COMBICONTROL

GB Instruction Manual

Mat.No. Rev.

00C5CEB-K140 1D

C5 Compact

Preface

Karl E. Brinkmann GmbH reserves itself the right to change/adapt specications and

technical data without previous notication.

The safety and warning reference specied in this manual is not exhaustive. The manual

and the information contained in it is made with care. KEB don´t accept a guarantee for

misprint or other errors or resulting damages.

The marks and product names are trade marks or registered trade marks of the respective

title owners.

The information contained in the technical documentation, as well as any user-specic advice

in spoken and written and through tests, are made to best of our knowledge and information

about the application. However, they are considered for information only without responsibility.

This also applies to any violation of industrial property rights of a third-party.

Inspection of our units in view of their suitability for the intended use must be done generally

by the user. Inspections are particulary necessary, if changes are executed, which serve for

the further development or adaption of our products to the applications (hardware, software

or download lists). Inspections must be repeated completely, even if only parts of hardware,

software or download lists are modied.

Application and use of our units in the target products is outside of our control and

therefore lies exclusively in the area of responsibility of the user.

2

Inhalt

1. Description of the unit ............................................................................. 4

1.1 Application .............................................................................................................4

1.2 Construction ..........................................................................................................4

1.3 CE-certications ....................................................................................................4

1.4 Unitidentication ..................................................................................................4

1.5 Technical data ........................................................................................................5

1.6 Accessories ............................................................................................................6

2. Functional Description ............................................................................ 7

2.1 Real-time clock ......................................................................................................7

2.2 HSP5/485 interfaces to the inverter/servo axes ..................................................7

2.2.1 View of the inverter interfaces X1A...X1D for the axes 1..4 .....................................8

2.2.2 Assignment of the HSP5/485 interfaces ..................................................................8

2.2.3 HSP5 Operator with screw terminal (00F5060-9001) ..............................................9

2.2.4 HSP5 Operator with RJ45 socket (00F5060-9002) .................................................9

2.2.5 Adapter cable HSP5 interface operator .................................................................10

2.2.6 Comparison of the standards .................................................................................10

2.3 Voltage supply and digital inputs and outputs .................................................11

2.3.1 Assembly of the wires ............................................................................................11

2.3.2 Voltage supply of the control ..................................................................................12

2.3.3 Voltage supply for the inputs and outputs ..............................................................12

2.3.4 Digital inputs (X2.11…14) ......................................................................................13

2.3.5 Digital outputs (X2.15…18) ....................................................................................13

2.4 The operating unit .................................................................................. 14

2.5 Serial interface (X6A) ...........................................................................................14

2.6 Ethernet interface (X6B/X6C) ..............................................................................15

2.7 Description of the LED’s .....................................................................................15

2.8 Multi-function switch/button S1 .........................................................................16

2.9 File system ...........................................................................................................16

3. Software .................................................................................................. 17

3.1 Programming system CoDeSys .........................................................................17

3.2 Parameterizing system COMBIVIS .....................................................................17

3.3 Parameter description .........................................................................................18

3.3.1 Runtime and error monitoring ................................................................................18

3.3.2 Ethernet parameter ................................................................................................19

3.3.3 Real-time clock ......................................................................................................20

3.3.4 Process image .......................................................................................................21

3.3.5 Userdenition parameter .......................................................................................22

3.3.6 System parameter .................................................................................................23

3.3.7 Debugging .............................................................................................................24

3.4 System variables .................................................................................................25

GB - 3

GB - 4

COMBICONTROL

1. Description of the unit

1.1 Application

KEB COMBICONTROL C5 is a programmable control with direct connection upto four KEB

frequency inverters/servo axes of the series F5. The connection to the axes is created as

HSP5/485. All axes can be operated directly and synchronously with an inexpensive operator

with this fast, reliable connection. Cycle times down to one millisecond are realizable. This

manual describes the release of the rmware V1.4 and higher.

The axis control is programmed with the uniform IEC 61131-3 programming system CoDeSys

of the 3S-Software Company, Kempten (Germany) (www.3s-software.com).

1.2 Construction

The control consists of following modules:

• CPU and memory

• internal ash le system

• Switching power supply

• Real-time clock

• HSP5/485-interfaces to the inverter/servo axes

• Ethernet interfaces

• serial interface

• Control and error LED’s

• RUN/Reset switch

• Voltage supply connection

• four digital inputs

• four digital outputs

• Field bus interface (optional)

1.3 CE-certications

This unit was tested in accordance with the generic standard EN 61000-6-2 in the range of noise

immunity and corresponds to the EMC directive 89/336/EWG with changes/extensions.

1.4 Unitidentication

C5 Material number Description

Compact 14C5B00-1000 4DI/4DO

GB - 5

COMBICONTROL

1.5 Technical data

General

Dimensions (HxBxT) 125 x 44 x 144 mm

Weight approx. 260 g

Installation method 35 mm Mounting rail

Grounding via terminal strip or plug-in contact

Protective system (EN 60529) IP20

Operation temperature -10…45 °C (14…113 °F)

Storage temperature -25…70 °C (-13…158 °F)

Climatic category (EN 60721-3-3) 3K3

Environment (IEC 664-1) Pollution degree 2

Control

Operating voltage control (US) 18…30 V DC ±0 %

Power input control 3 W max.

Digital inputs/outputs

Wiring system cage-clamp terminals

Operating voltage inputs/outputs (UM) 18…30 V DC ±0 %

Output current max. 0,7 A per channel, short-circuit proof,

Input voltage/current according to IEC 61131-2 Type 1

free-wheeling diode integrated

Axis interface

Type HSP5/485

Connector RJ-45, 8-pole, screened

Cable Cat5, max. 100 m

Speed 38,4…250 kBaud

Use Connection to KEB F5 inverter/servo, process

data transmission, communication channel

Ethernet interfaces

Type IEEE802.3

10/100BaseTx

2-Port Switch

Connector RJ-45, 8-pole, screened

Speed 10/100 MBaud

autocrossover

COMBICONTROL

Use Connection to CoDeSys (programming sy-

Serial interface

Type DIN66019II, RS232, RS485 full/half duplex

Connector D-Sub 9 female

Speed 9,6…115,2 kBaud

Use Connection to COMBIVIS (control and axis

Memory of the programming system

Code 8 MB, double for online change

Data 12 MB

Retain 31 KB

Flag area 32 KB

Input 2 KB

Output 2 KB

stem, debugging, visualization).

Connection to COMBIVIS (control and axis

adjustment, Scope)

Connection to any devices (Socket-APi)

adjustment, Scope)

Connection to any devices (Socket-APi)

1.6 Accessories

Operators Material number

F5 HSP5/485, screw terminal 00F5060-9001

F5 HSP5/485, RJ45 00F5060-9002

Supply cable Material number

Cable RS232 for COMBIVIS 0058025-001D

Cable RJ45 open end (for operator -9001), 2,5 m 00F50C3-2025

Patch cable RJ45 (for operator -9002), 5 m 00F50C3-1050

GB - 6

COMBICONTROL

2. Functional Description

The C5 compact is mounted on a 35 mm mounting rail. The earthing occurs with a plug-in

contact or terminal connection X2.19/20.

2.1 Real-time clock

The integrated real-time clock is maintenance-free (no battery) and operates without power

supply for approx.30 days. After this time it must be adjusted again. A read out parameter

indicates the validity of the date and time. The control shall remain switched on min. 30 minutes

for complete loading. Leap years are recognized automatically up to the year 2099. Date and

time can be read and set via COMBIVIS or the control program.

2.2 HSP5/485 interfaces to the inverter/servo axes

Up to four KEB COMBIVERT F5 can be connected via the terminals X1A to X1D. The

connection occurs via reliability RS485 cables, which can be up to 100 m long. A shielded

standard cable with RJ-45 connector is used on the control side and appropriate operator

on the frequency inverter/servo. The process data of the required axes are exchanged by

the control in the cyclic or synchronous mode. Service 50 (1*32 + 2*16 Bit process data) is

used thereby. The parameter channel is free for the PLC program and COMBIVIS access

to the axes. Depending on the used axes the cycle time can be between 1 and 65 ms. The

process data assignment in the axes must be adjusted before starting the cyclic/synchronous

operation in parameters SY.16…31 (if not stored in the axes).

The process data are mapped-in as follows in the image of the control:

%IW8+9 %ID4 1. Word (32 Bit) of axis 1 %QD4 1. Word (32 Bit) to axis 1

%IW10 2. Word (16 Bit) of axis 1 %QW10 2. Word (16 Bit) to axis 1

%IW11 3. Word (16 Bit) of axis 1 %QW11 3. Word (16 Bit) to axis 1

%IW16+17 %ID8 1. Word (32 Bit) of axis 2 %QD8 1. Word (32 Bit) to axis 2

%IW18 2. Word (16 Bit) of axis 2 %QW18 2. Word (16 Bit) to axis 2

%IW19 3. Word (16 Bit) of axis 2 %QW19 3. Word (16 Bit) to axis 2

%IW24+25 %ID12 1. Word (32 Bit) of axis 3 %QD12 1. Word (32 Bit) to axis3

%IW26 2. Word (16 Bit) of axis 3 %QW26 2. Word (16 Bit) to axis3

%IW27 3. Word (16 Bit) of axis 3 %QW27 3. Word (16 Bit) to axis3

%IW32+33 %ID16 1. Word (32 Bit) of axis 4 %QD16 1. Word (32 Bit) to axis 4

%IW34 2. Word (16 Bit) of axis 4 %QW34 2. Word (16 Bit) to axis 4

%IW35 3. Word (16 Bit) of axis 4 %QW35 3. Word (16 Bit) to axis 4

GB - 7

GB - 8

COMBICONTROL

1 8

2.2.1 View of the inverter interfaces X1A...X1D for the axes 1..4

X1B (axis 2) —— —— X1A (axis 1)

X1D (axis 4) —— —— X1C (axis 3)

2.2.2 Assignment of the HSP5/485 interfaces

X1A…D Name Description Socket (top view)

1 TXD+ Transmission signal+

2 TXD- Transmission signal3 GND Reference potential

4 RXD+ Receive signal+

5 RXD- Receive signal6 GND Reference potential

7 EnTXD+ Handshake transmission

8 EnTXD- Handshake transmission

- Shielding Shielding

signal+

signal-

GB - 9

COMBICONTROL

2.2.3 HSP5 Operator with screw terminal (00F5060-9001)

X6E

X6E Name Description

1 TXD- Transmission signal2 TXD+ Transmission signal+

3 RXD- Receive signal4 RXD+ Receive signal+

5 EnTXD- Handshake transmission signal6 EnTXD+ Handshake transmission signal+

7 EnRxD- Handshake receive signal8 EnRxD+ Handshake receive signal+

9 GND Reference potential

10 VCC +24 V voltage output

- Shielding Shielding (see gure)

No cables may be connected

to terminal VCC. High voltage

can destroy the interface in the

control.

2.2.4 HSP5 Operator with RJ45 socket (00F5060-9002)

RJ45 Name Description

1 RXD+ Receive signal+

2 RXD- Receive signal3 GND Reference potential

4 TXD+ Transmission signal+

5 TXD- Transmission signal6 GND Reference potential

7 EnRxD+ Handshake receive signal+

8 EnRxD- Handshake receive signal-

- Shielding Shielding

The connection to the control is realized with a commercial CAT5 Patch cable for this operator.

COMBICONTROL

2.2.5 Adapter cable HSP5 interface operator

Screw terminal:

Color see below

Signal TXD+ TXD- GND RXD+ RXD- GND EnTXD+ EnTXD-

PIN 1 2 3 4 5 6 7 8

| | | | | | | |

PIN 4 3 9 2 1 9 8 7

Signal RXD+ RXD- GND TXD+ TXD- GND EnRxD+ EnRxD-

Color see below

RJ45 connection:

Color see below

Signal TXD+ TXD- GND RXD+ RXD- GND EnTXD+ EnTXD-

PIN 1 2 3 4 5 6 7 8

| | | | | | | |

PIN 1 2 3 4 5 6 7 8

Signal RXD+ RXD- GND TXD+ TXD- GND EnRxD+ EnRxD-

Color see below

C5 PCC

X1A…H

Operator

X6E

C5 PCC

X1A...H

Operator

RJ45

In c a s e o f p r o d u c t I o n o f o w n c o n n e c t I n g c a b l e s p l e a s e p a y at t e n t I o n t h a t t h e s I g n a l p a I r s ( e.g.

txd+ a n d txd -) a r e a s s I g n e d t o t h e c o r r e s p o n d I n g t w I s t e d c a b l e s (e.g. g r e e n a n d g r e e n /

w h I t e ). co n n e c t u n -u s e d s c o r e s a l w a y s t o gnd.

2.2.6 Comparison of the standards

Pair PIN EIA/TIA 568B EIA/TIA 568A DIN 47100 IEC 189.2 USOC

3 1 orange/white green/white green red black

3 2 orange green yellow orange yellow

2 3 green/white orange/white grey black orange

1 4 blue blue brown blue red

1 5 blue/white blue/white white white green

2 6 green orange pink green brown

4 7 brown/white brown/white blue yellow grey

4 8 brown brown red brown blue

GB - 10

COMBICONTROL

7mm

2.3 Voltage supply and digital inputs and outputs

Figure 2.3 Socket X2

Voltage supply Digital inputs and outputs

+ Voltage input (UM)

(internally interconnected)

- Voltage input (UM)

(internally interconnected)

+ Voltage input (US)

- Voltage input (US)

2.3.1 Assembly of the wires

Required tools:

Screw driver

SD 0,4 x 2,5 (DIN 5264)

1. Strip cable

Cable permissible cross-section

exible 0,2…1

Wire-end ferrule 0,13…0,34

1 11

2 12

3 13

4 14

5 15

6 16

7 17

8 18

9 19

10 20

mm2

mm2

Digital input 0

Digital input 1

Digital input 2

Digital input 3

Digital output 0

Digital output 1

Digital output 2

Digital output 3

PE

2. Plug screw driver into the square slot to the midside

GB - 11

GB - 12

COMBICONTROL

+

-

U

F1

X2.9

X2.10

3. Plug cable into the round slot, that no wires can be seen

from the outside.

4. Remove screw driver and check if cables are xed.

2.3.2 Voltage supply of the control

The voltage for supply of the control (US) occurs via terminals X2.9 and X2.10 in accordance

with picture 2.3.2 and is electrically insulated from UM. If the control is supplied with voltage,

the VCC-LED ashes (green).

Picture 2.3.2 Voltage supply of the control

U = 18…30 V DC ±0 %

F1 = 2 A type gG

2.3.3 Voltage supply for the inputs and outputs

The voltage for supply of the digital inputs and outputs (UM) occurs via the terminals X2.1 to

X2.8 in accordance with picture 2.3.3 and is electrically insulated from US.

%IW1

%IX1.0 Condition of the supply voltage in/outputs (UM)

%IX1.1

%IX1.2…%IX1.15 not assigned

Is set in case of overload at one or several outputs. Additionally the OL-LED (red) is set.

GB - 13

COMBICONTROL

+

-

U

F2

X2.1...4

X2.5...8

X 2.2 (+UM)

X 2.12 (I1)

+

-

X2.2 (+UM)

X2.5 (- UM)

X2.12 ( I1 )

П

X 2.16 (O1)

X 2.6 (- UM)

X 2.17 (O2)

X 2.7 (- UM)

Picture 2.3.3 Voltage supply for the inputs and outputs

U = 18…30 V DC ±0 %

F2 = 6,3 A type gG

2.3.4 Digital inputs (X2.11…14)

The digital inputs are potential-free to the control voltage US.

4 digital inputs 0...3

%IW0

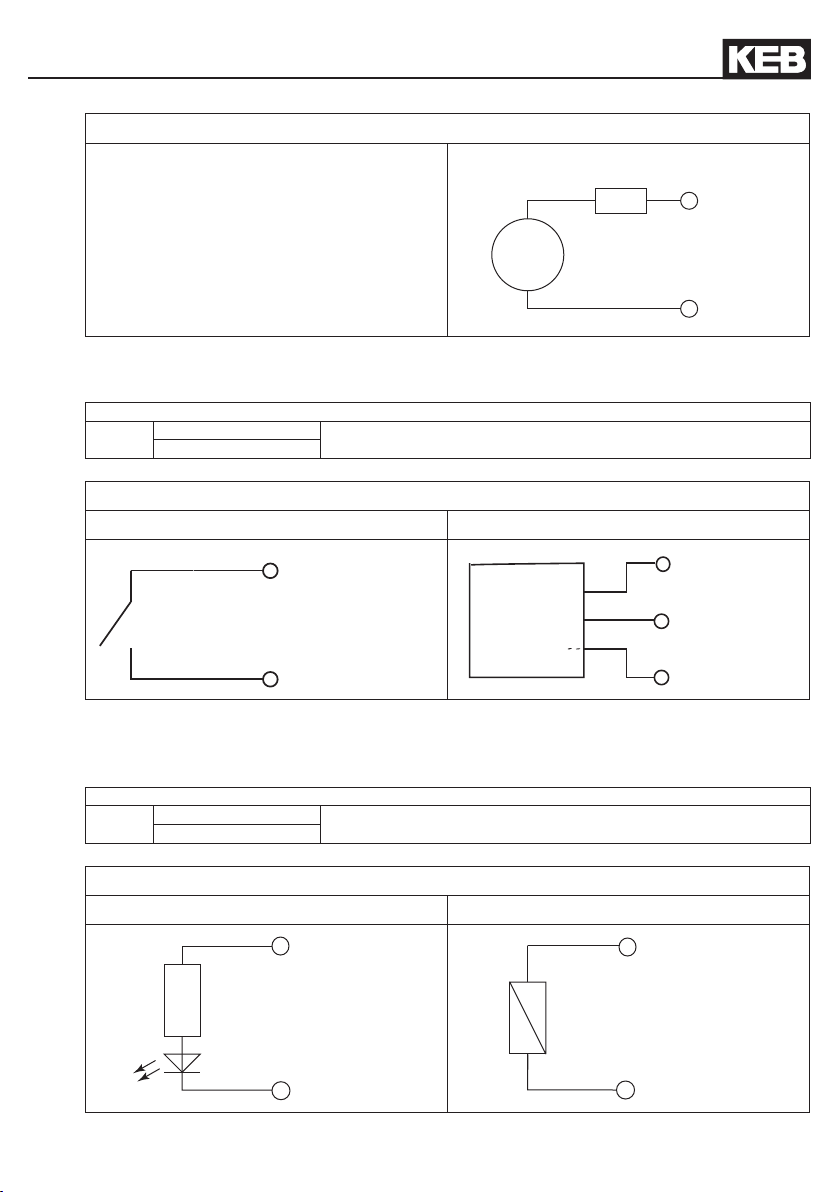

Picture 2.3.4 Connection of the digital inputs

%IX0.0…%IX0.3

%IX0.4…%IX0.15

Potential-free connection Connection e.g. via PLC

Condition of the digital inputs 0…3 not assigned

2.3.5 Digital outputs (X2.15…18)

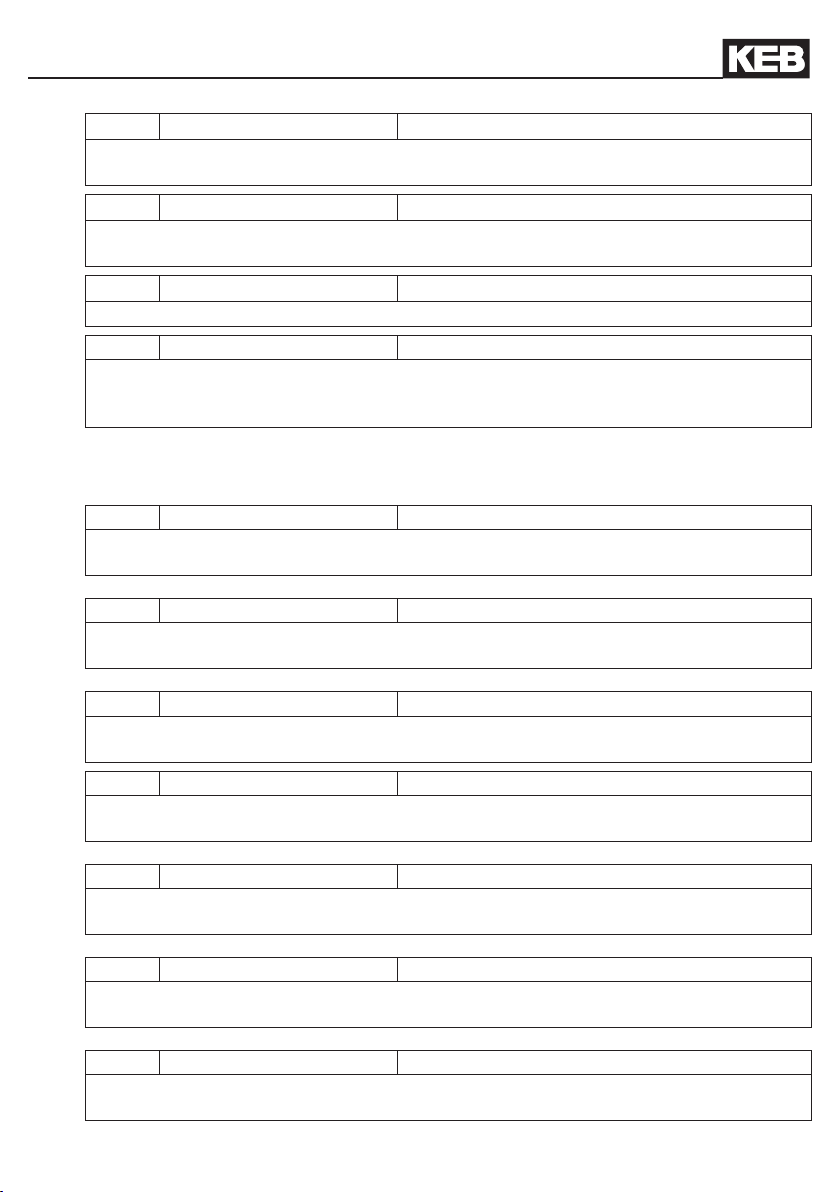

The digital outputs are potential-free to the control voltage US. A free-wheeling diode is inte-

grated in the unit, so that no external wiring is necessary at inductive load.

4 digital outputs 0...3

%QW0

Picture 2.3.5 Connection of the digital outputs

%QX0.0…%QX0.3

%QX0.4…%QX0.15

Ohmic load Inductive load

Condition of the digital outputs 0…3 not assigned

GB - 14

COMBICONTROL

54321

9 8 76

543 21

987 6

2.4 The operating unit

View Front Name Function Addition View from the

S1 Multi function switch/button

RUN Run-LED green

ERROR ERROR-LED red

OL Overload red

VCC Voltage supply (US) green

X6A Serial interface COMBIVIS

X6B Ethernet interface

X6C Ethernet interface

X1A…D Axis interfaces

2.5 Serial interface (X6A)

The socket X6A is a serial RS232/485 interface. It serves for the connection of the control

with a PC or other operating units via the protocol DIN66019II. Alternatively access to this

interface can occur by the control program.

X6A Name Description SUB-D9 socket

1 PGM No wiring ! (top view)

2 TxD Transmission signal RS232

3 RxD Receive signal RS232

4 RxD-A Receive signal RS485 A

5 RxD-B Receive signal RS485 B

6 PGM+ No wiring !

7 DGND Data reference potential

8 TxD-A Transmission signal RS485 A

9 TxD-B Transmission signal RS485 B

COMBIVIS/

CoDeSys

bottom

Part.No.: 0058025-001D

RS 232 cable

2,8 m

9pol. SUB-D coupling 9 pol. SUB-D connector

Housing (PE)

PC C5

GB - 15

COMBICONTROL

2.6 Ethernet interface (X6B/X6C)

The standardized 10/100 base-T interface supports the protocols TCP/IP and UDP/IP. The

two interfaces are internally connected as switch.

The following ports have these functions:

The CoDeSys port is adjusted to 1200 (as standard). The port can be changed with parameter Et.03. The control program is processed here by means of CoDeSys (only TCP/IP

possible).

The COMBIVIS port is adjusted to 8000 (as standard). It can be changed with parameter

Et.02. The access of COMBIVIS or other control/visualizations to parameters of the control,

the axes as well as if necessary by the control program dened parameter occurs here. TCP

or UDP is possible as protocol, at which encapsulated DIN66019II data telegrams will be

transferred.

The used IP address can be adjusted with parameter Et.01. In case that a cross-over cable

is used for the connection, make sure that the upper part of the IP address (network number)

is the same and the lower part of the IP address (Node number) is different from the PC IP

address. The IP address may not have been used in the entire connected Ethernet.

Protect C5 against unauthorized access

Each user within a network can take access to the control with knowledge of the IP address.

The C5 should be absolutely protected against unauthorized access. For the protection

• the write access on the COMBIVIS port can be limited with parameter et.09.

• CoDeSys can be protected with a login-password.

2.7 Description of the LED’s

Run-LED green

off PLC program stopped or not available

on PLC program in run mode

ERROR-LED red

off O.K.

on Program error, exact error cause can be determined via CoDeSys.

fast blinking Hardware error, control must be restarted

OL-LED red

off no error at the outputs

on Overload or short circuit at the outputs

VCC-LED green

off no voltage supply

on Voltage supply available

COMBICONTROL

2.8 Multi-function switch/button S1

The multi function switch/button is constructed as follows:

run (switch)

stop/reset

clear (button)

The button S1 is assigned with the following functions

Activity Function

Stop --> Run Program is started

Run --> Stop Programm is stopped, all variables are resetted

Stop --> Clear and hold (> 3 s) until

ERROR LED lights

Stop --> Clear and hold (> 10 s) until

ERROR and RUN LED light

2.9 File system

The le system consists of an internal ash memory (drive C:). Access can occur via CoDeSys

or directly from the program of the control.

Internalashmemory

This memory is accessed as drive C: and the boot project can be stored, which is automatically

loaded and started when switching on. Any other les (documentation, download lists, prescriptions, etc.) can be stored and read here. The following particularities must be observed:

• Access is possible only to les in the root directory.

• Only short le names (8.3 format) are possible.

• Reading takes place with high speed and can occur also at any time in the time-critical

cyclic operating modes of the control.

• Writing occurs at a slow rate, because the ash must be programmed here. Any data can

be written if the control is in stop condition, but only one le can be opened for writing. If

the control is in run condition, only blocks of max. 32KByte can be written into the opened

le. As soon as this block was completely stored in the background the next data can be

written.

• Data is not physically deleted. First they are internal marked as deleted. Thus the free available memory space decreases. The command "leformat" can be used via the CoDeSys PLC

browser. Thus the complete memory is formatted again. All data is irrevocable deleted.

• The deleted memory space can be make available again with the command "lecleanup"

without reformatting.

(reset warm)

After releasing the switch all retain variables are

resetted (reset cold)

All variables and the boot project are cleared (re-

set origin) after releasing the button.

GB - 16

COMBICONTROL

3. Software

3.1 Programming system CoDeSys

The axis control is programmed with the programming system CoDeSys of the company 3S-

Software (www.3s-software.com). This programming software is free-available in the Internet.

A KEB target information le (TNF) for the control is available as accessories, which contains

all required hardware specications. A library with rmware functional modules is further contained for access to the periphery (axes, real-time clock, switch, LED, le system). The use

of these functional modules is explained in the provided example projects.

The connection to CoDeSys occurs via the Ethernet interface X6B or X6C via IP protocol. For

this the control is connected with a 1:1 cable to the distribution system of an existing rm net

or by means of a cross cable directly to the network interface of a PC. IP-address and port

number can be adjusted at rst via COMBIVIS. TCP/IP (Level2) is selected with the following

adjustments in the CoDeSys communication parameter:

Address (as adjusted)

Port 1200 (or as changed)

Block size 512

Motorola Byteorder Yes

3.2 Parameterizing system COMBIVIS

The axis control can be parameterized and monitored with COMBIVIS. COMBIVIS is freeavailable in the Internet (www.keb.de). Access to all axes is possible via the control with

COMBIVIS. The control has the node address 0, the axes have the node addresses 1 to 4.

Connection with COMBIVIS occurs via Ethernet interface X6B or X6C via IP protocol or the

serial interface X6A. IP-address and port number can be adjusted rst via the serial interface

and COMBIVIS. Afterwards the protocol TCP or UDP as well as the correct IP-address of

the control is selected in the COMBIVIS IP protocol driver. The data port number is 8000, if

necessary it can be changed.

The following must be observed on access to axis:

• First the axes must be switched on, then the control, or the function block 'tSetModes' must

call-up in order to make the connection between control and axis. Thus the baud rate between

axis and control is adjusted to the highest possible value and the axis can be accessed via

COMBIVIS. (After power-on reset the inverter /servo starts always with 38,4 KBaud)

• If an axis is operated cyclically or synchronously, only the indirect set addressing can be

used in COMBIVIS. This applies also to download and scope

GB - 17

GB - 18

COMBICONTROL

3.3 Parameter description

3.3.1 Runtime and error monitoring

The ru-parameters serve for monitoring of the program ow.

ru.00 Status Address 0200h

Program status no prog no program loaded

prog OK program loaded

prog corrupt program checksum error

Control status run Program runs

Stop Program stopped

breakpoint Program is on break point

Error status err_cyctime The adjusted cycle time was exceeded

err_watchdog The length of the last PLC cycle exceeded the

maximum value, the PLC program was stopped.

ru.01 cycle time Address 0201h

This parameter indicates the cycle time adjusted by the PLC program in milliseconds.

This value is also used for the cycle time monitoring, a value of 0 ms means a free-running PLC program without cycle time monitoring.

ru.02 axis mode Address 0202h

The parameter indicates the axis conguration adjusted by the PLC program. There is a

differentiation between normal- and synchronous/cyclic operation.

ru.03 axis errors Address 0203h

The parameter indicates the axes which did not respond. This can have been released by

interruption of the cable to the axis or by switching off the axis. The value 0 means that all

monitored axes are connected correctly.

ru.04 min. process time Address 0204h

ru.05 max. process time Address 0205h

ru.06 response time Address 0206h

ru.07 process time Address 0207h

ru.08 idle time Address 0208h

The cycle time of a PLC program ow is composed of:

response time Time of recognizing the new program cycle up to the call of the PLC

program

process time Time, when the PLC program as well as all accesses by CoDeSys

and COMBIVIS are processed.

idle time Remaining time up to the next program cycle.

Parameter ru.04 / ru.05 displays the minimum/maximum process time and can be reset

by writing of any value.

GB - 19

COMBICONTROL

3.3.2 Ethernet parameter

The following parameters contain the values, which are needed for the communication via

the Ethernet interface.

et.00 MAC address Address 0300h

The MAC address (Media Access Control) is formed of 6 byte. The rst three bytes

contain the manufacturer's code (00-08-FA). Only the lowest 4 bytes are displayed here

„FAxxxxxx“. This address is assigned by the manufacturer and cannot be changed.

et.01 IP address Address 0301h

The IP address consists of 4 bytes and is the clear identication of one Internet participant (called node by such a way). In case of doubt the network administrator gives the

address to be adjusted.

When using a direct connection of control and PC with a cross cable, this IP address

should be adjusted in such a way that the difference is only in the lowest byte to the

address of the PC's (same network but different node).

et.02 COMBIVIS port number Address 0302h

The port number for the access via COMBIVIS is adjusted with this parameter. The standard value is 8000 and normally it is not changed.

et.03 CoDeSys port number Address 0303h

This parameter adjusts the port number, under which CoDeSys establishes the connection. The standard value is 1200 and normally it is not changed.

et.04 IP error count Address 0304h

Serves for the diagnosis of the IP protocol stack.

et.05 TCP connections Address 0305h

This parameter displays the number of active TCP/IP connections.

et.06 UDP connections Address 0306h

This parameter displays the number of active UDP connections.

et.07 PGM logged in Address 0307h

This parameter displays that there is an online connection to CoDeSys. A further login via

CoDeSys is not possible then.

et.08 TCP multicount Address 0308h

This parameter serves only for diagnostic purposes.

GB - 20

COMBICONTROL

et.09

This parameter denes the write protection password for the COMBIVIS data port. The

programming of the password occurs only via the serial interface. Then this password

must be entered here again for write access via the data port. Error message "operation

not possible" is displayed in case of locked data port write access. Value 0 switches off

the write protection password.

et.10

This parameter determines the IP address of the appropriate gateway. As soon as

a connection to IP slave address outside the own network shall be made by the control

program, this address is used. In case of doubt the gateway address to be adjusted can

be ask for by the network administrator.

et.11

The decision whether an IP slave address is outside of the own network is determined

with this mask. If this mask is 0.0.0.0 the standard masks are used depending on network

class A, B or C. In case of doubt the subnet mask to be adjusted can be ask for by the

network administrator.

et.12

This parameter adjusts the response delay for the Combivis-data port in ms. The network

utilization can be reduced by setting of higher values. A value of 0 enables the fastest

communication with the control, but a high network utilization is also generated.

et.14

Displays state informations for the Ethernet link.

data port password

gateway address

subnet mask

data port response delay

Link state

Address 0309h

Address 030Ah

Address 030Bh

Address 030Ch

Address 030Eh

et.15

Determines the adjustments of the Ethernet interface. Fixed values or automatic recognition can be adjusted here. The additional clearlock value 32 activates a special behavior,

which corrects link problems automatically with automatic detection on both sides (control

and switch).

3.3.3 Real-time clock

The internal real-time clock is adjusted and/or read-out with the following parameters.

rc.00

This parameter displays the time in hours and minutes in a 24-hours format. Writing on

this parameter adjusts the time.

Link mode

time

Address 030Fh

Address 0400h

GB - 21

COMBICONTROL

rc.01

This parameter displays the seconds in a range of 0...59. Writing on this parameter adjusts the seconds.

rc.02

This parameter displays the date in a DD-MM format. Writing on this parameter adjusts

the date.

rc.03

This parameter displays the year in four digits. Writing on this parameter adjusts the year.

rc.04 data valid Address 0404h

The real-time clock is running for approx. 30 days after switching off the supply. After this

it must be adjusted again. If this parameter has the value „false“, the date and/or time is

not correct. The clock must be adjusted.

3.3.4 Process image

pi.00 inputs Address 0500h

Displays the condition of the local inputs.See section in-/output module. Set 0 displays

the rst word, set 1 displays the second.word, etc.

pi.01 outputs Address 0501h

Displays the condition of the local outputs.See section in-/output module. Set 0 displays

the rst word, set 1 displays the second.word, etc.

pi.02 axis indata 1 Address 0502h

Displays the value of the rst process-input data (32 Bit) of the axes. Set 0 is for the data

of axis 1, set 1 for the axis 2, etc.

pi.03 axis outdata 1 Address 0503h

Displays the value of the rst process-output data (32 Bit) of the axes. Set 0 is for the

data of axis 1, set 1 for the axis 2, etc.

seconds

date

year

Address 0401h

Address 0402h

Address 0403h

pi.04 axis indata 2 Address 0504h

Displays the value of the second process input data (16 Bit) of the axes. Set 0 is for the

data of axis 1, set 1 for the axis 2, etc.

pi.05 axis outdata 2 Address 0505h

Displays the value of the second process-output data (16 Bit) of the axes. Set 0 is for the

data of axis 1, set 1 for the axis 2, etc.

pi.06 axis indata 3 Address 0506h

Displays the value of the third process-input data (16 Bit) of the axes. Set 0 is for the data

of axis 1, set 1 for the axis 2, etc.

GB - 22

COMBICONTROL

pi.07 axis outdata 3 Address 0507h

Displays the value of the third process-output data (16 Bit) of the axes. Set 0 is for the

data of axis 1, set 1 for the axis 2, etc.

pi.08 eldbusindata Address 0508h

Displays the value of the Fieldbus-input data. Set 0 displays the rst word, set 1 displays

the second word, etc.

pi.09 eldbusoutdata Address 0509h

Displays the value of the Fieldbus-output data. Set 0 displays the rst word, set 1 displays

the second word, etc.

3.3.5 Userdenitionparameter

ud.00 program operation Address 0800h

The current program operation mode (run/stop) is displayed or adjusted here. Furthermo-

re a reset or reset cold can be executed with this parameter.

ud.01 password Address 0801h

Password input for the corresponding user level. The following values for the password

step are possible:

200 User write protection (operating parameter cannot be changed)

440 User reading/writing

Note: The value for the reading/writing password can be changed with parameter ud.08.

ud.02 features Address 0802h

Display of the actual disconnected special functions (e.g. SoftMotion)

ud.03 IO module Address 0803h

This parameter displays the installed I/O module.

ud.04 eldbusmodule Address 0804h

This parameter displays the installed Fieldbus module.

ud.05 error counters rx Address 0805h

This parameter counts the receive errors during the communication with the axes. Set 0

displays the errors of axis 1, set 1 of axis 2 etc.

GB - 23

COMBICONTROL

ud.06 error counters tx Address 0806h

This parameter counts the errors during the transmission to each individual axis. Set 0

displays the errors of axis 1, set 1 of axis 2 etc.

ud.07 eldbuscommaxis Address 0807h

This parameter displays the axis, on which the eld bus accesses to by parameter communication.

ud.08 user r/w password Address 0808h

Parameters with write/read password level can be changed with the password input of

this parameter. The standard value is 440. This parameter can only be read/changed with

a special password.

ud.09 indirect set indicator Address 0809h

Display and adjustment of the set indicator for indirect parameter access.

ud.10 active set Address 080Ah

Display and adjustment of the active set.

ud.11 serial number (date) Address 080Bh

Displays the date of the unit serial No.

ud.12 serial number (counter) Address 080Ch

Display of the unit serial No.

ud.13 QS number Address 080Dh

Only for the internal use during the production of the unit.

3.3.6 System parameter

sy.01 software date Address 0001h

This parameter displays the date of the installed rmware.

sy.02 deviceidentier Address 0002h

This parameter displays the software-identication number (CFG-ID) for COMBIVIS.

sy.03 target-Id Address 0003h

Displays the CoDeSys identication number of the control.

sy.04 congurationselection Address 0004h

Selection of internal device data.

GB - 24

COMBICONTROL

sy.05 congurationdata Address 0005h

Output of internal device data.

sy.06 device address Address 0006h

This parameter determines the Fieldbus address.

sy.07 baud rate 66019II Address 0007h

The baud rate for the KEB DIN 66019II protocol is adjusted with this parameter.

sy.10 C5 Address 000Ah

Display of the unit type.

The following parameters serve for the operation of the inverter scope part of COMBIVIS.

sy.32 scope timer Address 0020h

sy.33 scopedata1den. Address 0021h

sy.34 scope data 1 set Address 0022h

sy.35 scopedata2den. Address 0023h

sy.36 scope data 2 set Address 0024h

sy.37 scopedata3den. Address 0025h

sy.38 scope data 3 set Address 0026h

sy.39 scopedata4den. Address 0027h

sy.40 scope data 4 set Address

0028h

3.3.7 Debugging

Parameters 06xxh are only used for the diagnosis during the production process.

GB - 25

COMBICONTROL

3.4 System variables

The following system variables are available in the PLC program:

SYSAXISMODE

Displays the axes control mode adjusted via the function block 'tSetModes'.

SYSERRORAXIS

Displays the failed monitored or cyclic/synchronous operated axes. In case of failure of an

axis the red error LED at the operating unit is switched on and the event "excpt_axis_error"

is released (if this event is activated). Then the control program can evaluate the defective

axes in SYSERRORAXIS. Additionally this condition is displayed in parameter ru.03.

SYSCYCLETIME

Displays the axes control mode adjusted via the function block 'tSetModes'. Value 0 means

that NO cycle time monitoring takes place and the PLC program is running free with a mi-

nimum of 1 ms. The cycle time determines the xed time interval the PLC program needs

for one cycle and into which the process data are exchanged with the axes during cyclic/

synchronous operation.

SYSERRORCYCLETIME

The red error LED at the operating unit is switched on, when exceeding the adjusted cycle

time. Event "excpt_cycle time_overow" is released (if this Event is activated) and the system

variable SYSERRORCYCLETIME is set on TRUE. Additionally this condition is displayed in

parameter ru.00.

SYSWATCHDOGMAX

Determines the max. watchdog time in n*44ms. Standard value is 3, that means the program

watchdog is adjusted to 132ms.

SYSERRORWATCHDOG

If a cycle of the PLC program needs longer than the maximum watchdog time (e.g. by a

endless loop), then the system variable SYSERRORWATCHDOG is set to TRUE and the

program is interrupted (PLC is on stop then). Additionally this condition is displayed in parameter ru.00.

SYSAXISTOUT

Determines the response time of the axes. The default value of 20 ms means a maximum

response time of 20 ms per axis. If necessary, this value must be increased in order to prevent

a time-out error at slow units.

GB - 26

Notes

GB - 27

Notes

KEB worldwide…

Karl E. Brinkmann GmbH

Försterweg 36-38 • D-32683 Barntrup

fon: +49 5263 401-0 • fax: +49 5263 401-116

net: www.keb.de • mail: info@keb.de

KEB Antriebstechnik Austria GmbH

Ritzstraße 8 • A-4614 Marchtrenk

fon: +43 7243 53586-0 • fax: +43 7243 53586-21

net: www.keb.at • mail: info@keb.at

KEB Antriebstechnik

Herenveld 2 • B-9500 Geraadsbergen

fon: +32 5443 7860 • fax: +32 5443 7898

mail: vb.belgien@keb.de

KEB Power Transmission Technology (Shanghai) Co.,Ltd.

No. 435 QianPu Road, Songjiang East Industrial Zone,

CHN-201611 Shanghai, P.R. China

fon: +86 21 37746688 • fax: +86 21 37746600

net: www.keb.cn • mail: info@keb.cn

KEB Antriebstechnik Austria GmbH

K. Weise 1675/5 • CZ-370 04 České Budějovice

fon: +420 387 699 111 • fax: +420 387 699 119

net: www.keb.cz • mail: info.keb@seznam.cz

fon: +49 3772 67-0 • fax: +49 3772 67-281

E-08798 Sant Cugat Sesgarrigues (Barcelona)

fon: +34 93 897 0268 • fax: +34 93 899 2035

Z.I. de la Croix St. Nicolas • 14, rue Gustave Eiffel

fon: +33 1 49620101 • fax: +33 1 45767495

Organizační složka

KEB Antriebstechnik GmbH

Wildbacher Str. 5 • D–08289 Schneeberg

mail: info@keb-combidrive.de

C/ Mitjer, Nave 8 - Pol. Ind. LA MASIA

KEB España

mail: vb.espana@keb.de

Société Française KEB

F-94510 LA QUEUE EN BRIE

net: www.keb.fr • mail: info@keb.fr

6 Chieftain Buisiness Park, Morris Close

Park Farm, Wellingborough GB-Northants, NN8 6 XF

fon: +44 1933 402220 • fax: +44 1933 400724

net: www.keb-uk.co.uk • mail: info@keb-uk.co.uk

Via Newton, 2 • I-20019 Settimo Milanese (Milano)

fon: +39 02 33535311 • fax: +39 02 33500790

net: www.keb.it • mail: kebitalia@keb.it

15–16, 2–Chome, Takanawa Minato-ku

fon: +81 33 445-8515 • fax: +81 33 445-8215

fon: +82 2 6253 6771 • fax: +82 2 6253 6770

Lesnaya Str. House 30, Dzerzhinsky (MO)

fon: +7 495 550 8367 • fax: +7 495 632 0217

fon: +46 31 961520 • fax: +46 31 961124

fon: +1 952 224-1400 • fax: +1 952 224-1499

net: www.kebamerica.com • mail: info@kebamerica.com

KEB (UK) Ltd.

KEB Italia S.r.l.

KEB Japan Ltd.

J–Tokyo 108-0074

mail: info@keb.jp

KEB Korea Seoul

Room 1709, 415 Missy 2000

725 Su Seo Dong, Gang Nam Gu

ROK-135-757 Seoul/South Korea

mail: vb.korea@keb.de

KEB RUS Ltd.

RUS-140091 Moscow region

net: www.keb.ru • mail: info@keb.ru

KEB Sverige

Box 265 (Bergavägen 19)

S-43093 Hälsö

mail: vb.schweden@keb.de

KEB America, Inc.

5100 Valley Industrial Blvd. South

USA-Shakopee, MN 55379

More and newest addresses at http://www.keb.de

© KEB

Mat.No. 00C5CEB-K140

Rev. 1D

Date 11/2009

Loading...

Loading...