Page 1

KeMes

A100

Angle measurement device

Operating instructions V 1.01

Translation of the original manual

Page 2

Document:V 1.01 / Document No.: 1008927

Filename: a100_pjen.pdf

Pages: 46

© KEBA

Specifications are subject to change due to further technical developments. Details presented may be

subject to correction.

All rights reserved.

KEBA AG Headquarters:

Gewerbepark Urfahr, 4041 Linz, Austria, Phone: +43 732 7090-0,

Fax: +43 732 7309-10, keba@keba.com

For information about our subsidiaries please look at www.keba.com.

Page 3

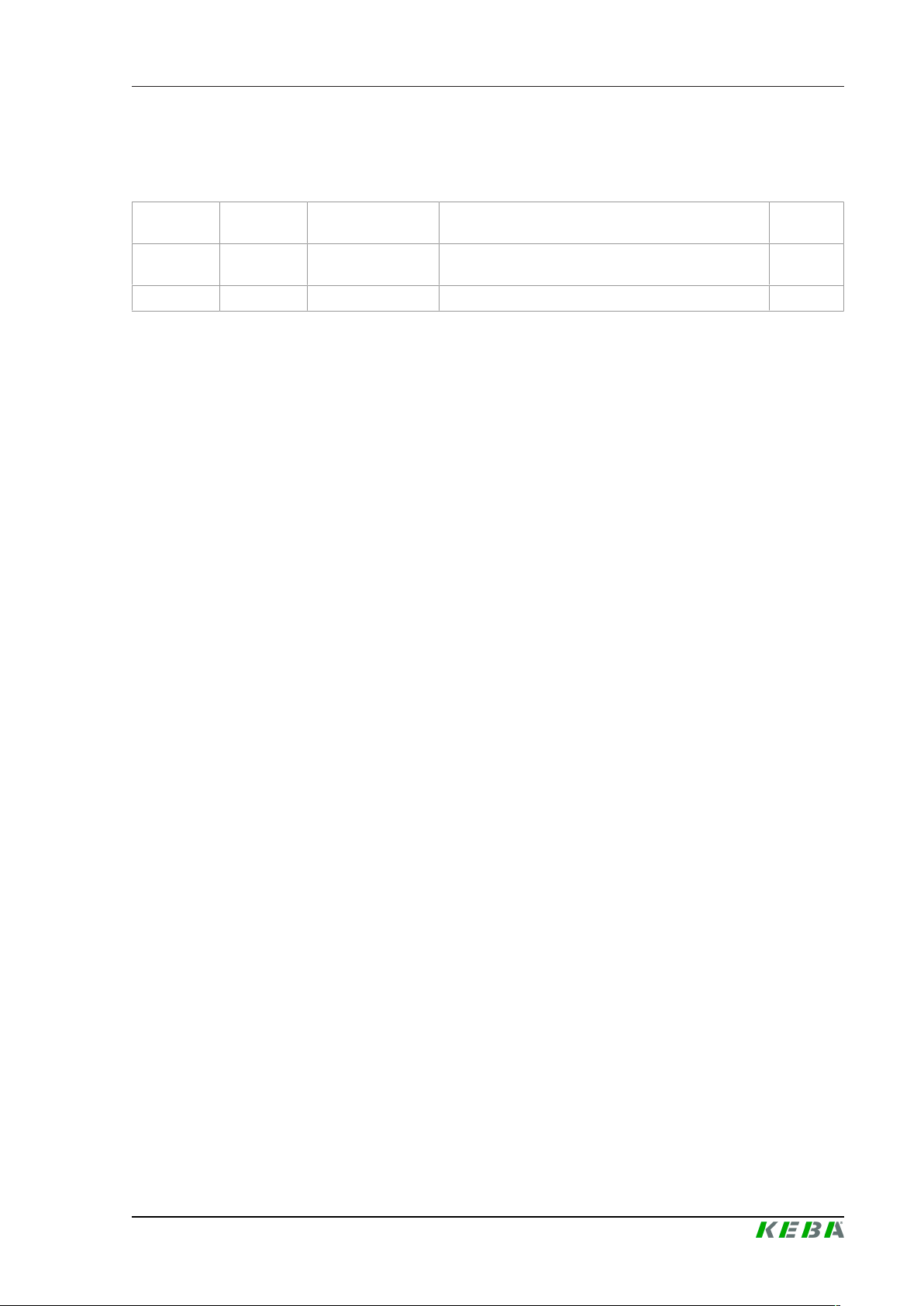

A100 Record of Revision

Record of Revision

Version Date Change in chapter Description

1.00 11-2017 - Newly created

1.01 02-2019 Technical data Updating laser data hli

hasl,

sthm, hli

Changed

by

Operating instructions V1.01

© KEBA

3

Page 4

A100

4

Operating instructions V1.01

© KEBA

Page 5

A100 Table of contents

Table of contents

1 Introduction ................................................................................................................

1.1 Purpose of the document.................................................................................

1.2 Intended use ....................................................................................................

1.3 Preconditions ...................................................................................................

1.4 Notes on this document ...................................................................................

1.4.1 Contents of the document..................................................................

2 Safety notes ................................................................................................................

2.1 Representation.................................................................................................

2.2 General safety notes........................................................................................

2.3 Safety notes for personal safety ......................................................................

2.4 Safety instructions for device maintenance .....................................................

3 Description of the device...........................................................................................

3.1 Front view ........................................................................................................

3.2 Rear view .........................................................................................................

3.3 Top view...........................................................................................................

3.4 Side view..........................................................................................................

3.5 Type plate ........................................................................................................

3.6 DataMatrix code...............................................................................................

3.7 Delivered accessories......................................................................................

7

7

7

7

7

8

9

9

10

11

11

12

12

12

13

13

13

14

14

4 Displays and operating elements .............................................................................

4.1 Operating panel ...............................................................................................

4.1.1 Display ...............................................................................................

4.1.2 Operating button ................................................................................

4.2 Menu structure .................................................................................................

5 Operation and handling .............................................................................................

5.1 General instructions .........................................................................................

5.2 Selection menu on the display .........................................................................

5.3 Operating modes .............................................................................................

5.3.1 Manual ...............................................................................................

5.3.2 Machine .............................................................................................

5.3.3 MachineS...........................................................................................

5.3.4 MachineE...........................................................................................

5.4 Positioning .......................................................................................................

5.5 Execution of the manual measurement ...........................................................

Operating instructions V1.01

© KEBA

15

15

15

15

16

17

17

19

23

23

23

24

24

24

25

5

Page 6

A100Table of contents

5.6 Carrying out an automatic measurement.........................................................

5.7 Data recording and personalization .................................................................

6 Diagnostics .................................................................................................................

6.1 Errors ...............................................................................................................

7 Maintenance................................................................................................................

7.1 Charging the battery ........................................................................................

7.2 Maintenance and service .................................................................................

8 Disposal ......................................................................................................................

8.1 Disposal of the module ....................................................................................

9 Technical data ............................................................................................................

9.1 In general .........................................................................................................

9.2 Environmental conditions.................................................................................

9.3 Laser ................................................................................................................

9.4 Charging device ...............................................................................................

9.5 USB cable ........................................................................................................

9.6 Measuring aid with centering adapter ..............................................................

9.7 Dimensions, weight..........................................................................................

28

30

33

33

34

34

34

36

36

37

37

38

38

38

39

39

39

10 Directives, standards and regulations ....................................................................

10.1 EU directives....................................................................................................

10.2 Standards.........................................................................................................

10.2.1 EMC Directive....................................................................................

10.2.2 General procedures and safety principles .........................................

10.3 Regulations ......................................................................................................

11 EU Declaration of Conformity ...................................................................................

12 Anhang: Apache TM License ......................................................................................

Index ............................................................................................................................

40

40

40

40

40

40

41

42

45

6

Operating instructions V1.01

© KEBA

Page 7

A100 Introduction

1 Introduction

Information

This product contains the open source SSL library "mbed TLS" that is licensed under the Open Source license ApacheTM 2.0.

A use of this product or parts thereof is only allowed with in conformity with

the ApacheTM License 2.0. A copy of this license can be found in "Appendix:

Apache TM License"

1.1 Purpose of the document

This document describes the KeMes A100 measurement device. In addition,

it lists information about use and operation.

1.2 Intended use

KeMes A100 is intended for measuring angles between two flat surfaces and

measuring sheet metal parts. KeMes A100 is intended for indoor use.

KeMes A100 may only be used for the types of use detailed in the technical

description and only in compliance with the described technical framework

conditions.

KeMes A100 has been developed, manufactured, tested and documented in

compliance with the relevant instructions and standards. Therefore, provided

that the instructions and safety precautions are properly observed, the product does not pose any danger to the health of persons or a risk of damage to

other property or equipment under normal circumstances.

1.3 Preconditions

This document is intended for specialist employees and trained personnel in

the industrial area who use KeMes A100.

1.4 Notes on this document

This manual is part of the product. It is to be retained over the entire life cycle of the product and should be forwarded to any subsequent owners or

users of the product.

This documentation must be legible and available to the specified personnel

and must be read and understood by them.

Operating instructions V1.01

© KEBA

7

Page 8

Information

The pictured devices used in this manual are visual examples. The devices

used by you may differ in their appearance.

1.4.1 Contents of the document

● Description of the device

● Operation

● Technical data

A100Introduction

8

Operating instructions V1.01

© KEBA

Page 9

A100 Safety notes

2 Safety notes

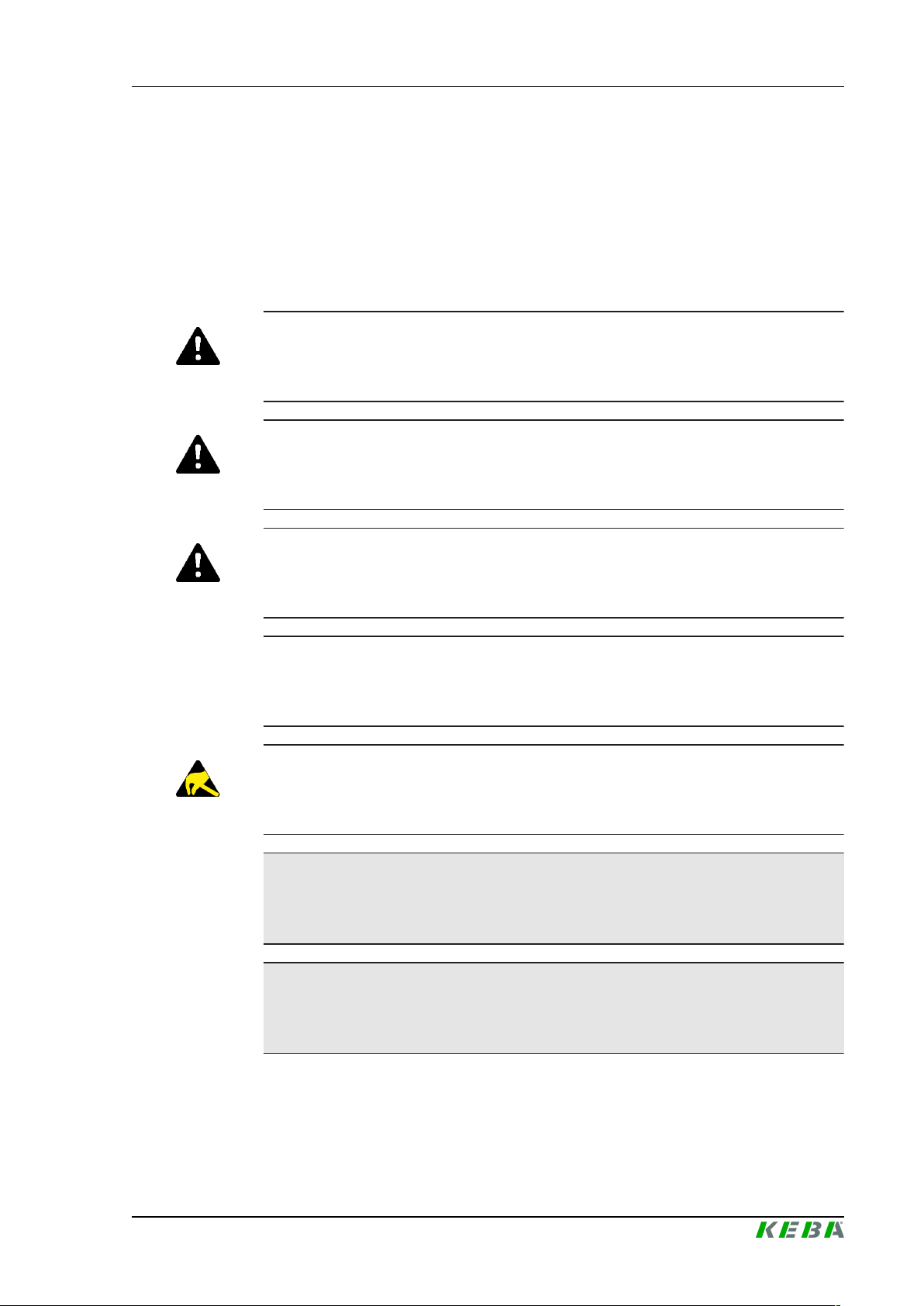

2.1 Representation

At various points in this manual, you will see notes and precautionary warnings regarding possible hazards. The symbols used have the following

meaning:

DANGER!

indicates an imminently hazardous situation, which will result in death or serious bodily injury if the corresponding precautions are not taken.

WARNING!

indicates a potentially hazardous situation, which can result in death or serious bodily injury if the corresponding precautions are not taken.

CAUTION!

means that if the corresponding safety measures are not taken, a potentially

hazardous situation can occur that may result in slight bodily injury.

Caution

means that damage to property can occur if the corresponding safety measures are not taken.

ESD

This symbol reminds you of the possible consequences of touching electrostatically sensitive components.

Safety information

Describes important safety-related requirements or informs about essential

safety-related correlations.

Information

Identifies practical tips and useful information. No information that warns

about potentially dangerous or harmful functions is contained.

Operating instructions V1.01

© KEBA

9

Page 10

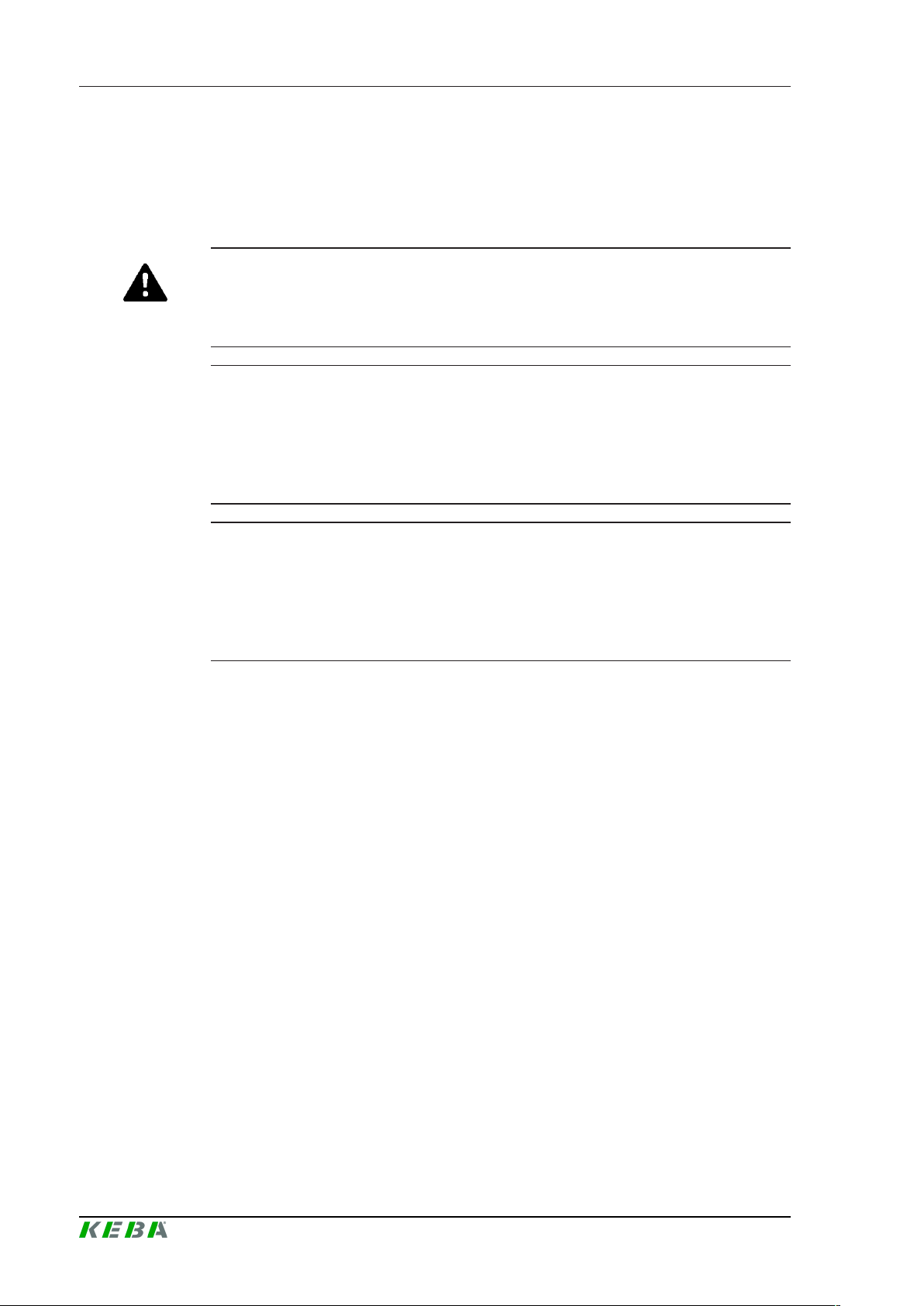

2.2 General safety notes

Read and observe all instructions in order to work with KeMes A100 safely

and without risk. The warning plates on the device must never be rendered

illegible.

WARNING!

The following areas of application are expressly excluded for KeMes A100:

● Use in areas where there is a risk of explosion or fire

Caution

Property damage due to temperature fluctuation!

KeMes A100 must be protected from moisture and direct sunlight. It must

not be exposed to extreme temperatures or temperature fluctuations. Otherwise, the precision of the device can be impaired.

A100Safety notes

Caution

Property damage due to magnetic field!

The device is equipped with magnets and therefore must be kept away from

any devices and objects that can be damaged by strong magnetic fields

(e.g. hard drives, credit cards, speakers, etc.).

10

Operating instructions V1.01

© KEBA

Page 11

A100 Safety notes

2.3 Safety notes for personal safety

CAUTION!

LASER RADIATION

DO NOT LOOK INTO THE BEAM

LASER CLASS 2

IEC 60825-1:2014

660 nm; 7 mW; pulsed

The laser beam must not be pointed at persons or animals. Avoid looking

into the direct or reflected laser beam.

The device must be switched off again after use. Ensure that it is not used

by unqualified personnel at any time.

WARNING!

Health hazard for persons with pacemakers, metallic implants and

hearing aids!

The device is equipped with magnets. Magnets can affect the function of

pacemakers and implanted defibrillators. A pacemaker can be switched into

test mode and cause discomfort. A defibrillator may stop working in some

cases.

2.4 Safety instructions for device maintenance

Caution

If this device is damaged, the device must be taken out of commission and

sent to our service partner for repair.

The device must not be opened.

Only the maintenance work expressly permitted by KEBA may be performed

(see Chap. "Maintenance").

Operating instructions V1.01

© KEBA

11

Page 12

3 Description of the device

3.1 Front view

Fig.3-1: Front view

A100Description of the device

1 ... Display 2 ... Operating button

3 ... Cover of USB or charging socket 4 ... Output for laser radiation (mirror)

3.2 Rear view

Fig.3-2: Rear view

1 ... Type plate 2 ... Magnets

3 ... Recesses for measuring aid

12

Operating instructions V1.01

© KEBA

Page 13

A100 Description of the device

3.3 Top view

Fig.3-3: Top view

1 ... Centering mark

3.4 Side view

Fig.3-4: Side view

1 ... Cover of charging socket (opened) 2 ... USB or charging socket

3.5 Type plate

The type plate is located on the back side of the device.

Fig.3-5: Type plate

1 ... Manufacturer, manufacturer ad-

3 ... Material number, serial number,

5 ... Note on electronic waste ordinance 6 ... CE mark

7 ... Laser warning plate 8 ... Laser class

9 ... Do not look into the beam 10 ... Please observe instructions

dress

country of origin

2 ... Product group, product name, revi-

sion number, technical data

4 ... QR code

Operating instructions V1.01

© KEBA

13

Page 14

3.6 DataMatrix code

The Data Matrix code is composed as follows:

1 2 3 4 5 6 * 1 2 3 4 5 6 7 8 9 0 * * *

Material number Serial number

3.7 Delivered accessories

The following accessories are included in the scope of delivery:

● 1 storage case

● Short description in various languages

● 1 measuring aid with centering adapter

● 1 USB charging device with additional adapter for different countries

● 1 USB cable

A100Description of the device

14

Operating instructions V1.01

© KEBA

Page 15

A100 Displays and operating elements

4 Displays and operating elements

4.1 Operating panel

The operator panel is on the front side of the KeMes A100. It is used for operation and status indication.

Fig.4-6: Control panel

The operator panel consists of:

● 1 display

● 1 operating button

4.1.1 Display

The display is used for the following tasks:

● Display of system menus

● Display of measured data

● Display of state of charge

4.1.2 Operating button

All control of the device is executed by the operating button.

Operating button Meaning

Press 1x briefly

Press 2x briefly

Press and hold

Press 1x briefly, then press

and hold

● Switch on the device and activate the mode used

most recently

● Manual termination of a measurement

● Restarting a measurement

● End measurement

● Return to the preceding menu item

● Switch off the device from the main menu

● Navigate forward within the menu level

● Increase set value

● Switch from individual measurement to continuous

measurement

● Execute selected action

● Navigate backward within the menu level

● Reduce set value

Operating instructions V1.01

© KEBA

15

Page 16

4.2 Menu structure

Menu Description

1 / 6 Manual Mode for manual measurements

2 / 6 Machine

3 / 6 MachineS

4 / 6 MachineE Similar to 3 / 6 MachineS, but with longer measurement duration

5 / 6 Settings

6 / 6 ErrLog Error memory for messages that have occurred

A100Displays and operating elements

Machine mode for automatic measurement (recommended measurement

method)

The measurement starts and stops automatically if the press beam is

moving faster than the set speed threshold.

Machine mode for automatic measurement.

The measurement operation is started even if the press beam moves

only slightly. The mode is used for:

● Hydraulic machines without laser protective devices

● Electric machines that do not have a clear jerk at the beginning of

their movement or that move with only short press beam strokes.

Settings (Disc format, Clock, Brightness, Format, AutoOff, Log, MStartTrig, MStopTrig, MSlow, MSpeed, MSens, MAccuracy, Reset)

16

Operating instructions V1.01

© KEBA

Page 17

A100 Operation and handling

5 Operation and handling

5.1 General instructions

Caution

Damage to property due to severe vibrations

Severe vibrations of the device (e.g. if the device drops to the ground) may

damage the electronics and the precision measurement unit or destroy the

device.

In any case, verification of the measurement results is required afterward,

e.g. using a reference angle.

If the device is damaged, the device must no longer be used and must be

sent to our service partner for repair.

Caution

Condensation of humidity in the device

● Do not expose the device to high humidity for an extended period of

time.

● If a cold device is brought into a significantly warmer environment (e.g.

after extended transport in a cold environment), condensation moisture

may form in the device.

Before using the device, you must wait until the temperature of the device is the same as the room temperature and the moisture has evaporated.

The materials and surfaces of measured objects used in practice are highly

varied, meaning that the manufacturer cannot make exhaustive suitability

specifications despite extensive test series. Therefore, before carrying out

qualified measurements, the user must check for suitability and sufficient accuracy of the measured object for the specific purpose in combination with

the respective materials and usage conditions.

For practical use of the measurement device, be aware that the surfaces of

the workpiece scanned by the laser along with its respective reflective properties form a functional part of the overall measurement system and thus influence the actually achievable accuracy. The achievable accuracy is also

affected by proper handling of the measurement device as well as by the environmental conditions; also refer to Chapter "Technical data".

The following items can have an influence on measurement precision and

repeat accuracy and must be observed:

● Alignment of the device with the workpiece: The longitudinal axis of

the housing of KeMes A100 must be aligned parallel to the bending

edge and tilted as little as possible in order to be symmetrical between

Operating instructions V1.01

© KEBA

17

Page 18

A100Operation and handling

the two legs of the workpiece. Observe a minimum distance of 20 mm

between the mirror and the workpiece surface. The measured distance

to both legs should be equal if possible.

● Poor planarity: Unevenness on the surface of the leg being measured

must be prevented.

● Non-homogeneity of the reflective properties: Different, reflective

properties of the legs being measured on the test specimen (e.g. soiling,

scratches, coating, discoloration, oils, welding chips, patches of corrosion, etc.) must be prevented. If necessary, the test piece must be

cleaned, or the selection of the measurement field must be changed.

● Soiling: Soiling on mirror and lens of the device must be prevented.

● Vibrations: If a measurement takes place on a machine, the legs of thin

sheets have the tendency to vibrate or reverberate when relaxing. Make

sure that the sheet metal legs do not vibrate during the measurement

operation.

● Unrelaxed angle: When measuring at the machine, make sure that the

bending tool has been lifted sufficiently and the legs of the angle are relaxed. The setting of the press brake for decompression must be adjusted as necessary.

● Deformations due to gravity: In case of thin sheets with legs of equal

length, elastic deformation can be caused by its own weight, depending

on the position of the sheet, therefore changing the angle compared to

an unloaded state.

● External magnetic fields: Make sure there are no generators of magnetic fields (e.g. electric drives) within a distance of 10 cm.

● Strong external light sources: There should be no light sources (e.g.

infrared lamps, other laser devices, strong reflections of the own laser

beam and high-frequency LED lightings) in the surrounding area of the

device.

● Condensation: Condensation on the surface of, e.g. test piece, lens,

mirror must be prevented. Slow adjustment to the ambient temperature

is necessary.

KeMes A100 is designed for reflecting metal surfaces such as:

● Metal sheets (e.g. aluminum, steel and stainless steel (cold-rolled or

descaled))

● Galvanized sheets

● Sheets with protective foil

The following material surfaces can be measured using KeMes A100 with

limited accuracy only:

18

● Scaled sheets

● Electrolytically galvanized sheets

● Painted sheets

● Enameled sheets

Operating instructions V1.01

© KEBA

Page 19

A100 Operation and handling

Normally, the following material surfaces cannot be measured using KeMes

A100:

● Dirty or corroded sheets

● Sheets with mechanical surface treatment

● Highly reflective sheets (glassy surfaces)

● Heavily scaled sheets

5.2 Selection menu on the display

KeMes A100 has a selection menu on the display. During operation, the current status is shown on the display. The operating button can be used to

navigate the menu.

Button operation for menu navigation

Press 1x briefly Switch to the next menu level or start an action

Press 2x briefly Exit a menu level or cancel an action

Press and hold Navigate forward within the menu level

Press 1x briefly, then

press and hold

Navigate backward within the menu level

Menu structure display

Main menu

(1st level)

Display

(2nd level)

Menu 1/6

Manual

Description

Manual measurement started

Result of manual measurement

Manual continuous measurement started

Manual continuous measurement

Operating instructions V1.01

© KEBA

19

Page 20

A100Operation and handling

Main menu

(1st level)

Menu 2/6

Machine

Menu 3/6

MachineS

Display

(2nd level)

Description

Calibration of acceleration sensor, device must not be in

motion

Measurement active / Waiting for new measurement

Downward movement detected

Result of automatic measurement

Automatic continuous measurement for setting up the device started

Automatic continuous measurement

Calibration of acceleration sensor, device must not be in

motion

Measurement active / Waiting for new measurement

Result of automatic measurement

Menu 4/6

MachineE

Automatic continuous measurement for setting up the device started

Automatic continuous measurement

Calibration of acceleration sensor, device must not be in

motion

Measurement active / Waiting for new measurement

Result of automatic measurement

Automatic continuous measurement for setting up the device started

Automatic continuous measurement

20

Operating instructions V1.01

© KEBA

Page 21

A100 Operation and handling

Main menu

(1st level)

Menu 5/6

Settings

Display

(2nd level)

Menu 1/13

Disc

Menu 2/13

Clock

Menu 3/13

Brightness

Menu 4/13

Format

Menu 5/13

AutoOff

Description

Formatting the internal memory. All data is deleted.

1)

Disc

Format?

Setting the real-time clock.

12.07.2018

09:36:39

Adjusting the display brightness from 0 to 16, default setting: 8

Brightness

8

Selection of the angle format

Format

---.-- (decimal degrees) or

Format

---°--' (degrees / minutes)

Time for automatic switch-off from 1 to 30 minutes, default

setting: 5

AutoOff

5

Menu 6/13

Log

Menu 7/13

MStartTrig

Activation of data recording (on/off), default setting: off

Log

Off

Mode for triggering the measurement in the "Machine"

operating mode ("move down" / "motion"). Default setting: "motion"

"move down": the measurement starts as soon as the

press beam moves faster than the speed set using the

MSpeed parameter.

"motion": the measurement starts as soon as the set

sensitivity of the MSens parameter has been exceeded.

Operating instructions V1.01

© KEBA

21

Page 22

A100Operation and handling

Main menu

(1st level)

Menu 5/6

Settings

Display

(2nd level)

Menu 8/13

MStopTrig

Menu 9/13

MSlow

Menu 10/13

MSpeed

Description

Mode for stopping the measurement in the "Machine"

operating mode ("move up" / "motion"). Default setting: "move up"

"move down": the measurement stops as soon as the

press beam moves faster than the speed set using the

MSpeed parameter and a constant angle is measured.

"motion": the measurement stops as soon as the set

sensitivity of the MSens parameter has been exceeded

and a constant angle is measured.

Setup parameters for longer measurement duration (up to

40s) in the "Machine" operating mode (off / on). Default

setting: off

MSlow

Off

Speed threshold for the motion detection of the press

beam in the "Machine" operating mode in the "move

down" and "move up" mode from 0 to 200 mm/s, default

setting: 20

2)

MSpeed

20

Sensitivity of the acceleration sensor from which a movement of the press beam in the "Machine" operating mode

Menu 11/13

MSens

in the "motion" mode and in the "MachineS" operating

mode is detected from 0 to 200, default setting: 50

3)

MSens

50

Menu 12/13

MAccuracy

Tolerance value from which a plateau in the angle value is

detected from 0 to 50 (1/value) °, default setting: 20

MAccuracy

4)

20

Reset of the Brightness, AutoOff, MSpeed, MSens and

Menu 13/13

Reset

MAccuracy parameters to the default settings1).

Settings

Reset?

Menu 6/6

ErrLog

1)

This function is started by pressing and holding the operating button. By

No more

errors!

KEMES A100

v01.03

Error memory for messages that have occurred. See

Chapter "Errors".

Switch-off and display of the installed software version

pressing it 2x briefly, the menu item is exited again without triggering the

function.

22

Operating instructions V1.01

© KEBA

Page 23

A100 Operation and handling

2)

If the value is too high, the motion of the press beam may no longer be de-

tected; at a value that is too low, faulty triggering is possible. Use in the "Ma-

chine" operating mode in "move down" and "move up" mode

3)

The lower the value, the earlier a motion of the press beam will trigger the

measurement operation. Use in the "Machine" operating mode in "motion",

"MachineS" or "MachineE" mode

4)

The lower the value, the earlier a fluctuating angle value will be ranked as

stable. The measurement is ended as soon as a stable angle has been detected and the press beam has moved upward.

5.3 Operating modes

The following operating modes are available:

● Manual (manual operating mode)

● Machine (automatic operating mode)

● MachineS (automatic operating mode)

● MachineE (automatic operating mode)

5.3.1 Manual

In "Manual" operating mode, the angle is measured by hand. For an exact

measurement result, it is recommended that the enclosed measuring aid be

used and that the device be held as still as possible.

The measuring aid without centering adapter can be used for acute angles

and small bending radii. For obtuse angles or large bending radii, the use of

the measuring aid is recommended.

At the end of the measurement, the current angle is indicated on the display.

5.3.2 Machine

In "Machine" operating mode, the angle at the press brake is measured. For

this purpose, the device must be attached to the upper tool.

In "Machine", KeMes A100 starts by calibrating the acceleration sensor. The

display indicates " " until the idle state has been reached. If the up-

per tool moves downward, the measurement operation is started.

After decompression, the measured angle is indicated on the display.

If the indicated angle value is flashing, only few measured values are available for determining the angle, and the displayed value is possibly incorrect.

By increasing the decompression path before the upward movement of the

press beam, the time for the measurement of the angle can be extended.

Operating instructions V1.01

© KEBA

23

Page 24

The correct final angle can only be measured if decompression has been

completed and the bent part has fully sprung back. In addition, the bent part

can be left in the matrix somewhat longer after bending has been completed.

By adjusting the 7 / 13 MStartTrig, 8 / 13 MStopTrig, 10 / 13

MSpeed and 11 / 13 MSens parameters in the 5 / 6 Settings menu

items, this operating mode can also be used for electric press brakes, limited

press beam openings or press brakes in which the press beam moves very

slowly. If the adaptation is insufficient for measuring a stable angle value,

"MachineS" operating mode is recommended.

5.3.3 MachineS

In "MachineS" (sensitive) operating mode, the angle is measured at the

press brake. For this purpose, the device must be attached to the upper tool.

The sequence is the same as in "Machine" operating mode. However, the

measurement operation is triggered even by slight vibrations of the press

beam.

A100Operation and handling

5.3.4 MachineE

In "MachineE" (extended) operating mode, the angle is measured at the

press brake. For this purpose, the device must be attached to the upper tool.

The sequence is the same as in "Machine" operating mode. In addition, however, the time period for which the laser is switched on for angle measurement is significantly extended.

The operating mode must be used if, in the "Machine" or "MachineS" operating modes, the device ends the measurement operation early because the

bending operation takes too much time.

5.4 Positioning

Since the measurement principle of KeMes A100 is based on reflection, attention must be paid to the correct positioning of the device.

During measurement, the laser beam is directed outward by a mirror. The

laser beam is visible to the observer as a thin line on the measured object.

The beam must be capable of hitting the two legs to be measured at an angle of 90°.

24

If the laser beam is not reflected on the metal sheet surface at an angle of

90°, no measurement is possible. For this reason, it is possible that workpieces with bores or cutouts cannot be measured. Faulty measurements

caused by reflections in the room cannot be ruled out either. If the beam

misses the legs, the distance between the device and the bending edge

must be reduced.

Operating instructions V1.01

© KEBA

Page 25

A100 Operation and handling

The laser beam is displayed more brightly in the area of 90° to the leg.

These areas are called measurement fields. Thus, users can identify during

measurement where the exact measurement position is, allowing them to

modify the position of the device as necessary. Note that this is a point measurement, and this is why a correct angle calculation on curved workpieces

and within the bending radius (important for workpieces with obtuse angles)

is not possible.

Information

For an exact measurement, a minimum distance of 20 mm between the device and the surface of the measured object is required.

Fig.5-7: Examples of positioning using the measuring aid

Fig.5-8: Examples of positioning using the upper tool

5.5 Execution of the manual measurement

For executing a manual measurement, use of the measuring aid is recommended. This allows the measurement result to be reached in less time and

with greater accuracy.

Operating instructions V1.01

© KEBA

25

Page 26

A100Operation and handling

In many cases, measurement accuracy is also greater because the measuring aid makes it possible to align the device parallel to the bending edge. For

parts with obtuse angles, using the centering adapter is recommended because otherwise, correct alignment when positioning the measuring aid is

possible but difficult. The centering adapter also protects the workpiece and

the device against mechanical wear.

Installation of the measuring aid

To install the measuring aid on the device, proceed as follows:

Fig.5-9: Installing the measuring aid

1) Position the two upper guiding lugs of the measuring aid on the upper

cutouts of the device (1).

2) Fold the lower part of the device in the direction of the measuring aid so

that the two lower bending lugs of the measuring aid rest within the

lower cutouts of the device (2).

Fig.5-10: Installing the centering adapter

26

3) Plug the centering adapter onto the measuring aid. When doing so, the

centering adapter must lock completely.

Operating instructions V1.01

© KEBA

Page 27

A100 Operation and handling

Information

If installed correctly, the measuring aid rests on the device completely.

The measuring aid has now been installed on the device, and the manual

measurement can be executed.

Carrying out the measurement

For the manual measurement, proceed as follows:

1) Attach the device onto the measuring aid.

2) Switch the device on by pressing the operating button.

3) Navigate to the "Manual" menu item by pressing and holding the operating button.

4) Place the device close to the workpiece so that the measuring aid

touches the bending edge.

5) Start the measurement (switch on the laser) by pressing the operating

button once.

6) Position KeMes A100 so that the laser beam can hit both legs of the object to be measured unobstructed at an angle of 90°.

7) Hold the device still until the measurement is completed and the laser

switches off automatically.

The measured result can be read off the display after the measurement has

ended. The laser is automatically switched off after the measurement.

Information

The measurement can be terminated early by pressing the operating button. After 40 seconds without a measurement result, the measurement is

ended automatically.

If the laser beam does not hit both legs at an angle of 90°, an alternative

position must be selected for the measurement.

Continuous measurement

Pressing and holding the operating button switches the device to continuous

measurement mode. In this mode, a continuous measurement is carried out

and the measured angle is displayed directly. The measurement must be

terminated by pressing the operating button 1x briefly.

In this mode, long sheet metal parts can be measured along the entire bending edge, for example.

Operating instructions V1.01

© KEBA

27

Page 28

5.6 Carrying out an automatic measurement

To carry out an automatic measurement, the device must be installed on the

upper tool.

Installation on the upper tool

Caution

Property damage due to incorrect positioning!

The device must be positioned at a sufficient height so that, after reaching

the target angle, sufficient space remains between the leg and the device.

Information

The upper tool must be magnetic so that KeMes A100 can be installed on

it.

KeMes A100 must rest on the upper tool throughout.

A100Operation and handling

For the installation of KeMes A100 on the upper tool, proceed as follows:

1) Create a gap of approx. 6 mm in the upper tool of the press brake by

shifting the stamp segments.

Information

The gap in the upper tool causes bending marks in the workpiece. If these

are not acceptable, honing tools or special tools with a machined slot must

be used.

2) Attach KeMes A100 so that the laser beam can penetrate the gap unobstructed and hit both legs of the object to be measured at an angle of

90°.

3) Align the device using the centering mark.

28

Operating instructions V1.01

© KEBA

Page 29

A100 Operation and handling

Fig.5-11: Gap in automatic mode

1 ... Stamp segments 2 ... Gap

Information

For a correct measurement result, the device must be attached in parallel

to the bending edge.

The device has now been installed on the upper tool, and a manual measurement can be executed.

Information

To aid in setting up the device, the device can be switched to continuous

measurement mode. In this mode, the laser is active for measurement, and

using a pre-bent part, you can check whether the measurement fields are

on the legs of the sheet or whether the device still needs to be adjusted on

the upper tool.

Carrying out the measurement

WARNING!

Personal injury risk due to the bending process!

During the bending process, the device must not be operated! Prior to operation, the press brake must be switched to a safe state.

Operating instructions V1.01

© KEBA

29

Page 30

A100Operation and handling

Information

The measurement in Machine operating mode is triggered by the motion of

the device. The measurement functions correctly only if the device moves

down with the upper tool and back (up) at sufficient speed during the measurement.

For measurement in Machine operating mode, proceed as follows:

1) Attach the device to the upper tool.

2) Switch the device on by pressing the operating button.

3) Navigate to the "Machine" menu item by pressing and holding the operating button.

4) Start automatic mode by pressing the operating button once.

5) Wait until the idle state has been reached (display shows" ").

6) Start the bending operation.

Automatic measurement is now active, and the measurement result can be

read off the display of the device after every bending operation.

Continuous measurement

For a recheck of the bent part, the device can be switched to continuous

measurement mode by pressing and holding the operating button. This activates the laser for measurement, and the bent part can be remeasured while

it still in the machine. By pressing the operating button 1x briefly, the laser

can be switched off and on again for the measurement. After the check,

pressing the operating button 2x briefly switches the device back to regular

Machine operating mode.

Information

If the pressing speed is low or the press beam stroke is short, the motion

sensor of the device does not trigger. In this case, the parameters for triggering the measurement must be adjusted, or "MachineS" operating mode

must be used.

5.7 Data recording and personalization

Data recording

The data recording can be activated and deactivated using settings menu

item 6 / 13 Log in the 5 / 6 Settings menu. This function is deactivated

by default.

30

Operating instructions V1.01

© KEBA

Page 31

A100 Operation and handling

If data recording is activated, an entry is created in file ANGLES.CSV after every measurement. Approx. 30,000 measurements are saved automatically.

After that point, the file is renamed to ANGLES.BAK and data recording is forwarded to a new ANGLES.CSV file.

The recorded data can be copied to a PC and evaluated there. To do so, a

connection to the internal memory of the device must be established. The

files (ANGLES.CSV and ANGLES.BAK) can then be transmitted to the PC using

a file explorer. The files can be opened and evaluated with Microsoft® Excel,

for example.

The serial numbers and, as an option, personalization data are saved in the

first line of the measurement value files. Measurement values are entered in

the other lines. One line corresponds to one measurement value. For the

measurement values, a comma "," is used to separate decimal places.

Column 1 Date of measurement

Column 2 Time of measurement

Column 3 Measured value in decimal degrees

Column 4

Operating mode in which measurement took place (0 ... Manual, 1 ... Machine, 2 ... MachineS, 3 ... MachineE)

● The following format was used for the date: dd.MM.yyyy

● The following format was used for the time of measurement: hh:mm:ss

dd Day (2-digit)

MM Month (2-digit)

yyyy Year (4-digit)

hh Hour (2-digit, 24-hour format)

mm Minute (2-digit)

ss Second (2-digit)

Personalization

KeMes A100 can be personalized. This personalization is shown when

switching on the device.

In order to personalize KeMes A100, a connection to the internal memory of

the device must be established. The KEMES.INI file can then be edited using

a text editor, such as Microsoft® Editor.

When first opening the file, the following content can be seen:

[USER]

;user name line 0 (max. 16 char.)

NAME0=

;user name line 1(max. 16 char.)

NAME1=

Max. 16 characters can be entered per line in fields NAME0 and NAME1. Umlauts cannot be displayed.

Operating instructions V1.01

© KEBA

31

Page 32

A100Operation and handling

Example:

[USER]

;user name line 0 (max. 16 char.)

NAME0=Company

;user name line 1(max. 16 char.)

NAME1=Operator

After editing, the file must be saved and the connection to KeMes A100 must

be disconnected. The next time KeMes A100 is switched on, the entered text

appears on the display.

Connecting the device and PC

The internal memory of the device can be accessed over the USB interface

in order to transmit the recorded measurement data to a PC and personalize

the device.

In order to establish a connection, the device must be switched on. Proceed

as follows to establish the connection:

1) Connect the USB cable to the device and PC. The message --DISC--

Connect? appears on the display.

2) Briefly press the operating button once to establish the connection. The

message --DISC-- Disconnect? is shown on the display.

The device is integrated onto the PC as a USB removable storage device

and is now connected. Using a file explorer, the data in the internal memory

of the device can be accessed.

In order to disconnect the device from the PC, proceed as follows:

1) Briefly press the operating button on the device once. The message --

DISC-- Connect? appears on the display.

2) Unplug the USB cable from the device and PC.

The device has successfully been disconnected from the PC.

32

Operating instructions V1.01

© KEBA

Page 33

A100 Diagnostics

6 Diagnostics

6.1 Errors

Errors Cause Measure

No display after pressing the

operating button

Beam is not switched off after

a completed measurement in

automatic mode

Beam maps a point instead

of a line

Battery is empty Charge the battery

Leg of the workpiece too

short or

Surface does not allow for

measurement

Beam does not leave the

measurement range, so measurement cannot be completed

Beam meets the sides of the

workpiece in the gap

Safety shut-down not responding

No measurement possible;

Switch off device by pressing

the operating button

Lift stamp higher after bending process so measurement

range can be exited reliably

Make gap wider or shift device in the upper tool to the

side so that the beam can

come out unobstructed

Immediately switch off;

Send in device to service

partner

If an error code (e.g. Err 1/1 00014 0x00000000) is shown on the display,

the error can be acknowledged by briefly pressing the operating button. The

message "No more errors!" is displayed. By pressing the operating button

again, the device returns to the main menu and can continue to be used. In

case the error appears again, restarting the device is recommended.

Caution

If the error does not go away or cannot be acknowledged, the device must

be sent back to the service partner for diagnostics and repair.

Operating instructions V1.01

© KEBA

33

Page 34

7 Maintenance

7.1 Charging the battery

Caution

Property damage due to incorrect power supply!

Only the charging device included in delivery may be used for the charging

process! Otherwise, the device may be damaged.

Proceed as follows to charge the battery:

1) Plug the charging device into the charging socket of the device.

2) Connect the charging device to the power supply.

The battery is now charging.

When the charging device is connected or the operating button is pressed, a

battery symbol appears on the display. It shows in alternating fashion that

the battery is charging (segments are filled in from right to left) as well as the

current battery charge (segments are lit up based on the charge). The symbol automatically disappears after a few seconds.

If the battery is completely charged, the battery symbol is displayed without

any non-lit segments. In case of a fault in the charging process, this filling of

the battery symbol is not displayed.

A100Maintenance

Information

When charging KeMes A100, faults on the power supply in an industrial environment line can impair the charging process. If this impairment occurs

repeatedly, then charging in a business environment, e.g. in an office

space, as well as selective testing of the network quality is recommended.

7.2 Maintenance and service

KeMes A100 (especially the mirror and lens) should always be kept clean.

Note the following points when cleaning the device:

● Wipe away soiling on the exterior of the device with a soft, damp cloth.

Do not use any cleaning agent or solvent.

● Clean the mirror and lens using a cotton swab or a lint-free cloth and

cleaning liquid (isopropyl, eyeglass cleaner, gentle glass cleaner). Exert

as little pressure on the mirror as possible when cleaning.

● Make sure the charging socket is covered to prevent dust from entering.

● Do not submerge the device in liquids.

34

Operating instructions V1.01

© KEBA

Page 35

A100 Maintenance

In case of non-use, it is recommended to keep KeMes A100 in its included

case to protect the device from dust.

If the device malfunctions despite careful preparation and test procedures, it

must be sent back to the service partner for repair.

Operating instructions V1.01

© KEBA

35

Page 36

8 Disposal

8.1 Disposal of the module

Caution

Please observe the regulations regarding disposal of electric appliances and

electronic devices!

● The symbol with the crossed-out waste container means that

electrical and electronic devices including their accessories

must not be disposed of in the household garbage.

● The materials are recyclable in accordance with their labeling.

You can make an important contribution to protecting our environment by reusing, renewing and recycling materials and old

appliances.

A100Disposal

36

Operating instructions V1.01

© KEBA

Page 37

A100 Technical data

9 Technical data

9.1 In general

Protection class: IP20

Measurement ranges: 30° to 150°

Minimum measurement distance: 20 mm to the surface

Resolution: 0.01°

Measurement accuracy: ±0.2°

Repeat accuracy: 0.1°

Power supply: 2 integrated LiPo batteries with safety circuits

Nominal battery voltage: 3.7 V

Battery capacity: 2x 330 mAh

*)

Reference measurement accuracy:

The following measuring positions can be used as a reference for the measurement accuracy, where 3 measurements are carried out, each with a different tilting angle (-35° / 0° / +35° around the longitudinal axis parallel to the

bending edge). The specified measurement accuracy represents the basic

accuracy of the measurement and is reached under the following reference

conditions:

*)

● Measurement object: Reference angle of 90°

● Material: Aluminum, full material wire-eroded

● Surface: bare, perpendicular to the bending edge (in the direction of motion of the laser) ground with grit 320, free of grease and dirt

● Temperature: 25 °C (for environment, device and measurement object)

and humidity 50-70%rH

● Measuring positions with the following measured distances between the

mirror and workpiece surface: 25 mm and 25 mm / 100 mm and 100

mm / 25 mm and 140 mm / 140 mm and 25 mm

Operating instructions V1.01

© KEBA

37

Page 38

1 ... Measuring position 2 ... Reference angle

A100Technical data

9.2 Environmental conditions

Operating temperature: +5 °C to +40 °C

Charging temperature: +5 °C to +40 °C

Storage temperature: -20°C to +45°C

Relative air humidity: 5% to 95% (non condensing)

9.3 Laser

Laser class: 2 in accordance with IEC 60825-1:2014

Wavelength: 660 nm

Laser output: 7 mW (pulsed)

Laser beam diameter: 3 mm (at the exit point)

Beam divergence: 35 mrad

Pulse frequency: 167 Hz

IEC 60825-1:2014, Tabelle 10, Bedingung 3:

9.4 Charging device

200 mm (most restrictive location); 36 µs (impulse duration in measuring aperture)

38

Designation: Switching Power Supply

Model: PSAI05R-050QL6

Operating voltage: 100 - 240 V AC, 50 - 60 Hz

Operating current: 300 mA

Charging voltage: +5 V

Operating instructions V1.01

© KEBA

Page 39

A100 Technical data

Charging current: 1 A max.

9.5 USB cable

Type: USB 3.0 connection cable

Connection A: Type A plug

Connection B: Type C plug

Cable length: 1 meter

9.6 Measuring aid with centering adapter

Dimensions (H x L x W): 14 mm x 158 mm x 65 mm

Fig.9-12: Front view of measuring aid with centering adapter

1 ... Guide tab for attaching to the de-

vice

9.7 Dimensions, weight

Height: 162 mm

Width: 49 mm

Depth: 15 mm

Weight: 75 g

2 ... Centering adapter

Operating instructions V1.01

© KEBA

39

Page 40

10 Directives, standards and regulations

10.1 EU directives

Directive 2014/30/EU EU directive on electromagnetic compatibility

Directive 2011/65/EU RoHS directive

10.2 Standards

To check the conformity of the system with the directives, the following nonbinding legal European standards were applied.

10.2.1 EMC Directive

Electrical equipment for measurement, con-

EN 61326-1:2013

trol and laboratory use - EMC requirements Part 1: General Requirements

A100Directives, standards and regulations

10.2.2 General procedures and safety principles

Safety Requirements for Electrical Equip-

EN 61010-1:2010

IEC 60825-1:2014

ment for Measurement, Control, and Laboratory Use – Part1 General Requirements

Safety of laser products - Part 1 Equipment

classifications and requirements

10.3 Regulations

Regulation (EC) No. 1907/2006 REACH EU chemicals regulation

Information

Duty to communicate information from the REACH regulation

In order to comply with the duty to communicate information in accordance

with Article 33 of the REACH regulation, detailed information on the ingredients are provided on our web page. For more detailed information, please

contact KEBA.

40

Operating instructions V1.01

© KEBA

Page 41

A100 EU Declaration of Conformity

11 EU Declaration of Conformity

Operating instructions V1.01

© KEBA

41

Page 42

12 Anhang: Apache TM License

Information

The ApacheTM License 2.0 is given in english.

Programm:

Apache License

Version 2.0, January 2004

http://www.apache.org/licenses/

TERMS AND CONDITIONS FOR USE, REPRODUCTION, AND DISTRIBUTION

1. Definitions.

"License" shall mean the terms and conditions for use, reproduction,

and distribution as defined by Sections 1 through 9 of this document.

"Licensor" shall mean the copyright owner or entity authorized by

the copyright owner that is granting the License.

"Legal Entity" shall mean the union of the acting entity and all

other entities that control, are controlled by, or are under common

control with that entity. For the purposes of this definition,

"control" means (i) the power, direct or indirect, to cause the

direction or management of such entity, whether by contract or

otherwise, or (ii) ownership of fifty percent (50%) or more of the

outstanding shares, or (iii) beneficial ownership of such entity.

A100Anhang: Apache TM License

"You" (or "Your") shall mean an individual or Legal Entity

exercising permissions granted by this License

"Source" form shall mean the preferred form for making modifications,

including but not limited to software source code, documentation

source, and configuration files.

"Object" form shall mean any form resulting from mechanical

transformation or translation of a Source form, including but

not limited to compiled object code, generated documentation,

and conversions to other media types

"Derivative Works" shall mean any work, whether in Source or Object

form, that is based on (or derived from) the Work and for which the

editorial revisions, annotations, elaborations, or other modifications

represent, as a whole, an original work of authorship. For the purposes

of this License, Derivative Works shall not include works that remain

separable from, or merely link (or bind by name) to the interfaces of,

the Work and Derivative Works thereof.

"Contribution" shall mean any work of authorship, including

the original version of the Work and any modifications or additions

to that Work or Derivative Works thereof, that is intentionally

submitted to Licensor for inclusion in the Work by the copyright owner

or by an individual or Legal Entity authorized to submit on behalf of

the copyright owner. For the purposes of this definition, "submitted"

means any form of electronic, verbal, or written communication sent

to the Licensor or its representatives, including but not limited to

communication on electronic mailing lists, source code control systems,

and issue tracking systems that are managed by, or on behalf of, the

Licensor for the purpose of discussing and improving the Work, but

excluding communication that is conspicuously marked or otherwise

designated in writing by the copyright owner as "Not a Contribution."

42

"Contributor" shall mean Licensor and any individual or Legal Entity

on behalf of whom a Contribution has been received by Licensor and

subsequently incorporated within the Work

Operating instructions V1.01

© KEBA

Page 43

A100 Anhang: Apache TM License

2. Grant of Copyright License. Subject to the terms and conditions of

this License, each Contributor hereby grants to You a perpetual,

worldwide, non-exclusive, no-charge, royalty-free, irrevocable

copyright license to reproduce, prepare Derivative Works of,

publicly display, publicly perform, sublicense, and distribute the

Work and such Derivative Works in Source or Object form

3. Grant of Patent License. Subject to the terms and conditions of

this License, each Contributor hereby grants to You a perpetual,

worldwide, non-exclusive, no-charge, royalty-free, irrevocable

(except as stated in this section) patent license to make, have made,

use, offer to sell, sell, import, and otherwise transfer the Work,

where such license applies only to those patent claims licensable

by such Contributor that are necessarily infringed by their

Contribution(s) alone or by combination of their Contribution(s)

with the Work to which such Contribution(s) was submitted.

If You institute patent litigation against any entity

(including a cross-claim or counterclaim in a lawsuit) alleging that the Work

or a Contribution incorporated within the Work constitutes direct

or contributory patent infringement, then any patent licenses

granted to You under this License for that Work shall terminate

as of the date such litigation is filed

4. Redistribution. You may reproduce and distribute copies of the

Work or Derivative Works thereof in any medium, with or without

modifications, and in Source or Object form, provided that You

meet the following conditions

(a) You must give any other recipients of the Work or

Derivative Works a copy of this License; and

(b) You must cause any modified files to carry prominent notices

stating that You changed the files; and

(c) You must retain, in the Source form of any Derivative Works

that You distribute, all copyright, patent, trademark, and

attribution notices from the Source form of the Work,

excluding those notices that do not pertain to any part of

the Derivative Works; and

(d) If the Work includes a "NOTICE" text file as part of its

distribution, then any Derivative Works that You distribute must

include a readable copy of the attribution notices contained

within such NOTICE file, excluding those notices that do not

pertain to any part of the Derivative Works, in at least one

of the following places: within a NOTICE text file distributed

as part of the Derivative Works; within the Source form or documentation,

if provided along with the Derivative Works; or, within a display generated

by the Derivative Works, if and wherever such third-party notices normally appear.

The contents of the NOTICE file are for informational purposes only and

do not modify the License. You may add Your own attribution notices

within Derivative Works that You distribute, alongside or as an addendum

to the NOTICE text from the Work, provided that such additional attribution

notices cannot be construed as modifying the License.

You may add Your own copyright statement to Your modifications and

may provide additional or different license terms and conditions for use,

reproduction, or distribution of Your modifications, or for any such

Derivative Works as a whole, provided Your use, reproduction,

and distribution of the Work otherwise complies with

the conditions stated in this License.

5. Submission of Contributions. Unless You explicitly state otherwise,

any Contribution intentionally submitted for inclusion in the Work

by You to the Licensor shall be under the terms and conditions of

this License, without any additional terms or conditions.

Notwithstanding the above, nothing herein shall supersede or modify

the terms of any separate license agreement you may have executed

with Licensor regarding such Contributions.

Operating instructions V1.01

© KEBA

43

Page 44

A100Anhang: Apache TM License

6. Trademarks. This License does not grant permission to use the trade names,

trademarks, service marks, or product names of the Licensor,

except as required for reasonable and customary use in describing the origin

of the Work and reproducing the content of the NOTICE file.

7. Disclaimer of Warranty. Unless required by applicable law

or agreed to in writing, Licensor provides the Work

(and each Contributor provides its Contributions) on an

"AS IS" BASIS, WITHOUT WARRANTIES OR CONDITIONS OF ANY KIND,

either express or implied, including, without limitation,

any warranties or conditions of TITLE, NON-INFRINGEMENT,

MERCHANTABILITY, or FITNESS FOR A PARTICULAR PURPOSE.

You are solely responsible for determining the appropriateness

of using or redistributing the Work and assume any risks

associated with Your exercise of permissions under this License.

8. Limitation of Liability. In no event and under no legal theory,

whether in tort (including negligence), contract, or otherwise,

unless required by applicable law (such as deliberate and

grossly negligent acts) or agreed to in writing, shall any

Contributor be liable to You for damages, including any direct,

indirect, special, incidental, or consequential damages of

any character arising as a result of this License or out of

the use or inability to use the Work (including but not

limited to damages for loss of goodwill, work stoppage,

computer failure or malfunction, or any and all other commercial

damages or losses), even if such Contributor has been advised

of the possibility of such damages.

9. Accepting Warranty or Additional Liability.

While redistributing the Work or Derivative Works thereof,

You may choose to offer, and charge a fee for, acceptance

of support, warranty, indemnity, or other liability obligations

and/or rights consistent with this License. However, in

accepting such obligations, You may act only on Your own

behalf and on Your sole responsibility, not on behalf of

any other Contributor, and only if You agree to indemnify,

defend, and hold each Contributor harmless for any liability

incurred by, or claims asserted against, such Contributor

by reason of your accepting any such warranty or additional liability.

END OF TERMS AND CONDITIONS

APPENDIX: How to apply the Apache License to your work.

To apply the Apache License to your work, attach the following

boilerplate notice, with the fields enclosed by brackets "[]"

replaced with your own identifying information.

(Don't include the brackets!) The text should be enclosed in the

appropriate comment syntax for the file format. We also recommend

that a file or class name and description of purpose be included

on the same "printed page" as the copyright notice for easier

identification within third-party archives.

Copyright [yyyy] [name of copyright owner]

Licensed under the Apache License, Version 2.0 (the "License");

you may not use this file except in compliance with the License.

You may obtain a copy of the License at

http://www.apache.org/licenses/LICENSE-2.0

44

Unless required by applicable law or agreed to in writing,

software distributed under the License is distributed on an

"AS IS" BASIS, WITHOUT WARRANTIES OR CONDITIONS OF ANY KIND,

either express or implied. See the License for the specific

language governing permissions and limitations under the License.

Operating instructions V1.01

© KEBA

Page 45

A100 Index

Index

A

Accessories

Scope of delivery ................................ 14

Ambient conditions

Technical data ....................................38

B

Battery

Charge ................................................34

C

Centering mark

Position ...............................................13

Charge

Battery ................................................34

Charging socket

Position ...............................................13

Codes

DataMatrix code.................................. 14

Cover of charging socket

Position .........................................12, 13

E

Errors....................................................... 33

G

General

Technical data ....................................37

I

Idle state.................................................. 23

Installation ...............................................28

L

Laser

Technical data ....................................38

Laser warning plate

Position ...............................................12

M

Machine (automatic operating mode)...... 23

MachineE (automatic operating mode) ... 24

MachineS (automatic operating mode) ... 24

Magnets

Position ...............................................12

D

DataMatrix code

General ...............................................14

Dimensions, weight

Technical data ....................................39

Display..................................................... 15

Menu................................................... 19

Position ...............................................12

Operating instructions V1.01

© KEBA

Manual (manual operating mode) ........... 23

Measuring aid

Installation........................................... 26

Menu

Navigation........................................... 19

Structure ............................................. 19

45

Page 46

A100Index

O

Operating button...................................... 15

Position ...............................................12

Operating modes

Machine (automatic operating mode) . 23

MachineE (automatic operating mode)....

24

MachineS (automatic operating mode)....

24

Manual (manual operating mode)....... 23

Operation................................................. 15

Output for laser radiation

Position ...............................................12

R

Recesses for measuring aid

Position ...............................................12

S

Scope of delivery..................................... 14

Status indicator........................................ 15

T

Type plate

General ...............................................13

Position ...............................................12

46

Operating instructions V1.01

© KEBA

Loading...

Loading...