Keating 14 PASTA NAT, 14 PASTA LP, 14 PASTA 208-240, 18 PASTA NAT, 18 PASTA LP General Manual

...

SPECIFICATIONS

Custom Pasta

PROJECT

Custom PastaTM System

Standard Features:

Saves on time and space

Automatic water fi ll

Stainless Steel cabinet

Polished Stainless Steel fryer vessel

Patented cook cycle

Two digital timers for precise cooking control

Starch overfl ow drain

Options:

□

Spark Ignition (on gas models)

□

Battery

□

Basket-Lift

□

Individual Serving Baskets

□

Common Drain Manifold

□

Drainboard

□

Faucet

Keating offers a Custom Pasta™ Cooking System designed to meet the needs of every kitchen. With our 14"

Custom Pasta Cooking System, water comes to a rolling

boil in less than 10 minutes. Available in sizes ranging

from 14" to 24", it's ideal for both bulk and single servings. The 14" Custom Pasta™ can cook up to six pounds

of dry pasta per load, yielding 110 lbs. of pasta per hour.

High production

The Custom Pasta™ Cooking System has the highest

energy input of any unit on the market today. A “pre-heat”

cycle utilizes the full energy input for fast pre-heating.

Keating’s patented “cook cycle” manages energy input,

which maintains a rolling boil throughout the cooking process. This means you can more easily accommodate rush

orders. The starch overfl ow drain eliminates starch build

up for better cooking results.

Safe and easy to use

A self-contained, self-fi lling and self-draining system, Keating’s water auto-fi ll feature automatically refi lls the cooker

when water level is low without affecting the boil. A panel

of indicating lights for water fi lling, power or pilot on, and

burners/elements on monitors the status of the unit at

all times.

□

380 or 480 Voltage

□

Water Depth 7 1/2"

□

Drop-In (on 14" only)

□

Casters

QUANTITY

ITEM NO.

TM

System

Casters Optional

Versatility

The Custom Pasta™ cooks more than just pasta - it's

ideal for boiling seafood, blanching vegetables, poaching eggs, cooking reconstituted meals and much

more. With Keating’s wide assortment of baskets

available, you can prepare individual servings as well

as large portions, plus you can cook different shapes

and sizes of pasta to perfect consistencies.

Rinse Tank

Add a custom Pasta Rinse Tank to your pasta cooker

and you have an all-in-one pasta station. Built with a

stainless steel vessel and front drain valve, the Rinse

Tank is available in 14"-24" sizes. Add a heavy duty

faucet with jointed neck for convenient water supply.

Sauce Warmer

For a complete and ultimate Custom Pasta™ Cooking System, include a stainless steel Sauce Warmer.

Each unit includes two 500 watt 120V heating

elements, infi nite temperature control and a front

drain valve for easy cleaning. The Sauce Warmer will

accommodate a 12" × 20" pan or any combination of

standard split pan sizes.

DATE

9902091 9902091

As continuous product improvement occurs, specifi cations

may be changed without notice.

www.keatingofchicago.com

PRINTED IN THE USA 07/2011 CustomPasta_2011

APPROVAL

SIGNATURE

FAX: 708-246-3100PHONE: 708-246-30001-800 -KEATINGMcCOOK, IL, 60525 USA8901 WEST 50th STREETKEATING OF CHICAGO, INC.

Custom PastaTM System

Description - The Keating Custom

Pasta™ System can be ordered in

natural gas, LP gas or electric in sizes

14", 18", 20" or 24" models. Units can

be batteried with no additional charge.

Rinse tanks and sauce warmers can

also be batteried: location in the battery must be specifi ed. Floor units are

mounted on eight inch legs, adjustable

for leveling the unit.

SPECIFICATIONS

Water vessel is made of 18 gauge

highly polished stainless steel. The 14"

model holds 5.5 gallons of water; the

18" model holds 8.5 gallons of water;

the 20" model holds 13.5 gallons of

water and the 24" model holds 19.0

gallons of water.

The 14" model has a 1 inch drain;

the 18", 20" and 24" models have a

1- 1/4" drain. Drains are located in the

front center of the cabinet, terminating

5 inches from the fl oor.

Cabinet - The cabinet, including the

splashback and the splashdeck, is

made of 16 gauge stainless steel.

Thermostats - Patented “cook cycle”

features dual thermostats, to maximize

preheat while controlling the boil. The

range is 100° to 250°F.

Water Auto-Fill - Two sensors control

the water auto-fi ll. The upper sensor

activates the solenoid valve to fi ll the

unit to the proper level. The lower sensor prevents the burners/elements from

coming on if the water level is below

it to prevent heat damage to the unit.

The unit also has a manual fi ll button

to allow additional water to fl ow into it

when needed and has a standard 3/8

inch female pipe connection on the

rear. Maximum incoming water pressure

cannot exceed 60 psi.

Starch Overfl ow - Starch overfl ow is

located in the front of the water vessel and ensures excess starch and

foam are regularly drained off. Used in

conjunction with the manual water fi ll,

it can also permit fl ushing of greater

amounts of water when needed.

Indicating Lights - Indicating lights

located on the front control panel indicate water fi lling, power on or pilot on

and burners/elements on.

Drain - The drain terminates 5" from the

fl oor and requires an open or trapped

drain, per local and national codes.

Baskets - Baskets are perforated

and are available in both full and split

styles.

Timers - Each unit comes with two 15

minute digital solid state timers.

Gas Connection - The gas connection

is in the rear of the unit, and is a 3/4

inch male NPT connection. Natural gas

requires a 4" water column pressure

and LP a 10" water column pressure. A

pressure regulator, rated at 1/2 psi is

built into each unit.

Electrical Connection - A 120 volt cord

with 3-prong grounded plug is supplied

with all gas units. Electric units are

available in 208-240V single or three

phase. Connection is made to a fi eld

wiring terminal block (see local codes

for supply line requirements). There is

a separate fi eld wiring terminal for the

120V control panel.

Special Order Options -

Battery, basket-lift, casters, common

drain manifold, drainboard, drop-in on

14" only, faucet, individual serving

baskets, 380 or 480 voltage, spark

ignition on gas models, and water depth

7 1/2".

INSTALLER - Check plumbing and gas codes for proper gas supply line sizing to sustain burner pressure when all gas

appliances are full on. Supply pressure must NOT be above 13.84" WC or gas valve damage may occur.

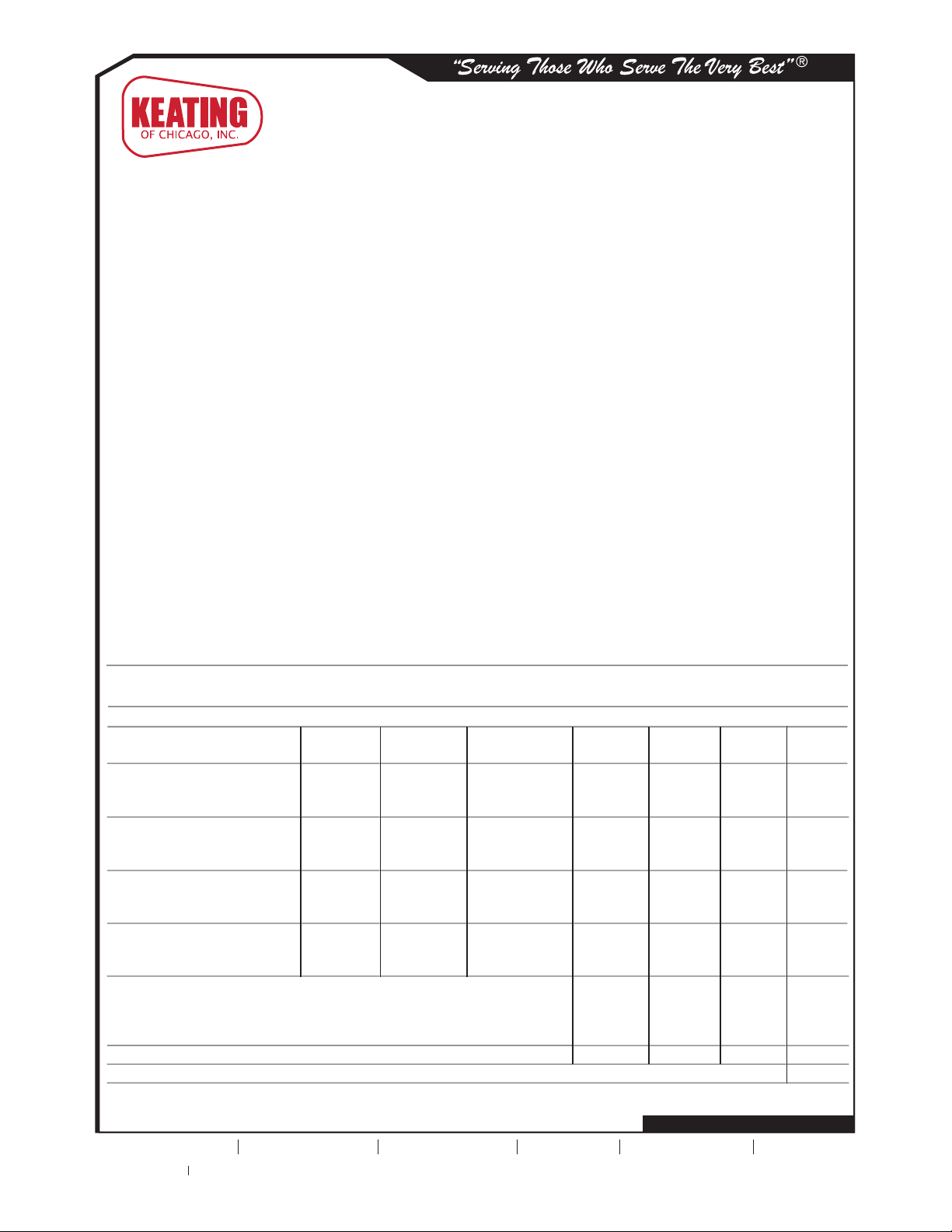

GAS/ELECTRICAL REQUIREMENTS AND DIMENSIONS

BTU INPUT/ KW @ 240V AMPS @ 220V Height Depth Width Weight

MODEL BURNER 1ø 3ø

14 PASTA NAT GAS 109,000 46 1/2" 31 1/2" 15 3/8" 170 lbs.

14 PASTA LP GAS 109,000 46 1/2" 31 1/2" 15 3/8" 170 lbs.

14 PASTA 208-240 15.5 65 32-56-32 46" 31 1/2" 15 3/8" 140 lbs.

18 PASTA NAT GAS 135,000 46 1/2" 33 1/2" 19 3/8" 235 lbs.

18 PASTA LP GAS 90,000 46 1/2" 33 1/2" 19 3/8" 235 lbs.

18 PASTA 208-240 21.4 89 52-52-52 46" 33 1/2" 19 3/8" 215 lbs.

20 PASTA NAT GAS 135,000 46 1/2" 35 1/2" 21 3/8" 250 lbs.

System

20 PASTA LP GAS 90,000 46 1/2" 35 1/2" 21 3/8" 250 lbs.

TM

20 PASTA 208-240 21.4 89 52-52-52 46" 35 1/2" 21 3/8" 235 lbs.

24 PASTA NAT GAS 165,000 46 1/2" 39 1/2" 25 3/8" 300 lbs.

24 PASTA LP GAS 145,000 46 1/2" 39 1/2" 25 3/8" 300 lbs.

24 PASTA 208-240 28.6 119 79-79-52 46" 39 1/2" 25 3/8" 285 lbs.

14 RINSE TANK 46 1/2" 31 1/2" 15 3/8" 33 lbs.

18 RINSE TANK 46 1/2" 33 1/2" 19 3/8" 55 lbs.

20 RINSE TANK 46 1/2" 35 1/2" 21 3/8" 69 lbs.

24 RINSE TANK 46 1/2" 39 1/2" 25 3/8" 70 lbs.

SAUCE WARMER - 8.5 AMPS (120V) 46 1/2" 27 1/4" 15 3/8" 120 lbs.

FAUCET SS/W JOINTED NECK 4 lbs.

Custom Pasta

NOT FOR OUTDOOR INSTALLATION - NOT FOR DOMESTIC INSTALLATION

As continuous product improvement occurs, specifi cations may be changed without notice.

PRINTED IN THE USA 07/2011 CustomPasta_2011

www.keatingofchicago.com

FAX: 708-246-3100PHONE: 708-246-30001-800 -KEATINGMcCOOK, IL, 60525 USA8901 WEST 50th STREETKEATING OF CHICAGO, INC.

Loading...

Loading...