Page 1

KEES, INC.

Installation & Maintenance Manual

DFG Series Direct Gas Fired

Make-up Air Heaters

Table of Contents

Page # Topic

1 Description of Operation

1 Receiving the Unit

1 Positioning the Unit

1 Curbing the Unit

2 Piping the Unit

2 Wiring the Unit

3 Optional Equipment

5 Controls Description

9 Troubleshooting Guide

13 Start-up of the Unit

15 Maintenance Schedule

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. Don't touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier.

FOR YOUR SAFETY

The use and storage of gasoline or other

flammable vapors and liquids in open

containers in the vicinity of this appliance is

hazardous.

WARNING: Improper installation, adjustment,

alteration, service or maintenance can cause

property damage, injury or death. Read the

installation, operating and maintenance

instructions thoroughly before installing or

servicing this equipment.

Page 2

INSTALLATION INSTRUCTIONS

Description of Operation

The KEES DFG series heater is a direct gas fired heater using 100% outside air. It is

designed for outdoor installation but may be mounted indoors provided the intake is

ducted to the outdoors. Natural gas or propane fuel the burner. The flame is modulated

to provide a constant preset discharge temperature or room temperature (optional). In

areas where freeze-ups may occur, it is recommended that a low temperature limit be

installed to protect the indoor space in the event of a burner shutdown.

Receiving the Unit

Upon receipt of the unit, carefully inspect it for any visible damage. Each unit is

inspected prior to shipment. If any damage is found, immediately notify the carrier and

file a claim with that carrier. Also, verify that the items shown on the packing list were

received and that they agree with what was ordered. Notify KEES, Inc. of any

discrepancies. Prior written permission must be obtained before any merchandise may

be returned.

Positioning the Unit

When determining the location for the roof curb, minimum clearances to combustible

materials must be maintained. Shown below are the tested minimum clearances. Local

codes prevail, however, if greater clearances are required. The intake of the unit should

not be placed in the direction of prevailing winds if at all possible. Make sure the top of

the curb is level so that a good seal can be made to the heater. Once the curb is set in

place, the roofing material can be finished around it.

Minimum Clearances to Combustibles

Service side or top ----------24.0 inches

All other sides ----------------0.0 inches

Curbing the Unit

The discharge of the unit, which is underneath the blower section, must be placed over

the roof curb. The other end of the unit rests on the support rail. Note: the standard

roof curb height is twelve (12) inches. In areas with heavy snowfall, a greater height

may be required.

1

Page 3

Piping the Unit

Applicable codes and standards must be followed in sizing and installing the gas piping.

A manual gas shutoff valve is provided for field installation. A 1/8" N.P.T. plugged

tapping must be installed immediately upstream of this valve for pressure test gauge

connection. The pressure at this tap must fall within the minimum and maximum

pressures shown on the nameplate in order for the unit to operate properly. 1/2" or

greater diameter pipe is recommended for the incoming pipe. Care should be taken

when fitting the piping, so that the manifold and gas train components do not get twisted

or damaged. If the minimum pressure is not met then the burner will not operate

properly. An auxiliary high-pressure regulator must be installed if the maximum is

exceeded.

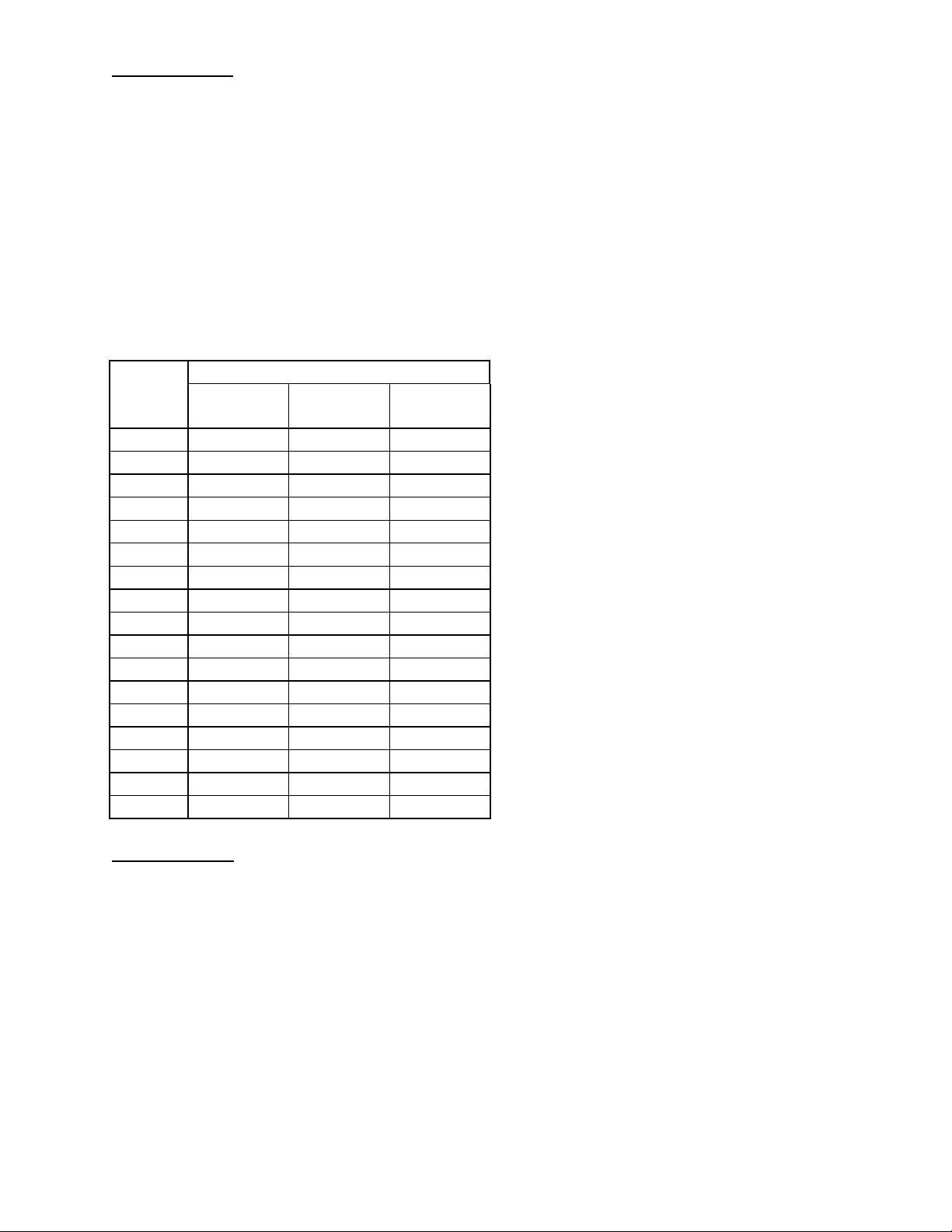

Unit Gas Piping Connection Size Chart

MBH Gas Pressure at the Unit

Input 7-8" NG

5-6” LP

100 ½" ½" ½"

200 ½" ½" ½" Note: Unless otherwise specified

300 ¾" ¾" ½" at the time of the order, the gas

400 ¾" ¾" ¾" piping will be sized according to

500 1" ¾" ¾" the 7-8" gas pressure column.

600 1" 1" ¾"

700 1-¼" 1" 1"

800 1-¼" 1" 1"

900 1-¼" 1-¼" 1"

1,000 1-¼" 1-¼" 1"

1,100 1-¼" 1-¼" 1-¼"

1,200 1-½" 1-¼" 1-¼"

1,300 1-½" 1-¼" 1-¼"

1,400 1-½" 1-¼" 1-¼"

1,500 1-½" 1-¼" 1-¼"

1,600 1-½" 1-½" 1-¼"

1,650 1-½" 1-½" 1-¼"

9-10" NG

7-8” LP

11-14" NG

9-14” LP

Wiring the Unit

Applicable codes and standards must be followed in wiring the unit. For main power

wiring, bring the wires into the factory supplied disconnect switch. If one has not been

factory provided, then a disconnect switch of sufficient ampacity must be installed

according to Article 430 of the National Electrical Code, ANSI/NFPA 70-1987. In this

case once it is installed and wired the wires should be run to the service switch inside

the control compartment. Connect any field wired control components according to the

electrical drawing furnished with the unit. Spark testing or shorting of the control wires

by any means will render the transformers inoperative. Do not allow this to happen, as

it is not covered under warranty.

The unit wiring diagram and parts list are in a plastic sheet protector inside of the control

compartment.

2

Page 4

OPTIONAL EQUIPMENT

LOW TEMPERATURE LIMIT SWITCH

This control is commonly called a Freeze Stat. This unit mounted, low limit thermostat will shut the

blower off if the discharge temperature drops below 40°F. A Bypass Timer which is part of the control will

allow the unit to run on a cold start-up. After 5 minutes, control power will pass through the low

temperature thermostat. If the remote panel has operating lights, the red light will glow on "ALARM".

Turn the unit

FLAME FAILURE RELAY

A relay is interlocked with the burner control module. When the burner fails to light within the allowable

time (30 seconds), the relay is energized, which opens the circuit to the blower starter, and shuts the unit

down. If the remote panel has operating lights, the red light will glow on "ALARM". Turn the unit

then back ON and then reset the burner control module.

MILD WEATHER THERMOSTAT

This control is often called an "Intake Air Thermostat". The sensing element of the thermostat is mounted

in the incoming air supply to the unit. If the temperature exceeds the setting of the thermostat, the burner

will de-energize. The burner will re-ignite when the outside air temperature falls below the thermostat set

point.

REMOTE CONTROL PANEL

This consists of either a three position “SUMMER-OFF-WINTER” switch in a flush mounting stainless

steel bezel plate and masonry box or two toggle switches (“FAN ON/OFF” and “HEATER ON/OFF”) in a

flush mounting stainless steel bezel plate on the kitchen hood face.

, and back ON, to reset the Bypass Timer.

OFF

OFF

,

REMOTE CONTROL PANEL WITH INDICATOR LIGHTS

Up to four labeled pilot lights are mounted on the face of the remote control panel, indicating primary

functions of the unit. The “SUMMER-OFF-WINTER” switch is included next to the pilot lights.

1 - Green - Blower Run Light – “BLOWER”

1 - Green - Burner On Light – “BURNER”

1 - Red - Low Temperature Failure Light – “ALARM”

1 - Red - Flame Failure Shut Down Light – “ALARM”

1 - Red - Clogged Filter Light – “FILTERS”

A minimum of two lights is available. If more than the standard 4-light panel is required, a circuit analyzer

panel must be used.

CLOGGED FILTER SWITCH WITH INDICATOR LIGHT

A pressure sensitive switch, mounted in the unit, will sense the air pressure drop across the filter. When

the filter becomes dirty, the switch will activate a light on the remote control panel, indicating a filter

change is required.

PREPURGE TIMER

A timer allows the unit blower to run for 1 minute, purging any gas residue in the unit, before the burner

circuit is allowed to energize.

TIME CLOCK

A time clock cycles the unit ON and

selected days, as needed.

, at selected times of the day. This time clock can also "skip"

OFF

115V DUPLEX SERVICE RECEPTACLE

The receptacle is mounted to the outside of the unit in a weatherproof enclosure. It provides power for

service equipment when the main power to the unit is shut off for service work. It requires a separate

115V circuit.

3

Page 5

CONTROL SYSTEM DIAGNOSTIC INDICATOR

This component is used as a diagnostic tool for troubleshooting burner problems. It attaches to the

burner control module monitoring the function of the module and storing in memory any failures that

occur.

AUDIBLE ALARM

An alarm horn is supplied with the remote control panel. On a flame failure, the horn will sound. A reset

of the flame failure relay will silence the horn.

DISCHARGE DAMPER WITH 2-POSITION MOTOR AND INTERLOCK

A motor operated Parallel Blade Damper can be added to the discharge of the unit. This will prevent the

warm air from escaping out of the building through the unit. The damper motor spring returns the damper

to a

CLOSED

outdoors.)

INTAKE DAMPER WITH 2-POSITION MOTOR AND INTERLOCK

A motor operated Parallel Blade Damper is installed to the fresh air intake of the unit. This keeps cold air

from entering the unit when

FILTER SECTION

The filter section with 1” cleanable or throwaway filters is supplied as standard on the units. 2" cleanable

or throwaway filters as well as Farr 30/30 throwaway filters are also available.

position during shutdown. (A discharge damper is recommended on units installed

SHUT-OFF

. (An intake damper is recommended on units installed indoors.)

INTAKE HOOD WITH BIRD SCREEN

This standard accessory is sized to fit the fresh air intake of the unit. It has 1/2" mesh birdscreen on the

face of the hood and is designed to help prevent rain or snow from entering the unit. It is shipped as a

loose item for field installation. It can be deleted on indoor units that are ducted to the outside.

GALVANIZED STEEL CURB

The standard roof curb is flat, 12" high, insulated and formed of 18 gauge galvanized steel. It fits under

the fan discharge of the unit. Other heights and one way or two-way pitches are available.

SUPPORT RAIL

It supports the rear of the unit and is sized to match the roof curb. Support legs may be necessary if an

intake hood is included.

FULL PERIMETER ROOF CURB

This curb goes under the full length of the main unit (burner and blower section). A support rail is not

required for the back of the unit. However, support legs may be necessary if an intake hood is included.

MODULAR CURB CAP AND CURB

The curb cap is custom sized to house an exhaust fan as well as the supply fan on one common curb.

The exhaust fan extension is also sized to meet NFPA96 requirements for discharge height. The supply

fan extension fits under the fan discharge like the standard curb described above.

HOUSING INSULATION

1" 1-1/2# density insulation is standard on the units. It is glued and pin spotted, to the inner surface of the

walls and ceiling of the unit. As an optional cost saving, it can be deleted from the burner and filter

sections if a discharge damper is included.

VIBRATION ISOLATORS

Isolators are standard equipment underneath the blower and motor. Floor rubber in shear, floor spring

and hanger spring isolators are also available to provide additional vibration isolation for floor mounted

and indoor hanging units. They are shipped as loose items for field installation.

4

Page 6

HIGH PRESSURE REGULATOR

It is necessary to install a high-pressure regulator upstream of the unit if the incoming gas pressure is

greater than ½ PSIG. This item ships loose for field installation and is available in 1” and 1-1/4” diameter

pipe sizes.

HIGH AND/OR LOW GAS PRESSURE SWITCH

As an option these switches are available to monitor high, low or high & low gas pressure to the burner.

If improper gas pressure is measured than the burner circuit is de-energized.

COIL COMPARTMENT (WITH OR WITHOUT COIL)

An insulated coil section for a chilled water coil can be factory installed. Housing includes access door,

drain pan and selected coil (if required). The coil compartment is custom-designed to fit the coil selected

and the unit housing size.

EVAPORATIVE COOLING SECTION

This section includes the housing, evaporative cooling media, submersible pump, float valve, overflow

coupling, drain pipe, flush valve and flow meter.

DISCHARGE LOUVERS

A field installed louver, with vertical and horizontal blades, which is designed to discharge air in four

directions. The blades are installed 2" apart, and can be manually adjusted to set direction of air flow.

CONTROLS DESCRIPTION & TESTING

1. LOW TEMPERATURE LIMIT SWITCH

This is a freeze protector. If the unit supply temperature is below the setting of this controller, it

will open the circuit (R-W) shutting the unit operation down and close the circuit (R-B) lighting the

optional “ALARM” light of the remote control panel. It also has a bypass timer that allows the unit

to run on a cold start without shutting it down.

Temperature Adjustment

Set: 40°. Bulb location in supply air duct of unit.

Test: Adjust setting above discharge temperature. The unit will shut down. (

testing run blower only.)

Timer Adjustment

Set: 5 minutes.

Test: Set timer at "0" minutes. The control circuit will be through low temp limit. Turn low temp limit up

and the unit will shut down. Set timer at 5 minutes; reset timer and adjust low temp limit to 40

setting and the unit will continue to operate through the time contacts. To reset timer turn power

"OFF" and back "ON".

NOTE:

For ease of

°

5

Page 7

2. DAMPER MOTOR

The function of the damper motor is to power open or spring return close the dampers on the

discharge or intake of the unit. It will seal off or open the building to the make-up air supply.

Test: Remove damper motor linkage cover. Energize unit. Damper motor will open, pushing linkage to

open the damper blades. De-energize unit. Damper motor will close damper blades by spring

return.

3. AIR FLOW SWITCH

The function of this switch is to prove proper air flow across the burner before the burner circuit

can be energized.

Set: 0.3" W.C. for DFG-10/12 units.

0.4” W.C. for DFG-15/18/20 units.

Test: Restrict inlet or discharge to unit 50%. Air flow switch should open circuit to burner.

4. HIGH TEMPERATURE LIMIT SWITCH

The function of this control is a manual reset thermal cutout for primary over-temperature

protection of the unit.

Set: 155°F for DFG-10/12 units.

190°F for DFG-15/18/20 units.

Test: Adjust unit to high fire. Place thermometer in unit discharge. Close intake down until unit has

excessive cabinet temperature. This limit should trip at 200°F.

5. MILD WEATHER THERMOSTAT

The function of this control is to sense inlet temperature and act as an economizer. It will take

the burner out of the circuit if the inlet temperature is above the control setting.

Set: 5°F below room or discharge temperature controller.

Test: Adjust control setting below inlet temperature. Burner circuit will de-energize. Adjust above inlet

temperature. Burner circuit will energize.

6. HIGH GAS PRESSURE SWITCH

The function of this switch is to de-energize the burner circuit if the gas pressure to the burner is

above its setting.

Set: 8" W.C. - Manual reset to energize.

Test: Using test gauge in parallel with sensing tubing, adjust unit to high fire, increase regulator

pressure at gauge above 8" W.C.

6

Page 8

7. LOW GAS PRESSURE SWITCH

The function of this switch is to de-energize the burner circuit if the gas pressure to the burner is

below its setting. Manual reset to energize.

Set: 2" W.C.

Test: Using test gauge in parallel with sensing tubing, adjust unit to high fire, decrease regulator

pressure at gauge below 2" W.C.

8. BURNER CONTROL MODULE

This module supervises the flame circuit and the energizing of the ignition/pilot and main gas

valves. A milli-volt circuit is used for flame detection and response.

Set: 1.25-5.0 Vdc signal on pilot flame.

Test: Fire unit, with manual shut-off valve decrease gas flow to burner until micro amp reading drops

and the relay causes the main gas valves to close. The safety circuit will cut out in 30 seconds.

9. ROOM OVERRIDE THERMOSTAT

The function of this thermostat is to cycle the unit to high fire if the room temperature requirement

is not being met. It overrides the ductstat on Maxitrol series 14 systems. It ships loose and

should be mounted in a location that has a representative temperature for the room.

Set: Desired room temperature.

10. ELECTRONIC MODULATING VALVE

The function of this control is to proportion the amount of gas to the burner to maintain the

desired discharge supply air temperature. This control uses an electric coil with a floating plunge

that will vary the force on a gas supply orifice supplying gas to the main burner. A 24V D.C.

signal positions the plunger inside the electric coil. At 0-5 volts it will be low fire; at 5-15 volts

modulation; and 15-24 volts at high fire.

Test: Check plunger for up and down motion by varying the voltage to the valve.

11. AMPLIFIER

This control converts 24 volts A.C. to 24 volt D.C. and varies the voltage to the modulating valve.

Test: Check input at transformer terminal for 24 volt A.C. -- check output at modulator terminals for 24

volt D.C. output while adjusting the temperature set point.

12. DISCHARGE AIR TEMPERATURE SENSOR

Discharge Control Units (Series 14):

The function of this sensor is to monitor discharge supply air temperature and with a temperature

sensitive element send a signal to the amplifier to make any necessary temperature adjustments.

Room Control Units (Series 44):

The function of this sensor is to monitor the discharge supply air temperature and with

temperature sensitive elements send a signal to the amplifier to maintain the maximum and

minimum discharge temperatures of the unit. It works together with the Room Selectrastat.

7

Page 9

13. REMOTE TEMPERATURE SELECTOR

The function of this dial is to set the desired discharge temperature the unit is to supply. This dial

working in conjunction with the discharge temperature sensor sends a D.C. voltage signal to the

amplifier that modulates the burner to a specific supply temperature.

14. ROOM SELECTRASTAT

The function of this room thermostat is to vary a D.C. voltage signal to the amplifier that will

modulate the burner to maintain a supply air temperature to satisfy space temperature.

15. CLOGGED FILTER SWITCH & LIGHT

The function of this control system is to sense by negative pressure a dirty filter condition and

signal that filter maintenance is required. With a negative pressure above the setting of the filter

switch (sensed on the leaving side of the filter), the switch will trip, energizing the filter light on the

remote control panel.

Set: A visual inspection should be made of the filters until the first cleaning is necessary. At this time

adjustment of the switch should be made. Turn switch adjustment clockwise until the switch

closes. After cleaning or replacing the filters, check to make sure the light is no longer lit.

16. TIME CLOCK

The function of this clock is to cycle the unit "ON" or "OFF" for a set time period during each 24

hour period on a constant running unit; or to cycle the unit from day to night for day/night

operating units. On day/night units, the remote control panel will have a time clock override

switch that can be used on the time "OFF" periods to switch the unit back on to constant running.

Set: Program the unit for the desired time "ON" and "OFF". Instructions are included with the time

clock.

17. PREPURGE TIMER

The function of this timer is to purge the combustion area and the discharge supply duct before

the burner flame safety circuit is energized.

Burner circuit power will energize the pre-purge timer. When the timed purging period is over,

the flame safety circuit will be energized.

Set: 1 minute.

18. AUDIBLE ALARM

The function of this alarm is to give an audible alarm signal down in the space, along with the

alarm light on the remote panel, when there is a burner flame failure.

On a flame failure, and after a 30 second safety timing period, the alarm contacts of the burner

control module will close. This will energize the flame failure light and the audible alarm. To

silence the alarm, the green reset button on the flame safety will need to be reset.

8

Page 10

TROUBLE SHOOTING GUIDE

If a service problem should occur, the following guide can be used to isolate and correct

the problem.

IMPORTANT:

Before this heater will operate, the following conditions must be met and, therefore,

should be checked before proceeding to the steps of the "Trouble Shooting" section

herein.

1. Adequate supply of air into intake of the unit -- check for obstructions in intake

hood and filters.

2. Proper fuel pressure -- all supply valves open and proper gas pressure supplied

as stated on unit identification plate.

3. All circuit breakers and disconnects turned on and adequate electrical power to

unit.

A. BLOWER MOTOR FAILS TO START. REMEDY

Probable

Cause:

1. Fuse blown in unit disconnect. Replace fuse.

2. Motor starter out on overload. Press red reset button overload.

3. Remote switch in OFF position. Turn to summer or winter position.

4. Unit shut down on flame safety. Press reset button on flame

safety relay.

5. Unit shut down on low Re-energize power to low

temperature safety. Temperature limit by turning

power “OFF” and then “ON”.

6. Defective motor. Replace motor.

7. No power to motor starter Check preceding controls

coil. for open circuit.

9

Page 11

B. BLOWER MOTOR STARTER

GOES OUT ON OVERLOAD. REMEDY

Probable

Cause:

____________________________________________________________________

C. PILOT WILL NOT LIGHT REMEDY

Probable

Cause:

1. Motor drawing too many amps. Slow blower RPM down.

2. Loose wiring. Check wire connections.

3. Low voltage to unit. Check power supply to unit.

4. Defective motor. Replace motor.

5. Belts too tight. Adjust belts for 1" deflection.

6. Defective blower bearings. Replace bearings.

7. Dirty blower wheel. Clean blower.

8. Defective starter overload. Replace starter overload.

1. No power to burner control Check preceding controls for

module. open circuit.

2. Air in pilot line. Purge air from pilot line.

3. Low gas pressure. Supply unit with pressure stated

on unit identification plate.

4. Burner control module locked Press reset button on

out. burner control module.

5. Pilot regulator out of Adjust unit pilot regulator to

adjustment. increase pilot gas supply.

6. Pilot regulator locked up. Gas pressure to unit is excessive;

decrease supply pressure.

7. Defective ignition transformer. Replace transformer.

8. Incorrect spark gap. Adjust gap.

9. Defective pilot solenoid valve. Replace valve.

10. Defective burner control Replace module.

module.

10

Page 12

D. PILOT LIGHTS, BUT FLAME SAFETY

LOCKS OUT AFTER 30 SECONDS REMEDY

Probable

Cause:

1. Defective flame rod. Check porcelain for cracks.

Replace rod if crack is visible.

2. Pilot flame too small. Adjust pilot gas regulator to

increase pilot flame.

3. Defective burner control If micro-amp meter measures

module. 3 milliamps or more to module

and it locks out, replace relay.

____________________________________________________________________

E. PILOT LIGHTS AND FLAME SAFETY

PROVES PILOT, BUT NO MAIN FLAME REMEDY

Probable

1. Main gas valve shut-off. Open main valve.

Cause:

2. Defective main gas valve. Replace valve.

3. Low gas pressure. Adjust gas pressure as stated

on unit identification plate.

4. Loose wiring. Check wire connections.

5. Deflective burner control Replace module.

module.

____________________________________________________________________

F. UNIT OVER-FIRE (Excessive

Temperature Rise) REMEDY

Probable

Cause:

1. Excessive gas pressure. Adjust gas pressure as stated on

unit identification plate.

2. Loose belts. Adjust belts for 1" deflection.

3. Dirty filters. Remove filters and clean.

4. Excessive external static Adjust motor sheave to increase

pressure. blower RPM (beware of over-

loading motor) or adjust temp.

rise using regulator inside unit.

5. Dirty blower wheel. Clean blower wheel.

6. Foreign matter on intake Remove obstruction.

screen.

11

Page 13

G. UNIT UNDER-FIRED (Temperature

Rise Too Low) REMEDY

Probable

Cause:

____________________________________________________________________

H. BURNER WON'T MODULATE --

ELECTRONIC CONTROL SYSTEMS

1. Lack of gas pressure. Adjust gas pressure as stated on

unit identification plate.

2. Lack of static external Adjust motor sheave to

pressure. decrease blower RPM or adjust

temperature rise using regulator

inside unit.

3. Gas line obstruction. Remove obstruction.

4. Dirty burner. Clean burner.

5. Defective gas valve. Replace valve.

6. Improper adjustment of Adjust temperature rise per

temperature rise. start-up card or instruction in

manual.

1. Refer to Maxitrol Series 14 Installation, Instruction and Field

Service Check List included in the next pages of this manual.

12

Page 14

START-UP OF THE UNIT

1. Turn the remote switch to the "OFF" position.

2. Turn the main disconnect switch to the "OFF" position.

3. Remove the control cabinet cover and the blower cabinet cover.

4. Turn all the manual gas shutoff valves to the "OFF" position.

5. Check to make sure that all wiring has been completed according to the furnished wiring

diagram including the installation of all field installed components.

6. Check all wiring terminals for tightness and good connection.

7. Make sure all manual resets have been reset.

8. Check all gas line connections for leaks including those within the unit.

9. Measure the incoming gas supply pressure at the field installed 1/8" tap upstream of the

unit. Verify that it falls within the minimum and maximum nameplate values.

10. Check that pulleys are in alignment and locked to the shaft.

11. Check for the proper input voltage (given on the nameplate).

12. Turn the remote fan switch to the "ON" or "SUMMER" position (depending on which

remote control option was ordered) and turn the main disconnect to the "ON" position.

13. Verify fan rotation, belt tension and motor amp draw. Make certain the blower motor is not

overloaded. Replace the blower cabinet cover.

14. Set the remote temperature selector above the outside air temperature to simulate a call

for heat.

15. Open pilot gas shutoff valve.

16. Turn the remote heater switch to the "ON" or "WINTER" position (depending on which

remote control option was ordered).

17. Verify that the burner control module energizes the ignition transformer, opens the pilot

valve, that the pilot flame is established and that the main valves are then energized.

18. Using a volt-ohmmeter, measure the flame signal at the +/- test jacks on the flame signal

amplifier (refer to the Honeywell RM7890 manual for more detailed instructions). The

signal should measure between 1.25 and 5.0 Vdc. Adjust the pilot pressure regulator to

obtain a value near the midpoint of the range.

19. If the outside air temperature is high, the high temperature limit may have to be jumpered

to prevent shutdown during the following high fire adjustment. Reset it to a value greater

than 120 degrees above the outside air temperature.

13

Page 15

20. Open the main gas shutoff valve. Disconnect the wire from the "A4" terminal block. This

will cause the unit to call for continuous high fire.

21. Check the outside air temperature and add the nameplate temperature rise to this value.

Measure the discharge air temperature. Adjust the main gas pressure at the main

pressure regulator until the proper discharge temperature determined above is reached.

On units with the Maxitrol MR212 valve, there is no separate regulator. Adjust the main

gas pressure at this valve (refer to the Maxitrol installation instructions).

22. Observe the main burner flame for proper flame length. The flame should be 13-16" in

length, as measured from the end of the burner to the end of the stable part of the flame

(exclude any wisps of flashes). If the flame is too long, if it contains excess yellow flame,

or if it tends to rise, low air velocity is indicated. If the flame is very short and all blue,

excess velocity is apparent. Shut down the heater and adjust the profile plates as

required.

23. If profile plates have been adjusted, then recheck the temperature rise as in step # 23.

Adjust the regulator if necessary.

24. Reconnect the wire to the "A4" terminal block. Disconnect the wire to the "A8" terminal

block. This will cause the unit to call for continuous low fire.

25. Reduce the low fire stop on the modulating valve until the flame tends to go out. Then

increase it to the smallest stable, full length fire. If a local weak spot appears, check for

clogged low fire air ports. Make low fire adjustments patiently. Due to the low gas flow

rate, response to adjustments will be slow. Refer to the Maxitrol installation instructions on

how to make these adjustments.

26. Reconnect the wire to the "A8" terminal block. Remove the jumper on the high

temperature limit. Reset the remote temperature selector to the desired discharge air

temperature.

27. Check unit for proper function of the control operations (refer to the Controls Description

and Testing section).

14

Page 16

MAINTENANCE SCHEDULE

Service and maintenance should be performed four times a year (three-month intervals)

or after every 2,000 hours of operation. The following items should be checked at each

inspection:

A) Check wear and tension of the belt; replace if necessary. (Tension of the new

belt should be re-adjusted after first two weeks of operation to compensate for

stretching.)

B) Check cleanliness of the burner. Clean air ports are essential for good burner

operation. Check the burner every two weeks, if required, because of dirty

atmosphere.

C) Check filters, if supplied, for cleanliness. Clean and replace, if necessary.

D) Check and clean blower wheel at least once a year. Inspection can be made by

removing the blower access panel. Clean as necessary.

E) Check ceramic insulators on flame rod and spark rod for cracks and

deterioration. Replace if necessary.

F) Check the motor. Clean air inlets of motor, if needed.

G) Check and clean end fittings of discharge air sensor.

H) Check damper linkage and operation. Oil linkage as needed.

I) Grease bearing on unit with pillow block bearings.

15

DFGI&M 12/04

Loading...

Loading...