1166 55

2211 00

G

INSTRUCTION MANUAL

Single language version and parts diagrams can be

down loaded from www

.keencut.co.uk

KC-ST/7298 JAN 13

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

1 Contents 1

2 Packing list

2.1 Unpacking your machine

3 Assembly

3.1 Preparing the Legs

3.2 Preparing to fit the Squaring arm

3.3 Fitting the Squaring arm

3.4 Fitting the Pull Bar (210 only)

3.5 Fitting the Wall mounting bracket

3.6 Fitting the Free standing kit (165 only)

3.7 Fitting the Free standing kit (210 only)

3.8 Fitting the Back panels

3.9 Fitting the Handle

4 Squaring

4.1 Checking your machine for squareness

4.2 Adjusting the squareness

5 Calibration

5.1 Calibrating the Vertical square

5.2 Calibrating the Squaring arm scale

5.3 Fitting the Sight-line strip

6 Operation

6.1 Using the Clamp

6.2 The Cutting Head in General

6.2.

1 The Cutting Head in General

6.2.2 How to use the Pull Bar System

6.3 The Cutting Blade

6.3.

1 The Cutting Blade

6.3.2 Changing the Cutting Blade

6.4 The Scoring Blade

6.5 Glass Cutting (Optional)

6.6 The Twin Wheel (TW) Cutter

6.6

1 Changing the Twin Wheel (TW) Cutter

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

1. Main body

2. Squaring arm

3. Left Back Support

4. Right Back Support

5. Long Back Support Screws

6. Short Back Support Screws

7. Back Support Fixing Block

8. Left Production Stop

9. Right Production Stop

10. Wall mounting bracket

11. M8 Screws and Washers

3

4

8

p

o

j

j

k

l

7

6

5

2 1

9

2.1 Unpacking your Machine 2.1

n

m

r

q

12. Spare blades

13. Main Handle

14. Hexagon wrenches 2.5, 3.0, 4.0, 5.0, 6.0mm

15. Spare Sight-line Strip (165 – 1 off, 210 – 2 off)

16. Vertical Scale

17. Optional Free Standing Kit

(Supplied separately – for 165 version only)

18. Pull Bar (210 only)

YOU WILL ALSO NEED:

17mm Spanner x 2

13mm Spanner x 1

210 only

NOTE: When taking the machine from the box ensure at least two people are lifting.

Remember to bend your knees and keep your back straight - this machine is heavy.

1. LEFT LEG - Slacken the bottom two screws and extend the telescopic leg to the

desired length. (This can be readjusted later). Tighten the screws to clamp

in position.

2. RIGHT LEG - Slacken the top and bottom screws in the Squaring Adjustment Block,

extend the telescopic leg by the same amount as the left leg and r

e-tighten the

screws.

3. Swing both legs out as far as they will go.

The first stages of assembly are carried out with the machine laying on the floor.

1

2

3 3

3.1 Assembly 3.1

Preparing the Legs

SteelTraK 210 only

3.2 Assembly 3.2

Preparing to fit the Squaring Arm

1. Remove the following:

A. One screw and spacer from each leg.

B. Two sets of hexagon headed bolts, washers and nuts from the Main Body

2. Lay the Squaring Arm flat adjacent to the machine, position the two long hexagon

nuts into the two large middle holes.

AA

BB

1

1

1

2

3

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

3.3 Assembly 3.3

Fitting the Squaring Arm

1

2

2

3

5

4

1. Remove the Squaring Adjuster Block from the right hand Leg by releasing the

middle screw only (take note how this is fixed in place as it will replaced after the

Squaring Arm has been fitted)

2. Slide the Squaring Arm in through the gap in the Main Body and screw the two

hexagon bolts and washers in place loosely (3 or 4 tur

ns will do).

3. Fit the screws with spacers through the Squaring Arm into the legs, put the screws

all the way in but do not tighten at this stage.

4. Move the cutting head to its lowest position.

5. Refit the Squaring Adjuster block by firstly sliding the steel bar into the opening in

the Squaring Arm, then align the heads of the two scr

ews in the Leg to fit the top and

bottom holes in the adjuster block. The screws fixing the Squaring Arm to the

machine should still be loose and allow it some movement to help alignment. Insert

and tighten the screw in the middle hole.

3.4 Assembly 3.4

Fitting the Pull Bar (210 only)

The SteelTraK 165 offers a fast, accurate and robust way to cut boards measuring up to

165cm (65”). The SteeltraK 210 utilises a ‘Pull Bar System’ to increase the cutting

length to 210cm (82”) without compromising the straightforward way the SteelTraK cuts

medium size boards. The ‘Pull Bar’ is only used when cutting between 165cm and

210cm and is automatically stowed out of the way when not in use by virtue of its

integral spring balance

At any stage of the assembly before standing the machine up, fit the Pull Bar using a

6mm Allen key:

1. Remove the Screw and Stub Shaft from the end of the Pull Bar.

2. Insert the end of the Pull Bar in the bracket as shown ensuring the handle at the

other end is facing in the corr

ect direction.

3. Insert the Screw and Stub Shaft and tighten.

2

1

3

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

3.5 Assembly 3.5

Fitting the Wall Mounting Bracket

NOTE A: If you are going to fit the Free Standing Kit (optional) turn to the next page.

NOTE B: Ensure the wall is stable and use the appropriate fixings.

1. Lift the top end of the machine (place it on a strong stool or chair) and fit the two

M8 scr

ews (supplied separately) through the black Top Bracket into the back of each

of the Legs. Tighten these and the adjacent two screws (four screws in all) to fix the

Legs to the top of the Main Body.

2. Fit the Wall Mounting Bracket to the top of the Main Body, fasten the screws

finger tight only

.

3. Get help to lift the machine up and position it against the wall in the desired position.

4. The Wall Mounting Bracket should lay flush against the wall. Mark the position of the

two V's on each side of the bracket with a short pencil.

5. Move the machine away and remove the Wall Mounting Bracket.

6. Attach the bracket to the wall in the marked position with appropriate fixings then

reposition and fasten the machine to the bracket.

2

3

4

5

6

4

1

NB.

SteelTraK

210 only

3.6 Assembly 3.6

Fitting the Free Standing Kit (optional 165 only)

NOTE: The Free standing kit is an optional extra and does not come packed

with the main machine. Assistance will be needed to fit the Free Standing Kit

1. Extend the telescopic leg to the same length as the front legs less 12cm (5")

2. Get help to hold the machine vertical and attach the bracket to the top of the

machine using the nuts and screws provided.

3. Swing down the stay and attach the fixing block to the plate on the bottom of the

Main Body

, tighten all three screws on the stay.

4. Adjust the telescopic leg so the machine stands evenly as shown.

5. Secure the top of the Legs to the Main Body by fitting the two M8 screws (supplied

separately) through the black plate into the back of each of the Legs, tighten these

together with the adjacent two scr

ews (four screws in all) to fix the Legs in position.

1

2

3

4

5

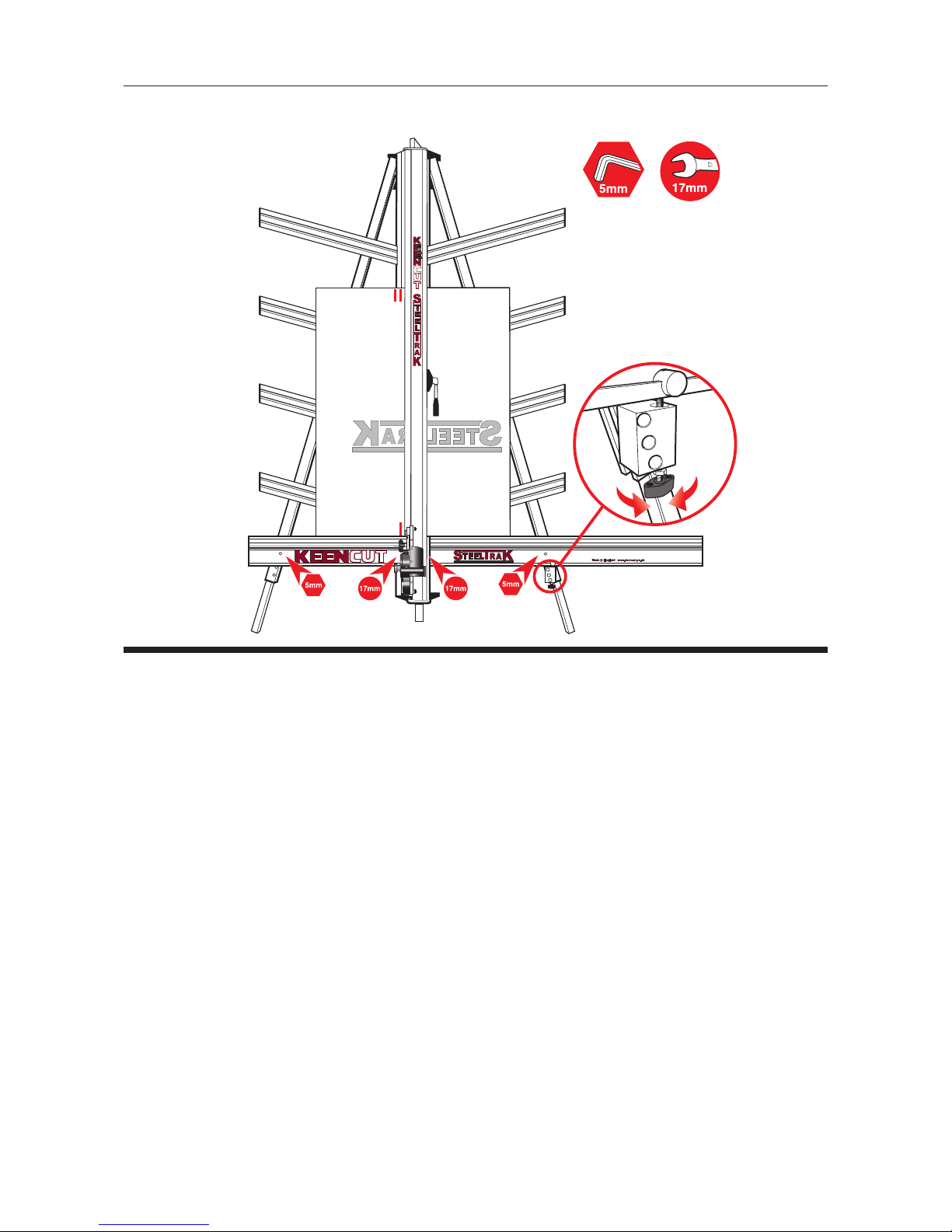

3.7 Assembly 3.7

Fitting the Free Standing Kit (optional – 210 only)

NOTE: The Free standing kit is an optional extra and does not come packed

with the main machine. Assistance will be needed to fit the Free Standing Kit

1. First carry out the fitting procedure (1 to 5) on the previous page.

2. Attach the bracket to the end of the Squaring Arm as shown using the two

bolts provided.

3. Adjust the telescopic leg so the machine stands evenly as shown.

3

2

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

3.8 Assembly 3.8

Fitting the Back Supports

1. Tighten the two sets of nuts and bolts fixing the Squaring arm two the Main Column of

the machine.

2. Tighten the two screws to clamp the Squaring Arm to the two Legs.

3. Separate the Supports into left hand and right hand.

NOTE: The screws fit into special grooves in the underside of the Supports. The

gr

ooves have teeth on their sides to match the teeth of the screw thread, the screw can

be fitted in the groove anywhere along its length but be careful to make sure the screw is

kept perpendicular to the Support and not screwed in out of line.

4. Place one of the 16 Long Screws in each of the holes along the legs of the machine,

fix each Support in tur

n ensuring the ends of the Supports are firmly against the Main

Column and the screws are aligned with the special grooves as explained above.

5. Fix the end of each Support in position with the Brackets and short screws as shown.

1 1

2 2

3

4 5

3.9 Assembly 3.9

Fitting the Handle

1. Remove the three screws from the top of the Cutting Head and fix the Handle in

place being sure it is the correct way round (as shown). Move the cutter head to

the middle of the Main Body

1

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

4.1 Squaring 4.1

Checking your machine for Squareness

For your machine to produce accurate square cuts the Squaring Arm needs to be

fixed at exactly 90° to the Main Column. to adjust the Squaring Arm first select a

sheet of foam core or foam board (3-6mm) at least 60cm x 100cm (24” x 36”) in

size. The larger the board the greater the accuracy.

1. Place the board on the machine

vertically as shown and apply the

clamp ensuring the bottom edge is in

firm contact with the Squaring Arm.

2. Select the cutting blade on the rotating

cutting head (see section 6). Cut into

the top of the board to produce a cut

approximately 3cm (1") long. Disengage

the cutter using the cutter r

elease lever.

Lower the cutter and make a similar cut

at the bottom of the board by pressing

the blade through the board about 3cm

(1") from the bottom edge of the board.

3. Unclamp and turn the board around and

place it back in the SteelT

rak but do not

clamp it.

NOTE: For the test to work the board

must be tur

ned laterally (like a page in a

book) not top to bottom.

Move the sliding head down and align

the board so that the cutting blade

enters the previous made cut at the

bottom edge of the board. Apply the

clamp. Release the blade..

4. Raise the sliding head and depress the

blade so that it engages with the top

edge of the board, if the machine is

squar

e the blade will enter the same cut

as made previously. if not refer to the

following page to make the necessary

adjustment.

1 2

4

3

4.2 Squaring 4.2

Adjusting the Squareness

NOTE: Before making any adjustments carry out the squareness check as described on

the previous page.

It is assumed that the board used for the test is still clamped in the machine. From the

test results determine if the last cut made in the top of the board is to the left or right of

the previous cut, as shown above:

1. Slacken the two screws(1 + 4) joining the Squaring Arm to the two Legs.

2. Slacken the left hand nut (2) joining the Squaring Arm to the Main Body, make sure

the right hand nut (3) is tight.

3. Release the clamp and position the board such that the blade is held in the cut on

the bottom edge of the boar

d, press down on the board to make sure it is in good

contact with the Squaring Arm.

4. Turn the squaring adjustment knob (5) on the right hand Leg in the direction shown

below dependant upon the position of the top two cuts.

If the second cut is to the right of the first cut turn the adjustment screw clockwise

when viewed from underneath.

If the second cut is to the left of the first cut turn the adjustment screw counter-

clockwise when viewed from underneath.

The adjustment screw should be moved so that when the blade is moved to the top of

the boar

d it cuts between the two existing cuts, the plastic sightline fixed to the

edge of the clamp gives an indication where the machine is going to cut.

5. Repeat the squareness check.

6. Tighten the screws (1,2, & 4) nut loosened in 1& 2 above.

2 3

5

1 4

5.1 Calibration 5.1

Calibrating the Measuring scales

The vertical measuring scale is supplied separate from the machine, the two horizontal

squaring arm scales are already attached to the machine but may not be positioned

accurately and will need calibrating.

Vertical scale: This measures the height of the board on the machine and is only used

for r

eference.

1. Take a small piece of board and accurately measure its' height, place the board in the

machine such that it lays over the groove where the scale is to be applied.

2. With a pencil, mark a fine line level with the top edge of the board adjacent to the

groove.

3. Remove the release paper fr

om the groove in the Main Body and stick the Vertical

scale in place such that the pencil mark lines up with the measured dimension in (1).

1

2

3

5.2 Calibration 5.2

Calibrating the Measuring scales

The two horizontal squaring arm scales are already attached to the machine but may not

be positioned accurately and will need calibrating.

Horizontal scales: The SteelTrak can be loaded from either side and the scales are

used by eye or using the stops to measur

e the required width of board that will be cut

off to the left or right of the cut line. the cutting blade, twin wheels and scoring tools cut

on the same line. the measuring scales are fixed to sliding stainless steel strips that can

be moved to allow accurate calibration.

1. Slide the two Measuring Stops onto the Squaring Arm being careful to align the pro

file of the stop and its locking bar to the profile of the Squaring Arm. The Measuring

Stops ar

e able to 'flip' in and out as required.

2. Set both stops at 15cm (6"), 'flip' one of the stops into place and the other out, then

place a piece of card in the machine and slide it to touch the stop that is flipped in.

Clamp the car

d in place select the cutting blade on the rotating cutter head and cut

the card.

3. Measure the cut width of the card, say it is 14.7cm (5 7/8"), slide the Measuring Scale

so that it r

eads the dimension measured i.e. 14.7cm (5 7/8"). Repeat the process

with the other Measuring Stop.

NOTE: If the scales move too freely it is simple to increase the friction. To avoid resetting the scales first choose any easily r

emembered dimension and set the stop. Slide the

scale from its groove, twist it and replace it to the remembered dimension.

1

1 2

1

5.3 Calibration 5.3

Fitting the Sight-line strip

The Sight-line strip is fixed to the clamp and then trimmed using the cutting blade to give

an accurate guide when cutting to trim lines, the edge of an image or pencil marks.

NOTE: Do not engage the Twin Wheel Cutter until reading its instructions for use in

Section 6. Engaging the T

win Wheel Cutter interferes with the Sight-line Strip and can

cause damage to it. A gap is left in the Sight-line Strip at a convenient height to enable

the Twin Wheel Cutter to be engaged.

1. Remove the worn Sight-line Strip by peeling it off and clean any surplus adhesive with

solvent cleaner on a cloth. Remove the backing paper and starting at the bottom

pr

ess the Strip firmly in the channel provided working upwards and cut off at a

convenient height. Leave a gap of 18cm (7”) and then fit the remainder of the strip.

For the 210 version one full length Strip and one cut in half will be required.

2. Place a piece of firm board up to 6mm (1/4") thick on the machine to bridge the gap

running down the back of the Main Body, this needs to be the full height of the

clamp.

3. Place a piece of card or foamboard 3-6mm (1/8"-1/4") thick under the full length of

the flexible part of the Sight-line strip, not under the aluminium clamp itself.

Depr

ess the clamp handle so that the Sight-line strip is pressed flat across the surface

of the board.

4. Keep fingers clear and using a block or tool hold down the top left corner of the strip

to start the cut. With the turr

et rachet disengaged (Scoring page 6) press the blade

lightly on to the surface of the Sight-line strip score along the full length. Repeat and

trim the Sight-line strip in 2 or 3 cuts.

NOTE: If a board is not available to go the full length of the clamp use two or more

pieces or trim the strip in stages.

NOTE: The Sightline Strip is fitted to your machine but may wear or get marked with

use. A spare strip is included with the machine, replacement strips are available

from your distributor.

1

3

4

2

6.1 Operation 6.1

Using the clamp

The Clamping system enables the operator to control the grip pressure by means of an

integral friction brake that maintains the clamping force at the pressure applied by the

operating lever. Soft materials can be held firmly without sustaining damage and solid

materials held rigidly without movement. By following the guidelines below it will help

you to get the most from the machine:

USE CLAMPING INSTRUCTIONS

Soft materials such as Use light to medium pressure. The underside of the clamp

Foamcore boards, grips an area nearly 4cm (11/2”) wide with a non-marking

Lightweight card, etc. sponge rubber reasonable force can be applied. If in doubt

clamp a sample first with the good surface facing outwards.

Harder materials such as PVC Use medium to heavy pressure.

foam board, MDF or Composite

boards such as Dibond.

Cropping to trim lines, Place material in approximate position under clamp, apply light

pencil marks, etc. clamp pressure to allow the material to be repositioned. Align

(See drawing) the trim marks with the edge of the Sight-line strip and clamp.

6.2 Operation 6.2

The Cutting Head in General

The Cutting Head runs up and down

the Main Body of the machine on two

stainless steel tracks and has zero side

movement giving perfect blade control.

The Main Body also encloses a balance

weight system that allows the Cutting

Head to be suspended at any height,

benefiting blade changing and

maintenance but also minimising the

effort required to lift the heavy duty

Cutting Head.

There are four cutting functions built into

the machine the top part of the Cutting

Head houses the Twin Wheel or TW

Cutter, the standard Composite TW

Cutter is used for cutting tougher

materials than a normal blade can

handle. Composite boards such as

Dibond (r) and other materials including

MDF, Masonite and Hardboard up to

4mm thick are all cut with ease in one

stroke. The TW cutter can be easily

engaged and disengaged at will.

An optional Aluminium TW Cutter is also

available for cutting aluminium up to

1.6mm (16swg) and can be attached to

the machine in just a few seconds. If you

need further advice regarding materials

please contact your supplier.

On the lower half of the Cutting Head is

the Multi-Cutter Head housing three

instantly selectable cutting tools. To

change between the cutting tools just

pull the Turret Handle

out to the left and rotate it one third of a

turn until the indicating label shows

which cutter is active.

The Multi-Cutter Head also incorporates the unique Keencut Ratchet System which

gives two main advantages. Firstly, it enables thick, tough materials to be cut in multiple

passes by setting the ratchet to cut through the board in stages giving the best cut

quality achievable and reducing operator effort to suit the operator. Secondly, it locks

the cutting blade at the required depth and holds it there mechanically so concentration

can be applied to pushing the blade through the material without having to worry about

applying effort to hold the blade in the material. Once the blade reaches the bottom of

the cut it the ratchet is automatically disengaged and the Cutting Head moves out to its

rest position ready to be set for the next cut.

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

6.21 Operation 6.21

The Cutting Head in General

The three cutting tools are:

1. The Cutting Blade - Using a standard Medium Duty utility blade (not Heavy Duty -

they will not fit) to cut PVC Foamboar

ds like Forex®, corrugated plastic such as

Correx®, card, matboard and many other types of rigid boards up to 13mm (1/2")

thick.

2. The Scoring Blade - A specially designed tool steel scoring blade is used to score

the surface of any brittle plastics including Acrylic's such as Perspex®, Plexiglass

and even some Polycarbonates. Once scored the plastic sheet is removed from the

machine and 'snapped' along the score line. Any thickness (up to 13mm 1/2") can

be scor

ed but tests should be carried out on a sample of the sheet to ensure it does

'snap' and to an acceptable quality (remember to use hand and face protection when

doing this).

3. Glass Cutting - A high quality tungsten carbide wheel is used to score glass. An

optional Glass Cutting Kit will be r

equired to use this facility, operating instructions for

glass cutting are not included in this manual and but are supplied with the Glass

Cutting Kit.

NOTE: Our research established that glass cutting is very rarely required by Sign makers

and Graphic workshops. That knowledge allowed us to exclude the fixed br

eakout ramp

and incorporate a level back board system enabling material to be loaded from left or

right for optimum material flow in any workshop.

1

2

3

6.22 Operation 6.22

How to use the Pull Bar System

Cutting boards above 165cm high is done so in two stages, the first using the Pull Bar

then disengaging the Pull Bar and using the handle directly connected to the Cutting Head.

To cut larger than about 165cm (65”):

1. Raise the Cutting Head to chest height, select the cutting tool required and engage it

in position r

eady for cutting.

2. Check the black plastic handle on the Pull Bar is pointing out towards you.

3. Push the Cutting Head up far enough so the stub shaft on the Pull bar can be twisted

to engage in the slot of the handle bracket (see above).

4. Using the Pull Bar push the Cutting Head to the top of the machine.

5. Insert the material to be cut into the machine and clamp in position.

6. Pull down on the Pull bar to cut, the stub shaft is designed so that it locks itself in

position when the Cutting head is moved up or down preventing the Pull bar from

being able to twist out of place.

7. When the board has been cut as far as the Pull bar will allow, slightly push the Pull Bar

up and twist it away from the Cutting Head to disengage it. Raise the Pull bar all the

way up to its r

est position

6. Continue the cut using the Cutting Head handle in the normal way.

3

6.3 Operation 6.3

The Cutting Blade

Basic Cutting Technique. Select the Cutting Blade position on the turret and clamp the

material in the machine.

1. Move the cutting head beyond the top of the material to be cut.

2. Press to engage the cutter.

Draw the cutter down to the bottom of the machine where it will disengage

automatically.

3. Should you engage the cutter by mistake or for any reason want to disengage the

cutter without moving it to the bottom of the machine pull down the Ratchet

Release Lever.

2

1

3

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

Ratchet Latch

The unique 'Ratchet Latch', enables thick dense materials (such as PVC foam board) to

be cut easily in stages. Count the number of 'clicks' to position the blade just below the

surface of the material to make your first cut then add an extra 'click' for the second and

subsequent cuts.

1. Pull down the Ratchet Release Lever to disengage the ratchet if required.

As a rough guide when cutting PVC foam boar

ds:-

Using the Blade Support Plates

The two support plates either side of the blade are designed to give maximum rigidity of

the blade when cutting har

d or dense materials.

To adjust the support plates swing down the cutter guard by undoing the guard locking

knob.

2. Turn the turret 1/2 turn until blade is pointing towards you, unlock the blade clamping

scr

ew, the support plates can be adjusted by sliding the black pin in the slot. Move

the plates to suit the material.

For cutting most materials the support plates can be set about 12mm (1/2 ”) from the

blade tip.

THICKNESS TAKE

3mm (1/8”) Initial surface cut + 1 additional cut

5mm (1/4”) Initial surface cut + 1 or 2 additional cuts

10mm (3/8”) Initial surface cut + 3 or 4 additional cuts

1

2

6.31 Operation 6.31

The Cutting Blade

The blades used are

'Medium Duty Utility Blades'

as shown above.

6.32 Operation 6.32

Changing the Cutting Blade

Changing the Cutting Blade

Unlock and swing down the cutter guard, rotate the turret so the cutting blade is

facing towards you.

3. Undo the blade clamping screw a number of turns to release the blade.

4. Change or turn over the blade, insert it back into the turret as far as it will go.

Tighten the blade clamping scr

ew

, the safety pin will engage to hold the blade in

position. At this point the position of the Blade Support Plates can be adjusted to

suit the thickness of material being cut, further tightening of the screw will clamp the

blade firmly in position.

Rotate the turret back to the cutting position. Replace the guard ensuring it is locked

closed.

3 4

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

6.4 Operation 6.4

The Scoring Blade

The scoring blade is designed to score Acrylics, Plexiglass and other similar rigid

plastics. Trials should be carried out on scrap materials first to ensure you obtain the

required standard of cut.

Scoring/Breaking Technique

Select the Scoring Blade position on the turret and clamp the material in the machine.

1. Disengage the Ratchet. Depress the Ratchet Lever and pr

event it from engaging when

released by depressing the rachet Lock Button. The Multi-cutter will move freely.

2. Clamp the target plastic in the machine. Starting at the top using a thumb depress the

Multi-cutter head so that the blade touches the plastic at the top.

3. Apply thumb pressure to the cutter and draw the blade down the material in one

continuous motion.

Remove the plastic fr

om the machine and snap it by hand.

CAUTION: USE GLOVES AND SAFETY GLASSES WHEN SNAPPING PLASTIC

Changing the Scoring blade

Unlock and swing down the cutter guard, rotate the turret so the scoring blade is facing

towar

ds you.

4. Release the blade clamping screw. Eject the blade using the black ejector pin

5. Replace the blade to the right of the clamping plate, push the blade in as far as it

will go and tighten the blade clamping scr

ew.

Rotate the turret back to the cutting position. Replace the guard ensuring it is

locked closed.

1 2

3 4

5

6.5 Operation 6.5

Glass Cutting

An optional Glass Cutting Kit will be required to use this facility, operating instructions for

glass cutting are not included in this manual but are supplied with the Glass Cutting Kit.

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

6.6 Operation 6.6

The Twin Wheel (TW) Cutter

The Twin Wheel Cutter is mounted on the upper part of the cutting head and is used

for cutting a range of tough, rigid materials. The standard machine is fitted with the

Composite TW Cutter and is used for cutting composite boards such as Dibond

®

and

other materials including MDF, Masonite and Hardboard up to 4mm. Many other softer

boards and card can also be cut, trials should be carried out to ensure the desired

quality of cut is obtained.

1. Engage the TW cutter by loosening the large hand knob (1/4 turn).

2. Depress the locking button and r

otate the cutter 90 degrees until the locking button

springs out to its rest position, tighten the hand knob firmly.

NOTE: The TW cutter will interfere with the Sightline Strip as it is being engaged, either

engage the cutter at the top end of the machine or cut away a portion of the sightline

strip at a convenient height (e.g. adjacent to the clamp handle) and move the cutter to

this position for engaging/disengaging.

3. Ensure the TW cutter is above the height of the top edge of the board, position the

material in the machine and apply the clamp.

4. Bring the twin wheel cutter down until it makes contact with the top edge of the

material and stop. T

ake a firm grip and then push the cutter down through the

material without stopping.

1

2

3

4

6.61 Operation 6.61

The Twin Wheel (TW) Cutter

The cutting wheels are made from high grade tool steel and are heat treated to give give

a long life but this is dependant upon daily use and the materials being cut. The signs of

the wheels wearing out are:

A rough finish predominately on the right hand side of the cut, with flaking on materials

such as MDF.

The board trying to turn under the clamp when being cut (also check the clamp

pressure).

Changing the twin wheel cutter

Hold the TW cutter onto the Cutting Head whilst unscrewing the large hand knob.

Once the hand knob has been r

emoved the TW cutter can be lifted free. Reverse the

procedure to fit the replacement TW cutter ensuring it is properly located against its

mounting plate before fastening the hand knob.

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

7.11 Maintenance 7.11

Cleaning

Keencut design machines to be as maintenance free as possible, however we do

r

ecommend regular cleaning. Do not wipe the squaring arm channels or remove any

debris with fingers, as it may contain sharp particles such as glass. Use a vacuum

cleaner if possible or if a soft brush is used, work slowly and do not allow particles to

flick off of the bristles.

Lubrication

It is important that the correct lubrication is used as ordinary oils and solvents can

adversely affect plastics, the diagram above shows the best lubricants for the various

parts of the machine. Do not use penetrating oils for lubrication on this machine.

1. Guide rods and rollers

Wipe using cleaning solvent on a cloth, and lubricate the surfaces very lightly with

petr

oleum jelly. The axles of the rollers are lubricated and sealed for life and need no

further attention.

2. Ratchet system

Use a light oil (3 in 1), one or two drops on the pivot point and one drop on the

ratchet teeth

3. Balance weight

Silicon Lubricant sprayed in from the top of the balance weight opening whilst the

cutting head is parked at the top of the machine

4. Ratchet release bar

Smear edge with petroleum jelly

5. Swinging Arm

Petroleum jelly around curved slot.

3

ä

1

5

2

4

ä

ä

ä

ä

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

7.12 Maintenance 7.12

The Clamp

Adjusting the Clamping Pressure

The pressure of the clamp is in relation to the amount of

pr

essure applied to the operating handle. However in

time the maximum clamping pressure can reduce due to

wear on the friction block (hidden within the machine),

compensation for this can be made by adjusting the two

small grub screws in the housing as shown. Turning the

screws clockwise until they stop moving them undoing

them one full turn should give an acceptable pressure,

but further small adjustment can be made to increase or

decrease the pressure as required. Care should be taken

not to tighten either grub screw fully or this will result in

undue wear of the friction plate.

Clamp Alignment

When cutting tough materials it is essential that the

clamping system operates at its' optimum, the moving

clamp bar must press evenly onto the boar

d being cut

and not clamp it only at the top or bottom.

1. Open the clamp by at least 1-2mm and remove the

plastic cover strip situated above the clamp handle it just

clips out of place, use the end of a small steel rule to

lever it fr

om its' groove.

2. The clamp adjuster is at the top end of the push rod

and is locked in position by two locking nuts.

n The silver nut has a normal right-handed thread,

slacken it using a 10mm wrench by

turning it

counter-clockwise when looking from below.

n Now slacken the black nut, this has a left hand thread

and should be tur

ned clockwise when viewed from

below.

n The 'adjuster' is the hexagonal bar between the two

nuts, by tur

ning it with the spanner it alters the clamps

alignment with the back of the machine.

3. Rotate the adjuster whilst observing the clamp from

the side and bring the clamp into parallel.

4. To check for parallel use 2 pieces of A4 paper, place

one under the bottom end of the clamp and hold the

other at the top end whilst depressing the clamp

handle, check that the clamp firmly grips pieces

of paper

.

5. Tighten the two locking nuts whilst holding the

adjuster in position with the second spanner, then

operate the clamp a few times, check and adjust

further if necessary

.

6. Finally, replace the plastic cover strip.

1

2

3

ä

ä

ä

ä

ä

7.13 Maintenance 7.13

Guide Wheel Adjustment

The Cutting Head slides up and down on two stainless steel Guide Rails (1) that are

embedded into the Slideway (2). Ther

e are four grooved Guide Wheels that run on the

rails, the two furthest away are fixed (A) and the two closest are adjustable (B). These

Guide Wheels are adjusted in the factory and should not under normal circumstances

require re-adjustment. However, the adjustment check and procedure is listed in the

event that the Cutting Head needs to be removed for any reason:

Adjustment Check:

The steel bar with the oval holes, the Spring Block (4), holds the two adjustable wheels

and is designed to flex, a small amount, like a spring and add tension so the Guide

Wheels are pr

essed onto the Rails. It is important that the tension is set correctly, use

a 0.15mm (0.006") feeler gauge or a stout piece of paper to measure the gap under the

Spring Block as shown. If the gap is too large or too small the adjacent wheel will

need adjusting.

Wheel Adjustment:

The Shafts that the adjustable wheels run on are eccentric and move the wheel into or

away from the rail as it is rotated.

n Using a 13mm spanner on the Locking Nut and a 5mm spanner (or grips) on the

squar

e end of the Shaft hold the Shaft still and loosen the Locking Nut by about half

a turn.

n Rotate the Shaft clockwise whilst using a feeler gauge or paper as above to measure

the gap under the Spring Block. If the Shaft will not rotate any further and the corr

ect

gap has not been achieved, turn it anti-clockwise and the correct adjustment should

be obtained within one full rotation of the Shaft.

n When the correct gap appears hold the Shaft still and tighten the Locking Nut.

4

1

A

A

B

B

7.14 Maintenance 7.14

Planned Maintenance Chart

Frequency: After 2 weeks of use and then every month thereafter

Adjust clamp pressure (page 7.1

2.)

Check clamp alignment (page 7.1

2.)

Check guide wheel adjustment (page 7.13.)

Lubricate Guide rods & rollers (page 7.1

1.)

Lubricate Ratchet system (page 7.1

1.)

Lubricate Balance weight (page 7.1

1.)

Lubricate Ratchet release bar (page 7.11.)

Lubricate Swinging Arm (page 7.1

1.)

In the first few weeks the clamp with

bed itself in and will need adjusting.

See instructions on page 7.1

1.

Using 2 pieces of A4 paper, place

one under the bottom end of the

clamp and hold the other at the top

end whilst depressing the clamp

handle, check that the clamp firmly

grips both pieces of paper. If not the

clamp will need aligning as above.

This should never go out of adjustment but is wise to check.

Wipe using cleaning solvent on a

cloth, and lubricate the surfaces very

lightly with petroleum jelly. The axles

of the rollers are lubricated and

sealed for life and need no further

attention.

Use a light oil (3 in 1), one or two

drops on the pivot point and one

drop on the ratchet teeth

Silicon Lubricant sprayed in from the

top of the balance weight opening

whilst the cutting head is parked at

the top of the machine

Smear edge with petroleum jelly

Petroleum jelly around curved slot.

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

Loading...

Loading...