Page 1

“The Right Control for Your Application.”

12095 NW 39 Street, Coral Springs, FL 33065-2516

Telephone: 954-346-4900; Fax: 954-346-3377

KB Electronics, Inc. www.KBelectronics.com

Dynamic Brake Module (Part No. 9598) Installation Instructions

Dynamic Brake Module (Part No. 9598) Installation Instructions

Dynamic Brake Module (Part No. 9598) Installation InstructionsDynamic Brake Module (Part No. 9598) Installation Instructions

Dynamic Brake Module (Part No. 9598) Is Designed for Use with

Dynamic Brake Module (Part No. 9598) Is Designed for Use with

Dynamic Brake Module (Part No. 9598) Is Designed for Use withDynamic Brake Module (Part No. 9598) Is Designed for Use with

KBVF Series Drives: Model Nos. KBVF-21D, 22D, 13, 23, 23D, 14, 24, 24D

KBBL Series Drives: Model Nos. KBBL-2P2D, 2P3D, 2P6D, 21D, 22D, 23D, 24D

SAFETY WARNING! Please read carefully before proceeding.

This product should be installed and serviced by a qualified technician, electrician, or electrical maintenance person familiar with its

operation and the hazards involved. Proper installation, which includes wiring, mounting in proper enclosure, fusing or other current

protection, and grounding can reduce the chance of electrical shocks, fires, or explosion in this product or products used with this product,

such as electric motors, switches, coils, solenoids, and/or relays. Eye protection must be worn and insulated adjustment tools must be

used when working with drive under power. This product is constructed of materials (plastics, metals, carbon, silicon, etc.) which may be a

potential hazard. Proper shielding, grounding, and filtering of this product can reduce the emission of radio frequency interference (RFI)

which may adversely affect sensitive electronic equipment. If further information is required on this product, contact our Sales Department.

The drive contains electronic start/stop circuits which can be used to start and stop the drive. However, these circuits are never to be used

as safety disconnects since they are not fail-safe. Use only the AC line for this purpose.

Be sure to follow all instructions carefully. Fire and/or electrocution can result due to improper use of this product.

It is the responsibility of the equipment manufacturer and individual installer to supply this Safety Warning to the ultimate end user of this

product.

IMPORTANT

The KBVF Series Installation and Operation Manual (Part No. A40288) and the KBBL Series Installation Instructions (Part No. A40152) must

be read and understood before attempting to operate the Dynamic Brake Module.

Items Included in this Package

Dynamic Brake Module, Installation Instructions, Interconnect Wires, Jumper (for KBVF Series Drives only), Warranty Registration Card.

Dynamic Brake Module Rating

Up to 25% continuous braking torque and 200% instantaneous braking torque (maximum 1 HP (0.75 kW)).

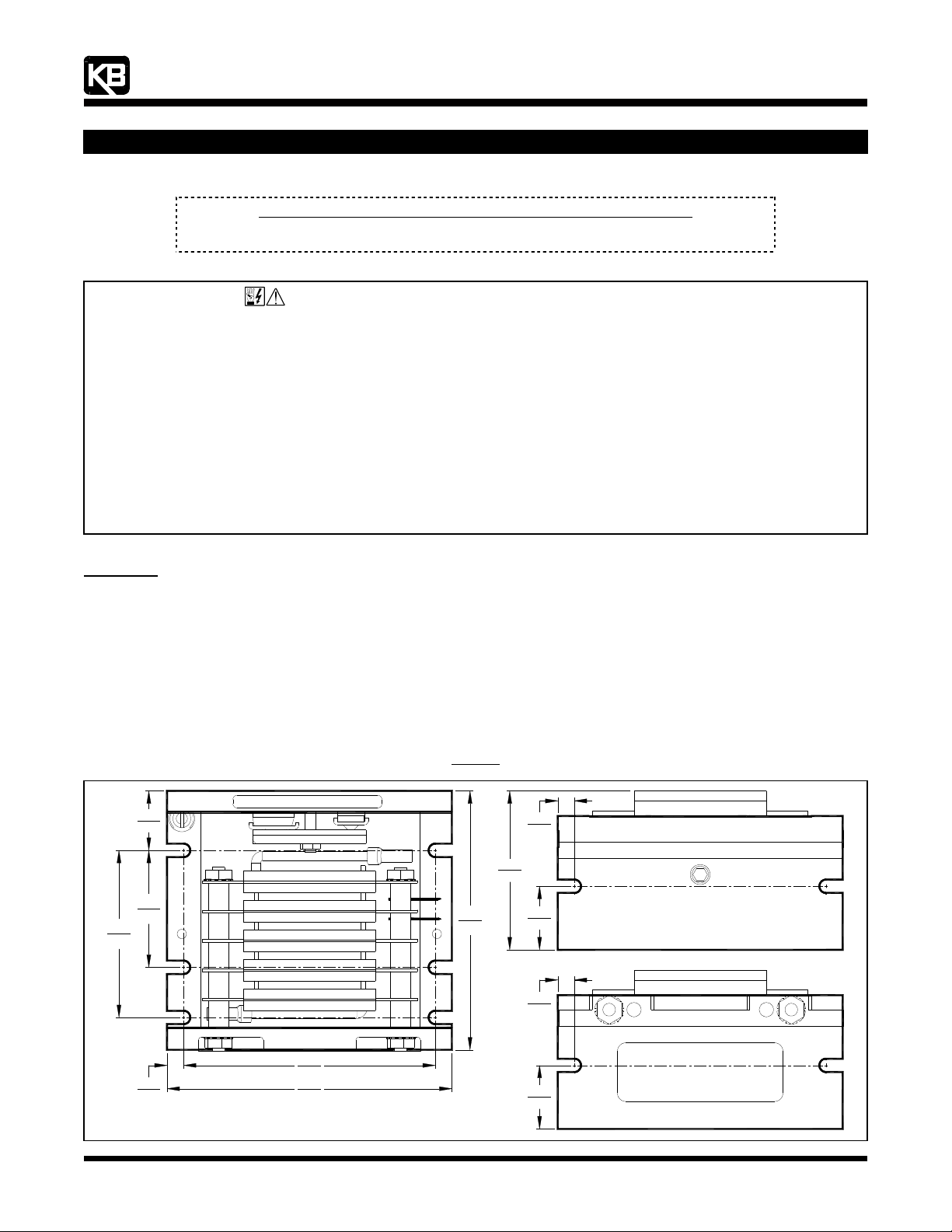

Figure 1

Mechanical Specifications (Inches/mm)

2.50

63.5

0.89

22.6

1.75

44.5

3.88

98.4

2.38

60.4

0.25

6.35

0.95

24.1

0.25

6.35

3.80

0.25

6.35

Recommended Mounting Screw (10 Places): #10

96.5

4.30

109

0.95

24.1

(A40148) – Rev. B – 7/18/2006 – Z4181B00 Page 1 of 4

Page 2

“The Right Control for Your Application.”

KB Electronics, Inc. www.KBelectronics.com

Dynamic Brake Module (Part No. 9598) Installation Instructions

Dynamic Brake Module (Part No. 9598) Installation Instructions

Dynamic Brake Module (Part No. 9598) Installation InstructionsDynamic Brake Module (Part No. 9598) Installation Instructions

1111 DESCRIPTION

DESCRIPTION

DESCRIPTIONDESCRIPTION

The Dynamic Brake Module (DBM) is designed to be used with the KBVF Series Drives (Model Nos. KBVF-21D, 22D, 13, 23, 23D, 14, 24,

24D) and the KBBL Series Drives (Model Nos. KBBL-2P2D, 2P3D, 2P6D, 21D, 22D, 23D, 24D). The DBM provides up to 25% continuous

braking torque and 200% instantaneous braking torque (maximum 1 HP (0.75 kW)).

2222 MOUNTING INSTRUCTIONS

MOUNTING INSTRUCTIONS

MOUNTING INSTRUCTIONSMOUNTING INSTRUCTIONS

WARNING! This DBM must be mounted in an enclosure. Care should be taken to avoid extreme hazardous locations

where physical damage to the DBM can occur due to moisture, metal chips, dust, and other contamination, including corrosive

atmosphere that may be harmful. See Safety Warning, on page 1. Do not use this DBM in an explosion-proof application.

Application Note: The enclosure should be large enough to allow for proper heat dissipation (including additional cooling, if required) so

that the ambient temperature does not exceed 45 °C (113 °F). Leave enough room to allow for any wiring that is required. See Figure 1,

on page 1.

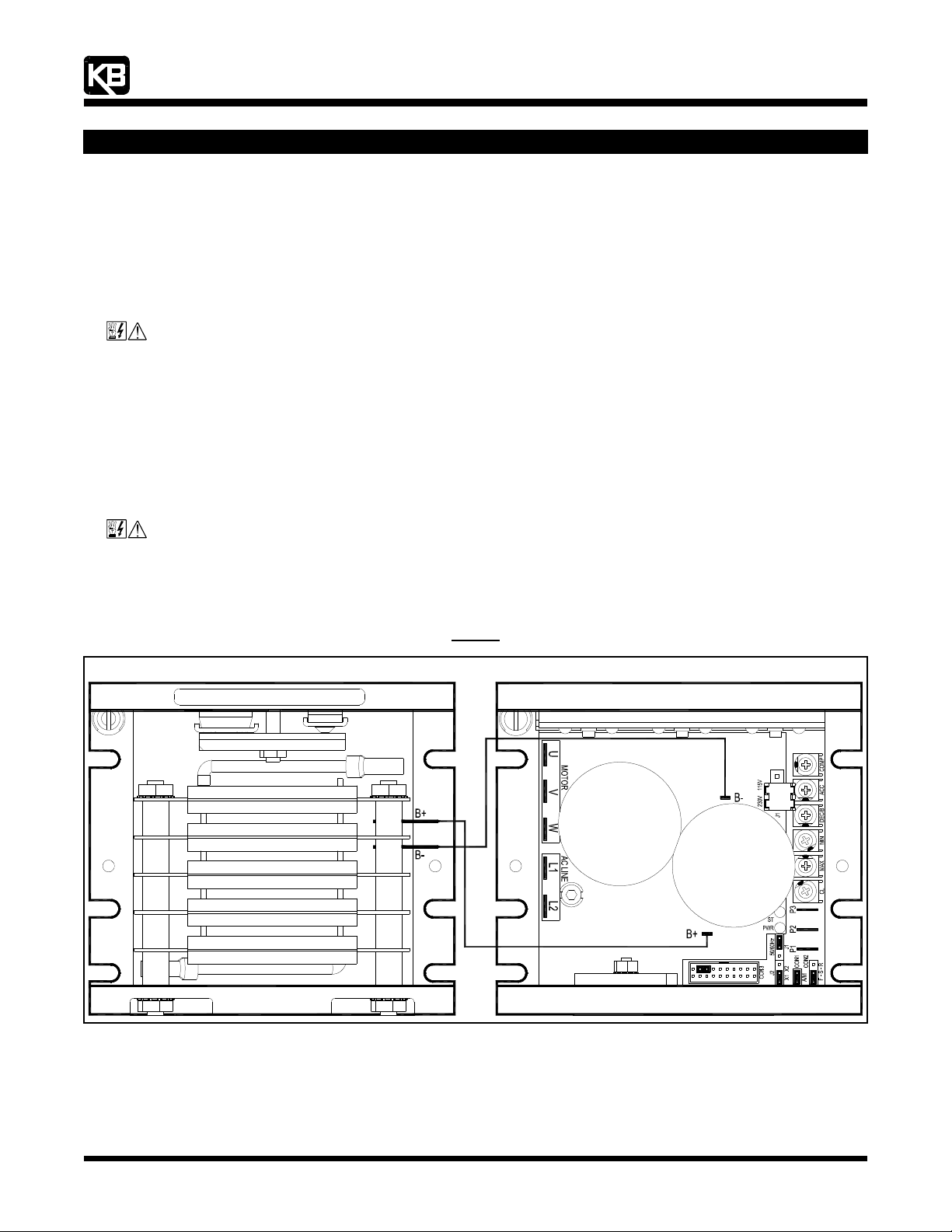

The DBM should be mounted close to the KBVF or KBBL Series Drive, as shown in Figure 2.

3333 WIRING

WIRING

WIRINGWIRING

WARNING! Read Safety Warning, on page 1, before using the drive. Disconnect main power when making connections

to the drive. To avoid electric shock, be sure to properly ground the drive.

12095 NW 39 Street, Coral Springs, FL 33065-2516

Telephone: 954-346-4900; Fax: 954-346-3377

The DBM should be wired to the KBVF or KBBL Series Drive using the 9” 18AWG red/black Interconnect Wires which are provided.

Terminal “B+” on the DBM connects to Terminal “B+” on the KBVF or KBBL Series Drive. Terminal “B-“ on the DBM connects to Terminal

“B-“ on the KBVF or KBBL Series Drive. See Figure 2.

Figure 2

Connection Diagram

Drive*Dynamic Brake Module

*Layout, trimpot settings, and jumper settings may vary slightly.

(A40148) – Rev. B – 7/18/2006 – Z4181B00 Page 2 of 4

Page 3

“The Right Control for Your Application.”

KB Electronics, Inc. www.KBelectronics.com

Dynamic Brake Module (Part No. 9598) Installation Instructions

Dynamic Brake Module (Part No. 9598) Installation Instructions

Dynamic Brake Module (Part No. 9598) Installation InstructionsDynamic Brake Module (Part No. 9598) Installation Instructions

4444 KBVF SERIES DRIVES ONLY

KBVF SERIES DRIVES ONLY

KBVF SERIES DRIVES ONLYKBVF SERIES DRIVES ONLY

In order for the DBM to operate properly with the KBVF Series Drives, the Decel Extend Feature must be disabled. This is accomplished

by installing the jumper (supplied), using long-nose pliers, onto pins 15 and 17 of CON3, as shown in Figure 3.

Disconnect main power when installing this jumper.

When installing the optional SIVFR Signal Isolator and Run/Fault Relay (Part No. 9597) in addition to the Dynamic Brake Module, do not

install the jumper on CON3, shown in Figure 3. The connector will be occupied by the End Connector of the Ribbon Cable which is used

to interface the SIVFR to the KBVF Series Drive. Set Jumper J5, on the SIVFR, to the “DBM” position. See Figure 4.

12095 NW 39 Street, Coral Springs, FL 33065-2516

Telephone: 954-346-4900; Fax: 954-346-3377

Jumper (Supplied) Installed on CON3 Pins 15 and 17

5555 KBBL SERIES DRIVES ONLY

KBBL SERIES DRIVES ONLY

KBBL SERIES DRIVES ONLYKBBL SERIES DRIVES ONLY

Setting Selectable Jumpers and Calibrating the Drive

The KBBL Series Drives with Hall Isolator Board have customer selectable jumpers which must be set before the DBM can be used. For

the location of the jumpers, see Figures 5 and 6.

In order for the DBM to operate properly, the Decel Extend Feature must be disabled on the KBBL Series Drives, as described in Section

5.1, on page 4. To setup and calibrate the KBBL Series Drive for use with the DBM, see Section 5.2, on page 4.

(KBVF Series Drives Only)

Figure 3

SIVFR Set for No DBM

(Factory Setting)

(J5 Installed in “NDBM” Position)

Figure 5

Expanded View of KBBL Series Drive Jumpers and Trimpots

Jumper J5 on the SIVFR

Figure 4

SIVFR Set for DBM

(J5 Installed in “DBM” Position)

Expanded View of Hall Isolator Board Jumpers and Trimpots

(A40148) – Rev. B – 7/18/2006 – Z4181B00 Page 3 of 4

Figure 6

Page 4

“The Right Control for Your Application.”

Calibration Setup in the 4Q Braking Mode

KB Electronics, Inc. www.KBelectronics.com

Dynamic Brake Module (Part No. 9598) Installation Instructions

Dynamic Brake Module (Part No. 9598) Installation Instructions

Dynamic Brake Module (Part No. 9598) Installation InstructionsDynamic Brake Module (Part No. 9598) Installation Instructions

5.1 DECEL EXTEND ENABLE/DISABLE SELECTION (J2): Jumper J2 is located on the KBBL Series Drive’s lower PC board. Jumper

J2 is factory set to the “X1” position to enable the Decel Extend Feature, which prevents the drive from tripping on Overvoltage

Faults when stopping the drive for high inertial loads. To disable the Decel Extend Feature (4Q Braking Mode), set Jumper J2 to the

“X2” position. See Figure 7.

12095 NW 39 Street, Coral Springs, FL 33065-2516

Telephone: 954-346-4900; Fax: 954-346-3377

Decel Extend Enable/Disable Selection

Decel Extend Enabled

(Factory Setting)

(J2 Installed in “X1” Position)

5.2 4Q BRAKING MODE: For 4Q Braking Mode, the drive must be calibrated to the motor, as described below. The % Brake Trimpot

is not operational in the 4Q Braking Mode. Do not operate the drive until completing this calibration procedure. Jumper J2

(X1, X2), on the drive’s lower PC board, must be set to the “X2” position to disable the Decel Extend feature, as described in Section

5.1, above.

4Q Braking Mode Calibration Procedure

1. Remove any load connected to the motor shaft.

2. With power disconnected, set Jumper J3 (CAL) to the “ON” position. Set Jumper J7 (MODE) to the “4Q” position. See Figure 8.

3. Apply power and close Terminals “FWD” and “COM”. The drive will run the motor up to the maximum speed in approximately

20 seconds. If the drive will also be operated in the reverse direction, this calibration must also be performed in the reverse

direction (by closing Terminals “REV” and “COM”).

The CAL status LED (located on the Hall Isolator Board) will flash according to the description below. If the calibration fails,

check the Hall Sensor connections.

CAL Status LED Flash Sequence: Flashes quick yellow while calibrating. Flashes quick green when the calibration has been

successfully completed. Flashes quick red if calibration fails.

4. Set Jumper J3 to the “OFF” position. The drive is now ready for application testing. See Figure 9.

Figure 7

Decel Extend Disabled

(4Q Braking Mode)

(J2 Installed in “X2” Position)

Figure 8

(J3 Installed in “ON” Position)

(J6 Installed in “ON” Position)

(J7 Installed in “4Q” Position)

(A40148) – Rev. B – 7/18/2006 – Z4181B00 Page 4 of 4

Dynamic Braking During Deceleration

(J3 Installed in “OFF” Position)

(J6 Installed in “ON” Position)

(J7 Installed in “4Q” Position)

Figure 9

(4Q Braking Mode)

Loading...

Loading...