Page 1

MACWINERY

DIVISION

6465

I8

NilLF

ROAD

STERLING

HEIGHTS,

Mi

4831

4

PnouE:

(586)

731

-3600

i

-800-860-1

?40

k!p&af$mpf??&!

FAX:

$5-

st i 0..

a

yt~

(586)

731

-7464

*

1-800-862-

1710

MODEL WS-I

8

BANDSAW

THANK YOU FOR PURCHASING WlTH KBC MACHINERY. ALL KBC

MACHINES ARE BACKED BY OUR

I

YEAR PARTS REPLACEMENT

WARRANTY. WHEN USED AS INTENDED, AND WlTH PROPER

MAINTENANCE

THIS MACHINE WILL PROVIDE YOU WlTH YEARS OF

TROUBLE-FREE SERVICE. IF YOU NEED PARTS SIMPLY

FILL OUT

THE PARTS REQUEST FORM, AND FAX OR E-MAIL YOUR REQUEST.

ALL OTHER QUESTIONS PLEASE CONTACT US

@

:

KBC MACHINERY

6465 18

MILE ROAD

STERLING

HEIGHTS,MI

48314

PH

(800) 860-1 740

FAX

(800) 862-1740

MACHlNERY@KBCTOOLS.COM

W.KBCTOOLSANDMACHlNERY.COM

www.

KBCTOOLS

.

COM

Page 2

PARTS

REQUEST

FORM

YOUR COMPANY NAME:

STATE/PROVINCE

YOUR NAME

PHONE

#

+

EXT

F.

#

MACHINE INFO:

MAKE/MANFACTURER

MODEL NUMBER

YEAR

MADE

PARTS REQUESTED:

PART#

DESCRIPTION

PLEASE INCLUDE

COPY(S) OF THE PARTS DRAWING EROM THE

MANUAL

AND CIRCLE THE PARTS NEEDED

FAX PARTS REQUEST TO (800)

862-1

740

E-MAIL PARTS REQUEST TO:

machinery@kbctools.com

THANKS; KBC MACHINERY

-

MICHIGAN

Page 3

LK

WBS-1603

3

SPEED

YS

1603N

3

SPEED

Page 4

UNPACKING AND CLEANING

Carefully unpl k the

band saw, stand, and all loose

items

from the cartons. Remove the protective caating

from the machined surfaces of the band saw. This

coating may

be

removed w~th a soft cloth moistened

with kerosene (do not use acetone, gasoline

a

lacquer

thinner

fa

thls purpose). After cleaning, cover all

unpainted surfaces with a

good quality paste

wax.

ASSEMBLING STAND, MOTOR PLA'CE, MOTOR AND MOTOR PULLEY

If you purchased ywr band saw with separate stand and

2.

Return the stand to the upright position and assemble

electricalr NOT factory

mwnted and wired, the stand

is

band saw to stand using four head screws, flat washers,

lock-

supplied as shown in Fig. A. then proceed as follows to washers and nuts. as shown in Fig. 6.

assemble the motor plate, motor and motor pulley.

1.

Turn the stand upside down.

Fig.

A

Page 5

3.

Using the four bolts, flat washers

Consult your Dealer or Catalog for the

for use with vour saw.

and hex head nuts

recommended motor

4.

Assemble motor pulley

11)

Fig. D to the motor shaft.

Make sure the set screw in the motor pulley engages with key

in motor shaft. Using

a

straight edge, make sure the motor

pulley

(11

and driven pulley

12)

are in alignment. If necessary,

both pulleys can

be

moved in or out.

The motor can also be

moved if necessary.

5.

Assemble the V-Belt

(3)

Flg.

E.

to the two pulleys and

adjust for proper belt tension by forwarding or backwarding

the motor. Keep pulleys in alignment when doing this.

Correct belt tension

is

obtained when there

is

approximately

1"

deflection in the center span of the pulleys with lighr finger

pressure.

ASSEMBLING BELT AND PULLEY GUARD

Place the belt and pulley guard

(1)

~ig.

E,

on the surface of

base "shelf".

Use the three hex. head screws to fasten in

Place.

Page 6

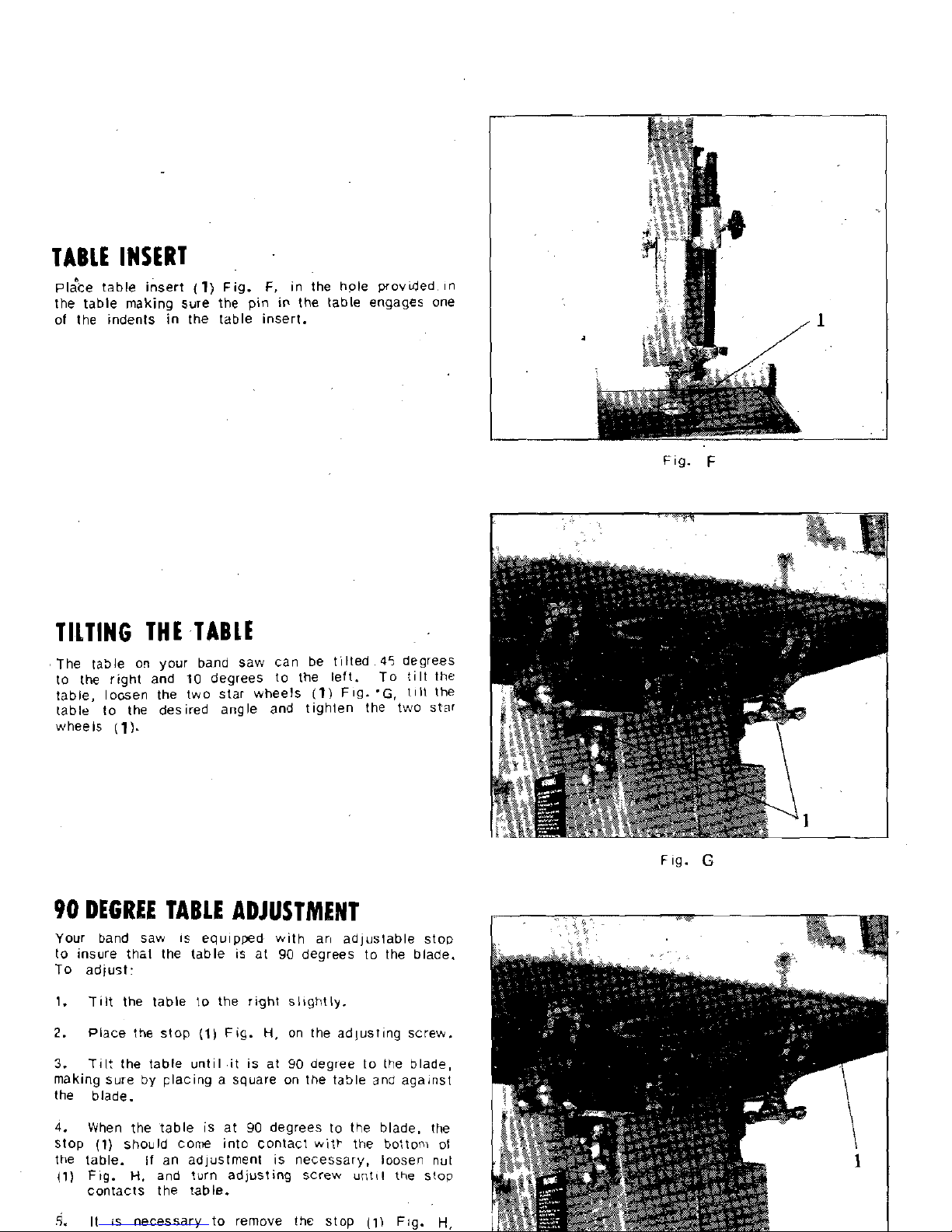

TABLE INSERT

pl;ce table insert (1) Fog.

F,

in the hole povded In

the table making sure the pln

IP

the table engages one

of the

Indents In the table insert.

TILTING THE TABLE

The table o~ your band saw can be tilted

45

degrees

to the rlght and

10

degrees to the left. To tilt the

table,

losen the two star wheels

(1)

I.

lilt thP

table to the desired angle and tighten the two star

wheels

(1).

Fig.

G

90

DEGREE TABLE ADJUSTMENT

Your band saw is equipwd with art adjustable stop

to insure thal the table is at

90

degrees to the blade.

To

adjust:

1. Tilt the table lo the right sl~ghtly.

2.

Place the stop

(I)

Fig.

H,

on the adlusting screw.

3.

Til: the table untilit is at

90

degree to (he blade,

making sure by placing a square on the

table ana against

the blade.

4.

When the table is at

90

degrees to the blade, the

Stop (1) should cone into contact

witk the bottom of

the table.

if an adjustment is necessary, loosen nut

(1) Fig.

H,

and turn adjusting screw unttl the slop

contacts the table.

R.

It is necessary to remove the stop

(1)

Fig.

H,

.

.

Page 7

ADJUS'CING BLADE 'CENSION

On the back of the upper wheel there is a slide bracket

to get the proper tension for

varlous widths ot blades.

W~lh the blade on the wheels, turn the star wheel

(1)

~i.

(I1 to raise or lower the wheel until you provide the

r~ght lenslon lo your blade Over straining is a common

cause of blade breakage and

other unsatisfactory blade

performance

Reiax the

tenslon when the machine is not in use.

TRACKING THE BLADE

After tension has been applied to the blade, revolve the wheels

slowly forward by hand and watch the blade

(1)

Fig.

(J)

to see

that

it

travels in the center of the upper tire.

If the blade

begins to creep toward the front edge, turn the black knob to

the left and this will

tilt

the top of the wheel toward the back

of the machine and will draw the blade toward the center of

the tire.

If the blade creeps toward the back edge, turn the

black knob to the right. Adjust the black knob

(2)

only

a

fraction of a turn at a tine. Never track the blade while-the

machine

is

running.

ADJUSTING LIPPER BLADE GUIDE ASSEMBLY

The upwr blade gufde asspmbly

(1)

Flg.

K,

should

alviays be set as close as possfble to the top surface

of the

mater~al befng cut by loosen~ng lock handle

12)

and moving the gu~de assembly

(1)

to the deslred

posIt1on.

Fig.

I

Page 8

The upper blade guide assembly should also be adjusted

so that the blade

guides

(1)

Fig.

L.

are flat ,wlh the

blade.

ADJUSTING UPPER BLADE GUIDES

I

&

AND BLADE SUPPORT BEARING

The.upper blade guides and blade support bearlngs are

adjusted only after the blade

IS

tensioned and tracklnq

properly.

To adjust proceed as

tollows:

1.

The upper blade guides (1,) Fig.

M,

are held in

place by

reans of the set screws

(2).

Loosen the set

screws

(2)

to move the guides

11)

as close as possible

to the side of the blade,

be~ng carelul not to p~nch

the blade. Then llghten the screws

(2).

2.

The upper blade support bearing

(31

Fig.

51.

.

pre~ents the blade lrom king pushed too lar lo the

back which could damage the

sel in the saw teeth.

The support

bearnng (3) should be set 11!64") SehlM

the blade by loosening knob screw (3) lo move :he

support

bearing

(3)

in or out.

3.

The blaae suppwt bearlng

(3)

sllould also be

adjusted so the back edge of the blade overlaps the

outside dlameter 01 the ball bearing by about 1

!1E".

The bearing

(3)

is

se! on an eccentric and to change

position

remove knob screw (4) and bearlng (3) Fig.

M.

Loosen knob screw (4). and reposition shaft that

F

19.

M

bearing

(3)

is

attached to.

ADJUSTING LOWER BLADE GUIDES

AND BLADE SUPPORT BEARING

The lovier blade

guides

ano blade support nc,lrlng

should be adl~sted at ?he sanie

t,nie as :le .lpper goldes

and bear~ng as fallows.

1. Loosen the two screws

(1)

Fig.

N

,

and nove

Ihe gu~des

(2)

as close as possble to tl,e sde of the

blade,

belng careful not to p~nch the blade.

the^

tlghlen screws (1).

2.

The lower blade support bearing

(3)

Fig.

N.

should be

adjusted so it

isabwt (1164") behind the back of the blade by

Nrning the knob

(4).

Page 9

CHANGING BLADES

To change blades, proceed as follows:

1. Remove the upper and

Laver wheel guards.

2.

Release tension on

the

band saw blade.

3.

Remove the table adjustment pln and table insert.

4. Slip the blade off the wheel and

guide it out through

the slot in the table.

5.

TO install a new blade, reverse the above

pro-

cedure.

BAND SAW BLADES

A band saw blade is a delicate piece of steel that is Any one of a number of conditions may cause a band

subjected to tremendous strain. You can

obtainlong saw blade to break. Blade breakage is, in some cases,

use from a band saw blade if you give it fair treatment. unavoidable,

belng the natural result ot the peculiar

Be sure you use blades of the proper thickness. width stresses to which such blades are subjected. It is,

and temper for the various types

of material lo be cut. however, often due to avoidable causes, most often to

lack of care or

iudgment on the-part of the operator in

Always use the widest blade possible. Use the narrow

blades only for sawing small, abrupt curves and for

fine delicate work. This

wlll save blades ?nd will

produce better work. Band saw blades may be pur-

chased, welded, set

and sharpen-ed ready for use.

For

cutttng wood and similiar materials.'we can supply

them in wtdths

of l/B. 3/16. 114, 3J8, 112 and 314

. .

mounting or adj;sti;lg the blade or guides.

he

most

common causes cfblade breakage are: (1) faulty align-

ments and adjustments of the guides. (2) forcing or

twisting a wide blade around a curve of short radius,

(3) feeding too fast, (4) dullness of the teeth or absence

of sufficient set.

(5)

excessive tightening of the blade,

(6)

top guide set too high above the work being cut,

171

usina a blade witha lumpv or improperly finished

~ncnes.

braze o; weld and,

(8)

cont in;ous runnlng

oi

the saw

blade when not in use for cutting.

I-

File and set the wood cuttino blades whenever vou

find it requires pressure to

mace them cut.

I!

a blaoe

is broken it can be brazed or welded; however, if it

New blades for the standard

18 inch Band Saw are 120 inches

has become badly work-harderled it

Soon

break Ion5 The adjustment will accommodate blader up toa maxi

in another

place. If yo" are not eaul~oed to file. sei

mum length of 121 inches and to a minimum length

OF

,

.7

and braze

weld blades take them to a saw

file; for

119.1/2" inches,

reconditioning. Under average

condit~ons, blades

should

be

resharpened after 4 hours of operation.

OPERATING THE BAND SAW

Before starting the machine, see that all adjustments

are properly made and the guards are in place. Turn

the pulley by hand to make sure that everything is

correc: BEFORE turning on the power.

Keep the top guiae down close to the wak at all times.

Do not force the material against the blade too hard.

Light contact with the blade will

ermit easier following

of the' line and prevent

undue friction. heating and

work-hardening of the blade at its back edge.

KEEP THE SAW

BLADE

SHARP and you will find

that very little forward pressure is required for average

cutting. Mcve

th stock against the blade steadily

and no faster than will give an easy cutting movement.

Avoid

twist~ng the blade by trylng to turn snarp corners.

Remember you must saw around corners.

CUT'TING CURVES

When cutting curves, turn the stcck carefully so that

the blade may follow without being twisted. If

a

curve

is so abrupt that it is necessary to repeatedly back up

and

cut a new keri, either a narrow blade is needed

or a blaae with more set is required. The more set a

blade has, the easier it will allow the

stock to be

turned,

but the cut is usually rougher than where a

medium amount of set is used.

In withdrawing the piece being cut, in order to change

the cut, or for any other reason, the operator must be

careful that he

does not accidentally draw the blade

off the wheels. In most cases it is easier and safer to

turn the stcck and saw out through the waste material,

rathe: than try to withdraw the stcck from the blade.

Page 10

Page 11

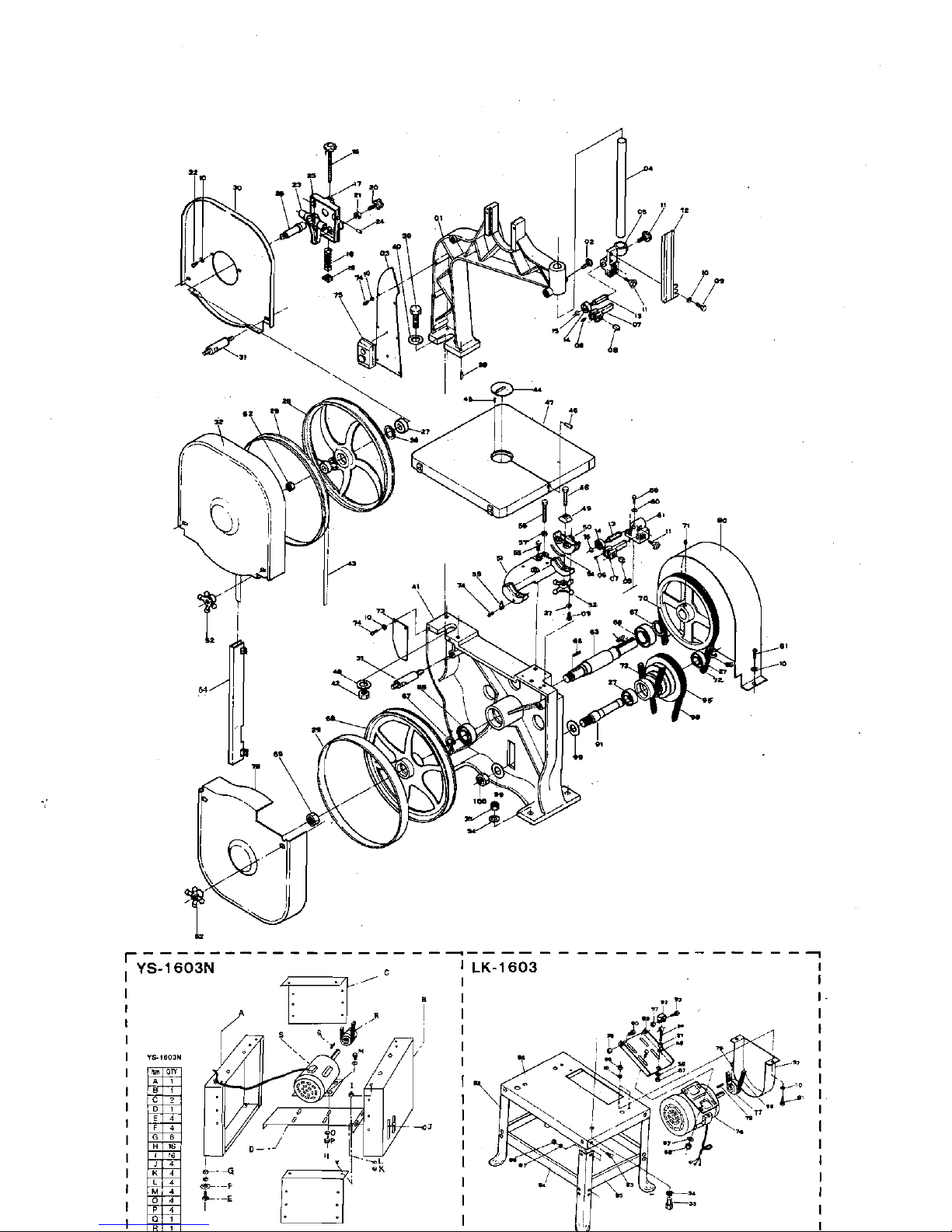

PARTS LIST

Description

I

5

1

Support Bracket For Upper Guide

I

11

6 i Screw

I

14

7 Guide Block 2

8 Square Guide Block 4

9 Cross Screw 8

I

10 1 Flat Washer

I

20

I I

rKnob Screw

1

14

12 Guard Plate

I

13 Spacking Sleeve

2

pp

14 Ball Bearing 620022 2

15 C-Clip 2

16 Blade Adjust Screw

I,

17 Upper Wheel Sliding Brkt.

I

18 Sorinr

I

.

-

19 Square Bolt

-

I

20 Knob Screw

I

21 Nut

1

Upper Wheel Shart

Ball Bearing 620222

,

..

29 Wheel Protector

2

30

1

Uooer Wheel Guard (Inner)

I

11

. .

31 Stud 4

32 Upper Wheel Guard

(Outter)

I

33 ScrLw 4

I

I

34 1 Flat Washer

18

35 1 Nut

I

6

36 1 C-Ring 4

37 Flat Washer 6

38 1 Pin 2

39 1 Screw

I

I

40 1 Flat Washcr

1

2

41

1

~ase

1

42 1 Nut

I

43 I Saw Blade

I

,

49 1 Trunnion Clamp Shoe

2

50 ( Trunnion

?

MEASUREMENTS:

52'x 23.2*x15*

CUFT

10.5

N.W.

Washer

Loading...

Loading...