200mm

688mm

90mm

Centre of Gravity

96mm

814mm

Page. 1

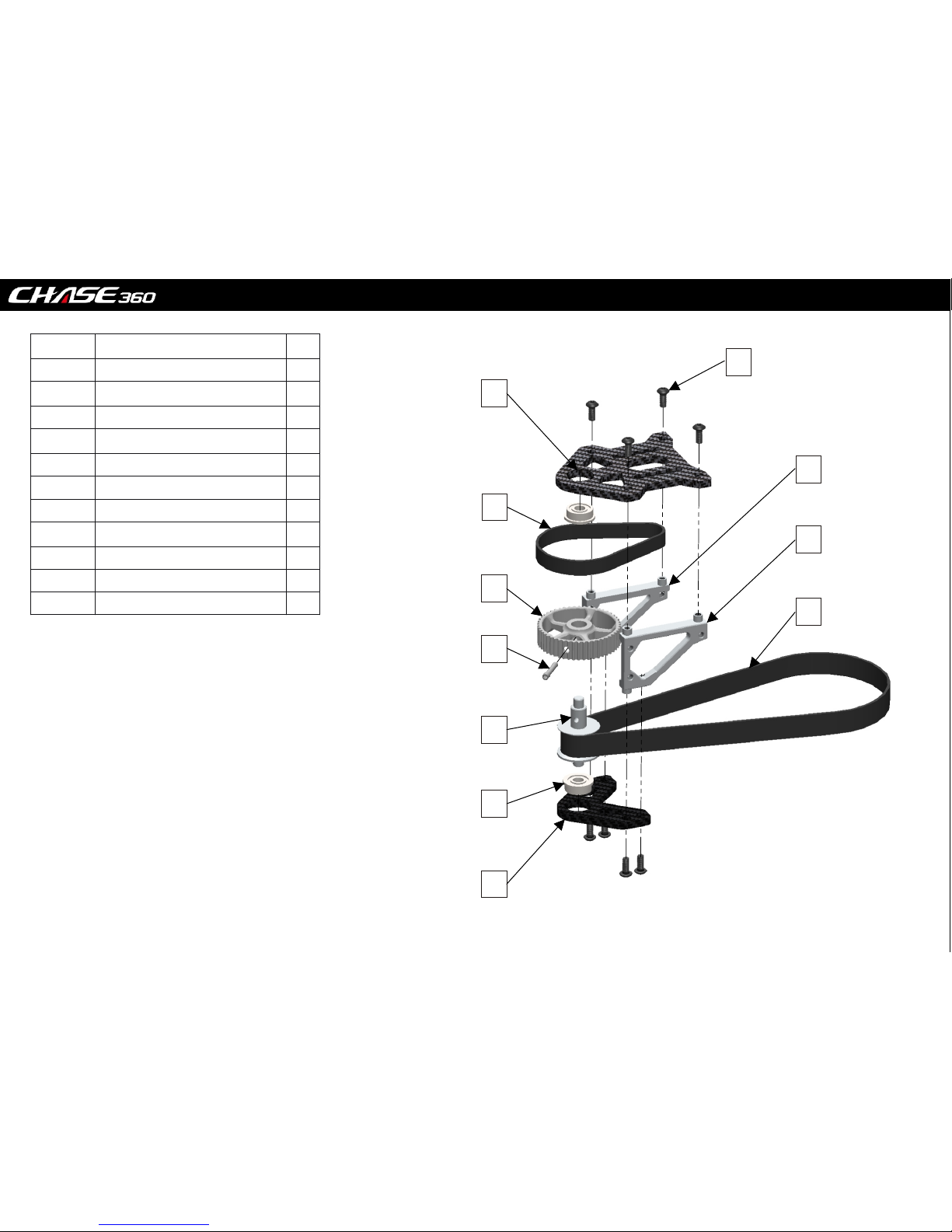

1

Main belt (147MXL-9MM)

Lower motor block

18T 2nd Stage pinion

1ST Stage pulley pin

Page. 2

2

3

4

5

6

7

8

9

10

11

ITEM NO.

DESCRIP TION

QTY.

1 1

2

8

3 1

4

1

5

1

6 1

7

2

8

9

10

11

1

1

1

1

Round head screw(M2.5 x 6)

Bearing (4x10x4)

Motor mount bracket right

Motor mount bracket left

Upper motor block

50T Pulley

1ST Stage belt (63MXL-6mm)

0.5mm MIN

0.5mm MIN

Turn the motor over by hand to test belt positioning.

Adjust the motor pinion height until the belt runs

central on the front pulley

Make sure your motor has

a flat ground on the shaft

for the pinion grub screw.

This step can be completed at any time.

But is easier before installing the 1st stage assembly into the model

2

1

3

4

Set Screw (M3)

Flat head screw M3X6

Motor(1880KV)

pinion 1 8T (1 9T )

1

2

1

1

ITEM NO

DESCRIP TION QTY.

1

2

3

4

Page. 3

tip : the pinion should be positioned as

close as possible to the top plate

to avoid rubbing and correct belt

alignment

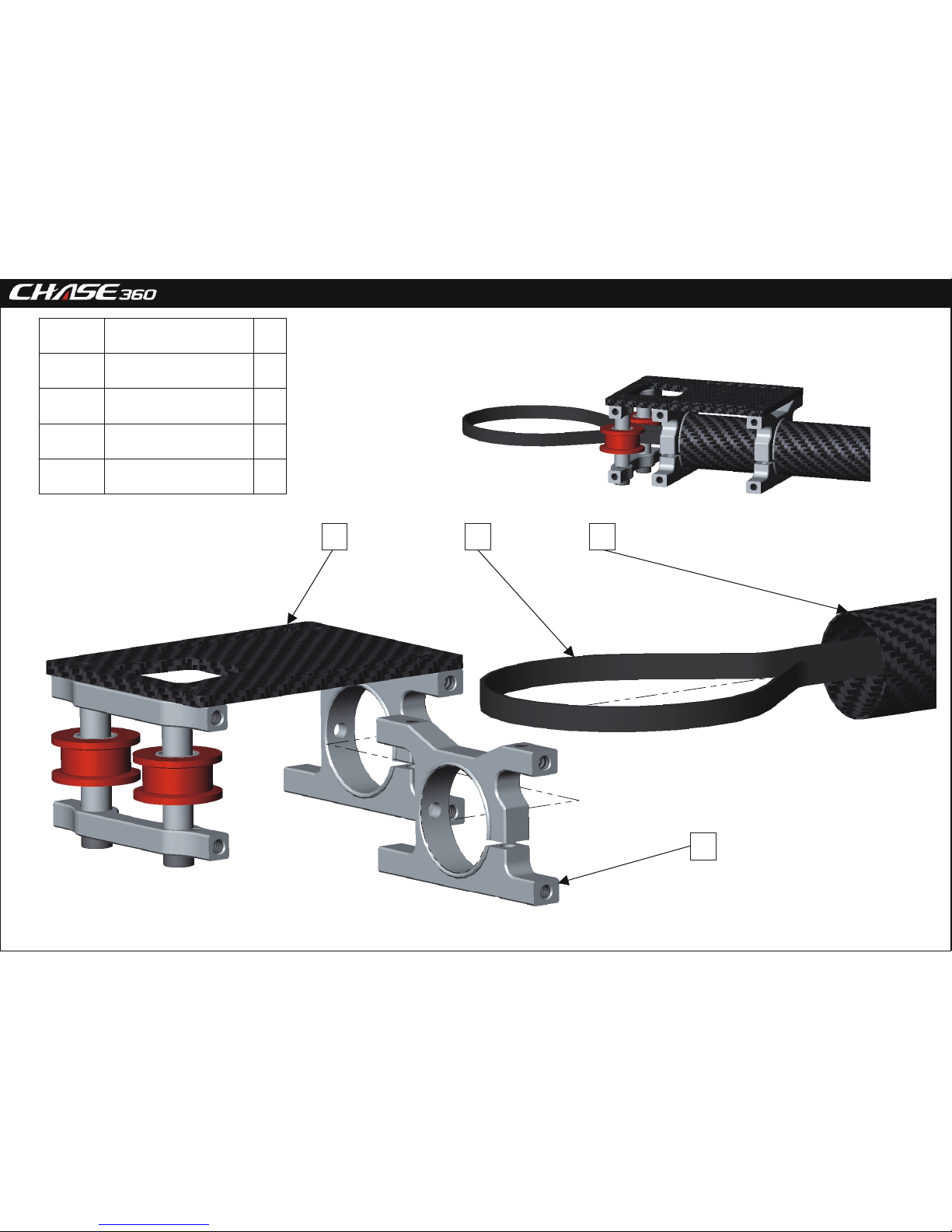

Bearing (3x7x3)

Belt guide pulley

spacin g wa sh er

Page. 4

GYRO TRAY

Boom Clamp

STEP 4

1

2

4

6

3

7

1

2

3

4

5

ITEM NO.

DESCRIP TION

QTY.

1 1

2

4

3 2

4

2

5

1

6 4

7

2

ITEM NO.

DESCRIP TION

QTY.

1 1

2

4

3 2

4

2

CAP Screw (M3 x 24)

UP Pulley holder SET

Spacer sleeve

Down Pulley holder SET

Flat head screw M2.5X6

15mm Nominal

Tip - It is best to position the servo arms on servos

(with 0 trim) closest to level during this step

.

6

4

Long side of the

brackets face

clockwise.

CYCLIC SERVO

Lock Nut (M2)

UPPER BEARING BLOCK

Bearing (8x16x5)

SERVO MOUNT

LOWER BEARING BLOCK

Page. 5

1

2

3

4 5 6 7

1

2

ITEM NO.

DESCRIP TION

QTY.

1 6

2

3

3 6

4

6

5

4

6 1

7

3

ITEM NO.

DESCRIP TION

QTY.

1 1

2

1

Round head screw (M2 x 6)

Round head screw (M2.5 x 6)

Bearing (8x16x5)

Power the servo to adjust the central

point at l ev el c on dition before ass em bl e

Recommended lipo 1200 - 1400 mah.

Size restrictions 39mm x 45mm x 116mm.

Or unlimited length with front tail servo

mount option (Refer to Step 26)

Mirror this step for

Left side frame.

Lipo tra y bu tt on ( right)

Side frame

LIPO 1200 - 1400mAh

Page. 6

1

2

4

3

1

2

4

3

Round head screw (M2 x 4)

ITEM NO

DESCRIP TION QTY.

1 1

2 3

3 1

4 1

canopy locating pin

ITEM NO

DESCRIP TION QTY.

1 1

2 2

3 1

4 1

Flat head screw M2.5X6

Lipo tray

Lipo tray fixed mount

ITEM NO

DESCRIP TION QTY.

1 LANDING GEAR - LEFT 1

2 LANDING GEAR - RIGHT 1

3 LANDING GEAR MOUNT 2

4 FROM STEP 6 1

5 8

Page. 7

lock the screws only after main

frame left is well-assembled.

1234

5

CAP Screw (M2.5 x 8)

FROM STEP 5

1

FROM STEP 2

1

FRAME SPACERS

2

Lipo sliding rail (right)

1

Round head screw (M2 x 4)

2

2

Page. 8

CAP Screw (M2.5 x 6)

5

1

2

3

4

5

ITEM

NO.

DESCRIP TION QTY.

1

2

3

4

5

6

7

6

7

CAP Screw (M2.5 x 8)

8

Frame Washer (Red)

7

8

1

2

4

3

5

6

Ensure no free play in the

tail shaft by fastening the Locking collar

and pinion against the bearings.

Tail shaft

Tail shaft locking collar

Tail Pinion (15T)

Set Screw (M3x3)

Tail Box

Bearings (4x8x3)

Page. 9

1

1

2

1

1

2

ITEM NO

DESCRIP TION QTY.

1

2

3

4

5

6

Tip: Tighten Screws in a few

stages to ensure the bracket

remains parallel with the tail shaft.

Refer to step 25 for details.

ITEM NO.

DESCRIP TION

QTY.

1

Fin Spacer

1

2

Tail Boom

1

3 2

4

Pitch Slider Bracket

1

5

Tail Belt

1

6 1

7

1

8 1

9

Tail control guide

2

10

1

11 1

Page. 10

11

1 2

345

8

7

6

10

9

12

12 2

CAP Screw (M2 x 10)

CAP Screw (M2 x 4)

CAP Screw (M2 x 6)

CF Vertical stabilizer

Tail boom brace mount

Heat shrink tubing

CAP Screw (ST2 x 6)

ITEM NO. DESCRIP TION QTY.

1 Parts From Step 4 1

2

Tail Belt 1

3 Parts from Step 10 1

4 Boom Clamp 1

Page. 11

1 2 3

4

X2

ITEM NO. DESCRIP TION QTY.

1 Parts From Step 5 1

2

Parts From Step 10

1

3

5

ITEM NO.

DESCRIP TION QTY.

1 Front canopy mounting bolt 1

2

1

Page. 12

1 2 3

1

2

CAP Screw (M2.5 x 6)

Frame Washer (Red)

4

5

4

Set Screw (M2.5x10)

Main shaft is symmetrical with

no top or bottom.

May be installed either way.

ITEM NO. DESCRIP TION QTY.

1 Parts From Step 12 1

2

1

3 1

4 1

5 1

6

1

Page. 13

ITEM NO. DESCRIP TION QTY.

1 Parts From Step 12 1

2

1

3 1

4 1

5 Parts From Step 4 1

6

1

1

2

3

4

5

6

1

2

3

4

5

6

Bearing (8x14x4)

First reduction gear(80T)

Bearing (10x15x4)

Auto-rotation gear (50t)

One way bearing(10x14x6)

CAP Screw (M3 x 24)

Lock Nut (M3)

Washer (8x10x0.5)

Main shaft

Page. 14

ITEM NO. DESCRIP TION QTY.

1 Parts From Step 12 1

2

1

3

2

1

2

3

Parts From Step 12

4

4

2

CAP Screw (M2.5 x 6)

Frame Washer (Red)

Page. 15

1

ITEM NO. DESCRIP TION QTY.

1 1

2

1

3 14

4 12

5 1

6

2

7

8

3

4

5

6

7

8

9

9

2

Set Screw (M2.5x10)

Frame Washer (Red)

Front canopy mounting bolt

CAP Screw (M2.5 x 6)

CAP Screw (M2.5 x 8)

Round head screw (M2 x 4)

1

Lipo sliding rail left

1

CF front electronics board

1

Side frame

note : factory pre-assembled

Page. 16

ITEM NO. DESCRIP TION QTY.

1 1

2

1

3 6

4 1

5 1

6

3

7

1

2

3

4

5

6

7

Oscillating bearing

Swashplate Internal

Linkage ball A

Swashplate Outer ring

Swashplate mounting pin

Round head screw (M2 x 4)

Bearing (20x27x4)

1

1

Page. 17

9.8

10

Larger ID faces

inwards

.

X2

2

3

4

5

6

7

1

2

3

4

Bearings (2x5x2.5)

CAP Screw (M3 x 24)

2

ITEM NO

DESCRIP TION QTY.

1

2

3

4

5

6

7

8

9

10

11

2

ITEM NO

DESCRIP TION QTY.

1

2

3

4

5

6

7

Flybarless linkage arm

Flybarless swashplate control arm

6

5

7

8 9

10

11

8

2

2

2

2

Main rotor holder

Bearings (5x10x4)

Linkage ball A

Round head screw (M2 x 6)

Main rotor branch control arm

2

4

2

4

2

Washer (5x9x0.8)

Damper rubber

2

Main rotor housing

1

Feathering shaft

1

Round head screw (M3 x 6)

Washer (3x8x0.9)

Washer (2x5x0.5)

Thrust bearing (F5-10M)

Washer (5x7x0.5)

Page. 18

X2

43mm

30mm

X3

X2

43mm

X3

ITEM NO. DESCRIP TION QTY.

1 6

2

3

1

ITEM NO. DESCRIP TION QTY.

1 4

2

4

3 2

ITEM NO. DESCRIP TION QTY.

1 1

2

1

2

1

2

1

3

2

Ball link A

Linkage rod (15mm)

Set Screw (M2.5x10)

Ball link B

Linkage rod (15mm)

Lock Nut (M2)

CAP Screw (M3 x 24)

Page. 19

ITEM NO. DESCRIP TION QTY.

1 2

2

1

3 1

4 2

1 2 3 4

Round head screw (M2 x 4)

Anti-rotation bracket

5 2

5

CAP Screw (M2.5 x 6)

Frame Washer (Red)

Anti-rotation bracket mount

Page. 20

23

ITEM NO. DESCRIP TION QTY.

1 2

2

4

3 2

4 2

5 2

ITEM NO. DESCRIP TION QTY.

1 2

2

2

3 2

6

5

4

3

2

1

8

9

7

1

3

2

6

7

8

9

CAP Screw (M2 x 5)

ITEM NO. DESCRIP TION QTY.

2

1

2

2

Bearings (3x6x2.5)

Thrust bearing (F5-10M)

Tail rotor holder

Linkage ball B

Washer (3.1x4.4x0.3)

Washer (2.1x5x0.7)

Flat head screw M2X7

Tail rotor T type holder

CAP Screw (M2 x 12)

Lock Nut (M2)

Tail blade

Page. 21

Note : Factory pre-assembled

ITEM NO. DESCRIP TION QTY.

1 1

2

2

3 4

4 1

5 2

6

2

7

4

1 2 3

5

6

7

8

8

1

1

Tail push bearing mount

Bearings (6x10x3)

E - clip (1.5mm)

T type arm

Ball link for tail holder

Pin

Tail push bearing

Set Screw (M3x3)

9

0

Check that the pitch slider fork is square

to the shaft and the slider does not bind.

loosen bolts and adjust if required.

Page. 22

1

2

3

4

5

6

7

8

9

ITEM NO. DESCRIP TION QTY.

1 2

2

1

3 1

4 1

5 2

ITEM NO. DESCRIP TION QTY.

6 1

7

2

8 1

9 1

Flange Bearing (2x5x2.5)

Lock Nut (M2)

Linkage ball A

CAP Screw (M2 x 4)

Tail rocket arm

Round head screw (M2 x 4)

Washer (2x5x0.5)

CAP Screw (M2 x 14)

Tail control arm

Rear servo mount option. Mini or Micro servo

Front servo mount option. Micro

servo ONLY.

12mm Nominal

The Chase 360 has 2 Tail servo

location options,

At the front, high in the frame for 1.

the lowest moment of inertia and optimal CG.

2. Under the tail boom at the rear of the frame.

Page. 23

ITEM NO. DESCRIP TION QTY.

1 1

2

4

3 2

ITEM NO. DESCRIP TION QTY.

1 4

2

1

3 2

4 1

1

2

3

1

2

3

4

Tail Servo

CAP Screw (ST2 x 6)

Servo Mount

Servo spacer

Round head screw (M2 x 4)

Tail Servo Fixed plate

Tail Servo mount

Page. 24

Screw reserved for boom

brace installation

Build the tail pushrod to suit your desired servo location

For rear mount servo Extension for front mount servo

Note :the boom brace may be mounted in multiple locations.

Page. 25

1 2 3 4 5 6

7

ITEM NO. DESCRIP TION QTY.

1 2

2

4

3

4

4 2

5 1

6

1

7

2

Tail boom brace

Tail boom brace end

Frame Washer (Red)

CAP Screw (M2.5 x 8)

CAP Screw (M2.5 x 6)

Tail boom brace mount

CAP Screw (M2.5 x 10)

Loading...

Loading...