Page 1

Service Manual

Model 1765

Contains Servicing/Calibration Information for

Models 136 and 176

Test Instrumentation Group

Keithley Instrumenthlnc.

28773 Aurora Road

Cleveland, Ohio 44139

(216) 248X400 . Fax: (216) 498-2704

BZiii;

Kaithley Instruments. Inc.

28775 Aurora Road/Cleveland. Ohio 44139/(216) 248-0400

Page 2

WARRANTY

We warrant each of our products to be free from defects in material

and workmanship. Our obligation under this warranty is to repair

or replace any instrument or partthereof which, within a year after

shipment, proves defective upon examination. We will pay local

domestic surface freight costs.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in Cleveland, Ohio.

You will be given ,prompt assistance and shipping instructions.

REPAIRS AND

CALIBRATION

Keithley Instruments maintains a complete repair and calibration

service as well as a standards laboratory in Cleveland, Ohio.

A Keithley service facility at our Munich, Germany office is

available for our customers throughout Europe. Service in the

United Kingdom can be handled at our office in Reading. Additionally, Keithley representatives in most countries maintain service

and calibration facilities.

To insure prompt repair or recalibration service, please contact

your local field representative or Keithley headquarters directly

before returning the instrument. Estimates for repairs, normal

recalibrations and calibrations traceable to the National Bureau of

Standards are available upon request.

Keithley Ins&nents, Inc.128775 Aurora Road/Cleveland, Ohio 44139/U.S.A./(216) 248400/T&x: 985469

WEST GERMANY: Keithiey Inshumentr GmbH/Heiglhofstrasse S/D-8003 Mitnchen 70/@89) 7l4-4&6.5/Telex: 52121 60

GREAT BRlTAIN: Keitbley Instruments, Ltd./l, B&ton RoadlCEReadi~ Berkshire RG2 ONU(O734) 86 12 87/T&~: 847047

WCE: Keithley htrvments SARL12 Bis, Rue Leon Blum/B.P. 60/91121 Palaiseau C&.x/(6) 011,51,55/Tekx: 600933F

NEIHERLANDS: Keithley Instrvments B.V./Leid&raatweg 149/Postbus 1190 /NL-WcerderJ(O34EO) 13 M3/Telex: 40 311

SWITZERLAND: Keithfey Instruments SA/Filiale DttbendorflKriesbachstr. 4fCH-8603 D&zndorf/Ol 82194 44/T&x: 57 536

AUSTRIA: Keitbley Instruments HandeL+Gesekbaft m.b.H.IDbbliier Hauptstr. 32/A-119C Wien/O222 314 289/T&x: 13 45 W

Page 3

TABLE OF CONTENTS

SECTION

1

1-l

1-4

1-6

1-E

l-i0

l-12

1-14

2

2-l

2-2

2.10

2-13

3

3-1

3-6

3.12

4

4-I

4-2

4-9

5

5-l

5-2

5-5

5-10

5-13

5.17

5-18

TITLE

GENERAL INFORMATION

iNTRODUCTlON

FEATURES..

WARRANPIINFORMATION

MANUAL ADDENDUMS

SAFETY SYMBOLS AND TERMS

UNPACKING AND INSPECTING

SPECIFICATIONS

r\CCC~~““lC~

GENERAL

MUTUAL ACCESS

MODEL 135 EXCLUSIVE ACC

MODEL 176 EXCLUSIVE ACC

rc”r”“I”I~NLc “CnlrlLAI I”N

GENERAL

MODEL 135 PERFORMANCE VERIFICATION

MODEL 176 PERFORMANCE VERIFICATION

lrlC”“T vr “rEI(CIII”N .............................................................

GENERAL

MODEL 135 OVERALL FUNCTIONAL DESCRIPTION

MODEL 176 OVERALL FUNCTIONAL DESCRIPTION ...............................

.....................................

........................................

....................................................................

.................................................

......................................................

,ORlES

...........................................................................

...........................................................................

MAINTENANCE (TROUBLESHOOTING. CALISRATIONI.

GENERAL

MODEL 135

TROUBLESH

MODEL 176 CALIE

MODEL 176 TROU

CURRENT FUSE RE

MODEL 1766 TROuurc:

.......................................................

CALIBRATION

DOTING

3RATION

IELESHDOTING

IPLACEMENT

“-‘-1HOOTING

............................................................

..............................

.............................................................

........................................

.............................................

......................................................

.......................................................

ESSORIES.,

ESSORIES

.......................................................

......................................

........... ..........................

................................

..................................

...............................

.......................

.........................

..........................................

..........................................

..........................

. . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

...............................

.............

PAGE

1-l

.................

.................

.................

::::

...............

..............

..............

..............

6

6-l

REPLACEABLE PARTS

GENERAL

...........................................................................

...............................................................

Page 4

Page 5

MODELS 135/l 76

GENERAL INFORMATION

Model 135/l 76 Service Manual

Section 1. General Information

l-l. INTRODUCTION

l-2, The Modeis 135/176 are low cos,. 4-l/2 d~gt,.

LCD dtsplav digatal muitimeters. The two me!ers are

unfque in that they are sfm~lar in electromc design ye,

different I” case design. The most obvious dhiference 1s

the phvwal dilference. The 176 is designed tnro a more

,rad,I,onal DMM case whlie the 135 is designed #“to a

hand held case. The 176 has more current ranges and a

w,der frequency span for ACV. They both have a basx DC

accuracy of 0 05% and also a basic OHMS accuracy of

0.2%. They also bastcallv have the same A/D converter

l-3. Thus manual 1s a comeinatmn of sewce rnformatjon

for both DMM’s (1 35 and 176) I, contans tnformarlon

necessary to maintain. caitbrate and troubleshoa Ihe

Model 135 and the Model 176,

1-4. FEATURES

l-5. The 135 and 176 have many d,s,,nc, fearures and

advantages some 01 which are l,s,ed below:

.

A 20000 count I,.‘-1 12 d,g,t, Iiqu,d crvstal dtspiav.

[LCD) ,w,h large 0 6 ,nch numerals The 176 has

functnn and fange ,nd,cators. The 135 and 176

have a low ba,,eiv lndlcator that hghts when there

IS less than 10% battery life rema,“i”g. Approprtale declmai point and minus stgn (~1 areaisodlsplayed, posirive polarttv IS ,mplied.

.

The Model 135 and 176 are bull, rugged. The hand

held case and the bench s,ze case are molded from

impact-res~stan, plastic. Effective ,npu, profection

prevents damage on ail functmns.

Htgh lrequencv (RFI probe allows YOU< 3MM !a

measure from 0~25V 10 30V rms AC ow a Fred

quency range from 1OOKHr 10 iOOMHz

50 ampere wrren, Shun, aiiow~ YOU, DMM 10

measure up 10 50A. AC or DC

Clamp on AC curie”, probe al,ows vour 9M11 !o

measure up 10 200A rms AC

Htgh Voiiage Probe allows your DMM ,c reas;‘r

from 1 OOOV 10 40KV DC

NOTE

l-6. WARRANTY INFORMATION

1-7~ The warranty is gwen on ,he instde front cover ci

,h,s instruction ma”“al~ If there IS a need 10 exercise ine

warranty contact the Kenhlev Representawe 10 vour area

to de,etm,“e the proper act,o” to be take” Kelrhiey slainfans serwce fac,l,,les I” the Untted Klngaom ‘.“,esr

Germany and I” ,he UnIted States Check ,ne !ns~de.roni

cover of lhls manual for addresses

l-8. MANUAL ADDENDUM8

l-9, ,mpr~vements or changes tha, affec, iqese ~nsfruments which occ”r affer pil”,l”g of the I”s,rdc,,on

Manual wlil be explained on anaddendum sheelartacnea

to the jnside back cover,

.

The 176 pushbuttons are color coded to the front

pane, for qwck and easy selecr~on of functton and

range. The 135 rotarv fun&on and range swlch

are easdy pos,r,oned to color coded functtons and

ranges. The decimal pan, is automatlcallv pow

tloned by the range pushbu,,on/rofarv switch. The

176 dlsplav annunciators indicate rhe selected

function and range. Improper range and function

comb,na,,ons are lndlcated bvcontradalng funcbon and/or range annunc,alors appear,ng a, the

same rime.

.

Stare of the arr technology and stable prectsio”

components have been used I” these two DMM’s

to prov,de iong term accuracy and m,“,mtze maintenance. Calibration IS required only once a year.

If aikal,“e battertes are used /SIX C cells I” the 176

or one 9 volt ceil for the 1351 battery IIfe can be as

long as 1000 hours for the I 76 and 100 hours for

the 135

.

Opttonal accessories can be ordered To extend the

measurement capabtlttvof me 135 and 176. Some

of these accessor,es are’

l-10. SAFETY SYMBOLS AND TERMS

1-l 1~ Safe,” symbols used ,n lhis manual are as foilows

The symbol&an rhe ~nstrumen, denores lha, ihe user

should refer 10 the operarIng insfrucf~ons

The symbol 1 on the ~nswumen, denotes rhat I OCOV

or more may be present on the ,erminai~s,

The WARNING used in th,s manual explains dangers

that could resulf tn personai tn,urv or dean

The CAUTION used I” ,h,s manual expiains hazar?s :?a,

could damage the ~nsrrumen,,

l-12. UNPACKING AND INSPECTION

1 13 The Models~l 35 and 1 76 were carelullv 8”speclea

borh mecha”,ca,,v and eiec,wallv before snipmenl “pan

rece,w”g either or bolh of these instrumeni~. unpack a!!

items from the sh,pp’“g container and check for a”” 00~5~

ous damagethat may have occurred during ira”s8, Reoor:

any damage 10 the shtppmg age”,, Retain and use :hi

orig,“a, packag,ng ma,er,a,s ,f reshIpme”, 15 “ecessar,

The followmg ,,ems are sh,pped wr,h alI ‘35 a”3 : :<

orders~

Page 6

GENERAL INFORMATION

MODELS 135/176

A. Model 135 or 176.

5, A copy ot the appiopnate

C. SuppIled Accessmes: 176 (Mod&l 1768 Battery Pack

with batteries, Modei 1691 Test Lead Set, 135 (9V

batterv. Model 1691 Test Lead Setl

D, Installed or separate opf~onal accesso~,es. as orderea

Operator’s Manual,

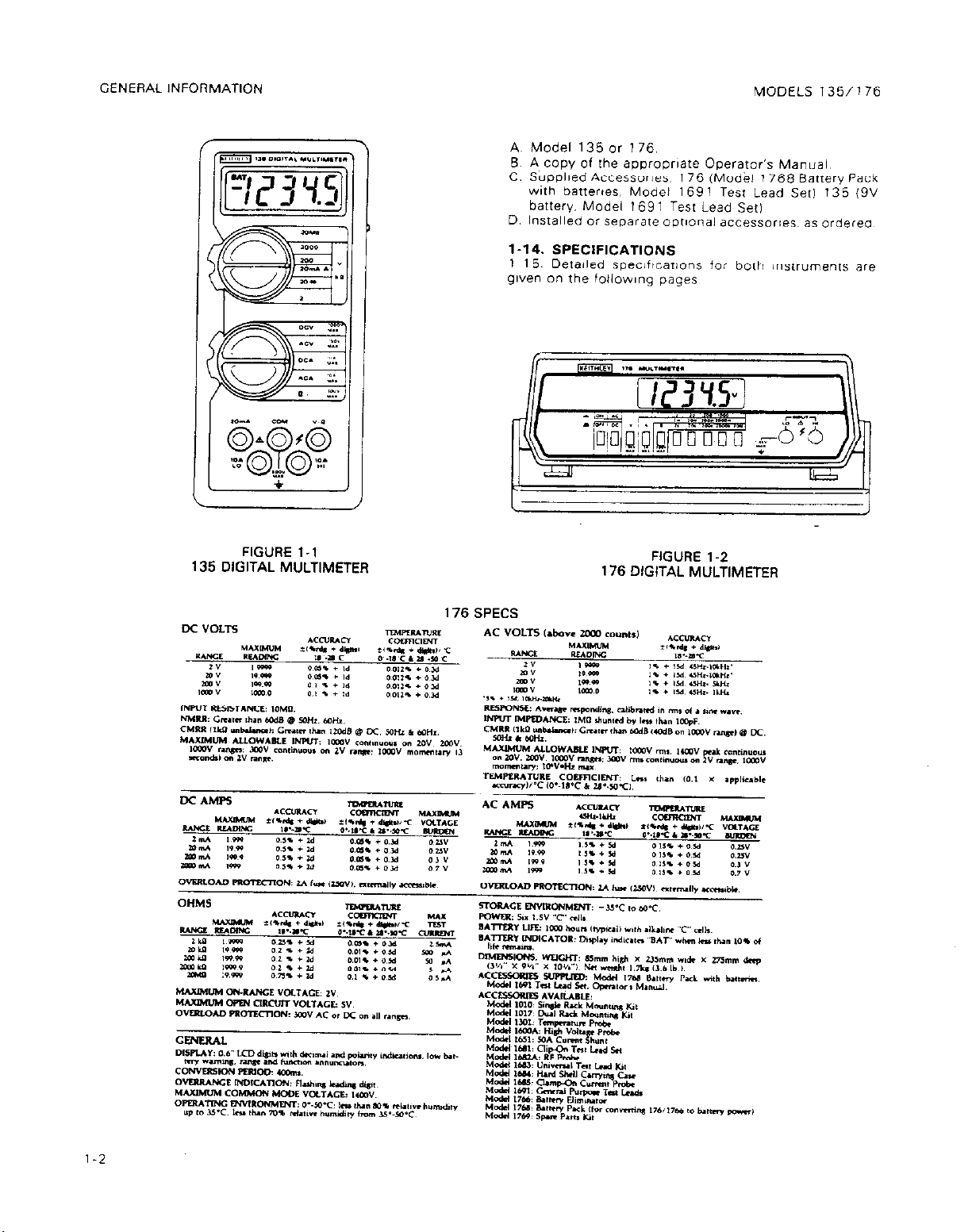

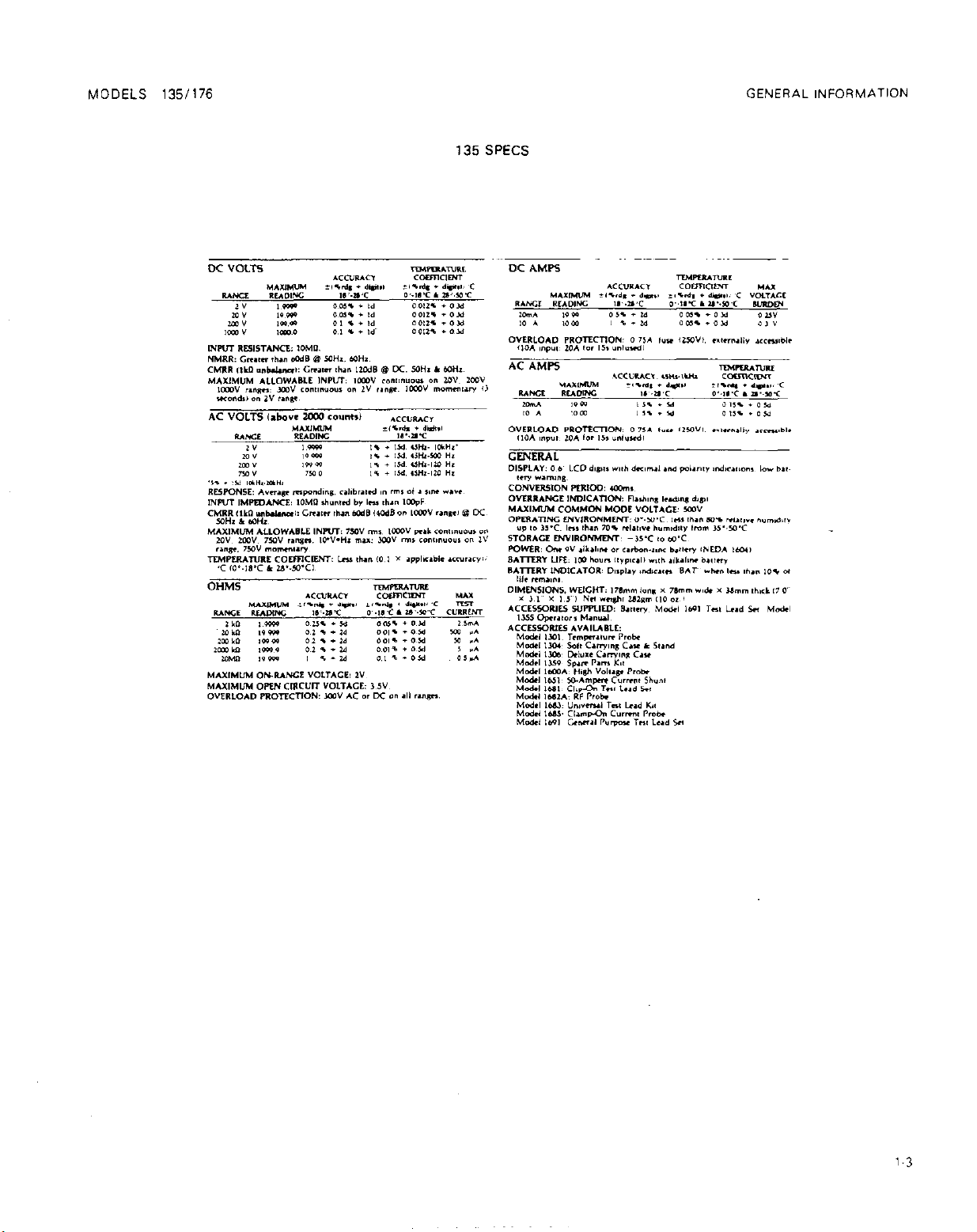

1-14. SPECIFICATIONS

l-1 5. Detailed speclflcations for both instruments are

given on the foilowIng pages

135 DIGITAL MULTIMETER

FIGURE l-l

176 DIGITAL MULTIMETER

FIGURE 1-2

176 SPECS

Page 7

MODELS 1351176

GENERAL INFORMATION

135 SPECS

l-3

Page 8

Page 9

MODELS 135/176

ACCESSORIES

Section 2. Accessories

2-1. GENERAL

This sect,on describes the various accessor,es and

opiio”s avatlable ior use wth Ihe Models 135 and 176.

Some of the followlng accesswe are for use only vath

the Model 135 and some are for use onlvwlth the Model

176~ These accessoi~es w,ll be clearly potnted out as ,o

which instrument they are used wlth~

2-2. MUTUAL ACCESSORIES

The following accessories can be used wrh e,ther rhe

Model 135 or the Model 176.

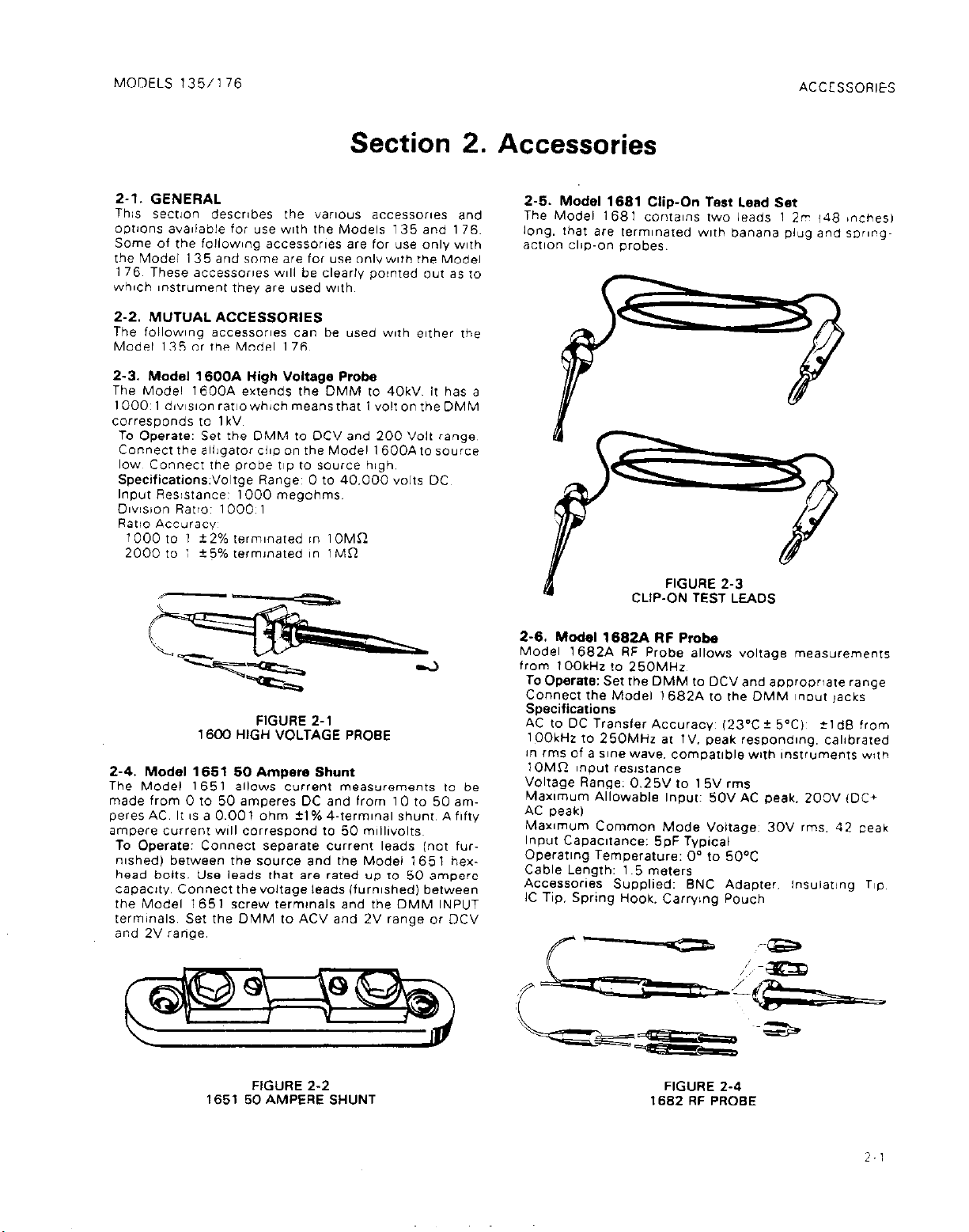

2-3.

Model 1 SOOA High Voltage Probe

The Mode! 16OOA extends the DMM to 40kV. it has a

1000: 1 d,v,s,on rar,owhich means that 1 volt on the DMM

Corresponds to 1 kV

To Operate: Set the DMM to DCV and 200 Volt range,

Connect the all~garor CLIP on the Model 1600Ato source

Iowa Connecl rhe probe top to so”ice high.

Specifications:Voltge Range: 0 to 40.000 volts DC

Input Reslsrance: 1000 megohms.

Dlvlsion RatlO. 1000 I

Ratto Accuracy~

1000 to 1 +2% terminated in IOMR

2000 to :

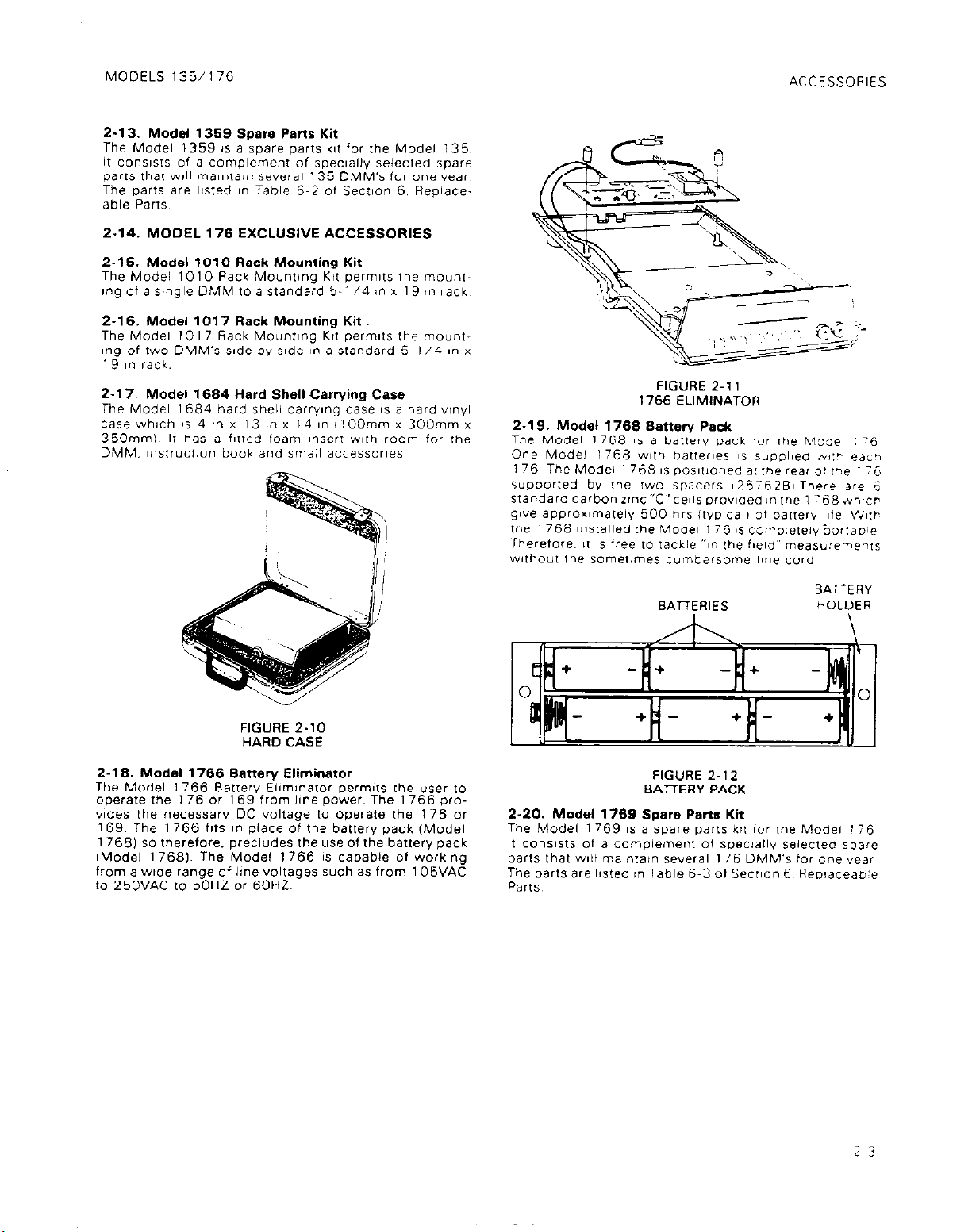

2-4.

Model 1651 50 Ampere Shunt

The Model 1651 allows current meawrements to be

made from 0 to 50 amperes DC and from 10 to 50 amperes AC, It 1s a 0.001 ohm *l% 4.terminal shunt. A fifty

ampere current WI,, correspond to 50 m,ll,volts~

To Operate: Connect separate current leads (not furmshed) between the source and the Model 165 1 hexhead bolts. Use leads that are rated

cap.xW Connect thevoltage leads ifurnlshedi between

the Model 1651 screw termmals and the DMM INPUT

terminals. Set the OMM 10 ACV and 2V range or DCV

and 2V range,

+5% terminated I” I Mn

FIGURE 2-1

1600 HIGH VOLTAGE PROBE

UP

10 50 ampere

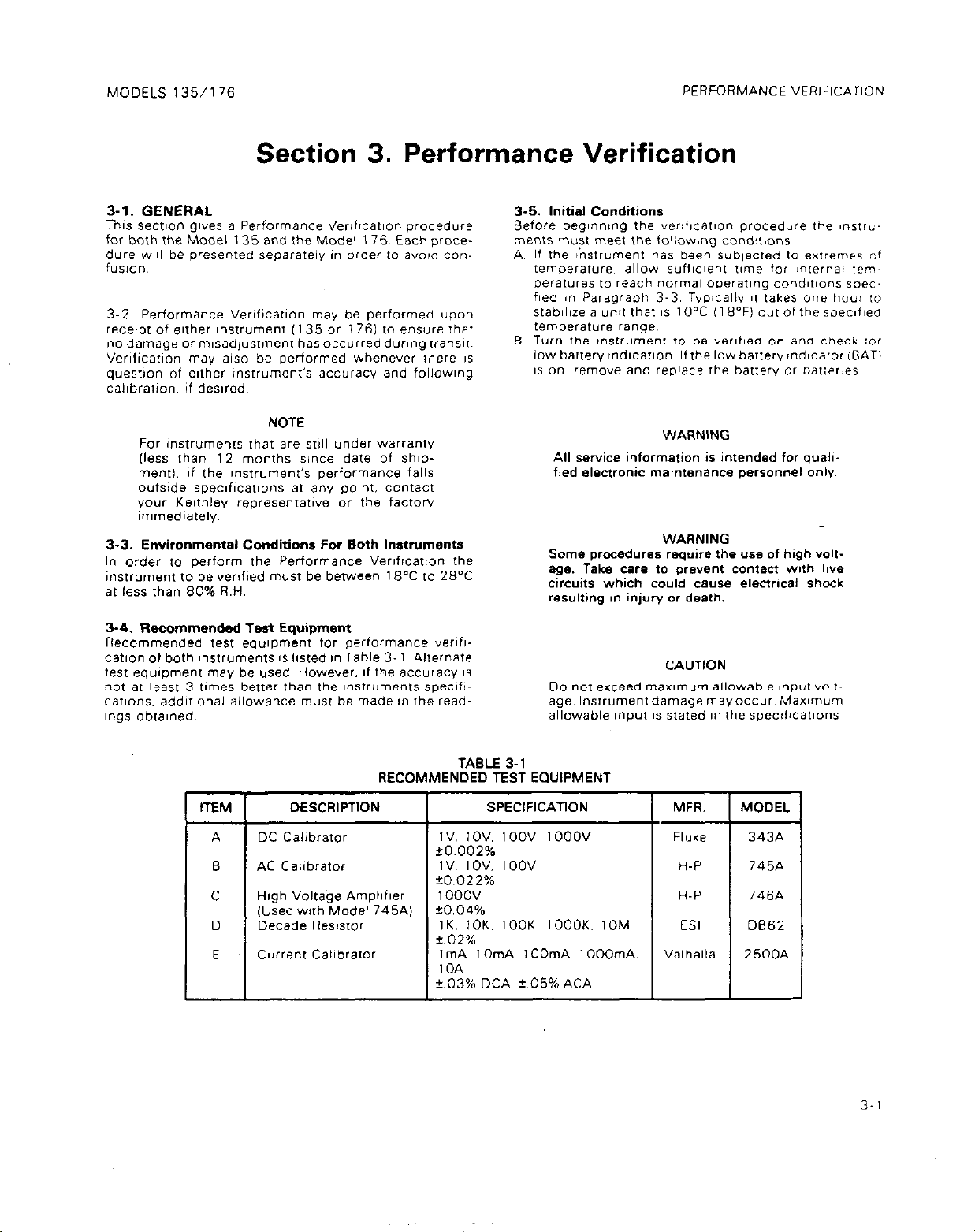

2-6.

Model 1681 Clip-On Test Lead Set

The Model 1681 contains two leads I 2rr 146

long. lhat are terminated w,th banana piug and sarongacI10” cltp-on probes.

FIGURE 2-3

CLIP-ON TEST LEADS

2-6.

Model 1682A RF Probe

Model 1682A RF Probe allows voltage measuremenrs

from 1 OOkHz to 250MHz

To

Operate:

Connect the Model 1682A to the DMM input ,acks

Specifications

AC to DC Transfer Accuracy: (7.3X? 5°C) tld6 !rom

1OOkHz to 250MHz at 1V. peak iespondlng. calibrated

i” ims of a slnewave. compat,ble with 1”5lr”ments wiin

1OMR Input res.,srance

Voltage Range: 0.25V to 15V rms

Maw&m Aliowable Input: 50V AC peak. 2OOV (DC+

AC ~eakl

Makmufk Common Mode Voltage. 30V rms. 42 peak

Input Capacitance: 5pF Typical

OperarIng Temperature: 0” to 50°C

Cable Length: 1~5 meters

Accessories Supplied: ENC Adapter. insuiaring TID,

IC Tip. Spring Hook. Carrymg Pouch

Set the DMM to DCV and appropriate range

inches,

FIGURE 2-2

1651 50 AMPERE SHUN1

FIGURE 2-4

1662 RF PROBE

Page 10

ACCESSORIES ACCESSORIES

MODELS 135/176

2-7. Model 1663 Universal Test

2-7. Model 1663 Universal Test

Two test leads. 1.2m (48 inches) long w,th 12 screw-in Two test leads. 1.2m (48 tnches) long vat,, 12 screw-in

tips. 2 banana plugs. 2 spade lugs. 2 alligator clips wfh tips. 2 banana plugs. 2 spade lugs. 2 alligator clips wfh

boors. 2 needle ups w,th chucks and 4 heavy duty ftp boors. 2 needle ups w,th chucks and 4 heavy duty ftp

plugs.

Plugs

FIGURE 2-5 FIGURE 2-5

1683 TEST LEAD KIT 1683 TEST LEAD KIT

2-S. Model 1686 Clamp-On AC Current Probe

2-S. Model 1686 Clamo-On AC Current Probe

The Model 1665 meawres AC current by clampIng onto The Model 1665 mea?.“& AC current by clampfng onto

a s,ngle conductor. Interrilptmn ot the current path IS a s,ngle conductor. Interrilptmn ot the current path IS

unnecessary, The Model 1665 detects current by sensing unnecessary, The Model 1685 detects current by sensing

the magneuc field produced by the current flow. the magneuc field produced by the current flow.

To

Operate:

Operate:

range. The DMM WI, dtsplay O.lV rms per ampere. range. The DMM WI, dtsplay O.lV rms per ampere.

Set the DMM to ACV and the appropriate To

Set the DMM to ACV and the appropriate

Lead Kit

Lead Kit

FIGURE 2-7

1691 TEST LEAD SET

Z-10. MODEL 135 EXCLUSIVE ACCESSORIES

2-l 1. Model 1304 Soft Carrying Case and Stand.

The Model 1304 IS a soft carrying case and stand (t,lt

baili for Kelthley’s hne of hand held instruments.

The instrument can be secured Inside the case wfth the

thumbscrew (suppledI. if dewed, The thumbscrew IS

also used 10 secure the stand (tilt bail) fo set the ,nsfrumen! upnghf.

1685 CLAMP-ON AC CURRENT PROSE

FIGURE 2-S

2-S. Model 1691 General Purpose Test Lead Set

The Mode, ,691 General Purpose Test Lead Se1 CO”SIS,S

of fwo 0,9 I mm (36 Inches) test leads wirh probe ups

iermlnated I” banana plugs

2-2

FIGURE 2-8

SOFT CASE AND STAND

FIGURE 2-9

1306 DELUXE CASE

2-12. Model 1306 Deluxe Carrying Case.

Model 1306 Deluxe Case is a rugged DMM carwng case

that IS large enough to accommodate the 135 plus varIOUS other DMM art~cies such as a spare battery. fes,

leads. ew

Page 11

MODELS 135/176

2-13. Model 1369 Spare Parts Kit

The Model 1359 is a spare parts kit for rhe Model 135

It CO”SISIS of a compIeme”t oi specially seiected spare

pans fhar wlil manta!” several 135 DMM’s for one year

The parts are INsted I” Table 6-2 of Sectlo” 6. Replaceable Parts,

2.14. MODEL 176 EXCLUSIVE ACCESSORIES

2.16. Model 1010 Rack Mounting Kit

The Mode, 1010 Rack Mounting Kit permits the mou”,-

,ng of a single DMM to a standard 5-l 14 in x 19 i” rack

2-16. Model 1017 Rack Mounting Kit.

The Model 1017 Rack Mounting Ktt permits rhe mount,“g of two DMM’s s,de by sde I” a srandard 5- 1 /4 I” x

19 I” lack.

2-17. Model 1684 Hard Shell Carrying Case

The Mode, 1684 hard she,, carrv~ng case IS a hard wny,

case which is 4 I” v 13 I” Y 14 I” (100mm x 300mm x

350mml~ Ii has a fltfed foam lnserf wth room for 1he

DMM. ~“struct!o” book and small accessories

FIGURE

1766

ACCESSORIES

2-l 1

ELIMINATOR

FIGURE 2-10

HARD CASE

2-18. Model 1766 Battery Eliminator

The Model , 766 Batrerv Ei,m~“ator permits the user to

operate the 176 or 169 from lhne power. The 1766 pro-

vldes the necessary DC voltage to Operate the 176 or

169.

The 1766 firs I” piace of the battery pack (Model

1766) so therefore, precludes the use of the battery pack

(Model 1768). The Model 1766 is capable of working

from a wde range of line voltages such as from 1 OSVAC

to 250VAC to 50HZ or 60HZ.

BAmEAY

BATTERIES

FIGURE 2-12

SAl-rERY PACK

HOLDER

2-20. Model 1769 Spare Parts Kit

The Model 1769 1s a spare parts ii, for ,he MOdeI : 76

it co”sIsts of a compiement of SPeclallY seiecreo space

parts that WIII ma~ntai” several 176 DMM’s lor cne veai

The parts are listeci I” Table 6~3 01 Seci~on 6 Rep!aceaale

Parts,

Page 12

Page 13

MODELS 135/l 76

Section 3. Performance Verification

3-1. GENERAL

This secf~on gtves a Performance Verilvzat~on procedure

for both the Model 135 and the Model 176. Each procedure wtil be presented separately I” order to avo,d confus,on,

3-2 Performance Verlficatlon may be performed upon

recetpt of enher ~nstr~rnenf (1 35 or 1761 10 ensure that

no damage or m,sad,ustmen, has occurred dung trans,,.

Verlficatlon may also be performed whenever there IS

quewcr of elther instrument’s acculacv and foIlowIng

cahbraron. if desired.

PERFORMANCE “ERlFlCATlON

NOTE

3-3. Environmental Conditions For Both Instruments

In order to perform the Performance Verlflcatton the

instr~men, to be venfied m”st be between 1 B’C to 2B’C

at less than 80% R.H.

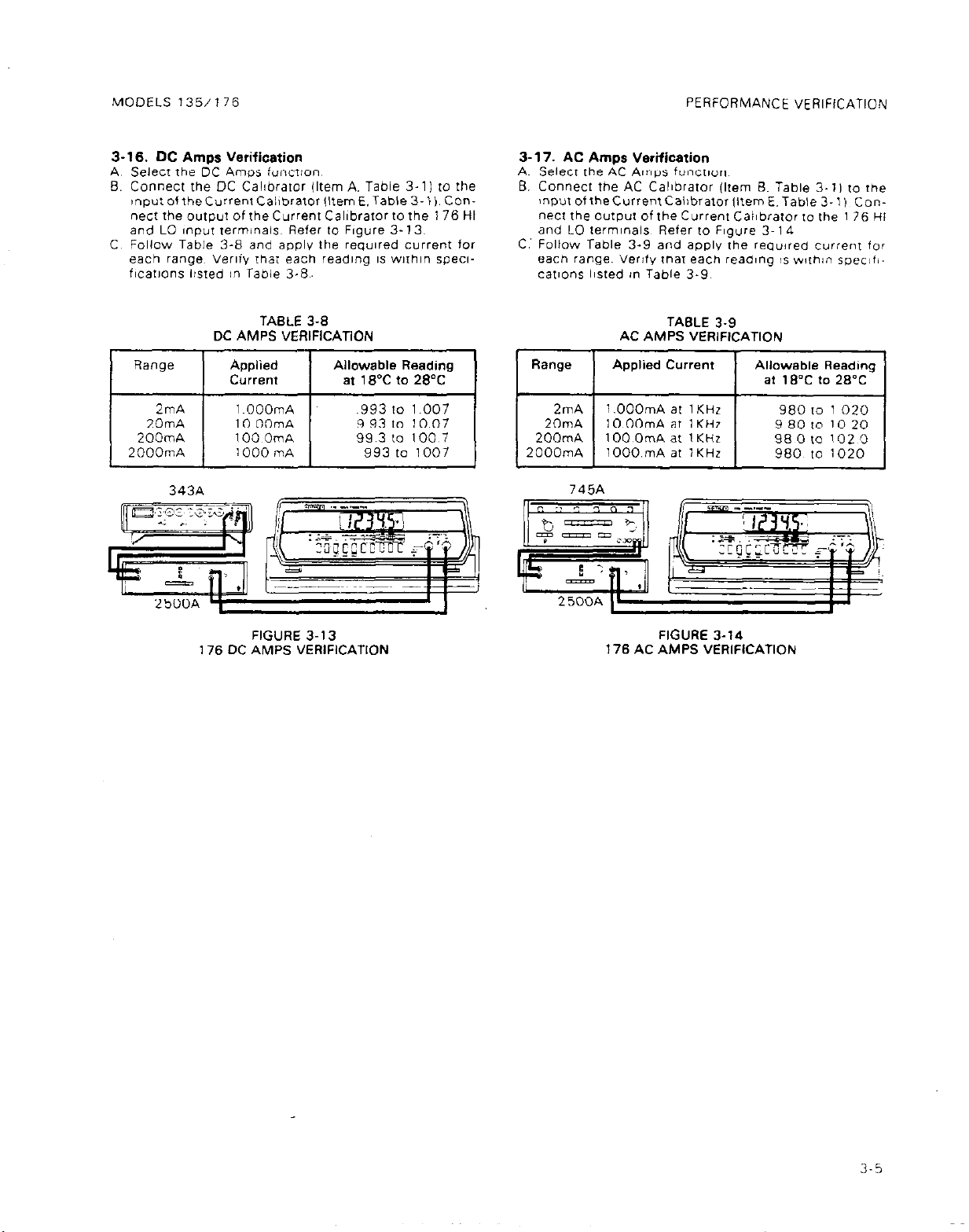

3-4. Recommended Test Equipment

Recommended test equipment for performance verlflcat,on of both instruments IS hsted in Table 3- 1 Alternate

test equipment may be used. However. 11 the accuracy IS

not at least 3 ttmes better than the instruments speclflcamns. addlnonal allowance mwt be made m the readI”@ obtalned.

RECOMMENDED TEST EQUIPMEN

TABLE 3-1

ITEM DESCRIPTION

A DC Calibrator 1v. 1ov. 1oov. 1ooov

B AC Calibrator 1v. IOV. IOOV

High Voltage Amplifier

C

(Used wth Model 745Ai *0.04%

D Decade Resistor 1K. 10K. IOOK. 1000K. 10M

E Cuirenf Calibrator 1 mA. I OmA. 1 OOmA. 1 OOOmA.

i-0.002%

+0.022%

1 ooov

+.02%

10A

+.03% DCA. +.05% ACA

WARNING

All service information is intended for qualtfied electronic maintenance personnel only.

WARNING

Some procedures require the use of high voltage. Take care to prevmt contact wth lwe

circuits which could cause electrical shock

resulting in injury or death.

CAUTION

SPECIFICATION

3-1

Page 14

PERFORMANCE VERIFICATION

3.6. MODEL 135 PERFORMANCE VERIFICATION

3-7. DC Volts Verification

A Select ihe WV funann.

B. Connect the DC Calibrator ,ltem A. Table 3-I) to the

135

C~ Follow Table 3-2 and apply the required DC Voltage

D, Repeat all checks with nega1,v.s voltage

V-R and COM fermnals. Refer to Figure 3- 1

fo, each range, “er~fy rhat each reading IS WI,,,,” speciltcatlons iwed tn Table 3-2.

MODELS 1351176

DC VOLTAGE PERFORMANCE CHECK

TABLE 3-2

Range Applied

Voltage

Allowable Reading

at 18’C to 28°C

FIGURE 3-l

135 DC VOLTS VERIFICATION

3-6. AC Volts Verification

A~ Select the ACV functmn.

B. Connecr the AC calibrator (Item 8. Table 3-l) to the

135 V-Rand COM termlnais. Refer fo Figure 3-2,

C, Follow Table 3-3 and ~DDIY the reaulred AC Voltaae

for each range. Venfy th’ai <he reading IS wlfhtn speciftca11ons Wed I” Table 3-3.

135 AC VOLTS VERIFICATION

FIGURE 3-2

746A

P

FIGURE 3-3

135 HI VOLTAGE ACV VERIFICATION

3-9. Resistance Verification

A. Select the OHMS funcrlon

By Conneci rhe Decade Resistor (Item 0. Table 3- 1) tothe

135 V-s2 and COM terrmnals. Refer 10 Flgure 3-4,

C. Follow Table 3-4 and apply the

for each range. Vertfythat each read,ng isw,th,n soeclficatrons Ifsted in Table 3-4

requfred ressstance

AC VOLTAGE PERFORMANCE CHECK

TABLE 3-3

Range

Applied Voltage

l,OOOOVat 10KHz

I O.OOOVat 500Hz

2oov 100OOVat120Hz

Allowable Reading

at 18°C to 28’C

~9885 to LO1 15

9,885to 10,115

98.85to 101,15

I

FIGURE 3-4

135 RESISTANCE VERIFICATION

Page 15

MODELS 135/l 76

PERFORMANCE VERIFICATION

TABLE 3-4

Allowable Reading

at 1wc to 28Y

9970 to 1,003o

9.978 to 10.022

99.78 to 100.22

997.8 to 1002.2

3.898 to 10.102

i

RESISTANCE PERFORMANCE CHECK

Range

2KR

ZOKR

200Kfl

2000KR

20MR

3-10. DC Amps Verification

A, Select the DC Amps function.

B. Connect the DC Calibrator ,l,em A. Table 3- 11 10 the

tnput of the Current Calibrator (Item E. Table 3-l I

Connect the OU,,,U, of ,he Current Calibrator to the

135’s mA and COM terminals. Refer 10 Figure 3-5.

C. Select the 20mA range and apply a 10,OOmA curren,

to the 135. Ver,fv that the reading IS with,” 9,93 to

10.07.

D. Select the 1 OA range and connect the outp”, of the

Current Calibrator 10 the 135’s 10A Hi and 10A LO

terminals Refer to Figure 3-6

E. Apply lO.OOA to the 135 and ver,fy tha, rhe reading

IS w,,h,” 3.88 to 10.12,

3-11. AC Amps Verification

A~ Select the AC Amps functlon and the 20mA range.

8. Connect the AC Calibrator (Item B. Table 3-l) to the

mput of the Current Calibraror (Item E. Table 3-11

Connect the output of the Current Callbrafor to the

135’s mA and COM term~nais. Refer 10 Figure 3-7

C~ Apply a 10,OO mA currenr a, 500H2 and verliy lhal

the readfng IS w,th,n 9~80 to 10.20~

D. Select the 10A range and connect fhe outp”, of the

Curren, Calibrator fo the 135’s 10A HI and 1 OA LO

terminals. Refer fo Figure 3-8.

E. Apply a 1 O.OOA current at 500Hz and ver,fv that fhe

readang IS wfhin 9.80 10 10.20.

343A

FIGURE 3-6

135 1OA DC AMPS VERIFICATION

FIGURE 3-7

135 AC AMPS VERfFlCATlON

343A

FIGURE 3-5

135 DC AMPS VERIFICATION

135 ,OA AC AMPS VERIFICATION

FIGURE 3-8

Page 16

PERFORMANCE VERIFICATION

3-12. MODEL 176 PERFORMANCE VERlFlCATlON

3-l 3. DC Volts Verification

A. Select the OC Volts functuon.

6. Connect the DC Calibrator IItem A. Table 3-l) to the

176’s HI and LO ~npu, ierminals. Refer to Fig’ure 3.9.

C. Follow Table 3-5 and apply the required DC Voltage

for each range, Verify tha, each readtng IS wtfhin specifications Ifsted I” Table 3-5.

D. Repeat all checks wtth negatwe voltage,

MODELS 135/l 76

FIGURE 3-10

176 AC VOLTS VERIFICATION

Applied

Voltage

TABLE 3-5

Allowable Reading

at 18°C to 28°C

DC VOLTAGE PERFORMANCE VERIFICATION

Range

4’ 1

I

FIGURE 3-9

I76 DC VOLTS VERIFICATION

3- 14. AC Voltage Verification

A. Select rhe AC Volts funcuon.

By Connect the AC Calibrator and HVAmpllfier iltems B

and C. Table 3-l) to the 176’s HI and LO terminals.

Refer to Figures 3-10 and 3-1 1.

C. Follow Table 3-6 and apply the required AC Voltage

for each range. Verlfythafeach reading iswithIn spec-

lflcatlons listed ,n Table 3-6.

I J

178 HIGH VOLTAGE ACV VERIFICATION

3-15. Resistance Verification

A, Select the OHMS funcnon.

8 Connect the Decade Re%$,or (hem 0. Table 3-I) to the

176 HI and LO ~npu, terminals. Refer to Figure 3.12.

C, Follow Table 3-7 and apply the reqwred resistance for

each ranae. Verlfv that each readina is within soeclfl-

cations ll;ted in fable 3.7~

RESISTANCE VERIFICATION

Range

FIGURE 3-l 1

TABLE 3-7

Applied

Resistance

Allowable Reading

at 18’C to 28’C

1

I

AC VOLTAGE PERFORMANCE CHECK

Range

;:: 1 1 ~OOOOVa, OOOOV at 1 OKHz 1 KHz

2% 1 1 ,OOOOVat O~OOOV at 20KHz 1 KHZ

2ov lO.OOOVat 1OKHz

2ov 10,OOOVar 20KHz

2oov 100 OOV a, 1 KHz

1 ooov 1OOOOVal IKHz

3-4

Applied Voltage

TABLE 3-6

Allowable Reading

at 18°C to 28°C

.9885 ,9885 to to 1.01 1.01 15 15

9,885 9485 to to X0515 10,115

9.885 to 10.1 15

9.485 to 10.515

98.85 10 101,15

988.5 to 101 1 5

176 RESISTANCE VERIFICATION

FIGURE 3-l 2

Page 17

MODELS 135/176

PERFORMANCE VERIFICATION

3-16. DC Amps Verification

A. Select the DC Amps tunctton.

8. Connect the DC Calsbrator (Item A. Table 3-l I to the

,nputottheCurrentCai,bra,~r ,ltemE.Table 3-11, Connecf the output 01 the Current Calibraror to the 176 HI

and LO l”p”r terminals. Refer to Figure 3- 13.

C, Follow Table 3-8 and applv the required c”rrenf for

each ranges Verliy ihat each reading IS wrhln spew

flcatlons ilsted I” Table 3-8,.

TABLE 3-6

DC AMPS VERIFICATION

Range

2mA 1~OOOmA ~993 IO 1~007 2mA 1 .OOOmA at 1 KHz 980 to 1320

20mA 1 O~OOmA 9.93 10 10.07 20mA I O.OOmA ar 1 KHz 9~80 10 IO 20

200mA 100 OmA 99.3 to loo,7 20OmA 100,OmA at 1 KHz 9aoto 1023

2000mA 1000 rnA 993 to 1007 2000mA lOOO,mA at IKHz 980 10 1020

343A

Applied

CtlrrWlt

Allowable Reading

at 16°C to 26°C

3-17. AC Amps Verification

A.

Select the !iC Amps funwon

B.

Connect the AC Callbraror jlrem 6. Table 3-1, to the

~“puiotIheCurrentCaiibrator,ltemE,Tab,e3-ti Connect the

and LO termnals Refer to F,gure 3-14

C,

Foliow Table 3-9 and apply the required curient for

each range. Vertiy that each reading 1s

cations ksted in Table 3-9

Range

I I

Outpu!

of the Current Callbraior IO the 1 76 Hi

TABLE 3-9

AC AMPS VERIFICATION

Applied Current

Allowable Reading

a* 19°C to 26°C

I

warhtn spew,-

176 DC AMPS VERIFICATION

FIGURE 3-13

176 AC AMPS VERIFICATION

FIGURE 3.14

3-5

Page 18

Page 19

MODELS 135/l 76

THEORY OF OPERATION

Section

4. Theory of Operation

4-l. GENERAL

Th,s sect,on contatns the c,rc”~, descrtpflons for The

Model 135 and Model 1 76. The iollowng dlscusslons of

c,rcu,t theory veil be separated <“to 2 maw sect\ons~ The

2 map, SeCtIOnS are:

I ) Model 135 Circuu Theory

21 Model 176 Czrcutt Theory

The ~nfprmat,on contaned I” each of these 5ectto”s IS

arranged I” the following manner.

1, Overall Functional Description

7.1 Stgnal Condittonrig

3) A/D Converter

4) Display

51 Power SUPPlY

To facilnate understandtng. each descrtptton IS accom-

panted wth slmpilfied schematIcs. blockdlagrams. tables

and graphs. Detacled st~emaiics of ,he Moaei 135 a”~

Model 176 are orovlded ,n Sewon 6

4-2. MODEL 136 OVERALL FUNCTIONAL

DESCRIPTION

The Mode, 135 1s a 4-1 i2 aqr. t20.000 co”“, hard

held DMM It has 4 DC voltage ranges. 4 AC voltage

ranoes. 5 res,srance ra”aes. 2 DC C”rre”l ranoes ant 2

The 135 was destgned for h#gh periormance ar zov? cosi

To meet these design goals the 135 takes advantage r,’

standard <off the shelf” components, The A/D c~)“vertel

was designed from scratch using dlscrete componenls for

lower power ‘onsumpt\on and ,mproved aeriorman:e

over prssen,ly available LSI A/D converters

Ftgure 4- 1 shops the overa,, bioce diagram 1-r xw mc^ei

135

V-Q

IAC CONVERTER ONLY)

ATTENUATOR

RESISTANCE

+e.4v

-5V ANALOG

+5V ANALOG

+5V DIGITAL

ANALOG

FIGURE 4.1

135 BLOCK DIAGRAM

Page 20

THEORY OF OPERATION

MODELS 135/l 76

4-3. Signal Conditioning

The Signal Condltlonlng for the Model 135 includes DC

arten~atmn iexcept on the 2 Volt range,. AC attenuation.

AC/DC conveis~an. Ohms conversion and current

ShUrxS.

A. DCV Signal Condittonlng consists of one lOMnpas-

swe dwder~ The taps tram this divider are inputted

dlrecrly to rhe A/D converter through the rotary range

watch S102. Table 4-1 state~~he associated attenuatton with each range, Potentiometer Rl 13 trims the

ga,n for the 20 Volt range. The overload protection

IS provided by the llmmng resistor Rl 15.

ACV

‘75OV range for ACV

B. ACV SIgnal Condmonmg consists of a 1 OMR pasSwe

dwlder. AC buffer amplifier and AC co”verWr. The

scalmg IS accompi~shed by the same 10MSIwsswe

dlwder that IS used for DCV scaling, After the divider

rhe :,gna, IS AC coupled ,nto U105 the AC Buffer

Ampl~flei. The slgnai is then applied 10 the averaging

piec~~~on rectlfler U 104, It IS driven at low lmpedan.ce

by the AC coupled buffer U104 performs the AC conversion, It then passes through a two stage low pass

filter which converts it to DC. This OC level IS applied

fo the A/D converter. Input resistance for the AC converter is 1 OfvUlshunrea by less than 100 pf.

TABLE 4-1

AND DCyA7TENUATlON

Rl 1 1 establishes AC zero while R 109 determ,nes the

full scale gain (19000 counts), R105 and C 108 provlde the low pas5 f,lter ro average the half wave recw

fled outputs Overload protection IS prowded by d,odes

CR104 ahd CR105 and currentllmttlngreslstorR1 10.

Figure 4-2 shows a simplified SchematIc of the AC

cOn”erter.

C

Resistance Signal Condltloning 1s accomplished iaxmetrically. That IS. a precision reference resistor and

Rx are put in ser,es wth a 2,5 volt reference, Therefore. the current developed i” the two ~BSIS~IIS 15 the

same. Taking the ratlo of rhe voltage drop across Rx 10

the drop across R<e,e,en<e coriectly caiculates ohms.

The value of the voltage reference IS irrelevant. as ,t

only serves to apply a source of currentto the ies,stors

(Rx and Rrc~ewncel. The preceding theory IS illustrated

mathematically in the following equations. Refer to

Figure 4-3,

I =

Vdisplay = ;;;f;,:;;;f$ X 10,000

Vdisplay =

Vdisp’av = , [Rref + Rp C Rx. Rp. Rx]

Vdisplay = & X 10.000 = & X 10.000

Vref

Rref + Rp + Rx

lL~ref+flp+R~]-i[~p+~xJ x’o.ooo

I [Rx1 -0

IRX

x 10.000

lOMR DIVIDER

v2v

!

4-2

90KR

1 OKR

2ov f---l*

2oov

750v

AC

COUPLING

SIMPLIFIED

BUFFER

UlO!i

- RECTIFIER - LOW PASS -

PRECISION

u104

FIGURE 4-2

AC CONVERTER BLOCK DIAGRAM

TWO STAGE

FILTER

R105

7

Cl08

Page 21

MODELS 135/176

THEORY OF OPERATION

The prectsion reference resistors are wallable from

the DC divider. Ap and Cl204 form the overload prote~llon for the Ref LO ,“put “ref is approxnnately 2.5

volts and is provided by pass rrans~stor QlOl, 0204

conducts much like a zener diode at approxlmafely

9 volrs to absorb the imtial overload as Rp heats up.

16 res,stance goes from 1 K to several megohms effec-

ttvely limttrig cuireni.

h--- Lo

FIGURE 4-3

SIMPLIFIED OHMS SCHEMATIC

CAUTION

Do not exceed maxtmu” allowable input

Instrument

IS unfused.

4-4.

A/D

The A/D converter IS really the heart of lhe znstrumer,

If 6 engmeered from dlscrere SSI CMOS and low

analog circuitry The operation of rhea/D converter 1s of

the dual slope pr,nc,ple. The tuning of rhe dual siope

measurement IS dwded into 3 pertods: Auto Zero, Sgnai

Integrate and Reference Integrate. The fo,low,ng fhree

SIeps lll”Strate the three measurement pertods

1, Auto Zero

The Auto Zero per,od is 100 rnsec in !engt* v11tzr

corresponds 10 10.000 clock pulses Dw?g :n,s

period the reference voltage IS stored on caoacilc:

C205~ Capacllor C206 stores +vos:-v~s2 Refer tc

Figure 4-5

Vref

damage may occur, 10A range

Converter

powe,

BUFFER

INTEGRATOR

D AC/DC Current measuremenrs have two ranges: the

20mA range and the 1 OA range. These two ranges are

3-l/2 d,g,t readings in order to keep, the burden voltage under 250mV, The 20mA range IS protected by

d,odes CR1 08. CR1 09 and Fuse Fl 01. The cuirent

shunt for the 10A range IS destgned to m,n,mize

~ntetnal heatlng I” the event of overloads Figure 4-4

is a simple block diagram showing AC/DC current

measurements~

FIGURE 4-4

BLOCK DIAGRAM FOR CURRENT MEASUREMENT

FIGURE 4-5

AUTO ZERO

DISPLAY

Page 22

THEORY OF OPERATION

MODELS 135/l 76

21 Signal Integrate

As wtth the Auto Zero phase the Signal Integrate

phaseisof lOOmsecdurat~on.The~nputafrheA/O

converter is first buffered by one half of U2 13 and

lhen the signal 1s integrated by the other half of

U213. When pOSitlveSignaiSareapplledtotheA./D

the ~nregrator generates a negawe go’ng ramp.

Thus can be seen al the output of the lntegraror ip~n

1). When negative signals are applied IO the A/D

the mregrator generates a powwe going ramp.

The level of the mtegrated signal at the end of this

permd islgnal integrate) is proportional to the

average of the appiled s!gnal during th!s pewd.

Since Signal Integration is a constant 100 “sec.

the converter exhibits high rejectron at 50Hz and

60Hz. Refer to Ftgure 4-6 for a slmpilfled dtagram

of Signal Integrate.

SIGNAL INTEGRATE (IOK COUNTS1

FIGURE 4-6

SIGNAL INTEGRATE

3’1 Reference Integrate

The Reference Integrate pernd for a full scale8nput

120.000 counts) is 200 “sec. During this period

the fntegrator is returned 10 a baselrne level by

applying a reference voltage of a polaray opposne

to that of the slgnal. This IS accomplished by

grounding the appropriate side of the reference

capacator~ The dtgltal output IS generated from the

latches wlthtn UlOl which store the number of

clock pulses required for the lntegraror to return

to baselme levels.

For inputs le?,s than full scale ifull scale = 20.000

countsI. the A/D automatically reverts to Auto

Zero. This happens I” the rime period of the 200

msecs remafmng after the return to baselme level.

Refer to Figures 4-7 and 4-8 for a slmplifled diagram of Reference integrate.

NEGATIVE REFERENCE

INTEGRATE (20K COUNTS AT FULL SCALE)

NEGATIVE

INPUTS TO A/D

POSITIVE REFERENCE INTEGRATE

(ZOKCOUNTSAT FULL SCALE)

INPUTS

TO A/D

POSITIVE REFERENCE INTEGRATE

Also Included rn the A/D are 2 adjustment potent~ometets. R205 is part of a translation network

which Insures rhat the comparator ourplit during

autozero IS at or near the threshold of U204C.

which is ihe zero crosstng flip flop. Therefore thus

adlustment controls symmetry between posmve

and negative jnputs Shorting C204 (as I” the cal

procedure) and adjusttng A205 for a reading of

~0000 accomplishes this symmetry adjustment.

The A/D gal” control (R102) IS rhe other adlustmen,. This potentiometer controls the %ference

voltage and compensates for all gain errors wlthfn

the dual slope A/D converter,

The A/D is rat~omerr~c. with dlfferenrlai reference

fnputs~ Therefore

Vd6play =

The full scale inputs for the A/D are as follows:

ACV.DCV.fi.DCA.ACA = +2V (full scale input)

4-5.

Input &dfer

The analog watches used for the A/D converter are

CMOS (U210. U2 1 1. U2 121. A low drift. low bias current buffer iU2 141 precedes the A/D input. The offsel for

thfs amplifier iU2 141 1s nulled w(Ih potentiometer R207.

4-6.

Reference Voltage

The reference voltage (Vwl IS provided by a dlwder network placed acnxs a temperature compensated zener

(CR1 101. One half of U 102 prowdes the zener wrh a self

regulamg bias, The reference voltage IS approx~marely

1.0 volts and can be fmely adjusted by R102.

FIGURE 4-8

(Ref ;‘““;if Lo) x 10.000

4-4

NEGATIVE REFERENCE INTEGRATE

FIGURE 4-7

4-7. Display

The 4-l/2 digIt Llquld Crystal Dlspiav IS driven by LSI

counter/driver U 10 1~ The Backplane and the segments

of the dtglts are driven dlrecrly by UlOl The zebra strip

connector transfers rhe dwe slgnais from the P-C board

Onto the LCD~

A low battery mdlcator is detected and actuated by one

half of U102. Thts an”““c~atcx. the minus srgn. and a,,

Page 23

MODELS 135/176

declmal pants are dwen by the exclusive OR gate arrays

U201 and U202.

The dtgmzed measuremen, data IS presented by out-

Put ifnes IO

wave having the same ampiltude and ‘reauency as rhe

Backplane l,“e. When rhe ii”e5 IO the d,splay segmenrs

are driven 180” our of phase with the Backplane the segments are ON. Conversely. when tn phase the segments

are OFF The dectmai points and rhe LO battery #ndlcaror

are Turned OFF and ON s,m,larly.

4-8.

The prec,s~on reference current source “102A also dou-

bles as the +5 volt supply. P,n 1 of U 102 IS the V+ supply

The 5 volt supply IS generated by a power ~““erter c~rcui,

(U1031. This device charaes capacitor C 102 and then

rwerses it. Thts effect,“& gene;ates -5 “pits. A “oi&,ge

doubler c$rc”tt consisting of C.103. C104. CR101 and

CR102 generates +8.4 KITS. Th,s voltage IS only used

on U104 which is the precision recttfler amplifier iUlO4)

of the AC co”“erter.

rhe LCD, These lines are dwen by a square

Power Supply

4-9. MODEL 176 OVERALL FUNCTIONAL

DESCRIPTION

The Model I 76 IS a 4. I /2 diglf. f20.000 count portable

bench DMM It has 4 DC “&age ranges. 4 AC “oirage

ranges. 5 ie~iSta”ce ranges. 4 DC current ranges and 4

4C current ranges. Along w,th theselunct,onsand ranges

tt has 100i.1VDC and AC “offs senstttvlty with 100mQ

res~siance se”~m”~ty The DC and AC current senstt>“,,”

IS 1uA.

The 176 was destgned for h,gh performance at tow cosr

To meet these design goals the 176 lakes advantage 01

standard “off rhe shelf” components. passive s~g”aI condltionlng and multlfuncrion components and CI~CUIIS,

The A/D converter was designed from scratch us,ng

dlscrere SSI CMOS c~mppnent~forlowpowerconsumpr!on and improved performance-aver presently available

LSI A/D converters.

THEORY OF OPERATION

2V ‘1

2ov

TABLE 4-2

Attenua~,on Factor

i’ 0

+i so

ACV AND DCV ATTENUATION

Rang.?

2oov

I ooov ?lOOO

OHMS

REFERENCE

VOLTAGE

/

ATTENUATOR

RI

.d

I I

IAC CONVERTER ONLYY)

+8,4V

FIGURE 4-9

176 BLOCK DIAGRAM

A/D

CONVERTER

OlSPL4Y

ANNUNCIATOR

DRIVERS

-5V

+5V DIGITAL

+?JV ANALOG

DIGITAL

J-5

Page 24

THEORY OF OPERATION

ZVRANGE R103

MODELS 135/176

R106

8.9775MQ

R108

gaoK~ _“_. .,, ..--

R108

90KR

R108

9KR

A108

1KR

4-12.

AC Volts

The AC Volts Signal Cond,!,on,ng cons,s~s of a passive

d,v,derfR109-Rl 11.Ri 14andC103~C106)andfheAC

converter During AC “okage measurements the measured sqnal IS aopl,ed 10 ihe dlwder and IS atten”aIed by

1,10.l00or1000forthe2V.20V.200orlOOOVrange

respectively, The capacitors (C 103 C 1061 are used for

~orni)e”salion for stray capacitance and for frequency

characrer,st~cs of rhe resisrors, There IS no capaaror used

on rhe 2V range for frequency compensation There are

onlytwocapacitors ,nrhecircu,tforanyotherrange~Th,s

reduces ,nteract,on between ranges and allows easy ISO-

lhon of taulrv capacitors~ The outputfrom the AC dlvtder

IS appl,ed to rhe AC converter where 8, IS recflfled and

scaled before being appI,ed to the A/D converter, Refer

to Figure 4-l 1

2OV RANGE

-

ilO

1OOOVRANGE

DCV SIGNAL CONDITIONING

FIGURE 4-10

1-2 VOLTS TO +2

VOLTS)

.-’ +, _ , ~107 R116

_. - _

R109

lKS2

The AC converter IS a preclson half wave reci~f~er with

high mpedance fnput and sufflclenr gal” 10 produce a

DC output equal to the ims value of a sine wave input

Following the sIgnal path. C 107 1s used as a DC blocking

capac~ror so thar DC oftsets ,n rhe measured signal do no1

affect fhe readmg. UlO8 IS a unify gain buiier used lo

eliminate loading 01 the AC dlwder and prwde Iow im.

pedance dwe for rhe acfual AC converter ” 109 Capa,tom C 109 and Cl 10 eliminate any problem due to the

offset voltage of U 108~ Rl 19 R 12 1 ad,us, the gal” of

the AC converter required to convert from fhe rect$hed

waveform average 10 rms equ~“aIeni, Resistors RI ! 7 and

4 1 18 adlusr 0~1 any error at zero due ro oifsers I” ” 109

U 109 uses feed forward compensation provided by C 1 14

and will become unsiable when any capac~riue load isuch

as a scope probe) IS attached near rhe ou1pu1 cjrcuitry 01

the CIP amp lU109)~ Refer 10 Figure 4.12

ilooo

FIGURE 4-11

AC VOLTS DIVIDER

d-&,%-TO AC CONVERTER

>E

J. --_ lOOKa PROTECTION

OPEN. C103. C104. Cl05

DEPENDING ON RANGE

4-6

R120 I-DCD’J’

AC Cal

CR107

Al 19

R118 50KR

ZERO AD.!

FIGURE 4-12

AC CONVERTER

Page 25

MODELS 135/l 76

THEORY OF OPERATION

+--REF LO

tars RI 07a;d R 108 are a150 the DC” dtvider, Us,ng the

1KR. 10KQ. 100KR. IOOOKn and 10MQ tapson

the dwder for ihe 2K.Q. 20Kn. ZOOKR. 2000Kfi and

20MR ran4e5,ihedls~lavedreadlnaistheac1ualres,si-

II

RX

Input HI Input LO

Ret HI Ref Lo

OHMS SIGNAL CONDITIONING SIMPLIFIED

PROTECTION

INPVT HI

UNKNOWN

RESISTOR

h

FIGURE 4-14

INPUT LO

6

PROTECTION

INPUT>

h

FIGURE 4-13

OHMS SIGNAL CONDITIONING

PROTECTION

lOKI2

4iOKn

PROTECTION

TO A/D INPUT 6”FFtR

OR AC CONVERTEP

lNP”T

“,.‘,:“, T

R106

0 1R

INPUT--------/i

FIGURE 4-l 5

AMPS SlGNAL CONDITIONING

Page 26

THEORY OF OPERATION

4-15. Input Buffer

FOLDOVER PROTEC-

TION RESISTOR ON

UllO

FIGURE 4-16

INPUT BUFFER

4-16.

A/O

The 176 A/D converter is essent~allv the heart of the

instrument. It has been engineered wrh discrete SSI

CMOS and Ibw power analog c~rcu,fry. This A/D con-

Convener

BOTTOM SIDE OF PCB

ON REV C PCE’S.

C1’18

O.lpF

MODELS 135/176

The Auto Zero period IS 100 msec I” length whtch

corresponds to 10.000 clock pukes. Dur,ng th\s

perlod the releience voltage IS stored on capacitor

c 1 1 7. capac,ror c 120 stores +Vasl “os2. Refer to

Figure 4-1 7.

21 stgm Integrate

As wth the Auto Zero phase the SIgnal integrare

phase 1s of 100 msec duralton. The input of the A/D

converter IS f,rst buffered by Ul 10 and then II IS

integrate0 by Ul 11, When posmve s,g”als are

applied to the A/D the ,nfegrator generares a negawe gang ramp. This can be seen ar the output 01

the !ntegrator (pin 11~ When negative signals are

applted to the A/D rhe integrator generates a pas,we go,ng ramp.

The ieve, of rhe integrated signal at me end of fhls

period tslgnal lntegratei IS proportional to the average Of the applied s,g”al dur>“g ,h,s pert& S,“ce

SIgnal Integrate IS a constant 100 msec. the A/D

co”“e~ter exh,b,ts h,gh re,ect,o” at 50Hz and 60Hz,

Refer 10 Ftgure 4-l 7.

3) Reierence lnteglate

The Reference Integrate perlod for a full scale ,nput

(20.000 co”nls, IS 200 msec, During rh,s period the

INTEGRATOR

Cl19

COMPARATOR

ITAANSISTORS

010,. 102. 103,

4-8

RE! LO

FIGURE 4.17

A/D CONVERTER

Page 27

MODELS 135/l 76

,ntegraror IS returned to a basei,ne level by appiylng

a reference voltage 01 a p&my oppos~re to that of

the SIgnal. This IS acompllshed by grounding the

appropriate side of the reference capacjtor The

d,g,,al output 1s generared from rhe latches wlthln

“107 which store rhe number of clock pulses

requmd for the integrator to r.?t”rn to basellne

levels

For ,np”ts Iess than tuil scale ifull scale = 20.000

coun,sl. rheA/D automat~caliy reverts ,oAufo Zero.

This happens in fhe fime perNod of the 200 msec

rema,n,“g after rhe return to baSelIne level

AIs, Included I,. the A/D are 2 ad,ustmeni pore”-

tiometers ‘8125 IS part ot a translation network

which insures that the comparator output dung

Auto Zero is at or near the threshold of VI 14C.

wh,ch IS the zero crossjng fltp flop, Therefore thts

ad,usrment conrrois symmetry between posweand

negmve ~ny)uts~ Shorting C 1 18 jas I” the Cal Procedure, and adlusting Rl 25 for a read,ng of 0000

accomplishes this symmetry adjustment,

The A/D gan conrio (RI301 IS the other adjust-

ment. Th,s potentiometer controls the reference

voltage and compensares for all gal” errors wtlhln

fhe d”ai slope A/D co”“er,er~

The A,D conver,er is rat~ometrlc wfh d~fferenrial

reference inputs, Therefore

THEORY OF OPERATION

0, Amps LC or DC

In reference IO Flgure 4- 15 CR101 pro,ects tne .ow

Vdtsplay = (Ref ,yil”u,‘,, Lo)

The full scale ,nputs for the A/D are as follows:

1. ACV = +2V (full scale mput)

2. DCV = ezv IfUll Scale inDuti

3. n = t2v (full Scale l&Ii

4, ACA = +~2V lfuli scalB InPut)

5. DCA = +.2V (full Scale InPUtI

x 10.000

4-l 7. Protection Circuitry

A,

DC volts

In reierence to Ftgure 4- 10. RI 03 protects the ~“strumenr from damage by llmitlng the current IO the tnput

buffer to about 2mA max~m”m, Extended

of greater than 300 volts on the 2VDC range may

damaae Rl 16.

B

AC V&s

in reference to Figure 4-l 1, Rl 16 protects the ~nstru-

ment from damage by l,m,,,ng rhe curren, to ihe AC

converter to

appl,cat,on of greater than 300 volts on the 2V AC

range may damage R 103~

C,

Ohms

In reference to Figure 4-13. there are three CO”POnents that protect Ihe ~nstrumenf in the eve”, voltage

1s appited lo rhe mput whtle on the Ohms lunct~on

TheseCompo”entsareR103. RTIOI andQ104, R103

works exacflyitke ildoesforDCvo,tagemeas”reme”,s

by limnng current $mo the tnpui buffer amplIfter

Q104 1s used as a tow leakage zener with a breakdown voltage of app,oxtmately 10 “olts~ RTl 01 1s a

positive temperature coeff~ctenf thermistor, RTI 0 1

I,m,ts the curie”, gofng 10 Q104 by increasing its

res,stance greatly when heated Thus happens when

volrage above 10 volts IS applvzd to the tnput When

vdfages of much greater value than 300 volts are

approximately

1 OmA maximum. Extended

a~pl~catlOn

Page 28

THEORY OF OPERATION

MODELS 135/l 76

power converter which generales -5 volts by chargmg

Cl27 with the +5V supply, then switchtng the pos111vB

lead of C 127 to ground and charyng C 130 to -5 vOltS~

CR108. CR109. Cl24 and Cl26 form a simple voltage

doubler drwen b” Cl 27 The result of the doubler equals

+8~4 volts wh,ch is used exclusively by U109 I” the AC

COnYerter.

The +5 volt supply IS spltr ,nto two separate lhnes, One

for the analog c,rcu,try and one lor the diglial ctrcutrry

The -5 volt suppiy IS used for rhe comparator. the analog

swtches and mosr of the OP amps.

The facr that CR1 I 1 IS stable wfh r,me and temperarure

enables it to also be used to deilve the prec,se 1 0000

volt and 0.1000 volt reference signals rhat are used for

Volts and Amps. respectively, Durmg voltage measure-

ments the CR 1 1 I voltage IS attenuated to 1~0000 volts

by Rl 13. Rl 15 and R130~ The 1 ~OOOOV s,gnai IS fed

to the A/D reierence ,nput~ During the Amps funcnon

fll 15 IS replaced by a secr~on 01 RlOB. Th,s atfenuares

the 1,OOOOV to 0,lOOOV wh,ch 1s a&led ,o thk A/D

reference (“put,

Page 29

MODELS 135/l 76

MAINTENANCE

Section 5. Maintenance (Troubleshooting, Calibration)

5-l. GENERAL

Model 135

Model 135

Model 135

Model 176

Model 176

Model 176

Model 1766 Troubleshooting

Caltbrat~on

TroubIeshoor<“g

Batrery Replacement. Fuse Replacement

Cai,brar,on

Troubleshooting

Battery Replacement. Fuse Repiacemenr

5-2. MODEL 135 CALIBRATION

The Model 135 recommended cal,bratlon equ,pmen, IS

!~sted I” Table 5-l Alternare equipment may be usea

However. the atc~rac” of rhe alternate equipment must

be ar ieast 3 limes bertei ihan the Model 135’s spec,f,-

cat,ons or equal to Table 5- 1 spec,f,catlons~

5-3. Environmental Conditions

Callbratlon shoula be peiformed under laboratorycondlW,“S having a” amble”, temperature of 23°C _+I ‘C and a

reiat,ve humld,ty 01 iess than 70%, If the instrument has

been sublected to temperaiures outside of this range. or

to h,gher hurmd,,“, aI,ow one hour mln~mum for Ihe

tnsrrument to stabtlize at the speclf,ed e”v,ronme”tal

cond,,,ons before beglnnlng the callbratlon procedure.

5-4. Calibration Procedure

NOTE

Cahbratlon should be performed bYqualifIed

personnel “sing acC”rate and reliable eq”,pment.

CAUTION

Do nor exceed the max,mum allowable input

voltage. Instrument damage maY occur. Maxmum allowable inpuTs are stated I” the spec-

ficatlon.

RECOMMENDED CALIBRATION EQUIPMENT

) ITEM 1 DESCRIPTION

ITEM DESCRIPTION

A A

8 8 AC Calibrator AC Calibrator

DC CaI,brator DC CaI,brator

TABLE 5-1

SPECIFICATION

I

SPECIFICATION

:ov 1oov. 1ooov :ov 1oov. 1ooov

+ 002% + 002%

I”. iv. 1ov. IOOV I”. iv. 1ov. IOOV

?022% ?022%

SOLDER SIDE OF A/D BOARD

FIGURE 5-1

1 MFR, \ MODEL )

MFR,

Fl”klZ Fl”klZ

H-P H-P

MODEL

343A 343A

745A 745A

Page 30

MAINTENANCE

MODELS 1351176

Remove the short from C204 Select the 2V range and

short the !nput termtnals (VR to COMI, Adjust R207

for ~0000.

Remove the short from the input terminals Wlto

COM)~ Apply + 1.9000VDC to VRand COM and adjust

R102 for +1.9000.

Select the 20V range and apply + 19.000VDC to V-n

and COM and adjust R1 13 for + 19.000.

Select the ACV funcflon and the 750V range. Short

the (“put term,nals (V-R to COM) and adfust Rl 11

for 000.0,

Select the 2V range. Apply 1.9000VAC at 500 Hz to

V-fl and COM and adfust RlOS for 1.9000.

R207

R205

I I

R102

Model 135 and provtde instruction on how to avold

damaging them when they must be removed or replaced.

A. Static sens~we dewces:

Reference Des,gnar,on Keithlev Part Number

0. The above Integrated clrcults should be handled and

transported only in protection contamers. Typically

they will be received I” anti-static tubes or elecrr~callv

conductive foam. Keep the devices in thefr origlnaf

containers until ready for use.

C. Remove the devices from their protectfve containers

only at a properly grounded work bench or table. and

of~lv after grounding yourself by using a wrest strap.

D. Handle the devices only by the body. Do not touch the

Pll7S.

E. Any pnnted c,rcu,l board (“to which a de”,ee IS to be

inserted must also be grounded to the bench or table.

F~ Use only ant,-stat,c type solder suckers.

G. Use only grounded t!p soldering irons.

H. After soldering the dewce ,“to the board. or properly

lnsertlng it 1nt0 the matmg receptacle, the devlce is

adequately protected and normal handlmg can be

resumed,

UlOl IC-286

u102 IC-288

u103

u201. u202

U203. U209

u204 IC-284

IC-287

IC-226

IC-103

SIDE VIEWS OF CALIERATION ADJUSTMENTS

FIGURE 5-2

5-6. TROUBLESHOOTING

The troubleshooting instructions contained I” this section

are Intended for quailfled personnel having a basic understandIng ot analog and dlglt.8 c,rcu,trv used I” a prec,s,on

test ,nstrument. The ~ns,r”~t,o”s have been wntten to

asssr in ~solat,ng the defective urcuit or subclrcult. IsO-

lat,ng the defective component has been left to the tech-

DlCla”

NOTE

For instruments that are still under warrantv

(less than 12 months since date of shipment).

If the instrument’s performance IS outside of

specafications at any point, contact your

Ketthlev representative or the lactorv before

attempt,“g troubfeshootlng or repeli other

than battery or fuse repiacement.

5-6. Special Handling of Static Sensitive Devices

CMOS dewces are deslgned TO functlon ar’very high

Impedance levels for low power consumpt~on~ For th,s

reason. a normal static charge bu,ld up on vour person or

clothing can be suff,cient 10 destrov these dev,ces. The

foliowlng steps hst the static sens~twe dev,ces ,n your

5-7. Troubleshooting Procedure

This section contatns tables ilsttng step-by-step checks

of the major DMM circuits described in Section 4. Theory

of Operations The following steps outl$ne rhe use of these

tables and provide ~nstrucrion for orepanno the DMM

for troubleshoot,ng. Read all of thede steps & trow

bleshootlng the ,nstrument~

To troubleshoor the wwrumenf 11 $5 necessary TO dwassembie the 135 case. To do th,s foilow the

I” paragraphs 5-4-l. 5-4-2. 5-4-3.

A. Power Suoplv

Start off troubleshooting with the power supply in

Table 5-1 there are several steps and checks thaw,,,

verify If the power supply IS ProVldirIQ the appropriate

voltage to the c,rc~,trv. if all checks I” Table 5-l prove

to be correct then proceed to step 6,

8. The next step 1s to check proper operation of the d,splay and the A/D converter, Check these c~rc~irs by

folIowIng Tables 5-2 and 5-3.

C. The signal condltlon!ng c~rcu~trv should be next in

hne to be checked. Problems with DCV or Ohms may

involve the attenuator. Follow Table 5-4 for DCVtroubleshootlng procedure and Table 5-5 lor Ohms

troubleshoot,ng procedures

NOTE

Make sure that rhe PC board 1s free of contamt”a”ts (oil. dirt. etc.). Contaminants on the PC

board wil degrade performance on DCV and

Ohms ranges.

steps

outlined

5-2

Page 31

MODELS 135/l 76

D, Problems with AC v&age or AC current may mvolve

the AC converrel~ Check rh,s c,rcu,f by follow,ng Table

5~6, If the prOblem ex,sts w,,h AC current Only see

step E

Ed If problems occur wth current readings. check the

shunts and related c~rcu~ti” as ouri,ned I” Table 5-7,

It should be nored that AC and DC current ranges use

the same shunts. theieiore problems w,,, occur on the

same ranges if The Shunts are at fauli,

F If a gross iallure ewsts rhaf ,nd,cates a poss;b,e blown

fuse. refer IO paragraph 5-9 for tlJse replaceme”,

lnsrructions.

G. Ail measuremenrs are referenced IO analog common

(COM (“put jack) unless otherwse noted I” tables.

WARNING

Some of the procedures in~thefollowing tables

require the use of high voltage. Take care to

prevent contact with live circuits which could

cause electrical shock resulting in injury or

death.

MAINTENANCE

step

t

2

3

4

5

6

7

Item/Component

J1019

SlOl

lJ102. ptn 1

CR1 10. cathode

u103.

Pl”

u103. pl” 8

CRlOl. cathode

c104. +terrmna, outpur

step

Item/Component Required Condillon

1

2 UlOl. 1 PI”

3 UlOl. 5

4

pl” Backplane. IOOHz -3OOHr

UlOl pins 5 volt sq”arewa”es I” or O”,

2. 3. 4.6-26. 37.40

5 U201 9 and 13 pins

u202 psns 1, 5. 9.

: 3

6 u202 2. 6. 8. pins

12

POWER SUPPLY CHECKS

TABLE 5-l

Rewired Condition

I

Remarks

Connected to a fresh +SV

battery

Turn on power

+5 Volts *5%

+1~25 “01,s +5%

5

-5 Volts ?5% lnverlel Ourpur

+5 volts 25%

+a.4 volts +I 0%

Retere1ce Lener

From U102

Voltage Doubler

TABLE 5-2

DISPLAY CHECKS

Remarks

Turn on Power. select any

funcflon or range excepr

ohms.

+5 volts ?5%

square wave.

Of phase wtth backplane

SIgnal

Backplane Waveform

Bar. rnl”“S

sign

snd dec,mal

PO!“, drivers

ApproprlateOPl,neh,ghO

Select all ranges

10 check all deco

lmal pOl”tS~

Page 32

MAINTENANCE

MODELS 135/176

Step I

2 Momtor &play

3

2

6 Monitor Display

7 UlOl p,n 32

8

9 U21 3 pm2

10

11 U213 p,n 5

12 U213 pin 7

13 External DC supply

14

15 u213 PI” 1

16 U204 p,n 12

Item/Comrmnent Rewired Condition I Remarks

1

u214 pin 6

u211 p,n 15

U21 1 short p,ns

5 and 15

C206

U213 pin ,

such as 343A

Monmr Display

A/DCONVERTERCHECKS

TABLE 5.3

Turn on Power. select 2VDC

range. short “01,s input.

,OOOO +l d,git

0000 “Oh

+1 00 VOITS

1.0000 +lO d,g,ts

0 to +5 Volt square wave Clock s,gnal

1 OOKHz +lOOHz

0~0 Volts *I OOm Volts

O,O Volts fl OOm Volts

1VOll to.3 volts

0 volts

0 Volts *40m Volts

Apply +1.9OOOV

1.9000 tl dig11

Waveform as shown in

Fzgure 5-3.

Waveform as shown m

Flgure 5-4~

Buffer Ou1put. A/O

Input

Reference Output

Connects reference

output toA/D input

If steps 4 and 6 are

correct Then the

A/D 8s func,ion,ng

properly,

Stored Auto Zero

Voltage

Integrator Summtng Junction

integrator Outpvt

Buffer Input

Buffer Output

Calibrarlon Point

If different check

U214 input

lntegraror OUtput

Comparator Output

!NTEGRATE

rl OOMS-j--200MS ,

;;: ~=&ON

INTEGRATOR OUTPUT WAVEFORM

l COMPARATOR WAVEFORM ’

I

I

INTEGRATE

COMPARATOR OUTPUT WAVEFORM

1 OOMSEC ZOOMSEC

SIGNAL

REFERENCE

INTEGRATE

I

FIGURE 5-3

IS A LOGICAL 1

DURIYG RAMPING

SIGNAL

I

REFERENCE AUTO ZERO OF

INTEGRATE

I

I

FIGURE 5-4

I

I

I

I

I

5-4

Page 33

MODELS 1351176

MAINTENANCE

For troubleshooting the DC anenuator tallow Table 5-4

-_- .._...__ _._ -.._

Sft3P Item/Component

I

2

External DC supply Apply + 1 ,900O Volts

such as 343A

3 U214

4

z

i

9 U214 p,” 6 1 000 volts f10 dlglts i .:dffer OUrpUt

L

pin 6

External DC supply

such as 343A 19 000 VOIIS~

U214

p,n 6

External DC supply

such as 343A 190.00 Volts,

U214 pin 6 1 ,9 Volts Z20 dlgits

External DC supply

such as 343A

Since ACV and DCV use the same attenuator. ver,f,cat,on

Of the DC arte”ua,or IS sufflclent to unsure that the AC

atten”aIOr IS functlonlng properly,

Required Condition

Turn on power. select the

ZVDC range, Short the #“put

and adjust R207 for ~0000 at

OUtpUt Of u2 14

Cai~brated Inpu,

1.9Volts

Select 2OV range Apply

1~9 volts A1 0 d,gns

Select 2OOV range Apply

Select 1OOOV ranges Apply : -aI,bra,ed input

1000 VOIW

AC Converter

Buffer ourput

Cal,brared lnw,

Buffer OUrpUt

Calrbrated Inpu,

j/ 3uffer output

TABLE 5-5

AC ATTENUATION CHECKS

step

Item/Component

Required Condition

Remarks

Remarks

I

2

3

4

5

6 External AC source Select 20VAC range and

7

8

9

10 External AC source Select 1 OOOVac range and

Ii

Monitor Display

External AC source Apply I .OOOO “01, RMS a,

such as WP745A 1KHz

Wiper of A 107

R105 pin 9 +1 i/Ott DC

such as H-P745A

Monitor Display 19.ooov Nominal

External AC source

such as H-P745A

w,th 746A

Monitor D~splav

WP745Awlh746A

Momtor Display

Select the 2VAC range and

short the input,

0000 ?5

1 Volt RMS nom,nai

apply

Selecr ZOOVAC range and

apply 190 OV at 500Hz

190,oov Nominal

d,g,ts

19,OOOV at 500Hz

apply 5oov at 1 OOHZ

500 ov Nominal

R 1 1 1 zero ad,ust

Caiibraied input

AC Buffer Output

AC Converter Input

output 01 u 104

Gatn of U104 IS ad,“SWd to prowde + 1

VDC ior 1 Volt AC

Calibrated Input

Cailbrared input

Calibrated lnpu,

Page 34

MAINTENANCE

MODELS 135/176

step

6

7

8

9

li)

11

12

13

14

15

16

Item/Component

Monitor Display

A105 pin 4

lnout HI to LO

Input HI to LO

1 K~precis~o”

res,stor

Monitor Display

lOK.Qprecision

reSIStOr

Momor Display

1OOKRpreclsion

res,stor

Momor Display

1000 K~precis~on

ft?S,SfCJf

Mon,tor D~splav

IOMnprec~sio”

resistor

Momtor Display

OHMS ATTENUATION CHECK

TABLE 5-6

Required Condition

Check A/D Converter

Select the 2kR range and

short the ,“D”t

.OOOO _Cl digIt

Approximately 2.5 Volts

Remove short and connect

ammeter from ln~ur HI to LO.

Measure open circuit voltage 3.5 Volts max

Apply to input

1 .OOOO *30 dtgits

Select 20KR range and awl\

1 OKR to input

10.000 ?22 digits

Selecl 200K.0. range and

apply 100 KR to Input

100.00 +22 dlglt

Select 200KQ range and

apply 1000 K.Q to ,“put

1000.0 f22 dig,%

Select 1 OMa range and

apply 1 OMS7 to the input

10.000 2102 digtfs

If incorrect check

QlOl. RTlOl or

Q204

Calibrated

res,stance

Checks accuracy of

Rl16-1Kfl

Calibrated

resistance

Checks accuracy of

R116 -9Kfi

Calibrated

reSlStance

Checks accuracy of

Rl 16.90KR

Calibrated

resistance

Checks accuracy of

Rll6-9OOKG

Calibrated

resistance

Checks accuracy 01

131 1 B-SM.SIleakage

of Q204 and leakage of c-21 1.

step

1

2 A112.Rll4

4

Item/Component

FlOl

External DC voltage

I

Disconnect the test leads and turn the 135 off

before replacing the battery or fuse. Put the

covers back into place on the

compartments

before resuming useof tne instrument.

5-6

(

:RENT SHUNTS CHECKS

Required Condition

Contlnuilv

TABLE 5-7

Correct shunt value for

specified range

Turn on power and select

DCA. 20mA range

0 to 1 Volt

. . .._....._..........____._

5-9. Battery and/or Fuse Replacement

A. A 9V battery IS supplied with the i”str”me”t but not

Remarks

Apply a know” , /2

full scale curient

and measure voltage across Stl”“l

Clamping mmt

CICC”, at +-0,7 Volt5

lnstalied.

cover from the battery cOmpartme”t by slidang it off I”

thedIrectIon of the arrow located on the battery cover

The battery connecior snaps on and off rhe term~nai

To mstall or replace the battery. remove the

Page 35

MODELS 1351176

MAINTENANCE

of the battery Improper insfaliat~on oi rhe batlery ~111

cause the connecting wires IO be severed by excess

strain. Proper installation requtres that the battery

be posmoned ,n such a manner lshown in Ftgure 5-5,

that the leads protruding tram the boor of the battery

connector lace reward the ourstde of the battery come

parrme”,~ If the insrrume”, IS going to be stored for

a long period of lime or I” a high remperature en”>ro”men,. remove the battery to prevent leakage damage

FIGURE 5-5

BAITERY INSTALLATION

‘3 A ,75 amp fuse protects the 20mA range. To gatn

access to the fuse. remove the fuse comperfment

covei in the same manner ae remowng the battery

compartment cover Remove the fuse by puillng out-

ward on the plasf~c tab that encircles the fuse body

install the pIasr,c tab on the “ew fuse and snap the

fuse back into ihe luse holder. DO not replace the fuse

w,th a h,gher rated value or mstr”mentdamagethat IS

not covered by warranty may occ”r~

NOTE

Some fuse covers incorrectly 8ndlcate the

fuse value at 2A~ 0,75A is rhe correct value.

5.10. MODEL 176 CALIBRATION

The Model 176 recommended callbratlon equipment IS

iisted ,n Table 5-1 Alternate equipment ma” be used.

However. the accuracY of ihe alternate equipment mus,

be at least 3 ,,mes better rhan the Model 176’5 speciflcanom or equal to Table 5-l speclflcatlons.

5-l 1. Environmental Conditions

The enwronmen~al condittons lhat are requred IO callbiate the 176 are outlined I” paragraph 5-3~

A Turn off rhe power (/I ihe Model i 766 ,s ,ns:a!ied,

d%sco”nect :he hne ‘oral

8 Turn Ihe instrumenl o”el so that Ihe bo!!om cover 1s

bang up. loose” the iour screws in the bO,lOrn pane,

C Hold the top and bottom covers together 10 prevent

the,, separai,on an* tu,n me 176 over 10 norma, pos,~

tion

I

Selecl the DCV funcrion and the 20V range Place

a shorl across Cl 18, Ad,usr R125 for a d~spiav ot

0~000 RemovetheshortfromC: 18afrertheaa!usrme”, IS made,

2,

Select the 2V range and short Ihe ~rpul lerm~na~s

,HI and LOI Ad,usi R 102 for a d!spiav of 0000

3~

Select Ihe ACV functjon and the 1OOOV range Wilh

rhe short s~,il apphed :o the input lerm8ne!s ac,~s,

Rl 18 ior a dtsplay of 000 0 Remove Ihe snort from

the tnput term,“als (HI am, LOI aflei the ad,ustmeni

IS made~

4

Select the DCV i~nct~on ano the 2V range ADDIY

+I 9000Vtothe~npurterm~nalsIHIandLOlfromihe

DC cal,bra,or Ihem A Table 5~ 1, Ad,usr R: 30 lo< a

dtsplav 01 1 9OOOV

Select the 20V range and applv * 13 OOOV 10 the

5.

input terminals (HI ans LOI from the DC caf~brator

lltem A. Table 5-l) Ad,usl RI07 for a Ctsp:ay zi

19~OOOV

6,

Select the AC” f”nc,~o” and the 2V range ADDI~

IV at IKHZ 10 the ,npur ,ermlnais ,HI ar* LO1 fro”.

the AC caI,bralor (Item So Table 5. Ii Adiusl 8 1 13

for a dtwiay of 1 0000

7,

Select the ZOOV range and apply 100 OOV a! 5KHz

rothe ,npu, term,nals from the AC caltbraror (Item 6,

Table 5- 1 ,. Adlust C 106 for a readlnq 01 100 OOV

8

5-12. Calibration Procedure

Cailbratlon should be performed by quaIlfled personnel

usmg accur.ate and r&able equ~pmem Perform rhe followfng procedure and make the adJustmenrs mdlcated to

ca,,braterhe Mode, 176, Togan access tothecaiibrarlon

adjustments. the 176’s top cover must be removed. Use

the folIowIng procedure 10 accomplish thts

WARNING

To prevenf a shock hazard, all test leads

should be removed

before removing

Do not exceed maximum allowable tnput

volrage. Instrument damage ma” occ”r~

Maximum allowable inputs are stated I”

the specifications.

from

the fop cover.

CAUTION

the input terminals

5-13. MQDEL 176 TROUBLESHOOTING

The troubleshoot,ng ~nstr”ct,o”s conralned 1” this sec.

tto” are (“tended for qualifled personnel hawng a Dasx

“nderstandmg ,,f analog and d,garal CI~CUI!‘” “se0 in a

precision ES, ,ns,rumen,, The ~“str”clions a”4 iables

have bee” wr,tfen to assts, ,n isolating the defective c!rCUII or subc,rcu,t. lsolar,ngthe defectwe compo”en1 has

been Iefl to the technictan

NOTE

For ~nsrrumenrs that are sttll under warlaniv

iless than 12 months since dare of shipment,.

11 the mstrument’s performance IS ouwde of

SpeClflCatlOnS at any pot”,. contact YOU,

Ke,thley repre~entaftve or the faclory before

atremptlng mubleshoomg or repair other

fhan battery or fuse replacements

Page 36

MAINTENANCE

MODELS 135/176

5-14. Special Handling of Static Sensitive Devices

CMOS dewces are deslgned tp function ar very high

mpedance ievels for low power consumption. For thls

reason. a normal stal,c charge burld “pon~ou, person or

clothmg can be suffictent 10 destory these devices. The

followmg table IS a ,151 oi the stattc senstrive dewces

iocated I” your 1 76~ In~tru~f,o”s on how to avo,d damag~“g these devices when they must be removed or replaced

are located I” paragraph 5.6,

static Sensitive oev1ces

Reference Deslgnarlon Kelrhiey Part Number

UlOl u104

u105. U106

u107

u112.u113.Ul18 31@7-1

Ull4

u115

U116. u122 IC-103

“117

VI19 IC-138

u120 k-139

u121 P-102

U123 HZ-288

X-226

IC-149

lc-286

IC-284

IC-285

IC-287

5-16. Troubleshooting Procedure

This sectton contatns tables hstlng step-by-step checks

of the ma,w DMM ~jrcu,,s described I” Section 4. Theory

of Operamh, The followng steps outline the use Of these

fables and pro”,de ,nsrr”cf,pn for preparrng the DMM for

tux,b,eshoof,ng. Read all of these steps before troubleshooting the instwment~

To troubieshopt the instrument iris necessary to remove

the top cover. Th,s can be accompl,shed by foilowng the

procedure outltned I” paragraph 5-1 1A. B. C and D,

A. Power Supply

Start off troubleshootmg wlfh the power supply. In

Table 5-8 there are several steps and checks that WIII

ver,fy If the power supply ,s provtdmg the approprzate

voltage to the ctrcu~try. If all the checks I” Table 5-8

prove TO be correcr. then proceed to step B.

8. A/Q Converter

The next step IS to check proper operation of the A/D

convener, ChecktheA/Dco”“eirerbyfollowtngTable

5-9,

C. The next step IS to check the slgnal conditlonlng cur-

cuttry Depending on the discrepjancy. s1xt wth the

appropriate attenuamr, Table 5-10 outlines the DCV

attenuator. Table 5-l 1 outlines the ACV attenuator

and AC converfer, Table 5-12 outl,nes the curreni

arfenuatlo”~

0. Ohms &urce

The Ohms source troubleshooting procedure IS outlined I” Table 5.13,

E. If a gross failure exnts that tndxates a possible blown

fuse. refer to oaraaraoh 5-16 for fuse repiacemenr

POWER SUPPLY CHECKS

TABLE 5-S

step

Item/Component

I I

1

2 Batteries

Tesr Point 1

3

TPl

4 TP2

TP3

5

6 TP5

7

U109 pin 7

‘All voltages are measured wth respect to (“put LO

Required Condition’

Turn on Power

x5v

>6.2V

+5.ov f20%

-5.ov C20%

1,2ov ICI 1,25v

+a.4v nominal

Remarks

6 fresh ‘C” cells

CR1 10 check

Analog +5V check.

This is SuppIled

from the batterfes

through “123,

Analog -5V check.

This 1s supplied

from Analog +5V

supply via U 1 17,

Band Gap

ence Check

(CRlll)

Analog +8.4V

check supplied by

U 1 1 7. used only for

u109.

Refet-

5-8

Page 37

MODELS 135/176

MAINTENANCE

A/D CONVERTER CHECKS

TABLE 5-S

step Item/Component Required Condition

(HI and L6

3’

4

9

10

11

12

13 u115 otn 15

14

15

16

Mon~for Dis~lav

TP6 +o~ooolv

TP7

Ul20 ptn IO

u107 01” 28

u115pin 1 5Hz. 0 to +5V square wave

Ul 11 bin 3

VI 11 p>n 7

Ul 11 p,n I

OOOOV iI dig,r

*0,0001v

IOOKHz nominal. 0 to +5V

square WaYe

I OHZ. 0 10 +5v square wave

2~5Hz. 0 to +5V squarewave

+70mV

230rn”

Nommal +1 2V

Remarks

UllO Input Buffer

Zero

Inpu, to A/D

0”

17

18

19 “111 PI” I

L

-

FOR +I VOLT INTO THE A/D CONVERTER

External Voltage

Source (343Al

Ul 11 p1n 7

FIGURE 5-6

Apply + 1 ,OV to Hi and LO

l”P”!

Ftgure 5-6

Figure 5-7

SUFFER WAVEFORM

I

+I 2”

NOMINAL

FIGURE 5-7

INTEGRATOR WAVEFORM

Page 38

MAINTENANCE

MODELS 135/i 76

DC ATTENtIATOR CHECKS

TABLE 5-10

step

Item/Component

I

2 External Source

3

4 Monitor D,splay

5

6 Externel Source

7 Monmr Display

8

9 External Source

10

11 Select the 1000VDC range

12 ml;l Source

13 Monttor Display

1343Ai

TP6

1343Al

(343A1

Monitor Display

Required Condition

Turn on

2VDC range

Apply +1,9V

1,9v Input Buffer Check

I .9ooov R 130 reference

seiecr the ZOVDC renge

Apply + 19V

19.000v R107 divide by 10

Select the ZOOV range

Apply + 1 SOV

190,OOV nomrnal

Apply 1 OOOVDC

1 OOO.OV nominal

power and select

TABLE 5-l 1

AC CONVERTER CHECKS

step Item/Component

Required Condition

Remarks

adjust

adjust

Divide by 100 check

Dlvlde by 1000 check

RWWirkS

1

2 External AC Source

3

4

5

6

7

8

9

10

11

12

(745A)

U108 lx” 7

Rl 17 PI” 9

External AC source

(745Al

Momor Display

External AC source Select 20VAC range and

(745A1

Momor Display

External AC source

1745A)

Monitor Display

External AC source Select the 1 OOOVAC range

(745A and 746A)

Momtor D~play 1 ooo~ov nominal

Turn on powerandselectthe

2VAC range

Apply ,Vrms at 1 KHz

1 ,OVrms

+1 .OVDC

Select the WAC range and

apply 1VAC at 20KHz

i .oooov “Omlnal

apply 10Vrms at 1OKHr

1 O.OOOV nominal

Select the ZOOVAC range

and apply 1 OOVrms at 5KHr

100.00 “Omlnal

and apply 1 OOOVAC at , KHz

Cailbrated input

Umty Gain Buffer

Output of AC converter, R 1 19 IS adjusted to gwe 1~0

VDC qufp”t for 1 ,O

VAC input. (High

impedance measur~ng here will load

down the reading.

Measumg at outout Of UlOS Wlil

cause oscillation.