Page 1

ANTI-PLUG REVERSING MODULE (APRM®-PC) WITH DYNAMIC BRAKING

KB PART NO. 9378

FOR USE WITH KBPC-240D SPEED CONTROL

INSTALLATION AND OPERATING INSTRUCTIONS

See Safety Warning on page 1

The information contained in this manual is intended to be accurate. However, the manufacturer retains the right to make

changes in design which may not be included herin.

A COMPLETE LINE OF MOTOR DRIVES

PATENTED © 1997 KB Electronics, Inc.

TABLE OF CONTENTS

Section Page

i. Safety Warning ........................................................................................ 1

I. Operation ............................................................................................ 2

II. Setup ............................................................................................... 2

III. Mounting ............................................................................................. 3

IV. Wiring ............................................................................................... 4

V. Limited Warranty ...................................................................................... 10

TABLES

1. APRM® Operation ...................................................................................... 2

2. General Performance Specifications ........................................................................ 2

3. APRM® to PC Connections ............................................................................... 5

4. Parts List ............................................................................................ 7

FIGURES

1. APRM® Mounted in the KBPC-240D ........................................................................ 3

2. KBPC-240D Jumper Removal ............................................................................. 4

3. Switch Mounting ....................................................................................... 5

4. Remote Relay Contacts ................................................................................. 5

5. Internal Wiring Diagram ................................................................................. 6

6. Schematic ............................................................................................ 8

7. Mechanical Specifications ................................................................................ 9

ii

Page 2

i. SAFETY WARNING! — PLEASE READ CAREFULLY

This product should be installed and serviced by a qualified technician, electrician or electrical maintenance person familiar with

its operation and the hazards involved. Proper installation, which includes wiring, mounting in proper enclosure, fusing or other

overcurrent protection and grounding, can reduce the chance of electric shocks, fires or explosions in this product or products used with

this product, such as electric motors, switches, coils, solenoids and/or relays. Eye protection must be worn and insulated adjustment

tools must be used when working with control under power. This product is constructed of materials (plastics, metals, carbon, silicon,

etc.) which may be a potential hazard. Proper shielding, grounding and filtering of this product can reduce the emission of radio

frequency interference (RFI) which may adversely affect sensitive electronic equipment. If information is required on this product, contact

our factory. It is the responsibility of the equipment manufacturer and individual installer to supply this safety warning to the ultimate user

of this product. (SW effective 11/92)

This control contains Start/Stop and Inhibit circuits that can be used to start and stop the control. However, these circuits are never

to be used as safety disconnects since they are not fail-safe. Use only the AC line for this purpose.

The input circuits of this control (potentiometer, Start/Stop, Inhibit) are not isolated from AC line. Be sure to follow all instructions

carefully. Fire and/or electrocution can result due to improper use of this product.

This product complies with all CE directives pertinent at the time of manufacture. Contact factory for detailed

installation instructions and Declaration of Conformity.

1

I. OPERATION.

The APRM®-PC provides anti-plug instant reverse and solid

state dynamic braking. It has been specifically designed for

installation into the KBPC-240D speed control. The patented

circuitry senses armature voltage and permits armature

switching to take place only when current levels are near zero.

This eliminates contact arcing normally associated with relay

reversing circuits.

Braking is achieved via an electronic circuit utilizing an SCR

and brake resistor. An LED indicates when the APRM® is in

the brake mode. Operation is made via a SPDT switch with

Switch Position Switch Connection

Forward (FWD) S1, S2 + -

Brake (BRK) None (Center off)* 0 0

Reverse (REV) S2, S3 - +

*Note: If no connection is made to S1, S2 and S3, the APRM® is in the brake

mode which will rapidly stop the motor.

TABLE 1 – APRM® OPERATION

Output Polarity

A1 A2

center off.

The unit installs easily into the inside cover of the KBPC control. Wiring is made via quick-connect terminals.

II. SET UP.

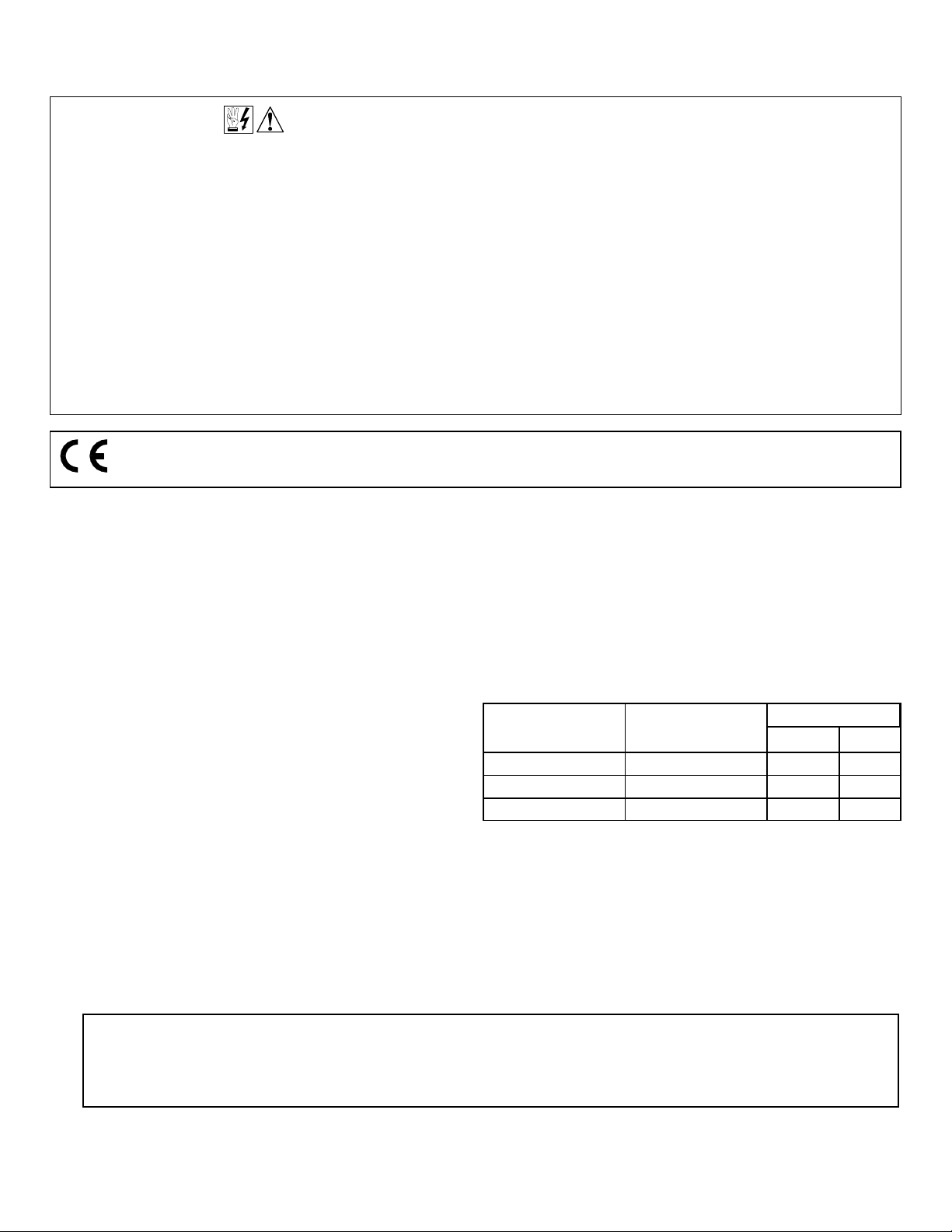

Be sure the Jumpers J1 and J2 on the APRM® are both set to the proper AC line input voltage, 115 or 230VAC. Note: This should be

the same setting as the Jumpers J2A and J2B are set for on the KBPC main board which should correspond to the correct AC line input

voltage. Refer to the KBPC-240D Installation and Operating Instruction Manual for complete information.

TABLE 2 – GENERAL PERFORMANCE SPECIFICATIONS

Input AC line voltage – 50/60 Hz ...................................................................115/230

Maximum number of run/brake or forward/reverse operations per minute* ........................................ 4

Ambient temperature range (°C)..................................................................... 0 – 50

*Based on a one (1) minute braking time.

2

Page 3

III. MOUNTING.

1. Mount the APRM®-PC on the 4 bosses located on the inside cover

of the KBPC-240D using the four (4) # 6-32 screws provided.

Position the APRM so that the brake resistor is toward the bottom of

the cover. Be sure not to trap any wires under the APRM mounting

bracket. (See fig. 1.)

2. To mount the FWD-BRK-REV switch in the KBPC first remove the

rubber plug in the FWD-BRK-REV position by unscrewing the retainer

nut on the inside cover. (See fig. 3 p. 5.)

3. Install the FWD-BRK-REV switch assembly into the front cover

making sure the key in the hole lines up with the keyway in the switch

bushing. Be sure the hex nut supplied is installed at the base of the

switch bushing before inserting switch into the KBPC cover.

4. Install the rubber switch boot with integral hex nut over switch lever.

Switch should be in the stop position to facilitate installation. Also,

the switch bushing threads should protrude no more than .25"

(6.4mm) or no less than .10" (2.6mm) through the front cover for

proper installation. Tighten the switch boot so that the bottom seals

against the cover label. Do not overtighten.

FIG. 1 – APRM® MOUNTED IN THE KBPC-240D

3

5. FWD-BRK-REV switch remote mounted. It is possible to operate the control with a remote FWD-BRK-REV

switch or with a remote relay. Carefully remove the three switch wires:

S1, S2, S3 from the APRM®. Wires

may be extended for remote operation,

but it is suggested that a shielded

cable be used. (See table 1 APRM

Operation, p. 2.)

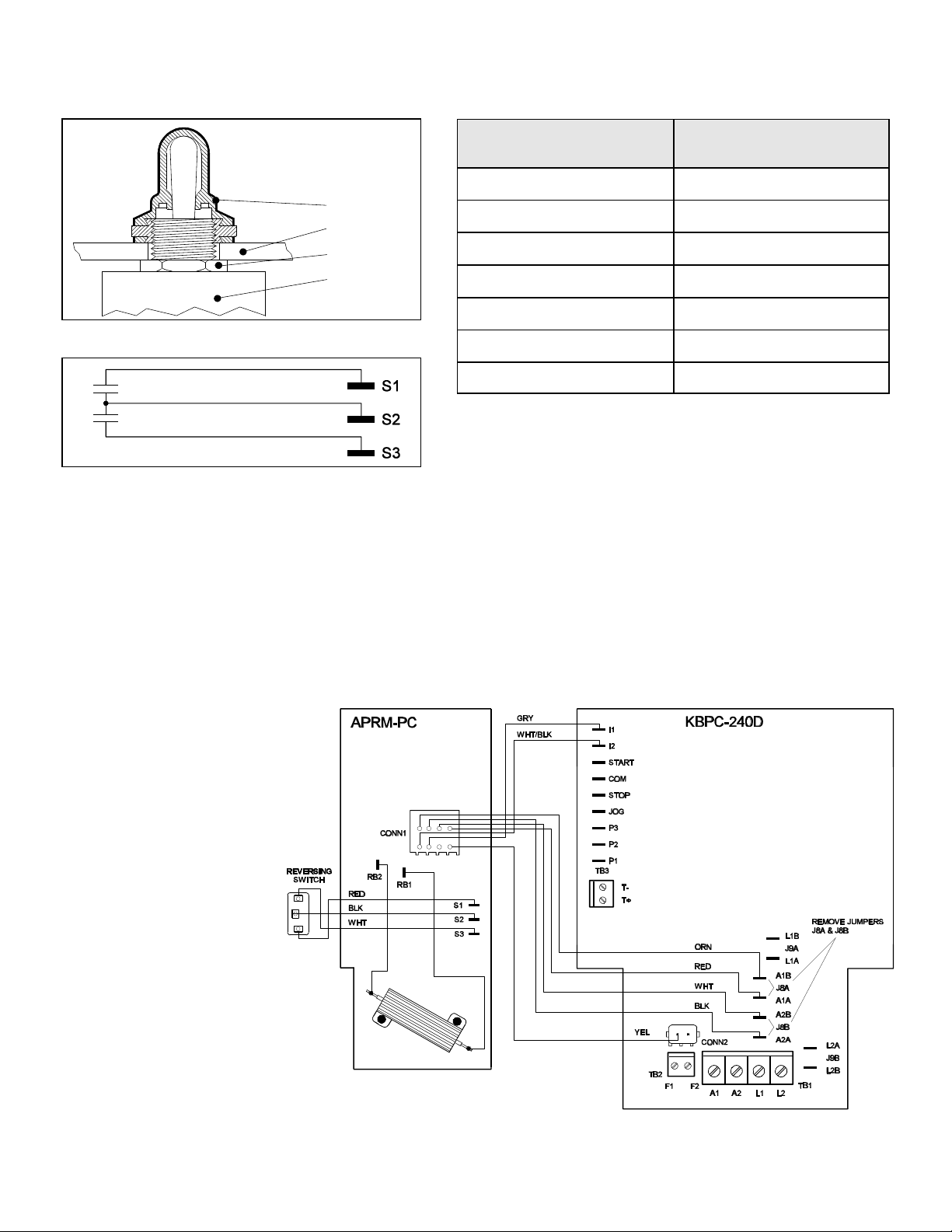

IV. WIRING. Do not wire control

with AC line connected.

1. Carefully remove from the KBPC main

PC board the 2 jumpers, J8A (connects A1A and A1B) and J8B (connects A2A and A2B). Note: Use long

nose pliers and rock terminal back

and forth to facilitate removal. (See

fig. 2.)

2. Install the wires from the APRM onto

the following terminals on the KBPC

main board. Refer to the internal wiring

diagram provided. (See fig. 5, p. 6.)

4

FIG. 2 – KBPC-240D JUMPER REMOVAL

®

Page 4

FIG. 3 – SWITCH MOUNTING

TABLE 3 – APRM® TO PC CONNECTIONS

RUBBER BOOT

COVER

HEX FACENUT

SWITCH BODY

FIG. 4 – REMOTE RELAY CONTACTS

APRM® Wire Color

Terminal Position on KBPC

PC Board

Red A1A

Orange A1B

Black A2A

White A2B

Gray I1

White / Black I2

Yellow F1*

*Note:

Newer models contain a connector on the yellow APRM® lead.

Observe correct polarity and insert the plug onto the mating

connector just behind terminal block TB2. (See fig. 5, p. 6)

5

To avoid erratic operation do

not bundle AC line and motor

wires with reversing, potentiometer, voltage following, enable, inhibit or other signal

wiring. Use shielded cables

on all signal wiring over 12"

(30 cm) – Do not ground

shield.

Note:

Reversing switch can be remotely mounted.

6

FIG. 5 – INTERNAL WIRING DIAGRAM

Page 5

FIG. 7 – MECHANICAL SPECIFICATIONS

INCHES

[mm]

7

V – LIMITED WARRANTY

For a period of 18 months from date of original purchase, KB will repair or replace without charge devices which our examination

proves to be defective in material or workmanship. This warranty is valid if the unit has not been tampered with by unauthorized

persons, misused, abused, or improperly installed and has been used in accordance with the instructions and/or ratings supplied.

The foregoing is in lieu of any other warranty or guarantee, expressed or implied, and we are not responsible for any expense,

including installation and removal, inconvenience, or consequential damage, including injury to any person, caused by items of

our manufacture or sale. Some states do not allow certain exclusions or limitations found in this warranty so that they may not

apply to you. In any event, KB's total liability, under all circumstances, shall not exceed the full purchase price of this unit. (rev

4/88)

KB ELECTRONICS, Inc.

12095 NW 39th Street, Coral Springs, FL 33065 • (954) 346-4900 • Fax (954) 346-3377

Outside Florida Call TOLL FREE (800) 221-6570

www.kbelectronics.com

(A40265) – Rev. B – 6/97

Loading...

Loading...