Keiser 1030, 1031 User Manual

Solenoid Valve Replacement for 1030/1031 Compressor

INTRODUCTION

KEISER CORPORATION has always taken pride in designing and engineering the

highest quality equipment on the market. This means that you will receive years of low

maintenance and minimal repairs from every one of our machines. Only the highest

quality products have the KEISER name on them.

WORD DEFINITIONS

SAFETY CAUTIONS and WARNINGS:

We've put a number of safety cautions in this book. We use the word Caution! to tell you

about things that could cause bodily injury to persons on or around the equipment if you

were to ignore the following instructions and the word Warning! to ensure the proper

installation of components and that the instructions are followed for the safety of the

users and for maximum machine life or the warranty is void.

HINTS:

We use the word Note! in this book to tell you about things that we recommend you

doing or things to be aware of before performing the instructions. These notes were

placed in the manual to aid you during a certain procedure.

Warning!

Failure to follow the assembly or operation instructions as provided by this

manual or any other instructions pertaining to the assembly and/or

operation of KEISER equipment will result in voiding the warranty and

could lead to serious injury.

Tools Required: ½ inch open-ended wrench

needle nose pliers

wire cutter

standard size Phillips screwdriver

These items have been provided: 8 zip ties

2 Allenair® valves

1 single to double adapter

Solenoid Valve Replacement for 1030/1031 Compressor

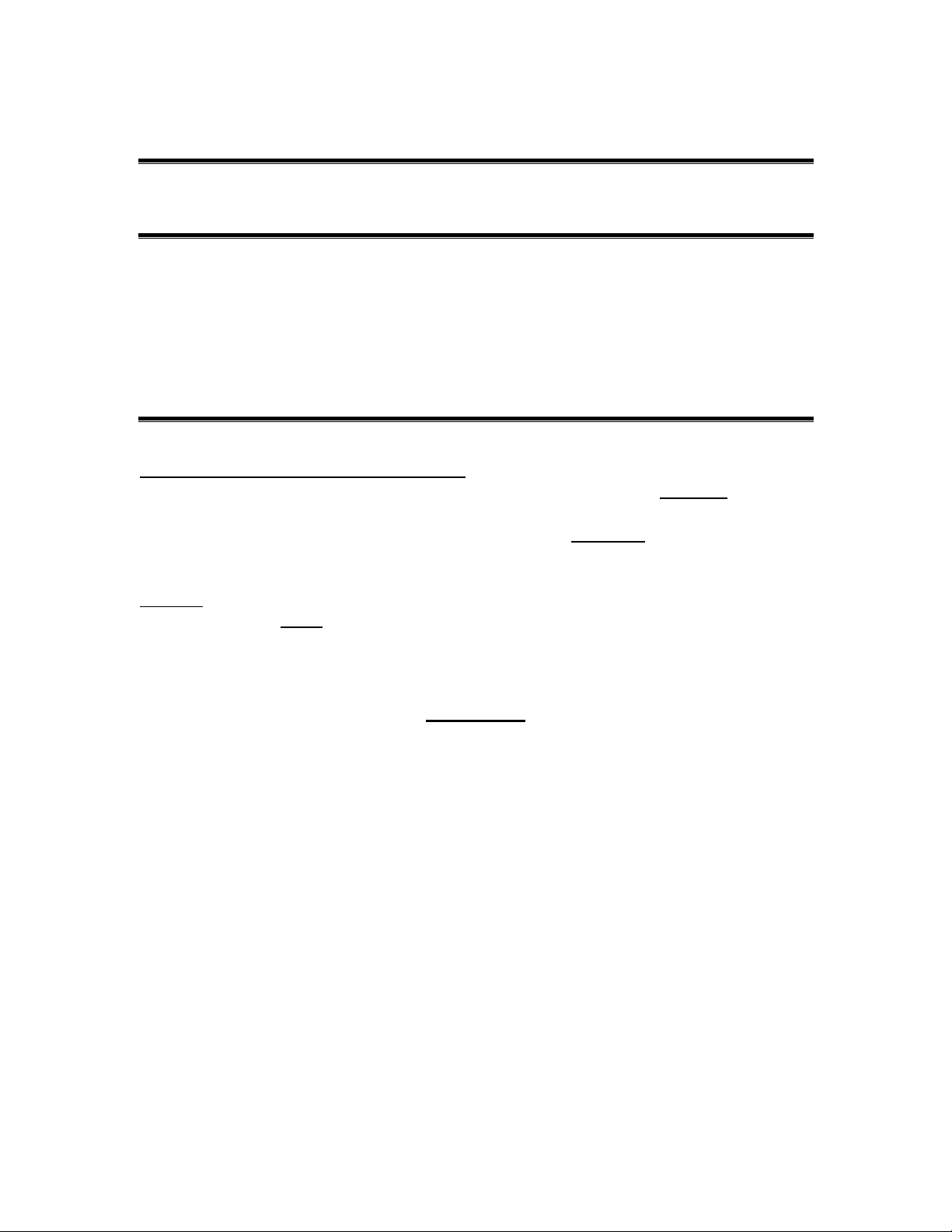

*WARNING: Unplug compressor before beginning. Before replacing valve, draw all

of the air out of the compressor by pressing both the + and – buttons on the exercise

equipment. When this is done, shut off valve to exercise equipment by turning the red

handle clockwise. When the valve has been turned off, it should be parallel to the

compressor like this:

The Mac® valve cannot be cleaned. Therefore, once faulty, it must be replaced.

The Allenair® valve functions well in this application, and it can be cleaned.

There are three steps for valve removal:

1 Dismount valves

2 Remove hoses

3 Remove electrical wires from circuit board

Step One: Dismount valve

First, remove the screws on either side of the valve. There are two.

Use the needle nose pliers to grab and hold the nut underneath the valve while using a

Phillips screwdriver to remove the screws from the top.

remove both screws

10-5508 Rev A Service Department (800) 888-70092

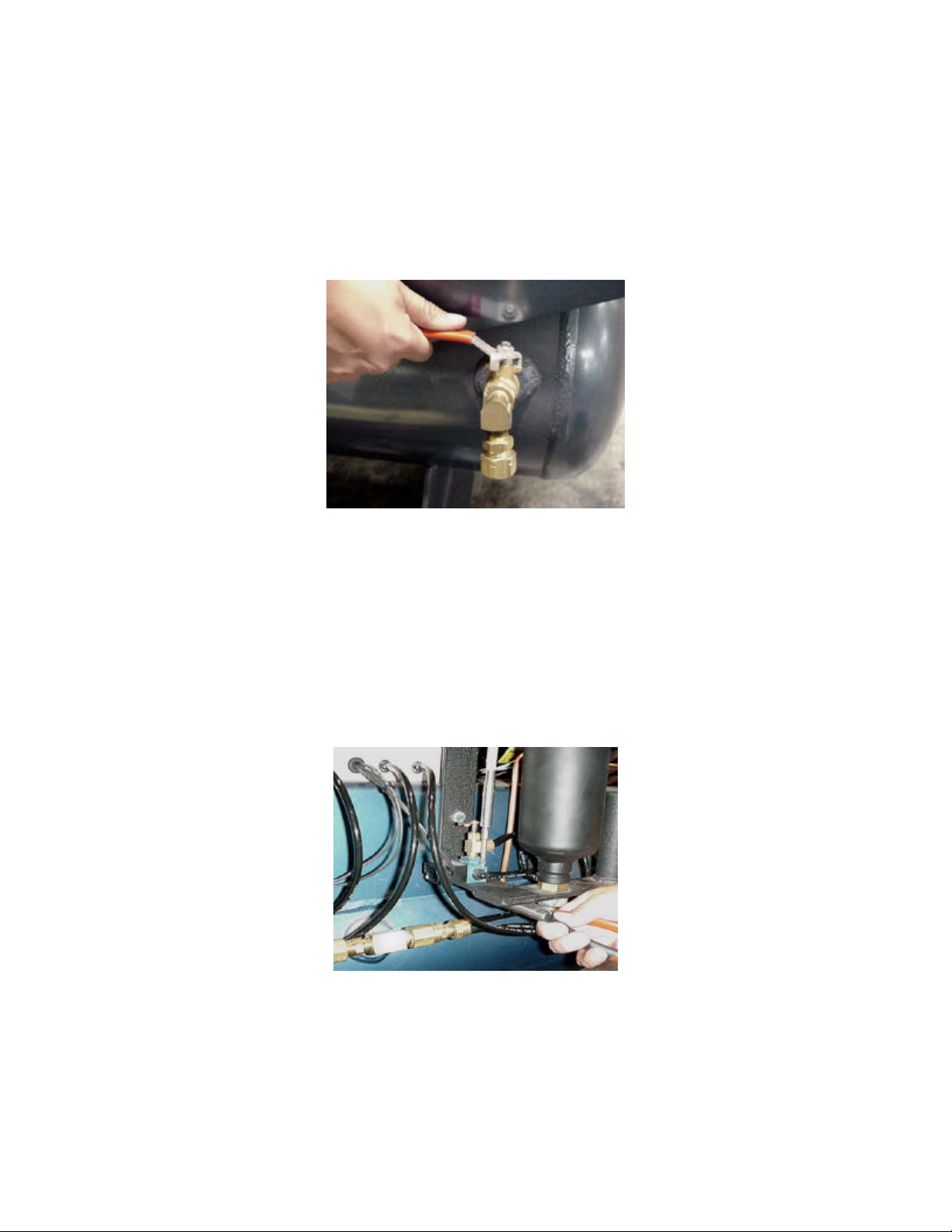

Step Two: Remove hoses

After the screws have been removed, take the ½ inch open-ended wrench, and loosen the

nut that connects the hose to the valve by turning it counter-clockwise, and remove the

hose.

Unscrew nut counter-clockwise

Next, cut the hose to the plastic elbow 3/8 inch from the end of the plastic elbow using

the wire cutter.

cut tubing

Repeat steps one and two to dismount the second valve before proceeding to step three.

Step Three: Remove electrical wires

First, clip the zip tie that is holding the four wires to the valves outside of the

compressor.

cut ties

10-5508 Rev A Service Department (800) 888-70093

Next, remove the lid to the computer control system box by unscrewing the screw on

either side.

remove two screws on lid

Then remove the rubber grommet by using the needle nose pliers to carefully pop it out

of the hole.

pop out grommet

Inside the computer control system box, cut all other zip ties holding the four wires.

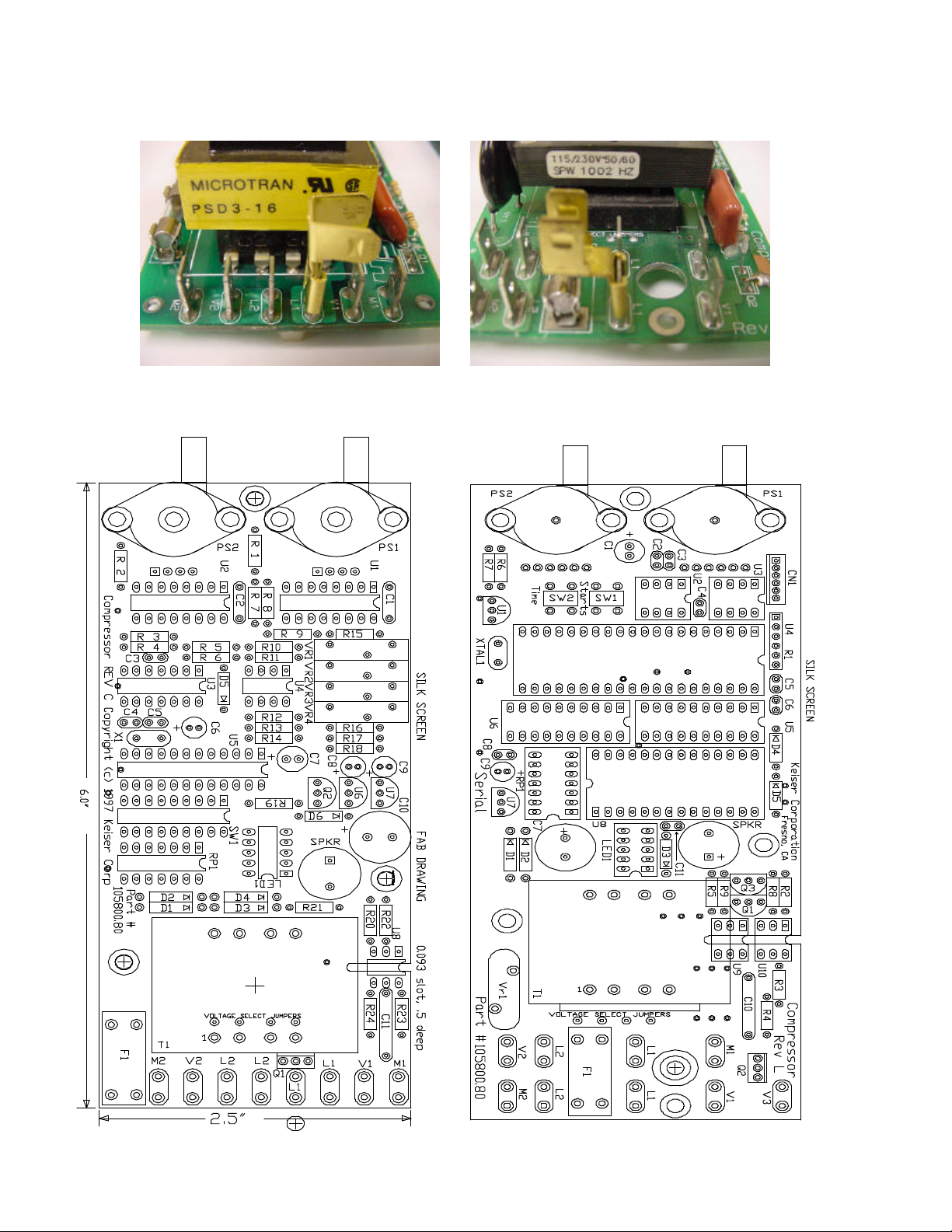

Trace each of the wires from the valve to the circuit board. There are two per valve, four

wires total. The connectors are marked V1 and V2 on the circuit board. Remove each

connector from the circuit board by pushing down on the board as you use the needle

nose pliers to pull up on the connector. This allows you to safely remove the connectors

without flexing or breaking the circuit board.

10-5508 Rev A Service Department (800) 888-70094

1030 Circuit Board Diagrams

Rev A, B, C Rev D - Current

10-5508 Rev A Service Department (800) 888-70095

Loading...

Loading...