Page 1

Part No. EP59-10864

Iss. B

Non-contact Tonometer

Service Instructions

ALWAYS READ THE INSTRUCTIONS

!

Keeler Limited, Clewer Hill Road, Windsor, Berks, United Kingdom. SL4 4AA.Tel No. +44 (0) 1 753 8

Fax No. +44 (0) 1 753 830247

57177

Page 2

CONTENTS

1.

Service Equipment Checklist and Technical Data ...1

2.

Puls

3.

Software installation guide ..3-5

air

Spare parts list 2

4.

Hardware set

5.

Dis-assembly and Re-assem

6. Dis-assembly and Re-assembly of the Puls

7.

Calibration and

8.

Cleaning

-up guide (Electronic unit) . .6-7

bly of the Puls

Verification

of the Optics ..23

Software Procedure ..10-22

air

2000/3000 8

air

EasyEye 9

9. Replacing the

10.

11. Replacing the Umbilical Cord Assembly Puls

Replacing the Umbilical Cord Assembly Puls

Air Filter . ...24

air

2000/3000...25-26

air

EasyEye ..27-28

Page 3

CONTENTS

12. Replacing the Main

13. Replacing the Pump and Pump Assembly Puls

14. Replacing the Pump and Pump Assembly Puls

15. Set-up of Mainfra

16. Upgrade Power Supply pcb Puls

frame and pcb Assemblies .29

me Mirror Assembly . .. 32

air

2000 ..33

air

2000/300

air

EasyEye .31

0..30

17. General T

18. Software Troubleshooting ....39-44

19. Replacement of Case Halves

20. Replacement of Case Halves

21.

Replacement of thermal printer Puls

roublesh

ooting . .34-38

Puls

Puls

air

2000/3000

air

EasyEye . .47-48

air

EasyEye

...45-46

..49

Page 4

1. SERVICE EQUIPMENT CHECKLIST AND TECHNICAL DATA

1. 2401-P-

2. 2401-P-

3. 2401-P-

4. 2401-P-

5. 2401-P-

6

2401

7. EP79-09146 14/15mm SPANNER

5100 TUBE & CONNECTOR ASSEMBLY

5119 RS232 COMMUNICATION CABLE

5127

PC SERIAL PORT CABLE ASSEMBLY

6736 CALIBRATION ELECTRONIC UNIT

6787 CALIBRATION JIG Pulsair 2000/3000

-P-

6005

CALI

BRATION JIG Pulsair (EasyEye)

8. EP79-09154 DAQ CABLE ASSEMBLY

9. EP79-09162 DAQ CARD 1200

10. EP59-10901 25 WAY DONGLE

11. EP84-01130

SOFTWARE INSTALLATION DISC V2.7

12. RP18-00094 LOCTITE 601 ADHESIVE

13. RP18-00318

This calibration function can only be carried out at KEELER LTD

BOSTIC CLEAR ADHESIVE

CALIBRATION OF TEST JIG

The test unit must be returned to Keeler for recalibration periodically {once a year} as per the

due date on

The items to be returned are as follows

1. CALIBRATION ELECTRONIC UNIT AND CABLE ASSEMBLES

2. TRANSDUCER ASSEMBLY

3.

CALIBRATION JIG & DUMMY EYE

4. DAQ CABLE ASSEMBLY AND CARD 1200

PLEASE RETURN TO

KEELER LIMITED

C

LEWER HILL ROAD

BERKSHIRE SL4 4AA

ATTN DAVE GRAHAM

the back of electronic unit.

WINDSOR

PAGE 1

Page 5

2.

Puls

air

Spare parts list

Parts common to all models

2401-P-

EP39-05869

EP39-06896

EP39-05500

2110-P-

PP02-82056

EP79-40899

RP18-00094

EP39-04639 NEEDLE VALUE

2401-P-

2401-P-

1024-P-

EP18-00203

EP18-00211

2401-P-

EP79-03334

EP79-05161

6744

7018

6664

6955

5062

6437

UMBILICAL CORD ASSEMBLY (2000)

P.C.B (2000)

BULB (2000)

CASE LEFT (2000)

CASE RIGHT (2000)

MAINFRAME ASSEMBLY

AIR FILTER ASSEMBLY

PUMP ADAPTOR

BSP\NPT ADAPTOR

BULB CONTACT

WIPES (PACK OF 24)

PTFE TAPE

CABLE-TIE

LOCTITE 601 RETAINER

air

Puls

SPIRAL PIN

M3 INSERT

Puls

air

model 2000 only

model 3000 only

2401-P-

2401-P-

1024-P-

EP19-01848

EP19-01856

2401-P-

EP79-03334

EP79-05161

2414-P-

2414-P-

EP29-50860 P.C.B (EasyEye)

EP39-50643

EP39-50651 SWITCH P.C.B

EP09-00501 CASE RIGHT (EasyEye)

EP09-00528 CASE LEFT (EasyEye)

1024-P-

EP39-

6963

6998

5118

6437

5002 UMBILICAL CORD ASSEMBLY (EasyEye

6002 MAINFRAME ASSEMBLY

DISPLAY P.C.B

5118 BULB

50387 SCREW PLUG

UMBILICAL CORD ASSEMBLY (3000)

P.C.B (3000)

BULB (3000)

CASE LEFT (3000)

CASE RIGHT (3000)

MAINFRAME ASSEMBLY

SPIRAL PIN

M3 INSERT

Puls

air

model EasyEye only

PAGE 2

Page 6

PAGE 2

Page 7

3. SOFTWARE INSTALLATION FOR PULSAIR CALIBRATION

ITEMS REQUIRED

1.

NATIONAL INSTRUMENTS PCMCIA ANALOGUE TO DIGITAL CONVERTER

2.

NATIONAL INSTRUMENTS SOFTWARE DISC (6.1V)

3.

PULSAIR CALIBRATION SOFTWARE DISC (2.7.0V)

LOADING PROCEDURE

IMPORTANT

It is

minimise possible problems with the PCM CIA card

1.

Place the

DOUBLE CLICK

2.

DOUBLE CLICK

3.

DOUBLE CLICK

4.

5.

Follow the on screen instructions.

FOR Windows 95 ONLY

DOUBLE CLICK

appears, then click ok.

NATIONAL INSTRUMENTS CD ROM DISC

that the National Instruments Software for the

My Computer on your Desktop.

the CD R

onto the set-up icon.

o

k. Click next at each screen instruction until the install screen

OM icon /Drive Letter in My Computer.

DOUBLE CLICK

select the language setting (this should be highlighted in blue).

onto the install

A.D.C

into CD-

is installed first to

ROM drive bay.

NI-DAQ

option

6. When ok box has been clicked, the computer will automatically re-

7.

After the computer has restarted, close the computer down completely and then switch

off.

8.

Connect the ribbon cable EP79-09154 to the ADC PCMCIA card carefully.

DAQ

9.

Place the national instruments PCMCIA

in the computer, ensuring that the card is in the correct position.(as the instruction written

on to

p of the DAQ

10.

Turn the computer back on.

11.

Windows 95/98 will automatically detect the new ADC card and install the appropriate

software for it.

CLICK ON TO START

12.

INSTRUMENTS DAQ

from the National Instruments DAQ program group, accept new device in socket 1or 2.

card) insert card

1200

in main menu, then

MENU.

Run the NI-DAQ Configuration Utility programme

-1200

card carefully into the PCMCIA slot

PROGRAMS

start.

and then select

NATIONAL

Page

3

Page 8

3. SOFTWARE INSTALLATION FOR PULSAIR CALIBRATION

13. Single click Configure, which will find the ADC PCMCIA card. F

wizard.

settings. Change the

OPC

14.

Then click X on the top right ha

utility. Click save if requested.

15.

Remove NI-DAQ CD disc from CD bay

16.

Place CD

Double Click

17.

Double Click

18.

Double Click Calibration Software V2.7.0

19.

Double Click SET-UP.

20.

21.

Allow Windows to install the calibration software. Click OK to Tonometer set up, and

then cl

files by clicking on the X in the right hand corner

DO NOT

to disabled, click ok to continue.

-ROM DISC for Pulsair Calibration (EP84-

ick the

change the

AO Polarity

My Computer on main desktop.

CD-ROM

install icon

AI Polarity/Range or Mode Settings

UNIPOLAR.

to

nd corner of the window for exit from configuration

icon.(CAL SW-V2-7) or (KEELER)

Follow all on screen instructions.

to install software. When completed click OK. Exit all open

folder(

Leave

Calibration S

Accessory

01130) into CD-ROM drive bay.

ollow the configuration

to there default

setting at none and

)

DONGLE SECURITY DEVICE SOFTWARE INSTALLATION

INSTRUCTIONS

Double Click

1.

Double Click CD-ROM

2.

3.

Select and

Double Click

4.

5.

When Aladdin device Driver Installation Utility for Win32 screen instruction appears

Single Click OK

6.

Exit all

open files by clicking on the X in the right hand corner.

My Computer on main desktop

icon.(CAL SW-V2-7) or (KEELER)

Double Click

Install Dongle

Hasp Command line Installer Latest version 120599 v3.83

Page

4

Page 9

3. SOFTWARE INSTALLATION FOR PULSAIR CALIBRATION

SHORT CUT INSTRUCTIONS

1.

To obtain a

main desktop.

2.

Select new

3.

At command line Select browse (single click). At browse, select folder programme files

(double click).

4.

At Programme files, select Tonometer, then (double click).

5.

At tonometer, select eye symbol with Tonometer, then

6. At create shortcut, the command line will read C:\

\

Tonometer

7.

When select a name for shortcut appears, it will read Tonometer. Single click

8.

A short cut symbol of

will take you into main Pulsair calibration software.

Short Cut

then Select short cut (single click)

\Tonometer. exe select next then (single click).

to the Calibration Software, first right click the mouse when in the

an eye will now appear. When you double click the eye symbol it

(double click).

Programme Files.

Finish.

Page

5

Page 10

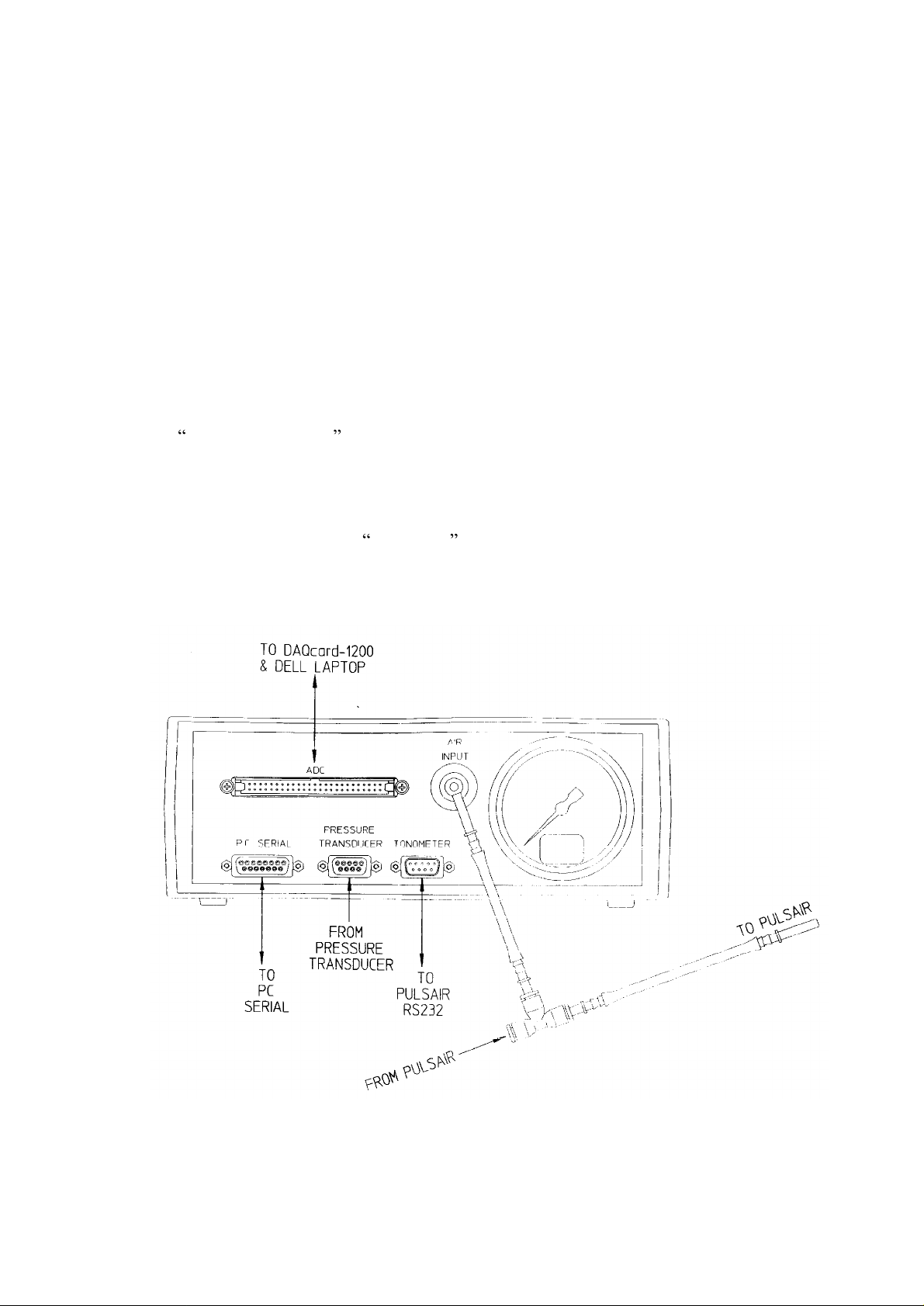

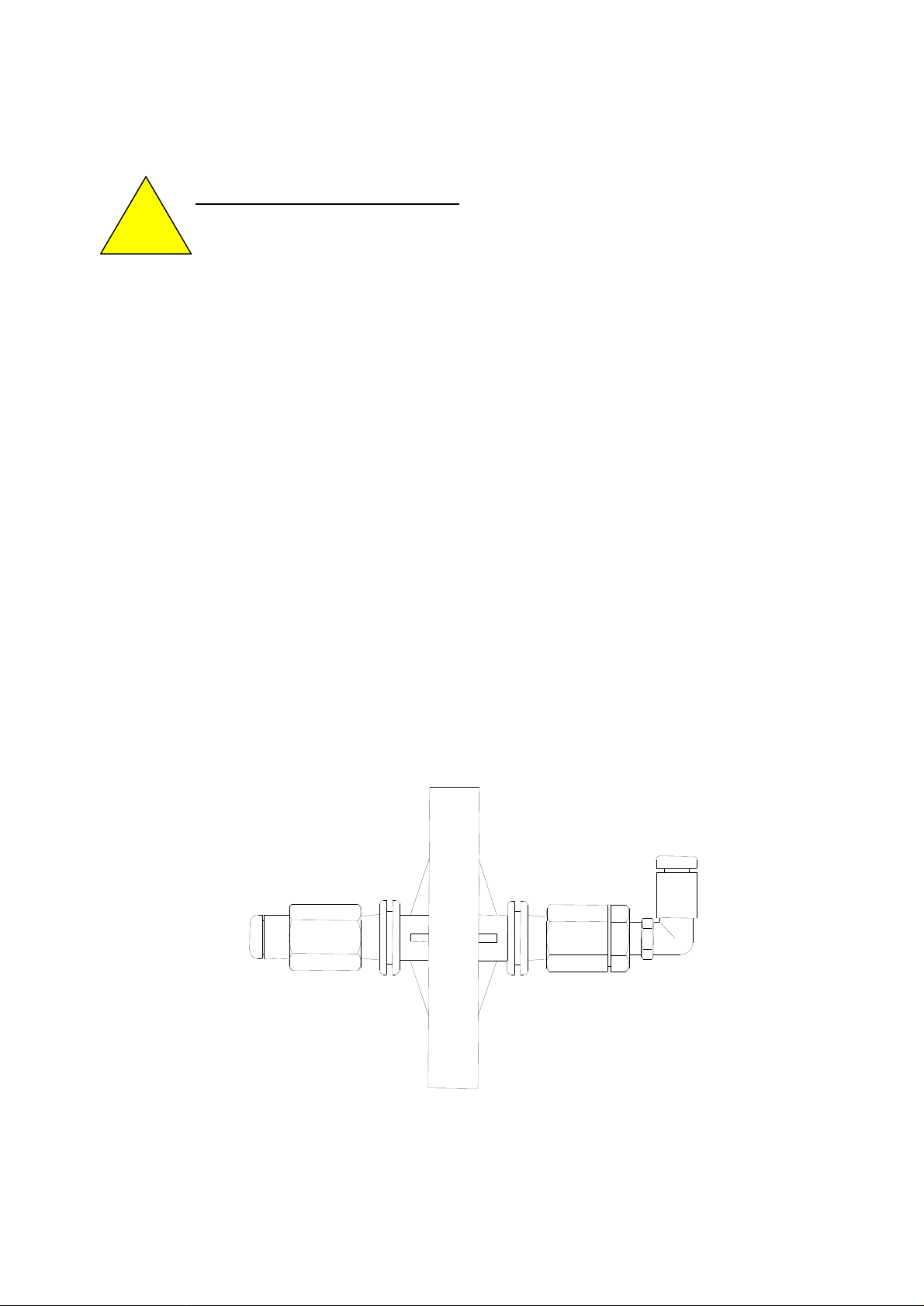

4. CALIBRATION JIG ELECTRONIC UNIT

Take cable assembly 2401

socket on the front of calibration electronic unit (as per fig 1)

Take the other end of cable assembly and

laptop computer.

Plug transducer assembly into nine way female socket on the front of calibration unit, which is

engraved Pressure Transducer (

Connect RS232 communication cable (2401

calibration unit, which is engraved Tonometer (as per fig 1)

Take the other end of the cable and connect into the back of the Puls

-P-

5127 (PC SERIAL) and connect into fifteen way A.D.C female

connect into the nine way male socket on the back of

as per fig 1)

-P-

5127) into nine way male socket on front of

air

tonometer mot

her unit.

FIG 1

Page 6

Page 11

4. CALIBRATION JIG ELECTRONIC UNIT

The last cable assembly to be connected is the national instruments

09154)

This is connected first to the multi way socket on the front of calibration unit engraved ADC

(as per fig 1).

Ensuring that the arrow on blue multi way

on ribbon cable.

Once connected, lock into position with locking clips. The smaller end is connected to the

DAQCard-1200

socket of

NOTE! WHEN CONNECTING DAQCARD INTO THE LAPTOP

!

DAQCARD

COMPUTER ENSURE LAPTOP IS SWITCHED OFF, AS THIS MAY

C

(EP79-09162)

ADC

sockets aligns with the arrow on multi way, plug

AUSE DAMAGE TO THE DAQCARD DEVICE

aligning first the white dots together as plug is pushed into

.

ADC

ribbon cable (EP79

-

Plug blue air tube as

INPUT

Connect dongle software security device to back of laptop computer. Locate into printer port

LP1.

NOTE! IF THE DONGLE IS NOT CONNECTED THE SOFTWARE WILL

!

sembly (2401

-P-5100) into the front of the electronic unit marked AIR

NOT BE ACCESSIBLE

Page 7

Page 12

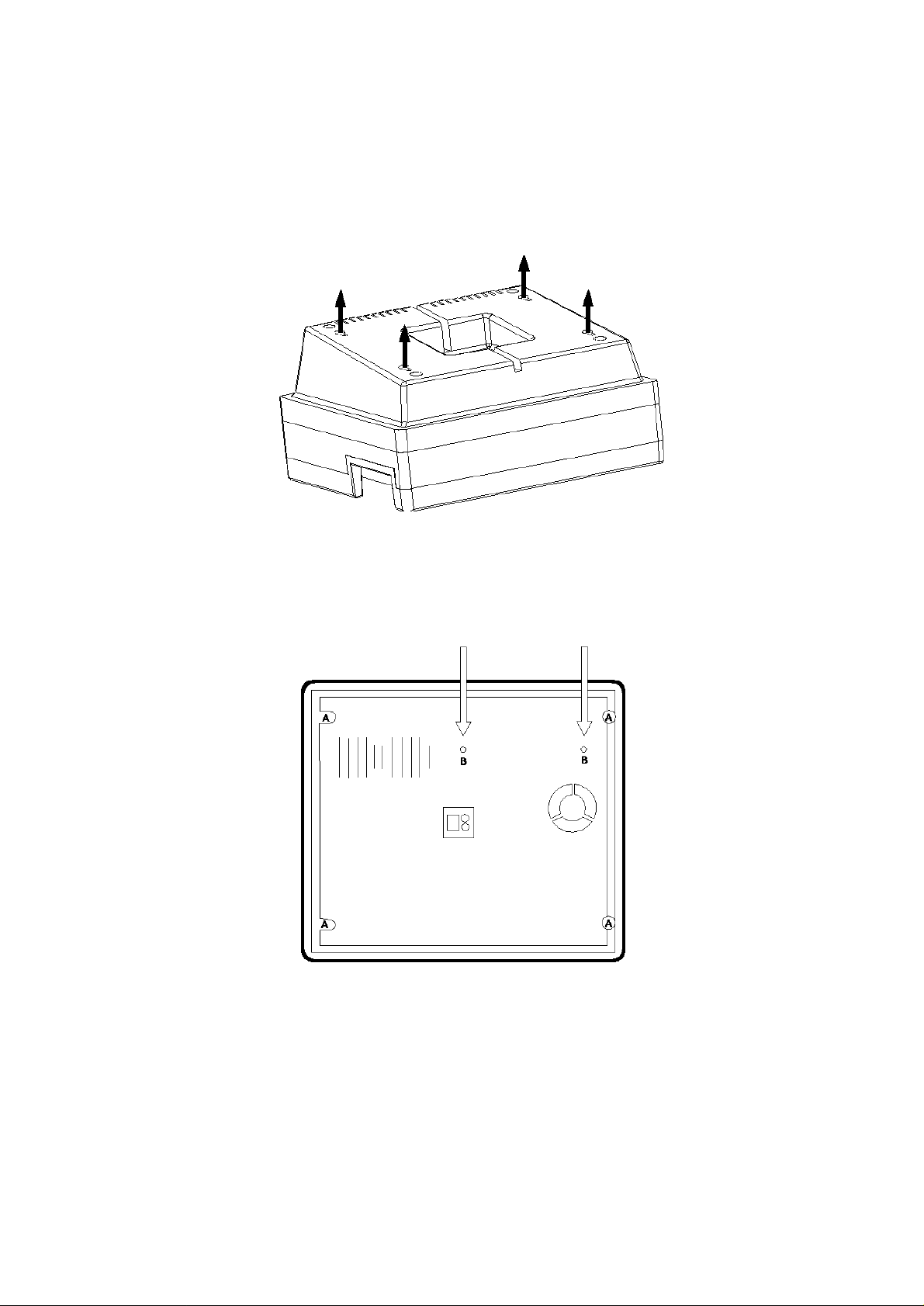

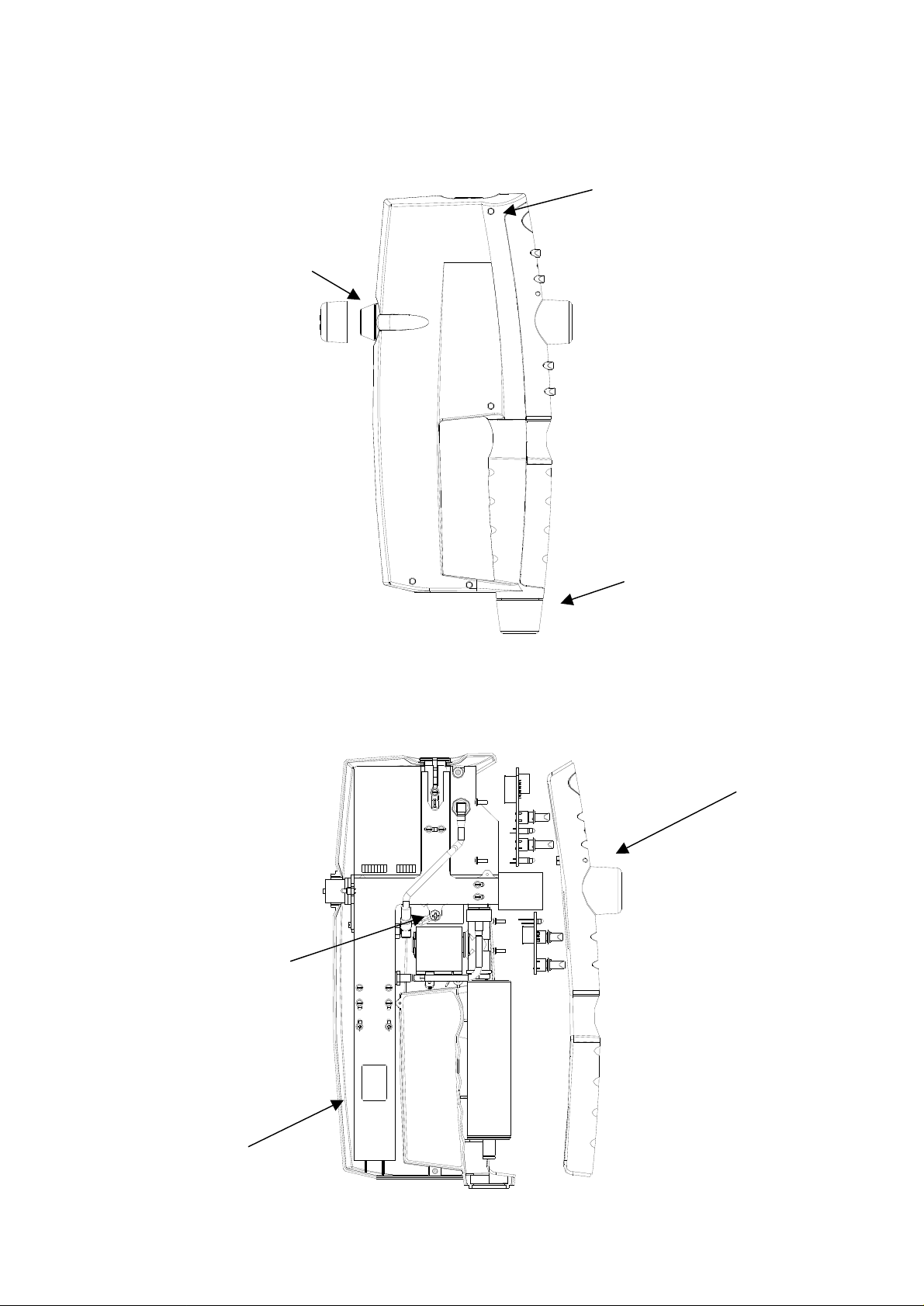

5. DIS-ASSEMBLY AND RE-ASSEMBLE OF PULSAIR

PULSAIR

1.

Remove the four M4 screws and shakeproof washers holding the base moulding to the

air

Puls

mother unit (as per fig 2)

2000/3000

FIG 2

2. While in same position remove the two M4 transit screws and shakeproof washers

holding the pump assembly in position at location B (as per fig 3)

FIG 3

3.

Remove the four M5 screws and shakeproof washers holding the top moulding to the

mother unit as seen in fig 3 position

Ensure when removing top moulding that the white microsw

4. Re-

assemble in reverse order fitting white plunger first

A

PAGE 8

itch plunger is not mislaid

Page 13

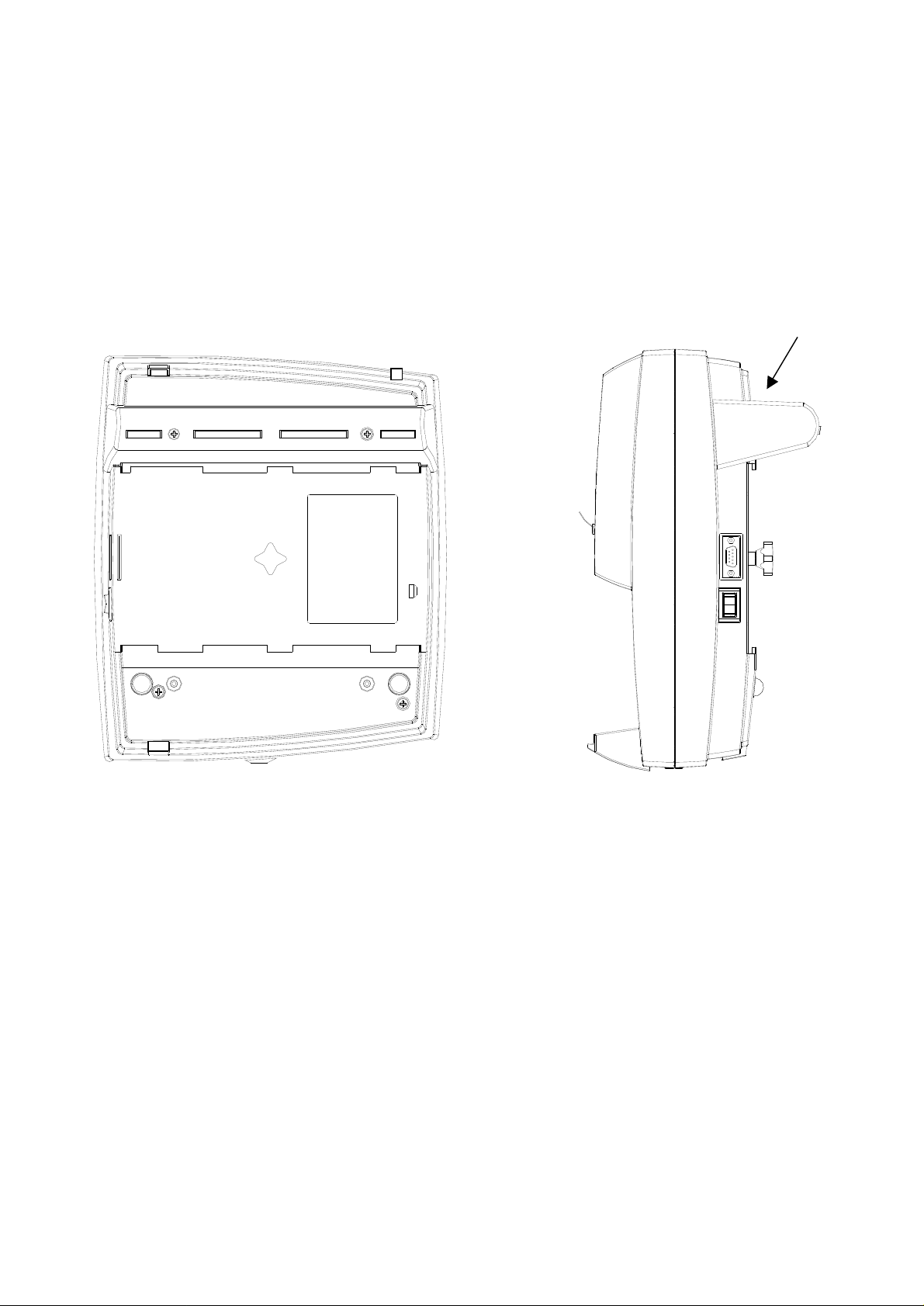

6. DIS-ASSEMBLY AND RE-ASSEMBLE OF PULSAIR

EasyEye

1. Remove the six M4 screws and shakeproof washers holding the base moulding to the

air

Puls

under the support (as per

top unit removing the wall/desk support A first to reveal the two hidden screws

fig 2A)

B

FIG 2A

2. While in same position remove the pump transit screw holding the pump assembly in position

at location B (as per fig 2A)

Ensure when removing top moulding that the white microswitch plunger is not mislaid

3. Re-assemble in reverse order fitting white plunger first

PAGE 9

Page 14

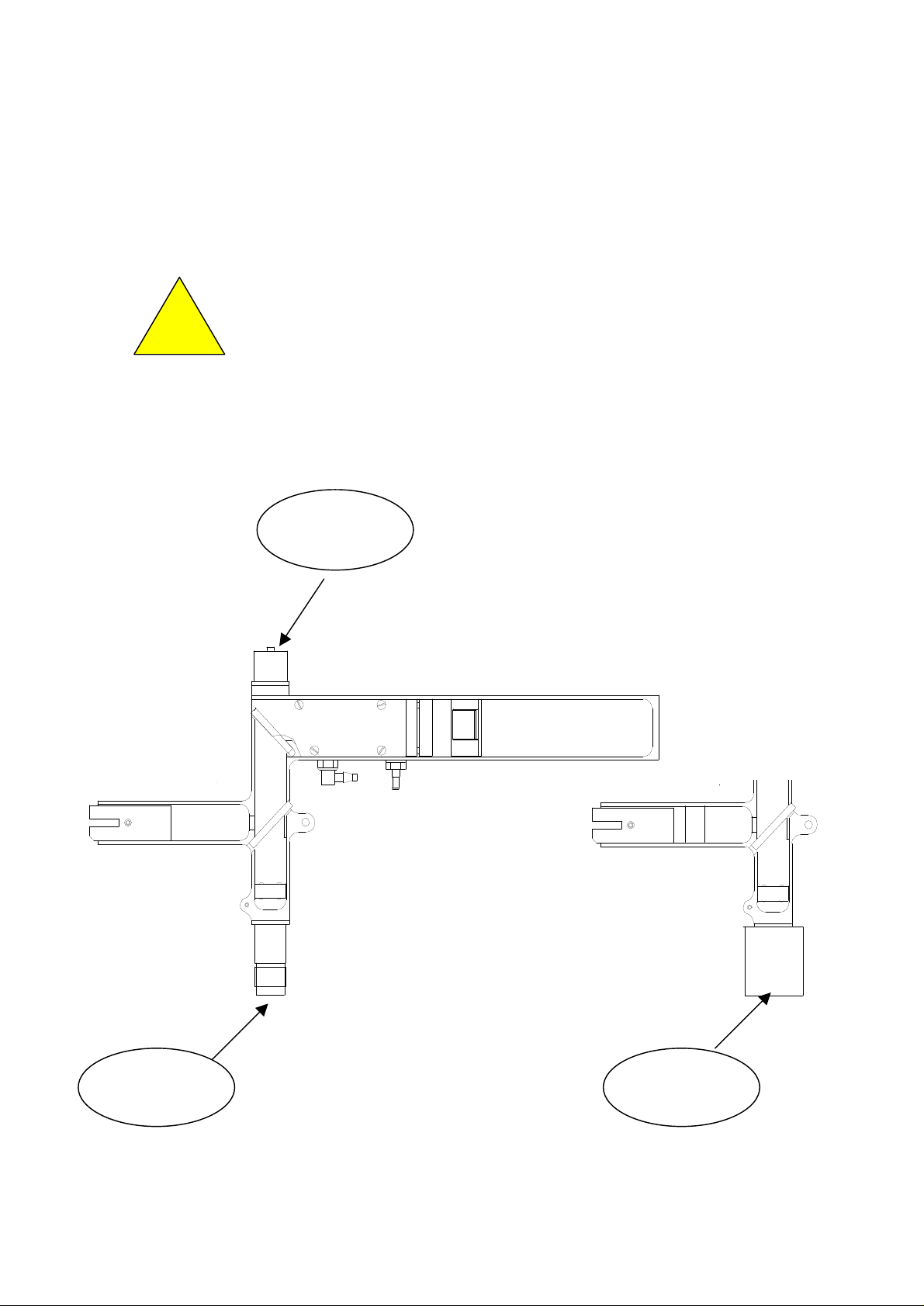

!

7

. CALIBRATION AND VERIFICATION PROCEDURE FOR

PULSAIR 2000

1.

Remove the 8 screws holding the top and bottom mouldings from the Puls

mother unit (as in fig 2).Remove the 6 screws for the Pulsair EasyEye refer to fig 2A

2.

Rem

ove the 2 transit screws if fitted from the pump assembly (as in fig 3) or fig 2A for

Pulsair EasyEye

3.

Disconnect the blue pipe from the umbilical cord assembly, which is connected to the

filter, which is located in the inner part of the Pu

4.

Connect the blue pipe from umbilical cord assembly and the connector assembly (2401

5100) from the calibration pressure gauge together and then into filter.

5.

Place the Puls

this stage)

work is taking place.

air

mother unit back into bottom moulding

as this is only a method of holding the Pulsair while calibration and repair

-3000-

air

ls

EasyEye

mother unit.

(do not replace the screws at

air

2000/3000

-P-

6.

Place the hand unit assembly onto the calibration jig, first removing puff tube shroud and

trim ring from front of the hand unit

7.

Locate the hand unit assembly from the Puls

and slide into the central locking device D (as per fig 4) LOCK

WITH LOCKING KNOB.

8.

Connect RS232 communication cable (2401

the back of Puls

air

mother unit.

When calibrating Puls

assembly. Procedure 19 and 20

air

2000/3000

air

-P-

5119) from calibration electronic unit to

onto the 3 pillars A - B and

INTO POSITION

Easyeye

use

(fig 34

the jig shown in fig 4a

and 34A).

9. Fit the mains lead to underside of the Puls

SWITCH ON

back of the mother unit

IF MAINFRAME ASSEMBLY

REPLACED REFER TO MAINFRAME MIRROR SETTING PROCEDURE

(SECTION 15

ELECTRIC SHOCK HAZARD

Electrical power is required f

). Fit the lead from the power supply for the Puls

OR MAIN P.C.B ASSEMBLY HAS BEEN

)

or the next operations

air

2000/3000

mother unit (

air

EasyEye

DO NOT

to the front or

C

Page 10

Page 15

7

. CALIBRATION AND VERIFICATION PROCEDURE FOR

FIG 4

A

PULSAIR 2000

E

D

C

-3000-

Z

B

EasyEye

X

4

4

LOCKING SCREWS

Y

PULSAIR

2000/3000

X Y Z

ind

The

screws and remove the head from the two dowels.

ecking head is now interchangea

FIG 4A

1

2

ble between the two

Z

E

4

D

3

calibration jigs undo the two locking

X

LOCKING SCREWS

4

Y

PULSAIR

EasyEye

10. Once the Pulsair is in position on calibration jig you must then follow the on screen instructions

from the calibration software.

Page 11

Page 16

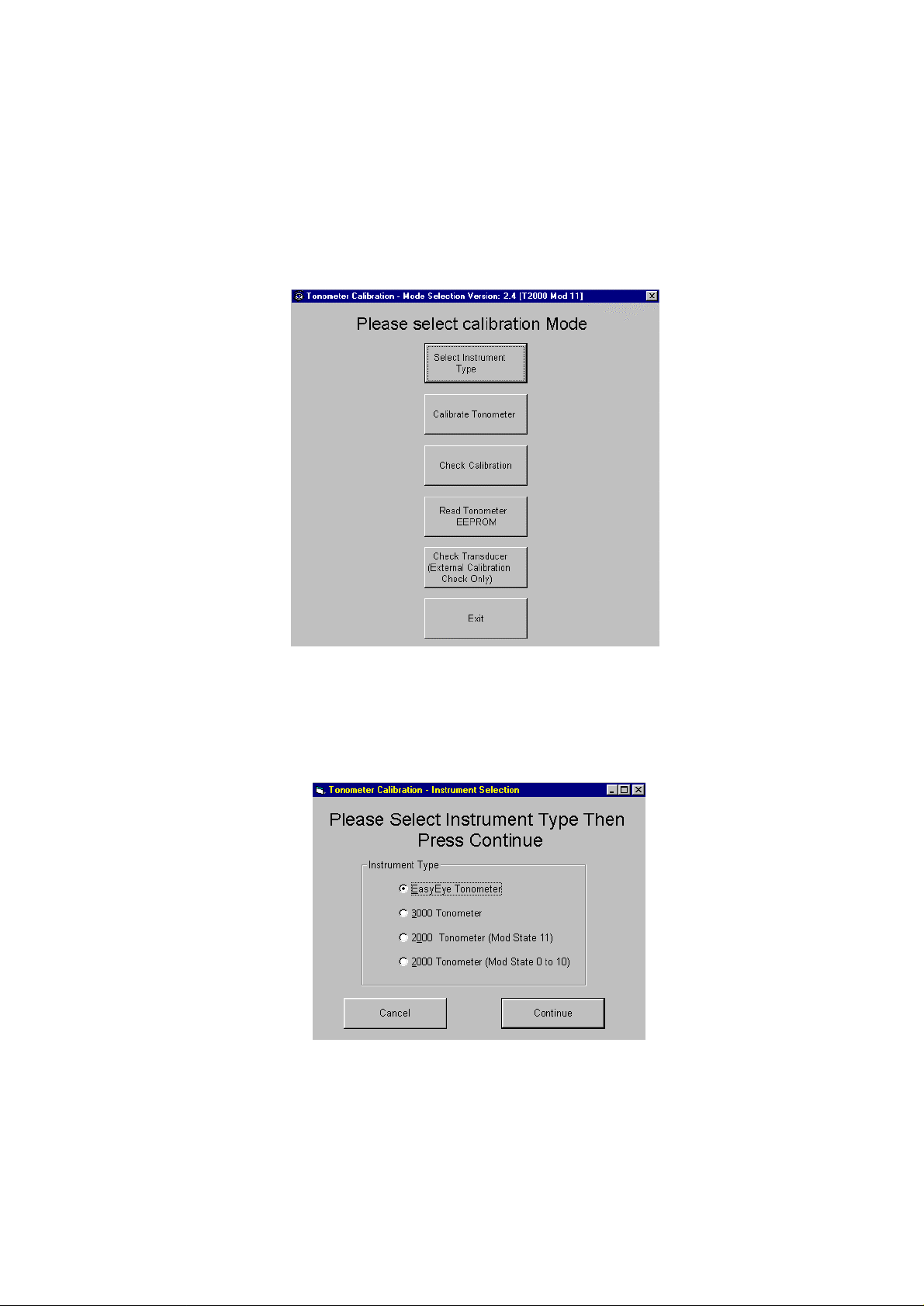

6. CALIBRATION AND VERIFICATION PROCEDURE FOR

PULSAIR 2000

Select the software icon, which is identified by an eye symbol on main screen menu. Double

click and this will take you into the main Puls

-3000-

air

menu (as per fig 5)

EasyEye

You are required to select a Puls

select instrument type

box. A tonometer menu will appear (as per fig 6)

FIG 5

air

instrument type; to achieve this you must first click on

FIG 6

You must now select a Puls

instrument type. This is verified by a black dot in the circular window

air

type to be calibrated by clicking

Page 12

onto appropriate Puls

air

Page 17

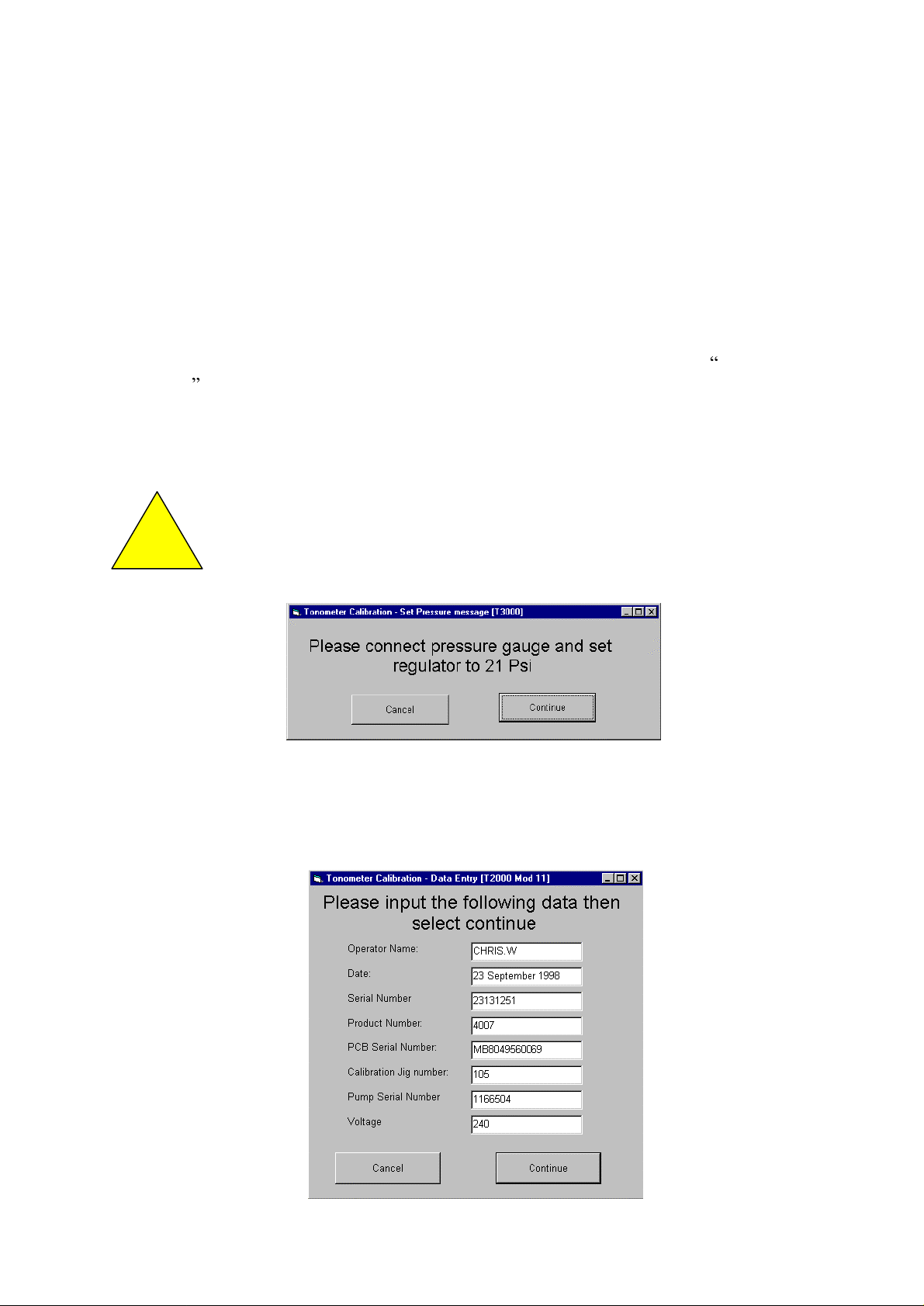

6. CALIBRATION AND VERIFICATION PROCEDURE FOR

PULSAIR 2000

WARNING IF INCORRECT PULSAIR TYPE IS SELECTED THE WRONG

CALIBRATION DETAI

Once selected press continue box to continue, this will take you back to main Puls

(as per fig 5)

You then have a choice of six instruction boxes. If calibration is required, select

Tonometer and follow on screen instructions.

When screen instruction has been carried out, press continue to proceed to the next screen

menu. This is for setting of pump pressure follow on screen instructions (as per fig 7)

!

THE PULSAIR

INFORMATION MENUS ENSURE CORRECT TYPE HAS BEEN

SELECTED

LS WILL BE INSTALLED INTO THE PULSAIR

EPROM AFTER CALIBRATION

TYPE IS DISPLAYED AT THE TOP OF ALL DATA AND

-3000-

EasyEye

air

menu

Calibrate

Press continue box and this will take you to

KEELER

for

records. Fill in data were required (as

FIG 7

DATA ENTRY

per fig 8)

. This information data is required

FIG 8

Page 13

Page 18

6. CALIBRATION AND VERIFICATION PROCEDURE FOR

PULSAIR 2000

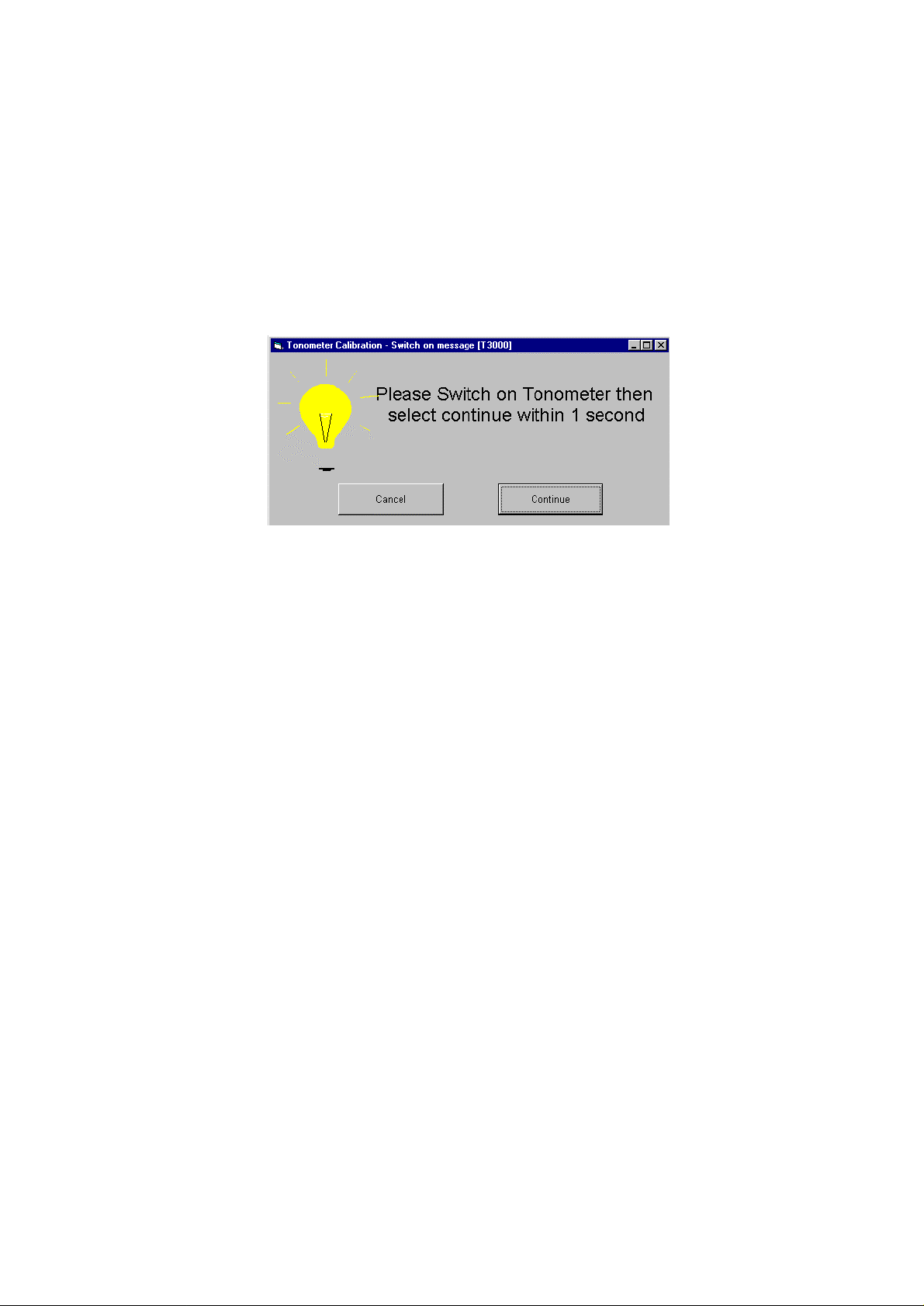

When completed press the continue box. A switch on screen message will appear (as per fig

9)

-3000-

FIG 9

EasyEye

ENSURE THAT THIS INSTRUCTION IS FOLLOWED AS STATED.

If the instructions are not followed as stated an error message will appear (as per fig 10)

The error message will take 16 seconds to appear. You must then click on the OK button,

which will take you back to main Puls

ENSURE WHEN COMMUNICATION IS MADE WITH THE

THAT THE

CALIBRATION PROCEDURE.

AS THIS WILL CAUSE AN ERROR BETWEEN THE CALIBRATION

SOFTWARE AND THE PULSAIR AND WILL RESULT IN YOU

HAVING TO EXIT THE PROGRAMME A

PULSAIR

IS NOT SWITCHED OFF DURING THE

air

menu to start procedure again.

ND RESTART.

PULSAIR

Page 14

Page 19

7

. CALIBRATION AND VERIFICATION PROCEDURE FOR

PULSAIR 2000

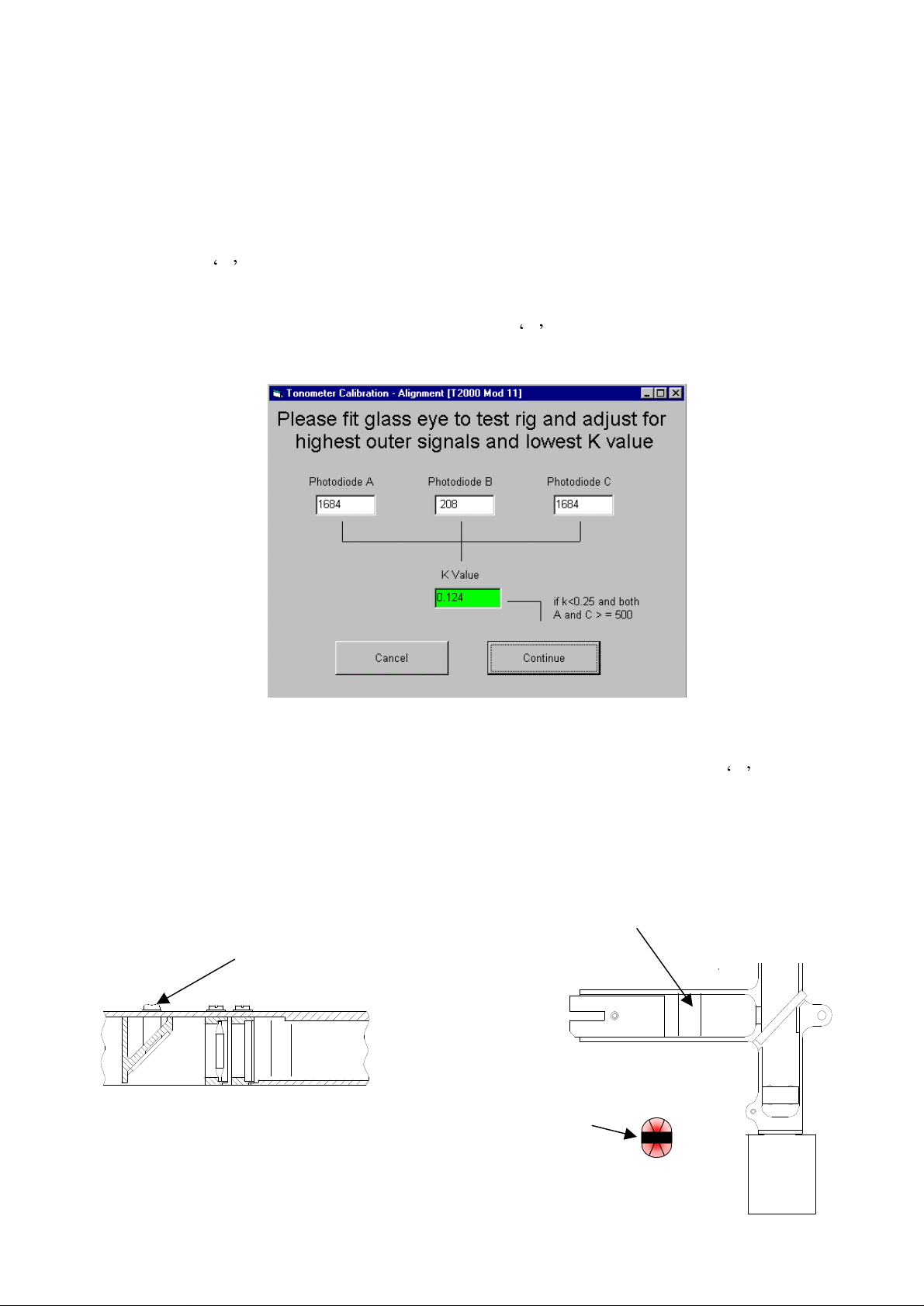

Fit dummy eye block to calibration jig in position E (as per fig 4

Follow on screen instructions for setting of

is achieved by

REFER TO SETTING OF MAINFRAME MIRROR ASSEMBLY PROCEDURE TO

using the

CORRECT METHOD FOR

X Y Z

adjusters

SETTING IS OBTAINED (SECTION 15

-3000-

FIG 10

K FACTOR

on the calibration jig (as per fig 4

ENSURE

EasyEye

and 4A

VALUE

(as per fig 11) the position

)

and 4A

)

)

FIG 11

Once correct K VALUE has been obtained the

to indicate that setting is correct.

Click onto continue box to proceed to next on screen instruction as seen in fig11A

FIG 11A

Page 15

K VALUE

box will change from red to green

Page 20

7

. CALIBRATION AND VERIFICATION PROCEDURE FOR

PULSAIR 2000

Remove

into the same position

Click onto continue box to proceed to solenoid time graph as indicated in fig 11A. This will

test valve response time for Pul

dummy eye from calibration jig position E and re-fit with pressure transducer block

sair

(as per fig 12)

-3000-

EasyEye

FIG 12

The time period in which the solenoid value will open is set automatically when the Pulsair

type is selected at beginning of calibration procedure.

This time period will change from 3.1ms normal time and 3.4ms turbo time on the

3000

and the

turbo time on

The time period is tested in steps of .3ms until correct time period is achieved and the

Pressure difference is not >

Each level is verified with 8 test puffs, (as seen in fig 12).

Once completed click continue box to proceed to next instructions.

Pulsair EasyEye

Pulsair 2000 mod state 1to10

then to

than the acceptable

a higher time period of 4ms normal time and 4.3ms

Page 16

Pulsair 2000 mod state 11

and

tolerance set in the software,

.

Pulsai

r

Page 21

6. CALIBRATION AND VERIFICATION PROCEDURE FOR

PULSAIR 2000-3000- EasyEye

You must now click onto the

now transfer calibration data into eeprom (as per fig 15).

Once completed the main data

A

tick

will now be displayed in the

data has been succesfully transferred as seen next to the EEPROM Data Written statement

OK

box below

information box will appear again (as per fig14)

EEPROM Status box.

Calibration eeprom Values Written

This will now verify that the eeprom

this will

FIG 15

FIG 15A

Page

16

Page 22

7

. CALIBRATION AND VERIFICATION PROCEDURE FOR

PULSAIR 2000

The next graph to appear is the Align Timing Regress graph (as per fig 13)

The Puls

pressure versus t

Once completed the plot of internal versus external ADC VALUES will appear on right hand

side of main graph.

All other calibration details will appear at bottom of graph.

ENSURE CORR

the

air

continue

will fire 32 times automatically to produce two graphs, the plot of external

he plot of internal pressure (as seen in fig 13)

ECT PULSAIR TYPE IS SELECTED AT THE TOP OF GRAPH

button is pressed

-3000-

EasyEye

before

FIG 13

Page 17

Page 23

7

. CALIBRATION AND VERIFICATION PROCEDURE FOR

PULSAIR 2000

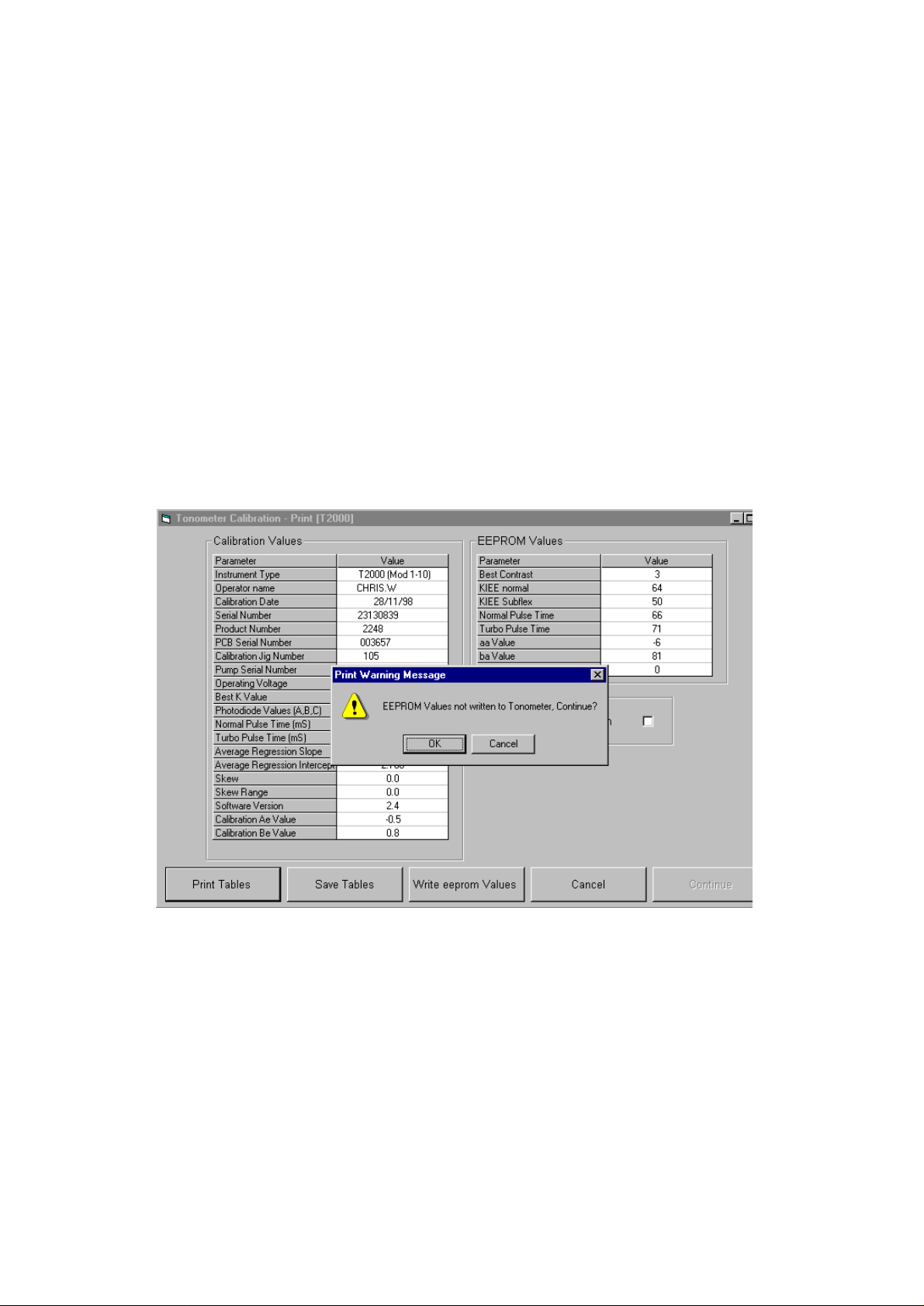

The tonometer s Calibration data details will appear next (as per

Ensure all details are correct before clicking onto

At this stage

all calibration details are ready to be transferred to the Puls

-3000-

WRITE EEPROM VALUES,

EasyEye

fig 14)

air

eeprom,

FIG 14

A verification box will now appear to ensure you that the deta

(as per fig 15)

ils will now be transferred

ENSURE WHEN CALIBRATION IS COMPLETED THAT THE PUMP

ADAPTOR LOCK NUT IS SEALED WITH LOCTITE 601 ADHESIVE

Page 18

Page 24

Page 19

Page 25

6. CALIBRATION AND VERIFICATION PROCEDURE FOR

PULSAIR 2000-3000- EasyEye

You must now click onto the

now transfer calibration data into eeprom (as per fig 15).

Once completed the main data

A

tick

will now be displayed in the

data has been succesfully transferred as seen next to the EEPROM Data Written statement

OK

box below

information box will appear again (as per fig14)

EEPROM Status box.

Calibration eeprom Values Written

This will now verify that the eeprom

this will

FIG 15

FIG 15A

Page 19

Page 26

7

. CALIBRATION AND VERIFICATION PROCEDURE FOR

PULSAIR 2000

At this stage if the calibration data has not been transferred, the continue button will not be highlighted

and will not allow you to proceed,

If you were to click onto

reminder that you must write to the eeprom before the completion of the calibration.

When calibration is completed, click continue box to return to main menu.

Print tables or Save tables, a warning message will appear (as per fig 16) as a

-3000-

EasyEye

FIG16

PAGE 20

Page 27

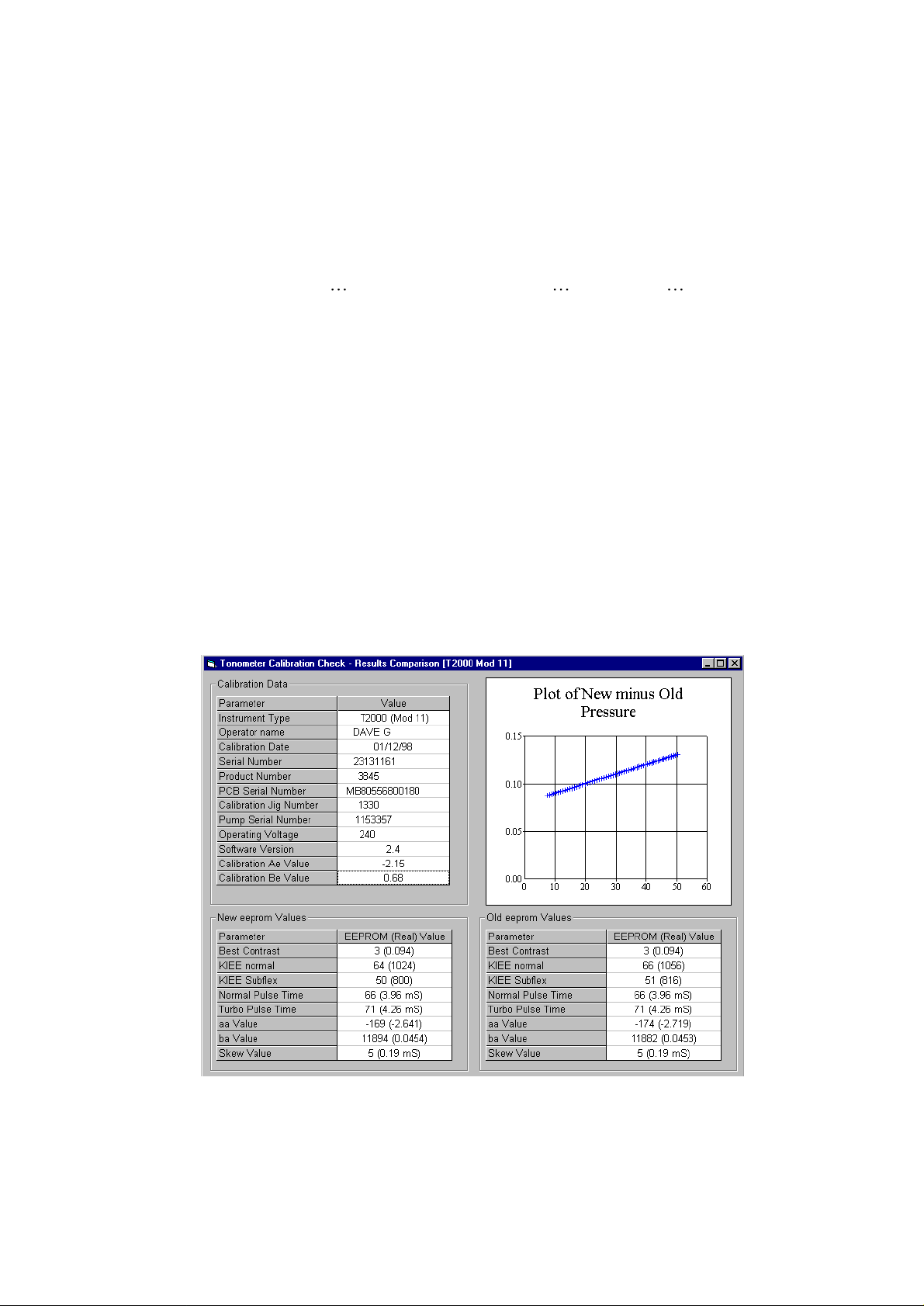

by clicking onto the highlighted Check Calibration box.

7

. CALIBRATION AND VERIFICATION PROCEDURE FOR

PULSAIR 2000

To verify calibration you must start at main Puls

Select Instrument Type

Then

air

Puls

Then select

All on screen instructions except for the se

the previous calibration instructions, but will change after the Align Timing Regress graph as

(per fig 13).

At this stage a new graph will appear, which is the comparison graph (as per fig17). This will

v

NOTE! The pump pressure on screen instruction will not appear in this part of the

procedure, as the pump pressure must not be adjusted in the verification of the Puls

calibration.

2000 mode state 0-10

CHECK CALIBRATION

erify the calibration

where you must then select correct Puls

air

Puls

2000 mode state 11

-3000-

air

tting of pump pressure (

EasyEye

menu as before

Puls

air

air

3000

see note

to be checked i.e.

air

Puls

) are the same as

EasyEye

air

FIG 17

The software will compare old eeprom

be calculated to see if they correspond

values against the new eeprom values, which will then

Page 21

Page 28

7. CALIBRATION AND VERIFICATION PROCEDURE FOR

PULSAIR 2000

The pressure errors of the Puls

The errors at 10 and 20mmHg should not exceed more than

occurs the Puls

air

must be recalibrated.

air

will now be displayed on the graph (as seen in fig17)

-3000-

EasyEye

Plot of Ol

Pressure

plus or minus

d minus New

1 mmHg. If t

his

FIG 17A

If when checking the old eeprom values against the new values (as seen in fig 17A) the Best

Contrast is set at a value of 255 and the KIEE normal is set at a value of 255 it would indicate

that the cal

The Pulsair must now be recalibrated, as the unit will not auto fire when focussed on the eye.

Once completed, click continue box to return to main Puls

When finished,

communication cable from back of Pulsair.

Refit blue pipe from umbilical cord assembly to filter assembly and add tested label (EP39

05372) to top of pump assembly diaphragm block

Remove hand unit from calibration jig

Re-assemble puff tube shroud

and

fig34A

Re-fit transit screws to pump and 8 screws holding

Re-fit

Refer to

ibration data is corrupt.

DISCONNECT MAINS LEAD

the 6 screws

procedure 5 and 6.

holding

and trim ring to hand unit an

the

top and bottom moulding

Page 22

air

menu

from mother unit. Remove RS2

d locking screw. Refer to fig34

the

top and bottom moulding

to the

air E

P

uls

asyeye

32

-

air

(P

uls

in reverse order.

2000/3000

)

Page 29

8

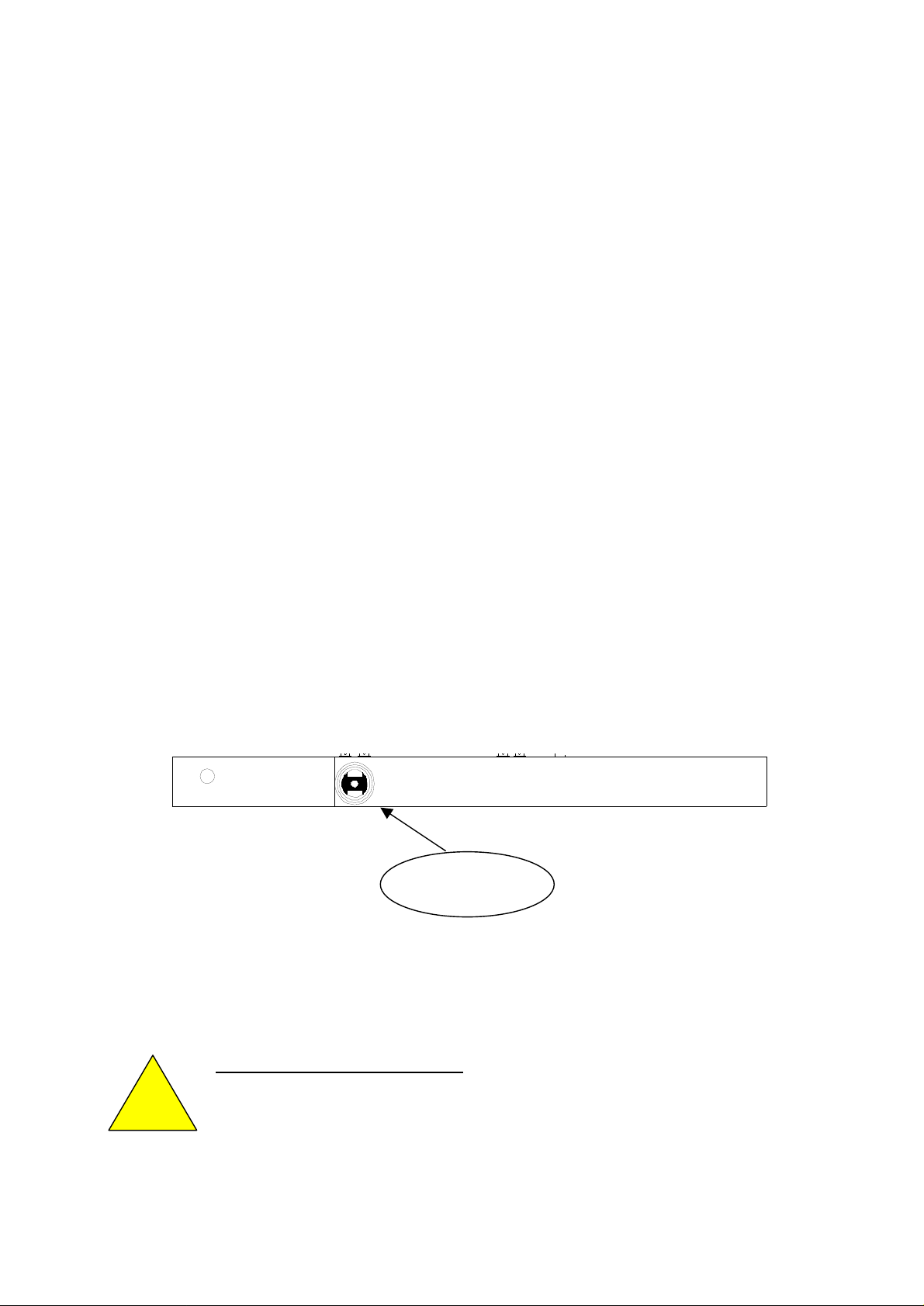

. CLEANING OF THE PULSAIR OPTICS

1.

First remove puff tube shroud and eyepiece shrouds before cleaning procedure can

take place.

!

2.

Using the cleaning wipes (2110

from fro

Ensure when cleaning the lenses that they are not touched with the

fingers as these are coated lenses and will easily smear

nt of puff Tube assembly and viewing lens assembly (as per fig18)

CLEAN

THIS FACE

-P-

7018) in a circular motion remove any dirt deposits

Pulsair 2000/3000

CLEAN

THIS FACE

FIG 18

Page 23

PULSAIR EasyEYE

CLEAN

THIS FACE

Page 30

9. REPLACEMENT OF AIR FILTER

Electrical power is not required for this operation and the mains suppl

!

Should be removed before starting next operation.

1.

Remove top and bottom mouldings as described in procedure 5 and 6

ELECTRIC SHOCK HAZARD

y plug

2.

Disconnect blue tube from both sides of filter assembly (as in fig 19)

3.

Remo

ve filter from bracket and replace with new filter assembly (2401

Reconnect blue tubes

4.

Refer to calibration procedure 7 for recalibration instructions.

5.

Refer to re-assemble of Pulsair procedure 5 and 6

-P-

6744)

FIG 19

Page 24

Page 31

Page 24

Page 32

10

. UMBILICAL CORD ASSEMBLY REPLACEMENT

PULSAIR

Electrical power is not required for this operation and the mains supply plug

!

ELECTRIC SHOCK HAZARD

Should be removed before starting next operation.

2000/3000

air

top and bottom mouldings as described in procedure

1.

Remove the Puls

2.

Disconnect blue tube from filter in mother unit.

3.

Remove either M4 nut from earth stud on microswitch bracket or M4 screw from

transformer

4.

Remove cable ties holding earth wiring to wire loom, unplug 8 way Molex connector

from power supply P.C.B.

5. Remove M3 screw holding P clip and blue pipe from power supply P.C.B

6.

Remove umbilical cord assy from mother unit.

7. At

hand unit end, remove puff tube shroud, trim ring, eyepiece shroud and M3 locking

screw at bottom of hand moulding (as per fig 34).

5

and 6

side of

8. Remove top hand unit moulding

9.

Disconnect Molex connector containing 8 wires from P.C.B.(as per fig 20)

10.

Remove the M3

11.

Remove the screw holding yellow wire and bulb contact to top of mainframe. Cut the blue

tube from hand unit value to mainframe and then remove the umbilical cord assembly.

NOTE!

ca

12. Re-assemble new umbilical cord assy in reverse order.

For re-calibration.

The blue tube removed from hand unit value must be replaced before reassemble

n take place.

screw from centre of mainframe holding earth wires (as per fig 20).

Refer to calibration procedure 7

Page

25

.

Page 33

M3 CENTRE

AND

EARTH WIRES

10

. UMBILICAL CORD ASSEMBLY REPLACEMENT

MOLEX

CONNECTOR

PULSAIR

2000/3000

BULB CONTACT

SCREW

SCREW

BLUE TUBE

FROM VALVE

FIG 20

Page

26

Page 34

11

. UMBILICAL CORD ASSEMBLY REPLACEMENT

EasyEye

Electrical power is not required for this operation and the mains supply plug

!

1.

2.

3.

4.

5. At the hand unit end, unscrew the puff tube shroud and the end cap from the hand unit

Should be removed before starting next operation.

Remove the Puls

Disconnect blue tube from filter in the mother unit.

Unplug the 8 way Molex connector from power supply P.C.B.

Remo

mouldings

moulding to the bottom moulding.

ELECTRIC SHOCK HAZARD

air

top and bottom mould

ve the umbilical and cable gland assemble from the mother unit.

refer

to Fig 34A, remove the four

ings as described in procedure

locking

5 and 6

screws holding the top hand unit

6.

Remove

7.

Unplug the 8-way

the handunit value

8.

Remove the M3 screw from centre of

moulding

9.

Cut the blue tube from hand unit value to

the

NOTE!

can take place.

12. Re-assemble new umbilical cord assy in reverse order.

For re-calibration.

the top hand unit moulding and the front panel assembly

molex

(as per fig

(as per fig 20A).

reservoir

you

now remove the umbilical cord assembly.

The blue tube removed from hand unit value must be replaced before reassemble

connector

20A).

from the P.C.B

mainframe holding

the

mainframe, disconnect the blue tube from

and

remove the clip

it to the bottom hand unit

Refer to calibration procedure 7

from the coil on

.

Page

27

Page 35

CONTACT

11

. UMBILICAL CORD ASSEMBLY REPLACEMENT

MOLEX

CONNECTORS

EasyEye

BULB

SCREW

M3 CENTRE

SCREW

CLIP

(COIL)

BLUE TUBE

FROM VALUE

FIG 20A

Page

28

Page 36

reconnected from mainframe assembly with brass restrictior.

12

. REPLACEMENT OF MAINFRAME & P.C.B. ASSEMBLIES

! Electrical power is not required for this operation and the mains supply plug

!

Shou

1.

Disconnect

procedure 10

2.

Remove the four screws holding P.C.B. to mainframe and earth wire; disconn

to transducer. Replace defective part (mainframe assembly or main hand unit P.C.B)

3.

Ensure when re-assembling that the serial number label is removed from the P.C.B and re

attach

7mm cut out to clear solder earth pad (as per fig 21) and blue tube to transducer is

4.

Fit M2 washer between bulb contact and P.C.B prior to the fitting of the mainframe;

ensure the second bulb contact is fitted to the mainframe and the earth lead is attached.

5. Re-

6.

assemble umbilical cord assembly to bottom hand unit moulding.

Fit

the dummy ha

EasyEye prior to calibration so setting of mainframe mirror assembly can be carri

(See fig 24 procedure 15

attached

ELECTRIC SHOCK HAZARD

ld be removed before starting next operation.

the

umbilical cord assembly from hand unit as d

and 11

ed to the top of the mainframe.

. (from operation 7 onwards is required)

ndunit case (EP29-04207) Pulsair 2000/3000(EP39-50272) Pulsair

.) and fig 24A for Pulsair

escribed in

The insulation tape must be fitte

Easy Eye ensure the calibration ring

the

previous

ect blue tube

d to the P.C.B with

ed out.

is

7.

Refer t

(CUT OUT 7MM SQUARE IN RP99-99325 TAPE

TO CLEAR SOLDER EARTH PAD)

o calibration procedure 7

for recalibration instructions.

FIG 21

ATTENTION

Observe precautions

For handling

Electrostatic

Devices

RP99-99325

Page 29

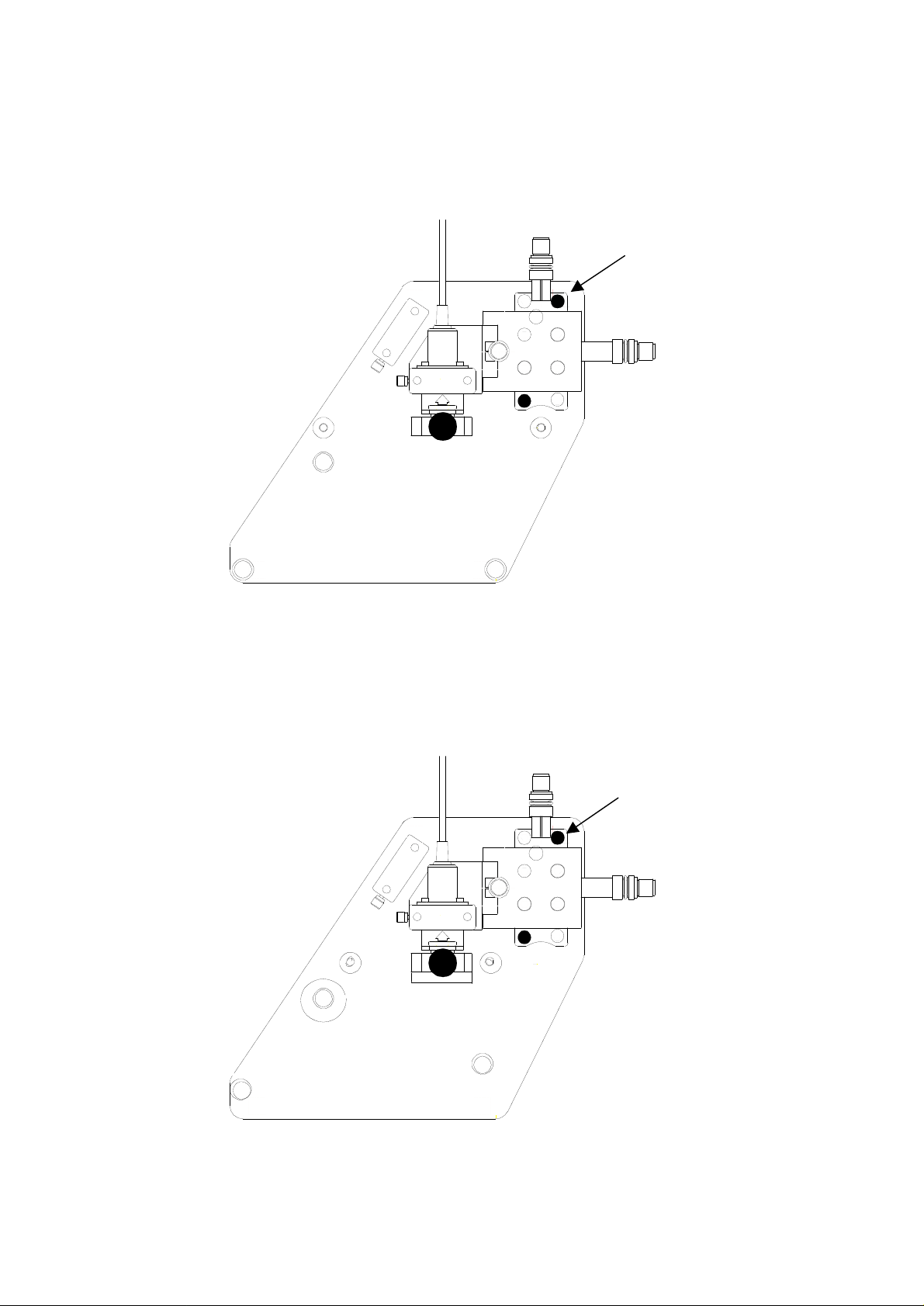

Page 37

13. REPLACEMENT OF PUMP PARTS

PULSAIR 2000/3000

! Electrical power is not required for this operation and the mains supply plug

!

1.

2.

3.

4.

should be removed before starting next operation.

Disconnect blue tube fitting from elbow connection on side of pump adaptor as in

(fig22A)

Remove the three

WHITE, GREEN/YELLOW)

Remove coil and valve assembly from side of pump adaptor as in (fig 22C), using 14 and

15mm spanners.

Remove filter silencer from underside of pump adaptor fitted to pump block (as per fig

22D).

ELECTRIC SHOCK HAZARD

mains

wires connected to the coil and valve assembly

as

in (fig 22B).

(BLACK,

5.

Remove pump adaptor (EP39-05869) and BSP/NP

(as per fig 22E) using 14mm spanners

ENSURE WHEN REFITTING BSP/NPT

82056) is secured around thread

6.

Replace faulty components and re-assemble in reverse order.

7.

Refer to calibration procedure 7 for re-calibration instructions.

D

s

adaptors a small amount of PTFE tape (PP02

E

T adaptors (EP39

-06896) from pump

N

L1

B

-

A

FIG 22

Page 30

C

Page 38

A

14.

REPLACEMENT OF PUMP PARTS

PULSAIR

! Electrical power is not required for this operation and the mains supply plug

!

should be removed before starting next operation.

1.

Disconnect blue tube fitting from elbow connection on si

(fig

22A/A

2. Remove the two

in (fig 22A/

3.

Remove coil and valve assembly from side of pump adaptor as in (

and 15mm spanners.

4.

Remove filter silencer from underside of pump adaptor fitt

5.

Remove pump adaptor (EP39-05869) and BSP/NPT adaptors (EP39

(

fig 22A/D) using 14mm spanners

ENSURE WHEN REFITTING BSP/NPT

6.

82056) is secur

ELECTRIC SHOCK HAZARD

)

wires connected to the coil and valve assembly

B)

ed around threads

EasyEye

adaptors a small amount of PTFE tape (PP02

de of pump adaptor as in

(BLACK, WHITE )

fig 22

A/C ) using

ed to pump block (as per fig ).

-06896) from pump

a 14

as

-

7.

Replace faulty components and re-assemble in reverse order.

8.

Refer to calibration procedure 7 for re-calibration instructions.

B

C

D

FIG 22A

Page 31

Page 39

15

. SETTING OF MAINFRAME MIRROR ASSEMBLY

AND TARGET FOR PULSAIR EasyEye

1.

Place

the

hand unit assembly onto calibration jig as shown in (FIG 4

this stage ensure that the dummy

2.

Refer to calibration procedure 7

setting of K value is required (as per fig 23)

3.

Loosen the two screws holding the mirror assembly in position on mainframe

24) and adjust until the best reading is obtained on K value. Refer to example shown

below.

hand unit case is fitted.

and follow on screen instructions for calibration until the

or 4a

NOTE

).

! At

(as per fig

FIG 23

.

4. A and C photodiode value should be set equally first before obtaining the best K value.

Once achieved, lock mirr

5. Only on the Pulsair EasyEye will you see the bow tie target when you view through the

Eye

lens, the target must be adjusted to the central position as shown in fig 24A.

Adjust mirror

screws

FIG 24

or assembly into position as per fig 24.

Pulsair EasyEye

Adjust target

screws

BOW TIE

TARGET

FIG 24A

Eye lens

PAGE 32

Page 40

16

. UPGRADE OF POWER SUPPLY (P.C.B.)

THIS PROCEDURE APPLIES TO PULSAIR 2000 ONLY

1. Verify voltage at diode D6 (anode side of diode) and PL4/1 connectors on power supply

P.C.B. as per figure 25. If voltage is 17 volts, the power supply P.C.B

! Electrical power is not required for this operation and the mains supply plug

!

2.

First remove P.C.B. from the mother unit by disconnecting wire looms PL1-PL4 and PL3

From the P.C.B plug connections.

3. Remove the five-

4.

The P.C.B. can now be removed.

5.

The next part of this procedure should only be carried out on

3000 has a higher drive voltage of 23.8 volts on the solenoid value

ELECTRIC SHOCK HAZARD

Should be removed before starting next operation.

m3 screws holding the

power supply P.C.B. in position.

Pul

. must be modified.

sair

2000

as the Pulsair

6. REPLACE resistor R4 from 1k5 to 1k8 OHMS (

voltage at D6 from 17 volts to 19.95 volts which enables the solenoid value to be more

responsive.

7. Re-

8.

assemble power supply P.C.B. in reverse order.

Refer to calibration procedure 7

R4

. For re-calibration.

on Puls

air

2000 only

) this will increase

ATTENTION

Observe precautions

For handling

Electrostatic

Devices

Page 33

C12

Page 41

ct

orientation

17. GENERAL TROUBLE SHOOTING

PULSAIR WILL NOT AUTO FIRE

Envelope of bulb discoloured

Front puff tube lens contaminated with splash back from tear film - R

puff tube lens

Puff

tube lens orientation incorrect or broken (as per fig 26) - R

mainframe is required

Calibration data erased in eeprom - R

No red light from hand unit - Check

equires replacement of bulb

- R

equires recalibration

6volt line to bulb and bulb contacts are n

equires cleaning off the

equires realigning or new

ot broken

FIG 26

NOTE! Corre

PULSAIR HAND UNIT FAILURE

Electrical power is required for the next test operations and the mains supply plug

should be inserted into the

ELECTRIC SHOCK HAZARD

Pulsair

mother-unit before starting.

Page 34

Page 42

17. GENERAL TROUBLE SHOOTING

Hand unit display will not function

Pulsair 2000/3000

Verify the T2amp fuse inside the

If faulty remove and replace.

Verify crimps on fuse holder

If faulty remove crimps and solder wires to fuse holder.

Verify the 10volt

required for this test (Edge connector PL1 pins 3&4)

If there is low or no voltage verified at this point, the transformer must be replaced.

Verify the 5volts DC supply from pow

and red wires are required for this test (PL4 edge connector on power supply PCB pins 1&4)

If there is low or no voltage verified at this point, the power supply P.C.B must be replaced

AC supply from transformer to power supply. The red and orange wires are

Pulsair

mother unit

er supply P.C.B in mother unit, to hand unit. The black

Verify the

The black and red wires are required for this test (Edge connector PL2 on main P.C.B 1&4)

If there is low or no voltage verified at this point, the umbilical cord asse

Hand unit will not puff on demo

Pulsair 2000/3000

Verify the 400ma fuse inside mother unit

If faulty remove and replace

Verify crimps on fuse holder

If faulty replace crimps and solder wires to fuse holder

Verify t

are required for this test (Edge connector PL1 on power supply P.C.B pins 1&2

If there is low or no voltage verified at this point, the transformer must be replaced

5volts DC supply from power supply P.C.B to the inside of the hand unit main P.C.B.

mbly must be replaced

he 20volts AC supply from transformer to power supply P.C.B. The Grey and blue wires

)

Page 35

Page 43

17

. GENERAL TROUBLE SHOOTING

Verify the 19.9volts DC supply on the Puls

the power supply P.C.B in the mother unit to the hand unit solenoid valve. The black and blue

wires are required for

(Edge connector PL4 on power supply PCB pins 1&2)

If there is low or no voltage verified at this point, the power supply P.C.B must be replaced

Verify the 19.9volts DC supply on the Puls

the

hand unit on the main P.C.B. The black and blue wires are required for this test (Edge

connector PL2 on main P.C.B pins 1&3)

If there is low or no voltage verified at this point, the umbilical cord assembly must be replaced

Verify inside

If faulty remove and replace

Verify airflow from pump.

If no airflow from the pump the pump must be replaced

Pulsair

this test

mother

unit the inline fuse to the pump (T250ma)

air

2000 and 23.8volts DC on the Puls

air

2000 and 23.8volts DC on the Puls

air

3000 from

air

3000 in side

PULSAIR MOTHER UNIT NO POWER

Pulsair 2000/3000

Verify fuses on under side of

If faulty remove and replace

Verify mainswitch on side of

If faulty remove and replace

Verify

If faulty replace

Pulsair

mains power cord lead

Pulsair

Pulsair

INCONSISTENT AIR FLOW

Check pump adaptor for air flow

If faulty repl

Check pump assembly for airflow

If faulty replace

ace

mother unit

mother unit

Page 36

Page 44

17. GENERAL TROUBLE SHOOTING

BATTERY not charging Pulsair easyeye

Check 5amp fuse inside Pulsair

If faulty replace

PRINTER will not function Pulsair easyeye

Check paper is pre

Check lid is shut

Check printer is switched on

If Printer is faulty refer to section 21

NO POWER

Check voltage from wall mounted P.S.U

12volts should be present.

sent inside printer

Pulsair easyeye

If faulty replace

NO POWER Pulsair easyeye

Verify the voltages from the mother unit power supply P.C.B

Check the voltages at the molex connector

SK1

pin8

(orange) = common

SK1 pin7

SK1 pin6

SK1 pin5

SK1 pin4

SK1 pin3 (white) = -12volts

If faulty replace the P.S.U

(blue) = 24volts

(yellow) = 6volts

(red) = 5volts

(black) = common

MOTH

SK1

Page 37

ER UNIT

Page 45

17. GENERAL TROUBLE SHOOTING

NO POWER Pulsair easyeye

Verify the voltages at the hand unit P.C.B

Check the voltages at the Molex connector

SK2

pin8

(orange

SK2 pin7 (yellow) = 6volts

SK2 pin6

SK2 pin5

SK2

SK2 pin3

If faulty replace the pulsair umbilical cord assembly (Procedure 11)

(blue) = 24volts

(red) = 5volts

pin4

(black) = common

(white) = -

) = common

12volts

HAND UNIT

SK2

Page 38

Page 46

18

. TROUBLE SHOOTING THE SOFTWARE

When calibrating or verifying the calibration of the Puls

show warning messages or graphs to give a indication that there is a problem with the Puls

this stage

Communication Link Error

communication cable has not been connected between the Puls

or when switching on the Puls

time period requested.

of the procedure (as seen in fig 27)

FIG 27

(as shown in fig 27) is an indication that the RS232

air

after being instructed by the software, has not taken place in the

air

the software has been designed to

air

and calibration electronic unit,

air

at

FIG 28

The graph above - Puff Pressure Error

pressure transducer on calibration jig. This would suggest

pump (no air pressure!) or that there may be a connection problem

If the correct pump pressure is not set to 21psi this warning graph will then also appear.

(fig 28) indicates that there is no pressure seen by the

Page

that there is a pressure problem from

with air pipes from air filter!

39

Page 47

18

. TROUBLE SHOOTING THE SOFTWARE

The graph below (Pressure versus Time) shows how the Puls

set a Pulsair 3000 valve time out setting to a time period of 3.1ms (as shown in fig 29) this has

not been ach

Once this has occurred the software is designed to go back above the point of failure to try and

reset the time period

This has also failed (as seen in fig 29).

At this stage the umbilical

Refer to procedure 9 and 9A for replacement of umbilical cord assembly.

ieved as illustrated.

by reducing the time period s adjustment in step of.06ms.

cord assembly must now be replaced, as the valve is faulty.

air

calibration software has tried to

FIG 29

The graph reference (fig 30)

fallen out of

The reason for this could be as follows! Low output pressure from pump assembly, Pump adaptor

faulty or requires internal cleaning. Air filter blocked requires replacing.

Leak in main

the recommended calibration specification pressure setting of 21psi.

air system (mother unit or hand unit)!

Puff PressureWarning

Page 40

is an indication that the pump pressure has

Page 48

18. TROUBLE SHOOTING THE SOFTWARE

When fault of pressure problem has been identified and then rectified the Puls

recalibrated.

air

must be

FIG 30

The graph reference (fig31 and 31A)

overfl

ow

indicates that there is no internal pressure profile or a low signal from the hand unit s

P.C.B pressure transducer (as seen in fig 31 and 31A).

Run time error 6 overflow will only appear on Puls

A faulty internal transducer, t

restrictor could be the cause of this problem.

!

should be removed before starting next operation.

If found to be the transducer on the hand unit Printed circuit board, the printed circuit board must

be replaced

Reference procedure 12. Rep

After replacement the Puls

Electrical power is not required for this operation and the ma

!

ELECTRIC SHOCK HAZARD

he air pipe not connected to transducer, blockage in air pipe

lacement of Mainframe and P.C.B assemblies.

air

must be recalibrated

INTERNAL PUFF WARNING

and

Run time error 6

air

mod state 0-10 units

- refer to recalibration procedure 7.

ins supply plug

Page 41

Page 49

18

. TROUBLE SHOOTING THE SOFTWARE

FIG 31

FIG 31A

Page 42

Page 50

18

. TROUBLE SHOOTING THE SOFTWARE

In reference to (fig 32)

0.000 in red.

This is a warning that the bulb is not functioning correctly, which may be caused by

broken bulb contact, a blown bulb or a faulty bulb

Verify the voltage to bulb from power supply (check 6-volt power line),

Verify the main frame optical system; check fig 24 or 24a

mainframe mirror assembly)

Ensure tran

similar fault

sducer has not been left on calibration jig when setting

Alignment

.

of

K value

there is no reading shown in the K value box, only

of procedure15

K value,

. (

Setting of

this would give a

a loose or

FIG 32

If the dongle security device is not connected into the back of laptop computer which is located

into printer port LP1, a Error message will app

Fig 33

Page 43

ear (as per fig 33)

Page 51

18.

TROUBLE SHOOTING THE SOFTWARE

When calibrating a Pulsair you are requested to select an instrument type a Puls

air EasyEye

Puls

fig 6).

If the inc

to10 the Puls

requested to write calibration values to the eeprom.

The software has been design

will reject your request to write calibration to the eeprom.

The same effect will be seen if trying to calibrate a Pulsair

and selecting a 2000 mod state 0-10 instrument type

A warning will now be displayed as seen as

(fig 33A)

orrect Puls

or a Puls

air

calibration software will allow you to calibrate the Puls

air

2000 mod state 11 or a Puls

air

type has been selected when calibrating a Puls

ed to detect at this stage that there has been a selection error and

Comms Error!

air

2000 mod state 0 to10 (refer to

EasyEye/

Error writing values to eeprom

air

2000 mod state 0

air

until you are

3000/2000 mod state 11

air

3000

FIG 33A

To correct this error you must first click onto the OK on the

onto the continue box to return

You must then re

The software will not be able to distinguish between the Pulsair

Pulsair 2000 mod stat

To verify that the correct type after calibration has been selected you must auto fire the

Pulsair on to the glass eye.

The Pulsair 3000 display will show a flashing Er and the 2000 mod state 11 will show a zero

and two flashing dots.

-select the correct Pulsair to be calibrated and re-

e 11 after calibration if the incorrect

to the start of the calibration procedure 7.

PAGE 44

Comms error

start the calibration.

EasyEye

Pulsair

type has been selected

box and then click

Pulsair

3000 and the

Page 52

19

. REPLACEMENT OF CASE HALVES

PULSAIR 2000/3000

! Electrical power is not required for this operation and the mains supply plug

!

Should be removed before starting next operation.

1. Unscrew puff tube shroud and remove (as per fig 34)

2.

Remove trim ring by sliding over case halves

3.

Unscrew eye piece shroud and remove

ELECTRIC SHOCK HAZARD

4.

Remove M3 locking screw from bottom

5.

Remove top case half

6.

Unscrew M3 centre locking screw holding mainframe and remove.

7.

Remove bottom case half.

8.

Replace bottom case halves with new adding spirol pin(

(EP79-01561) , add bostic clear adhe

9. Re-

assemble in reverse order

of top case half

EP79-03334) and M3 insert

sive to slot in case half to retain display p.c.b

PAGE 45

Page 53

19

. REPLACEMENT OF CASE HALVES

PUFF TUBE

SHROUND

TRIM

RING

PULSAIR 2000/3000

EYE PIECE

SHROUND

M3 LOCKING

SCREW

PAGE 46

FIG 34

Page 54

20. REPLACEMENT OF CASE HALVES

PULSAIR EasyEye

! Electrical power is not required for this operation and the mains supply plug

!

Should be removed before starting next operation.

1.

Unscrew the puff tube shroud from the case halves and remove (as per fig 34A)

2. Unscrew end cap on unbilical cord assembly and remove from case halves

(As per fig 34A)

ELECTRIC SHOCK HAZARD

3. Push the Allen key supplied through the four screw plugs to access the cap headed screws

Unscrew the four screws holding the two cases halves together.

4.

Remove the top case half

5.

Remove the front panel assembly.

6.

Unscrew the M3 centre locking screw holding the mainframe and P.C.B.

7.

Remove the bottom case half

8.

Replace top and bottom case half adding new spiral pin (EP79-03334) to top case half and

led covers (EP39-50387) if required

9. Re-

assemble in reverse order.

PAGE 47

Page 55

4 LOCKING

BOTTOM

20. REPLACEMEN

PULSAIR EasyEye

PUFF

TUBE

T OF CASE HALVES

SCREWS

AND PLUGS

M3 C

LOCKING

SCREW

ENTRE

END CAP

FIG 34A

FRONT

PANEL

CASE

PAGE 48

Page 56

PAGE 49

Page 57

21.

Electrical power is not required for this operation and the mains supply plug

Shoul

1.

REPLACEMENT OF

ELECTRIC SHOCK HAZARD

!

Unscrew the top assembly from the base as described in section

d be removed before starting next operation.

THERMAL

PRINTER (PULSAIR EasyEye)

6

ATTENTION

Observe precautions

For handling

Electrostatic

Devices

2.

Unplug the printer switch wiring loom from the powers supply P.C.B

3.

Unplug the two ribbon cables from the lid which a

P.C.B

4. Remove the three screws from inside of the lid holding the printer in position

5.

Remove the printer p.c.b located on the side of the top moulding.

6. Open the printers lid and then extract the printer.

7. Before fit

discarded. Attach P.C.B from old printer prior to re-

8. Relocate the printer into the top assembly, before tightening the screws shut the printer s

lid to allow the print

ting the new printer remove the lid attached, this is not required and can be

er roller and gearing to be aligned correctly.

re connected to the power supply

fitting.

9.

Re assemble in reverse order

Page 49

Loading...

Loading...