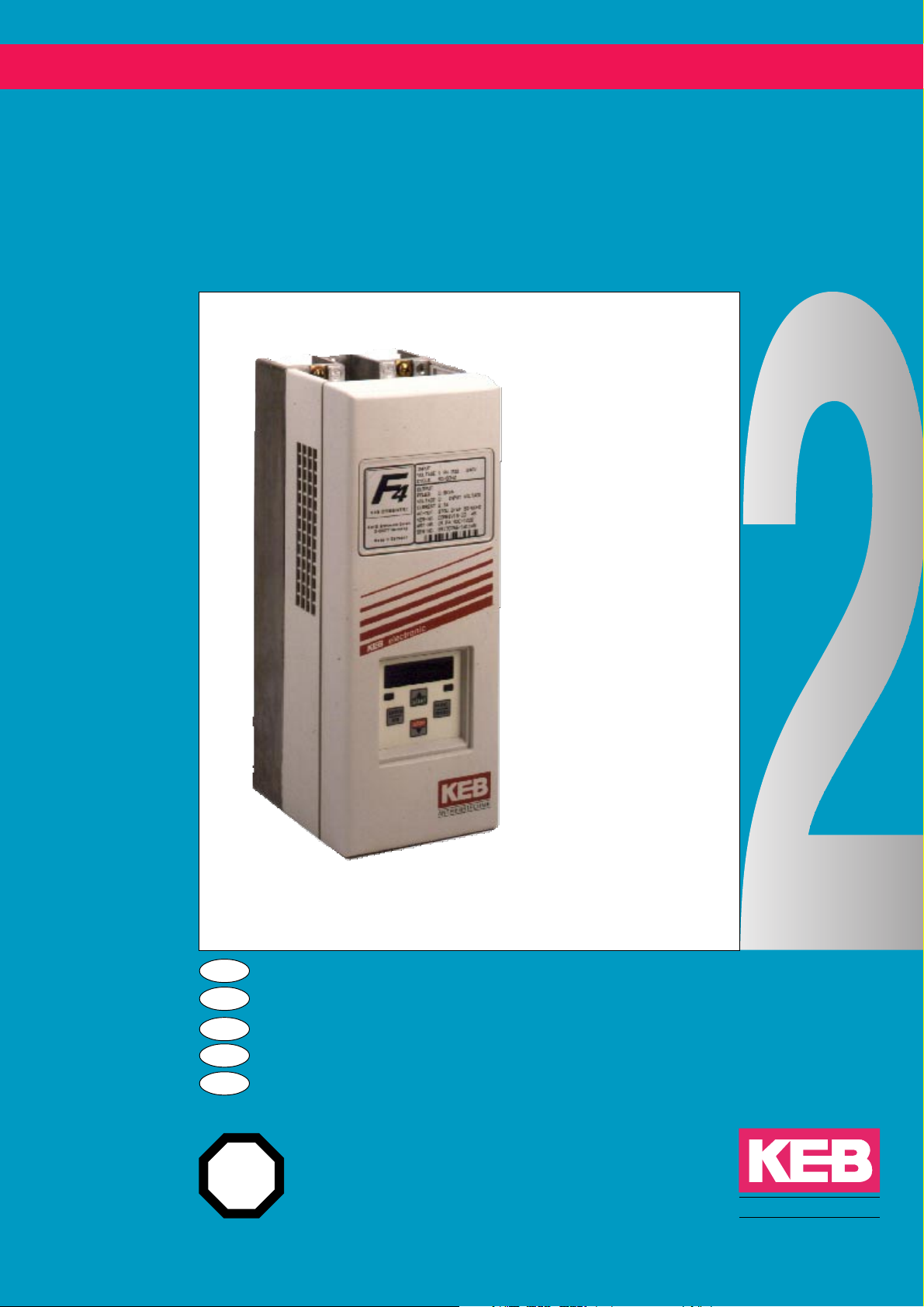

COMBIVERT

00.F4.S0B-K111

D

GB

F

I

E

STOP

0,37...0,75 kW

BETRIEBSANLEITUNG KEB COMBIVERT F4-S

INSTRUCTION MANUAL

MANUEL D'INSTRUCTIONS

MANUALE D'ISTRUZIONE

MANUAL DE INSTRUCCIONES

Erst Betriebsanleitung Teil 1 lesen !

Read Instruction manual part 1 first !

Lisez d'abord le manuel d'instructions partie 1 !

Prima leggere le manuale di istruzione 1 parte !

Leer manual de instrucciones parte 1 antes !

ANTRIEBSTECHNIK

10/98

D

Seite 3............... 24

GB

Page 25 ............. 46

F

Page 47 ............. 68

Diese Betriebsanleitung muß jedem Anwender zugänglich gemacht

werden.Vor jeglichen Arbeiten muß sich der Anwender mit dem Gerät

vertraut machen. Darunter fällt insbesondere die Kenntnis und Beachtung der Sicherheits- und Warnhinweise. Die in dieser Betriebsanleitung verwendeten Pictogramme entsprechen folgender Bedeutung:

Gefahr Achtung, Information

Warnung Unbedingt Hilfe

Vorsicht beachten Tip

This instruction manual must be made available to any user. Before

working with this unit the user must be familiarized with it. This is

especially true for the attention, safety and warning guides. The

meaning of the pictograms used in this manual are:

Danger Attention, Information

Warning observe at Help

Caution all costs Tip

Ce manuel d'instructions doit être rendu accessible à tout utilisateur.

Avant tous travaux, l'utilisateur doit se familiariser d'abord avec le

variateur, notamment tenir compte des mesures de sécurité et des

avertissements. Les pictogrammes utilisés dans ce manuel ont les

significations suivantes:

I

Página 69 ......... 90

I

E

Pagina 91 ......... 112

Danger Attention, Information

Avertissement à respecter Aide

Précaution obligatoirement Astuces

Questo manuale di instruzioni deve essere messo a disposizione di

tutti gli utenti. Prima di impregare questa apparecchiatura. L' utente

deve prima familiarizzare con essa. In particolar modo prestare

attenzione alle sottoindicate direttive di avvertimento e sicurezza

personale nell ' utilizzo dell ' apparecchiatura.

Pericolo Attenzione, Informazione

Avvertimento osservare Aiuto

Cautela assolutamente Suggerimento

Este manual de instrucciones debe ser accesible a todos los usuarios.

Antes de conectar el convertidor, el usuario debe de familiarizarse

con el convertidor, especialmente debe de tener en cuenta las

medias de seguridad y advertencias. Los pictogramas utilizados en

este manual tienen los significados siguientes:

Peligro

Advertencia

Precaución

Atención

de obligado

cumplimiento

Información

Ayuda

Nota

© KEB 00.F4.S0B-K111 10/98

Table of Contents

ANTRIEBSTECHNIK

1. General .......................................................... 26

1.1 Product Description ............................................... 26

1.2 Identifikation of the unit ......................................... 27

2. Power Circuit................................................. 27

2.1 Performance Data................................................... 27

2.2 Dimensions ............................................................. 26

2.3 Installation Instructions ......................................... 26

2.4 Terminals ................................................................. 29

2.5 Connection of the Power Circuit ........................... 29

3. Control circuit ................................................... 30

3.1 Assignment of Terminal Strip X1 ........................... 30

3.2 Connection of the control ...................................... 30

3.2.1

3.2.2

3.2.3

Digital inputs ............................................................

Analog input .............................................................

Outputs .....................................................................

30

30

31

GB

4. Operation of the unit .................................... 31

4.1 Digital operator ....................................................... 31

4.1.1 Interface operator...................................................... 31

4.1.2

4.2 Parameter Summary............................................... 33

4.3 Password Input....................................................... 33

4.4 Operating Display ................................................... 34

4.5 Basic Adjustment of the Drive............................... 35

4.6 Special Adjustments .............................................. 37

4.7 The Drive Mode....................................................... 42

4.7.1

4.7.2

4.7.3

4.7.4

Keyboard ..................................................................

Start / Stop Drive ......................................................

Change Direction of Rotation ...................................

Preset Set Value .......................................................

Leave Drive Mode ....................................................

32

42

42

42

42

5. Error Diagnosis ............................................. 43

6. Index............................................................... 44

7. Password ..................................................... 113

25

General

1. General

1.1 Product Description

GB

In selecting the KEB COMBIVERT you have chosen a frequency inverter

with the highest demands on quality and dynamic.

It exclusively serves for a stepless speed regulation of

the three-phase motor.

The operation of other electrical utilization equipment is

forbidden and can lead to the destruction of the unit.

This instruction manual describes the COMBIVERT F4-S

- 0.37kW / 230V-class

- 0.75kW / 230V-class

Through small dimensions and an optimal price the unit is convincing with

following features:

- operator-friendly interface

- low switching losses due to IGBT power circuit

- short-time overload up to 200%

- extensive protection devices for current, voltage and temperature

- conditional short-circuit and earth-fault-proof

- immunity to interference according to IEC1000

- potential-separated digital inputs

- programmable relay output

- DC-brake

- 3 fixed frequencies

- slip compensation

- auto-boost

- output voltage stabilization

- speed search

- adjustable current limits for acceleration and constant operation

- fast commissioning by way of keyboard (Drive-Mode)

- optional networking via gateway with Interbus-S, CAN and Profibus

26

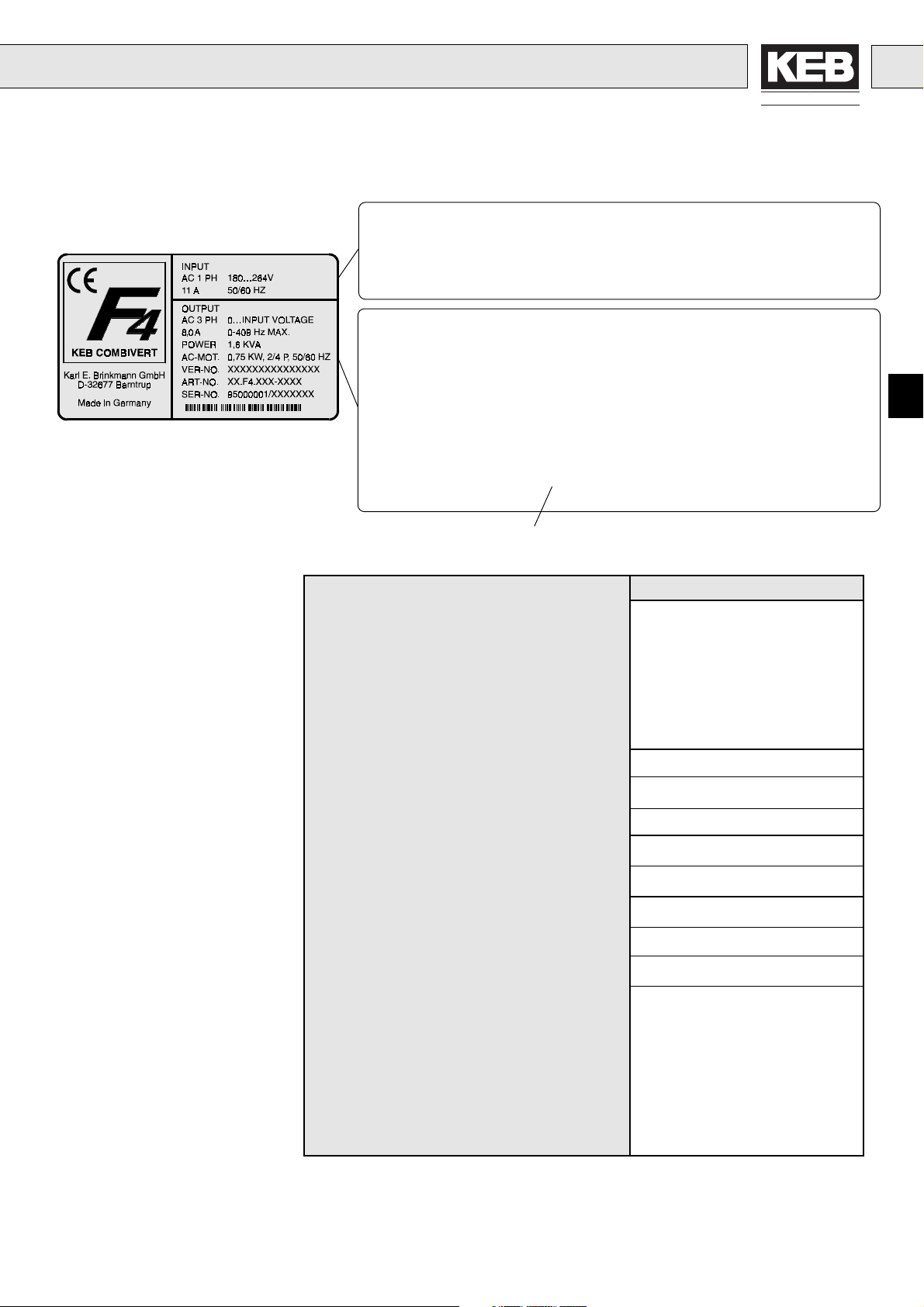

1.2 Identification of the unit

General

ANTRIEBSTECHNIK

Input Specifications:

Input mains perm. mains voltage range

Input current during nominal load mains frequency

Output Specifications:

Output phases Output voltage range

Output current during nominal load Output frequency range

Max. output rated power of the inverter in relation to 230VAC

Recommended nominal data of the motor to be used

COMBIVIS Identification number:

Part number: 07.F4.S0C-1220

Serial number:

GB

2. Power Circuit

2.1 Performance Data

The following performance

data apply to 2/4-pole

standard motors. For other

pole numbers the frequency

inverter must be

dimensioned onto the rated

motor current. With regard

to special-purpose or

medium frequency motors

please contact KEB.

Unit Size

Size 05 07

Nominal power output

1)

[kVA] 0,9 1,6

Peak current ( <30s) [A] 4,6 8,0

Nominal output current [A] 2,3 4,0

Max. rated motor power [kW] 0,37 0,75

Max. switching frequency [kHz] 8 8

Power loss [W] 35 50

Load capacity 30s max. peak current

Mains voltage [V] 180...264 ± 0 %

Network phase 1

Mains frequency [Hz] 50 / 60 ± 2

Output voltage [V] 3 x 0 ... U

Mains

Output frequency [Hz] 0...409,58

Max. permissible mains fuse [A] 10 20

Supply cross section

2)

[mm2] 1,5 2,5

Permissible temp. limit value -25...70°C storage

-10...45°C in operation

Relative humidity max.95% (without precipitation)

Design-/protective system IP20

Noise suppression

3)

EN 50081-1/ 50082-2

Noise immunity IEC 1000 4-2/-3/-4/-5/-6

Emitted interferences EN55011-B / EN 55022-A

1)

In relation to 230V rated voltage

2)

Recommended minimal cross section at rated power and cable length up to 100m (copper).

3)

Only with optional built-in filter und shielded, grounded motor cable on both sides

27

Power Circuit

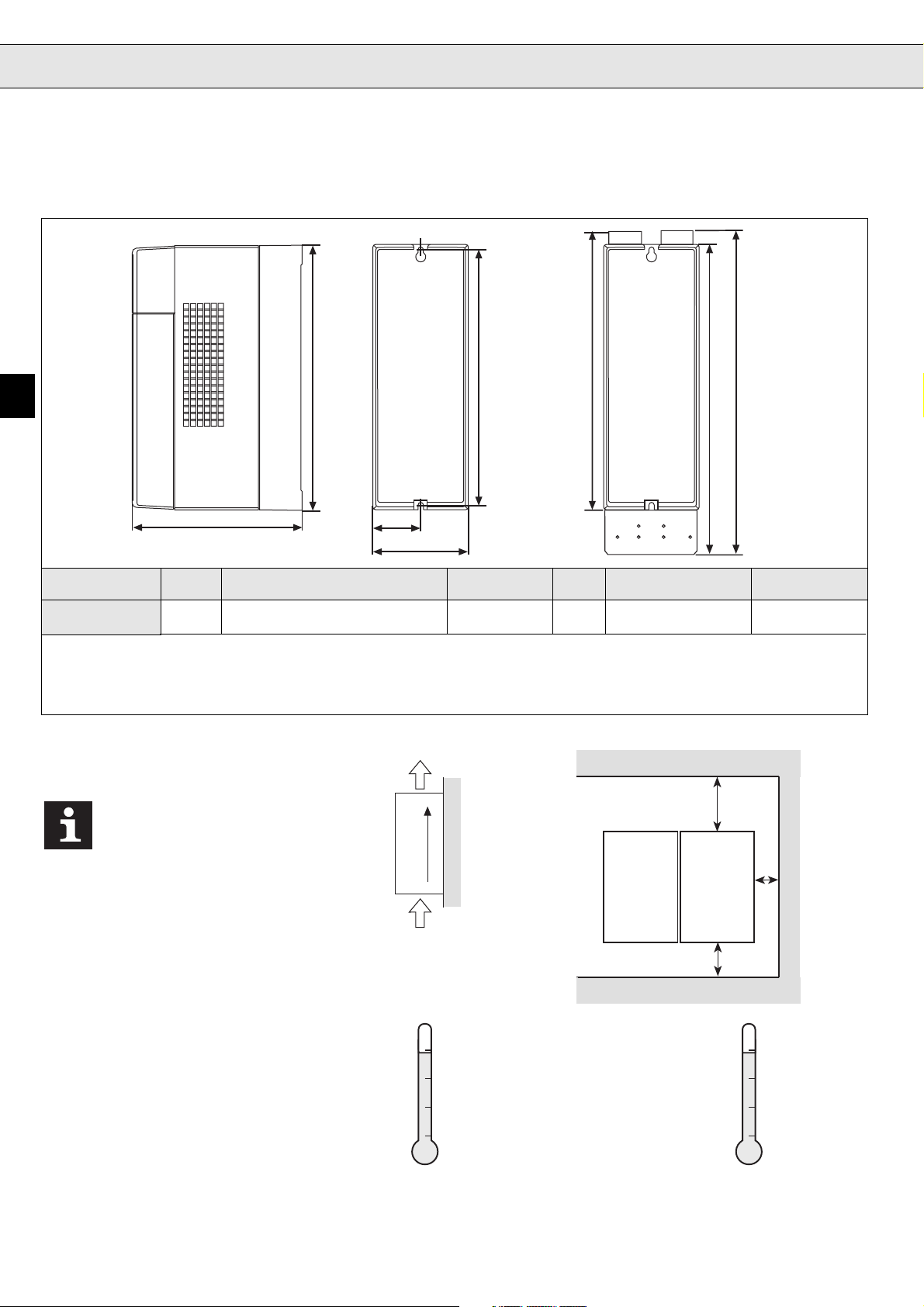

2.2 Dimensions

Ø F

GB

C / C1

Size A B B1 B2 B3 C C1 F G H H1 Weight [kG]

C 90 230 264 260 300 115 165 5 45 220 240 1,5

B1/C1/H1 with submounted filter

B2 with screening plate

B3 with submounted filter and screening plate

2.4 Installation

Instructions

Installation height max.

2000 m. At installation

heights over 1000 m a

power reduction of 1% per 100m

must be taken into consideration.

B

G

A

H

Direction of the cooling fins

Always install vertically!

B2B1 B3

minimum clearance in mm

150

F4 F4

100

30

28

Transport-/

Storage

temperature

max +70°C

min -25°C

Cooling agent inlet

temperature/

ambient temperature

during operation

max +45°C

min -10°C

Power Circuit

ANTRIEBSTECHNIK

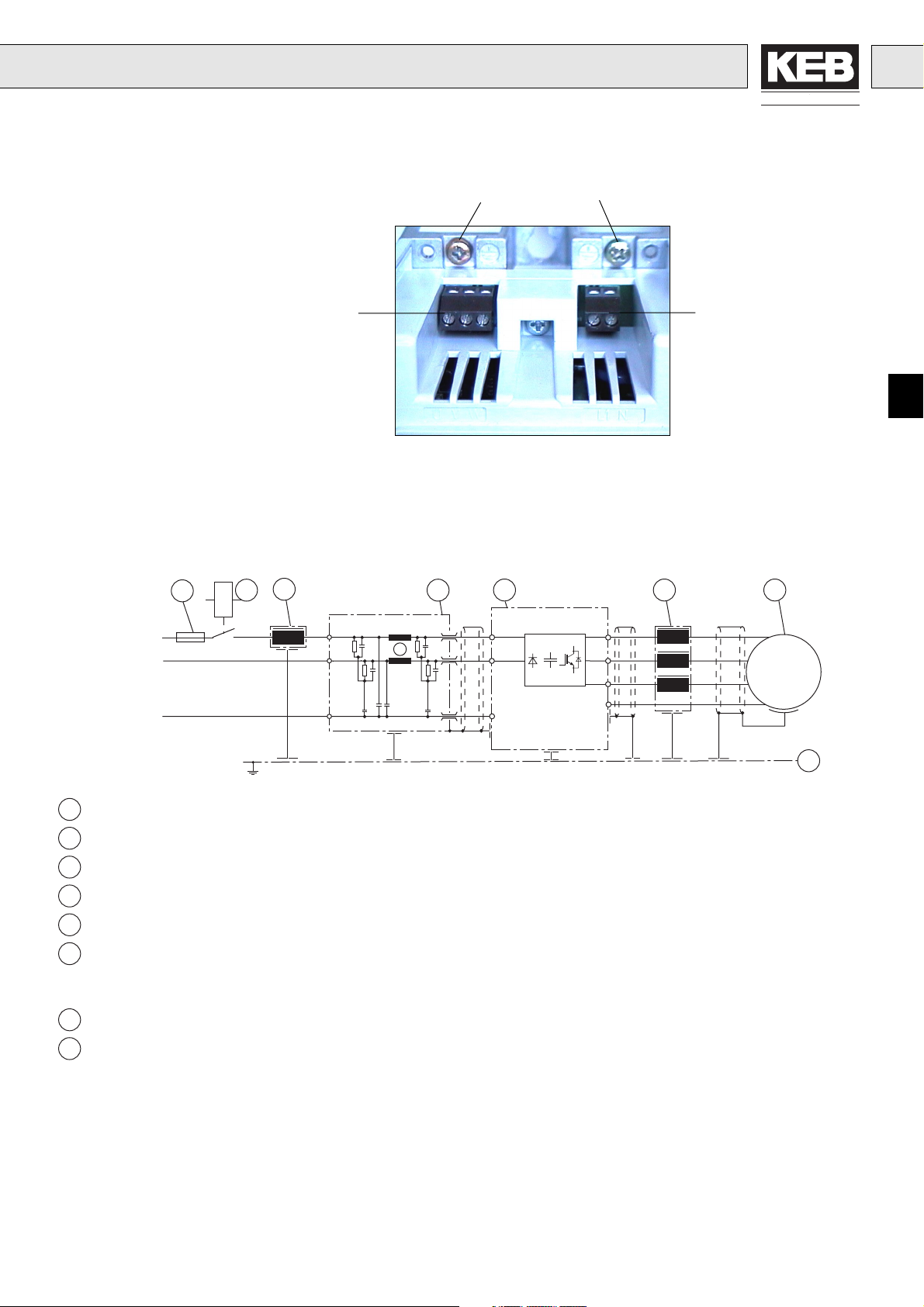

2.3 Terminals

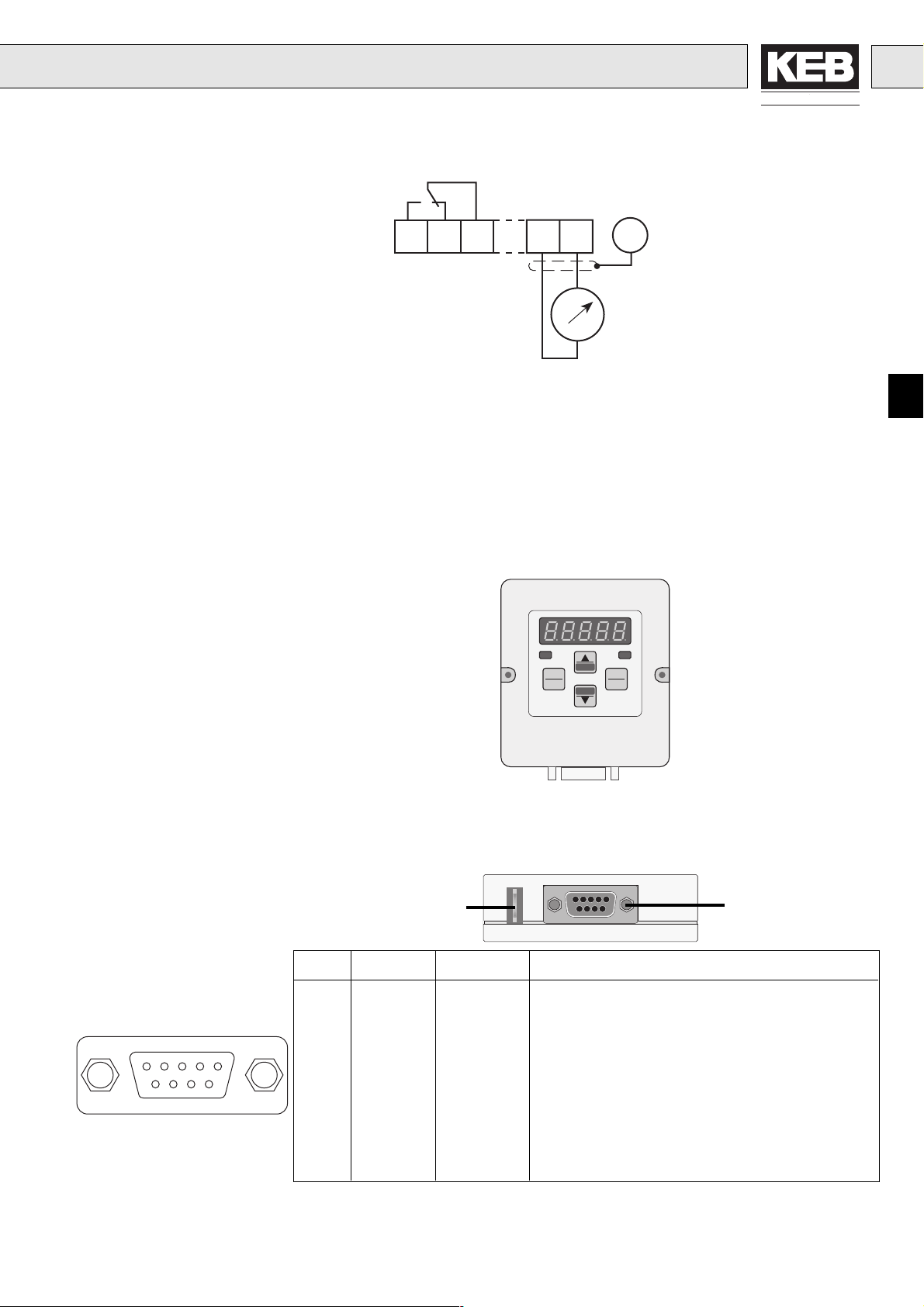

2.5 Connection of the

Power Circuit

1

L1

N

PE

2

Motor

connection

3

L1

N

PE

U V W

4

Earth terminals

Mains

connection

L1 N

5 6 7

L1

N

PE

U

+

V

W

PE

U

V

W

PE

U1

V1

W1

PE

3

GB

M

~

Mains fuse (see „Technical Data“)

1

Mains contactor !!! Generally switch only the phase !!!

2

Input reactor (Part.No. Size 05: 00.90.291-4848 / Size 07: 00.90.291-2948)

3

Interference suppression filter (GEN.No. Size 05: 05.U4.00C-B600 / 07: 07.U4.00C-B600)

4

KEB COMBIVERT F4-S

5

Motor choke (Part.No. Size 05: 00.90.290-4245 / Size 07: 00.90.291-2845)

6

!!! Only use up to 4 KHz switching and 51 Hz output frequency !!!

For other switching or output frequencies ask KEB.

Motor

7

Mounting plate

8

8

29

Installation and Connection

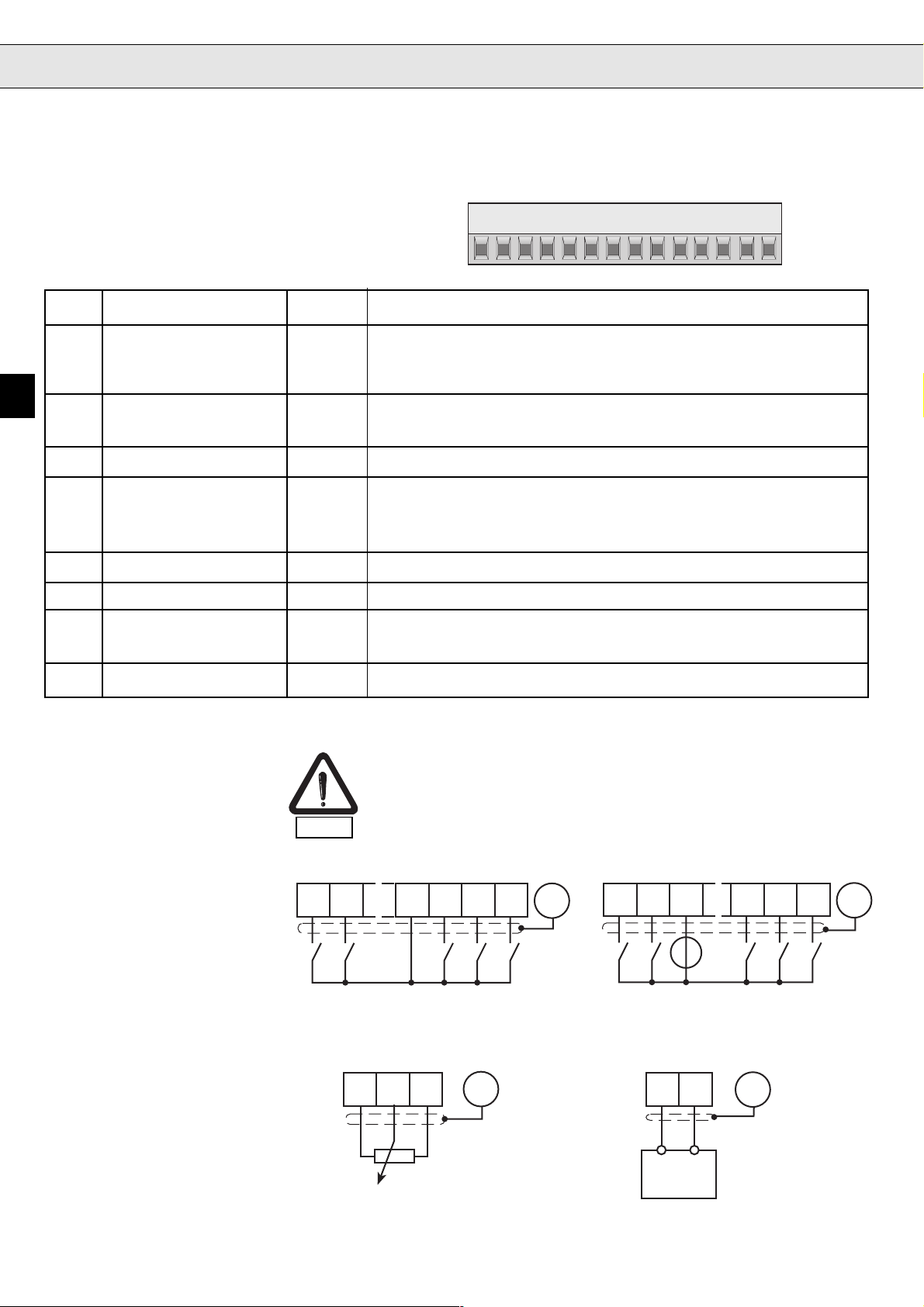

3. Control circuit

3.1 Assignment of

Terminal Strip X1

PIN Function Name Description

X1.1 NO contact RLA Relay output (30V DC / 1A)

X1.2 NC contact RLB Function see parameter CP.22

GB

X1.3 Main contact RLC ( factory setting: fault indication)

X1.4 Fixed frequency 1 I1 X1.4 + X1.5 = fixed frequency 3

X1.5 Fixed frequency 2 I2 no input = analog set value

X1.6 Digital Ground 0V Zero potential for digital in-/outputs

X1.7 +10V CRF Supply voltage for set value potentiometer (max. 4mA)

X1.8 Set value input REF 0...10VDC for analog set value

X1.9 Common COM Ground for analog in- and outputs

X1.10 Analog output AOUT Analog output of real frequency 0...10VDC = 0...100Hz

X1.11 15V +15V voltage supply for digital in-/outputs (max. 100mA)

X1.12 Reverse R Preset rotation; forward has priority

X1.13 Forward F

123456789101112

13 14

X1.14 Control release ST/RST Power modules are enabled; Reset at opening

3.2 Connection of the

control

In order to prevent a malfunction caused by interference voltage supply on

the control inputs, the following directions should be observed:

- Use shielded/drilled cables

- Lay shield on one side of the inverter onto earth potential

- Lay control and power cable separately (about 10...20 cm apart)

EMCEMC

EMC

3.2.1 Digital input

EMCEMC

InternalInternal

Internal voltage supply

InternalInternal

4 5 11 12 13 14

- Lay crossings in a right angle (in case it cannot be prevented)

ExternalExternal

External voltage supply

ExternalExternal

4 6 12 13 14

PE

5

+

13...30VDC

3.2.2 Analog input

Internal analog set-point

setting 0...10V

789 PE

External analog

set-point setting

89

PE

PE

30

R = 3...10 kΩ

+-

SPS

0...10 DCV

Ri = 56 kΩ

START

STOP

FUNC.

SPEED

ENTER

F/R

3.2.3Outputs

Installation and Connection

ANTRIEBSTECHNIK

4. Operation of the

unit

4.1 Digital operator

Part-No. 00.F4.010-2009

123 910

Relay output:

30V DC / 1A

PE

Analog output:

+

0...10VDC / max. 5mA

at Ri 56 kΩ const.

0...1mADC at

Ri ≤ 5 kΩ const.

As an accessory to the local operation an operator is necessary. To

prevent malfunctions, the inverter must be brought into

nOP

status

before connecting/disconnecting the operator (open control release

terminal X1.14). When starting the inverter without an operator, it is

started with the last stored values or factory setting. The operator is

obtainable in different versions:

5-digit LED Display

Interface control

Transmit "LED flickers"

Operating-/Error display

Normal "LED on"

Error "LED blinks"

GB

4.1.1 Interface operator

Part-No. 00.F4.010-1009

12345

6789

Double function keyboard

In the Interface operator there is an additional isolated RS232/RS485Interface integrated.

PE-Connection

RS232/RS485

PIN RS485 Signal Meaning

1 –– reserved

2 – TxD Transmitter signal/RS232

3 – RxD Receiver signal/RS232

4 A' RxD-A Receiver signal A/RS485

5 B' RxD-B Receiver signal B/RS485

6 – VP Voltage supply-Plus +5V (I

= 10 mA))

max

7 C/C' DGND Data reference potential

8 A TxD-A Transmitter signal A/RS485

9 B TxD-B Transmitter signal B/RS485

Informations about other versions of operators contact KEB!

31

Operation of the Unit

4.1.2 Keyboard

GB

When switching on KEB COMBIVERT the value of parameter CP.1

appears. (See Drive mode to switch the keyboard function)

The function key (FUNC)

changes between the

parameter value and

FUNC.

SPEED

parameter number.

With UP ( ) and DOWN

( ) the value of the

parameter number is

increased / decreased with

changeable parameters.

START

STOP

START

STOP

Principally during a change, parameter values are immediately accepted

and stored non-volatile. With some parameters it is not useful, that the

adjusted value immediately be accepted. When this type of parameter is

changed, then a point appears behind the last digit.

By pressing ENTER the

adjusted value is

accepted and non-volatile

ENTER

F/R

stored.

If a malfunction occurs during operation, then the actual display is

overwritten by the alarm message. The alarm message in the display is

reset by ENTER.

error

ENTER

F/R

With ENTER the error message is only reset in the display. In

order to reset an error oneself, the cause must be removed

and a reset on terminal X1.14 or a power-on reset must occur.

In the Inverter status display (CP. 2) the error is still displayed.

32

4.2 Parameter Summary

Operation of the Unit

ANTRIEBSTECHNIK

Display Parameter Adjust. range Resolution

Factory setting

CP. 0 Password input 0...9999 1 CP. 1 Actual frequency display - 0,1 Hz CP. 2 Inverter status display - - CP. 3 Actual load - 1 % CP. 4 Peak load - 1 % CP. 5 Rated frequency 0...409.58 Hz 0.0125 Hz 50.0 Hz

CP. 6 Boost 0...25.5 % 0.1 % 2 %

CP. 7 Acceleration time 0.01...300 s 0.01 s 10 s

CP. 8 Deceleration time 0.01...300 s 0.01 s 10 s

CP. 9 Minimal frequency 0...409.58 Hz 0.0125 Hz 0 Hz

CP.10 Maximal frequency 0...409.58 Hz 0.0125 Hz 70 Hz

CP.11 Fixed frequency 1 ±0...409.58 Hz 0.0125 Hz 5 Hz

CP.12 Fixed frequency 2 ±0...409.58 Hz 0.0125 Hz 50 Hz

CP.13 Fixed frequency 3 ±0...409.58 Hz 0.0125 Hz 70 Hz

CP.14 Max. ramp current 10...200 % 1 % 140 %

CP.15 Max. constant current 10...200 % 1 % 200 %

CP.16 Speed search 0...7 1 0

CP.17 Voltage stabilization 150...649 V,oFF 1 V oFF

CP.18 Slip compensation -2.50...2.50 0.01 0=oFF

CP.19 Autoboost -2.50...2.50 0.01 0=oFF

CP.20 DC-braking 0...9 1 0

CP.21 Braking time 0...100 s 0.01 s 10 s

CP.22 Relay output 0...25 (0...24)

1)

12

CP.23 Frequency level 0...409.58 Hz 0.0125 Hz 4 Hz

GB

1)

Value 0...24 is valid as of software version 1.1

4.3 Password Input Ex works the frequency inverter is supplied without password protection,

this means that all changeable parameters can be adjusted. After

parameterizing the unit can be barred against unauthorized access. The

adjusted mode is stored.

ENTER

Locking the

Password

CP-Parameter

UP

FUNC

ENTER

Releasing the

Password

CP-Parameter

UP

FUNC

33

Operation of the Unit

4.4 Operating Display

Actual frequency display

GB

Inverter status display

The 4 parameters below serve to control the frequency inverter during

operation.

Display of the actual output frequency with a resolution of 0.0125 Hz. The

rotation of the inverter is indicated by the sign.

Output frequency 18.3 Hz, rotation forward

Examples:

Output frequency 18.3 Hz, rotation reverse

The status display shows the actual working conditions of the inverter.

Possible displays and their meanings are:

" no Operation " control release (terminal X1.14) not

bridged, modulation switched off, output voltage = 0 V,

drive is not controlled.

" Low Speed " no rotation preset ( terminal X1.12 or

X1.13), modulation switched off, output voltage = 0 V,

drive is not controlled.

" Forward Acceleration " drive accelerates with a forward

direction of rotation.

Actual load

Peak load

" Forward Deceleration " drive decelerates with a forward

direction of rotation.

" Reverse Acceleration " drives accelerates with a reverse

direction of rotation.

" Reverse Deceleration " drive decelerates with a reverse

direction of rotation.

" Forward Constant " drive runs with a constant speed

and a forward direction of rotation.

" Reverse Constant " drive runs with constant speed and

a reverse direction of rotation.

Other status messages are described at the parameters, which they cause.

Display of the actual inverter rate of utilization in percent. 100% rate of

utilization is equal to the inverter rated current. Only positive values are

displayed, meaning there is no differentiation between motor and

regenerative operation.

This display makes it possible to recognize short-term fluctuations of the

rate of utilization by storing the highest value that occurred. The display

occurs in percent (100% = inverter rated current).

34

With the UP or DOWN key the peak value can be reset when the

unit is on. Switching off the unit deletes the peak value.

Operation of the Unit

ANTRIEBSTECHNIK

4.5 Basic Adjustment

of the Drive

Rated frequency

Boost

The following parameters determine the fundamental operating data of

the drive. They should be checked and/or adapted to the application.

With the adjusted frequency here the inverter reaches a maximal output

voltage. The adjustment of the motor rated frequency is typical here.

Note: Motors can overheat when the rated frequency is incorrectly

adjusted!

U

A

Adjustment range: 0...409.58 Hz

Resolution: 0.0125 Hz

100%

Factory setting: 50.0 Hz

Customer adjustment: _______ Hz

CP. 5

f

In the lower speed range a large part of the motor voltage decreases on

the stator resistance. In order that the breakdown torque of the motor

remains almost constant in the entire speed range, the voltage decrease

can be compensated by the boost.

U

A

Adjustment range: 0...25.5 %

Resolution: 0.1 %

Factory setting: 2.0 %

Customer adjustment: _______ %

CP. 6

CP. 5

f

Adjustment: - Determine the rate of utilization in no-load operation during

rated frequency

- Preset about 10 Hz and adjust the boost, so that about the

same rate of utilization is reached as with the rated frequency.

When the motor, during continuous operation, drives with low

speed and too high voltage it can lead to an overheating of the

motor.

GB

Acceleration time

The parameter determines the time needed, in order to accelerate from

0 to 100 Hz. The actual acceleration time is proportional to the frequency

change.

CP. 7 x delta f

actual acceleration time =

100 Hz

Adjustment range: 0.01...300 s

f

100 Hz

Resolution: 0.01 s

Factory setting: 10 s

Customer adjustment: _______ s

CP. 7

t

Example: CP. 7 = 10 s ; the drive should accelerate from 10 Hz to 60 Hz

delta f = 60 Hz - 10 Hz = 50 Hz

actual acceleration time = (50 Hz / 100 Hz) x 10s = 5 s

35

Operation of the Unit

GB

Deceleration time

Minimal frequency

The parameter determines the time needed in order to decelerate from 100

to 0 Hz. The actual deceleration time is proportional to the frequency change.

CP. 8 x delta f

actual acceleration time =

100 Hz

Adjustment range: 0.01...300 s

Resolution: 0.01 s

f

100 Hz

Factory setting: 10 s

Customer adjustment: _______ s

CP. 8

t

Example: CP. 8 = 10 s ; the drive should decelerate from 60 Hz to 10 Hz

delta f = 60 Hz - 10 Hz = 50 Hz

actual deceleration time = (50 Hz / 100 Hz) x 10s = 5 s

Frequency on which the inverter runs without presetting an analog set

value. Internal limiting of the fixed frequencies CP.11…CP.13.

f

Adjustment range: 0.0...409.58 Hz

Resolution: 0.0125 Hz

CP.10

Factory setting: 0.0 Hz

Customer adjustment: _______ Hz

CP. 9

U

10 V0 V

REF

Maximal frequency

Fixed frequency 1...3

terminal X1.4

terminal X1.5

terminals X1.4+X1.5

Frequency on which the inverter runs with maximum analog set value.

Internal limiting of the fixed frequencies CP.11…CP.13.

Adjustment range: 0.0...409.58 Hz

Resolution: 0.0125 Hz

Factory setting: 70 Hz

Customer adjustment: _______ Hz

Three fixed frequencies can be adjusted. The selection of the fixed

frequencies occurs with the terminals X1.4 and X1.5.

Adjustment range:0.0...±409.58 Hz

Resolution: 0.0125 Hz

Factory setting: 5/50/70 Hz

Customer adjustment 1:______ Hz

Customer adjustment 2:______ Hz

Customer adjustment 3:______ Hz

If presetting occurs outside of the fixed limits of CP.9 and CP.10, then the

frequency is internally limited.

36

Operation of the Unit

ANTRIEBSTECHNIK

4.6 Special

Adjustments

Max. ramp current

Max. constant current

The following parameters serve to optimize the drive and adaption onto

certain applications. These adjustments can be ignored at the initial startup.

This function protects the frequency inverter against switching off by

overcurrent during the acceleration ramp. When the ramp reaches the

adjusted value here, then it is stopped as long as the current decreases

again. CP.2 displays "LAS" at active function.

Adjustment range:10...200%, 200% = oFF

Resolution: 1 %

Factory setting: 140 %

Customer adjustment: _______ %

This function protects the frequency inverter against switching off due to

overcurrent during constant output frequency. When exceeding the

adjusted value here, the output frequency is reduced until the value drops

below the adjusted value. CP. 2 displays "SSL" at active function.

GB

CP.14

CP.15

on

off

on

f

Adjustment range:10...200%, 200% = oFF

Resolution: 1 %

Factory Setting: 200 %

Customer adjustment: _______ %

off

f

real

set

t

LAD-stop

t

Current limit

t

t

37

Operation of the Unit

GB

Speed search

Voltage stabilization

When connecting the frequency inverter onto a decelerating motor, an

error can be triggered by the differing rotating field frequencies. At

activated speed search the inverter searches the actual motor speed,

adapts its output frequency and accelerates with the adjusted ramp onto

the given set value. During speed search CP.2 displays "SSF". The

parameter determines, under what conditions the functions operate. With

several conditions the sum of the value must be entered.

Example: CP.16 = 5 means at control releas and after reset

Adjustment range: 0...7 Value Condtion

Resolution: 1 0 function off

Factory setting: 0 1 at control release

Customer adjustment: _______ 2 at switch on

4 after reset

This parameter can adjust a regulated output voltage in relation to the

rated frequency. Because of this voltage variations at the input as well as

in the intermediate circuit only have a small influence on the output voltage

(U/f-characteristic). The function allows, among other things, an adaption

of the output voltage onto the special motors. In the example below the

output voltage is stabilized onto 230 V (0% boost).

Adjustment range:150...649 V, oFF

Resolution: 1 V

Factory setting: oFF

Customer adjustment: _______ V

U

N/UA

250 V

CP.17 = 230 V

190 V

CP.5 = 50 Hz

UA at UN = 250V unstabilized

UA at UN = 250V stabilized

UA at UN = 190V stabilized

UA at UN = 190V unstabilized

UN = mains voltage

UA= output voltage

f

38

Operation of the Unit

ANTRIEBSTECHNIK

Slip compensation

Autoboost

Slip compensation balances the speed changes caused by the load

variation. In order to activate the function, set the value at 1.00 and

optimize as directed in the examples below.

Adjustment range: -2.50...2.50

Resolution: 0.01

Factory setting: 0.00 (= oFF)

Customer adjustment: _______

GB

Autoboost causes an automatic I*R-compensation by raising the output

voltage during high load torques. The magnetizing current remains

constant. To activate the function set the value to 1.00 and optimize as

directed in the examples below. Check the motor voltage to see, whether

it returned to the normal value after no load of the drive. Otherwise reduce

CP.19.

Adjustment range: -2.50...2.50

Resolution: 0.01

Factory setting: 0.00 (= oFF)

Customer adjustment: _______

Slip compensation and autoboost work on the basis of preset

motor data. When using a special motor or in case of

overdimensioning of more than one size, then both functions

should be deactivated.

M

1

23

n

1) good - speed remains stable at increasing torque

2) bad - speed decreases with increasing torque

3) bad - speed is increased too much at load

CP.18

CP.19

CP.19

CP.18

OK !

f/n

real

=

=

=

=

load

f

n

real

f

n

real

f

n

real

f

n

real

39

Operation of the Unit

GB

DC-braking

With DC-braking the motor is not decelerated by the ramp. Quick braking

is caused by DC voltage, which is applied onto the motor winding. This

parameter determines how the DC-braking is triggered.

Value Activation

0 DC-braking deactivated

1 DC-braking at switch off of the direction of rotation and in

reaching 0Hz. Braking time is dependent on CP.21 or until

the next direction of rotation presetting.

2 DC-braking as soon as the direction of rotation presetting

is absent. Braking time dependent on the real frequency

3 DC-braking, as soon as the direction of rotation changes.

Braking time dependent on the real frequency.

4 DC-braking at switch off of the direction of rotation and the

real frequency goes below 4 Hz.

5 DC-braking, when the real frequency goes below 4 Hz.

6 DC-braking, as soon as the set value goes below 4 Hz.

7 DC-braking deactivated

8 DC-braking deactivated

9 DC-braking after switching on the modulation on. Braking

time is dependent on CP.21.

Braking time

Factory setting: 0

Note: Enter-Parameter

Customer adjustment: _______

The braking time is evaluated depending on CP.20 as follow:

- entered time = braking time

- entered time relates to 100 Hz and decreases/increases

proportionally to the real frequency.

f

100 Hz

Adjustment range: 0.00...100 s

Resolution: 0.01 s

f

f

ist

real

Factory setting: 10 s

Customer adjustment: _______

t

t

B

Breal

ist

Calculation of the braking time:

CP.21* f

=

t

B

real

real

100 Hz

CP.21

t

40

Operation of the Unit

ANTRIEBSTECHNIK

Relay output

Relay output (terminal X1.1...X1.3) is adjusted in the factory as a fault

relay. This parameter can adjust the function of the output onto any

function listed in the table below.

Value Function

0 No function

1 Generally on

2 Fault relay

3 No function

4 Overload alert signal (10s before switch off)

5 * Overtemperature alert signal inverter

6 * Overtemperature alert signal motor (10s before switch off)

7 No function

8 Max. constant current (stall, CP.15) exceeded

9 Max. LA-/LD-Stop (CP.14) exceeded

10 DC-braking active

11 No function

12 Rate of utilization (CP.3) > 100%

13 No function

14 Actual value=set value (CP.2 = Fcon, rcon; not at noP, LS, error, SSF)

15 Accelerate (CP.2 = FAcc, rAcc, LAS)

16 Decelerate (CP.2 = FdEc, rdEc, LdS)

17 Right handed rotation (not at noP, LS error)

18 Left handed rotation (not at noP, LS error)

19 Real direction of rotation = set direction of rotation

20 Real value > frequency level CP.23

21 Set value > freqeuncy level CP.23

22 No function

23 Operating signal (after initialization as long as no error is active)

24 Run signal

25 No function (not available since software version 1.1)

GB

Frequency level

Factory setting: 2

Note: Enter-Parameter

* available as of software

version 1.1

Customer adjustment: _______

This parameter determines the switching point for the relay output

X1.1...X1.3 at CP.22 = "20” or “21”

After the switching of the relay, the frequency can move within a 0.5 Hz

window, without the relay dropping off.

Adjustment range: 0.0...409.58 Hz

Resolution: 0.0125 Hz

Factory setting: 4 Hz

Customer adjustment: _______

41

Drive mode

4.7 The Drive Mode The drive mode is a operating mode of KEB COMBIVERT to start the

drive manually by the operator. After switching the control release the set

value and rotation presetting is done exclusively by the keyboard. In order

to activate the drive mode the corresponding password in CP.0 must be

entered. The display switches over as follows.

Direction of rotation

F=forward / r=reverse

noP = no control release /

LS = neutral position

Status

4.7.1 Start / Stop Drive

GB

4.7.2Change Direction

of Rotation

4.7.3 Preset Set Value

Modulation blocked

Drive not controlled

START

Drive accelerates onto

the adjusted set value

ENTER

F/R

FUNC.

SPEED

Drive decreases to 0 Hz and

switches the modulation off

STOP

Drive operates with

adjusted set value

Drive changes direction

of rotation

Display changes when key is

pressed to set value display/

presetting

4.7.4 Leave Drive Mode

42

STOP

START

Set value can be changed

with UP/DOWN at pressed

FUNC/SPEED key

To exit the drive mode the inverter must be in status “stop” (Display noP

or LS). Press the FUNC and ENTER keys simultaneously for about 3

seconds in order to leave the drive mode. The CP-parameters appear in

the display.

FUNC.

SPEED

+

ENTER

F/R

for 3 seconds

Error Diagnosis

ANTRIEBSTECHNIK

5. Error Diagnosis

Undervoltage

Overvoltage

Overcurrent

Overload

Error messages are represented with an "E. " and the corresponding

error in the display of the KEB COMBIVERT. The displays and their

causes are described below.

Occurs, when the intermediate ciruict voltage falls below the permissible value.

Possible causes are - input voltage too low or unstable

- inverter power too small

- voltage loss due to incorrect cabling

- power supply by generator/transformer breaks down,

because ramps are too short

GB

Occurs, when the intermediate circuit voltage rises above over the

permissible value.

Possible causes are - input voltage too high

- disturbance voltages at the input

- delay ramps too short

Occurs, when exceeding the peak current or at ground fault.

Occurs when a too high load is applied for more than the allowed time

(see "Performance Data"). Possible causes for this are

- error or overload in the application

- inverter incorrectly dimensioned

- motor incorrectly wired

Cooling down phase

completed

Overheat

no Overheat

Current limit resistor error

After error E. OL you must wait for a cooling down time. This message

appears after the cooling down phase is completed. The error can be

reset.

Occurs, when the heat sink temperature > 85°C. Possible causes for this

are - insufficient cooling

- surrounding temperature too high

Internal or external excess-temperature error do not occur anymore.

Error "E. OH" can be reset.

Current limit resistor not bridged, occurs for a short time during the turn on

phase and is reset immediately. If the erorr message remains the following

may be the cause - incorrect or input voltage too small

- high loss in the supply line

43

Indice

7. Index

A

Acceleration time 33, 35, 45

Actual frequency display 33, 34, 45

Actual load 33, 34, 45

Analog inputs 30

Analog output 30

Autoboost 33, 39, 45

B

GB

Basic Adjustment 35

Boost 33, 35, 45

Braking time 33, 45

C

Change Direction 42

Common 30

Control circuit Version S 30

Control release 30

Cooling down phase 43

Current limit 37

current limit 37

Current limit resistor error 43

D

DC-braking 33, 40, 45

Decceleration time 36

Deceleration time 33, 45

Digital inputs 30

Digital Mass 30

Drive Mode 42

E

Error Diagnosis 43

Error messages 43

F

Fixed frequency 30, 33, 36, 45

Forward 30

Frequency value 33, 41, 45

I

LED 31

load variation 39

M

Max. constant current 33, 37, 45

Max. ramp current 33, 37, 45

Maximal frequency 33, 36, 45

Minimal frequency 33, 36, 45

modulation 34

Modulation blocked 42

Motor data 39

N

no Overheat 43

O

Operating Display 34

optimize 39

Overcurrent 43

Overheat 43

Overload 43

Overvoltage 43

P

Password input 33, 45

Peak load 33, 34, 45

peak value 34

R

Rated frequency 33, 35, 45

Relay output 30, 33, 41, 45

Releasing 33

RS232/485 31

S

Set value input 30

Slip compensation 33, 39, 45

Special Adjustments 37

Speed search 33, 38, 45

Start / Stop 42

U

Undervoltage 43

I*R-compensation 39

Interface operator 31

interference voltage supply 30

Inverter status display 33, 34, 45

K

Keyboard 31, 32

L

LAD-stop 37

44

V

Voltage stabilization 33, 38, 45

X

X1 30

Quick referenz

ANTRIEBSTECHNIK

Display Parameter Adjust. range Resolution

Customer setting

CP. 0 Password input 0...9999 1 CP. 1 Actual frequency display - 0,1 Hz CP. 2 Inverter status display - - CP. 3 Actual load - 1 % CP. 4 Peak load - 1 % CP. 5 Rated frequency 0...409.58 Hz 0.0125 Hz ____________

CP. 6 Boost 0...25.5 % 0.1 % ____________

CP. 7 Acceleration time 0.01...300 s 0.01 s ____________

CP. 8 Deceleration time 0.01...300 s 0.01 s ____________

CP. 9 Minimal frequency 0...409.58 Hz 0.0125 Hz ____________

CP.10 Maximal frequency 0...409.58 Hz 0.0125 Hz ____________

CP.11 Fixed frequency 1 0...±409.58 Hz 0.0125 Hz ____________

CP.12 Fixed frequency 2 0...±409.58 Hz 0.0125 Hz ____________

CP.13 Fixed frequency 3 0...±409.58 Hz 0.0125 Hz ____________

CP.14 Max. ramp current 10...200 % 1 % ____________

CP.15 Max. constant current 10...200 % 1 % ____________

CP.16 Speed search 0...7 1 ____________

CP.17 Voltage stabilization 150...649 V,oFF 1 V ____________

CP.18 Slip compensation -2.50...2.50 0.01 ____________

CP.19 Autoboost -2.50...2.50 0.01 ____________

CP.20 DC-braking 0...9 1 ____________

CP.21 Braking time 0...100 s 0.01 s ____________

CP.22 Relay output 0...25 (0...24)

1)

1 ____________

CP.23 Frequency level 0...409.58 Hz 0.0125 Hz ____________

GB

1)

Value 0...24 is valid as of software version 1.1

The function key (FUNC) changes between the

parameter value and parameter number.

With UP ( ) and DOWN ( ) the value of the parameter

number is increased/decreased with changeable

parameters.

Password input:

Locking the

CP-Parameter

Password

○○○○○○○○

FUNC

ENTER

UP

Releasing the

CP-Parameter

START

STOP

Password

○○○○○○○

FUNC

FUNC.

SPEED

STOP

START

ENTER

UP

45

GB

46

ANTRIEBSTECHNIK

7. Password

a) CP-Parameter "read only"

b) CP-Parameter "read/write"

ENTER

Password

UP

FUNC

ENTER

Password

UP

FUNC

c) Drive mode activ

✂

FUNC

ENTER

Password

UP

X X

a)

100

b)

200

c)

500

113

114

ANTRIEBSTECHNIK

D

Vor Auslieferung durchlaufen alle Produkte mehrfach eine Qualitäts- und Funktionskontrolle, so

daß Fehler auszuschließen sind. Bei Beachtung unserer Betriebsanleitung sind keine Störungen zu

erwarten. Sollte sich trotzdem ein Grund zur Reklamation ergeben, so ist das Gerät mit Angabe der

Rechnungsnummer, des Lieferdatums, der Fehlerursache und der Einsatzbedingungen an uns

zurückzusenden. Für Fehler, die aufgrund falscher Behandlung, falscher Lagerung oder sonstigen

allgemeinen Irrtümern auftreten, übernehmen wir keine Verantwortung. Prospekte, Kataloge und

Angebote enthalten nur Richtwerte. Technische Änderungen jeder Art behalten wir uns vor. Alle Rechte

vorbehalten. Nachdruck, Vervielfältigung und fotomechanische Wiedergabe sind ohne schriftliche

Genehmigung durch KEB auch auszugsweise verboten.

GB

Prior to delivery all products pass several quality and performance inspections so that malfunctions

can be ruled out. When used in accordance with the operating instructions failure is most unlikely.

However, if you have cause for complaint the unit should be returned stating invoice number, delivery

date, cause of failure and field conditions. We do not accept the responsibility for failures due to misuse,

wrong storage or similar causes. Leaflets, catalogues and quotations contain only standard values. We

reserve the right to make technical changes without obligation. All rights reserved. Any piratic printing,

mimeograhing or photomechanical reproduction, even in extracts, is strictly prohibited.

F

Avant la livraison tous les produits passent par différents contrôles fonctionnels et qualitatifs de

manière à éliminer les mauvais fonctionnements. L'apparition de défauts sur ces produits est très

improbable s'ils sont raccordés et utilisés selon les recommandations des manuels d'instructions.

Néanmoins, si un défaut apparaissait, le matériel doit être retourné en indiquant le numéro du bon de

livraison, la date d'expédition et les détails apparents du défaut ainsi que le type d'application. Un

mauvais emploi, de mauvaises conditions de stockage ou d'autres causes de ce type excluent notre

responsabilité en cas de défectuosité. Les documents techniques et commerciaux, les offres de prix

ne contiennent que des valeurs standards. Nous nous réservons le droit de procéder à des

modifications techniques sans préavis. Tout droit réservé. Toutes contrefaçons imprimées, ou

reproductions photomécaniques; même partielles, sont strictement interdites.

I

Prima di essere spediti, tutti i nostri prodotti sono soggetti a severi controlli di qualità e

funzionamento, questo al fine di evitare malfunzionamenti. Se utilizzati seguendo il manuale di

istruzione si evita qualsiasi malfunzionamento. Comunque, qualora dovesse verificarsi un guasto,

l'unità dovrà essere rispedita specificando il numero di bolla, la data di spedizione, i dettagli del guasto

ed il tipo di applicazione. Non si assumono responsabilità per errori dovuti a manomissioni, cattivo

stoccaggio o simili. Ci riserviamo di effettuare qualsiasi modifica senza preavviso alcuno. Tutti i diritti

sono riservati. Qualsiasi riproduzione non autorizzata, anche parziale, è rigorosamente proibita.

I

E

Antes de la expedición, todos nuestros productos han sido sometidos a severos controles de

calidad y funcionamiento, con la finalidad de evitar funcionamientos defectuosos. La posibilidad de

defectos es casi improable utilizando estos productos de acuerdo con el manual de instrucciones. Sin

embargo, si sé detectase algún defecto, la unidad deberá ser devuelta indicando número de

expedición, fecha de envio, causa del fallo y condiciones de instalación. No sé aceptarán

responsabilidades debidas a un mal uso, almacenaje defectuoso o causas similares. Los documentos

ténicos y comerciales indican sólo valores estándar. Nos reservamos el derecho de efectuar

modificaciones técnicas sin previo aviso. Todos los derechos reservados. Cualquier reproducción

parcial o total, no autorizada, está totalmente prohibida.

115

116

ANTRIEBSTECHNIK

Karl E. Brinkmann GmbH

Försterweg 36 - 38 • D - 32683 Barntrup

Telefon 00 49 / 52 63 / 4 01 - 0 • Fax 00 49 / 52 63 / 4 01 - 1 16

Internet: www.keb.de • E-mail: info@keb.de

KEB Antriebstechnik GmbH & Co. KG

Telefon 0049 / 37 72 / 67 - 0 • Telefax 0049 / 37 72 /67 - 2 81

Tel.: 0043 / 7243 / 53586 - 0 • FAX: 0043 / 7243 / 53586 - 21

Wildbacher Str. 5 • D - 08289 Schneeberg

E-mail: info@keb-combidrive.de

KEB Antriebstechnik Austria GmbH

Ritzstraße 8 • A - 4614 Marchtrenk

E-mail: info@keb.at

Herenveld 2 • B - 9500 Geraadsbergen

Tel.: 0032 / 5443 / 878 • FAX: 0032 / 5443 / 7898

Xianxia Road 299 • CHN - 200051 Shanghai

Tel.: 0086 / 21 / 62350922 • FAX: 0086 / 21 / 62350015

Z.I. de la Croix St. Nicolas • 14, rue Gustave Eiffel

Tél.: 0033 / 1 / 49620101 • FAX: 0033 / 1 / 45767495

6 Chieftain Buisiness Park, Morris Close

Park Farm, Wellingborough, GB - Northants, NN8 6 XF

Tel.: 0044 / 1933 / 402220 • FAX: 0044 / 1933 / 400724

Internet: www.keb-uk.co.uk • E-mail: info@keb-uk.co.uk

Via Newton, 2 • I - 20019 Settimo Milanese (Milano)

Tel.: 0039 / 02 / 33500782 • FAX: 0039 / 02 / 33500790

Internet: www.keb.it • E-mail: kebitalia@keb.it

Tel.: 0081 / 233 / 29 / 2800 • FAX: 0081 / 233 / 29 / 2802

KEB Antriebstechnik

E-mail: info@keb.de

KEB China

E-mail: cn_keb@sina.com

Société Française KEB

F - 94510 LA QUEUE EN BRIE

E-mail: sfkeb.2@wanadoo.fr

KEB (UK) Ltd.

KEB Italia S.r.l.

KEB - YAMAKYU Ltd.

711 Fukudayama, Fukuda

J - Shinjo-Shi, Yamagata (996-0053)

E-mail: kebjs001@d4.dion.ne.jp

1F, No.19-5, Shi Chou Rd., Tounan Town

KEB Taiwan Co., Ltd.

R.O.C. - Yin-Lin Hsian / Taiwan

Tel.: 00886 / 5 / 5964242 • FAX: 00886 / 5 / 5964240

E-mail: keb_taiwan@mail.apol.com.tw

KEBCO Inc.

1335 Mendota Heights Road

USA - Mendota Heights, MN 55120

Tel.: 001 / 651 / 4546162 • FAX: 001 / 651 / 4546198

Internet: www.kebco.com • E-mail: info@kebco.com

© KEB 00.F4.S0B-K111 03/2001

Loading...

Loading...