these metals would generate a thermal emf of about 0.25 microvolt

At the other extreme, germanium has a thermoelectric power of about 320 ,iv/oC, and silicon

will develop about 420 jrv/% against copper.

Standard physical handbooks contain tables

of thermoelectric powers of materials.

Since the Model 147 input circuit is made

of pure copper, the best junction is copper

to copper. HOWeVer, copper oxide in the

junction will cause thermal emf's on the

order of 100 nanovolts per oC or less.

Also, differences in processing of two

pieces of copper can cause thermal emf's

of up to 0.2 microvolt per OC. The Model

1483 Kit contains all necessary equipment

to make very low thermal copper crimp joints.

See paragraph 2-6.

Besides using similar metals, thermal

d.

emf's can be reduced by maintaining constant

temperatures, Keep all circuits from open

windows, fans,

similar sources which vary temperature. Connect leads or lugs as close as possible.

Minimize thermal gradients by placing all Separate only with insulation of high heat

junctions physically close on a large heat conductivity.

sink.

fore making a connection.

Thoroughly clean all copper leads be-

air conditioning vents and

Crimp together

FIGURI? 7.

use the same metal or metals having

Gold, silver and low-thermal soldcr

This means a temperature

COPPER "AI"ERI

L Bw.II BOLT

Thermal Sink Construction.

1S

Page 22

OPERATION

MODEL 147 NULL DETECTOR

the ends of each copper wire;

bolt the lugs for each connection point together; mount all

stacks of lugs on a thick metal plate having high thermal conductivity. Thermal conductivity between the junctions and the heat sink can be kept at a high level by using mica

washers or high conductivity ceramics for electrical insulation.

Several other techniques will reduce the effects of thermal emf's.

e.

suppression circuit to buckout constant voltages.

If connections must be soldered, use

only cadmium-tin low-thermal solder, such as supplied in the Model 1483 Kit.

metals -

including regular solder -

well-controlled oil bath or a good heat sink is used.

may be used and low thermal emf's obtained if a

Thermal voltages may be calculated

Use the zero

Unlike

from the thermoelectric power of the materials in the junction and the possible temperature difference between the junctions.

z-15.

conductor can produce large signals compared to the instrument's sensitivity.

MAGNETIC SHIELDING.

a. In the

Low

resistance

circuitry

used with the Model 147, magnetic

Lines

cutting a

The amount

of signal developed is proportional to the area enclosed by the circuit and the rate of

change of magnetic flux. For example, motion of a 3-inch diameter Loop in the earth's

magnetic field will induce a signal of several tenths of a microvolt.

size of the Loop or moving it more rapidly will increase the signal.

Increasing the

Magnetic fields

from ac power lines will cause even more difficulty.

To reduce the effect of magnetic fields, use magnetic shielding. Where high ac

b.

magnetic fields are present, it may be necessary to magnetically shield the measuring

circuit , the unknown emf circuit or auxiliary equipment in the circuit. Magnetic shielding is available from

several

companies in the form of plates, foil or cable.

Twist input leads to minimize the area enclosed by the circuit loop,

c.

experimental Layout for minimum enclosed area is also of particular

Z-16.

a.

AC SHIELDING.

Due to its narrow bandwidth, the Model 147 is somewhat insensitive to ac voltages

value.

Planning the

superimposed upon a dc signal at the input terminals. However, ac voltages which are

large compared with the dc signal may drive the Model 147 ac amplifier into saturation,

erroneously producing a dc output at the demodulator.

Usually it is sufficient to connect

the cases of all apparatus in the measurement circuit together and ground at one point.

This provides a "tree" configuration, which minimizes ground

which all shields are connected should be as near as possible

Loops.

to

The common point at

the

circuit

ground of the

Null Detector at its input.

Improper shielding can cause the Model 147 to react in one or more of the following

b.

ways :

Needle jitter or instability,

1.

High offset (dc bias). Changing the power cord polarity or the connection between

2.

from 10% to 20% of full scale.

the LO and GND Posts may affect the amount of offset.

Slow response time, sluggish action and/or inconsistent readings between ranges.

3.

Amplifier saturation. Observe the wave form with an oscilloscope connected to the

4.

DEMODULATOR TEST Jack (Figure 3).

With the input shorted, it should approximate the

16

0466R

Page 23

MODEL 147 NULL DETiXTOR

----~

FIGURE 8. Normal Wave Form at Demodulator

with Input Shorted. Scale is 0.1 v/cm

vertical and 10 msec/cm horizontal.

o?'I:I?A'TION

wave form shown in Figure 8. If excessive pickup occurs, the wave Lorm will reseml,le

that of Figure 9.

The circuit will operate reasonably well as long as the wave form is

not clipped, as shown in Figure 10. At this point a dc offset is introduced.

To minimize pickup, keep the circuit away from ac sources. Shield as carcfullp as

c.

possible. Connect all shields together at the low side of the input or at the LO Terminal,

The voltage induced due to a magnetic flux is proportional to the arca of the loop. 'ThCSk-

fore, minimize loop arcas in the shield connections as

nect

the shield at only one point. Run all wires in the circuit along the same path, so

well as the

input circuitry.

CO,,-

the loop area is only the small difference in position of two adjacent wires.

Strong third harmonic magnetic fields - 180 cps for 60-cps units - may create an

d.

8-cps beat

possible nearby sources, such as heavy-duty transformers.

measuring circuit as far as possible from the magnetic field.

at

the Null Detector output and meter. To reduce this effect, turn off all

Remove the Node1 147 and the

If removal does not greatly

reduce the beat, magnetic as well as electrostatic shielding around the circuit ~nlny be

necessary,

For information concerning your particular shielding problem, contact Pcrl:cc-

tion Mica Corp., 1322 North Elston Street, Chicago, Illinois.

The 8-cps beat will be more apparent at the output terminals, since the meter is

e.

filtered. To minimize the beat,

USC the filter circuit shown in Figure 11.

the Null Detector's l-volt output at Eull scale to 10 millivolts.

duced by a factor of 1O:l.

If the 330 microfarads is objectionably large, increase rhc

resistor sizes by 10 times and use a 33-microfarad capacitor.

The 8-cps beat is re-

Since the recorder outpu;

This divides

0466R

Ii

Page 24

'OPERATION

is now only 10 millivolts, a non-polar capacitor is not necessary.

The Model 147 line frequency rejec-

f.

tion refers to the total ac voltage appearing at the input terminals, Therefore, the

Null Detector is affected by the sum of the

ripple in the working standard and the unknown source. Because of this, working

standards having high ac ripple components

will significantly reduce the amount of ac

voltage which may be tolerated in the unknown.

Model

147

MODEL 147 NULL DETECTOR

Shielding is preferable to input fil- FIGURE 11.

g.

ters. Resistive-capacitive filters add corder Output. If~tha 8-cps beat disturbs

noise (equation 1), and the resistance value the measurements, this circuit will reduce

must be subtracted from the maximum source the beat 1O:l.

resistance in Table 2. Inductive-capacitive

filters rend to create loop instabilities

within the Null Detector. Capacity alone across the input, however, is less Likely to

cause Loop instabilities,

2-17.

a.

cal connections will have on the potential being measured. IR drops, which in most circuits are insignificant, now become important.

a resistance of approximately 10 milliohms per foot.

6-inch length of this wire will produce five microvolts.

volt would mean using a wire 0.0006 inch long.

b.

be used to eliminate this error. Refer

to Figure 12.

c.

the zero suppress may be used to nullify

the voltage.

d.

the measuring system fluctuate, they will

develop fluctuating voltages which will

appear as noise or drift in the system.

CIRCUIT CONNECTIONS.

When measuring in the microvolt and nanovolt regions,

Four-terminal connections can often

If an unwanted IR drop is constant,

If the currents or resistances in

and it may be used to filter ac components in some cases.

For example, No. 20 AWG copper wire has

A l-milliampere current through a

FIGURE 12.

Connections.

8-cps Filter Circuit for Re-

consider the effect the physi-

To reduce this drop to 0.5 nano-

Current

3

Using Model 147 with 4-Terminal

Leads

Model 147

Leads

ii

t

2-18.

a.

Switch on the back panel (Figure 3).

Use only 250~volt MDL fuses.

b.

The Model 147 can operate satisfactorily from 60 or 50-cps sources, but the best ac re-

jection is achieved when the filter is set for the line frequency.

OPERATING FROM SOURCE OTHER THAN 117 VOLT, 60 CPS.

If the ac power source is 234 volts,

No other adjustment is necessary.

For 50-cps ac pave-s sources,

change the sideband filter capacitors, CL03 and C104.

use a screwdriver to change the Line Voltage

Change the fuse from l/8 ampere to l/16 ampere.

Use Keithley part

Page 25

MODEL 1.47 NULL DI:TL':CTOR

ClOS-.109M (C103) and C45-.0155M (C104) for 50 cps.

Refer t" Figure 32 for compon<!nt III-

cation.

2-19. RACK MOUNTING. (See Figure 13.)

The Model 147 is shipped for bench use with four

a.

feet

and a tilt-bail.

'i'hC :~i"dcl

4002 Rack Mounting Kit c"nverts the instrument t" rack mounting t" the standard i:I,\ (RL<I?-L\)

19-inch width.

To convert the Model 147, rem"vf the four screws at the bottom ot each sidii "1 t!~<!

b.

instrument case.

Lift off the top cover assembly with

To rem"ve the feet and tilt bail from the bottom cover assembly,

Item

(See Fig. 13) Description

1 cover Assembly

the

handles;

save c11e four SCi-fi”S.

turn the two scr(ii.:s Il<'ilT

Keithlcy

Part

No.

17162C

Qunntit!

I

2 Cover Assembly, Bottom (Supplied with

Model 147)

3

4

Angle, Rack

Screw, Slotted, lo-32 UNC-2x1/4 (Supplied

with Model 147)

5 Front Panel (Supplied with Model 147)

176950 1.

1462413

7

--4

---

1

TABLE 5. Parts List for Model 4002 Rack Mounting Kit.

@SCREW

/

i(j)FR PANEL

IGURE 13.

0466R

Exploded View for Rack Mounting,

Using Model 4002 Rack Mounting Kit.

19

Page 26

Ur'Diu~LUN

MODEL 147 NULL DETECTOR

the back.

The two pawl-type fasteners will release the cover and allow it to drop off.

Remove the feet and the tilt bail and replace the cover (2).

c. Attach the pair of rack angles (3) to the cabinet with the four screws (4) previously

removed. Insert the top cover assembly (1) in place and fasten to the chassis with the

two pawl-type fasteners at the rear.

Store the top cover with handles, feet and tilt-

bail for future use.

20

0466R

Page 27

MODEL 147 NULL DETECTOR

APPLICATIONS

SECTION 3.

3-l. GENERAL.

meters in null circuits, These are just samples of the circuits available and they do

not exhaust all the possible circuits. The setups which follow demonstrate how the Elodel

147 may be used.

3-2. WORKING SOURCES.

tage increment available on 6-dial potentiometers.

a stable battery working source with the potentiometer,

are generally limited by several inherent problems - instability, short-term noise of

several microwIts, pocr line regulation, and several millivolts of ripple,

ripple may produce dc voltage due to a slight rectifying action at connection points and

switch contacts. Also, working sources having high ac ripple components will significant-

ly reduce the amount of ac voltage which may be tolerated in the unknown. This is because the sc rejection of the Model 147 refers to the total ac voltage appearing at its

input terminals, and, therefore, is affected by the sum of the ripple voltages in the working BOUWB and the unknown source.

Follow the operating instructions in Section 2.

p~oints brought up in paragraph 2-11 and following,

ThFs section contains dfagrams using the Model 147 with various potentio-

The Model 147 permits resolution compatable with the smallest vol-

APPLICATIONS

When working at this resolutton, use

Line-operated working sources

This hig!I

NOTE

Pay particular attention to the

FIGURE 14.

KElTHLEY MODEL 147

POTENTIOMETER

Circuit Using Guildline 9144 with Keithley Model 147 Null Detector.

.-

GUILDLINE 9144

0466R

21

Page 28

AH'LICATIONS

MODEL 147 NULL DETECTOR

KEITHLEY MODEL 147

GUILDLINE 436301.

POTENTlOMETER

FIGURE 15.

Circuit Using Guildline 4363DL with Keithley Model 147 Null Detector.

KEITHLEY MODEL 147

“NXHOYH

GUlL DL /NE 9120

EYF

POTENT/OMETER

FIGURE 16. Circuit Using Guildline 9120 with Keithley Model 147 Null Detector.

22

0466

Page 29

MODEL 147 NULL DI:TIICTOR

Al?PI.ICATLoNS

FIGURE 17. Circuit Using Riddle 605001 with Keithley Model 147 Null Detector.

KEITHLEY MODEL /47

I

?

STD. CELL

em

000

r;;ir, isl

LttN 7556

POTENTlOMETER

,

FIGURE 18. Circuit Using Leeds & Northrup 7556 with Keithlcy Model 147 Null Ljctcctor.

1466

23

Page 30

APPLICATIONS

KEITHLEY MODEL 147

r

1

ITl I

D.C. GENERATOR ‘8 6 6

999

1 KELVlN RATIO BRIDGE p 0 1

I PPP,

I I

q’ ’

DETECTOR BOOR

ES./. 240

RESISTANCE

STANDARD RS 925

SD P

IO

80

f0

*ID 0

MODEL 147 NULL DETECTOR

24

0466

Page 31

MODEL 147 NULL DETKTOR

CIRCUIT DESCRIPTION

SECTION 4.

4-1.

a dc amplifier. Feedback is applied to the whole loop.

is amplified, demodulated, dc amplified and applied to the meter. A feedback network

samples the signal at the output and compares it to the input. The dc input signal and

the feedback signal are compared in the input transformer primary.

creases the voltage-difference signal between the two.

difference signal; line-frequency sidebands of the 94-cps signal arc filtered out.

ac signal is then demodulated by a saturated transistor switch and enters a dc amplifier,

which has a feedback capacitor to filter out the demodulator ripple. The dc amplifier

output is connected to the meter, the output terminals and the feedback network. Ihe

feedback resistors determine full-scale range. The zero suppress signal is conneclcd to

the feedback point in the input circuit.

GENERAL.

The Model 147 consists of a chopper, ac amplifier and demodulator systcim followed 1,::

a.

A mechanical chopper converts the dc input signal to a 94-cps signal. 'The 312 signal

b.

CIRCUIT DESCRIPTION

(See Figure 20.)

'The transformer in-

The ac amplifier amplifies the

Th<!

FIGURE 20.

The power source for the Model 147 is either line voltage or the rechargeable

c.

battery.

highly regulated supplies.

amplifier circuits.

it is necessary and when the line voltage is connected.

4-2.

a.

JlOl, to the center contact of the chopper, GlOl. (See Figure 21.)

0466~

Voltage from either source is applied to a dc-to-dc inverter and then to tnrec

There is also a battery charging circuit to charge the battery when

Refer to Schematic Diagrams 18512F, 17352D and 173531) for circuit designations.

INPUT CIRCUIT.

The dc input signal is connected through the high terminal of the INPUT Receptacle,

Block Diagram of Model 147 Amplifier Circuits.

The three supplies furnish power to the oscillator and the

NOTE

The feedback signal

25

Page 32

CIRCUIT DESCRIPTION

MODEL 147 NULL DETECTOR

r

.

*

FIGURE 21.

The feedback signal, Vf (the dc amplifier output voltage, Vo, times the feedback ratio,

B )l

is the difference between the two, Vd = Vin - Vf.

applied to the Model 147, Vf is zero and the voltage across the primary is entirely Vin.

As the output voltage rises,

"in,

determines the amplifier gain.

is applied to the center tap of the input transformer, TlOl.

applies a positive and a negative square-wave signal across each half of the primary.

The magnitude of the square wave is proportional to the difference between the dc input

and the feedback signals.

internal ac pickup.

is applied to the transformer primary.

Or p V, = Vin.

The input compartment is designed to insure high thermal stability and to minimize

b .

1. .

circuitry.

input receptacle is 99.5% copper; the impurities add to the mechanical strength without

creating large thermal emf's.

copper pins and rotor.

lugs.

soldering -

Model 147 Input Circuit.

Vf fncreases and Vd decreases to a small value, then Vf =

Only p, which depends upon the RANGE and FUNCTION Switch settings,

TlOl steps up this signal and applies it to the grid of tube Vl.

Thermal stability is obtained in part by using only copper wire in the input

The input transformer primary and the chopper leads are pure copper.

The low voltage portion of the FUNCTION Switch uses pure

All connections to components are made with pure copper crimp

Connections between components are made by bolting the lugs together - not

to reduce thermal emf's.

The dc input signal, Vin, is applied to the chopper.

The signal, Vd,

When the dc input signal is initially

stepped up by the transformer

'The chopper alternately

The

.

2. The input compartment is doubly shielded against magnetic and electrostatic

pickup on all sides.

further minimizing pickup.

c. The feedback network is formed from the output of the dc amplifier back to the

center tap of the primary of transformer TlOl.

feedback ratio used for each range.

4-3. AC AMPLIFIER.

a. The ac amplifier circuit amplifies the 94-cps difference signal which corresponds

76

The wires are physically placed to maintain minimum loop area,

The RANGE Switch, SlO2, selects the

0466R

Page 33

MODEL 147 NULL DETECTOR

to the dc input signal.

The signal is applied to the grid of tube Vl and further ampli 1 ic'j;

by tube V2. A low-noise silicon transistor, Q3, provides n hi.gb impedance load frx \':i.

The signal is then amplified by transistors Q4 and 00. Potentiometer I<109 , botwe~~l tiie 03

emitter and Q4 base, adjusts the gain to compensate for beta variations. In addi~cioii ,

each stage has some local degeneration.

Transistor Q5 is for impcdancc matchi~n):. 'I‘ll i!

difference signal is amplified by transistors (27 and 98, whicll also form ii full-vavc

signal for demodulation.

A series high-Q filter

b.

from

the plate of V2 to circuit ground provides riotit, rcjection at the power-line frequency sidebands. 7'11e values of capacitors Cl03 and i:l(lt+

depend upon the power-line frequency. Due to the high Q of the inductor, the iil,ter

forms sharp notches at 34 cps and 154 cps for 60-cps power lines and 44 cps and 144 cps

for 50-cps power lines.

'The ac amplifier's 94-cps gain and phase characteristics al-c

affected very little.

The tube type and bias point of Vl are selected for low-noise operation at 94 cps.

c.

The high-Q tuned circuit in the plate of Vl has a good signal-to-noise ratio, and it

provides a narrow bandwidth around 94 cps.

The tuned circuit's Q is lowered on tile

higher ranges for amplifier stability.

4-4.

DEMODULATOR. Transistors Q9 and QlO in inverted configuration form a trnnsislor

switch demodulator. 'They convert the 94-cps wave from the ac amplifier into a dc vo1ca~:i

with ripple component. Resistors R123 and R124 sum the voltages from each to form rl lullwave rectified signal. Jack J102 allows access to observe the wave form.

'i‘llI 94-cps

oscillator furnishes a square-wave drive for the demodulator.

4-5.

DC AMPLIFIER.

The demodulator signal is amplified by two low-drift, high-gain silicon transistors,

a.

Qll and Q12, in differential configuration to compensate for temperature drift. Transis-

tors 413 and Q14 form the second amplifier stage. Total gain is about 500.

follow

current at zero output.

output stage

-

transistors

Q15 and 916 in pnp-npn configuration - draws litclc

Diodes DlOl and D102 limit the output currCnt, protecting

'The emitter-

transistors Q15 and Ql6.

A feedback loop with capacitor Cl15 around the dc amplifier acts as an integrator,

b.

filtering the ripple component of the demodulated wave form, The effective capacity,

which is approximately the value of Cl15 times the dc amplifier gain, and the feedback

factor (or open-loop gain) determine the response speed of the system.

The capacitive

feedback also lessens the noise in the amplifier outside the system bandpass.

4-6. OSCILLATOR. The oscillator circuit, stable to 0.1 cps, has three parts: phase-shift

network for a 94-cps signal, an amplifier to drive the chopper,

and a transistor switch

and phase compensation network for the square-wave demodulator drive.

The phase-shift network consists of capacitors C301 through C303, resistors 11319

thzough R321, and the combined resistance of R303 and R318, which bias transistor Ql7.

The input impedance of the emitter follower,

tive value of this last resistance.

Transistor Ql8 compensates for signal losses in the

phase-shift network. Potentiometer R319 adjusts the signal frequc?ncy.

the filament of a low-power subminiature tube, Raytheon CK544,

417, has little loading effect on the effec-

Resistor 1~322,

provides variable dcgcn-

eration to maintain a sine wave output to the amplifier.

0365

27

Page 34

CIRCUIT DESCRIPTION

From the phase-shift network, the signal is amplified and used to drive the chopper.

h .

'Transistor 919 matches the impedance of transistor Q20 to the phase-shift network.

tentiometer

R313 adjusts the signal amplitude.

From transistor 420; the signal is applied

MODliL 147 NUL,L DIXECTOR

PO -

to the primary of tratwformer T301, which drives the class B stage, transistors Q22 and

Q23.

After amplification the sine-wave signal is applied to the chopper, GlOl. Transistor

Q21 develops the bias voltage for the class B stage, providing ambient temperature compensation for the chopper-drive signal amplitude. The center taps of transformers 'T301

and T302 supply dc current for the class B stage.

c. 'The chopper drive signal is also applied to the primary of transformer T302.

The

transformer drives transistors Q24 and Q25 through a phase-compensating network, resistors

R308 to R310, R323 and capacitor C309, which compensates for the chopper phase shift.

the transistors alternate between saturation and cut off to form a square-wavt? drive for

the demodulator, transistors Q9 and QlO.

4-7. ZERO SUPPRESS.

The zero suppress circuit provides a regulated voltage from the power supplies to

a.

buckout steady background potentials in the input signal. The IO-turn FINE Control,

potentiometer

R168,

is connected between -12 and -1-12 volt outputs.

The resistors I~165

to R167 and R172 in the COARSE Switch, S103, further divide the voltage. The suppress

voltage is divided by an Evenohm 0.25% resistor, R140, copper resistor Rl37A, and copper

resistor R141. Using copper resistors for the lowest voltage points shunted by Evenohm

resistors provides thermal and resistive stability.

An adjustable current, supplied through resistor R138, provides compensation for

b.

resistive

4-8.

offset. Potentiometer R239 adjusts the current fed to the feedback point.

POWER SUPPLIES (See Figure 22.)

The power supply for

the

Model 147 ,is powered by

an unregulated supply :from the line voltage or rechargeable battery. Either source feeds

n dc-to-dc inverter and three highly regulated supplies with outputs of +12, -12, and

il.2 volts.

The line voltage, battery and battery charging circuit are controlled through the

a.

POWER SUPPLY Switch, S201. When the switch is in AC,

These power all the other Model 147 circuits.

the battery is charged if nccessarq

and the power supply uses line voltage. When the switch is in OFF, the battery charging

circuit

will operate if necessary; all other circuits are off.

When the witch is in

I~ATTIZRY, the power supply uses the battery; the other two circuits can not operate.

11 . T:he unregulated supply consists of a full-wave rectifier, diodes DZ.12 and D213, and

n droppi.ng resistor, R232.

The AC CONNECTED Lamp,

DS201, is in series with resistor R226,

whj.ch is connected directly across this supply, For battery operation the primary of

rrnnsl'onner T201 is disconnected.

c.

Voltage

Vertex circuit.

voltage to transformer T202.

carrier frequency.

from the unregulated supply or the battery is applied to the dc-to-dc in-

Transistors 928 and Q29 form a switching network to supply an interrupted

The switching frequency is about 2 kc, well away from the

Transformer T202 has a

saturable

ferrite cot". The inverter

circuit

supplies voltages to the three regulated supplies, which are basically the same series

regu.Lator

d . For the 1~12 volt supply,

i-rnnsfonncr T202.

is div:idcd by resistors R208 and R209 and compared L

28

design.

diodes D206 and D207 full-wave rectify the signal from

The signal is applied to the pass transistor, Q30.

the zencr diode reference, D205.

The output of Q30

0466R

Page 35

MODEL 147 NULL DETECTOR

CTRCUIT I1I:SCR1~l"~IoN

FIGURE 22.

Block Diagram of Model 147 Power Supplies and Battery Clrarging Circuit.

Transistors Q34 and Q33 amplify any potential difference and apply a signal to the base

of transistor Q32.

collector voltage of Q33 directly dctcrmincs the current through (132, which comes

the -12 volt supply.

the base of transistor Q31,

junction.

Diode D203 limits the base-to-emitter voltage of the Q30 alld Q3L combinati,ln;

thus also limiting the current which it will pass.

Diodes 0204 and D205 fix the emitter voltage of (~32; tlrcrclfore, the

i:rom

The

current

and therefore the

drop through

resistor I<216 determines the voli~a?ge at

output

voltage througli the base-cmiltcr

Diode I)203 protects

the

pxs transistur

Q30, if the output of the supply is shorted.

For the -12 volt regulated supply,

e.

from transformer T202.

The signal is applied to the pass transistor, Q35.

R217 and R218 divide the 435 output,

ground as a reference.

apply a signal. to transistor Q37.

Transistors Q38 and 939 amplify any potcutial diftcrc!ncc and

Transistors 435 and Q36 form a Uarlillgton combi~n;lLi~x,~i ~

and work similarly to that in the ~1+12 volt supply.

supply draws a higher current than the ~1.12 volt supply,

D208 and U209, to protect the pass transistor.

diodes D210 and D211~ Trill-wave rectify the signill

Resistors

thereby comparing it to the ~112 volt supply, usi,n>:

'l'hc differences arc

LIlaC Clue -12 volL

and therefore uses two diodes,

The negative "bootstrap" curreni supply)

is from a filter, resistor R225 and capacitor C210.

The -+I..2 volt supply operates in the same manner as the 112 volt supply with those

f.

di,fferences. The output of the pass transistor, Q40,

1~1.2 volt supply divided down one

tenth.

'The operating voltages for tlic comparator stage,

Q43 and Q44, are obtained from the +12 and -12 volt supplies.

is compared to lllC output of ti1c

ikccpt for the compnra~or

stage, npn transistors arc used.

4-Y.

BATTERY CHARGING CIKCUIT.

The battery charging circuit operates when the I'OWER SUPPLY Switcii, SZOI, ins iii A(:

a.

or OFF position, and only when the battery needs charging.

04661~

29

Page 36

CIiWJIT DESCRIPTION

The battery voltage is compared to a reference by two cascaded transistors, Q26

b.

and 427.

When it is low, a charging current from transformer T201 is applied to the battery

MODEL 147 NULL DETECTOR

through the BATTERY CHARGING Lamp, DS202, transistor Q27 and diode D216. The reference

is zener diode D214; the reference voltage is adjusted by potentiometer R228. The

difference between the battery and the reference potentials determines the magnitude of

the charge current through Q27. A silicon diode, D216, prevents the battery from being

run down because of leakage currents through 927, a germanium power transistor.

Diode

D215 limits the base-to-emitter voltage of the Q26 and Q27 combination, so no more than

400 milliamperes (the rated maximum charge current of the battery) can flow in the circuit.

This circuit protects the bat,tery. It decreases the charging current to a trickle-

c.

charge rate as the battery terminal voltage approaches the reference voltage. It also

limits the charge current if the battery was used beyond its ampere-hour capacity. Note,

however,

reversal of a cell may occur,

that the battery can be damaged if it is used far beyond its capacity. A polarity

causing heavy circulating currents within the battery.

30

0365

Page 37

MODi?L 147 NULL DIZECTOR

SECTION 5.

5-l.

cedurcs for the Model 147.

possible to maintain the instrument's specifications.

5-2.

high-quality electronic equipment.

Principal maintenance is an occasional chopper rcplaccment.

GENERAL. Section 5 contains the maintcnancc, troubleshooting and calihmtion pro-

It is recommended these procedures be followed as c:loscly 3s

MAINTENANCE SCHEUUJX.

The Model '1.47 requires no periodic maintenance beyond the normal cnrc requirc.d ~1

a.

Components operate well below nmximum ratiirgs.

Suggested Model 147 calibration schcdulc is as follows:

b.

Every four to six months, cl~cck the Model 147 with Llle Keithley Model. 260 N;li,a-

1.

volt source. This will show if the Null Detector is maintaining its specified accurac;?.

Approximately every year, perform an operational check on the amplifiers (par-a-

2.

graph 5-10). This will indicate how well the Null Detector ,is operating.

3. Normally,

are replaced.

the Model 147 does not need recalibrating unless critical components

These part changes are call.ed out by the various circuits in tliis Section

MAINTENANCE

(See paragraph 5-4.)

5-3. PARTS REI'MCEMliNT.

a. The Replaceable Parts List in Section 6 describes the clcciriccil components of :h~

Null Detector. Repl.ace components only as ncccssary,

which meet the specifications.

R322, which is a subminiature tube filament,

matched transistors (Qll, Q12, Q22, 423) and the two input tubes.

coded 80164 in the Replaccablc Parts List arc purchased only from Keithley Ins~run~cnts

or its representative. (If tlic Low-Tlicrmal~ Function Switcll, 5101, i,i?<!dS L^<~!/>l:,cme,,L, ri'-

turn the unit to i(eithtcy :Instrumcnts for this repair).

Component

Battery pack assembly

Mechanical chopper assembly (SW paragraph 5-4.)

Input receptacle assembly

Copper feedback resistor assembly R137

Evanohm resistor assembly

i:vanoh~n resistor assembly

Function switch plate assembly (see paragrnpll 5-3n)

Input transformer assembly

The Model 147 uses few special parts except for resistor

the components listed in 'Table 6, several

and USC onl~y rcliabltl replncements

mke S"lf parLs

BA201

GlOl

JlOl

11139

Rl40

SLOl

'SlOl.

TABLE 6.

and the proper lead length.

instructions given in paragraph 5-3.

04691~

Model 1.47 Pre-assembled Components.

USC only Kcithley parts for replaccmcnts;

Tlicsc parts have lugs crimped on Lhcm

iolloi;

Page 38

MAINTENANCE

>IOtII:L 1~11~7 NULL I)ETECTOR

I

FIGURE 23,

placing, duplicate location and order of lads on posts.

nations.

The physical location of components in the input compartment is critical.

11 .

rcpl.acement parts in 1-11~ exact pos:i.tion shown in Figure 23.

extraneous ac signals; see paragraph 2-15.

posts greatly affects offset and noise in the Model 147.

cnch lead as it is removed.

6 Kep nuts in the input compartment is 15 inch-pounds.

No .

ili~ich have lugs crimped on them. When replacing these parts,

metallic abrasive,

~Vol~low the procedures necessary for good low-thermal connections.

5-4. CHOPPER REPLACLWi?NTS.

The chopper is designed ~Cor long lift. I~l"wfvcr) since iC is mechanical, it will

ii

eventually wear and become noisy. At this point,

Removal Procedures.

11 .

1.

move the three thumb screws in the input compartment and the three chopper lead lugs.

Model 147 Input Compartment.

Refer to Figure 7 for general connection construction.

Replace in reverse sequence.

such as Scotch Brite, found in the Model 1483 Kit, or its: equivalent.

Llisconnect the chopper dri.vc coil at connector 5302 (Figure 29).

Note exact physical Location of parts. If re-

Figure 30 gives circuit dcsig-

Circuit loops will introduce

The order of the copper lugs on the insulated

'Tag or record the number on

Maximum torque applied to the

Table 6 lists components

clean the lug with a non-

replacement is necessary.

Carefully re-

I

Place

:1 2

0466R

Page 39

MODEL 147 KLILL DEl:CC:COR

:.?,\~I !:'I i ::,:'..::I

Carefully slide the degaussing coil, 1.302 (t?igurc 29),

2.

l'rom ti,(i chopper lbd~:;

remove the "1.d chopper.

Replacement Procedures.

c.

Slide the degaussiug coil,

1.

L302 , over the new chopper body irom illc bo!~c,!ll.

Orient so that tllc cut-nrit i.n I-11" coil lits over the ch"ppcr dri~vi! l~cnd.

Mount the chopper and coil in the input compartment.

2.

i)rcss Leads as silLlw:l

in Fj.gure 23.

Degaussing Coil Adjustment Procedures.

d.

With the input shorted, USC the ZERO SUPP1~L:S.S Contrill~s L:" cance 1~ any T/~e~livil~

1.

emf's in the Model 147 input circuit.

USC n differential input LU tile .Cypc 1103

Oscilloscope (~I and - inputs) to obscrvc the wave Lorm bctwecn tllc: collectors oi irai:sisters Q9 and QlO (Points P and Q, Figure 34).

The wave form amplitude varies as tllc degaussing coil is moved along the clltipper

2.

body. Potentiometer R301 (Figure 30) determines tbc effect "f the coil "n the wvc!

form.

Adjust both tbc coil and the potentiometer for mini.mum ;ImpliLudi,.

,:<~Lii~~l-sL

the.rcd and black leads t" the degaussing coil ir necessary.

3. An 8-cps beat at points P and Q may bc present.

USC battery operalion i" ~-c<!ucc

the beat; refer to paragraph 2-3.

5-5. 'TROUBLESHOOTING.

1%~ following procedures give instructions for repairing troubles which mii:ht occ111'

a.

in the Hodcl 147.

mcnt parts.

'Table 7 lists equipment recommended for troubleshooting.

cannot be readily located or repaired,

Use these procedures to troubleshoot and use only spwil:j~w! rcplacc-

cOntact Kcithley Instruments or its 'cl'~~scnl;li:ii,et-

Paragraph 2-19 describes how to remove the Null Detector covc1'.

Paragraphs 5-8,

b.

checking "ut the pow"r supply,

order given. Tables 10,

refer

to

Section 4 to find

The Schematic Diagrams,

5-9 and 5-10 give step-by-step proccdurcs for trouh1L'sho"iin;: arid

oscillator and amplifier circuits.

11 and 13 are troubleshooting tables for these circuits.

the

more crucial components and to detcrminc their iunclioi!.

1.8512F, 17352D and 17353D, contain the voltages at certai~n

pojnts in the circuit.

Before troubleshooting inside the Model 147,

(paragraph 5-6).

Always check out the power supply and the "sci.lI.at"r

circuits before touching the amplifier circuits.

check the extfrnal circuits

'I?," amplifier circuits

often appear faulty only because of a defect in the power suppty or

oscillator circuits.

11 Lllf L~I:oLIl~ II

Follow these in i~!lC

Xl so

0466R

Page 40

MAINTENANCE

MODEL 147 NULL DETECTOR

Instrument

llewlett-Packard Model 5512A Electronic

Monitor oscillator frequency

USC

Counter, 300-kc counting rate, *O.l%

accuracy

Keithley Instruments Model 1488

Short INPUT Receptacle

Low-Thermal Shorting Plug

Keithley Instruments Model 260

Signal source for calibrating Model 147

Vanovolt source

<cit%ley Instruments Model 2603

Connect Models 147 and 260

Low-Thermal Input Cable

(eithley Instruments Model 660 or 660A

Check voltage at output terminals

3-uarded DC Differential Voltmeter,

!-O.OZ%, to 1 millivolt

XA Model WV98B Senior Voltohmyst, 11 I$]

Check dc voltages throughout circuit

input resistance, i3% accuracy, 0 to

1500 volts dc

Cektronix Type 503 Oscilloscope, dc to

'I,50 I--

Check wave forms for troubleshooting and

-alibrating

I

TABLE 7. Equipment Recommended for Troubleshooting and Calibrating the Model 147.

these instruments or their equivalents.

use

5-6. PRELIMINARY TROUBLESHOOTING PROCEDURES.

Before troubleshooting,

a.

check the outside circuits to the Model 147.

Null Detector from all external effects:

Disconnect all outside circuits from the INPUT and OUTPUT Receptacles, and GND

1.

and LO Terminals.

Connect the Model 1488 Shorting Plug to the INPUT Receptacle.

2.

COARSE Control to OFF,

If battery operation is trouble free, set the POWER SUPPLY Switch to BATTERY.

b.

connect the power cord from the ac power line.

earth ground or to a cornman test equipment ground.

NOTE

Often, after checking out according

to

will function normally. This points to problems in the circuits

outside the Null Detector. Refer

to

Table 4 to check the external

circuit,

C. If ac operation is used,

check the Line Voltage Switch for correct position and the

Fuse for correct rating.

Isolate the

Set the ZERO SUPPRESS

Dis-

Ground the Model 147 case to a convenient

paragraph S-6, the Model 147

34

0466R

Page 41

COlltrOl

Dcsig. Kcf.

Paragraph

ac amplifier gain adjust

R109

34

5-10

Imeter adjust

battery charging adjust

current compensation adjust

dcgaussing coil compensation

oscillator amplitude adjust

oscillator frequency adjust

TABLE 8.

Model 147 Internal Controls. The Table lists all internal controls, the

figure picturing the location,

5-7.

CHECK OUT AND CALIBRATION PROCEDURES.

The following procedures give the steps to check out and calibrate the Nod"1 147

a.

R228

I~239

R301

R313

R319

I

I

36

29

30

37

37

and the paragraph describing the adjustment.

5-8

5-11

5-4

5-9

5-9

circuits. If a circuit fails to check out at any point, refer to the circuit's trrxll)l<-shooting table. Continue as long as the points check out. Use the equipment l~istcd in

Table 7.

Procedures arc given for the power supply,

b.

oscillator and amplifier circuits.

These cover the principal adjustments t" bring the instrument within specifications.

If the Model 147 is not within specifications after performing these checks and

c.

calibrations, contact Keithley Instruments or follow the troubleshooting proccdurcs io

find the fault.

NOTE

Make sure the power supply and oscillator circuits are operating

correctly before chcckin~ the amplifiers. All circuits dcpcnd

upon properly functioning power supplies.

If taken out of order,

the resulting adjustment may be faulty.

5-8.

outputs

check out at any point, refer to Table 10.

POWI?R SUPPLY CIIiSCK OUT AND CALIBRA'L'ION.

All circuits depend upon the power supplies.

a.

must

be correct before further checks ar" mad".

Therefore, the 1.12, -12 and ~el.2 v"lL

If the power supplies fail to

After clearing the trouble, continue the

check.

Procedures for Checking Regulated Power Supplies.

b.

0466R

35

Page 42

MAINTENANCE

MODEL 147 NULL DIITECTOR

1. Connect the Model 1488 Shorting Plug

as follows:

POWER SUPPLY Switch

RANGIS Switch

FUNCTION Switc'h

ZERO SUPPRESS COARSE Control

Line Voltage Switch

FIGURE 24. Correct Wave Form in dc-to-dc

Inverter. Point E, Figure 35, was

monitored.

Scale is 5 v/cm vertical,

0.2 mseclcm horizontal,

Connect the Null Detector t" the ac power line.

position.

to

the INPUT. Set the Model 147 controls

OFF

100

?1LLLIVOLTS

OFF

Set to line voltage

Plug in the power cord. The AC

2.

CONNECTED Lamp should light.

Measure the voltage at the Yellow-

3.

White wire on the POWER SUPPLY Switch

front deck (Point A, Figure 29). It

should be -18 volts dc -i2 vdc.

Turn the POWER SUPPLY Switch to AC.

4.

Use the oscilloscope

to

check the wave form

at point E (Figure 35) in the dc-to-dc

inverter.

Wave form should resemble that

in Figure 24.

5. Measure the signal levels and ripple

with respect to low of the three regulated

supplies.

c.

1.

Table 9 gives the values.

Procedures for Charger Circuit.

Disconnect the battery pack; do not

Lot the terminals touch the chassis.

Put the POWER SUPPLY Switch in AC

Set the charger bias voltage to -8.1 volts dc (measured with i3% voltmeter) at

2.

point C,

3.

side of the battery is ground.

charging circuit works.

the brighter the l.ight,

Regulated

Power

SUPPlY

~I+12 volt B il.6 to 12.8

-12 volt C 11.9 to 13.1

.I-1.2 volt D 1.16 to 1.28

TABLE 9.

Figure 35.

Adjust potentiometer R228 (Figure 36) for this value.

Connect the battery; make sure rhe polarity is correct (red to red).

The BATTERY CHARGING Lamp should light, showing the

'The lamp brightness directly indicates the charge current -

the greater the current.

iQxi.mum Ripple,

Test Point,

Figure 30

Signal Level,

volts dc

millivolts

peak-to-peak

0.3

2.0 460 * 70

0.2 2oi 3

Signal Level, Maximum Ripple and Resistance for Regulated PoWer Supplies.

IJse the oscilloscope and the Voltohmyst for the measurements.

‘36

The positive

Resistance

to Ground,

ohms

850 ilO

0466R

I

Page 43

MODEL 147 NULL DliTEC'I'OR

5-9.

OSCILLATOR CIIECK OUT AND CALIBRATION.

Page 44

MfYLNTENANCE

FIGURE 25.

Correct Wave Form at Point F

(Figure 30) in Oscillator Circuit.

Ls 2 v/cm vertical, 2 mseclcm horizontal.

If it does.not but resembles Figure 26,

Transistors Q22 and Q23 are matched for gain.

Keithley Instruments.

SCalt-

MODBL 147 NULL DETECTOR

Set the oscillator frequency to

2.

94 cps 20.1 cps with p"tenti&wter R319

(Figure 37).

Set the oscillator signal amplitude

3.

to 15.4 volts peak-to-peak 1~0.2 v peak-

to-peak,

measured on the oscilloscope.

Adjust with potentiometer R313 (Figure

37).

Check the wave form at point F.

4.

It should be essentially sinusoidal, as

in Figure 25.

NOTE

If transistors Q21, Q22 or Q23 are

replaced, it may be necessary to

change resistor R307. A 27-kilohm

resistor should provide the proper

bias for Q22 and Q23. The wave form

at point F should resemble Figure 25.

use a 15-kilohm resistor for R307,

Order replacements only from

FIGURE 26.

A

Improper Wave Forms at Point F (Figure 30) in Oscillator Circuit.

B

Wave A

indicates the wrong bias; wave B is distorted. Scale for both is 2 v/cm vertical,

2 msec/cm horizontal.

S-10.

AMPLIFIER CHECK OUT AND CALIBRATION.

a .

Th" cheek out and calibration of the amplifier circuits is divided into tw" parts:

"perntivnal check and gain calibration.

~

The operational check does not have to be followed

38 0466R

Page 45

MODEL 147 NULL DETECTOR MAINTENANCE

TROUBLE

PROBABLE CAUSE

Unable to adjust fre- Shorted chopper drive

quency to 94 cps

Distorted, off-frequency wave form at

circuit for 94 cps at Q19 emitter (Point

Defective Q17, Q18

or (219

point 11 (Fig, 29 or

37) with chopper

disconnected

Low voltage, dis-

torted wave form at

Defective Ql7, Q18,

Ql9 or R322 (Fig. 26B)

point F (Fig. 30)

Defective QZO, Q21,

Q22, Q23 or R313

(Fig. 26, A or B) faulty components.

Improper bias to Adjust R307 as in note.

Q22 ard Q23 (Fig.

260.)

UnstaJll~e frequency

Defective Q17, R319

C301, C302, C303 or Q17 or R319 are most Likely parts.

R321, R320, R303, R318

SOLUTION

Disconnect chopper at 5302. Cheek

H, Fig.

29 or 37).

ChCCk for

shorted wiring and chopper coil.

Voltage at point 11 should bc 1 to

2 volts peak-to-peak, sine wvc.

If not,

check conqmnents; rcpl,lcc

if faulty.

Check components; replace if fault!

Check the voltage, Q20 to Q23,

given on schematic 17353D.

Replace

Check components; replace. <f I,!I!! I~:\

Oscillator Circuit Troubleshooting Table.

by gain calibration.

TABLE 11.

Use this to check the Model 147 operation. If the amplifiers fail

to check out at any point, refer to Table 13.

the check.

NOTE

Check the power supply and oscillator circuits before adjusting the

amplifiers.

the other

two circuits

If

may need recalibration.

Operational Check Procedures.

b.

Connect the Model 1488 Shorting Plug to the INPUT.

1.

as follows:

POWER SUPPLY Switch

RANGE Switch 0.3

FUNCTION Switch

ZERO SUPPRESS COARSE Control

ZERO SUPPRESS FINE Control

On the 0.3-microvolt range,

(6:, of full scale).

It me,y be higher if the Shorting Plug is not used.

the meter offset should be less than 0.2 microvolt

After clearing the trouble, continue

are changed, the amplifier circuit

set the front panel controls

BATTERY

MICROVOLTS

OFF

At one end of rotation

046611

39

Page 46

MAINTENANCE

Connect the Model 260 to the Model 147 INPUT Receptacle with the Model 2603 Input

3.

Cable.

Adjust the Model 260 for LOO-nanovolt output.

MODEL 147 NULL DETECTOR

NOTE

Follow the operating instructions in the Model 260 Instruction Manual.

the input compartment, making good connections and similar details arc very im-

portant in the nanovolt and microvolt regions.

Connect the oscilloscope to the Model 147 OUTPUT. Sot the oscilloscope amplifier

4.

to dc coupling, 0.2 volt/cm,

the O.l-microvolt range.

SUPPRESS Controls to compensate for residual thermal emf's.

Switch to -+ or -; observe the wave form on the oscilloscope.

10% to 90% of final

value)

time base to 0.1 or 0.2 second/cm. Set the Model 147 to

Turn the Model 260 POLARITY Switch to OFF.

Set the ZERO

Turn the Model 260 POLARITY