KeContact P20

Quick Installation Guide

|1| Specifications for the electrical connection

The mains supply line must be hardwired to an existing house installation and

correspond to the nationally applicable legal conditions.

Selection of the RCD circuit breaker:

Each charging station must be connected to a separate RCD circuit breaker. No

RCD circuit breaker of at least Type A.

Dimensioning the Line circuit breaker:

Determine the nominal current in accordance with the specifications on the type

Pay attention to the handling instructions, safety notes and

installation guidelines in the “KeContact P20 Installation manual”!

WARNING!

!

Not observing the safety instructions can result in risk of death,

injuries and damage to the device! KEBA AG assumes no liability for

claims resulting from this!

Electrical hazard!

The installation, commissioning and maintenance of the charging

station may only be performed by correctly trained, qualified and

authorized electricians who are fully responsible for the

compliance with existing standards and installation regulations.

Only connect voltages and circuits in the right-hand connection

area (Ethernet, terminals for control lines) that have a secure

separation to dangerous voltages (e.g. sufficient isolation).

The charging station is set to 10 amps in the delivery state.

Set the maximum EVSE current capacity by setting the DIP-switches in

coordination with your installed line circuit breaker (see chapter “DIP-switch

settings”).

other circuits may be connected to this RCD circuit breaker.

In derogation with this, a RCD circuit breaker Type B can be a requirement by the

vehicle manufacturer. If the electric vehicles are not known (e.g., semi-public

area), the use of an RCD circuit breaker Type B is useful.

plate, in coordination with the desired charging current (DIP switch settings for the

pre-adjusted maximum EVSE current capacity) and the mains supply line.

I

DIPswitch

≤ I

Breaker

≤ I

Cable

≤ I

Rating

|2| Opening the connector panel

Cover screws

Unscrew the two cover screws

[S] on the bottom side of the

housing cover.

Remove the housing cover.

Removing the connector panel cover

Unscrew the four screws with

which the connector panel cover

is mounted and remove the

connector panel cover.

|3| Preparing the cable insertion

Breaking out the cable insertion

openings

Place the housing on a stable

support pad and use a hammer

and flathead screwdriver to

carefully break out the required

cable insertion openings.

Then insert the corresponding

feedthroughs (cable glands or

double-membrane seals)

Use the cable gland when

connecting from above!

|4| Mounting the charging station

Mark and drill the four holes using the supplied drilling template and a spirit

level.

Water drainage

The water drainage from the top side to

the rear side of the charging station must

be ensured. Therefore, observe the

following:

Only a vertical installation of the

charging station is permitted.

The charging station must be

mounted at an angle of 90° (no

inclination is permitted!).

|5| Electrical connection

The cable sheathing must reach into the housing.

Mounting the charging station

Turn the hanger bolts into the

anchors until the thread still

protrudes approx. 2 cm ('x').

Use the shims [A] to compensate

for any unevenness and to

ensure a water drainage behind

the device.

Position and mount the charging

station using the supplied

washers and nuts.

[A]…shim

[B]…charging station housing

[C]…washer

Connecting the mains supply line

[D]…nut

Shorten the connection wires to

the appropriate length; these

should be kept as short as

possible.

The PE conductor must be longer

than the remaining conductors!

Strip approx.12 mm from the

connection wires.

Wire end sleeves are

recommended for finely stranded

wires.

Perform the connection of the

mains supply line [L1], [L2], [L3],

[N] and [PE].

1-phase connection

It is also possible to perform a 1-phase

connection of the charging station. Use

the terminals [L1],[N] and [PE].

Supply terminals

The supply terminals are designed as

spring-type terminals.

Insert the flathead screwdriver

(blade with 5.5 mm) into the

supply terminal as shown on the

picture.

Terminal data:

- inflexible (min.-max): 0.2 – 16 mm²

- flexible (min.-max): 0.2 – 16 mm²

- AWG (min.-max): 24 – 6

- flexible (min.-max) with wire end

sleeve:

Without/with plastic sleeve

0.25 – 10 / 0.25 – 10 mm²

- Stripping length: 12 mm

- Flathead screwdriver: 5.5 mm

1 / 2

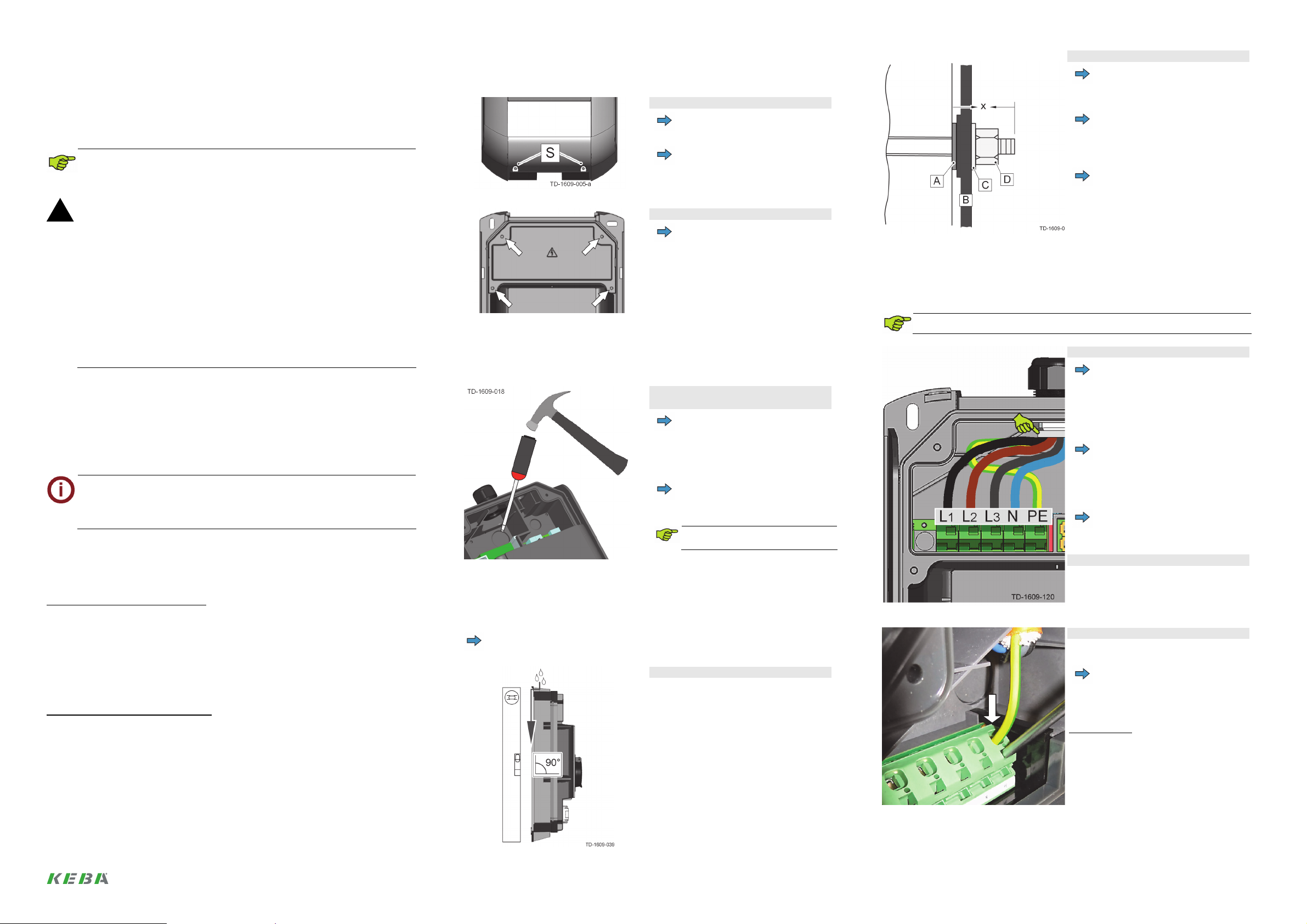

|6| DIP-switch settings

SETTING THE AMPERAGE (DSW1) (*1)

Curr

ent

10A

13A

16A

20A

25A

32A

(*1) Preadjusted maximum current value for the EV charger (control pilot duty cycle).

D1.6 D1.7 D1.8

OFF OFF OFF

ON OFF OFF

OFF ON OFF

ON ON OFF

OFF OFF ON

ON OFF ON

■…Indicates the position where to push down the DIP switch.

Position of the DIP-switches DSW1/2

[DSW1]…configuration

[DSW2]…addressing

Amperage settings with DSW1

Example setting for 16A.

Figure

Min. cable

cross

section

≥ 1.5 mm²

≥ 1.5 mm²

≥ 2.5 mm²

≥ 2.5 mm²

≥ 4.0 mm²

≥ 6.0 mm²

|7| General commissioning process

1. Remove all residual installation and connection materials from the connection

area.

2. Before

3. Check whether all unused cable glands are properly sealed with blind plugs or

4. Ensure that the voltage of the mains supply line is switched on.

5. Perform the specified initial tests according to the locally applicable regulations

6. Close the connector panel cover to the charging station.

7. Mount the housing cover.

Commissioning mode

The charging station can be placed into a commissioning mode for supporting the

initial system test. During this, a self test of the device is performed (interlocking,

contactor activation, current measurement, etc.) and the result is displayed.

After successful test without connected vehicle, the contactor is switched for limited

time in order to facilitate the initial tests. A normal charging procedure is not possible

in commissioning mode. The interlocking of the connector socket is activated to

prevent a cable from being plugged in.

Switching on the charging station in commissioning mode via the supply voltage leads

for security reasons in an error state (white-red-red-red) to prevent an unattended

activation.

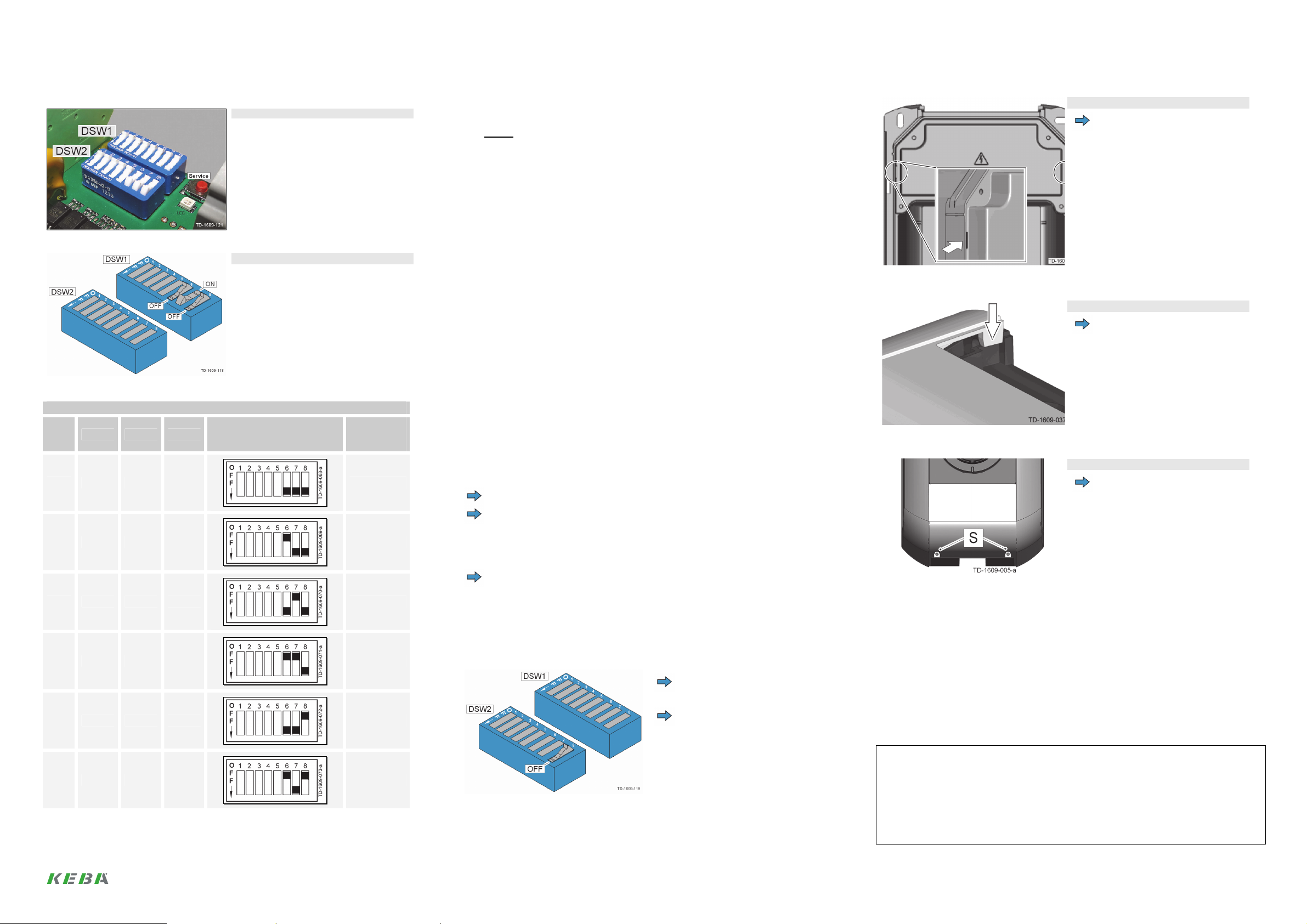

Activating the commissioning mode

Deactivating the commissioning mode

commissioning, check all screw and terminal connections for firm seating!

dummy screw fittings.

After 15 to 20 seconds, the status LED must flash green slowly.

The device performs a self test every time it is switched on.

and laws.

Set the DIP-switch DSW2.8 to ON.

Perform a reset of the charging station. To do this press the [Service

button] for 1 second.

The commissioning mode is now activated and is indicated by the orange

status LED (lights continuously).

You now have the option for approximately 5 min. to contact with standard

test probes using the measuring device ( e.g. Astaco® test probes from

BEHA) and to perform the necessary tests.

After 5 min. have elapsed, the contactor is deactivated in the charging

station is shut down.

Set the DIP-switch DSW2.8 to

OFF again.

Perform a reset of the charging

station. To do this, press the

[Service button] for 1 second or

switch the power supply voltage

off/on.

The charging station starts up

DSW2.8 = OFF

again in normal mode and is

ready for operation.

|8| Closing the Wallbox

Housing mark

Fitting the housing cover

Cover screws

© KEBA 2014

Subject to alteration in the course of technical advancement. No guarantee is offered for the

accuracy of the information provided. All rights reserved.

All brand and product names are trademarks of their respective companies. Technical

information in this document is subject to change without notice.

Document: Revision 1.00 / Release date: 06.02.2014 / Article no.: 93408

KEBA AG, Postfach 111, Gewerbepark Urfahr, A-4041 Linz; www.kecontact.com

Tighten the four screws until the

mark on the connector panel

cover is even with the housing

surface.

The connector panel cover must

seal the housing properly.

Fit the housing cover at the top

and push the cover downwards

slightly.

Make sure that the housing cover

is seated correctly at the top in

the housing guides.

Secure the housing cover at the

bottom using the two cover

screws [S].

2 / 2

Loading...

Loading...