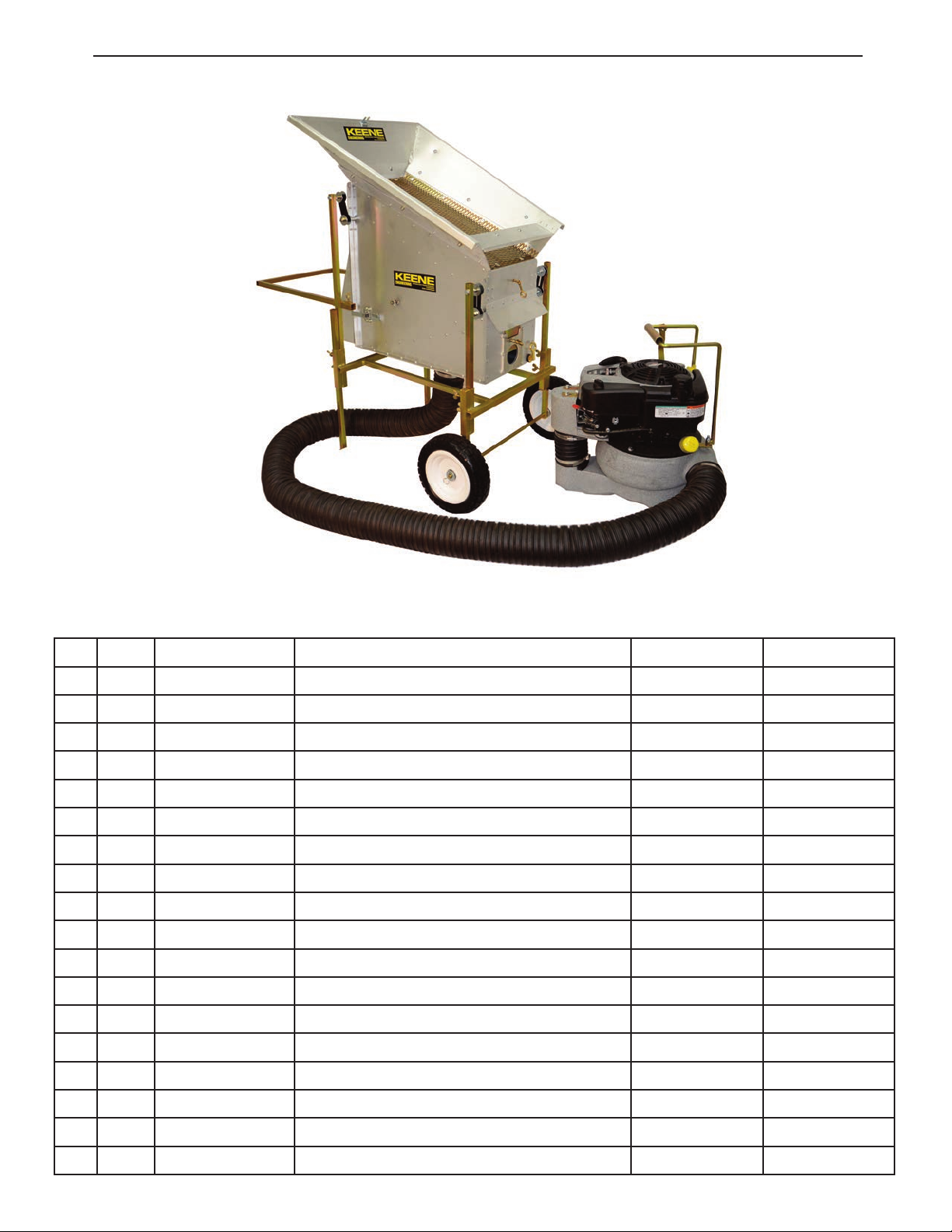

MODEL 190 ASSEMBLY & OPERATING INSTRUCTIONS

Parts list

# QTY Part # DESCRIPTION COST EXTENSION

1 1 190FA 190 Frame Assembly $225.00 $225.00

2 1 190AX 190 Axel and Hardware $24.95 $24.95

3 2 190WHEEL 190 Wheels Foam filled $24.95 $49.90

4 9 190WB 190 wing bolts $3.50 $14.00

5 4 190SB 190 Support belts $5.95 $29.75

6 1 190DRLF 190 Dry washer body less frame $1,095.00 $1,095.00

7 1 190HS 190 Hopper Support $35.00 $35.00

8 1 190HF 190 Hopper Flare $150.00 $150.00

9 1 190RC 190 Riffle Cartridge $59.95 59.95

10 1 190RT 190 Riffle Tray $79.95 $79.95

11 1 190VAP 190 Vibrator Mounting Plate $39.95 $39.95

12 1 190HA 190 Plastic Hose adaptor $19.95 $19.95

13 1 190V 190 Vibrator $89.95 $89.95

14 1 190VB 190 Vibrator Bearing $29.95 $29.95

15 1 190BGA 119 Blast Gate assembly $29.95 $29.95

16 2 SS72 4" hose clamps $3.00 $6.00

17 1 151AH 4" duct hose 10 foot long $70.00 $70.00

18 1 151EBA B/S Motor and Blower assembly $685.00 $685.00

Congratulations you have purchased the finest quality American

made dry washer in the world. The package should last a lifetime

if you take care of it properly.

Keene Engineering is proud to introduce the Model 190 series Dry washer & High Banker Dredge

Combination. The 190 Series is the most advanced and user friendly on the planet with “Six Unique

Patents” to its credit.

“Soft Bed Technology”, creating a whopping 7 milliamps of constant current, resulting in an electro-

static charge ten times greater than any other dry washer. It also creates a positive charge on all dust

particles that reacts to the negative charge of the ground, creating “virtually a dustless environment”.

“Blast Gate Technology“ provides for Infinite adjustment of vibration and air pressure. “Scrubbing

Pins” separates and Liberates stubborn gold and creates an even flow of material.

“Enclosed riffle bed” Creates a dust free environment and a compact single unit design for an extremely efficient machine. In a matter of minutes the 190 transforms to an extremely effective high

banker and dredge. The 190 dry washers provides unmatched fine gold recovery.

1. Please read the Briggs and Stratton manual for Safety issues specification and maintenance.

You need to completely read all the safety and operating instructions on the new Briggs and Stratton

powered blower assembly. This engine was engineered for the application. It is set up with a two

part air cleaner system for superior air filtration and longevity. It has a greater oil capacity including

the new oil filter system. The flywheel is heavier to insure smooth operation and no kick back when

starting.

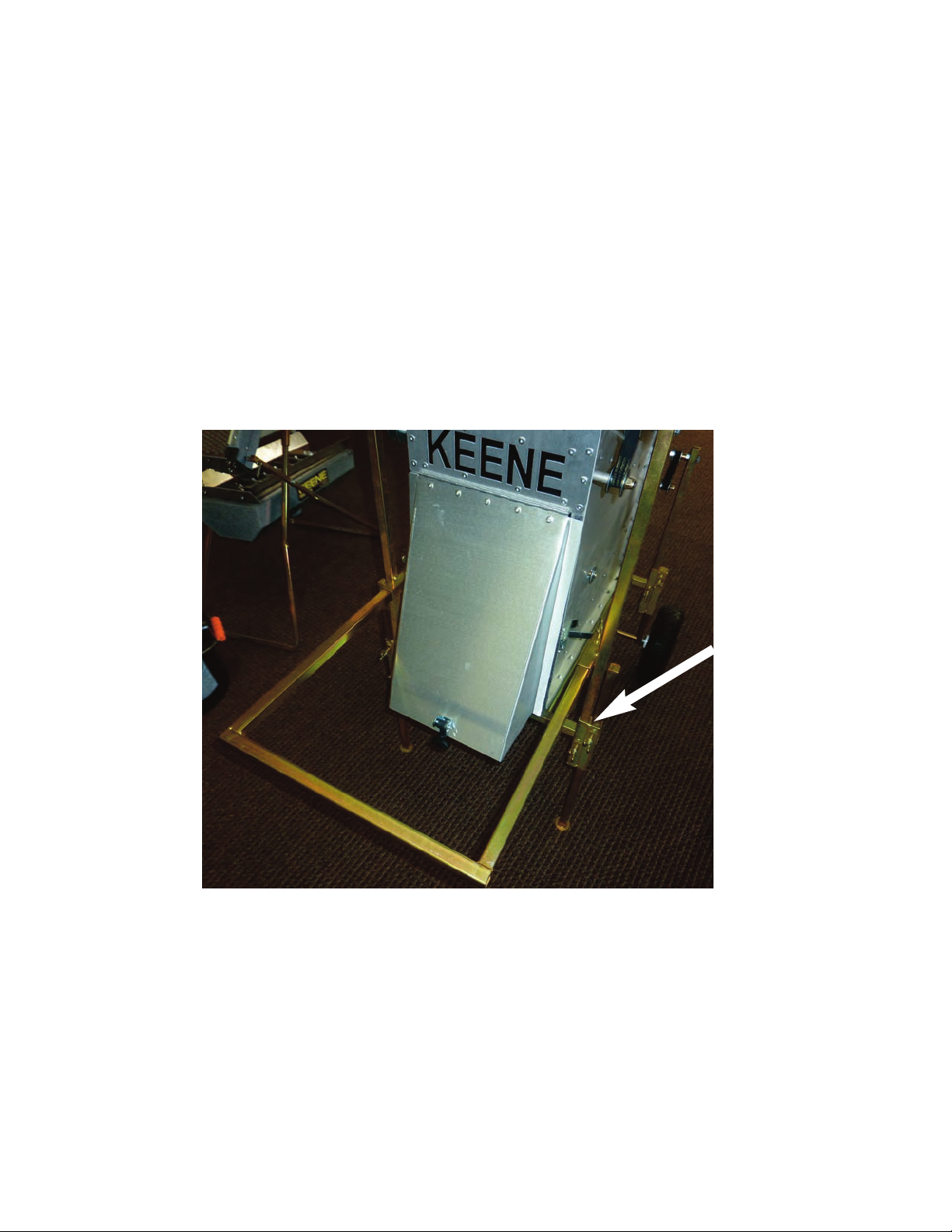

2. Assemble the frame and wheels as per diagram. All the parts are held in place with the large

wing bolts. Do not over tighten, just finger tight is adequate for all frame hardware. The wheels are

held on with a flat washer and cotter pin. There should be no tools required for this assembly.

3. The vibrator assembly must be bolted into position before use. There is easy

access to hardware just remove the dry washer cloth cartridge inside the dry washer.

The only tool you will need is a Philips head screw driver # 2. As you can see by the

picture the Vibrator bolts in from the outside in.

Next Slide the Riffle cartridge under the lip located just under the scrubbing pins.

This picture shows the riffle board in place and the riffle board locked down with the

locking cam. The riffle faces towards from the opening for dry washing It is important to

place the riffle cartridge in correctly so that the Lexan openings inside the riffle cartridge lines up with the aluminum support base openings. If it is not lined up this can

cause the dead air spaces to be off and can effect the fine gold recovery.

4. The 190 main aluminum Body should now be fully assembled as a dry washer.

You can now lift the aluminum body and suspend it from the 4 belts. You can place a

half twist if the belts for transportation. The half twist makes the belt slightly tighter so

the belt is less likely to slip off of the support brackets especially during transportation.

The 190 dry washers have 4 main adjustment points

1.

Raise and lower the handle and when the desired angle is achieved then tighten the large

wing bolts to lock into place. We suggest raising the front of dry washer approximately 2

inches above level to start, and then adjust as needed for optimum recovery. For higher

volume of material to pass, lower the handle slightly and this will increase the drop on

the riffle board. We also recommend that when you are in the adjusting stage leave the

large discharge door open so you can watch the material run. I like to see an action in

the riffle similar to a ripple of water over the riffles. If the riffle runs to fast you will not see

the wave action.

\

To adjust the angle of the sluice, loosen the wing bolts below the large handle.

Adjust

Angle

of Sluice

Picture shows the blast gate in that half open position and you can

also see the flow gate off set weight knob

2. The blast gate can be open and closed with the large wing nuts. The blast gate

controls the air pressure under the riffle board. It also provides some speed control on

the vibrator. We suggest that you operate the dry washer blast gate in half open position

to start, and then adjust as necessary. Fully open provides less air pressure on more

vibration. Closed causes stronger lift in the riffle board for heavier material.

\

3. Flow control gate is located under classifier screen adjust with out of balance eye-

bolt at the lower end of the classifier screen. This is used to control the feed into the recovery tray. We suggest that you run this at an 80% closed position. Material will

continue to flow since the gate is made with fingers so the material flows consistently.

4. Engine and Blower assembly require some adjustment. Typically we run around

80% of engine throttle. For heavier material you may have to run the engine up to 90%

throttle. For lighter you turn the engine down.

The Riffle board assembly just slides in until it stops under the aluminum lip. Then slide

the riffle board in and lock into place with the cam. The riffle board faces uphill for dry

washing and down hill for a wet application.

Riffle Board Cartridge

Inside the riffle cartridge there is a layer of Lexan plastic, perforated rubber, silkscreen

material with a backing of a polyester carpet.

Each material places a very special part in generating the optimum fine gold recovery

and a static electricity. Silk Screen Cloth is one of the toughest materials available,

very abrasion and tear resistant. The compounds of cloth make it the ultimate for a dry

washer due to the high static charge that it generates and it robust nature. The perforated rubber layer vibrates against the silk cloth and provides high levels of static electricity. The Lexan plastic is the perfect material to store the static charge for a strong

even charge in the 190,160 and the 151S dry washer. The Lexan also provides dead

air space under each that enhances supper fine gold recovery. The bottom layer polyester carpet enhances the static charge and also provides an even balance of airflow

through the cloth cartage.

Loading...

Loading...