Keating 2009 Installation Manual

Users Manual

INSTANT RECOVERY®GAS FRYER

SERIES 2009

READ AND SAVE THIS MANUAL FOR FUTURE REFERENCE.

IMPORTANT:

RECORD THE MODE L AND SERIAL

NUM BERS OF THIS INSTANT RECOVERY

GAS FRYER IN THE SPACES PROVIDED.

Keep a copy of your bill of sale. The date on the bill establishes the warranty period should

SERIAL NO. ______________________________

®

MODEL NO. _____________________________

KEEP THESE NUMBERS FOR FUTURE REFERENCE.

service be required. If service is performed, it is in your interest to obtain and keep all receipts. Keating

commercial fryers are not intended for household use.

The Owner’s Guide provides specific operating instructions for your model. Use the Instant

®

Recovery

Gas Fryer only as instructed in this Service Guide.

CONTENTS:

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . i

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

INSTALLATION

DAMAGE DURING SHIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

DROP-IN FRYER COUNTER CUT-OUT/INSTALLATION . . . . . . . . 1

FIRST STEPS

POSITIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

VENTILATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

NATIONAL CODE REQUIREMENT . . . . . . . . . . . . . . . . . . . . . . . . . 2

GAS CONNECTORS & PIPE SIZE . . . . . . . . . . . . . . . . . . . . . . . . . 2

FLEXIBLE GAS CONNECTION

& QUICK DISCONNECT DEVICES . . . . . . . . . . . . . . . . . . . . . . . . . 3

RESTRAIN ING DEVICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ELECTRICAL CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

LEVELING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

PLACING YOUR KEATING FRYER IN OPERATION

FILLING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

LIGHTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

SHUTDOWN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

COOKI NG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

TIME R PROGRAMMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

OIL BREAKDOWN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

DRAINING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

CLEANING AND BOIL-OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

OPERATOR SELF HELP CHECK LIST . . . . . . . . . . . . . . . 11

PREVENTATIVE MAINTENANCE

PREVENTIVE MAINTENANCE CHART . . . . . . . . . . . . . . . . . . . . . 11

HI-LIM IT CHECK BI-MONTHLY . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

THER MOSTAT CALIBRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

THER MOSTAT BULB POSITIONING . . . . . . . . . . . . . . . . . . . 11-12

WARRANTY REPAIRS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

TROUB LESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-15

ORDE RING PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-30

WIRING DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31-47

WARRANTY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Keep this manual for training new personnel.

part# 038142

1-800-KEATING

www.keatingofchicago.com

gasFryer2009

01/14

i

WARNING

Improper installation, adjustment, alteration,

service or maintenance can cause property

damage, injury or death. Read the installation,

operating and maintenance instructions thoroughly

before installing or servicing this equipment.

FOR YOUR SAFETY

Do not store or use gasoline or other

flammable vapors or liquids in the vicinity of

this or any other appliance.

*As continuous product improvement occurs, specifications may be changed without notice.

Purchaser should post in a prominent location instructions to be followed in the event the user

smells gas. This information shall be obtained by consulting the local gas supplier.

THE EQUIPMENT IS TO BE INSTALLED TO

COMPLY WITH THE BASIC PLUMBING CODE

OF THE BUILDING OFFICIALS AND CODE

ADMINISTRATORS INTERNATIONAL, INC.

(BOCA) AND THE FOOD SERVICE

SANITATION MANUAL OF THE FOOD AND

DRUG ADMINISTRATION (FDA).

IF NOT INSTALLED, OPERATED AND

MAINTAINED IN ACCORDANCE WITH THE

MANUFACTURER'S INSTRUCTIONS, THIS

PRODUCT COULD EXPOSE YOU TO

SUBSTANCES IN FUEL OR IN FUEL

COMBUSTION WHICH CAN CAUSE DEATH

OR SERIOUS ILLNESS AND WHICH ARE

KNOWN TO THE STATE OF CALIFORNIA TO

CAUSE CANCER, BIRTH DEFECTS OR OTHER

REPRODUCTIVE HARM.

PROPANE GAS MAY EVENTUALLY LOSE ITS

ODOR AND PRECAUTIONS SHOULD BE

TAKEN TO ASSURE THAT PROPANE GAS IS

NOT PRESENT EVEN THOUGH YOU DO NOT

DETECT AN ODOR. IF THERE IS ANY DOUBT,

YOU SHOULD CALL YOUR LOCAL PROPANE

GAS SUPPLIER FOR ASSISTANCE.

WARNING

Improper installation

can cause damage,

injury or death.

ShockBurnsGas

POST THIS LABEL IN A

PROMINENT LOCATION

ON YOUR UNIT

WARNING

Do not store flammable

liquids near this or any

other appliance.

INTRODUCTION

Instructions in this manual should be read thoroughly

before attempting to operate this Keating Gas Fryer.

All installation and service on Keating equipment must

be performed by qualified, certified, licensed and/or

authorized installation or service personnel.

Operating information for Keating equipment has been

prepared for use by qualified and/or authorized

personnel.

Keating equipment is made in the U.S.A. and has

American sizes of hardware. All metric conversions are

approximate.

INSTALLATION INSTRUCTIONS

Proper installation will assure top performance.

Alterations of any kind to your equipment will void the

warranty. Before uncrating, check equipment carefully

for damage.

IF EQUIPMENT ARRIVES DAMAGED

Keating does not assume responsibility for loss or

damage incurred in transit.

IMPORTANT

This merchandise has been thoroughly inspected and

carefully packed before leaving our plant.

Responsibility for its safe delivery was assumed by the

carrier at the time of shipment. Claims for loss or

damage to the contents should, therefore, be made

upon the carrier, as follows:

CONCEALED LOSS OR DAMAGE

Concealed loss or damage means loss or damage

which does not become apparent until the

merchandise has been unpacked. The contents may

be damaged in transit due to rough handling even

though the carton may not show external damage.

When the damage is discovered upon unpacking,

make a written request for inspection by the carrier’s

agent within fifteen days of the delivery date. Then file

a claim with the carrier since such damage is the

carrier’s responsibility. By following these instructions

carefully, we guarantee our full support of your claims

to protect you against loss from concealed damage.

VISIBLE LOSS OR DAMAGE

Any external evidence of loss or damage must be

noted on the freight bill or express receipt, and signed

by the carrier’s agent. Failure to adequately describe

such external evidence of loss or damage may result

in the carrier refusing to honor a damage claim. The

form required to file such a claim will be supplied by

the carrier.

DO NOT RETURN DAMAGED MERCHANDISE

TO KEATING. FILE YOUR CLAIM AS ABOVE.

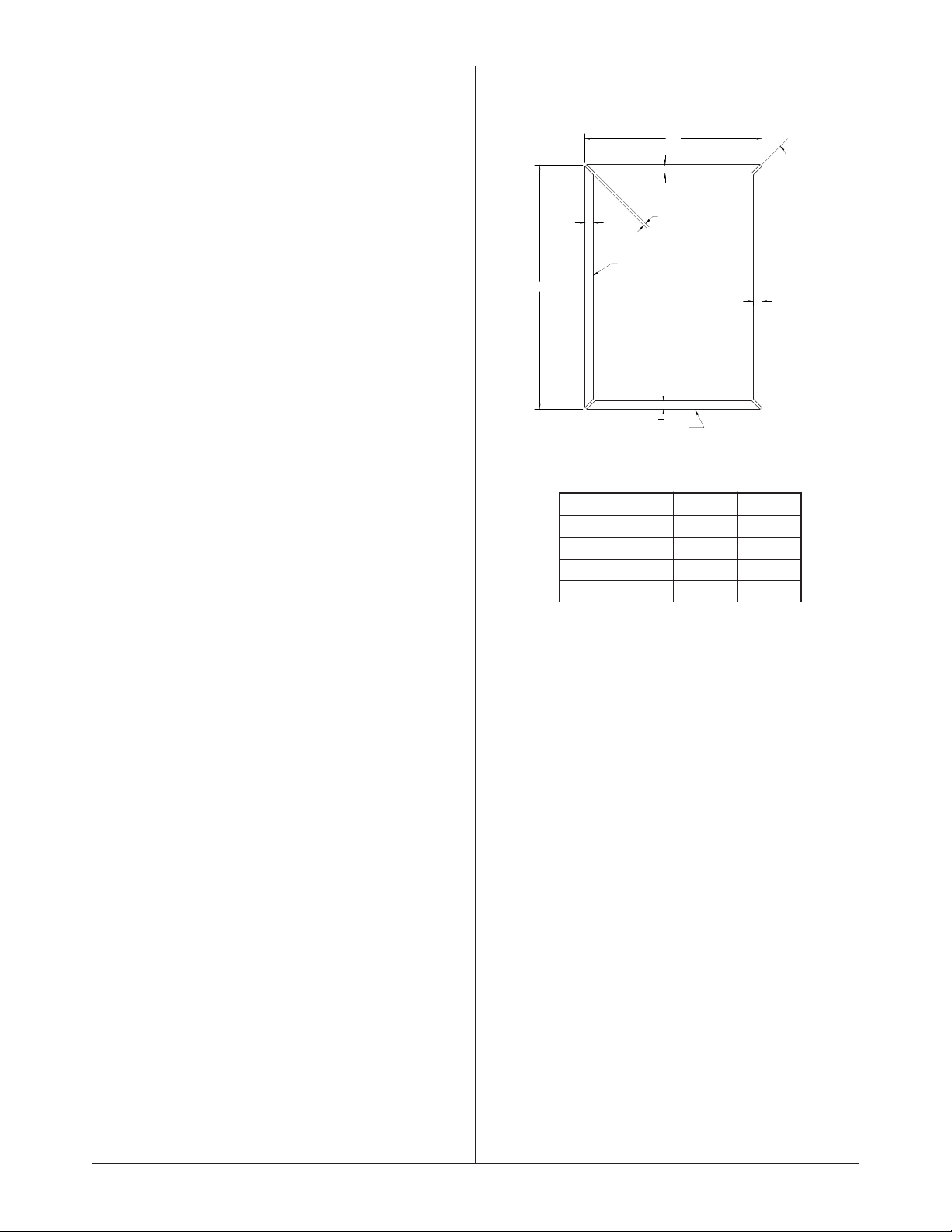

INSTALLATION NOTES

1. All Drop-In Fryers must be 16" from any open flame.

2. Fryer must be located no more than 5" from counter

top front.

3. Cabinet must be reinforced to support full weight of

fryer in use (Fryer, oil, food, etc.).

4. Fryers must be properly ventilated and located

under an exhaust hood.

DROPPING THE FRYER INTO THE COUNTER TOP

It is only necessary to place the fryer in such a positon

that the front edge overlaps the front raised edge of

the opening.

Push the fryer forward as far as it will go holding the

fryer on approximately a 15° angle, and then drop the

rear of the fryer into its proper position lowering it

down gently so you do not deform the table or

equipment stand.

FIRST STEPS

POSITIONING

Keep appliance area free and clear of any

combustibles. Position the Keating Gas Fryer 6 inches

(152mm) from any combustible material. A minimum of

24 inches (610mm) should be provided at the front of

the Keating Gas Fryer for servicing and proper

DROP-IN FRYER COUNTER

CUTOUT/INSTALLATION

1

FRYER

“A” “B”

10×11 DI

13" 211/2"

10×11 DI E2000

13" 22"

14DI

16" 231/2"

18DI

20" 29"

5/8"

TYP.

45°

“A”

5/8"

DETERMINED BY

CUTTING TOOL

USED

5/8"

“B”

BEND UP 90° ON ALL SIDES

TO FINAL OPENING SIZE (“A” X “B”),

THEN CLOSE CORNERS BY WELDING

AN INSERT PIECE (OR OTHER SUITABLE

METHODS) FOR A LEAK FREE FIT.

1/8"

CUT LINE

5/8"

operation. Air for combustion enters the fryer from the

bottom of the cabinet and the bottom of the control

panel.

DO NOT BLOCK BOTTOM OF KEATING INSTANT

RECOVERY

®

GAS FRYER CABINET. DO NOT

OBSTRUCT FLUE.

Your Keating Instant Recovery

®

Gas Fryer is designed

to be serviced from the front.

MINIMUM CLEARANCE

MINIMUM CLEARANCE

SUITABLE FOR NON COMBUSTIBLE FLOORS

VENTILATION

The Keating Gas Fryer must be installed in an area

providing adequate air supply and ventilation. Do not

obstruct the flow of combustion and ventilation air.

Proper ventilation is one of the important

considerations for efficient operation of the Keating

Gas Fryer. It should be installed so that the products of

combustion are removed efficiently without producing

drafts that will interfere with proper burner operation.

The intake for the exhaust fan should not be placed

close to the flue of the Keating Gas Fryer to insure

proper air flow necessary for combustion. The area

around the front and bottom of the Keating Gas Fryer

must be kept clear and unobstructed. In the U.S.A. the

ventilation systems must conform to the ANSI/NFPA96

latest edition. “A minimum of 18" (457mm) should be

maintained between the flue outlet and the lower edge

of the grease filters.” Must be installed at least 16"

away from any open flame. It is the responsibility of the

owner and the local installer to comply with national

and local codes.

NATIONAL CODE REQUIREMENT

The installation must conform with local codes, or in

the absence of local codes, with the National Fuel Gas

code, ANSI Z223.1 or the Natural gas Installation

Code, CAN/CGA-B149.1 or the Propane Installation

Code, CAN/CGA-B149.2. Flexible connectors must

comply to ANSI Z221.69/CAN/CGA1.16. Keating

equipment is designed and manufactured to operate

only on the type of gas specified by the user and

indicated on the serial plate located inside the door.

The gas may be natural, propane or manufactured.

The type of gas cannot be converted to another gas

fuel by turning or engaging a switch.

GAS CONNECTIONS AND PIPE SIZE

A single Keating Gas Fryer requires a standard gas

pipe size of 3/4 inch (19mm) I.D. connection. Multiple

fryers with a common manifold will require a minimum

of 1 1/4 inch I.D. gas supply line. The size of the gas

supply pipe is very important. If the pipe is too small

you will have low gas pressure at the Keating Gas

Fryer manifold. Low gas pressure will cause slow

recovery and/or delayed ignition, amongst other

problems. If you have a question about gas pipe size,

call your local gas company.

Before connecting new pipe to the Keating Gas Fryer

the pipe must be blown out to remove all foreign

particles. These particles in the controls or burners

may cause improper or dangerous operating

conditions.

Pipe joint compounds that are used on threaded joints

of appliance piping shall be resistant to the action of

liquefied petroleum gases (Loctite PST 56765). When

using pipe joint compound do not apply to the first two

threads. Use only a very small amount and only on

male threads. This will prevent clogging of burner

orifices and the gas valve. Never use compound on

female threads as it might be pushed into the gas

valve.

Have your installer check for gas leaks using a soap

and water solution before operating.

DO NOT USE AN OPEN FLAME TO CHECK FOR

GAS LEAKS.

1) The Keating Gas Fryer and its individual shut off

valves must be disconnected from the gas supply

piping system during any pressure testing of that

system at test pressures in excess of 1/2 psi (3.45kPa)

(13.84 in WC). High pressure can damage the gas

valve causing a hazardous condition. Excessive

pressure introduced to the fryer may void the warranty.

2.) The appliance must be isolated from the gas supply

piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than

1/2 psi (3.45 kPa).

NOTE: Keating fryers use a constant pilot that will emit

a very small amount of gas at all times.

NOTE: Line pressure must be kept below 10” (Nat),

13” (LP) during leak test to avoid damage to the gas

valve.

If more than one gas unit is on the

same supply line, you may require a

larger line. Consult your local gas

company to assure adequate volume

and pressure. Refer to serial plate for

proper gas requirement for your

particular model.

Clearances

Combustible Non-Combustible

Construction Construction

Back 6" 0"

Right Side 6" 0"

Left Side 6" 0"

2

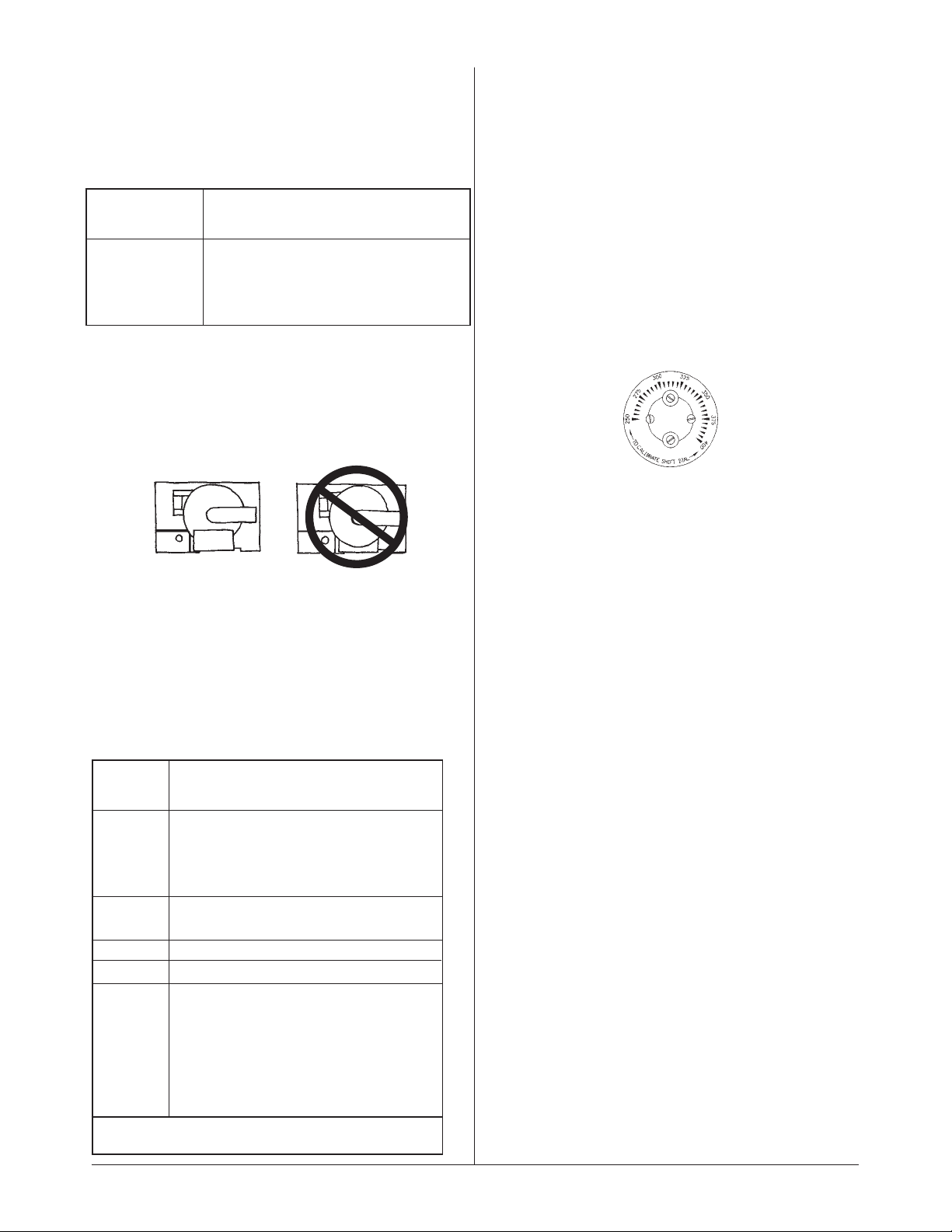

WAR NIN G

Do not use

open flame

to check for leaks.

3

FLEXIBLE GAS CONNECTORS AND QUICK

DISCONNECT DEVICES

For an appliance equipped with casters:

The installation shall be made with a connector that

complies with the Standard for Connectors for

Movable Gas Appliances, ANSI Z21.69 or the

Standard for Connectors for Moveable Gas

Appliances, CAN/CGA-6.16, and a quick disconnect

device that complies with the Standard for QuickDisconnect Devices for Use With Gas Fuel, ANSI

Z21.41 or the Standard for Quick Disconnect Devices

for Use with Gas Fuel, CAN1-6.9.

RESTRAINING DEVICES

1.) Adequate means must be provided to limit the

movement of the appliance without depending on the

connector and the quick-disconnect device or its

associated piping to limit the appliance movement.

Fryer must also be restrained to prevent tipping when

installed so that hot liquid splashing is avoided.

2.) The restraint means must be

attached to the rear of the Keating Gas

Fryer within 2" of the center line width

and approximately 1-5/8" from the

bottom of the cabinet back to allow the

restraining bolt to be anchored to the

cabinet back between the cabinet

bottom and inner liner.

IF DISCONNECTION OF THE

RESTRAINT IS NECESSARY, IT MUST BE

RECONNECTED WHEN THE KEATING GAS FRYER

IS RETURNED TO ITS ORIGINALLY INSTALLED

POSITION.

INSTALLATION

The installer is responsible for attaching the tipping

restraint. See page 3 for drop-in installation.

ELECTRICAL CONNECTION

The Keating Gas Fryer, when installed, must be

electrically grounded in accordance with local codes,

or in the absence of local codes, the National Electrical

Code, ANSI/NFPA No. 70. or the Canadian Electrical

Code, CSAC-22.2 as applicable. A wiring diagram is

located on the last page or on the inside of the door. In

the U.S.A. and Canada, the electrical supply must be

120 VAC, 60 Hz.

This appliance is equipped with a three-

prong 120 Volt NEMA 5-15 (grounding)

plug for your protection against shock

hazard and should be plugged directly

into a properly grounded and polarized

three-prong receptacle. Do not cut or

remove the grounding prong from this

plug. (Model AA has no electric

connection).

LEVELING

The Keating Gas Fryer will operate at its highest

efficiency when properly leveled. Place a level on the

fryer from side to side. For fryer on legs, the bottom

foot of the leg is adjustable. Turn counterclockwise to

increase height, or clockwise to decrease height until

level. For fryers with casters, the casters are

adjustable by loosening the jam nut and turning the

caster in or out. When the desired level is reached,

tighten the jam nut. Adjustments of more than 3/4"

cannot occur with any caster. The same procedure

should be followed to level the fryer from front to back.

PLACING KEATING GAS

FRYER IN OPERATION

NEVER LEAVE YOUR FRYER OPERATING

UNATTENDED.

(When all previous instructions have been completed).

Check the serial plate on the panel inside the door to

determine if the burner is set up for the proper type

gas before connecting the quick-disconnect or piping

from the building gas supply pipe.

a. Maximum INCOMING gas pressure

NATURAL GAS – 7 inches W.C. with burners on

LP GAS – 11 inches W.C. with burners on

b. Fryer MANIFOLD gas pressure

NATURAL GAS – 4 inches W.C. with burners on

LP – 10 inches W.C. with burners on

ALWAYS disconnect fuel source and power

supply before servicing.

NEVER move a fryer when full of oil.

NEVER introduce objects or liquids into fryer,

while operational, which are not designed or

made for cooking.

THIS FRYER MAY NOT BE ALTERED, MODIFIED

OR CHANGED IN ANY WAY.

NOTICE

Restraining devices

required.

WARNING

Plug into a

properly grounded

three-prong receptacle.

4

FILLING

NOTE: Before filling the fryer make certain the fryer

vessel is sanitized, dry and the drain valve is

completely closed.

NOTE: Solid shortening can not be used in a Keating

Model AA Gas Fryer. If solid shortening is used, it

should be melted prior to filling the fryer vessel.

Damage done by melting solid shortening in the fryer

vessel will void the warranty.

Oil expands when heated. The “Max” line has been

provided to ensure optimum cooking while ensuring

the safety of the operator. Do not overfill the fryer

vessel.

Max Line

Fill the fryer vessel with oil or MELTED solid shortening

up to the “Max” line.

BE SURE THE HEAT TRANSFER TUBES ARE

COMPLETELY COVERED WITH OIL BEFORE

SWITCHING THE FRYER ON. IF OIL LEVEL DROPS

BELOW TOP OF HEAT TRANSFER TUBES, SEVERE

DAMAGE TO FRYER AND INJURY TO OPERATOR

MAY RESULT.

LIGHTING INSTRUCTIONS

(See lighting instructions plate attached to the inner

door of Keating Gas Fryer.) Model AA does not

require an electrical connection.

Make sure that the Keating Gas Fryer is plugged in. If

not your fryer will not operate. Make sure that the main

gas valve on the gas supply line to the Keating Gas

Fryer is in the “ON” position.

AIR IN THE GAS SUPPLY LINE MAY REQUIRE A

LONGER THAN NORMAL PERIOD OF TIME TO LIGHT

YOUR FRYER DURING INITIAL INSTALLATION OR

AFTER OVERNIGHT SHUTDOWN

NOTE: Unless you have an AA model, your fryer

cannot be operated during a power failure.

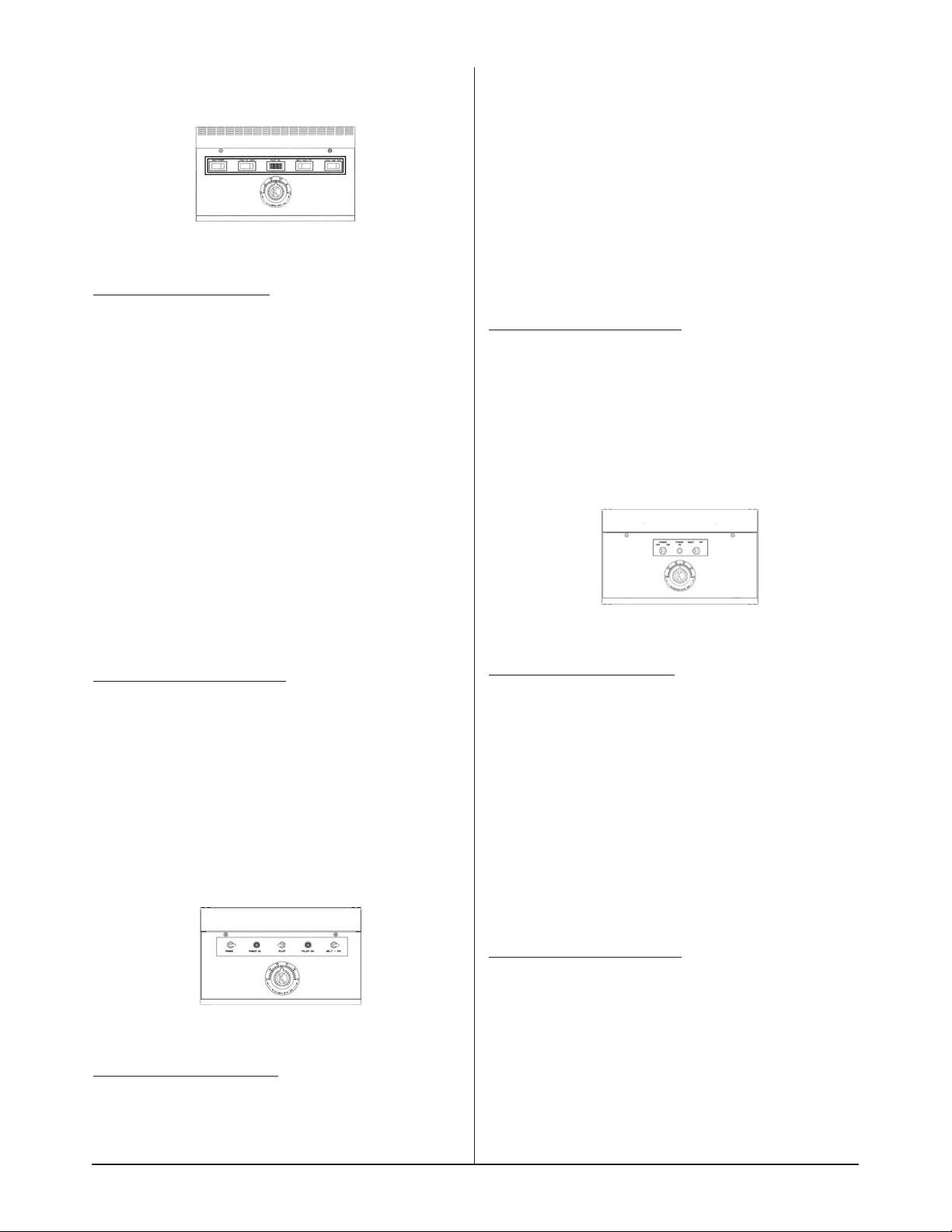

AA MODELS OPERATING INSTRUCTIONS

AA CONTROL PANEL – SERIES 2000

AA CONTROL PANEL – SERIES 2006

AA CONTROL PANEL – SERIES 2010

START-UP PROCEDURE

WARNING: DO NOT START FRYER WITHOUT

FIRST FILLING FRY POT.

STEP 1. Set thermostat to the "OFF" position.

STEP 2. Turn "MAIN POWER" switch to the "OFF"

position.

STEP 3. Turn gas valve knob to "PILOT" position.

STEP 4. Light constant pilot located on left side of

pilot runner tube.

STEP 5. Push and hold the gas valve knob for 30

seconds and release.

STEP 6. With the pilot still on, turn gas valve knob to

the "ON" position.

STEP 7. Set thermostat to desired temperature, turn

"MAIN POWER" switch to the "ON"

position. The burners will come on.

SHUTDOWN PROCEDURE

STEP 1. Set thermostat to the "OFF" position.

STEP 2. Turn "MAIN POWER" switch to the "OFF"

position.

STEP 3. Turn gas valve knob to the "OFF" position.

STEP 4. Turn gas supply valve to the "OFF" position.

STEP 5. Check to make sure all burners and pilot are

extinguished.

POWER

OFF ON

5

SERIES 2000 BB MODELS

OPERATING INSTRUCTIONS

BB CONTROL PANEL – SERIES 2000

START-UP PROCEDURE

WARNING: DO NOT START FRYER WITHOUT

FIRST FILLING FRY POT.

STEP 1. Set "MELT-IDLE-FRY" switch to "IDLE"

position and thermostat to the "OFF"

position.

STEP 2. Turn "MAIN POWER" switch to the "ON"

position.

STEP 3. Light constant pilot located on left side of

pilot runner tube.

STEP 4. Hold the "PUSH TO LIGHT" switch in until

the amber "PILOT ON" light comes on.

STEP 5. Set thermostat to desired temperature.

STEP 6. Set "MELT-IDLE-FRY" switch to "FRY." The

burners will come on. Select "MELT" with

solid shortening until liquid shortening is 1"

from full, then switch to the "FRY" position

after packing shortening around burner

tubes.

SHUTDOWN PROCEDURE

STEP 1. Set "MELT-IDLE-FRY" switch to "IDLE"

position and thermostat to the "OFF"

position.

STEP 2. Turn "MAIN POWER" switch to the "OFF"

position. Its green light will go off.

STEP 3. Check to make sure all burners and pilot are

extinguished.

SERIES 2006 BB MODELS

OPERATING INSTRUCTIONS

BB CONTROL PANEL – SERIES 2006

START-UP PROCEDURE

WARNING: DO NOT START FRYER WITHOUT

FIRST FILLING FRY POT.

STEP 1. Set thermostat to the "OFF" position.

STEP 2. Turn "MAIN POWER" switch to the "ON"

position. The power ON light will illuminate.

STEP 3. Hold the "PUSH TO LIGHT" switch over

until the amber "PILOT ON" light comes on.

Release switch.

STEP 4. Set thermostat to desired temperature.

STEP 5. Set "MELT-FRY" switch to "FRY." The

burners will come on. Select "MELT" with

solid shortening until liquid shortening is 1"

from full, then switch to the "FRY" position

after packing shortening around burner

tubes.

SHUTDOWN PROCEDURE

STEP 1. Set thermostat to the "OFF" position.

STEP 2. Turn "MAIN POWER" switch to the "OFF"

position.

STEP 3. Check to make sure all burners and pilot are

extinguished.

SERIES 2006 BB SPARK IGNITION

OPERATING INSTRUCTIONS

BB SPARK IGNITION CONTROL PANEL – SERIES 2006

START

-UP PROCEDURE

WARNING: DO NOT START FRYER WITHOUT

FIRST FILLING FRY POT

STEP 1. Set thermostat to the "OFF" position.

STEP 2. Turn "MAIN POWER" switch to the "ON"

position.

STEP 3. Set thermostat to desired temperature.

STEP 4. Set "MELT-FRY" switch to "FRY." The

burners will come on. Select "MELT" with

solid shortening until liquid shortening is 1"

from full, then switch to the "FRY" position

after packing shortening around burner

tubes.

SHUTDOWN PROCEDURE

STEP 1. Set thermostat to the "OFF" position.

STEP 2. Turn "MAIN POWER" switch to the "OFF"

position.

STEP 3. Check to make sure all burners and pilot are

extinguished.

6

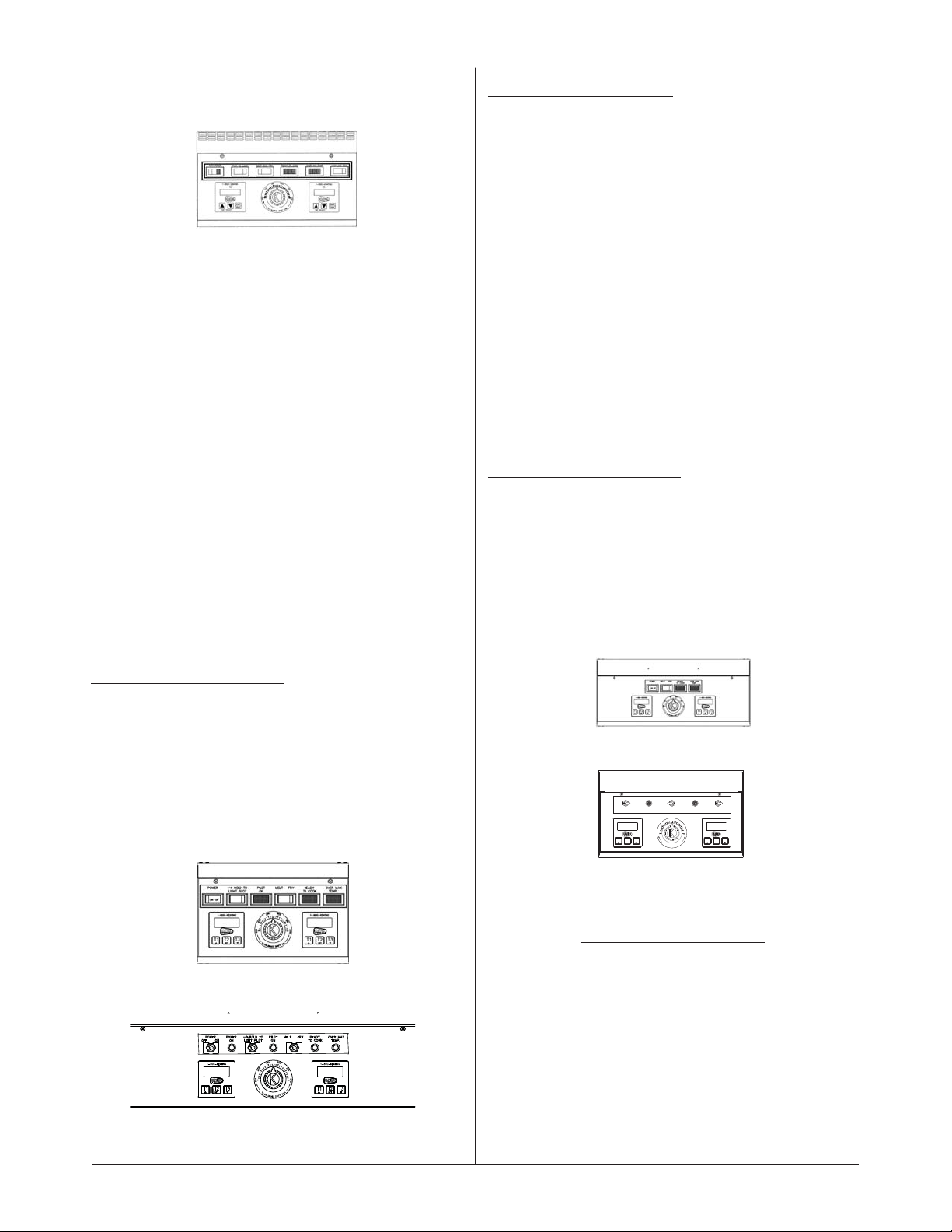

SERIES 2000 TS MODELS

OPERATING INSTRUCTIONS

TS CONTROL PANEL – SERIES 2000

START-UP PROCEDURE

WARNING: DO NOT START FRYER WITHOUT

FIRST FILLING FRY POT.

STEP 1. Set "MELT-IDLE-FRY" switch to "IDLE"

position and thermostat to the "OFF"

position.

STEP 2. Turn "MAIN POWER" switch to "ON"

position. Its green light and the timers will

come on.

STEP 3. Light constant pilot located on left side of

pilot runner tube.

STEP 4. Hold the "PUSH TO LIGHT" switch for 30

seconds. The pilot runner tube will light.

STEP 5. Set thermostat to desired temperature.

STEP 6. Set "MELT-IDLE-FRY" switch to "FRY" with

oil in the fry pot. The burners will come on.

Select "MELT" with solid shortening until

liquid shortening is 1" from full mark then

switch to the "FRY" position after packing

shortening around burner tubes.

SHUTDOWN PROCEDURE

STEP 1. Set thermostat to the "OFF" position.

STEP 2. Turn "MAIN POWER" switch to the "OFF"

position. Its green light will go off.

STEP 3. Check to make sure all burners and pilot are

extinguished.

SERIES 2006 TS MODELS

OPERATING INSTRUCTIONS

TS CONTROL PANEL - SERIES 2006

TS CONTROL PANEL - SERIES 2009

START

-UP PROCEDURE

WARNING: DO NOT START FRYER WITHOUT

FIRST FILLING FRY POT.

STEP 1. Set thermostat to the "OFF" position.

STEP 2. Turn "MAIN POWER" switch to "ON"

position. Its green light and the timers will

come on.

STEP 3. Light constant pilot located on left side of

pilot runner tube.

STEP 4. Hold the "PUSH TO LIGHT" switch for 30

seconds. The pilot runner tube will light.

STEP 5. Set thermostat to desired temperature.

STEP 6. Set "MELT-IDLE-FRY" switch to "FRY" with

oil in the fry pot. The burners will come on.

Select "MELT" with solid shortening until

liquid shortening is 1" from full mark then

switch to the "FRY" position after packing

shortening around burner tubes.

SHUTDOWN PROCEDURE

STEP 1. Set thermostat to the "OFF" position.

STEP 2. Turn "MAIN POWER" switch to the "OFF"

position. Its green light will go off.

STEP 3. Check to make sure all burners and pilot are

extinguished.

SERIES 2009 TS SPARK IGNITION

MODELS OPERATING INSTRUCTIONS

TS SPARK IGNITION CONTROL PANEL SERIES 2006

TS SPARK IGNITION CONTROL PANEL SERIES 2009

START-UP PROCEDURE

WARNING: DO NOT START FRYER WITHOUT

FIRST FILLING FRY POT.

STEP 1. Set thermostat to the "OFF" position.

STEP 2. Turn "MAIN POWER" switch to "ON"

position. Its green light and the timers will

come on.

STEP 3. Set thermostat to desired temperature.

STEP 4. Set "MELT-IDLE-FRY" switch to "FRY" with

oil in the fry pot. The burners will come on.

1-800-KEATING

275

250

T3T2

T1

SET

1-800-KEATING

350

375

T3T2

T1

SET

L

A

T

O

I

C

D

A

T

L

F

I

I

B

H

R

S

E

A

T

MELT - FRYPOWER POWER ON PILOT ONPILOT

325

300

7

Select "MELT" with solid shortening until liquid

shortening is 1" from full mark then switch to the

"FRY" position after packing shortening around burner

tubes.

SHUTDOWN PROCEDURE

STEP 1. Set thermostat to the "OFF" position.

STEP 2. Turn "MAIN POWER" switch to the "OFF"

position. Its green light will go off.

STEP 3. Turn gas supply valve to the "OFF" position.

STEP 4. Check to make sure all burners and pilot are

extinguished.

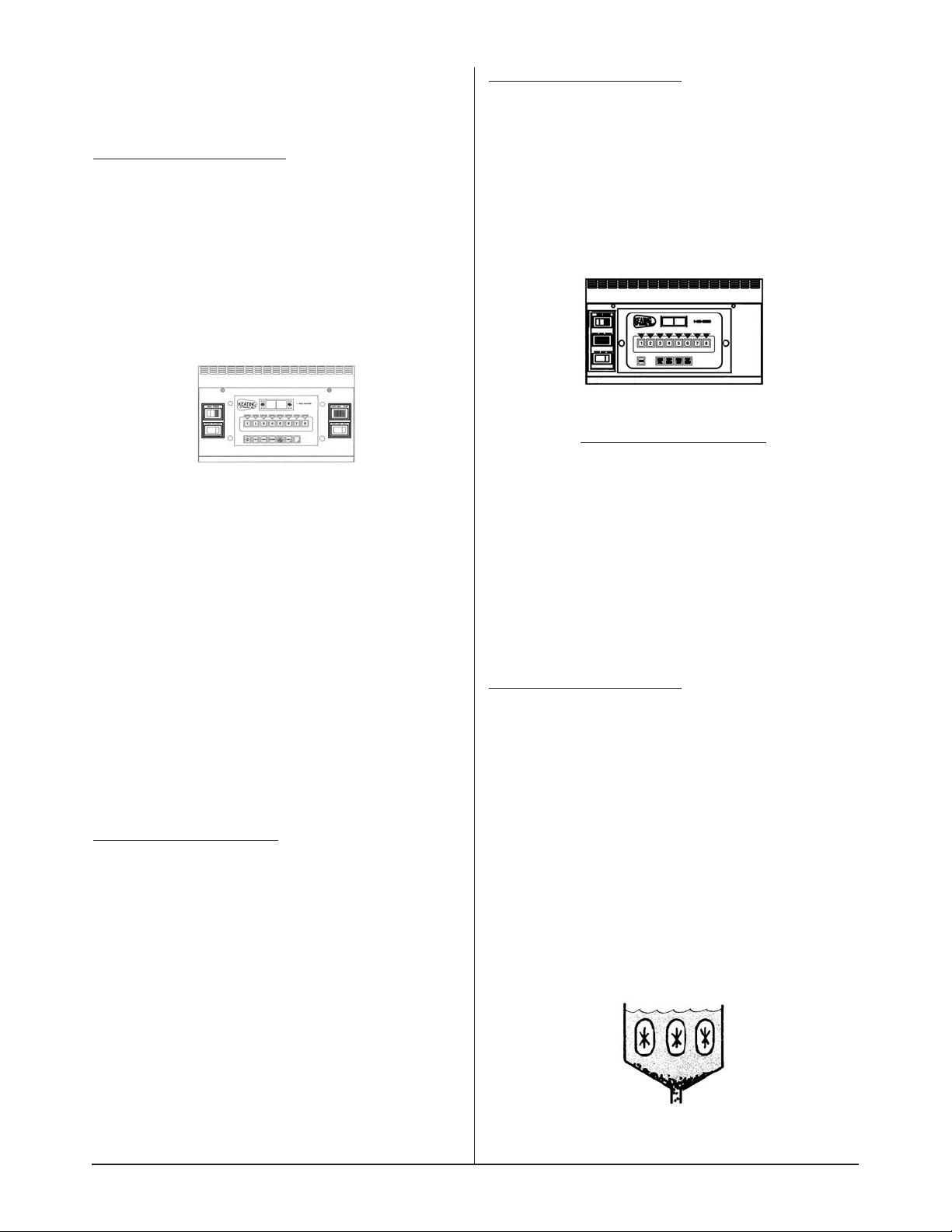

SERIES 2000 - 2010 CPU MODELS

OPERATING INSTRUCTIONS

CPU CONTROL PANEL SERIES 2000

CPU CONTROL PANEL SERIES 2009

CPU CONTROL PANEL SERIES 2010

START-UP PROCEDURE

WARNING: DO NOT START FRYER WITHOUT

FIRST FILLING FRY POT.

STEP 1. Light mini pilot located next to the left

burner when facing fryer.

STEP 2. Turn gas supply to the ‘ON’ position.

STEP 3. Depress the main power switch to the ‘ON’

position.

STEP 4. Make sure CPU is turned off.

STEP 5. Engage the (Push to Light) switch and hold

until indicator light remains on or the pilot

runner tube remains lit.

STEP 6. Turn the CPU on by pressing on/off button.

STEP 7. Select melt cycle or heat cycle.

STEP 8. Select the desired temperature. See the

computer manual for more information.

SHUTDOWN PROCEDURE

STEP 1. Turn CPU off by pressing the on/off button.

STEP 2. Depress the main power switch to the off

position.

STEP 3. Turn gas supply to the "OFF" position.

STEP 4. Wait five minutes before restarting or

relighting fryer.

SERIES 2000 CPU SPARK IGNITION MODELS

OPERATING INSTRUCTIONS

CPU SPARK IGNITION SERIES 2000

START-UP PROCEDURE

WARNING: DO NOT START FRYER WITHOUT

FIRST FILLING FRY POT.

STEP 1. Turn gas supply to the ‘ON’ position.

STEP 2. Depress the main power switch to the ‘ON’

position.

STEP 3. Turn CPU to the ‘ON’ position.

STEP 4. Select melt cycle or heat setting.

STEP 5. Select the desired temperature. See the

computer manual for more information.

SHUTDOWN PROCEDURE

STEP 1. Turn CPU off by pressing the on/off button.

STEP 2. Depress the main power switch to the ‘OFF’

position.

STEP 3. Turn gas supply to the "OFF" position.

STEP 4. Wait five minutes before restarting or

relighting fryer.

COOKING

Keating's Instant Recovery®Gas Fryer is designed to

provide maximum production efficiency and deliver

high quality food products. Low- temperature cooking,

highly polished stainless steel and a true COLD ZONE

mean extended oil life. Follow cooking procedures on

next page for your model.

Cold Zone

OPERATION OF THIS FRYER SHOULD BE LIMITED

TO PERSONNEL WHO HAVE BEEN THOROUGHLY

TRAINED IN OPERATING PROCEDURES.

CARE SHOULD BE TAKEN WHEN LOWERING

BASKETS INTO FRYER TO PREVENT SPLASHING

HOT OIL FROM FRYER VESSEL.

If your fryer has timers, push the “T1,” “T2” or “T3”

button on the digital timer(s). For fryers with automatic

basket lift, basket(s) will lower into fryer vessel.

When timer(s) sounds, carefully lift basket(s) out of hot

oil. For fryers with automatic basket lift, a buzzer will

sound and the basket(s) will rise automatically. Allow

oil to drain before removing.

DO NOT LIFT BASKETS DIRECTLY OUT OF THE

FRYER VESSEL WITHOUT DRAINING AS SEVERE

INJURY MAY RESULT.

USE ONLY KEATING APPROVED BASKETS IN

YOUR FRYER. NEVER OVERFILL FRY BASKETS.

DO NOT BANG BASKETS ON BASKET HANGERS

OR ON FRYER VESSEL.

Place basket(s) on basket hanger on splashback of

fryer and allow to drain.

SHUTDOWN INSTRUCTIONS

Always turn the fryer off each night. See Shutdown

procedure.

TS MODEL TIMER

OPERATING INSTRUCTIONS

PART # 056921

DIGITAL TIMERS

The electronic timers, standard on TS

models, provide a clearly visible and

accurate display and are very easy to use.

Three different, independent cook times

can be set using this timer - T1, T2, and T3.

PROGRAMMING

To program the timers, the unit must be in the idle mode.

Press and hold the set button for approximately two

seconds. The display will show “SEt”. Press T1, T2, or T3

for the cook time to be programmed. The display will show

the current setting for that cook time. Use the up or down

button to increment or decrement the setting. When the

setting is correct, press and hold the set button again for

approximately two seconds. The display will show "StO" for

approximately two seconds and the timer will return to

normal operation. Repeat the process as necessary for the

other timers.

OPERATING LOGIC

When the timer is powered up, the display will show the

time setting for the cook time that was operated last and

the relay output contacts will be open. To start a cycle,

press the desired cook time button (T1, T2 or T3). The

display will begin to countdown from the preset time

setting and the relay output contacts will close. During

the countdown the colon will flash at a one-second rate.

When the countdown has reached "00:00" the relay

output contacts will open, the display will flash, and the

audible alarm will sound. To cancel the audible alarm,

press any button.

PAUSE FEATURE

To pause a cycle in progress, press any button. The relay

output contacts will open, the display will flash, and the

countdown will pause. To resume the countdown, press

any button. The display will resume the normal

countdown and the relay output contacts will close.

CANCELING A CYCLE

To cancel a cycle in progress press and hold any button

for approximately two seconds. The relay output contacts

will open and the display will show the time setting for

the channel last used.

OIL BREAKDOWN

As part of a “Preventive Maintenance Program”, the oil

in your fryer needs to be filtered regularly. The initial

investment in the frying system is far less than the total

overall costs of oil during the life of the fryer, and with

regular filtering, you can realize substantial savings in

oil costs, as well as maintenance charges. We have

listed some of the conditions which are catalysts in the

breakdown of oil:

1. Contact with Oxygen

2. Carbonization of Crumbs and Food Particles

3. Non-Stainless Steel Surfaces

4. Keep Salt and Seasonings Away From Oil

5. Prolonged High Temperatures

DRAINING

Operator in safety gear

ALWAYS SHUT THE FRYER OFF COMPLETELY

BEFORE DRAINING. THE FRYER SHOULD BE

DRAINED ONLY UNDER THE SUPERVISION OF

PROPERLY TRAINED PERSONNEL. A DRAIN PIPE

AND COVERED CONTAINER SUITABLE FOR USE

WITH HOT OIL SHOULD BE USED TO ENSURE THE

SAFETY OF THE OPERATOR.

8

9

1. Operator should be outfitted with proper attire

including:

•Oil and heat resistant gloves

•Oil and heat resistant apron

•Safety goggles

•Oil and heat resistant footwear

2. Turn off the fryer and open the door.

3. Put suitable container under drain valve.

4. Drain oil from fryer by slowly turning handle. The

drain will be completely open after 1/4 turn.

5. After fryer drains close the drain valve.

6. Filtering may be done at this step.

NOTE: Fryers with a central filter and under fryer filter

will drain differently. (See page 9.)

CLEANING AND BOIL-OUT

FOR A SINGLE FRYER

When cleaning and boiling out your fryer use Keating

Sea Powder and Keating Klenzer to keep your fryer in

top condition.

1. Operator should be outfitted with proper attire

including:

•Oil and heat resistant gloves

•Oil and heat resistant apron

•Safety goggles

•Oil and heat resistant footwear

Turn the fryer off. Remove baskets and screen.

2. Drain oil from fryer, see draining.

A KEATING FRYER OR FILTER SHOULD BE DRAINED

ONLY UNDER THE SUPERVISION OF PROPERLY

TRAINED PERSONNEL. WHEN DISCARDING OIL, A

COVERED RECEPTACLE APPROVED FOR USE WITH

HOT OIL SHOULD BE USED. USE OF A NON-APPROVED

RECEPTACLE OR METHOD OF DRAINING THE OIL

COULD JEOPARDIZE THE SAFETY OF THE OPERATOR.

3. Remove oil container to a secure area to prevent

accidental spillage.

4. Close the drain valve.

5. Fill fryer vessel to “Max” line with water.

6. Set thermostat and turn fryer on to bring water to

a gentle boil. Once boil has been reached, turn

fryer off.

UNDER NO CIRCUMSTANCES SHOULD THE

FRYER AND FILTER BE LEFT UNATTENDED

DURING BOIL-OUT. TRAINED PERSONNEL MUST

BE PRESENT DURING THE PROCEDURE TO

PREVENT BOIL OVER OR TO TURN OFF THE

POWER IF WATER DROPS BELOW HEATING

TRANSFER TUBES.

7. Dissolve

2

/3 cup of Keating Sea Powder for every

five gallons of water and let soak for 1/2

hour. If

there is a large build-up of carbonized grease,

allow for fryer to soak overnight.

8. While soaking, a natural fiber brush may be used

to scrub the tubes and inside walls of fryer. Drain

the water and Sea Powder into a dry suitable

receptacle and remove from cooking area.

Sprinkle Keating Klenzer liberally on tubes and

sides of fryer vessel. A non-abrasive scouring pad

may be used to remove the now softened

carbonized grease. Thoroughly rinse fryer vessel

with potable water to remove all Klenzer. Prior to

refilling with oil, wipe the inside of the fryer vessel

making sure all water and Klenzer have been

removed.

NOTE: Do not pump water through the filter system.

DO NOT DAMAGE OR REPOSITION THERMOSTAT

PROBE AS THIS MAY AFFECT THE ACCURACY OF

THE FRYER.

DO NOT MIX WATER AND HOT OIL

9. Close the drain valve.

10. Check thermostat bulb positioning.

11. Refill the fryer with new or filtered oil.

TO AVOID DAMAGING THE FRYER, DO NOT

POWER WASH, SPRAY OR HOSE IT DOWN WHILE

CLEANING IT.

CLEANING AND BOIL-OUT FOR A FRYER

WITH BUILT IN FILTER SYSTEM

When cleaning and boiling out your fryer use Keating

Sea Powder and Keating Klenzer to keep your fryer in

top condition.

DO NOT PUMP WATER THOUGH YOUR FILTER

SYSTEM.

REFER TO YOUR FILTER MANUAL FOR

INSTRUCTIONS ON PROPER USE

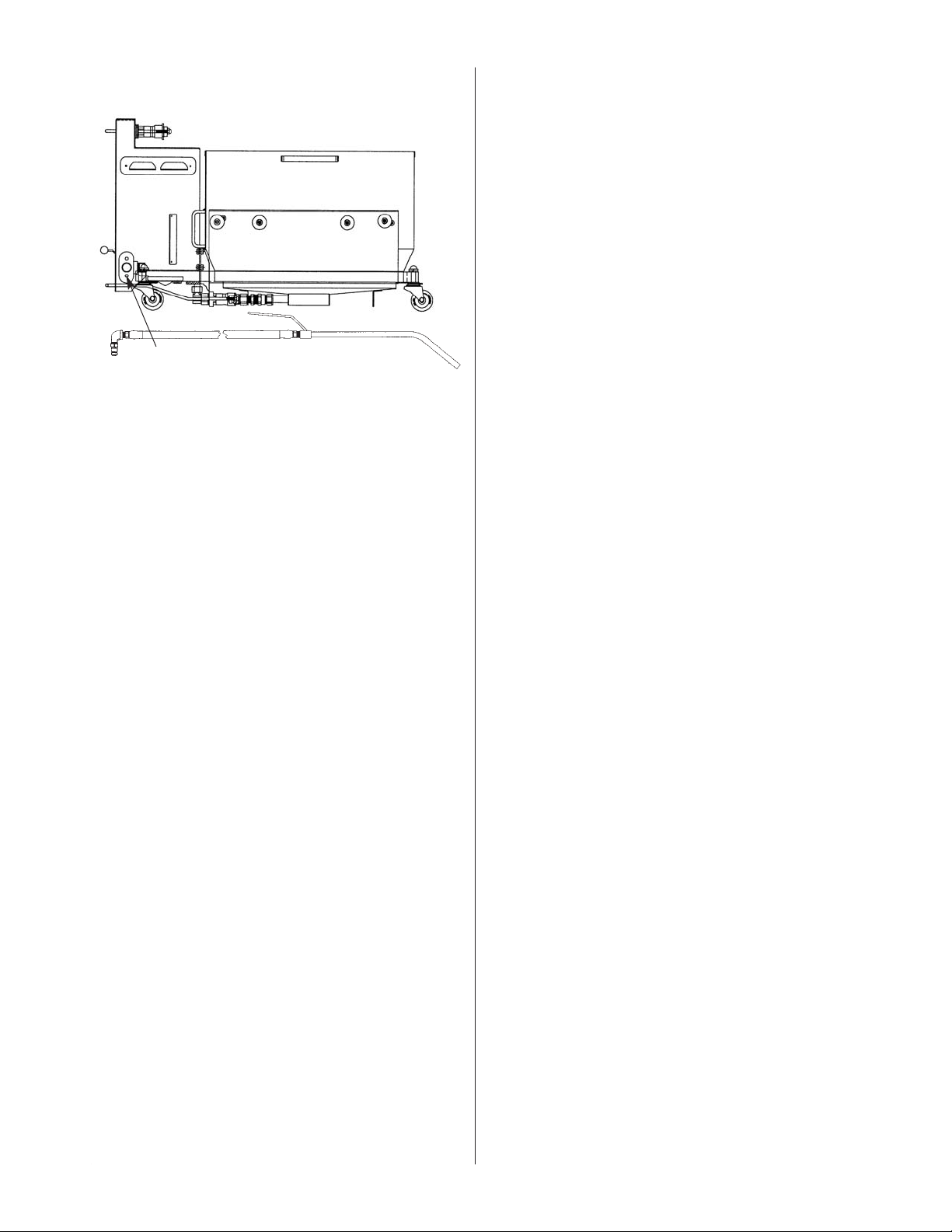

SAFE & EASY FILTER

(SIDE VIEW)

A KEATING FRYER OR FILTER SHOULD BE

DRAINED ONLY UNDER THE SUPERVISION OF

PROPERLY TRAINED PERSONNEL. WHEN

DISCARDING OIL, A COVERED RECEPTACLE

APPROVED FOR USE WITH HOT OIL SHOULD BE

USED. USE OF A NON-APPROVED RECEPTACLE

OR METHOD OF DRAINING THE OIL COULD

JEOPARDIZE THE SAFETY OF THE OPERATOR.

1.Operator should be outfitted with proper attire

including:

–Oil and heat resistant gloves

–Oil and heat resistant apron

–Safety goggles

–Oil and heat resistant footwear

2. Turn the fryer off.

A cleaning hose and wand have been provided for

discarding oil.

3. Attach cleaning hose to quick disconnect located on

the bottom right side of your filter.

4. Remove baskets and screen. Drain fryer into the

central filter drawer.

5. Open the discard valve located near the quick

disconnect in the filter cabinet.

6. The hose may now be used to pump the oil into the

shortening handling system and discarded properly.

7. Remove oil container to a secure area to prevent

accidental spillage.

8. Close the drain valve.

9. Fill fryer vessel to “Fill Level” line with water.

10. Set thermostat and turn fryer on to bring water to a

gentle boil. Once boil has been reached, turn fryer

off.

UNDER NO CIRCUMSTANCES SHOULD THE

FRYER AND FILTER BE LEFT UNATTENDED

DURING BOIL-OUT. TRAINED PERSONNEL MUST

BE PRESENT DURING THE PROCEDURE TO

PREVENT BOIL OVER OR TO TURN OFF THE

POWER IF WATER DROPS BELOW HEATING

TRANSFER TUBES.

11. Dissolve 2/3 cup of Keating Sea Powder for every

five gallons of water and let soak for 1/2 hour. If

there is a large build-up of carbonized grease, allow

fryer to soak overnight.

12. While soaking, a natural fiber brush may be used to

scrub the tubes and inside walls of fryer. Pump the

water and Sea Powder into a dry suitable

receptacle and remove from cooking area. Sprinkle

Keating Klenzer liberally on tubes and sides of fryer

vessel. A non-abrasive scouring pad may be used

to remove the now softened carbonized grease.

Thoroughly rinse fryer vessel with potable water to

remove all Klenzer. Prior to refilling with oil, wipe the

inside of the fryer vessel making sure all water and

Klenzer have been removed.

DO NOT DAMAGE OR REPOSITION THERMOSTAT

PROBE AS THIS MAY AFFECT THE ACCURACY OF

THE FRYER.

DO NOT MIX WATER AND HOT OIL

13. Close the drain valve and disconnect the cleaning

hose from filter machine.

Quick disconnect will remain hot for approximately

15 minutes.

14. Check thermostat bulb positioning (should be 1

paper thickness away from heat tube).

15. Refill the fryer with new or filtered oil.

Wait until filter drawer is cool before cleaning,

approximately 15 minutes.

16. Remove filter drawer, drain, clean and dry.

17. Prepare filter drawer and return to filter cabinet.

TO AVOID DAMAGING THE FRYER, DO NOT

POWER WASH, SPRAY OR HOSE IT DOWN WHILE

CLEANING IT.

18. Pump must be primed with oil after boil-out with

water.

Failure to lubricate pump may cause severe

damage to Filter System.

Connect hose here to discard oil

10

11

OPERATOR SELF HELP

Before calling for service, review this list. It may save

you both time and expense. This list includes

common occurrences that are not the result of

defective workmanship or materials in this appliance.

NOTE: For a fryer with a Central Filter or Safe & Easy

®

Filter always check the rear drain operating handle

before attempting to use the fryer. A safety switch

prevents the fryer from operating if the handle is not

pushed in completely and latched. (See figure 3-2)

Figure 3-2

Rear Drain Operating Handle

PREVENTIVE MAINTENANCE

Preventive maintenance should be done in daily,

weekly, monthly and yearly intervals as necessary.

Following preventive maintenance procedures will help

keep your fryer working efficiently. Proper care and

servicing will lead to years of quality performance.

PREVENTIVE MAINTENANCE CHART

HI-LIMIT CHECK BI-MONTHLY

Place an accurate thermometer in the oil. If the Hi-Limit

Control doesn’t shut off the fryer between 425°F and

450°F, have it replaced.

THERMOSTAT CALIBRATION

You will need:

One screwdriver with 1/8" wide flat blade

One accurate fryer thermometer

1. Set thermostat to desired frying temperature.

2. Allow fryer to cycle three times.

3. Place an accurate thermometer in the oil.

Thermostat calibration

NOTE: Locate thermometer in same position for every

calibration. Left front corner of fryer vessel at the High

Limit Bulb is recommended.

4. If temperature of fryer is found to be more or less

than 15°F off, remove the thermostat knob. There

are (4) screws holding the dial plate in place.

Loosen the screws and reset the dial plate to

match the thermometer reading.

BEFORE REPLACING, TEST THERMOSTATS

These operational problems can easily be corrected

by thermostat bulb positioning.

Keating’s patented thermostat application is

accurate within 2°F of the dial setting between

250°F – 350°F. This accuracy is attained only if the

thermostat bulb is placed properly against the heat

transfer tube. To quickly and accurately test for

proper bulb placement, a single thickness of

writing paper should be pulled through between

the tube and the bulb with medium resistance.*

1. *For gas fryers 14":

The end of thermostat bulb should touch the

burner tube.

2. For gas fryers 10×11, 18" & larger:

If the bulb is too loose, the paper will slip through

with little or no resistance. A fryer with a thermostat

bulb that is too loose will overshoot.

Overshoot: The thermostat takes a long time to

cycle and then misses its preset temperature by

20°F - 40°F yielding a poor quality product.

If the bulb is too tight, the paper will either not pull

through or it will tear. A fryer with a thermostat bulb

that is too tight will short cycle.

Short Cycle: The thermostat will cycle rapidly while

the fryer is in the idle mode; the temperature will be

erratic.

TIME

FRAME

OPERATOR/OWNER

Daily

Check lights and controls.

Check that the oil is up to “Max” Line.

Clean all baskets.

Drain, strain or filter oil.*

Weekly

Drain and clean fryer.*

Boil-out fryer.

Bi-Monthy

Monthly

Hi-Limit & Test procedures.

Check calibration of the thermostat.

Yearly

QUALIFIED SERVICE PERSONNEL ONLY

Check burner flame color and adjust

air shutters.

Remove and clean all orifices.

• Clean Pilot Runner Tube.

• Check and replace wing turbulators.

*High production facilities should be checked more often. Contact

your local service company to perform maintenance and repairs.

OCCURRENCE SOLUTION

Fryer does not

operate:

Check power cord, unit plugged in?

Thermostat is in the “off” position.

Check gas supply.

Reset High Limit.

Thermostat Bulb Positioning 10×11, 18 & larger

Fryer Gas

DO NOT ADJUST THERMOSTAT SET SCREW - IT

VOIDS ANY WARRANTY ON PART

WARRANTY REPAIRS

Keating's warranty begins with the date of

installation. In the event that your Fryer, under

warranty, needs repairs other than routine cleaning,

you are required to contact

KEATING OF CHICAGO, INC. (1-800-KEATING)

before calling a local service company.

SERVICE

Servicing should only be performed by qualified and

licensed service companies.

THERMOSTAT REQUIRED TEST EQUIPMENT:

Multimeter (for testing continuity)

CHECKING CONTINUITY WITH THE MULTIMETER

1. Rotate the thermostat shaft until an audible click

is heard.

2. Rotate the thermostat shaft left and right ten

times causing the switch to click on and off ten

times, while using the Multimeter to verify

continuity.

3. If the switch does not show continuity during all

ten trials, replace the thermostat.

DISASSEMBLING THE THERMOSTAT WILL VOID

THE THERMOSTAT WARRANTY.

1. Set compression ring onto capillary end of bulb

finger tight,

1

/2" from end of capillary.

2. Insert new thermostat bulb through control panel

back.

3. Apply oil resistant flexible sealant onto

compression fitting thread before installing fitting

into fryer vessel.

4. Position bent portion of bulb against far right heat

transfer tube and install compression fitting

snugly into fryer vessel.

5. Adjust bulb so at least 2" of bent portion of it is

next to heat transfer tube and tighten

compression nut onto compression fitting for

fryer 10x11, 18 & up. The end of thermostat bulb

should touch the burner tube for 14" fryers.

6. Replace burners.

7. Replace control panel back.

8. Slide back fabric shield over capillary and

carefully coil capillary. Avoid crimping.

9. Reconnect wires to thermostat body.

10. Replace two screws which hold thermostat body

to control panel.

11. Replace control panel.

12. Replace three retaining screws and washers

which hold dial plate in place.

13. Replace thermostat knob.

14. Connect electric power source. Turn on gas and

pilots.

15. Boil out fryer.

16. Refill fryer with oil to “Max” line.

17. Start fryer, preheat and calibrate with

thermometer.

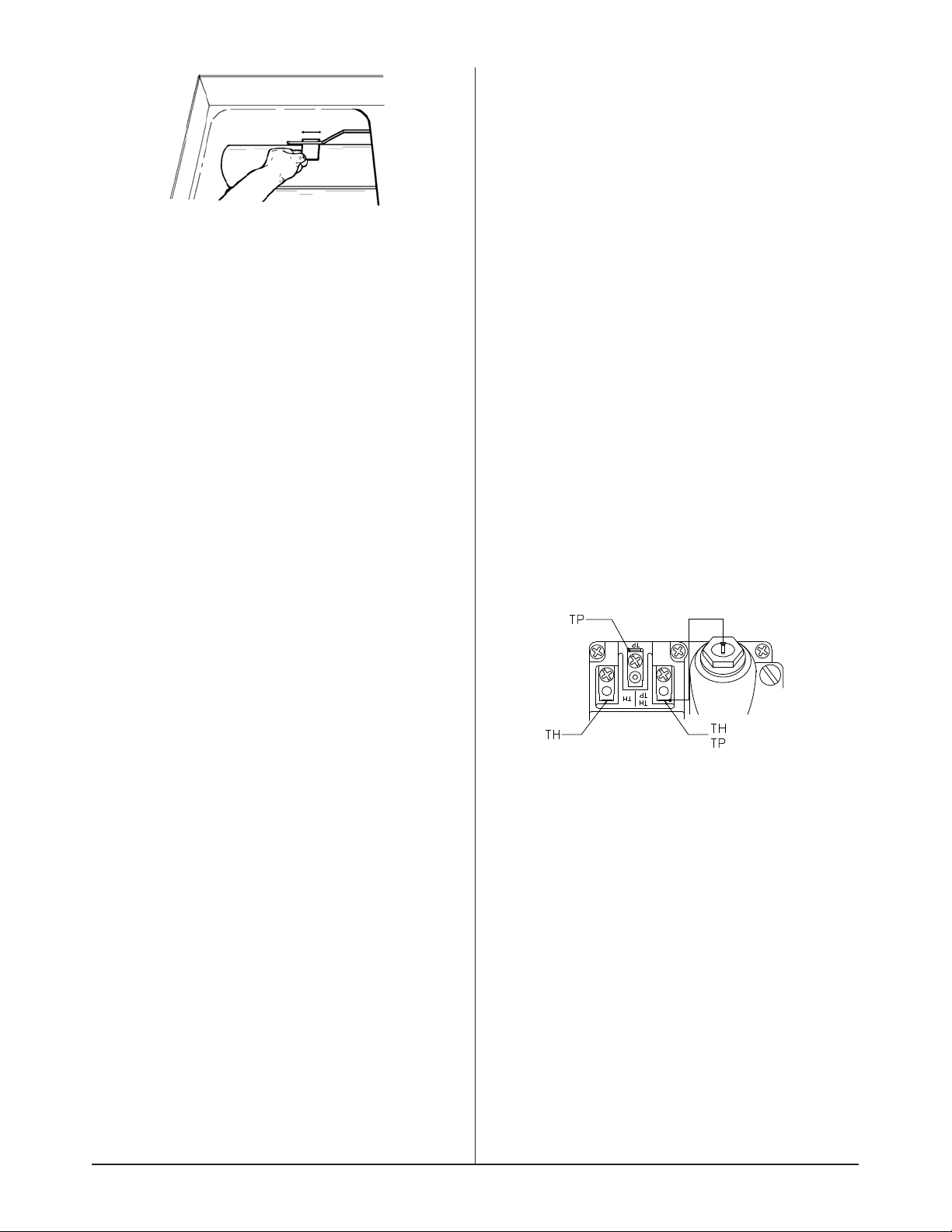

TROUBLESHOOTING

Millivolt Gas Valves

Part # 023625 (natural) & 023624 (LP)

MILLIVOLT CONTROL VALVE

To check Resistance of the gas valve, connect one

wire to the valve as shown.

1. Resistance between the THTP & TH terminals

must be 11.5⍀±0.2⍀

2. Resistance between the THTP & TP terminals

must be 10.0⍀±0.2⍀

If resistance is outside of specifications listed, the gas

valve must be replaced.

Before replacing thermopile check millivolt

readings.

THERMOPILE READINGS:

With all wires connected, with the pilot on and burners

off, the thermopile reading at the TP&THTP terminals

should be ~325mv. With the burners on, the millvolt

reading should be ~200mv. A replacement thermopile

part # is 022770.

12

13

PROBLEM PROBABLE CAUSE SOLUTION

Constant pilot won’t light. a. Gas isn’t turned on.

b. Clogged constant pilot tubing.

c. Constant pilot valve isn’t turned on.

a. Turn manual gas valve on. If using

flexible connector with quick

disconnect, make sure quick disconnect

is completely engaged.

b. Turn fryer and manual gas valve off.

Clean tubing.

c. Turn constant pilot valve on and adjust

pilot flame height to 3/8” to 1/2” flame.

Runner pilot tube won’t light. a. Gas isn’t turned on.

b. No electricity to fryer (BB & TS models).

c. Gas valve knob in incorrect position

(AA & CMG models).

d. Hi-Limit has been activated.

e. Clogged runner pilot orifice(s).

f. Drain valve isn’t pushed in completely

(fryers with built-in filter system).

a. Turn manual gas valve on. If using

flexible connector with quick

disconnect, make sure quick disconnect

is completely engaged.

b. Plug fryer into approved outlet.

c. Rotate gas valve knob to pilot position.

Depress and hold for 30 seconds.

d. Push Hi-Limit reset button located under

control panel.

e. Turn fryer and manual gas valve off.

Clean orifice(s) and other parts as

necessary.

f. Push in and latch drain valve handle to

activate rear drain safety switch. Turn off

fryer & turn back on.

Runner pilot won’t stay lit.

a. Verify if size of incoming gas line to fryer

and manifold gas pressure are

adequate.

b. Turn fryer and manual gas valve off.

Clean orifice(s) and pilot tube.

c. Adjust pilot flame height.

d. If it takes more than 60 seconds for pilot

to stay lit, replace flame switch control.

e. Push Hi-Limit reset button located under

control panel.

f. Install or adjust flue restrictors. If problem

persists, contact your HVAC

representative.

g. Perform millivolt tests. Replace faulty

thermopile or gas valve.

h. See diagnosis on page 14.

SERVICE DIAGNOSIS

The following diagnosis is only to be used as a guide to qualified service personnel. Keating

recommends that you use a qualified service company. Call 1-800-KEATING if you need

assistance in locating a qualified service company.

TROUBLESHOOTING CHART

a. Low gas supply or pressure.

b. Dirty runner pilot tube or pilot orifice(s).

c. Low pilot flame height.

d. Flame switch control is faulty

(BB & TS models).

e. Hi-Limit has been activated.

f. Exhaust problems or drafts in kitchen.

g. Thermopile or gas valve is faulty

(AA & CMG models).

h. Delayed ignition.

Burners will not light. a. Gas valve knob in incorrect position

(AA & CMG models).

b. Switch not set to fry (BB & TS models).

c. Thermostat is faulty.

d. Fry/Off/Melt switch (BB & TS models) or

On/Off switch (AA & CMG models) is

faulty.

e. Faulty gas valve.

a. Rotate gas valve knob to ON. Turn

power switch ON. Set thermostat to

desired temperature.

b. Set MELT/IDLE/FRY switch (or

MELT/FRY switch) to FRY. Set

thermostat to desired temperature.

c. Push and hold in Hi-Limit test button. If

burners come on, replace thermostat.

d. Replace switch.

e. Replace gas valve.

Fryer overshoots temperature setting. a. Thermostat bulb improperly placed.

b. Thermostat out of calibration.

a. Adjust bulb position. See pages 11-12 –

Thermostat Bulb Positioning.

b. Calibrate thermostat. See page 11 –

Calibration.

Delayed ignition. a. Dirty runner pilot tube or pilot orifice(s).

b. Low pilot flame height.

c. Exhaust problems or drafts in kitchen.

d. Low gas supply or pressure.

a. Turn fryer and manual gas valve off.

Clean orifice(s) and pilot tube.

b. Adjust pilot flame height.

c. Install or adjust flue restrictors. If

problem persists, contact your HVAC

representative.

d. Verify if size of incoming gas line to fryer

and manifold gas pressure are

adequate.

Oil in fryer vessel smokes. a. Oil has begin to breakdown.

b. High carbon content in oil.

c. Dirty fryer vessel.

d. Inferior grade of oil.

e. Fryer is overheating.

f. Hi-Limit Control has failed.

a. Replace oil.

b. Filter oil completely, replace if necessary.

c. Boil-out fryer.

d. Check with supplier for the grade of oil

needed for your cooking applications.

e. Check calibration of thermostat (See

page 10) and replace if necessary.

f. Check if Hi-Limit trips at 425º F. If not,

replace Hi-Limit.

Fryer vessel boiling over. a. Over-filling fryer with oil.

b. Product overloaded in fryer vessel.

c. Oil breakdown causing foaming.

d. Water in the cold zone.

a. Fill fryer up to “Max Level” line as oil will

expand when heated.

b. Follow recommended cooking

production figures in determining proper

size of loads

c. Replace oil.

d. Stir oil repeatedly with a paddle until

water boils off. Filter oil. If necessary,

allow oil to cool. Drain about one quart

of it to remove remaining water.

TROUBLESHOOTING CHART (continued)

14

Loading...

Loading...