Page 1

Industrivej 3-9

DK 9460 Brovst

Tel. +45 9823 6266

Fax. +45 9823 6144

25.04.12

KEF-MOTOR A/S

Instruction Manual

PSD 5 – BO 50/5 – POD 5 - PODA 5

Industrial Grinders

Page 2

1

Introduction

You can connect your dual grinder in many ways. This manual includes the following

options for use of your dual grinder:

PSD 5 for grinding,

BO 50/5 for grinding and belt grinding

POD 5 for polishing

PODA 5 for polishing and deburring

EU declaration of conformity

hereby declares that

KEF Double Ended Grinder PSD 5, BO 50-5, POD 5 are manufactured in accordance

with the provisions of the COUNCIL DIRECTIVE of 17. May 2006 (2006/42/EC) – The

Machinery Directive (order no. 561 of 25 June 1994 with subsequent amendments)

Also on accordance with:

The council directive of 19 February 1973 (73/23/EEC) – The Low Voltage Directive

– with later amendments (order no. 797 of 30 August 1994)

The council directive of 3 May 1989 (89/336/EEC) – The EMC Directive – with later

amendments (order no. 796 of 5 December 1991 with subsequent amendments)

KEF-MOTOR A/S

Industrivej 3-9

DK-9460 Brovst

Denmark

www.scantool-group.com

Tel.: +45 98 23 62 66

Fax: +45 98 23 61 44

Page 3

2

Table of contents

1 TRANSPORT & HANDLING 3

1.1 TRANSPORT 3

1.2 HANDLING 3

1.3 PLACING 3

2 DIRECTIONS FOR USE 4

2.1 OPERATION 4

2.2 SAFETY RULES FOR STATIONARY POWER TOOLS. 4

2.3 MAINTENANCE 6

3 BELT ARM 7

3.1 ASSEMBLY AND MOUNTING OF BELT ARM 7

3.2 CHANGING OF GRINDING BELT 8

3.3 MAINTENANCE OF BELT ARM 9

3.4 USE OF BELT ARM 9

4 VFCB-COMPLETE EXHAUST UNIT 10

4.1 ASSEMBLING AND MOUNTING OF VFCB – COMPLETE EXHAUST UNIT 10

4.2 MAINTENANCE OF VFCB-EXHAUST UNIT 10

5 POLISHING MACHINE 13

5.1 ADJUSTMENT THE POLISHING MACHINE. 13

6 DEBURRER 11

6.1 ASSEMBLING AND MOUNTING OF DEBURRER 11

6.2 CHANGING OF DEBURRER/STEEL BRUSH 11

6.3 MAINTENANCE OF DEBURRER/STEEL BRUSH 12

6.4 USE OF DEBURRER 12

7 SPARE PARTS 14

7.1 MACHINE LINE UP OF PSD 5 14

7.2 PSD 5 BASIC MODEL 15

7.3 PSD 5 COVER 16

7.4 PSD 5 BELT ARM 17

7.5 VFCB-EXHAUST SYSTEM FOR PSD 5 19

7.6 POD 5 W/SPINDLE 23

7.7 DEBURRING COVER FOR PODA 5 21

7.8 24

8 TECHNICAL DATA 24

8.1 TECHNICAL SPECIFICATIONS 24

8.2 DIMENSIONS 24

8.3 WIRING DIAGRAM 25

8.4 DISA SWITCH W/EMERGENCY STOP 26

8.5 8.5 PSD 5 CONNECTED TO EX16 DUST EXTRACTION 27

8.6 GUARANTEE 28

Page 4

3

1 Transport & handling

1.1 Transport

PSD 5 Industrial belt grinder and others are delivered on a pallet packed in protective

wrapping.

1.2 Handling

The machines can easily be transported on the pallet on which they are delivered. If the

machine is delivered on a pedestal you must insure that the pedestal is secured to the

pallet.

1.3 Placing

Mounting of the machine must take place on a firm level ground. It must be fastened to the

ground by means of the four fittings which are used to fasten the machine to the pallet. It is

provided with no-volt release protection switch and connected for the wanted voltage. The

electrical connection must be performed by an authorized electrician, and it is important to

control that the motor (and the exhaust unit) have the correct direction or rotation (please

see the arrow on the motor).

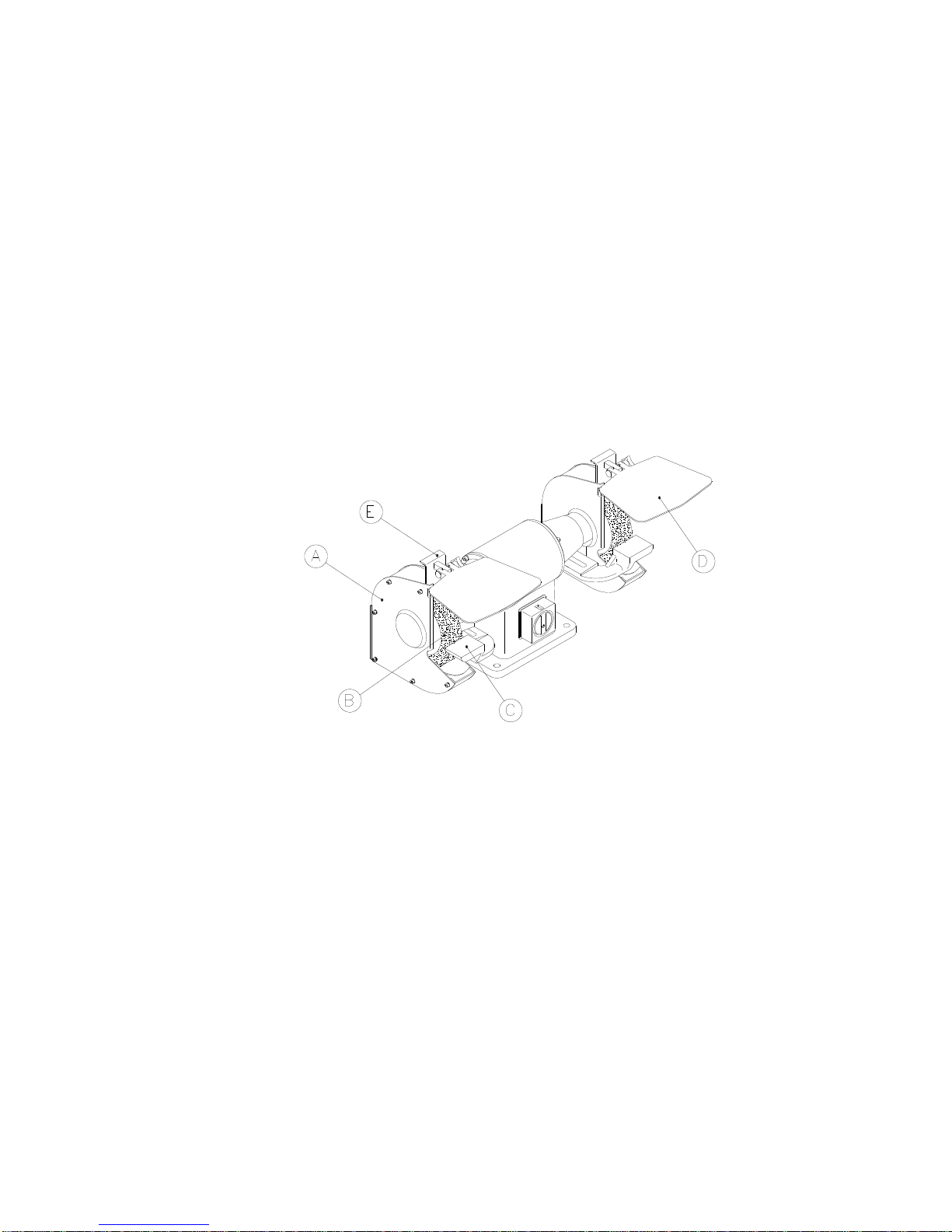

Fig.: 1.1

Before use you must control that the outer cover (A) (se fig.: 1.1) is solidly mounted on the

inner cover. The outer cover must stay mounted during use and should only be dismounted

during change of grinding wheel. The grinding wheel (B) must be able to rotate freely

without being loose. The tool rest (C) must be adjusted to a distance of approximately 2 mm

from the grinding wheel.

The eye shield (D) must be clean and adjusted into the right position and the spark arrester

(E) must also be adjusted to a distance of approximately 5 mm from the grinding wheel and

slightly fastened.

The first time you start the belt grinder please let it run at max speed without using it for 5

minutes. Make sure to stay in a safe distance during the machine start-up.

Page 5

4

2 Directions for use

2.1 Operation

After adjustment and connection the machine is ready for use. The grinding kan take place

by the contact wheel (E) or on the surface grinding table by opening the cover (H). When

you start grinding please start by letting the material touch the grinding wheel lightly and

thereby avoid pressuring the grinding wheel to prolonge the lifetime of it. The lifetime of a

grinding belt is also prolonged if you start with a light pressure. Please make sure not to

overload the motor. Let it run at max speed before start grinding. Grind at max speed and if

possible have the material tightened in clamps as it is safer than holding the material in

your hands. Avoid grinding on the side of the grinding wheel unless you are using a cup

wheel. Do not stop the grinding wheel by pushing any material against it but let it stop by

itself. It is very important to keep the working area well lighted.

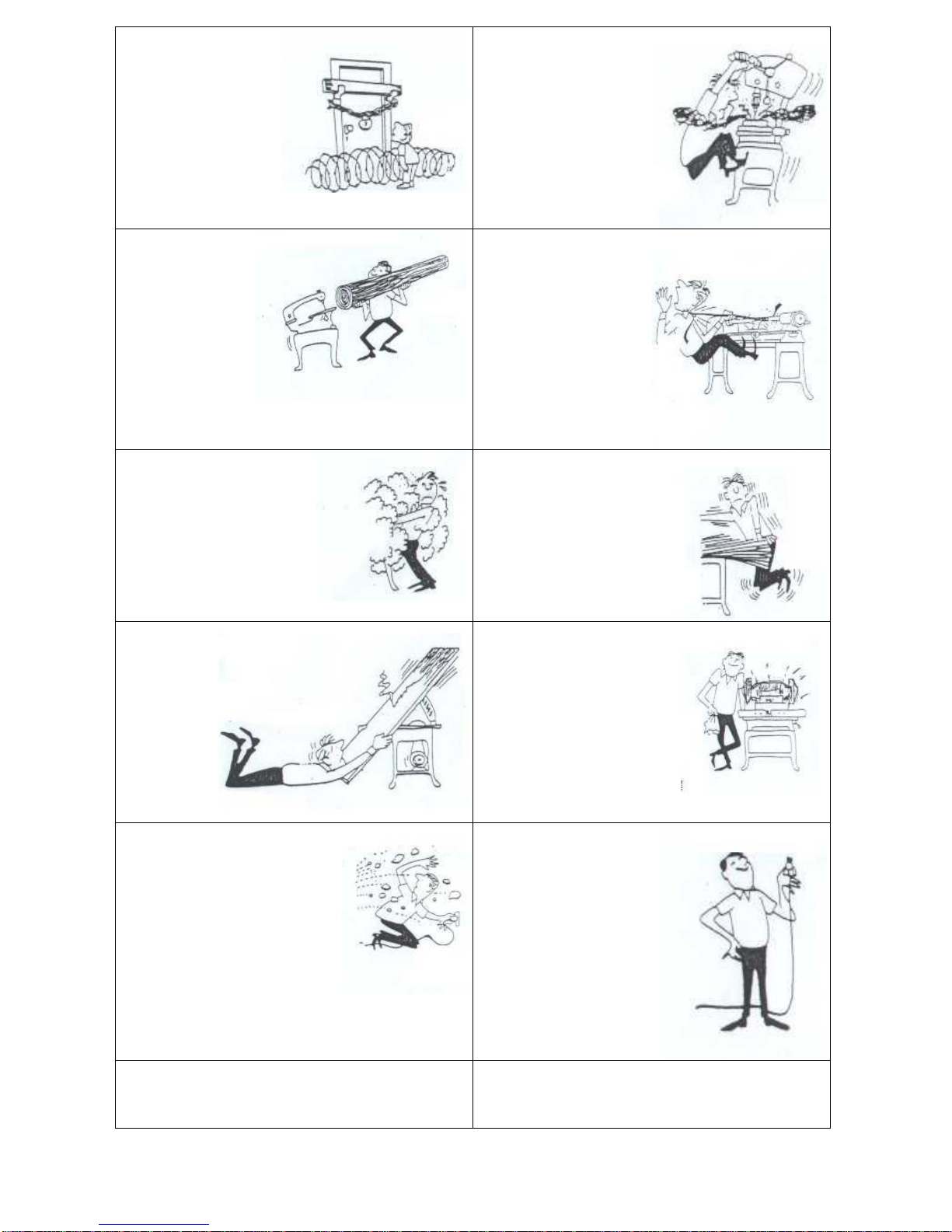

2.2 Safety rules for stationary power tools.

Follow them to achieve best results and full benefit from your new machine.

The good craftsman respects

the tools with which he works.

He knows they represent years

of constantly improved design.

He also knows that they are

dangerous if misused.

The safety rules are based on

approved practices in industrial

and home shops.

1. Know your power

tool. Read the

owner’s manual

carefully. Learn its

applications and

limitations, as well

as the specific

potential hazards

peculiar to this tool.

2. Keep guard in place

and in working order.

3. Ground all tools. If tool is equipped with threeprong plug, it should be plugged into a three-hole

electrical receptacle. If an adapter is used to

accomodate a twoprong receptacle, the

adapter wire must be

attached to a known

ground. Never

remove the third

prong.

4. Remove adjusting keys

and wrenches. Form

habit of checking to see

that keys and adjusting

wrenches is removed

before turning it on.

5. Cluttered areas and benches invite accidents.

6. Avoid dangerous

environment. Don’t use

power tools in damp or wet

locations or expose them to

rain. Keep your work area

well lighted.

6. Keep children away.

All visitors should be

kept in a safe distance

from work area.

Page 6

5

8. Make workshop

kidproof with

padlocks, master

switches, or by

removing starter keys.

9. Don’t force tool. It will

do the job better and be

safer at the rate for

which it was designed.

.

10. Use right tool.

Don’t force tool or

attachment to do

a job it was not

designed for.

11. Wear proper apparel. Wear no loose clothing,

gloves, neckties, rings,

bracelets, or other

jewelry which may get

caught in moving parts.

Non-slip footwear is

recommended. Wear

protective hair covering

to contain long hair.

12. Always use safety

glasses. Also use face or

dust mask if cutting

operation is dusty.

Everyday eyeglasses only

have impact resistant

lenses. They are NOT

safety glasses.

13. Secure works. Use

clamps or vise to hold

works, when pratical. It’s

safer than using your

hands and it frees both

hands to operate tool.

14. Don’t

overreach.

Keep proper

footing and

balance at

all times.

15. Maintain tools with care. Keep tools sharp and

clean for best and safest

performance. Follow

instructions for lubricating

and changing accessories.

16. Disconnect tools before

servicing and when changing

accessories such as grinding

wheels, polishing mops,

grinding belts, blades, bits,

cutters, etc. Never leave a

running maschine, wait till the

Machine has stopped. If parts

of the machine are out of order

the Machine shold not be used

befour it has been repaired.

17. Reduce the risk of

unintentional starting.

Make sure switch is in off

position before plugging

in.

18. Use recommended accessories. Consult owner’s

manual for recommended accessories. Use of

improper accessories may cause risk of injury to

persons.

19. Never work in a way that can hurt you. Do not

stand in a bent position. Stand straight. Alkohol and

other drugs are not to be taken while working with

the machine.

Page 7

6

2.3 Maintenance

Keep the machine in a dry place so the grinding wheels or belts will not risk getting any

damp or rain.

The grinding wheel will often get uneven because of use and therefore we recommend that

you level the grinding wheel off frequently. When the grinding wheel is worn more than 25%

we recommend that you change to a new wheel. An uneven grinding wheel causes

vibrations which with time will damage the bearings in the machine. Damaged tool rests,

eye shields and covers must be replaced to avoid personal damage.

When to change the grinding wheel please dismount the spark arrester (A) (see fig.: 2.1),

then dismount the outer cover (B). The reverse nut (C) and the outer flange is to be

unscrewed, now the outer flange and the grinding wheel can be dismounted. The new

grinding wheel is not allowed to exceed the measures shown on the sign on the machine. It

is also very important that the hole dimension is correct.

The grinding wheels are provided with labels placed around the holes on both sides of the

grinding wheel. If these labels are missing or damaged they must be replaced by new ones

of the same dimension.

The new grinding wheel is to be mounted between the two flanges (D) and the reverse nut

(C) screwed on and fastened. The reverse nut (C) is to be fastened so tightly that it can

hold the grinding wheel tight but on the other hand it is not to be tightened too much as it

can cause unwanted stress in the grinding wheel.

Fig.: 2.1

Page 8

7

3 Belt Arm

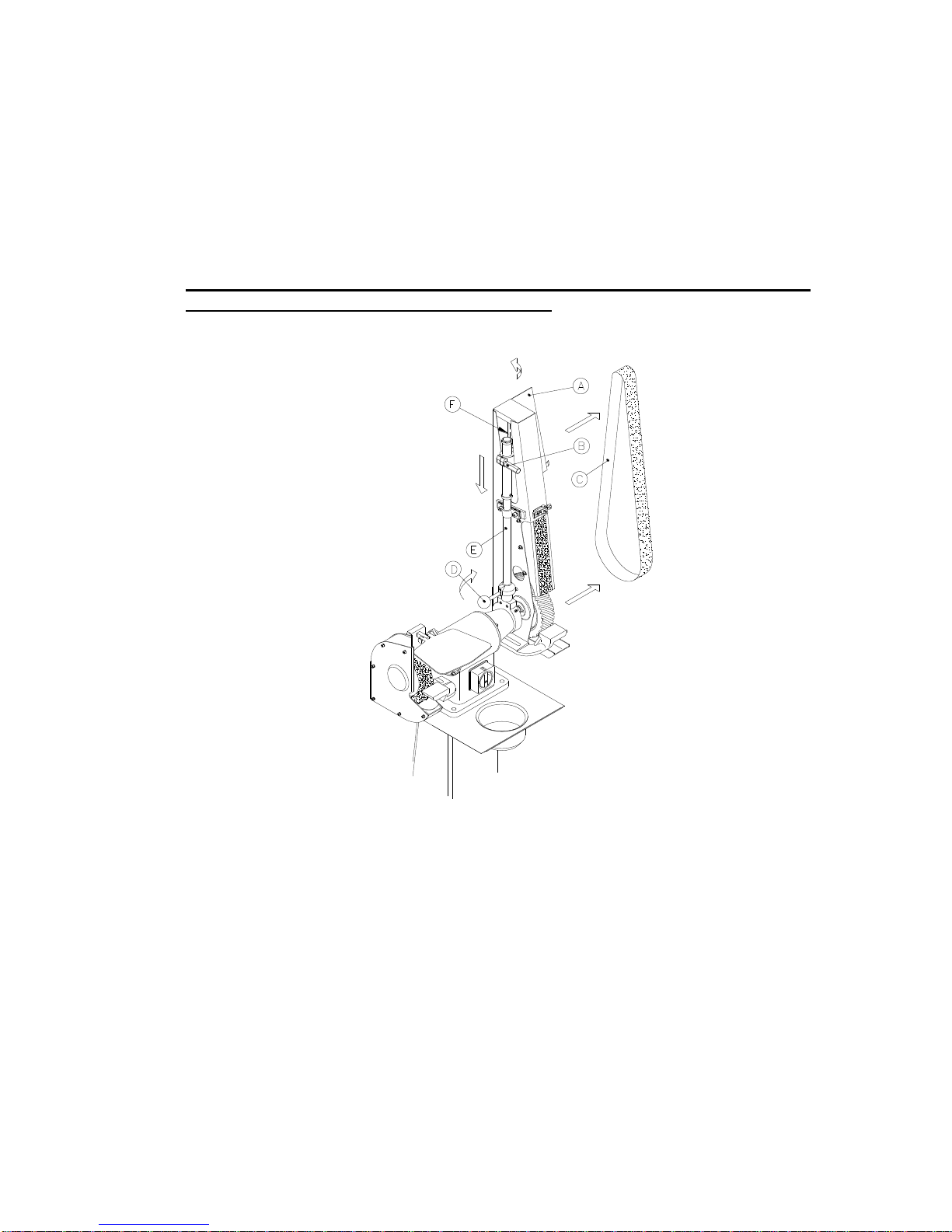

3.1 Assembly and mounting of belt arm

If the grinding machine is mounted with a grinder cover or a deburrer cover these must be

removed completely before mounting the belt arm.

Mount the telescopearm (A) to the cover (B) by using the fitting for the telescope arm (C)

and mounting the cover (B) by putting a screw through the side plate into the holder for the

telescopearm (D). The topwheel (E) must be inside the cover (B).

Fig.: 3.1

The fitting for the telescopearm (C) is not alloved to be fastened harder than it is

still possible to adjust the direction of the grinding belt.

The belt arm can be tilted to the wanted inclination. After this the holder for the

telescopearm (D) is fastened by tightening the two screws placed in the ring on the

holder. The flanges, contact wheel and the reserve nut are now put in (pls. see the

drawing of belt arm for order). Please make sure that the top wheel (E) and the

contact wheel run parallelly. The position of the contact wheel can be adjusted with

the distance rings attached.

The topwheel (E) can be loosened and adjusted so that it fits the wanted grinding

belt lenght. The same way you can tighten the grinding belt.

Page 9

8

3.2 Changing of grinding belt

When the grinding belt is worn out it must be replaced which is done the following

way: The top plate (A) (se fig.: 3.2) on the cover is opened and the handle (B) is

pulled down. This way the pressure on the grinding belt will be lowered (C), so that

it can be dismounted and a new grinding belt can be mounted in reverse order.

Please control that the arrows on the back of the grinding belt run in the same

direction as they point. When the new grinding belt is mounted it is necessary to

adjust by the handle (D) for parallel running. The belt is loosened so that the

telescopearm (E) and top wheel (F) can be turned with until the grinding belt runs

straightly on the contactwheel. After this the handle is fastened (D).

It is only allowed to do this adjustment by pulling the grinding belt with the

hands and NOT with power on the machine.

Fig.: 3.2

There are many kinds of grinding belts so therefore it is very important to choose

the right type of belt. There are many things to consider before choosing the belt:

material to be grinded - grit size - belt material - glue.

In connection to this we can tell you that there are different kinds of contact wheels

with various softnes and shapes for different purposes.

Page 10

9

3.3 Maintenance of belt arm

Empty the spark arrester (A) (see fig.: 3.3) to avoid hot sparks damaging or

deforming grinding belt and contact wheel. If the machine is equipped with VFCBexhaust unit you must control if the suction channels need cleaning. The dust bag

must be emptied when necessary. The contact wheel (B) needs changing if the

edges are too rounded. The belt must be replaced when it is defective. Change the

graphite pad (C) on the belt arm when necessary.

Fig.: 3.3

When changing the contact wheel the grinding belt (D) must be dismounted as

described above. The reverse nut (E) must be dismounted and the flange (F) can

be taken off with the contact wheel (B). The new contact wheel (B) is to be mounted

in reverse order.

3.4 Use of belt arm

Grinding at the belt arm can be done either at the contact wheel or on the grinding

surface. You can also dismount the grinding surface for direct unsupported grinding

on the grinding belt. Let the material touch the grinding belt softly and avoid uneven

grinding as it can damage the grinding belt and overload the motor.

Page 11

10

4 VFCB-complete exhaust unit

4.1 Assembling and mounting of VFCB – complete exhaust unit

The following description of assembling and mounting of VFCB-exhaust unit is valid both if

it is a VFCB-220 or if it is a VFCB-121. The mounting order is exactly the same for both

models.

The guard (A) (see fig.: 5.1) is first mounted on the back of the machine and there after as

shown on the VFCB-motor. Dismount the blindstopper at the back of the machine and

mount the connector (B). Dismount the switch on the machine without dismounting the

wires. Lead the wire (C) through the connector (B) and mount the protection hose (D) on

the connector (B). Mount the wires from the VFCB-exhaust unit on the switch (see wiring

diagram). Mount the switch again. Dismount the blind guards on the cover or the belt arm

and instead mount the guard (E) with exhaust connecting piece, also remember to mount

the cork washer (F). Finally adjust the suction hoses (G) and mount the clip washers (H).

VFCB-exhaust unit must before use be mounted with suction hoses on the suction

connecting piece (I), which then must be connected with central exhaust unit. If the central

exhaust unit has no cyclone, the exhaustion from the VFCB-exhaust unit must be

connected to a cyclone, which then again is connected to the central exhaustion. If there is

no central exhaustion, dust bags (J) can be mounted on the exhaust connecting unit (I).

In case the VFCB-exhaust unit is mounted on the PSD 5 double grinder, the casted pipe

bendings (K) can be used to mount the VFCB-exhaust unit on the grinding machine by what

the guard (A) and the suction hoses (G) with accessories can be left out.

Fig.: 4.1

4.2 Maintenance of VFCB-exhaust unit

Nothing on a VFCB-exhaust unit requires maintenance except that it is necessary to make

sure that the suction hoses are intact and the suction channels are clear.

Page 12

11

5 Deburrer

5.1 Assembling and mounting of deburrer

The deburrer cover is to be assembled in the order shown in fig.: 5.1. The four

screws in the end cover (A) must be unscrewed and the mounting plate (B) is to be

placed on the end cover (A), the four countersinked machine screws M6x20 (C) are

retightened. Now the deburrer cover (D) can be remounted through the two slashes

in the mounting plate (B). The cover can be repudiated back and forth so the steel

brush (G) can be used best possible. The inner flange (F) is put on the shaft with

the steel brush (G) and the outer flange (H). At last the reverse nut (I) is screwed on

the shaft and tightened. Before the lid on the deburrer cover (D) is closed the eye

shield is mounted (J) as shown in fig.: 4.1. If you are not to grind a pipe material

you can dismount the grinding system for pipe grinding (K) and the flat grinding

system beneath can be used instead.

Fig.: 5.1

5.2 Changing of deburrer/steel brush

When the steel brush is worn approximately 10 % it must be replaced by a new brush. This

is easily done by opening the lid on the deburrer cover (D). Here you dismount the reverse

nut (I) and the flange (H) can be taken off with the steel brush. The new steel brush is

mounted in reverse order. Often it will be necessary to adjust the grinding system (K) before

the new steel brush is put in its place.

Page 13

12

5.3 Maintenance of deburrer/steel brush

Nothing on the deburrer/steel brush needs maintenance except that it is necessary to adjust

the grinding system as the steel brush is worn. The eye shield and other accessories must

be replaced immediately if they are damaged.

5.4 Use of deburrer

When the deburrer cover is correctly mounted the grinding system (A) (see fig.: 5.2) needs

adjusting which is done by adjusting the height of the grinding system when the screw (B)

is unscrewed. The distance to the steel brush is adjusted by loosening the handle (C) below

the cover. As mentioned earlier the grinding system for pipe grinding (A) can be dismounted

and the flat grinding surface beneath can be used for grinding of plate or bar material.

This adjustment of the grinding system can only be made when the machine is NOT

plugged.

Fig.: 5.2

Before the deburring is started it is important that the motor is running at max speed and

the deburring must be done at as high speed as possible. If it is possible please hold the

material with clamps as it is safer than holding the material right in your hands.

If the motor is helped at stopping the rotation it can result in overheating and destruction.

The best result will be achieved if the material is softly put towards to steel brush. Avoid

uneven deburring to avoid damaging the steel brush and overloading the motor.

Do not stop the steel brush rotation by pressing a material to it but let it rotate freely until it

stops by itself.

It is very important to have the work space well lighted as well as the Law for Safety and

Health at Work Act demands that there must be an exhaust unit mounted on the deburring

cover. This is easily done by mounting a VFCB-exhaust unit on the machine.

Page 14

13

6 Polishing machine

6.1 Adjustment the polishing machine.

Placing of the machine must take place on a firm and level surface. Now secure the

polishing machine to the work table or the floor by using the four holes in the base used for

mounting the machine to the pallet.

Please wire the machine according to the given voltages stated in this manual and on the

motor sign. Check for correct direction of rotation on the motor. All wiring must be

performec by an authorized electrician.

Fig.: 6.1

Before start operating please check if the polishing discs (A) (see fig.: 6.1) are firmly

secured to the rotor. The polishing disc is mounted when the machine is disconnected. The

polishing disc (A) must rotate freely without being loose.

Checks and adjustments are only to be performed when the machine is disconnected.

Make sure to be in a safe distance from the machine while it is running for the first time.

Page 15

14

7 Spare parts

In this chapter there are split drawings and matching spare parts lists.

7.1 Machine line up of PSD 5

Fig.: 7.1 (A) Motorpart, (B) Grinding cover, (C) Belt arm, (D) VFCB-exhaust unit.

Page 16

15

7.2 PSD 5 basic model

Fig.:7.2 Drawing of PSD 5 basic model

Spare parts list for PSD 5 basic model

Pos.nr.

Type

Ident. Nr.

1

Collar bushing E 308

0995681

2

Screw M6x20 CH Z

4345678

4

Bearing end shield V

0187860

5

O-ring 50x45x3 mm

1385259

6

Wave spring 50x44x0.6

0100331

7

Bearing 6205 2Z/C3

0104221

8

Cable 4x0.75mm² sort

0129420

9

Cable lead-in PG11

0105154

10

Blind stop PG11

2112512

11

Stator housing

1313711

12

Split pin ø4x8

0711179

13

Rotor cpl.

0766917

14

Bearing end shield H

1461142

15

DISA switch 230 V

0188807

16

DISA switch 440 V

0188817

17

Skrew M4x10

0100427

18

Switch for DISA switch

0110049

19

Earth cable

1461327

Page 17

16

7.3 PSD 5 cover

Fig.: 7.3 Split drawing of PSD 5 cover

Spare parts list for PSD 5 cover

Pos.nr.

Type

Cover L

Cover R

1

Eye shield for PSD 5

1311948

1311948

2

Cross handle Ø32 M6 DIN 6335

0922021

0922021

3

Disc 6.4x1.6

0737631

0737631

4

Carriage bolt 6x50

0932043

0932043

5

Nut M10 Z

5438761

5438761

6

Spring wave ring 10.2

0132606

0132606

7

Spark arrestor PSD 5 L-piece

0744859

0744859

8

Spark arrestor PSD 5 U- piece

0744840

0744840

9

Washer DIM 6 Z

1323060

1323060

10

Flange screw M10

1311956

1311956

11

Screw M5x10 CH Z

0120628

0120628

12

Washer DIM 5 Z

0737666

0737666

13

Lid PSD 5 cover

0745111

0745111

14

Cover PSD 5 indv. Kpl.

1065078

1065079

15

Screw M6x20 CH Z

4345678

4345678

16

Flange inner

0921572

0921572

17

Grinding wheel

- - 18

Cardboard labels

0920080

0920080

19

Flange outer

1105183

1105183

20

Nut M20x1.5

0744824

0744816

21

Cover PSD 5 outer

0745073

0745081

22

Disc 3/8” Z

0101491

0101491

23

Screw M10x30 Z

0236004

0236004

24

Grinding system

0744409

0744425

25

Fittings for cover PSD 5

0114974

0114974

26

Nut M8

0231350

0231350

Page 18

17

7.4 PSD 5 belt arm

Fig.: 7.4 Split drawing of PSD 5 belt arm

Page 19

18

Spare parts list for PSD 5 belt arm

Order number

Pos. Nr.

Type

Right

Left

1

Top screw

2078212

2078212

2

Sliding pipe for belt stand

9480687

9480687

3

Machine screw M4x4 Z

0737618

0737618

4

Lock ring DIM 42, DIN 472

7655123

7655123

5

Ball bearings 6302 2Z

1462846

1462846

6

Distance pipe ø22/15x10

2155002

2155002

7

Top roll

9480681

9480681

8

Shaft for top roll

2078200

2078200

9

Disc for top roll

9480693

9480693

10

Screw M6x16 CH Z lowered head

0120625

0120625

11

Pointed screw M5x10

0737605

0737605

12

Holder for top roll

9480679

9480679

13

Spring for telescope arm

9480694

9480694

14

Pipe for telescope arm

9480682

9480682

15

Spring holder for telescope arm

2078202

2078202

16

Handle for grinding belt M8x30

2078204

2078204

17

Pipe bushing for telescope arm

2078206

2078206

18

Pipe holder for telescope arm

9480692

9480692

19

Pipe cotter pin ø5x25

2078208

2078208

20

Håndle for adjustment of grinding belt

2188010

2188010

21

Fittings for telescope arm

1533813

1533813

22

Washer DIM 8 Z

0132594

0132594

23

Screw M8x25 CH Z

7676512

7676512

24

Distance ring

4318001

4318001

25

Pointed screw M8x12

0105026

0105026

26

Holder for telescope arm

2078211

2078211

27

Grinding system

0744425

0744409

28

Disc 3/8” Z

0101491

0101491

29

Screw M10x30 Z

0236005

0236005

30

Box cover for belt arm

1533780

1533781

31

Washer DIM 5 Z

0102555

0102555

32

Screw M5x10 CH Z

0120628

0120628

33

Felt washer

1533816

1533816

34

Cover plate

1533812

1533812

35

Distance ring ø30/20x6mm

1551176

1551176

36

Collar bushing PSD 5

0995681

0995681

37

Star handle ø40 M8 DIN 6335

1443593

1443593

38

Auto disc 5/16” Z

5437850

5437850

39

Spark arrestor

1533808

1533808

40

Nut M5 Z

0737623

0737623

41

Flange inner

0921572

0921572

42

Contact wheel 200x50x20

1532170

1532170

43

Square table

1533807

1533818

44

Flange outer

1105183

1105183

45

Double sticking tape

2004899

2004899

46

Graphite pad 50x270

2004898

2004898

47

Nut M20x1.5

0744824

0744816

48

Grinding belt

0215080

0215080

50

DN-bearing ring for belt arm

0120510

0120510

Page 20

19

7.5 VFCB-exhaust system for PSD 5

Fig.: 7.5 Split drawing of VFCB-exhaust system for PSD 5

Page 21

20

Spare parts list for VFCB-exhaust unit for PSD 5

Pos.nr.

Type

VFCB-220

VFCB-121

1

Fan housing L. outer

0781266

0781266

2

Screw M5x16 CH Z

0120626

0120626

3

Washer DIM 5 Z

0102555

0102555

4

Disc Ø5.5x26,5x2.5

0233030

0233030

5

Fan wheel VFCB alu.

0995703

0995703

6

Screw M6x16 Z

0300604

0300604

7

Washer DIM 6 Z

1323060

1323060

8

Fan housing L. inner

0785628

0785628

9

V-Ring 16A

0654329

0654329

10

Spring 5x5x14

0100609

0100609

11

Screw M8x16 Z

0120510

0120510

12

Auto disc 5/16” Z

5437850

5437850

13

Clamp for VFCB holder

1065297

1065297

14

Fan housing R. inner

0781258

0781258

15

Fan housing R. outer

0785636

0785636

16

Power engine

1043072

1043064

17

Thread piece PG11

0920011

0920011

18

Protection hose 18x13 400mm

0920400

0920400

19

Dust bag

0811793

0811793

20

Screw M4x16 w/round head

0737610

0737610

21

Cork washer 120x9

2006728

2006728

22

Connecting piece exhaust

1444190

1444190

23

Screw M5x10 CH Z

0120628

0120628

24

Washer DIM 5 Z

0102555

0102555

25

Tightening belt 68/85

1944266

1944266

26

Suction hose

2006731

2006731

27

Exhaust pipe

2006720

2006720

28

Cork washer

0111730

0111730

29

Elbow for VFCB

0111729

0111729

30

Pedestal for PSD 5

1065094

1065094

31

Table PSD 5*

0771317

0771317

32

Water cup

0771333

0771333

33

Disc ø13x24x2.5

0105167

0105167

34

Screw M12x40 Z

7654320

7654320

Table for PSD 5 with belt arm or deburrer has nr.: 077131

Page 22

21

7.6 Deburring cover for PODA 5

Fig 7.6 Drawing of parts in deburrer

Spare parts list for deburrer for PODA 5

Pos.nr.

Type

Cover R

Cover L

1

Disc 6.4x1.6

0737631

0737631

2

Cross handle ø32 M6 DIN 6335

0922021

0922021

3

Bolt for wood 6x50

0932043

0932043

4

Eye protective guard PSD 5

1311948

1311948

5

Nut M10 Z

0516637

0516637

6

Washer 10.2

0132608

0132608

7

Chest screw M10

1311956

1311956

8

Safety nut M4

0737615

0737615

9

Pointed screw M5x6 spids

0737606

0737606

10

Fittings for handle for deb./steel brush

0110166

0110166

11

Flange

1105183

1105183

12

Bushing, reducing 32-20mm

5003220

5003220

13

Steel brush 250x32x32

1531419

1531419

14

Nut M20x1.5

0744824

0744816

15

Håndle for deburrer/steel brush

0110168

0110168

16

Holder for grinding system

0920072

0920072

17

Grinding system for deburrer

0920073

0920073

18

ST-handle VC. 192/25P-M5x10

1943596

1943596

19

Drawer for grinding system f/deburrer

0920074

0920074

20

Screw M8x16 CH

0120622

0120622

21

Auto disc 5/16” Z

0132310

0132310

22

Washer DIM 8 Z

0132594

0132594

23

Star handle ø40 M8 DIN 6335

1443593

1443593

24

Deburrer cover

0920075

0920076

25

Machine screw M6x20 UHJX Z

0920020

0920020

26

Mounting plate

0250101

0250102

27

Termunal box lid MF71

0189421

0189421

28

Machine screw M4x12 Z

0737610

0737610

Page 23

22

7.7 POD 5 w/flange

Fig 7.7 Split drawing of POD 5 w/flange

Spare parts list for POD 5 w/flange

Pos.nr.

Type

Left

Right

1

Polishing guard Left

0921432

0921434

2

Disk 6mm

0737631

0737631

3

Skrew M6x10

0110089

0110089

4

Distance ring ø20x30x6

1551176

1551176

5

Spindle

1532367

1532375

6

Polishing Mop ø200x20xø6

1531557

1531557

Page 24

23

7.8 POD 5 w/spindle

Fig 7.8 Split drawing of POD 5 w/spindle

Spare parts list for POD 5 w/spindle

Pos.nr.

Type

Left

Right

1

Polishing guard Left

0921432

0921434

2

Disk 6mm

0737631

0737631

3

Skrew M6x10

0110089

0110089

4

Flange inner

0921572

0921572

5

Polishing Mop ø200x20xø6

1531506

1531506

6

Flange outer

1105183

1105183

7

Nut M20x1,5

0744824

0744816

Page 25

24

8 Technical data

8.1 Technical specifications

Model

PSD 5

BO 50/5

POD 5

Grinding belt

-

50x1600

-

Motor effect in Watt

1100

1100

1100

Rpm.

2800

2800

2800

Contact wheel

-

200x50xø20

-

Grinding wheel

200x38xø20

-

-

Polishing Mop to spindle

-

-

200x20xø6

Polishing Mop to flange

-

-

200x20xø20

IP class

54

54

54

Class F F

F

Amp

1,9/3,3

1,9/3,3

1,9/3,3

Cos

0,81

0,81

0,81

Weight

38 24

The noise level for these machines varies from 76 dB(A) (PSD 5/POD 5) to

88 dB(A) (BO 50/5) according to the measuring directions in the Department for

Work Safety and Health notice nr. 561 on devices of technical aids. Eye and

ear protection must be worn during use of the above machines.

8.2 Dimensions

Fig.: 7.1

Model A B C D E F G H I J

PSD 5

250

300

280

330

930

1190

1680

125

400

720

BO 50/5

250

300

280

330

930

-

1680

125

400

565

Page 26

25

8.3 Wiring diagrams

PSD 5, BO 50/5 and POD 5 industrial grinding machines can be wired 3 x 400 V,

50/60 Hz or 3 x 230 V 50/60 Hz. Please see wiring diagrams below.

Max. Volt

Max. Volt

Page 27

26

Disa Switch w/emergency stop

8.4

Page 28

27

8.5 PSD 5 connected to EX16 Dust Extraction

Page 29

28

8.5 Guarantee

If within 2 year of purchase this machine supplied by KEF A/S becomes

defective due to faulty materials or workmanship we guarantee to repair or

replace the machine or defective part or parts free of charge provided that:

1. The product is returned complete to one of our Service Branches or Official

Service Agents.

2. The product has not been misused or carelessly handled and in particular

has not been used in a manner contrary to the operating instructions.

3. Repairs have not been made or attempted by other than our own Service

Staff or the staff of our Official Service Agents.

4. Documentary proof of purchase date is produced when the goods are

handed in or sent for repair.

5. Wear parts are not covered by the warranty

KEF A/S offers you five years guarantee on the electrical motor if the

motor becomes defective or even burns-out within the first 5 years from

date of invoice.

Loading...

Loading...