EXCALIBUR 3S Manual

Single language versions and parts diagrams can be down loaded from www.keencut.co.uk

Thank you for choosing the Keencut Excalibur 3S. Every

eort has been made to bring you a precision engineered

product with the promise of many years of valuable

service. In order to obtain maximum benet from your

machine please read these instructions carefully. For advice

and assistance or replacement parts please contact your

distributor or Keencut.

PLEASE NOTE THIS IS A TEMPORARY MANUAL

1

Contents

2 Packing List

2.1 Unpacking your machine

3 Assembly

3.1 Adjusting the legs

3.2 Preparing to t the squaring arm

3.3 Fitting the squaring arm

3.4 Fitting the support arms & wall mounting bracket

3.5 Attaching machine to wall with mounting bracket

3.6 Fitting the optional free standing kit

4 Squaring

4.1 Checking the machine for squareness

4.2 Adjusting the squareness

5 Calibration

5.1 Calibrating the vertical scale

5.2 Calibrating the squaring arm scales

5.3 Fitting the sightline strip

6 Operation

6.1 Using the clamp

6.2 The multi-tool cutter and the counterbalance

6.3 Using & changing the cutting blade

6.4 Cutting thick material using the ratchet latch

6.5 Using and changing the scoring blade

6.6 Using & changing the twin wheel cutter

7 Maintenance

7.1 General maintenance

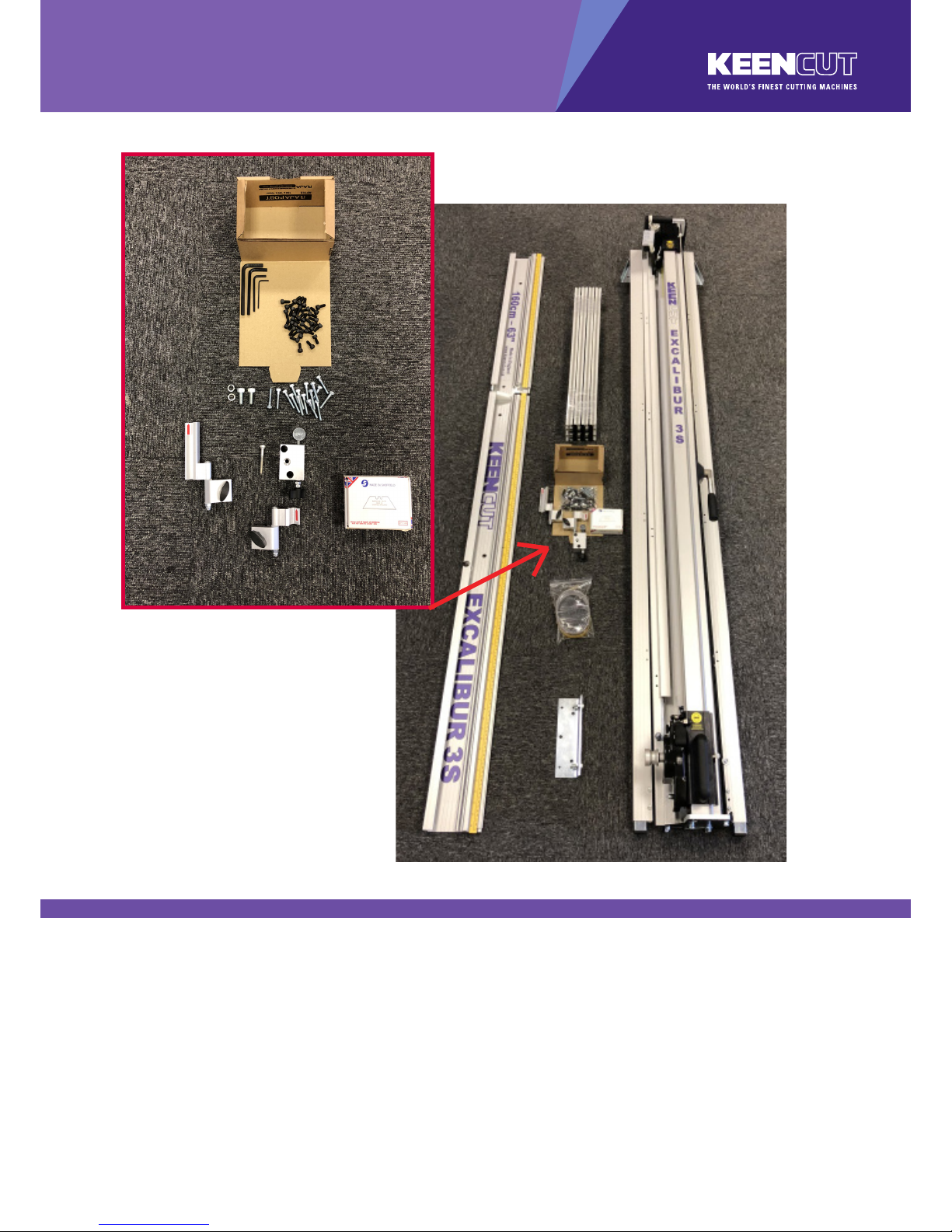

2.1

Unpacking your machine

NOTE: * When lifting the main body from the box, DO NOT lift using the black handles on the

cutters.

1. Main body *

2. Squaring arm

3. Left & right hand support arms

4. Vertical scale & spare sightline strip

5. Wall mounting bracket

6. Hexagon wrenches

2.0, 3.0, 5.0, 6.0 mm

7. Short support arm screws

8. Long support arm xing screws

9. Leg xing screws & washers

10. Left hand production stop

11. Right hand production stop

12. Squaring adjuster block & xing screw

13. Spare blades

❶

❸

❷

❹

❺

❻

❼

❽❾

❿

⓬

⓫

⓭

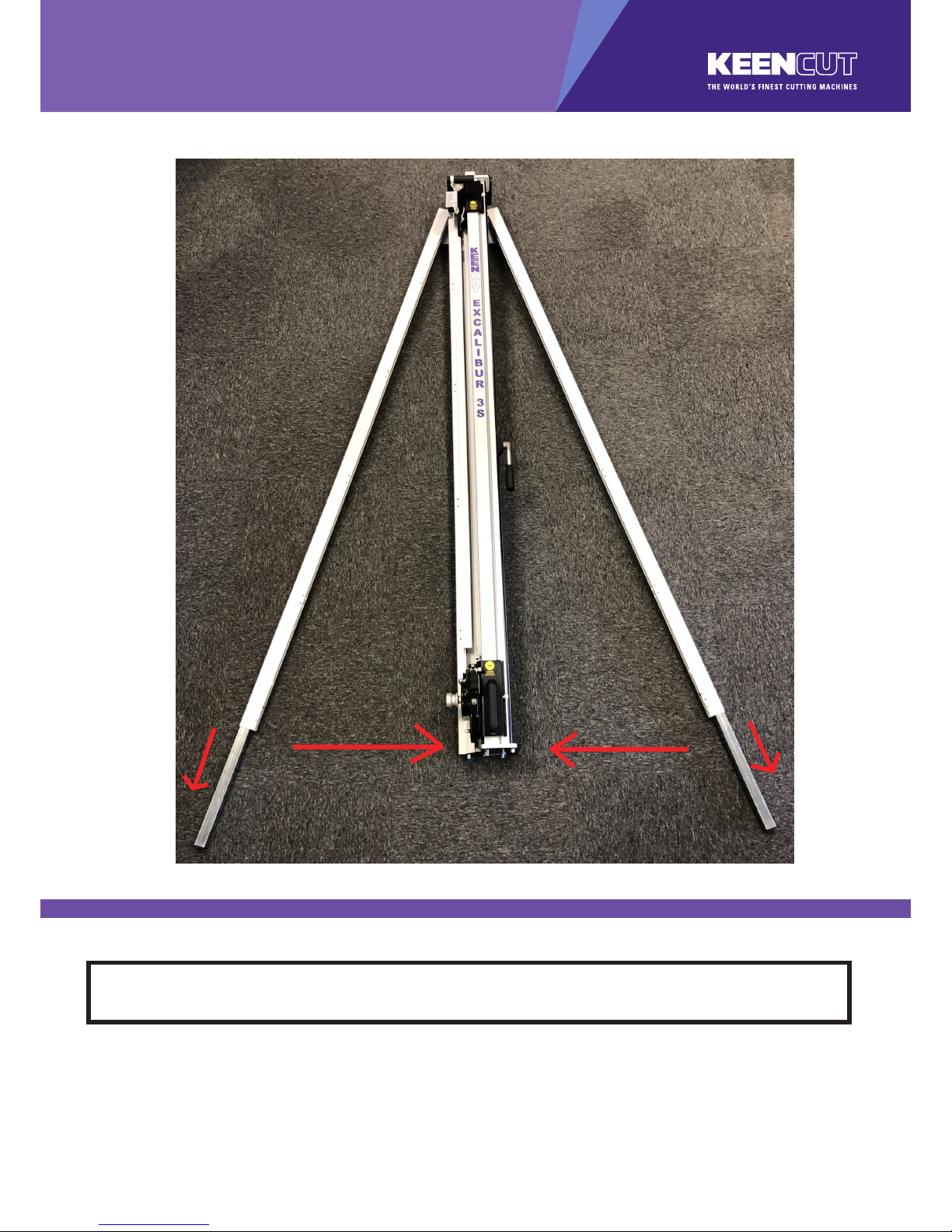

3.1

Assembly

The rst stages of assembly are carried out with the machine laying on the oor.

NOTE: When lifting the main body from the box do not lift using the black handles on the cutters.

DO NOT untie balance weight cord at this stage.

Remove the main body from the box and lay it on the oor, remove the packaging from the bottom

end.

1. Slacken the bottom two screws on each leg using the 5mm hexagon wrench and extend the

telescopic parts to the desired length. (These can be re-adjusted later before xing the

machine to the wall). Tighten screws rmly to clamp in position.

2. Swing both legs outwards as far as they will go.

Adjusting the legs

❶

❶

❷❷

3.2

Assembly

Preparing to t the squaring arm

1. Move the lower cutting head to the middle of the main body.

2. Remove the following:

A. One screw from each leg, using 5mm hexagon wrench.

B. Two sets of hexagon headed bolts, washers and nuts from the main body using 17mm

spanners.

C. Remove small screw and two washers from the back of the squaring arm using 3mm

hexagon wrench. (Right hand side ONLY).

Ⓐ

Ⓑ

Ⓒ

3.3

Assembly

Fitting the squaring arm

1. Slide the squaring arm in from the left hand side through the gap in the main body and align

the corresponding screw holes.

2. Fit the two hexagon bolts from the back of the main body, t the washers and nuts nger tight

only.

3. Fit the scews through the squaring arm into the leg using the 5mm hexagon wrench, do not

tighten fully.

4. Ret the squaring adjuster block by rstly sliding the steel bar into the opening in the squaring

arm, then align the heads of the two screws in the leg to t the top and bottom holes in the

adjuster block. The screws xing the squaring arm to the machine should still be loose and

allow it some movement to help alignment. Insert and tighten the screw in the middle hole.

5. Tighten the two hexagon bolts and screws as in 2 and 3 above.

6. Untie and release the balance weight cord, ensure the clamp is closed by pushing down on

the clamp handle then slide the both cutting heads to the bottom.

❶

❷

❸

❹

❺

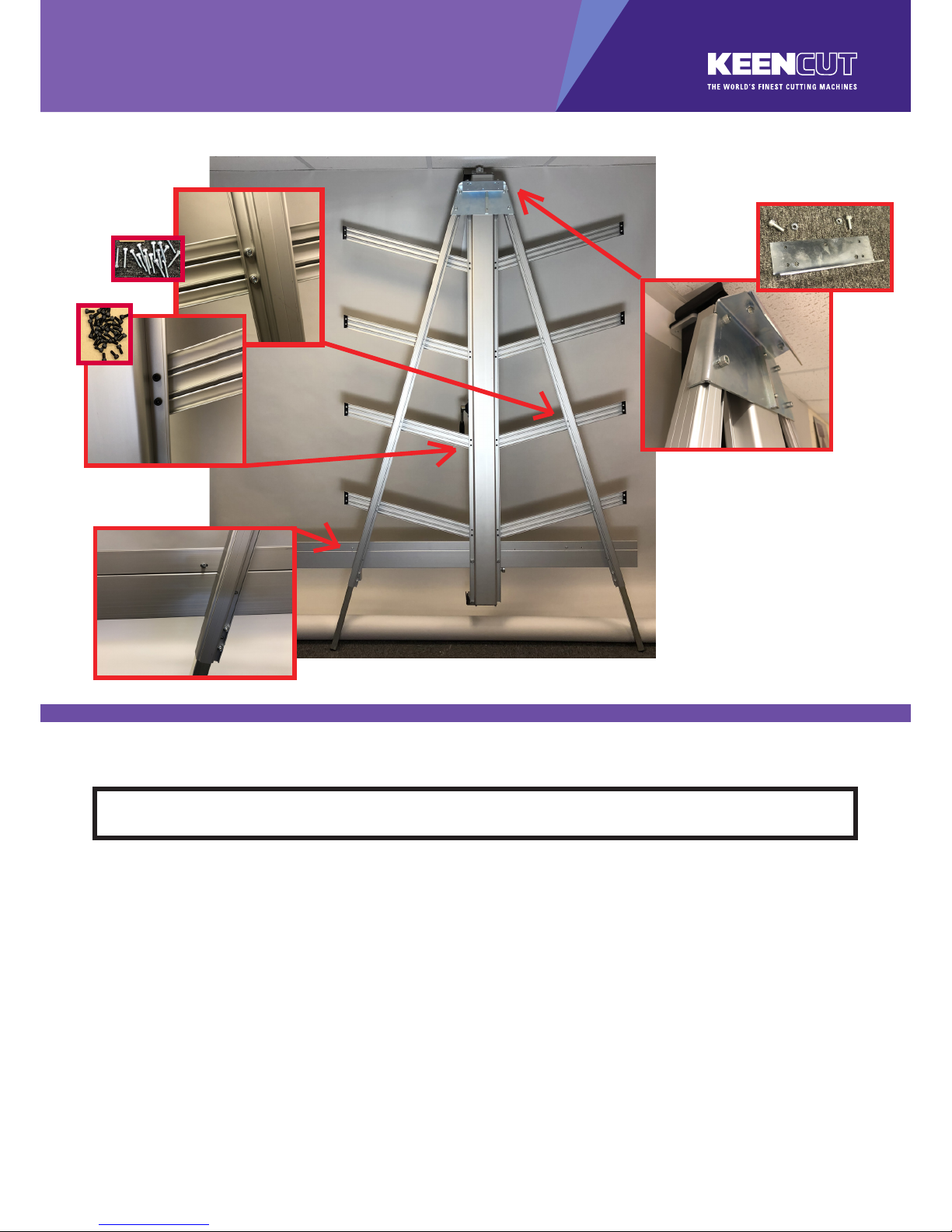

3.4

Assembly

Fitting the support arms & wall mounting bracket

1. Get help to slowly lift the machine and lean it so the front faces towards the wall. Carefully

place a scrap of card or board between the top end of the machine and the wall to prevent

any damage.

NOTE: Ensure the machine is tied or held in position safely whilst the following

steps are carried out.

2. Replace the screw and two washers in the squaring arm using the 3mm hexagon key.

3. Fit the two screws to secure the legs at the top of the main body using the 6mm hexagon key,

tighten both screws fully. Tighten the other two adjacent screws.

4. Fit the support arms:

NOTE: The screws t into special grooves in the underside of the supports. The grooves have

teeth on their sides to match the teeth of the screw thread, the screw can be tted in the groove

anywhere along its length but be careful to make sure the screw is kept perpendicular to the Support

and not screwed in out of line.

Use one of the long screws in each of the holes along the legs of the machine and short

screws to x the support arm to the main body. Ensure the ends of the supports are rmly

against the main body and the screws are aligned with the special grooves as

explained above.

5. If a free standing kit is to be tted to the machine proceed directly to page 3.6.

6. Fit the wall mounting bracket to the top of the main body, fasten the screws nger tight

only.

❷

❸

❻

❹

❹

3.5

Assembly

Attaching machine to wall with mounting bracket

NOTE A: If you are going to t the free standing kit (optional) turn to next page.

NOTE B: Ensure the wall is stable and use the appropriate xings.

1. Stand the machine vertical and turn around so the machine is now facing away from the wall.

2. The wall mounting bracket should lay ush against the wall. Mark the position of the wall

xings with a short pencil.

3. Move the machine away and remove the wall mounting bracket.

4. Attach the bracket to the wall in the marked position with appropriate xings then reposition

and fasten the machine to the bracket.

Proceed to page 4.1.

❶

❷

❹

❸

3.6

Assembly

Fitting the optional free standing kit

1. Attach the bracket to the top of the machine using the nuts and screws (provided with the

main machine).

Extend the telescopic leg to the same length as the front legs less 12cm (5”).

Assistance will be needed for the following stages

2. Get help to stand the machine up and hold it while the free standing leg is xed to the

bracket using the 6mm hexagon wrench.

3. Swing down the stay and attach the xing block to the back of the main body, tighten all

three screw on the stay (using 5mm & 6mm hexagon wrenches).

4. Extend the telescopic leg so the machine stands evenly.

NOTE: The free standing kit is an optional extra and does not come packed with the main

machine.

❶

❷

❸

4.1

Squaring

Checking the machine for squareness

For your machine to produce accurate square cuts the main body needs to be set so that is is 90o

to the squaring arm, for the following procedure you will need a piece of card or mount tboard at

least 60cm x 100cm (2’ x 3’). The larger the board the more accurate you can set the machine.

Place the board on the machine vertically as

shown and apply the clamp ensuring the bottom

edge is in rm contact with the squaring arm.

Select the cutting blade on the lower cutting head

(see section 6). Cut into the top board to produce

a cut approximately 3cm (1”) long. Disengage

the cutter using the cutter release lever. Lower

the cutter and make a similiar cut at the bottom

of the board.

Unclamp and turn the board around (like the

page in a book) and place it back in the machine

so the same edge is still on the squaring arm but

do not clamp it. Align and engage the blade so it

enters the previous made cut at the bottom edge

of the board. Now apply the clamp.

Raise the cutter to the top of the board, if the

machine is square the blade should enter

the same cut as made previuosly. If not refer

to the following page to make the necessary

adjustment.

❶ ❷

❸ ❹

4.2

Squaring

Adjusting the squareness

NOTE: Before making any adjustments carry out the squareness check as desribed in the

previous page.

It is assumed that the board used for the test is still clamped in the machine. From the test results

determine if the last cut made in the top of the board is to the left or right of the previous cut, as

shown above:

1. Slacken the two screws (A) joining the squaring arm to the two legs.

2. Slacken the left hand nut (B) joining the squaring arm to the main body, make sure the right

hand nut (C) is tight.

3. Release the clamp and position the board such that the blade is held in the cut on the bottom

edge of the board. Press down on the board to make sure it is in good contact with the

squaring arm.

4. Turn the squaring adjustment knob (4) on the right hand leg in the direction described next

dependent upon the position of the top two cuts. If the second cut is to the right of the rst cut

turn the adjustment screw clockwise when viewed from underneath. If the second cut is to

the left of the rst cut turn the adjustment screw counter-clockwise when viewed from

underneath. The adjustment screw should be moved so that when the blade is moved to the

top of the board it cuts between two existing cuts, the plastic sightline xed to the edge of

the clamp gives an indication where the machine is going to cut.

5. Repeat the squareness check.

6. Tighten the screws/nut (A, & B).

Ⓐ

ⒶⒷ

❹

Ⓒ

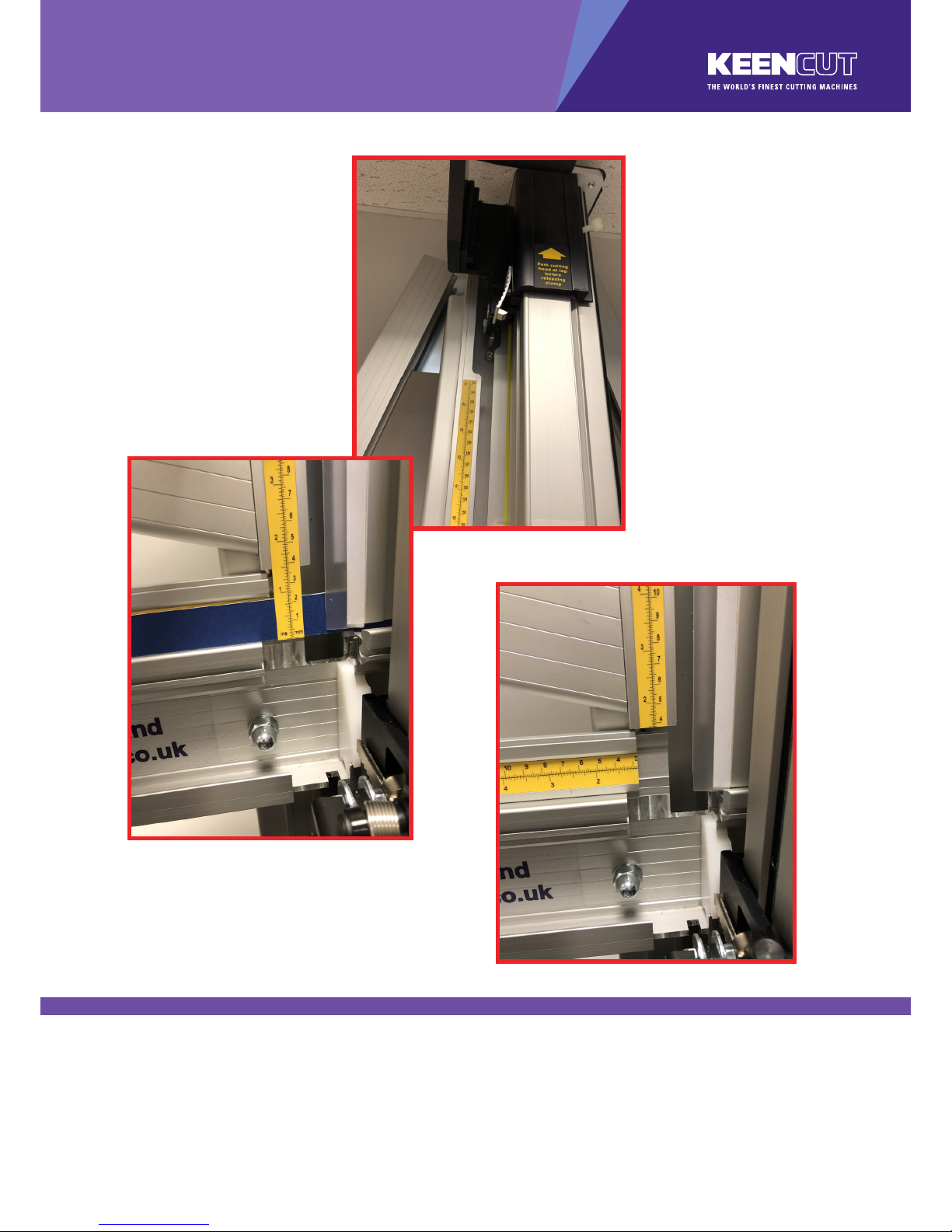

5.1

Calibration

Calibrating the verical scale

1. Trim the bottom of the scale at zero with scissors.

2. Remove the paper backing tape and carefully place the rule adjacent to its groove in the

main body and with the zero end resting inside the material channel of the squaring arm.

When aligned stick the rule in its groove.

3. Again trim the rule at the bottom end as shown.

❷

❷

❸

5.2

Calibration

Calibrating the squaring arm scales

The top edge of the squaring arm slides left to right to enable calibration. Use the 3mm hexagon

wrench to loosen the screw in the back of the squaring arm if adjustment is necessary.

1. Slide the production stop onto the outside edge of the squaring arm as shown.

2. Clamp a piece of card in the machine and move the production stop to it.

3. Cut the card and measure, adjust the sliding scale so that the production stop indicates the

measured size.

4. Repeat the process for the other side of the machine.

❶

❷

5.3

Calibration

Fitting the sightline strip

NOTE: The sightline strip is tted to your machine but may wear or get marked with use. A

spare strip is included with the machine, replacement strips are available from your distributor or

Keencut.

The sightline strip is xed to the clamp and then trimmed using the cutting blade to give an accurate

guide when cutting to trim lines, the edge of an image or pencil marks.

NOTE: Do not engage the twin wheel cutter until after reading its instructions for use in section 6.

Engaging the twin wheel cutter interferes with the sightline strip and can cause damage to it. A gap is

left in the sightline strip at a convenient height to enable the twin wheel cutter to be engaged.

1. Remove the worn sightline strip by peeling it o and clean any surplus adhesive with solvent

cleaner on a cloth. Remove the backing paper and starting at the bottom press the strip rmly

in the channel provided working upwards and cut o at a convenient height. Leave a gap of

18cm (7”) and then t the remainder of the strip.

2. Place a piece of rm board up to 6mm (1/4”) thick on the machine to bridge the gap running

down the back of the main body, this needs to be the full height of the clamp.

3. Place a piece of card or foam board 3-6mm (1/8”-1/4”) thick under the full length of the

exible part of the sightline strip, not under the aluminium clamp itself. Depress the

clamp handle so that the sightline strip is pressed at across the surface of the board.

4. Keep ngers clear and using a block or tool hold down the top left corner of the strip to start

the cut. With the turret rachet disengaged (scoring page 6) press the blade lightly on to the

surface of the sightline strip and score along the full length. Repeat and trim the sightline strip

in 2 or 3 cuts.

NOTE: If a board is not available to go the full length of the clamp use two or more pieces or trim

the strip in stages.

❶

❷

❸

❹

6.1

Operation

Using the clamp

The clamping system enables the operator to control the grip pressure by means of an integral

friction brake, that maintains the clamping force at the pressure applied by the operating lever. Soft

materials can be held rmly without sustaining damage and solid materials are held rigidly without

movement. By following the guidelines below it will help you to get the most from the machine.

USE CLAMPING INSTRUCTIONS

Soft materials such as

Foamcore boards, lightweight

card, etc.

Use light to medium pressure. The underside of the clamp grips an

area nearly 4cm (11/2”) wide with a non-marking sponge rubber

and reasonable force can be applied. If in doubt clamp a sample

rst with the good surface facing outwards.

Harder materials such as

PVC foam board, MDF or

composite boards such as

Dibond.

Use medium to heavy pressure.

Cropping to trim lines, pencil

marks, etc. (see drawing).

Place material in approximate position under clamp, apply light

clamp pressure to allow the material to be repositioned. Align the

trim marks with the edge of the sightline strip and clamp.

6.2

Operation

The multi-tool cutter head & counterbalance

The Excalbur 3S is tted with two sliding carriages running on a vertical slideway and each carriage

is tted with a cutting head. The top carriage is tted with a twin wheel cutter for use with rigid boards

such as aluminium composite panels, MDF, hardboards. Refer to ‘Using the twin wheel cutter’ for

more details. The lower or multi-tool cutter head has a rotating turret arrangement where either of

the two cutting tools can be selected:

The cutting blade The scoring blade

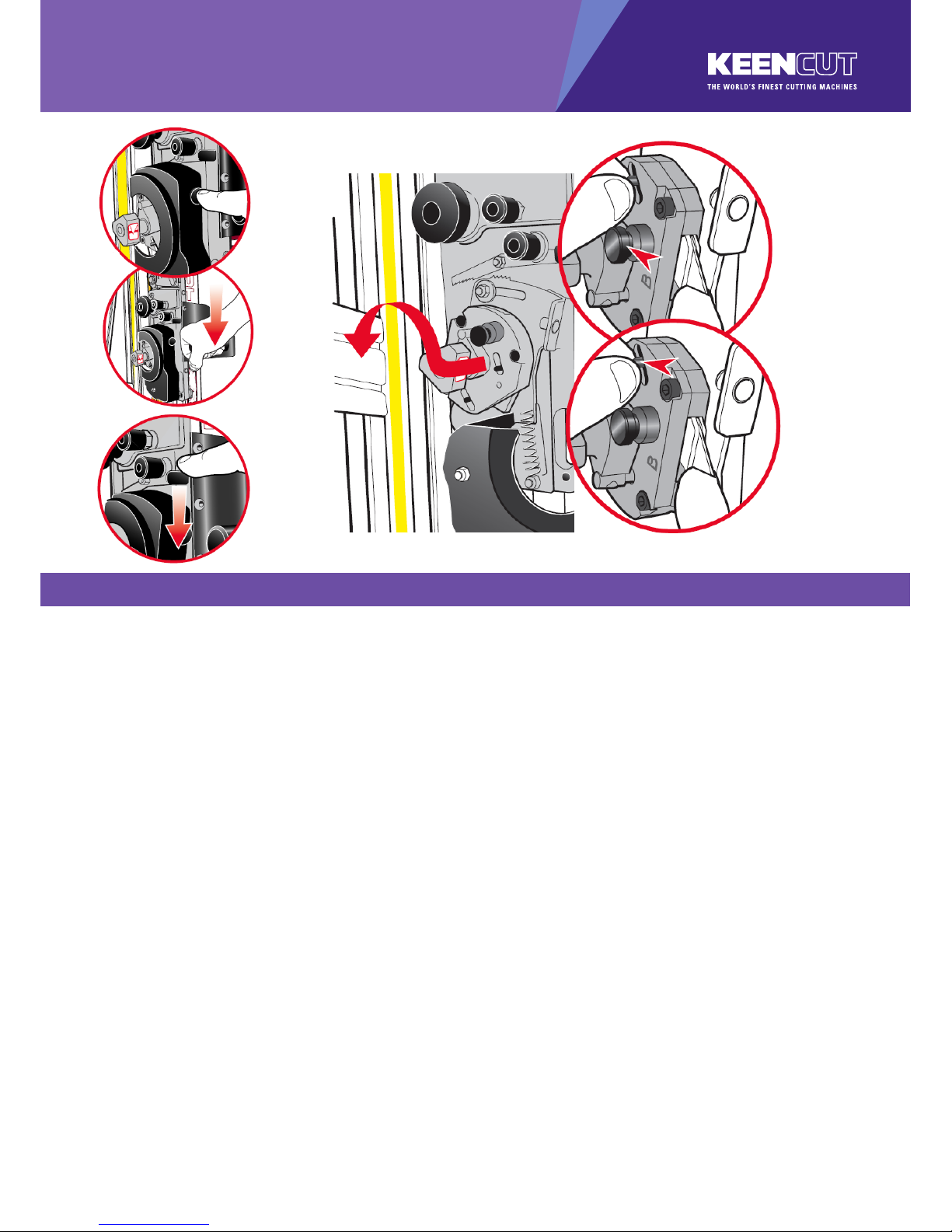

1. To select a dierent cutter pull the turret handle out to the left about 6mm (1/4”) and rotate in

either direction, the turret will click into the correct position for the cutter indicated. Please

note that there are three positions on the turret but only two positions are used on this version

of the Excalibur.

2. The indicator label seen in the cutter guard window shows which cutter is active.

3. The counterbalance can be attached to either cutting head for easy, fatigue free working. it

is normally attached to the twin wheel cutter but to attach it to the multi-cutter head, lock the

twin wheel carriage in place using the white plastic thumb screw. Raise the multi-cutter to

engage the counterbalance rocker, press the lower head of the rocker to connect it to

the carriage.

❶

❷

❸

6.3

Operation

Using & changing the cutting blade

Basic cutting technique: Select the cutting blade position on the turret and clamp the material in

the machine.

Move the cutting head beyound the top pf the material to be cut.

1. Press to engage the cutter. Draw the cutter down to the bottom of the machine where it will

disengage automatically.

2. Should you engage the cutter by mistake or for any reason want to disengage the cutter

without moving it to the bottom of the machine pull down the cutter and release lever.

Using the blade support plates: The two support plates either side of the blade are designed to

give maximum rigidity of the blade when cutting hard or dense materials. To adjust the support plates

swing down the cutter guard by undoing the gurad locking knob.

3. Turn the turret ½ turn until blade is pointing towards you and unlock the blade clamping

screw. The support plates can be adjusted by sliding the black pin in the slot. Move the plates

to suit the material.

For cutting most materials the support plates can be set about 12mm (1/2”) from the blade tip.

Changing the cutting blade:

4. Unlock and swing down the cutter guard, rotate the turret so the cutting blade is facing

outwards.

5. Undo the blade clamping screw a number of turns to release the blade.

6. Change or turn over the blade, insert it back into the turret as far as it will go. Tighten the

blade clamping screw, the safety pin will engage to hold the blade in position. At this point

the position of the blade support plates can be adjusted to suit the thickness of material being

cut, further tightening of the screw will clamp the blade in position.

7. Rotate the turret back to the cutting position. Replace the guard ensuring it is locked closed.

❶

❷

❸

❹

❺

❻

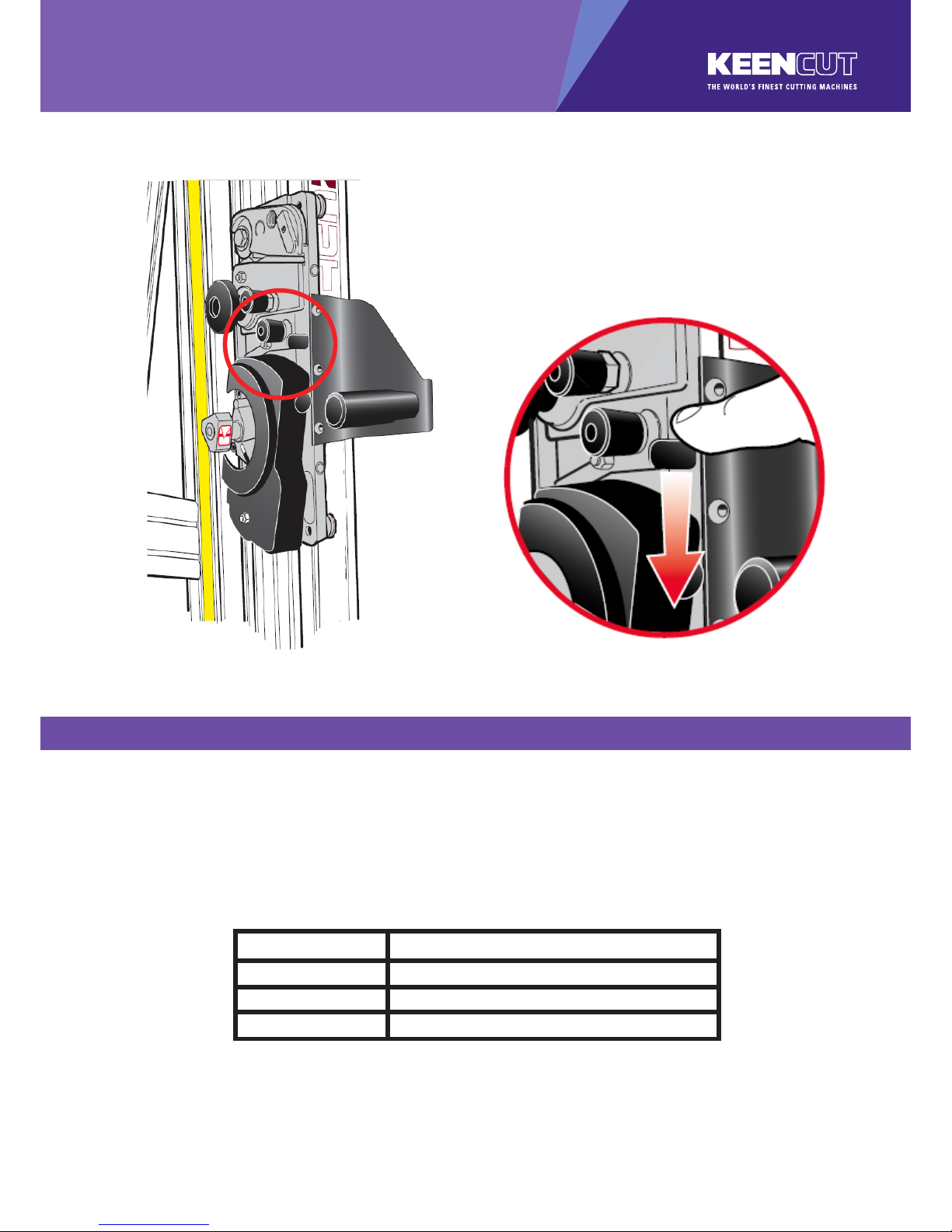

6.4

Operation

Cutting thick material using the ratchet latch

Ratchet latch

1. A unique feature of the Excalibur is the ‘ratchet latch’, this enables thick dense materials

such as PVC foam board to be cut easily in stages. Count the number of ‘clicks’ to position

the blade just below the surface of the material to make your rst cut then add an extra ‘click’

for the second and subsequent cuts.

2. Pull down the latch lever to disengage the ratchet if required.

As a rough guide when cutting PVC foam boards:

THICKNESS TAKE

3MM (1/8”) Initial surface cut + 1 additional cut

5MM (1/4”) Initial surface cut + 1 or 2 additional cuts

10MM (3/8”) Initial surface cut + 3 or 4 additional cuts

3. Should you engage the cutter by mistake or for any reason want to disengage the cutter

without moving it to the bottom of the machine pull down the cutter release lever.

4. For some operations (such as scoring acrylic) the ratchet latch needs to be disengaged, so

that nger pressure is used to make the score/cut. This is done by pulling the black knob on

the edge of the spring spool down to face towards the user. To re-engage the ratchet latch

push the small black knob away so it points upwards.

❶

❷

6.5

Operation

Using & changing the scoring blade

The scoring blade is designed to score acylics, Plexiglas and other similiar rigid plastics. Trials

should be carried out on scrap materials rst to ensure you obtain the required standard of cut.

Scoring/breaking technique

Select the scoring blade position on the turret and clamp the material in the machine.

1. Turn the ratchet hold-o knob to disengage the ratchet.

2. Clamp the plastic to be scored in the machine, position and depress the cutting head so the

blade touches the plastic at the top.

3. Apply thumb pressure to the cutter and draw the blade down the material in one continuous

motion.

4. Remove the plastic from the machine and snap it by hand.

CAUTION ALWAYS USE HAND AND EYE PROTECTION WHEN SNAPPING PLASTIC

Changing the scoring blade

Unlock and swing down the cutter guard, rotate the turret so the scoring blade is facing outwards.

4. Release the blade clamping screw.

5. Eject the medium duty utility blade using the black ejector pin, replace the blade to the right of

the clamping plate, push the blade in as far as it will go and tighten the blade clamping screw.

Rotate the turret back to the cutting position. Replace the guard ensuring it is locked closed.

Replacement medium utility blades are available from Keencut or your distributor.

❶ ❷

❸

❹

❺

6.6

Operation

Using & changing the twin wheel cutter

The twin wheel cutter is mounted on the upper cutting head and is used for cutting rigid materials

such as aluminimum composite panel and MDF up to 3mm (1/8”). Many other softer boards and

card can also be cut, trials should be carried out to ensure the desired quality of cut is obtained.

NOTE: The twin wheel cutter must be parked above the top level of the clamp when not in use

otherwise the cutter will interfere with the sightline strip if the clamp is operated.

1. Position the material in the machine and apply the clamp.

2. Bring the twin wheel cutter down until it makes contact with the sheet edge and stop. Take a

rm grip and then push the cutter down through the material without stopping.

The cutting wheels generally last more than a year with average use but this is dependant upon daily

use and the material being cut. The signs the wheels are wearing out are:

• A rough nish predominantly on the right hand side of the cut, with aking on material such as

MDF.

• The bottom of the cut bursting out rather than being cut neatly.

• The board trying to turn under the clamp when being cut (also check the clamp pressure).

Changing the twin wheel cutter

Lock the cutting head at a convenient height using the white nylon locking screw.

3. Hold the twin wheel cutter and its guard to prevent them from falling and remove the screw

with a 6mm hexagon wrench.

4. Slide the cutter towards the top of the main body and lift out.

Replacement wheels or cutters are available from Keencut or your distributor.

❷

❹

❺

7.1

General maintenance

Cleaning

Keencut machines are designed to be virtually maintenance free, however we do recommend

regular cleaning. Do not wipe the squaring arm channels or remove any debris with ngers, as it

may contain sharp particles such as glass. Use a vacuum cleaner if possible or if a soft brush is

used, work slowly and do not allow particles to ick o the bristles.

Lubrication

The slideway can be cleaned and lubricated occasionally using a silicone lubricant. Removing any

excess with a cloth. The multi cutter assembly may require dusting out periodically do not lubricate

or adjust without seeking further advice from your distributor or Keencut.

Except glass cutting oil on the glass cutting wheel only

Adjusting the sliding bearings

1. Attach the balance weight (see page 6.2) to the other cutting head, hold the cutter at waist

height and place a 2mm hexagon wrench on the top adjustment screw. Move the cutting

head up and down and tighten the scew very gradually until the cutting head dows not

fall under its own weight. Loosen the screw by the smallest amount you can until it does fall

under its own weight. Repeat the process with the other three adjustment screws A.

Adjusting the clamp pressure

2. The pressure of the clamp is in relation to the amount of pressure applied to the operating

handle. However in time the maximum clamping pressure can reduce due to wear on the

friction black (hidden within the machine), compensation for this can be made by adjusting the

two small grub screws B in the operating handle housing as shown. Turning the screws

clockwise will increase the maximum clamping pressure.

3. Turn both screws all the way in and then undo by a quarter of a turn, slight adjustment can be

made to ne tune the pressure. Do not operate the clamp with the adjustment screws tight.

DO NOT USE OIL ON ANY PART OF THE MACHINE

❶

Ⓐ

Ⓐ

Ⓐ

Ⓐ

❷

Ⓑ

Loading...

Loading...