BBiigg Bench

ASSEMBLY INSTRUCTIONS

Thank you for choosing the Keencut Big Bench.

Every effort has been made to bring you a superbly

built product with the promise of many years of

good service.

Keencut – the world’s finest cutting machines

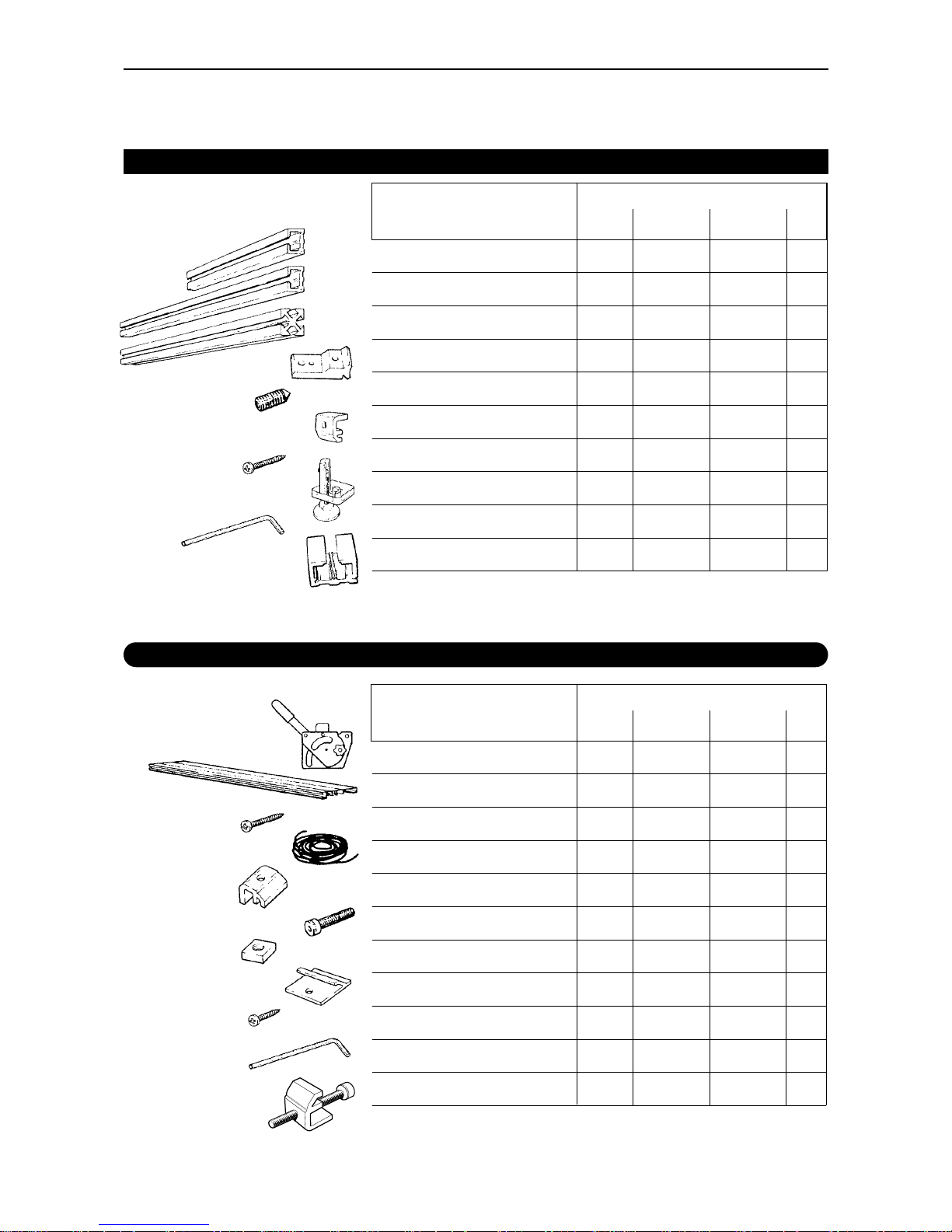

2 Packing List 2

You should have;

Packed in the Rectangular Boxes:

Short beam 4 6 8 10

Long beam 4 8 12 16

Leg 4 6 8 10

Joining Bracket 16 28 40 52

Grub Screw 48 84 120 156

Worktop Fixing 4 6 8 10

Long Screw 4 6 8 10

Height Adjuster 4 6 8 10

4mm Hexagon Wrench 1 1 1 1

Spacer 1 1 1 1

QUANTITY FOR BIG BENCH

ITEM

1.0,1.5 2.0, 2.5, 3.0 3.5, 4.0, 4.5 5.0

Packed in the TUBE:

Lift & Hold (Left & Right) (1,1) (1,1) (1,1) (1,1)

Base Extrusion 1 1 1 1

Large Screw 6 6 6 6

Silicon Cord 1 1 1 1

Base Clamp 2 3 4 5

Cap Screw 2 3 4 5

Square Nut 2 3 4 5

Worktop Connector 2 4 6 8

Small Screw 2 4 6 8

5mm Hexagon Wrench 1 1 1 1

Levelling Bracket & Screw 2 4 6 8

QUANTITY FOR BIG BENCH

ITEM

1.0,1.5 2.0, 2.5, 3.0 3.5, 4.0, 4.5 5.0

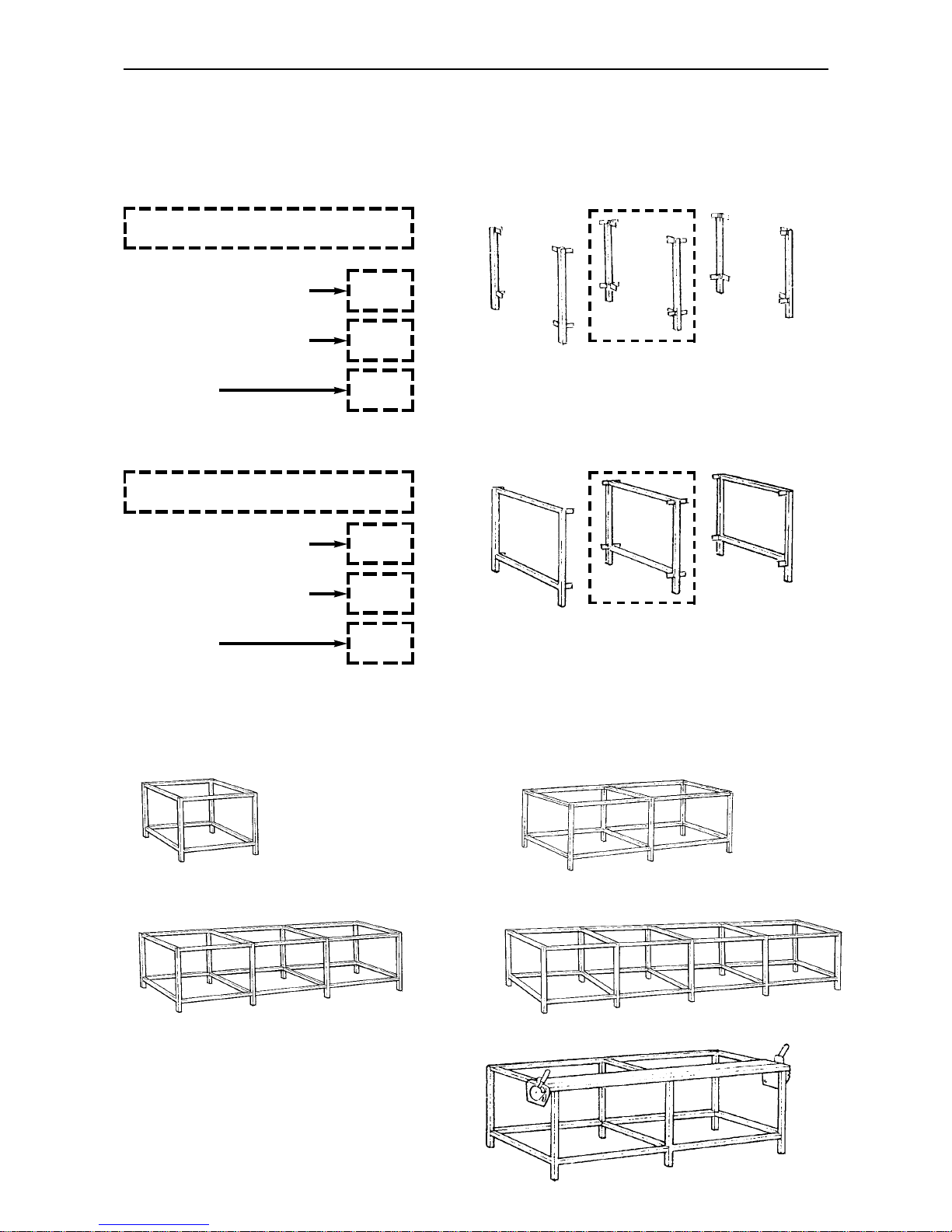

3 Order of Assembly 3

The Order of assembly is important – the following diagrams are for quick reference

only and are to enable the reader to familiarise themselves with the general assembly of

the Big bench, the detailed assembly is described in 4 stages.

Stage 1

Fix the brackets to the legs.

The 1.0m & 1.5m Big bench have only 4 legs,

please disregard the middle pair of legs.

x1

x1

x1

Stage 2

Construct the end frames.

Disregard the middle frame if you are building

a 1.0m or 1.5m Big bench.

2.0m, 2.5m & 3.0m Big bench

x2

3.5m, 4.0m & 4.5m Big bench

x3

5m Big bench

x1

2.0m, 2.5m & 3.0m Big bench

x2

3.5m, 4.0m & 4.5m Big bench

x3

5m Big bench

Stage 3

Join the end frames and cross beams to produce the bench.

Middle legs

Middle frame

1.0 & 1.5 Big bench 2.0, 2.5 & 3.0m Big bench

3.5, 4.0 & 4.5m Big bench 5m Big bench

Stage 4

Attach the Javelin lift & hold mechanisms

and base extrusion.

Stage 1

1. Put a grub screw backwards into each of the joining brackets – do not place screws in the

other holes.

NOTE:

The following instructions will assume the Big bench has six legs (2.0, 2.5 or 3.0). If

you are constructing a (1.0 or 1.5) Big bench please omit the middle frame.

✗

✗

✗

✓

➤

a

2. Using the spacer, fit the brackets to the top of

each leg as shown – ensure:

a). The brackets are fitted the correct

way round.

b). The spacer is slightly above the top

level of the leg, so when

constructed the top level of the leg

is not above the beam.

c). The grub screws are tightened fully.

3. Attach brackets to the

bottom of the legs (and the

same way round as shown

above), using a tape measure

or spacer to position them to

suit your requirements.

a

✗

✔

3.1 Assembly 3.1

Stage 2

1. Fit the two short beams between

each pair of leg assemblies

ensuring the small groove in the

beam is uppermost.

2. Pulling the two legs

together (to close

any gaps between

the end of the beam

and the legs) tighten

all the grub screws.

Stage 3

1. Place one end frame on the floor with the

brackets pointing upwards and position

a long beam over each bracket (again

ensure the small groove in the beam will

be uppermost).

2. Place either:

the other end frame (if you are

constructing a 1.0m or 1.5m

big bench)

or

The centre frame (if you are constructing

a 2.0m, 2.5m or 3.0m Big bench)

over the beams and tighten the grub screws

ensuring there are no gaps between the beam

ends and the legs.

3. 2.0m, 2.5m or 3.0m

Big bench only

Stand the frame onto its feet

and position the remaining

long beams between the

frame and the remaining end

frame, tighten all the grub

screws again ensuring there

are no gaps between the

beam ends and the legs.

TOP

3.2 Assembly 3.2

4. Put grub screws in each of

the two large holes of the

bracket, only screw them in

2 or 3 turns.

5. Fix the height adjusters into

the bottom of each leg.

Position the adjuster in one of

the internal grooves of the leg

(ie. the same groove the

brackets are fitted).

Position the bottom

of the aluminium

bracket level with

the bottom of the

leg and tighten the

grub screw fully.

TOP

3.3 Assembly 3.3

Stage 4

1. Place the base extrusion on the edge of the

bench so the lip hangs over the front edge of the

legs. Slide the square nuts into the recess as

shown and place one near to each leg. Slide the

workshop fixing plates into their groove and

position them at approximately equal spaces along

the base extrusion.

2. Using the 5mm hexagon wrench fix the base

extrusion in place on the bench with the base

clamps and cap screws.

3. Fix the lift & hold mechanisms to each end of the

base extrusion with three self taping large

screws on each end, do not at this stage tighten

the screws fully.

View from underneath

SQUARE

NUT

WORKTOP

FIXING PLATE

ba

3.4 Assembly 3.4

Stage 4 – cont’d

4. Fix the Worktop in place using

a) The large workshop fixing and large

screws as shown.

b) the small screws to fix the worktop

fixing plates.

5. Position the Javelin cutter onto the two

lift & hold mechanisms by sliding the

tongue into the slot inside the end caps

of the Javelin.

6. Move the cutting head to one end of

the Javelin and depress the blade,

adjust the position of the lift & hold

mechanism so the blade runs centrally

in the slot on the base extrusion,

tighten the three screws to fasten the

lift & hold.

Repeat for the other end.

Move lift & hold to align

blade in slot

Position brackets approximately

as shown

NOTE:

The friction knob on each mechanisms can

be adjusted to hold the Javelin at any height

which makes accurate lining up easier when

in use.

7. Position the bench in place and using an accurate spirit level adjust the feet to ensure the top

surface of the table is flat. If the table is not flat, particularly along it’s length, there may be difficulty

in holding the workpiece in place along the full cut length.

Plan View

3.5 Assembly 3.5

8. If a thin film or paper is being cut check that the material can be gripped along the full length of the

bench. Pass a small piece of the material about 25cm (10") wide under the cutter and ensure it is

held in place, carry this out along its full length.

Should the cutter not grip adjacent to a bench leg, adjust the foot to slightly raise that part of the

bench and test again.

Should the paper not be gripped by the cutter bar between the legs, place a levelling bracket and screw

in the beam on the underside of the base extrusion. Position it in the middle of the area that is not

clamping and tighten the screw until the paper is clamped efficiently. Check the whole cutter bar is

clamping, add more levelling brackets and adjust if necessary.

KEENCUT Limited

Baird Road, Willowbrook Industrial Estate,

Corby, Northamptonshire UK, NN17 5ZA.

Tel: +44 (0) 1536 263158 Fax: +44 (0) 1536 204227

E-mail: info@keencut.co.uk

KEENCUT INC. (North American Sales)

366-3560 Pine Grove Ave. Port Huron, Michigan,

48060 USA.

Toll Free: 1 800 240 KEEN (5336)

Tel: 1 (519) 652 0970 Fax: 1 (519) 652 0396

E-mail: northamericansales@keencut.com

www.keencut.co.uk

INSPIRED DESIGN –PRECISION ENGINEERING

Loading...

Loading...