KEENCUT Evolution E2 User Instructions

Evolution E2

Inspired Design – Precision Engineering

USER INSTRUCTIONS

Thank you for choosing the Keencut Evolution E2. Every effort

has been made to bring you a precision engineered product

with the promise of many years of valuable service. In order to

obtain maximum benefit from your machine please read these

instructions carefully. For advice and assistance or replacement

parts please contact your distributor or Keencut.

Keencut Limited, Baird Road, Willowbr

ook Industrial Estate, Corby

, Northants, ENGLAND NN17 5ZA.

Telephone: 01536 263158 Fax: 01536 204227 E-mail: info@keencut.co.uk

www.keencut.co.uk

KC-EDITION 7168-01/12

1 Contents

2 Before Set Up

2.1 Installation Recommendations

2.2 Check and Adjust Worktop Flatness

The Fixing Bracket Jacking Screws

2.3 Position the Fixing Brackets

3 Set Up

3.1 Fit the Lift Handles (remove strapping)

3.2 Adjust for Alignment

3.3 Position the Base Fixing Brackets

3.4 Check and Adjust the Clamping

3.5 Adjust for Flatness and Grip - paper test

3.6 Build up Bench Surface

4 Operation

4.1 About the Blades - inserting and setting the blade - blade

depth adjustment

4.2 Blades and Blade Holders

4.3 Changing the Blade Holder

4.4 Inserting the Graphik Blade

4.5 Changing the Depth

4.6 The Rotary Cutter (Textile cutting Attachment)

4.7 Using The Rotary Cutter

4.8 Changing The Rotary Blade

4.9 Medium Duty Blade Holder

5 Maintenance

5.1 Cleaning and Lubrication - (warning note)

Adjusting the Cutting Head Sliding Bearings.

1

Contents

1

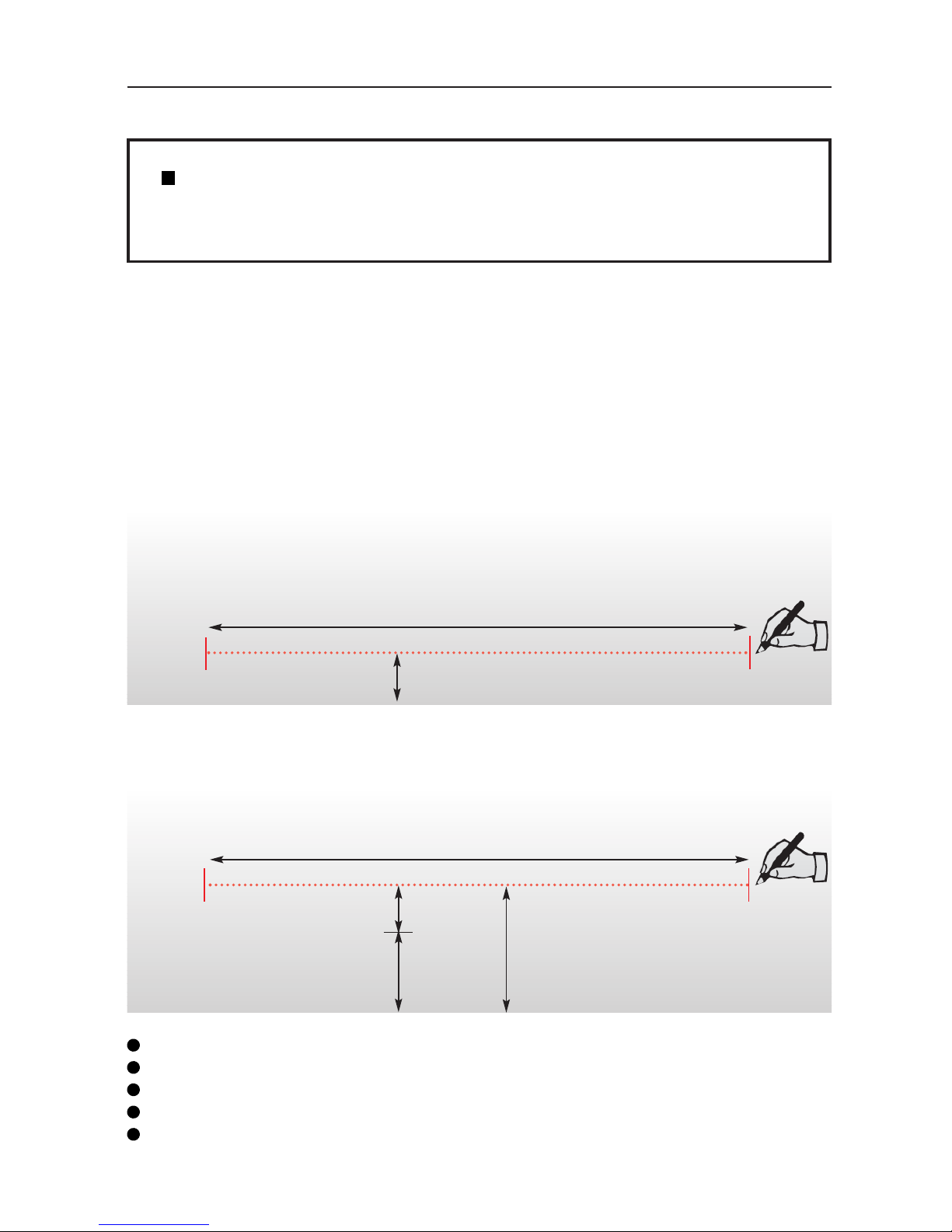

2.1 Before Set Up 2.1

Overall length of cutter

Worktop

9.5cm

Overall length of cutter

Worktop

15cm

24.5cm

9.5cm

Evolution E2 160cm (64”) overall length 193cm (74”) 4 base fixing brackets

Evolution E2 210cm (84”) overall length 243cm (94”) 5 base fixing brackets

Evolution E2 260cm (104”) overall length 293cm (114”) 6 base fixing brackets

Evolution E2 310cm (124”) overall length 343cm (133”) 7 base fixing brackets

Evolution E2 360cm (144”) overall length 393cm (153”) 8 base fixing brackets

CHECKING THE BENCH FOR INSTALLATION

Please note! As part of the installation there are a number of checks and

adjustments to be made and it is important to perform them correctly to ensure

consistent top quality performance for the life of the machine.

The Evolution E2 Cutter Bar can be fixed to a KEENCUT Proteus bench or to an existing

work bench. The bench should be rigid with a flat worktop (within 3mm (1/8") overall)

and made from MDF or similar material to accept fixing screws.

To enable the flip-over storage function to operate the Evolution E2 must be fitted close

to the edge of the bench but if it is required nearer the centre of the bench do remember

that cutting tough materials will be more difficult if the operator needs to stretch too far

to reach the cutter head.

If the cutter is to be mounted along the edge of the bench draw a line 9.5cm in from the

edge of the worktop and the length of the cutter as listed below.

Should you want to use the cutter, for example 15cm in from the edge, draw the line

15 + 9.5 = 24.5cm from the edge of the worktop.

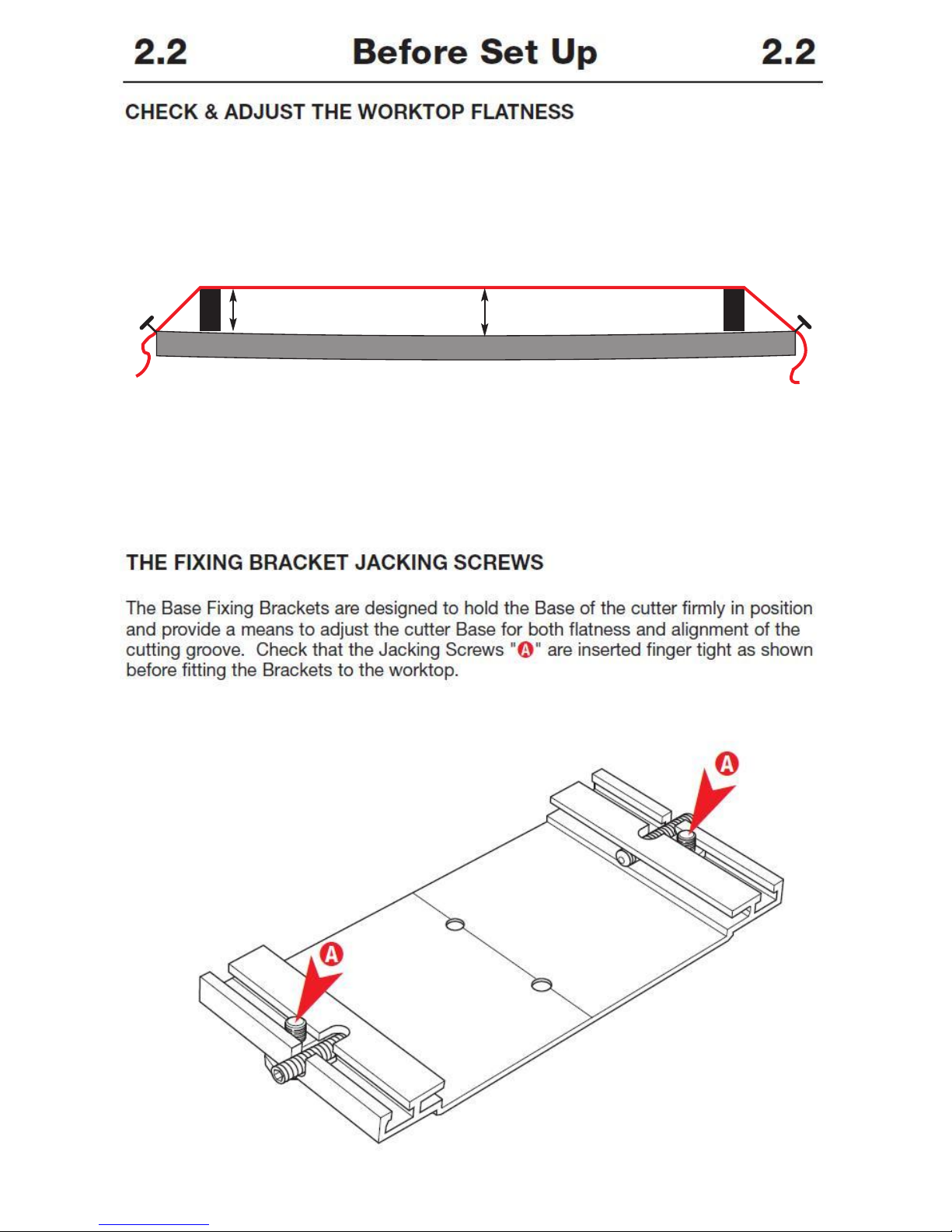

2.2 Before Set Up 2.2

CHECK & ADJUST THE WORKTOP FLATNESS

Check the flatness of the worktop by stretching a thin piece of strong thread between

two blocks (of the same height) approximately over the line. Measure the highest and

lowest part of the worktop under the thread, the difference between the two measurements should be no more than 3mm (1/8"). If it is greater it will be necessary to adjust

the surface flatness with a new top or by using spacing pieces under each bracket.

?mm

?±3mm

¸

worktop

§

§

Adjust the surface flatness by adding packing pieces made from 1.5mm - 3mm (1/16" 1/8") thick rigid material such as PVC Foamboard, under the Base Mounting Brackets as

they are installed (next section).

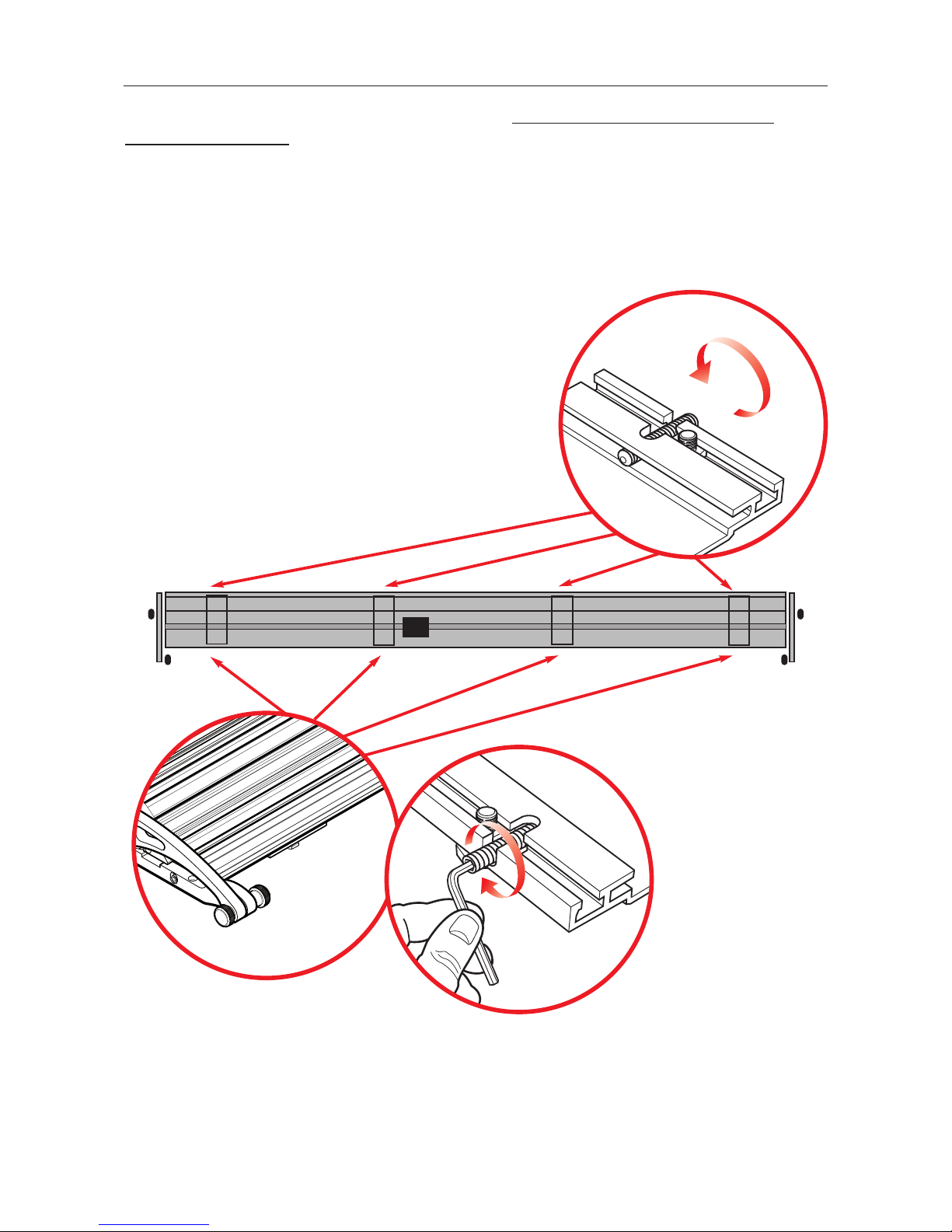

THE FIXING BRACKET JACKING SCREWS

The Base Fixing Brackets are designed to hold the Base of the cutter firmly in position

and provide a means to adjust the cutter Base for both flatness and alignment of the

cutting groove. Check that the Jacking Screws "

A " are inserted finger tight as shown

before fitting the Brackets to the worktop.

A

A

➤

➤

18cm (7")

43.5cm (17

1

/

8

")

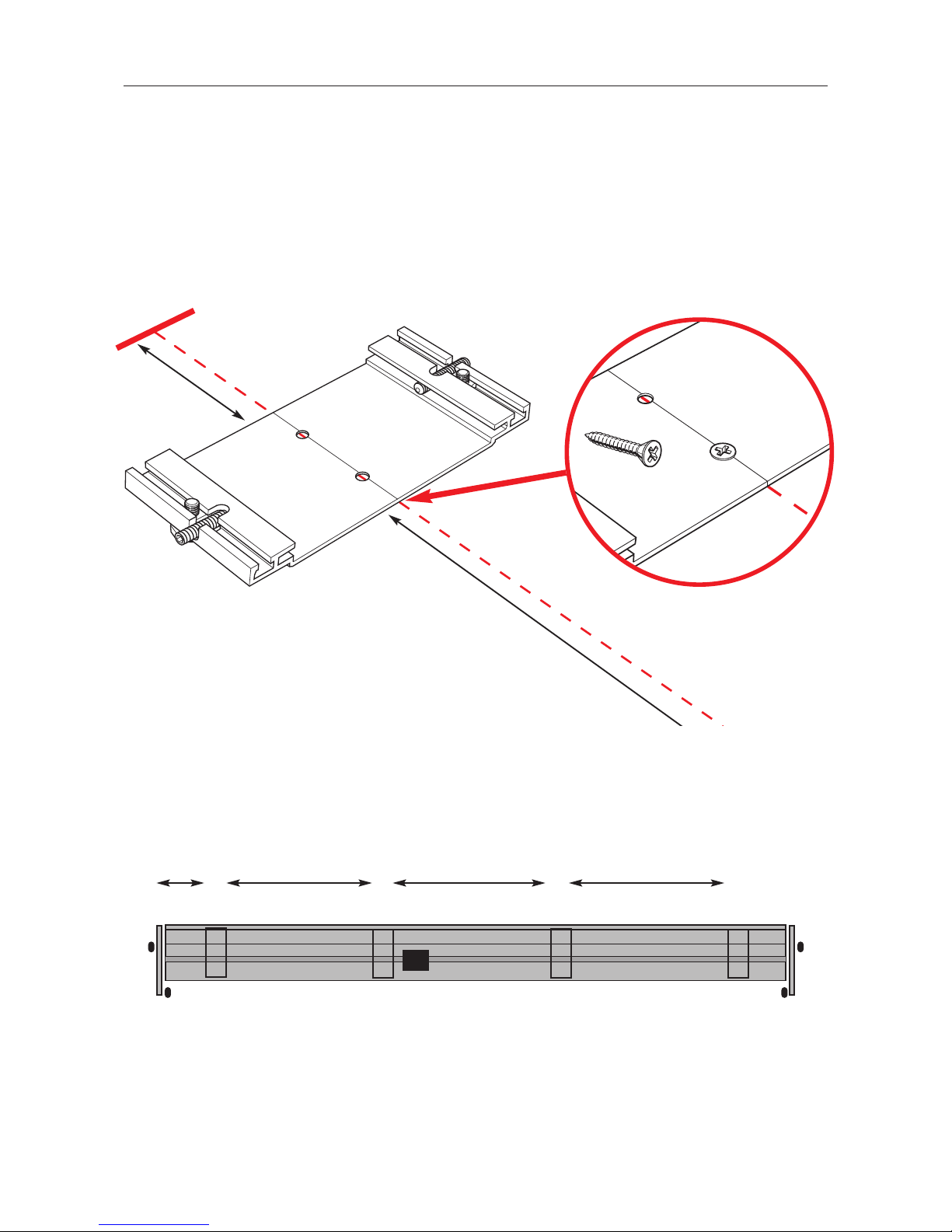

2.3 Before Set Up 2.3

SET OUT THE FIXING BRACKETS

Place a Bracket 18cm (7") from the end of the pencil line as shown, ensuring that the

groove in the centre of the Bracket is aligned with the pencil line and fix to the worktop

using two short screws "

D" provided. Fix the remaining brackets accurately along the

line leaving a 43.5cm (17

1

/8") gap between each one. Check that the brackets are all

aligned correctly and if not remove the incorrectly positioned bracket and replace slightly

to one side of the original position to create new screw holes.

43.5cm (17

1

/8") 43.5cm (171/8")43.5cm (171/8")

18cm

(7")

● Example:

Evolution 160, 4 base fixing brackets

1234

Evolution E2 160cm (64”)

D x 2

2.4 Before Set Up 2.4

Lift the Evolution E2 cutter bar from its crate but do not remove the clear plastic

stretch-wrap bands holding the base to the cutter bar. Place the Evolution E2 centrally

on the Brackets and manoeuvre it until the base is located properly down on each of

the Brackets.

Tighten the grub screws "

B" at the back of each of the Brackets by 4 full turns and then

tighten the front grub screws "

A" fully (approx 4- 6 turns). Remove the clear plastic

stretch-wrap bands.

➤

➤

➤

B

A

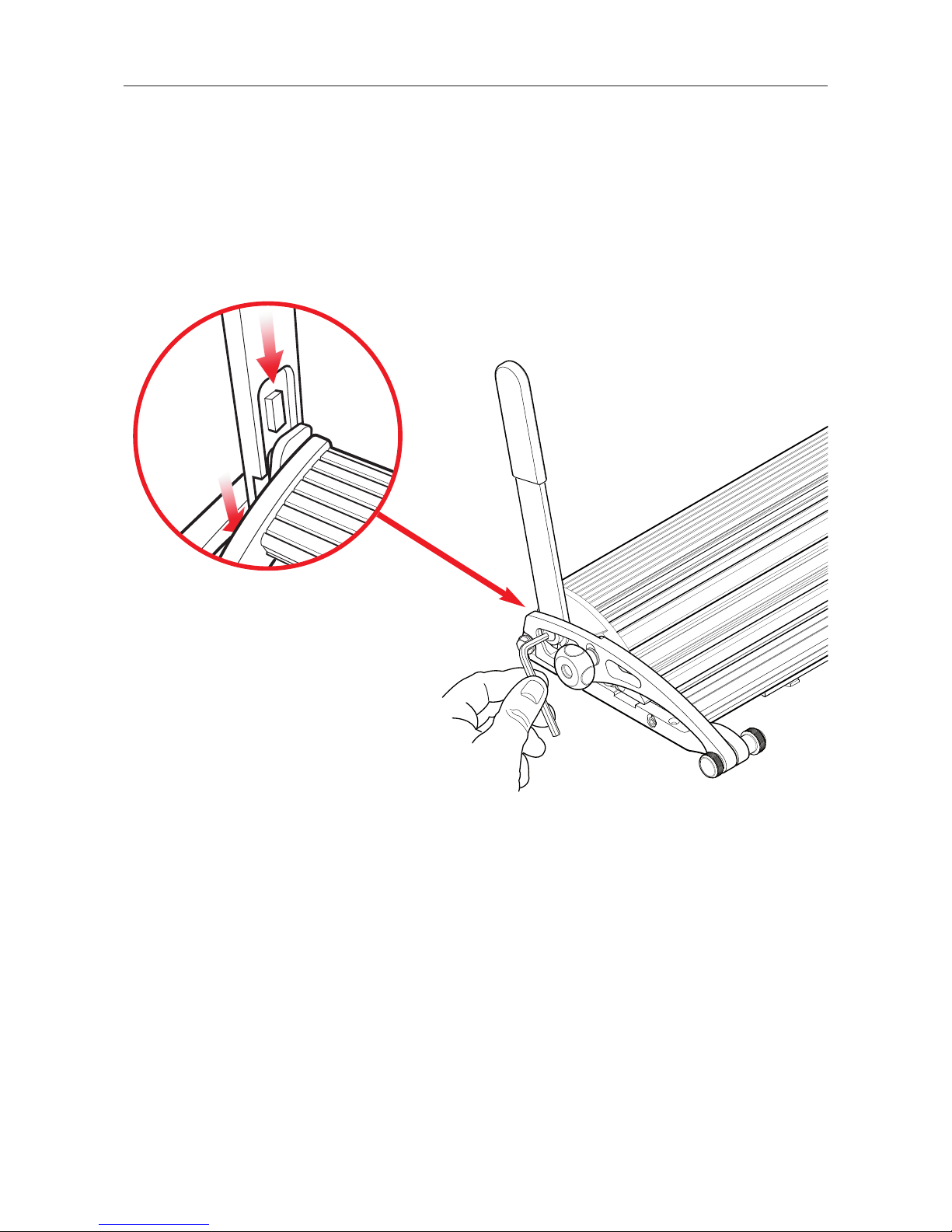

3.1 Set Up 3.1

FIT THE LIFTING HANDLES

Fit the Lift & Hold Handles at each end of the cutter bar. Position the machined section

of the handle towards the centre of the Evolution E2 and insert it into place at the angle

shown (Fig 1). Once in position straighten so that the rectangular feature on the handle

fits into its mating hole in the adjacent black steel component attached to the machine.

Fully tighten the fixing screw (Fig 2) using the 5mm Allen key provided.

1

2

CHECK & ADJUST THE CUTTING GROOVE ALIGNMENT

The Evolution E2 cutter bar has been adjusted to a straightness of 1:15000 along its full

length using a laser beam controlled instrument. It is desirable to adjust the cutting

groove in the aluminium base to match the straightness of the cutter bar and the base

brackets provide the means to do so.

The back of the cutting groove in the Evolution E2 Base should be in line with the edge

of the cutter bar to allow the blade in the cutting head to run the full length of the

machine without touching either side of the groove, if it does not....

Loading...

Loading...