OVAL 6

INSTRUCTION MANUAL

Keencut – the world’s finest cutting machines

1 Contents 1

2 Packing list

2.1 Unpacking your machine

3 Assembly

3.1 Fitting the Beam and Cutting Head

3.2 Fitting the Tur ntable

3.3 Fitting the Clamp Bars

4 Operation

4.1 Setting the size of the oval/circle

4.2 Setting the blade depth and using the Clamps

4.3 Cutting an oval/circle

4.4 Calibrating the Scales

4.5 The Centre Pointer

4.6 Cutting small ovals and circles

5 The Craftsman Toolset (optional)

5.1 Embossing

5.2 Penlining

5.3 Cutting V-grooves

5.4 Cutting glass ovals/circles

5.5 Cutting glass ovals/circles (Cont’d)

6 Looking After Your Oval 6

6.1 Maintenance & Blades

Introduction

Thank you for choosing a Keencut Oval 6. Every effort has been made to bring you a

superbly built product with the promise of many years of good service. Please read

these instructions carefully in order to obtain maximum benefit from your machine and

remember, in case of difficulties ask your distributor or Keencut Limited for assistance.

Once familiar with the many functions of the Oval 6 and the advantages of the unique

turntable system, your own creativity will enable you to produce very satisfying and

individual work that is the hallmark of the successful framer.

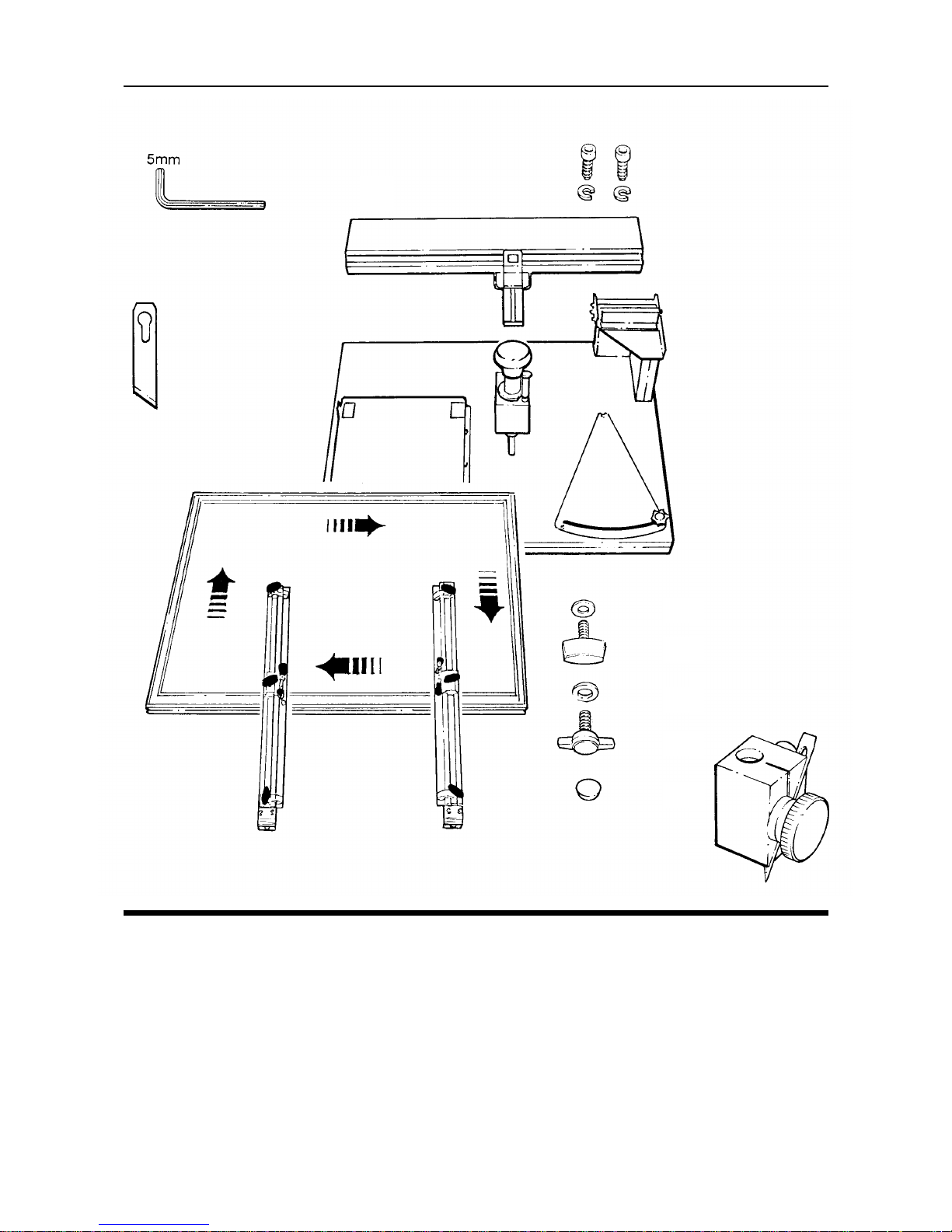

2.1 Unpacking your Machine 2.1

9. M8 washer x 2

10. M6 thumbscrew x 4

11. M6 washer x 4

12. M6 screws x 2

13. M6 spring washer x 2

14. Blades

15. 5mm Hexagon wrench

16. Plastic feet x 6

1. Main Base

2. Beam

3. Turntable

4. Cutting Head

5. LH clamp bar

6. RH clamp bar

7. Bevel/vertical blade holder

8. M8 thumbscrew x 2

x 4

x 4

x 2

x 2

x 6

NOTE: Do not carry the machine by the Turntable or Beam.

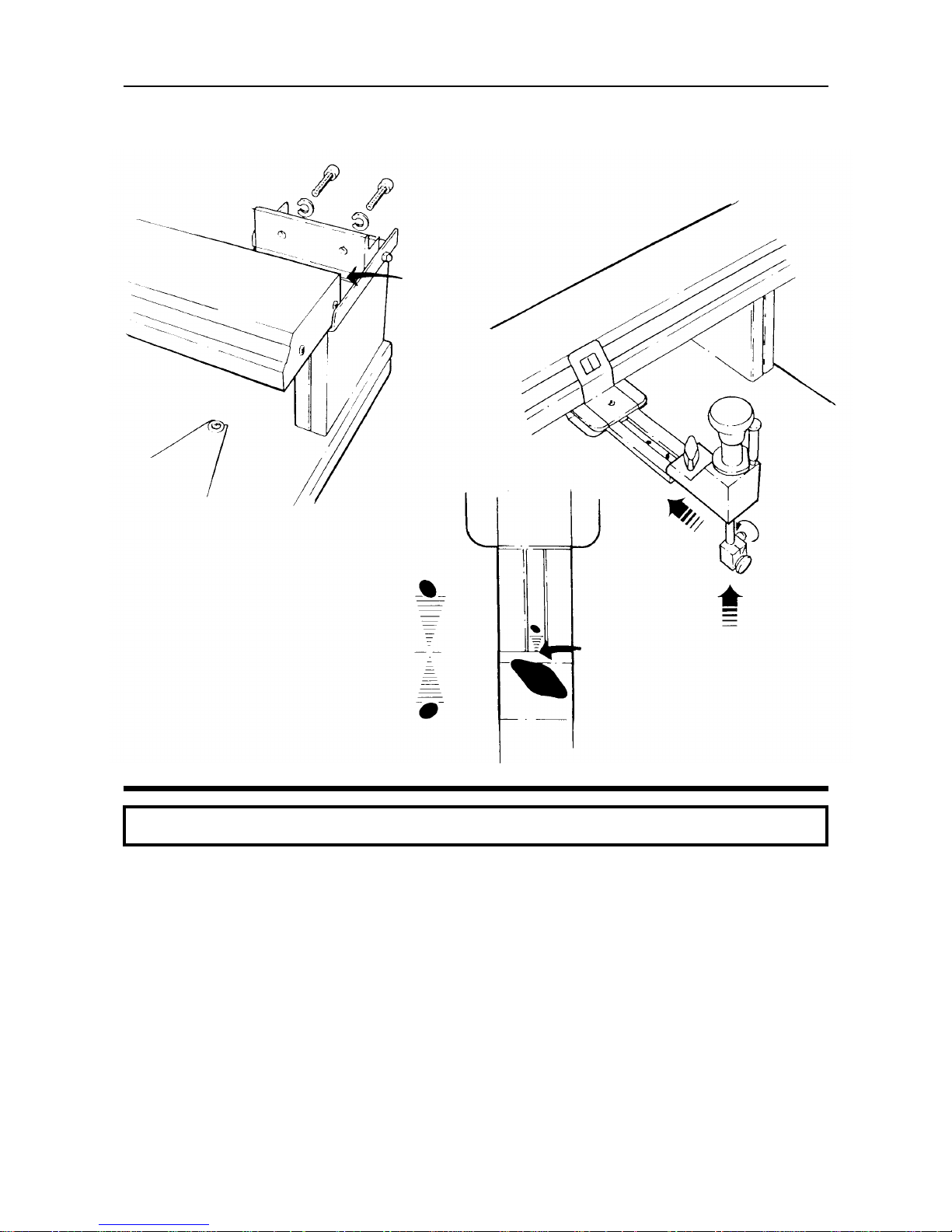

1. Attach the Beam to the hinge of the Main Base using the two M6 screws and

spring washers.

2. Ensure precise alignment of the Beam by positioning it carefully on the small

ledge of the hinge.

Tighten the two socket screws firmly using the 5mm hexagon wrench.

3. Fit the Cutting Head to the Beam by sliding it onto the bracket until the edge of

the aluminium block aligns with the centre of the ‘Lazy oval scale’ as shown.

Tighten the thumbscrew.

4. Fit the Blade Holder to the shaft on the Cutting Head and fasten it by tightening

the black plastic thumbscrew.

The machine is now set to cut ovals 10cm and larger. For smaller ovals see

‘4.6’.

3.1 Assembly 3.1

Fitting the Beam and Cutting Head

1. Line up the red arrow under the Turntable with the red arrow on the Main Base.

2. Place the Turntable with its four tabs inside the tabs of the Main Base and slide

the Turntable from left to right, the tabs will drop into alignment preventing the

Turntable sliding further.

3. Fit and tighten the four M6 thumbscrews and washers.

NOTE:

The optional MAXI Tur ntable attaches in the same way as the standard Turntable.

When cutting on the Oval 6 the blade tip runs on a sheet of glass this is not

supplied with the machine. Cutting on to a glass surface is the most safe, reliable and

economical method. A “self healing mat” can be used but the surface will deteriorate

rapidly when bevel cutting. A matboard cutting mat will quickly be destroyed and will

allow the blade to penetrate and damage the printed grid below.

CAUTION: USE EYE PROTECTION WHEN CUTTING GLASS

Cut a sheet of 3mm (

1

/8”) glass to the following size: (do not use 2mm glass)

Table type Size – metric Size – imperial

Standard 453 x 642mm 17

13

/16” x 251/4”

Maxi 642 x 802mm 25 1/4” x 319/16”

There is no need to polish the edges. Place the glass in the recess of the Turntable on

the printed grid.

3.2 Assembly 3.2

Fitting the Turntable

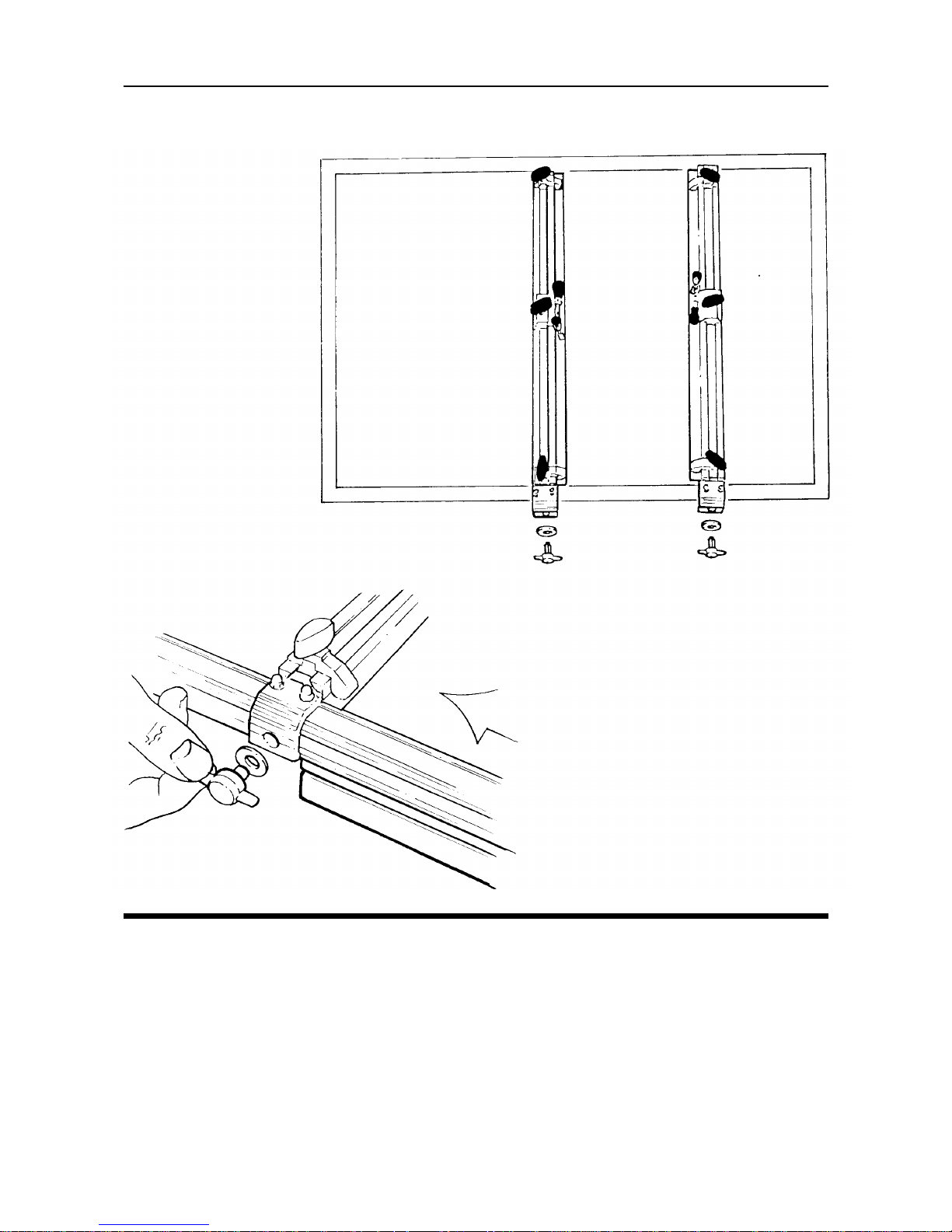

1. Find the two Sliding Nuts in one of the long edges of the Table.

2. Fit the two Clampbars to the Turntable using the M8 thumb screws and washers.

3.3 Assembly 3.3

Fitting the Clamp Bars

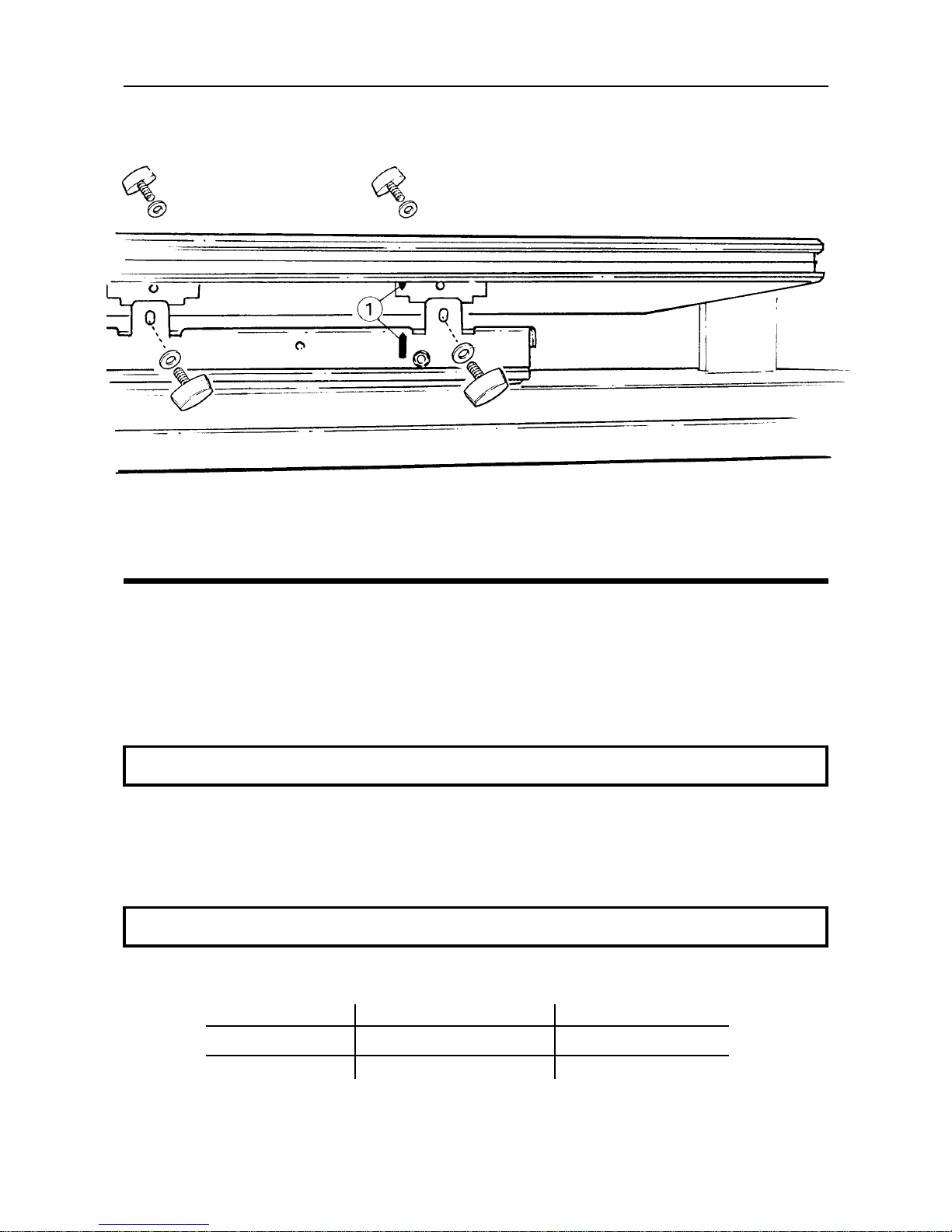

There are two scales that require setting dependant upon the size of the oval/circle:

1. The width of the oval (or diameter of the circle) is set on the beam scale by

squeezing the release lever and cutter head support then sliding the cutter until

the red line in the window indicates the required dimension. The scale can be

read in inches or centimetres.

Scale If the measuring scale itself slides too easily set the cutting head to

tightening 10 (cms. or ins.), slide the scale from its groove by about 10cm [4”]

and twist it to lightly distort the strip. Replace the scale and check

the friction, slide the scale to again read 10.

2. The difference between the width and length of the oval is set on the differential

scale, turn the knob counter-clockwise by half a turn to release and set to the

required dimension, lock in position. For a circle set the pointer as far to the right

as it will go (not necessarily the ‘zero’ on the scale). The scale will be set to either

inches or centimetres and can be changed by turning the scale over as follows:

3. Set the scale to zero and remove the two screws then remove the knob and

pointer. Turn the scale over and carefully refit the pointer ensuring the small pin is

located in the hole (as shown), refit the knob and loosely refit the two screws.

Adjust the scale so that it reads zero then moderately tighten the two screws.

If you find the machine does not cut accurately the scales require calibrating – refer to

the next section.

4.1 Operation 4.1

Setting the size of the Oval/Circle

1. Setting the blade depth

The blade should be set deep enough to penetrate the board being cut with a

clearance of approximately 1.5mm [

1

/16”] under the blade holder (thickness of

regular matboard).

a. Loosen the blade clamping knob and remove the old blade.

b. Place two thicknesses of matboard together on the turntable.

c. Lower the blade holder (by rotating the cutting head knob) leaving the blade

slots clear.

d. Fit the blade in the slot allowing it to drop so the tip touches the turntable

and tighten the blade.

NOTE: If the material being cut is thicker than regular matboard use a piece of the

material for the depth of cut and a piece of regular matboard to set the clearance.

2. The clamping system

The clamping system consists of two clamp bars each with two corner stops and

a toggle clamp. For small and medium size mats only two of the corner stops

positioned diagonally opposite are normally required (fig. 2a). For larger mats use

all four corner stops, for extra security the corner stops can be used as additional

clamps (fig. 2b.). The toggle clamps are adjustable to take different thicknesses of

board, turn the black rubber cap to adjust.

The scales on the turntable frame and the clamp bars are all set so that the ‘zero’

indicates the centre of rotation of the table. So, if a mat is centred in the clamps

according to the scales the oval will be produced in the centre of the mat.

2b

2a

4.2 Operation 4.2

Setting blade depth and using the clamps

1. Lift and park the beam to give easy

access to the turntable.

2. Set the two clamp bars to 10 either

side of the zero point on the table

edge scale. Set the corner stops to 8

on the clamp bars. Position the matboard coloured face up and clamp in

place using the toggle clamps.

3. Lower the beam. Set the width scale

to 10 and the differential scale to 4

(14-10 = 4), Twist and lower the

cutting head so the blade rests on

the eventual fallout.

4. Do not touch the cutting head knob

yet and rotate the turntable for

approximately

1

/4 of a turn to align

the blade.

5. Keep turning and smoothly apply

finger pressure to the top of the

cutting head knob, continue turning

until the fallout moves. Raise and

twist the knob to park the cutting

head.

NOTE: If the size of the oval does not reflect the sizes set refer to the next

section on ‘Calibrating the scales’

Vertical cutting

The vertical blade is of the same type as that used for bevel cutting (SM02 or SM03 for

small oval/circles) but held in a different slot in the blade holder. The blade depth is not

as critical but should be long enough to cut through the material without the base of the

blade holder touching the surface of the matboard and not so far extended that the

blade tip bends when cutting.

Use the same procedure as explained above, a cleaner cut will be produced by placing

the matboard in the machine coloured face down as the thickness of the vertical blade

can displace the edges of the cut upwards producing a small burr on the coloured edge.

4.3 Operation 4.3

Cutting an Oval/Circle

Bevel cutting The following refers to cutting a 14 x 10 oval centrally in a matboard

20 x 16 (cms. or ins.)

Small variations in cut dimensions can occur dependant upon the size and proportion of

the oval, in most cases the error is insignificant but care needs to be used when cutting

ovals below 10 cm [4”]. If in doubt check before cutting and correct as follows:-

Metric

For this example say an 8cm wide by 11cm long

oval is required:-

1. Set the width to say 1cm less than the

finished mat size ie. 7cm

2. Set the differential to the same dimension

as for the finished mat ie. 11cm-8cm. = 3cm.

3. Cut the oval in the normal way.

4. Measure the width of the oval, let us say

it is 7.2cm for example.

5. Compare the 7.2cm with the dimension

read on the width scale.

6. Slide the width scale (Not the cutting head)

until it reads 7.2cm.

7. Measure the length of the oval, let us say

it is 11.3cm, and calculate the difference

between it and the width measured

previously ie. 11.3cm-7.2cm = 3.1cm.

8. To correct the differential scale loosen

the two screws and the knob, swing the

scale until it reads 3.1cm, re-tighten the

screws and the knob.

9. Reset the machine to width = 8cm.

& difference = 3cm. Then cut the

finished oval.

Imperial

For this example say a 3” wide by 4” long oval

is required:-

1. Set the width to say 1/2” less than the

finished mat size ie. 21/2”

2. Set the differential to the same dimension

as for the finished mat ie. 4” - 3”. = 1”.

3. Cut the oval in the normal way.

4. Measure the width of the oval, let us say

it is 3 1/16” for example.

5. Compare the 3 1/16” with the dimension

read on the width scale.

6. Slide the width scale (Not the cutting head)

until it reads 3 1/16”

7. Measure the length of the oval, let us say

it is 4 “, and calculate the difference

between it and the width measured

previously ie. 4 “ - 3

1

/16” = 1 1/16”

8. To correct the differential scale loosen

the two screws and the knob, swing the

scale until it reads 1 1/16”, re-tighten the

screws and the knob.

9. Reset the machine to width = 3”. &

difference = 1” then cut the finished oval.

4.4 Operation 4.4

Calibrating the scales

1. Using the centre pointer

The centre pointer indicates the centre of rotation of the turntable to enable the

matboard to be placed without using the scales on the turntable. It is used for

precise positioning when cutting multiple openings. The centre pointer should be

pivoted into its park position under the beam when not in use.

NOTE: When using or setting the centre pointer always set the differential scale to the

circle setting or position the turntable at 90° to the beam (portrait position).

1.1 Mark the centre position of the oval or circle on the matboard.

1.2 Swing the centre pointer from under the beam until it stops.

1.3 Place the matboard so that the centre mark is under the centre pointer.

1.4 Move the clamps to secure the board and cut the opening.

2. Adjusting the centre pointer for accuracy

The printed turntable grid is correctly installed when the centre lines align with the

zero points on the turntable edge scales. The centre pointer should exactly

indicate the crossed centre lines on the turntable grid when the differential scale

is set to cut a circle or the turntable is in the ‘portrait position’.

Set the differential scale to the circle position and swing the centre pointer into

position. If the centre pointer appears to point to the centre of grid rotate the

turntable and check that it does so for a complete revolution. If it does not

proceed as follows:-

2.1 Lift the beam.

2.2 Observe the socket screw with an eccentric head

which limits the travel

of the centre finder. Fix the 5mm hexagon wrench to it and lower the beam.

2.3 Adjust the pointer laterally by tur ning the eccentric screw until the pointer is

at the centre of the grid.

2.4 If adjustment front to back is necessary first lift the beam and observe the

small screw

in the end of the pivot which locks the pointer in place. Fit

3mm hexagon wrench and loosen it.

2.5 Lower the beam and adjust the pointer until it is at the centre of grid, lock

the screw.

2.6 The height of the pointer can be adjusted using screw

.

4.5 Operation 4.5

The Centre Pointer

NOTE: When cutting very small ovals/circles better results can be achieved using the

more acute SM03 blade.

1. Small ovals

Distortions will occur when making very small diameter circles or ovals owing to

the self alignment action of the tools.

1.1 Note the position of the cutting head against the lazy oval scale.

1.2 Set the machine to make the desired size and cut the oval/circle.

If the top of the oval leans to the right move the cutting head towards the beam.

If the top of the oval leans to the left move the cutting head away from the beam.

1.3 Loosen the thumbscrew allowing the cutting head to move towards or

away from the beam.

1.4 Cut another oval in a different part of the board, check the setting and

repeat the adjustment as necessary locking the thumbscrew each time.

The machine is now set to produce upright ovals in the size range for which it was

adjusted. Over 10cm [4”] the ovals will remain upright throughout the range.

2. Small circles

When cutting small circles the effect of the self alignment action is slightly

different, the blade can become uncontrollable and very inaccurate. Moving the

cutting head towards the beam as explained above will correct it.

1.1

SM03

1.3

4.6 Operation 4.6

Cutting small Ovals and Circles

1. Cut an oval/circle of the desired size.

2. Do not alter the differential setting

but increase the oval/circle width

setting.

The ‘Craftsman Toolset’ includes two types of embossing tool:-

A half round edged wheel that produces a narrow embossed line

A flat edged wheel that produces a wide embossed line

A half round edged wheel A flat edged wheel

3. Fit the embossing tool and lower it

onto the matboard surface.

4. Do not touch the cutting head knob,

rotate the turntable by at least

1

/4 turn

to align the embossing tool.

5. Whilst turning apply firm pressure to

the cutting head knob and continue

for one or two turns until the indent

line is of the desired depth.

6. Remove the mat or leave it in place if

you wish to fill it with a pen line.

5.1 The Craftsman Toolset (optional) 5.1

Embossing

2. Penlining

Embossing an indent before drawing the penline provides a smooth surface for

the ink, prevents bleeding and ensures a reliable alignment for the pen. For most

lines the thin half round embossed indent is appropriate, for a very thick pen use

the broad flat embossing tool.

2.1 Ensure that the pen is drawing freely with no excess ink and that it is

accurately clamped in the pen holder. The tip should protrude 5-10mm

[

1

/

4” to

1

/

2“] below the bottom of the holder.

2.2 Do not change the width or differential settings after producing the

embossed indent.

2.3 Place a small sheet of thin paper on the mat so that one clean edge is

across the embossed line. Lower the pen until the tip is on the paper about

8cm [3”] from the paper edge.

2.4 Do not touch the cutting head knob at all - gravity is quite sufficient.

Rotate the turntable whilst holding the paper to align the pen tip.

2.5 The pen will run off of the edge of the paper and into the embossed indent.

Rotate the turntable slowly and consistently for at least two turns removing

the paper but do not stop turning.

2.6 Lift the pen whilst the tur ntable is still moving and twist the cutting head

knob to park it.

5.2 The Craftsman Toolset (optional) 5.2

Penlining

1. Cut an oval/circle of the desired size.

2. Do not alter the differential setting

but increase the oval/circle width

setting.

The initial hand pressure on the cutting head controls the speed of the blade entry in to

the mat surface and the continued pressure can affect the depth.

3. Fit the glass scoring tool and lower it

onto the matboard surface. Rotate

the table (without touching the cutting head knob) to align the tool then

press on the cutting head knob to

make a light indent 2cm [1”] or

so long.

4. Remove the glass scoring tool and fit

the V-groover.

5. Lower the V-groover and carefully

place the tips of the two blades in

the indent.

6. Place a hand on the cutting head

knob and rotate the turntable one full

revolution applying firm constant

pressure on the cutting head knob.

7. Stop when the blades stop cutting

the thin strip from the matboard.

Inspect the V-groove and remove the

finished mat from the clamps.

NOTE: The blade tips of the V-groove tool are set one behind the other but

when viewed from the cutting direction the tips should appear to meet exactly without

overlap. The V-groove width and depth may be changed by adjusting the nylon

screw in the centre of the blade holder. Two SM02 blades are used in the

V-grooving tool.

5.3 The Craftsman Toolset (optional) 5.3

Cutting V-grooves

1. Clamp a piece of matboard on the

turntable that is larger than the glass

blank do not lay the glass on it yet.

2. Set the width and differential scales to

the desired size of oval and fit the

glass scoring tool to the cutting head.

3. Lower the cutting head and with light

pressure score the oval shape on the

matboard.

WARNING: Wear eye and hand protection when handling glass.

4. Measure the scored shape to confirm

the accuracy.

5. Place the glass blank on the matboard and lower the cutting head

onto a small piece of paper or

thin card.

6. Rotate the turntable and apply finger

pressure only to the cutting head

knob, run the glass cutting wheel off

the paper, then whilst still applying

finger pressure remove the paper.

5.4 The Craftsman Toolset (optional) 5.4

Cutting glass Ovals/Circles

7. Rotate the turntable one complete

revolution only. Stop when the score

line joins up.

WARNING: Wear eye and hand protection when handling glass.

8. Tur n the glass over on the matboard

or a felt surface.

9. Press around the score line with the

thumb or tap it to make the cut.

10. Starting 1mm [

1

/16”] from the score

line score four radial lines to the outside edge.

11. Turn the glass over.

12. Starting at the edge press with the

thumb or tap to break each score to

remove the cut piece.

5.5 The Craftsman Toolset (optional) 5.5

Cutting glass Ovals/Circles

Blades

The Oval 6 has been designed to use standard craft knife blades:-

Material Operation use blade...

Regular matboard Cutting all except very small ovals/circles SM02

Regular matboard Cutting very small ovals/circles SM03

Thick matboard and foamcore Cutting all sizes of oval/circle SM03

All materials Cutting V-grooves SM02

Replacement blades and glass cutting wheels are available through your Keencut distributor or from Keencut direct.

Cleaning and Lubrication

● Clean the Oval 6 frequently with a damp or dry cloth and keep it covered when not in use.

Dirt can spoil your work

● Do not use solvents, they can harm the paint finish, remove silicone lubrication and effect plastic components.

● Lubrication. Use lubricant spray, apply it with a pad or cloth. Wipe off any excess liquid with a clean cloth.

● Do not use oil, grease or all-purpose penetrating oils and sprays. Silicone spray may be used on the operating

disc under the table if ever required.

Fault Finding

Fault Causes and Suggestions

Start/Finish mark - Hand Pressure applied to the cutting head before the turntable

had rotated to align the cutter

- Pressure applied to the cutting head too suddenly

- Blade depth not correct

Cutting needing more than two - Change Blade

revolutions on regular matboard - Apply more pressure

Poor finish on the bevel - Blunt or broken blade

- Insufficient hand pressure on the cutting head

Excessive blade wear or tip - Glass cutting surface scored

breakages - Blade depth incorrect

A double cut around part of - Blade depth incorrect

the bevel - Inconsistent pressure on the blade

- Not enough pressure on the cutting head during cutting

Extreme lazy ovals (not vertical) - Turntable rotating in the wrong direction

- Slide block wrongly set and adjusted (see ‘Cutting small ovals’)

Ovals or circles not centred - Scales not accurately set or adjusted on the clamp bars or

in matboard turntable edge.

V-groove not meeting up after - Blade tips need resetting to meet exactly when viewed from the direction

one revolution of cut. Please note that the blades are set one behind the other when

viewed from below.

The

Dexter No. 3

blade is also

suitable.

SM02

Glass

cutting wheel

SM03

6.1 Looking After Your Oval 6 6.1

Maintenance and Blades

Loading...

Loading...