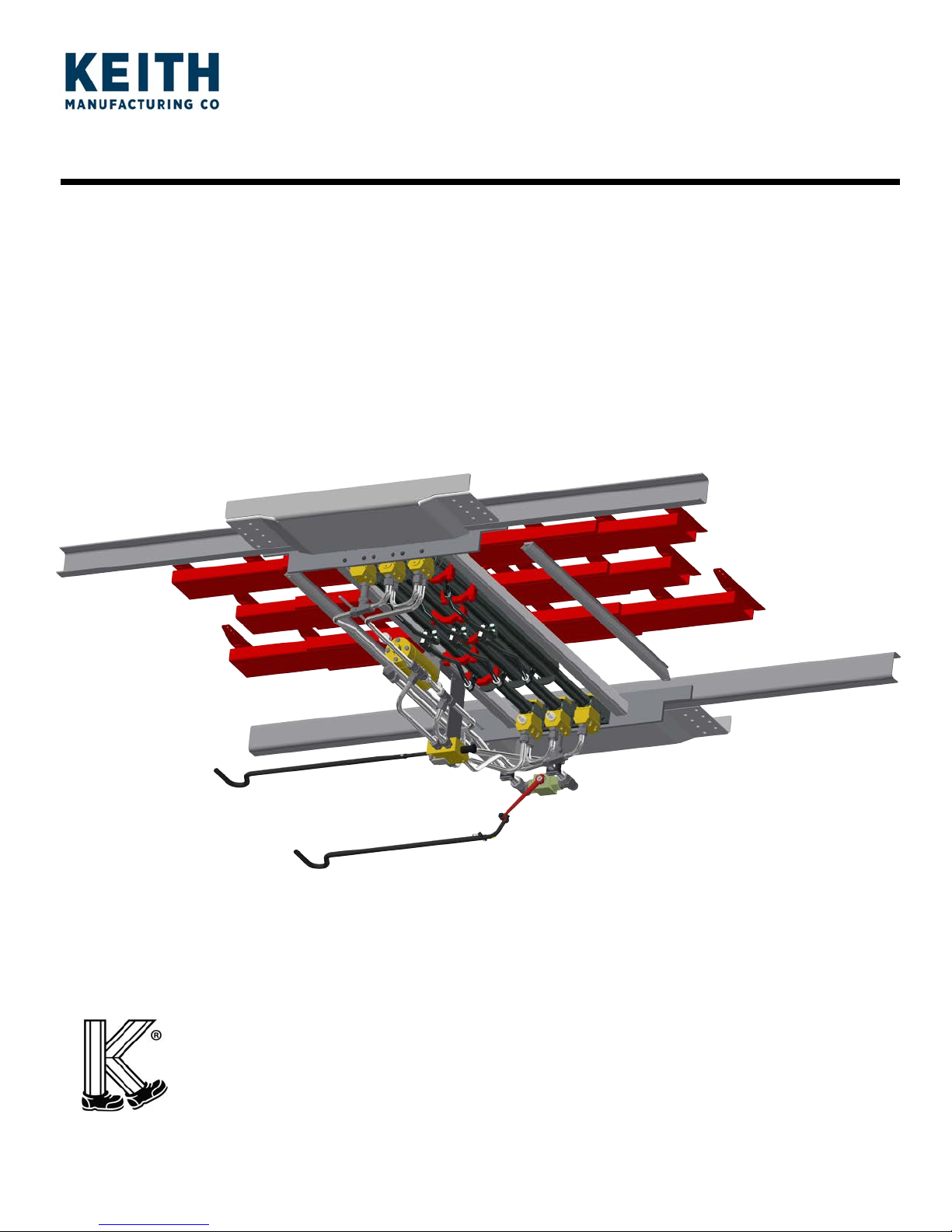

Keith RUNNING FLOOR II DX, RUNNING FLOOR II DXE, KRFII-3, KRFII-4, KRFII-3.5 Owner's And Operator's Manual

RUNNING FLOOR II

KEITH Manufacturing Co.

www.KeithWalkingFloor.com

World Headquarters

Toll-Free: 800-547-6161

Phone: 541-475-3802

Fax: 541-475-2169

®

DX/DXE

10002001

OWNER / OPERATOR MANUAL

Original Instructions

©2018 KEITH Manufacturing Co. All Rights Reserved. KEITH, KEITH logo and WALKING FLOOR are registered trademarks of KEITH

Manufacturing Co. Equipment manufactured by KEITH Manufacturing Co. is protected by numerous patents both domestic and foreign.

DOC06179 Rev. B

OWNER / OPERATOR MANUAL RUNNING FLOOR II® DX / DXE

Table of Contents

Introduction iii

Declaration of Incorporation iv

KEITH WALKING FLOOR® Drive Unit Limited Warranty v

Warranty Registration Card vii

1.0 Safety 1

1.1 General Safety 1

1.1.1 Intended Function and Expected Use: 1

1.1.2 Improper Use 1

1.1.3 Training 2

1.1.4 Personal Protective Equipment 2

1.1.5 Airborne Noise Emission 2

1.1.6 Temperature 2

1.1.7 Lighting 3

1.1.8 Movement Around the System 3

1.1.9 Hydraulic Oil Safety 3

1.2 Design / Installation Safety 3

1.2.1 Kit Components 3

1.2.2 Installation 3

1.2.3 Danger Zones 3

1.2.4 Electric Components and Installation 4

1.2.5 Hydraulics 4

1.2.6 Controls 4

1.3 Marking of Machinery 5

1.3.1 Safety Decals 5

1.3.2 Serial Plates 9

2.0 Specications 10

2.1 Hydraulic Drive Unit 10

2.2 General Wet Kit Specications 11

2.3 Floor to Wet Kit Connection Diagram 12

3.0 Operation 13

3.1 How It Works 13

3.2 Oil Flow Diagrams 14

3.3 Component Location Guides 16

3.4 Drive Component Identication 19

3.5 Start-Up Operation 20

3.5.1 Before initial start-up: 20

3.5.2 After initial 6 working hours OR rst week of operation: 20

3.6 Pre-Trip Checklist 20

3.7 Manual Controls 21

3.8 Electric On/Off, Manual Load/Unload - Wireless Remote Control 22

3.8.1 4 Channel Remote Control Transmitter 22

3.8.2 4 Channel Remote Control Receiver 24

i DOC06179 Rev. B

OWNER / OPERATOR MANUAL RUNNING FLOOR II® DX / DXE

3.9 Electric On/Off & Electric Load/Unload - Wireless Remote Control 25

3.9.1 4 Channel Remote Control Transmitter 25

3.9.2 4 Channel Remote Control Receiver 27

3.10 Electric On/Off & Electric Load/Unload - Cabled Remote Control 28

3.11 Manual Override of Electric Controls 29

4.0 Maintenance 31

4.1 Life Extending Conditions 31

4.2 Preventative Maintenance 31

4.2.1 Monthly Service (25 operating hours) 31

4.2.2 6-Month Service (150 operating hours) 31

4.3 Bolt Torque Requirements 32

4.4 Cross-Drive Wear Component Diagram 33

4.5 Flooring Wear Component Diagrams 34

5.0 Troubleshooting 35

5.1 Check List 35

5.2 Problem / Solution - Troubleshooting 35

5.3 Adjustments & Repairs 35

5.4 Technical Support 35

6.0 Contact Information 36

ii DOC06179 Rev. B

OWNER / OPERATOR MANUAL RUNNING FLOOR II® DX / DXE

Introduction

We at KEITH Manufacturing Co. are very happy that you have decided to equip your trailer with the KEITH

RUNNING FLOOR II® DX/DXE unloading system. We take great pride in the fact that we manufacture the

®

simplest and lowest maintenance self-unloading system available. Installing the KEITH

®

DX/DXE unloader in your trailer provides you with the versatility to load or unload virtually any type of

II

RUNNING FLOOR

material.

®

The following pages contain information on the operation of your KEITH

RUNNING FLOOR II® DX/DXE

unloader.

In addition, we have provided general information on the type of hydraulic wet kit that will be needed on your

tractor. Please contact a KEITH Manufacturing Co. representative or visit our website www .KeithWalkingFloor.

com for more specic recommendations regarding pumps, lters and pressure relief valves and approved

equivalent equipment. It is critical to adhere to the outlined hydraulic wet kit specications. Failure to follow

the guidelines concerning required operation pressures can lead to your system operating improperly.

®

Please review the entire manual before operating the KEITH

RUNNING FLOOR II® DX/DXE unloading

system. If you have any questions or concerns, do not hesitate to contact our factory toll-free at 800-5476161 or via email at TechDept@KeithWalkingFloor.com where our trained personnel will be happy to assist

you.

®

Thank you again for equipping your trailer with a KEITH

Sincerely,

Keith Foster R. Mark Foster

Founder President

iii DOC06179 Rev. B

®

RUNNING FLOOR II® DX/DXE unloader.

OWNER / OPERATOR MANUAL RUNNING FLOOR II® DX / DXE

Declarati on of Incorporati on

Declaration of Incorporation

Manufacturer:

KEITH Manufacturing Co.

401 NW Adler Street

Madras, OR 97741

USA

Hereby declares that the following partly complete machinery,

KEITH

2017 onward

Complies with the following essential health and safety requirements of Directive 2006/42/EC:

1, 2, 3, 4, 1.1.1, 1.1.2, 1.1.3, 1.1.5, 1.1.6, 1.1.7, 1.3.1, 1.3.2, 1.3.4, 1.3.6, 1.3.9, 1.5.3, 1.5.4,

1.5.5, 1.5.6, 1.5.8, 1.5.9, 1.5.15, 1.6.1, 1.6.2, 1.6.4, 1.7.1, 1.7.1.1, 1.7.2, 1.7.3, 1.7.4

The relevant technical documentation is compiled in accordance with part B of annex VII.

In response to a reasoned request by national authorities, relevant information on the partly

complete machinery will be transmitted as hard copies or digital files, unconstrained by

intellectual property rights.

This partly completed machinery must not be put into service until the final machinery into which

it is to be incorporated has been declared in conformity with the provisions of Directive

2006/42/EC.

The person authorized to compile the technical file is:

KEITH WALKING FLOOR Europe

Harselaarsweg 113

3771 MA Barneveld

The Netherlands

®

RUNNING FLOOR II®DX/DXE system mobile kit, serial numbers from year

_________________________________

R. Mark Foster

President

Madras, Oregon, USA April 5, 2017

iv DOC06179 Rev. B

OWNER / OPERATOR MANUAL RUNNING FLOOR II® DX / DXE

KEITH

®

WALKING FLOOR

®

Drive Unit

Limited Warranty

KEITH WALKING FLOOR® Drive Unit Limited Warranty

A summary of the warranty conditions are as follows:

The warranty period is for the first equipment owner only.

•

A warranty card must be filled out and returned to KEITH.

•

The standard warranty period is for (1) one year for the Drive system (for non-hydraulic components only, such as

•

electrical components, drive frame, cross drives, floor shoes, flooring and components from other suppliers) from date

of sale by trailer manufacturer.

The limited hydraulic warranty period is for (2) two years for the hydraulic parts and components from date of sale by

•

trailer manufacturer.

The Drive system must be installed by your trailer builder according to recommended KEITH installation instructions

•

and procedures.

KEITH maintenance and operating procedures have been properly followed.

•

In the case of a malfunction, the trailer manufacturer, and KEITH must be informed immediately.

•

The following issues are not covered by the warranty:

Malfunction of equipment, or problems caus ed by equipm ent, which was not sup pli ed b y KEIT H.

•

Malfunction caused by the use of dirty oil, or oil of the wrong type.

•

Malfunction caused by overheated oil: maximum temperature 140 °F [60 °C].

•

Malfunction caused by corrosive materials.

•

Malfunction caused by over loa din g or im pr oper use as stated in KEITH manuals.

•

Malfunction caused by improper repair work, or repair work which is carried out by third parties.

•

Filter elements and components are subject to normal wear-and-tear and are not warranty items.

•

Defects in electrical components caused by incorrect connection and/or incorrect voltage levels.

•

The warranty is void if:

The Drive system is used for purposes which have not been recommended by KEITH.

•

The wet kit is not as recommended in KEITH manuals.

•

The Drive system is not installed properly.

•

Loads in excess of legal limits are moved as defined in KEITH manuals and operating instructions.

•

Hydraulic components are damaged by excessive heat: 140 °F [60 °C].

•

Heat damage caused by a bad hydraulic pump on the truck or hydraulic wet kit.

•

Damage caused by using an end dump or dump truck wet kit.

•

Heat damage caused by not fully opening and closing the ball valve.

•

Warranty Information:

Two Year Limited Hydraulic Warranty

KEITH Manufacturing Co. hereby warrants, only to the first owner of a new KEITH®Drive system from the factory

or selling distributor, that the Drive system hydraulic parts and hydraulic components shall be warranted as free

from defects in material and workmanship for a period of two years to the first registered owner from the date of

the sale.

This warranty does not cover normal wear and tear, maintenance, or heat damage. It is not to be construed as a

service contract.

Owners Obligation: To qualify for warranty co verage, a warranty card must be completed and the equipment

must be subject to normal use and service as described in KEITH manuals and warranty information.

Note: Prevention of excessive heat in the hyd ra u lic system is the single most important factor for long system

life. Bad pumps, improper wet kits and hydraulic restrictions cause excessive heat and will damage the hydraulic

system. Heat damage will void the warranty.

v DOC06179 Rev. B

OWNER / OPERATOR MANUAL RUNNING FLOOR II® DX / DXE

One Year Limited Non-Hydraulic Component Warranty

KEITH Manufacturing Co.

selling distributor that the product (for non-hydraulic components only, such as electrical components, drive frame, cross

drives, floor shoes, flooring and components from other suppliers) shall be free from defects in material and workmanship

for a period of

Definition of Normal Use and Service:

distributed, non-corrosive material, properly restrained and secured, on properly maintained public roads, with gross

vehicle weights not in excess of factory rated capacity. For stationary installations, normal use and service means the

conveying of uniformly distributed, noncorrosive materials, with weights not in excess of factory rated capacity.

Sole and Exclusive Remedy:

Manufacturing Co.’s

replacement of the defective part(s) at a facility authorized by

exclusive remedy for all contract claims, and all tort claims including those based on the strict liability in tort and

negligence. Any defective part(s) must be shipped freight prepaid to the nearest

facility or nearest

Except As Expressly Set Forth Above, KEITH Manufacturing Co. Makes No Warranties:

Express, implied or statutory, specifically: No warranties of fitness for a particular purpose or warranties of merchantability

are made. Further,

as, but not limited to, loss of use of the product, damage to the product, towing expenses, attorney’s fees and the liability

you may have in respect to any other reason.

Tort Disclaimer: KEITH Manufacturing Co.

liability based on strict liability in tort and negligence.

one year

KEITH Europe

KEITH Manufacturing Co.

hereby warrants, only to the first owner of a new

after delivery or sale to the first registered owner.

Normal use and service means the loading and/or unloading of uniformly

If the product covered hereby fails to conform to the above stated warranty,

sole liability under this warranty and the owner’s sole and exclusive remedy is limited to repair or

KEITH Manufacturing Co.

facility. Please contact KEITH for additional information on proper locations.

will not be liable for incidental damages or consequential damages such

shall not have any liability in tort with respec t to the produc ts, inc ludi ng any

®

KEITH

Drive system

This is the owner’s sole and

KEITH North America/South America

from the factory or

KEITH

If This Warranty Violates Law:

provision shall be inapplicable in such jurisdiction and the remainder of the warranty shall not be affected thereby.

To the extent any provision of this warranty, contravenes the law of any jurisdiction, that

Warranty Return Policy

1.) Contact

Authorization” (RGA) number before returning any item for repair or replacement. The following information is needed

to ensure parts are returned as quickly as possible.

2.) Prior approval and a RGA number is needed when returning any unused product for credit. Make sure the RGA

number is on the outside of the shipping carton and all paperwork is included. Return all material on a Freight Prepaid

Basis.

Revision Date April 2017 DOC06222 Rev. A

KEITH Manufacturing Co.

a. Company name e. Part number

b. Contact name f. Quantity

c. Address g. Reason for return

d. Phone number h. Customer’s account number

at 1-800-547-6161 or TechDept@KeithWalkingFloor.com for a “Returned Goods

vi DOC06179 Rev. B

OWNER / OPERATOR MANUAL RUNNING FLOOR II® DX / DXE

Warranty Registration Card

Note: To validate the warranty, the registration information must be lled out completely and returned to

KEITH Manufacturing Co. within ten (10) days of purchase and/or installation.

Please ll out the Warranty Registration form on our website at www.KeithWalkingFloor.com or ll out the

Warranty Registration Card below and mail, fax or email it to:

KEITH Manufacturing Co.

P.O. Box 1

Madras, OR 97741-0001

Fax: 541-475-2169

TechDept@KeithWalkingFloor.com

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

This warranty registration card must be completed and on le at KEITH Manufacturing Co. in order for

the warranty period to begin on the purchase date. If no purchase date is registered, the beginning of the

warranty will automatically revert to the manufacture date.

Name / Company Name: _______________________________________________________________

Address: ____________________________________________________________________________

City, State / Prov.: ___________________________________________ Postal Code: ______________

Country:____________________________________________________________________________

Tel: _______________________________________ Fax: ____________________________________

E-Mail: _____________________________________________________________________________

SYSTEM DATA:

Date of Purchase: ____________________________________________________________________

Model / Serial Number: ________________________________________________________________

Purchased From: ____________________________________________________________________

Type of Material Loaded/Unloaded: ______________________________________________________

I have fully read the KEITH Manufacturing Co. warranty information and fully understand and agree to the

terms of the warranty.

Name: ___________________________ Date: __________ Signature: __________________________

vii DOC06179 Rev. B

OWNER / OPERATOR MANUAL RUNNING FLOOR II® DX / DXE

1.0 Safety

1.1 General Safety

1.1.1 Intended Function and Expected Use:

1.1.1.1. The KEITH® RUNNING FLOOR II® DX/DX-Europe system is a reciprocating slat

conveyor primarily intended to load, hold, or unload bulk materials. It can also handle

unit loads such as pallets by using special handling techniques and possibly additional

safety controls. The system is supplied as a kit primarily intended for installation into

mobile trailers or truck bodies. The oor is often loaded through an open trailer top

or through the rear doors. The oor typically discharges material out the rear door. It

is hydraulically actuated, powered by a pump mounted either to a PTO or an electric

motor. The basic system is controlled by mechanically-actuated valves, but has the

option for electrically-actuated valves. The system is compatible with options and

accessories to improve performance. For example, it can be electrically controlled

by hardwired switches or a wireless remote. A CleenSweep® device can improve

clean out. Floor slat styles are selected based on the materials to be conveyed. The

standard system handles a wide array of materials in a non-hazardous, non-explosive

environment. Special modications may be required for special environments like food-

grade applications or explosive conditions.

1.1.2 Improper Use

1.1.2.1. This equipment has been manufactured in accordance with state-of-the-art technology

and the acknowledged safety regulations. Nevertheless, dangerous situations could

arise from improper use, which could endanger life and limbs of personnel and cause

severe damage to the equipment and other assets. This equipment may only be used

for its intended purpose. It may only be operated in impeccable technical condition and

in accordance with the proper use and this user manual. Problems, which could affect

safety, must be resolved immediately. The manufacturer is not liable for any damage

caused by improper use or arbitrary modications. The installation, commissioning,

operation, and maintenance instructions must be followed as outlined in this manual.

1.1.2.2. Personnel must not enter the danger zone(s) when the system is enabled. Specically,

nobody should be inside, under, or behind the trailer in the unloading zone during

operation. Additionally, no one should be in a full or lling trailer. Lock-out and tag-out

procedures must be followed before accessing the drive area.

1.1.2.3. The maximum load capacity must not be exceeded. (See Specications section)

1.1.2.4. The hydraulic power source must not exceed the pressure and ow ratings. Install a

relief valve to ensure the maximum pressure is not exceeded.

1.1.2.5. Control circuitry must not be altered or bypassed.

1.1.2.6. Safeguards must not be altered or bypassed.

1.1.2.7. The oor structure must not be altered.

1.1.2.8. The oor should not be used to handle any material other than specied.

1.1.2.9. The user and system designer must understand the characteristics and safe handling

requirements of the material that is being conveyed.

1 DOC06179 Rev. B

OWNER / OPERATOR MANUAL RUNNING FLOOR II® DX / DXE

1.1.2.10. Bulk materials are by nature unstable and owable. Avoid burial by avoiding contact with

the material.

1.1.3 Training

1.1.3.1. Operators must read and understand this manual before operating or maintaining the

machine. Only qualied, trained personnel may execute commissioning, operation, and

maintenance of the system.

1.1.4 Personal Protective Equipment

1.1.4.1. Always wear protective equipment appropriate for risks associated with each phase of

the system’s life, including transportation, installation, assembly, operation, inspection,

maintenance, and dismantling, disabling, and scrapping. As a minimum, this includes

the following personal protective equipment:

• Safety glasses

• Gloves

• Welding/grinding protection

• Thermal protection such as coats

• Protective/traction shoes

• Helmets

• Hearing Protection

1.1.5 Airborne Noise Emission

1.1.5.1. There is not a dened workstation; sound pressure levels emitted by the

®

FLOOR

a distance of 1 meter from the surface of the

modules were measured at a height of 1.6 meters from the oor surface and

WALKING FLOOR

®

system at the drive

area.

• The A-weighted emission sound pressure level = 74.8 dB.

• The peak C-weighted instantaneous emission sound pressure level = below 63 Pa.

1.1.5.2. Slower oor speeds result in less noise.

1.1.6 Temperature

1.1.6.1. Operation of the system generates heat in the hydraulic oil. Hot oil can damage the

internal seals, resulting in a failure to operate.

1.1.6.2. Overheated oil can degrade rapidly. Hot oil and the resulting hot surfaces can cause

burns. Do not allow the oil temperature to exceed 140 °F [60 °C].

1.1.6.3. KEITH recommends some or all of the following temperature control measures

depending on the circumstances. High duty cycle systems and hot environments will

require more control measures.

• Maintain adequate oil level in the reservoir.

• Install a thermometer or sensor to monitor oil temperature.

• Install a cooler.

• Set a sensor to automatically shut down the system if oil temperature exceeds

140 °F [60 °C].

WALKING

2 DOC06179 Rev. B

OWNER / OPERATOR MANUAL RUNNING FLOOR II® DX / DXE

1.1.7 Lighting

1.1.7.1. Do not use or service the system in an environment of insufcient light.

1.1.8 Movement Around the System

1.1.8.1. Hydraulic oil can be slippery. Clean up oil spills immediately.

1.1.9 Hydraulic Oil Safety

1.1.9.1. See the MSDS for the oil used in your system for further information about hydraulic oil

safety.

1.1.9.2. In an accident involving high pressure equipment, this product may be injected under

the skin. Such an accident may result in a small, sometimes bloodless, puncture wound.

However, due to the system’s driving force, material injected into a ngertip can be

deposited into the palm of the hand. Within 24 hours, there is usually a great deal of

swelling, discoloration, and intense throbbing pain. Immediate treatment at a surgical

emergency center is recommended.

1.1.9.3. Do not use high pressure systems in the vicinity of ames, sparks, and hot surfaces.

Use only in well ventilated areas.

1.1.9.4. Use only designated appropriate ll and drain ports for the oil.

1.2 Design / Installation Safety

1.2.1 Kit Components

1.2.1.1. The kit consists of a drive unit, ooring, and miscellaneous boxed parts. These modules

are intended to be anchored in a shipping frame or stacked at and braced with

dunnage for shipping and storage.

1.2.2 Installation

1.2.2.1. Use designated lifting points as provided.

1.2.2.2. Only use equipment with appropriate capacity ratings to lift and handle

components.

1.2.2.3. Use appropriate lifting procedures when handling loose or boxed components.

1.2.2.4. The oor must be installed far enough away from other equipment or xtures to prevent

the moving parts of the oor module from creating a crush or pinch hazard.

1.2.3 Danger Zones

1.2.3.1. The reciprocating action of the oor creates pinch and shear points by nature.

Specically, drive area cylinder, cross-drive, and slats approaching each other,

frame components, or walls. These and any other relevant exposed areas must be

guarded.

1.2.3.2. The oor must be incorporated into surroundings such that movement of the material

on the oor does not create crushing, burial, drawing in, or entrapment hazards. The

system must be designed to limit access to the material ow path.

3 DOC06179 Rev. B

OWNER / OPERATOR MANUAL RUNNING FLOOR II® DX / DXE

1.2.4 Electric Components and Installation

1.2.4.1. KEITH recommends connecting to earth ground (whenever possible).

1.2.4.2. Wiring must be connected consistent with local codes and regulations, including

electromagnetic interference regulations.

1.2.4.3. Adequate electric overcurrent protection must be provided.

1.2.5 Hydraulics

1.2.5.1. Hydraulic piping and components must be constructed of materials that are rated for

system pressures, and must be installed with best industry practices. Follow all pipe,

tubing, tting, and hose manufacturer installation and routing guidelines.

1.2.5.2. Hydraulic piping should be supported and isolated from vibration. Contact a KEITH

representative for recommendations on installation.

1.2.5.3. Place protective shrouds around the hydraulic tubing in any areas that may have

operators or people frequently nearby.

1.2.6 Controls

1.2.6.1. The control panel must be located such that it is easily accessible for all sizes and

capacities of people, and allows the operator to move freely (whenever applicable).

1.2.6.2. Control devices must be located outside of danger zones, such that any exposed

persons in danger zones are visible from the control station.

1.2.6.3. An acceptable means must be provided to monitor the status and movement of the

load.

1.2.6.4. The oor can generate enormous horizontal force which can destroy improperly

designed surroundings. The oor module must not be allowed to compact material

against an end wall or door, or end walls and doors must be designed to absorb these

forces.

1.2.6.5. Do not allow the oor to move material toward the front of the trailer when material is

contacting the front wall. KEITH recommends installing limit switches to prevent this. In

the absence of a sensor switch, the operator must be keenly aware of the load position,

and the control system must require the operator to hold the run signal in the on

position to continue running, such that releasing the run signal causes the oor to stop

(momentary signal).

1.2.6.6. Material compacted against closed doors can force the doors open dangerously fast

when the door latch is released. The impact can cause serious injury or death. Do not

allow the oor to run when the doors are closed. Do not open a door when it is possible

that material may be compacted against it. KEITH strongly recommends installing a

control interlock switch to prevent the oor from running when the door is closed. KEITH

also recommends a door latch that can be remotely actuated by someone away from

the door area unload zone.

4 DOC06179 Rev. B

OWNER / OPERATOR MANUAL RUNNING FLOOR II® DX / DXE

1.3 Marking of Machinery

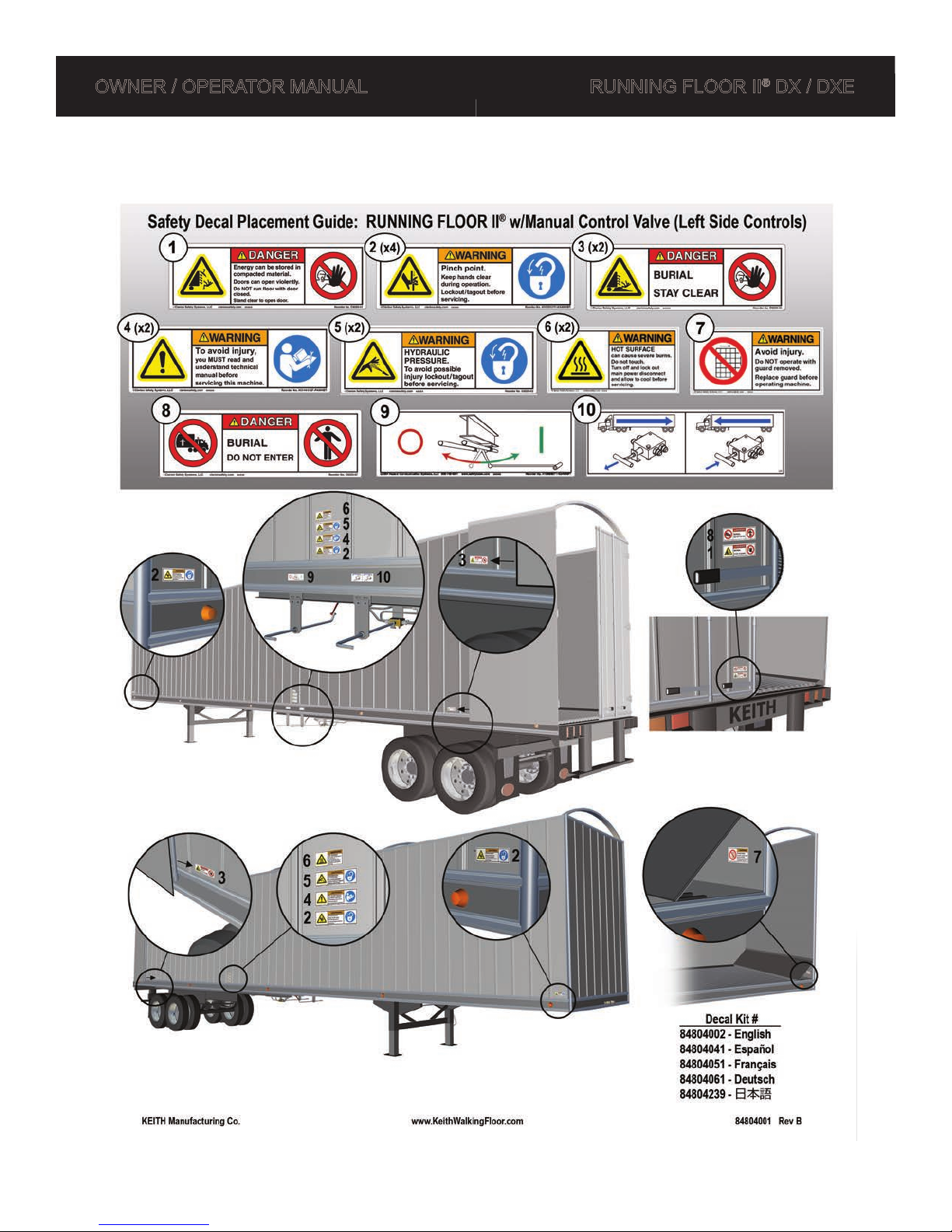

1.3.1 Safety Decals

5 DOC06179 Rev. B

OWNER / OPERATOR MANUAL RUNNING FLOOR II® DX / DXE

6 DOC06179 Rev. B

Loading...

Loading...