KBC KBC-20VS Operator's Manual

MACHINERY

DlVlSION

6465

18

MlLE

ROAD

STERLlNG

HEIGHTS,

MI

4831

4

PHONE:

(586)

731

-3600

*

1

-8W-860-1740

FAX:

(586)

731

-7464

.

1

-800-862-1

740

MODEL

20"

VS

DRILL PRESS

THANK YOU FOR PURCHASING WlTH KBC MACHINERY. ALL KBC

MACHINES ARE BACKED BY OUR

1

YEAR PARTS REPLACEMENT

WARRANTY. WHEN USED AS INTENDED, AND WlTH PROPER

MAINTENANCE

THIS MACHINE WILL PROVIDE YOU WlTH YEARS OF

TROUBLE-FREE SERVICE. IF YOU NEED PARTS SIMPLY

FILL OUT

THE PARTS REQUEST FORM, AND FAX OR E-MAIL YOUR REQUEST.

ALL OTHER QUESTIONS PLEASE CONTACT US

@

:

KBC MACHINERY

6465 18

MILE ROAD

STERLING

HEIGHTS,MI

48314

PH

(800) 860-1740

FAX

(800) 662-1740

MACHINERY@KBCTOOLS.COM

-

WWW.KBCTOOLSANDMACHlNERY.COM

www.

KBCTOOLS

.

COM

PARTS REQUEST

FORM

YOUR COMPANY NAME:

STATE/PROVINCE

YOUR NAME

PHONE

#

+

EXT

FAX

#

MACHINE INFO:

MAKE/MANFACTURER

MODEL NUMBER

YEAR

MADE

PARTS REQUESTED:

PART#

DESCRIPTION

PLEASE INCLUDE COPY

(S) OF THE PARTS DRAWING EROM THE

MANUAL

AND CIRCLE THE PARTS NEEDED

FAX PARTS REQUEST TO (800)

862-2740

E-MAIL PARTS REQUEST TO:

machinery@kbc tools. corn

THANKS; KBC MACHINERY

-

MICHIGAN

VARIABLE SPEED

DRILLING

-

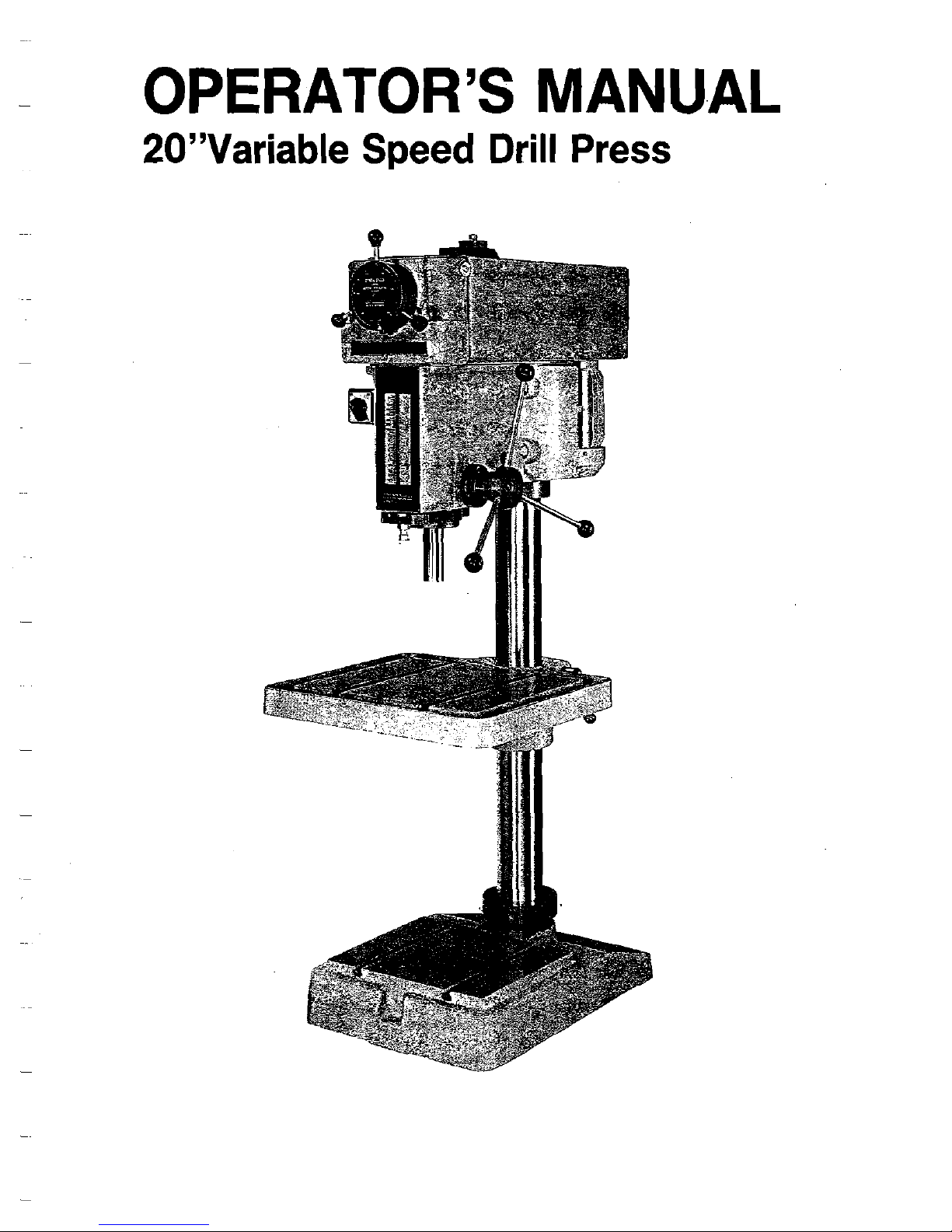

OPERATOR'S

MANUAL

2O"Variable

Speed

Drill Press

WARNING

1.

Read the operator's manual carefully.

Lcarn the tools applications and

limitations, as well as the specific

potential hazards peculiar to it. Knou

your power tool.

2.

Always wear approved safety

glasseslfaceshields while using this

machine.

3.

Make certain the machine is properly

grounded.

4. Before operating the machine, remove tie,

rings,

watchcs, other jeuelry, and roll up

sleeves above the elbows. Remove all

loose clothing and confine long hair. Do

NOT wear gloves.

5.

Keep the floor around the machine clean

and free of scrap material, oil and

grease.

6.

Keep machine guards in place at all times

when the machine is in use.

If removed

for maintenance purposes, use extreme

caution and replace the guards

immediately.

7.

Do

NOT

over reach. Maintain a balanced

stance at all times so that you do not fall

or

lcan against blades or other moving

parts.

8.

Support the workpiece adequately at all

limes during an operation to maintain

control of your work. Never hold the

workpiece

by

hand while drilling.

9.

Make all machine adjustments or

maintenance with the machine unplugged

from the power source.

10.

Ucc

the right tool. Don't force a tool or

attachment to do

a

job which it was not

designed for.

11.

Make certain the motor switch is in the

OFF position before connecting the

machine to power.

12.

Give your work undivided attention.

Looking around, carrying on a

conversation, and "horse-play' are

careless-acts that can result in serious

injury.

13.

Make a habit of checking to see that keys

and adjusting wrenches are removed

before turning on the machine.

14. Keep visitors a safe distance from the

work area.

15. Use recommended accessories; improper

accessories may he hazardous.

16.

Replace warning labels if they become

obscured or removed.

17. Failure to comply with these warnings

may result in serious injury to the

operator.

11.

Do NOT make cuts requiring more power

than is available on

the machine.

SPECIFICATIONS:

MODEL ZOVS-DT-1 2OVS-DT-TAP

DRILLING CAPACITY

CAST IRON

..................................................................

1-112"

..................................

1-112"

STEEL

...........................................................................

1- 114"

..................................

1- 114"

.....................................................

TAPPING CAPACITY

.........................................

314-

.................................................

...........

...............................

COLUMN DIAMETER

..

4"

4"

MAXIMUM DISTANCE SPINDLE TO COLUMN

....

10"

..............................................

10"

SPINDLE TRAVEL

.......................................................

6-112"

..................................

6-112"

SPINDLE DISTANCE TO BASE

................................

39"

..............................................

39"

SPINDLE DISTANCE TO TABLE

..............................

28-112"

..............................

28-112"

TABLE SIZE

..................................................................

22"x19-112"

.................

22x19-112'

NUMBER OF T-SLOTS

...............................

..

......

2

....................................................

2

T-SLOT SIZE

...............................................................

518"

.........................................

518"

CENTERS

.......................................................................

8-718"

..................................

8-718''

SPINDLE TAPER

..........................................................

MT-3

....................................

MT-3

SPINDLE SPEEDS

........................................................

VARIABLE

..............

VARIABLE

SPINDLE RPM

..............................................................

300.2,

000

......................

150.2, 000

MOTOR

..........................................................................

1-

112

HP, 1 Ph

.............

2

HP, 3 Ph

........................................................................................

1151230V

.......................

2-SPEED

.......................................................................................

PREWIRED

115V

.....

220V

ONLY

OVERALL HEIGHT

.....................................................

69"

..............................................

69"

BASE SlZE

...................................................................

26"x1gN

...............................

26"x111"

TABLE TRAVEL

.........................................................

20"

..............................................

20"

NET WEIGHT (APPROX.)

...........................................

720

LBS

...........................

740

LBS

.

SHIPPING WEIGHT (APPROX.)

.................................

754

LBS

...........................

774

LBS

.

CLEANING

After uncrating, remove protective coating from

all bright surfaces with a soft cloth moistened

with kerosene. Do

not

use acetone, gasoline or

lacquer thinner

-

these will damage painted

surfaces.

To prevent rust, wax the table with

paste wax.

INSTALLATION

The most accurate and vibration-free operation

will require the machine to be bolted to the

floor.

While this is not absolutely necessary, it

is highly recommended. The drill press should

be level and

rest solidly on the floor.

Place

shims under the three bolt holes to level the

drill press.

Equal pressure should be applied to

all three nuts when tightening to prevent

distorting the base.

RAISING HEAD

The drill press head is lowered on the column

to ease crating and transportation.

Before

operating the drill press, the head will need to

be raised to the operational level:

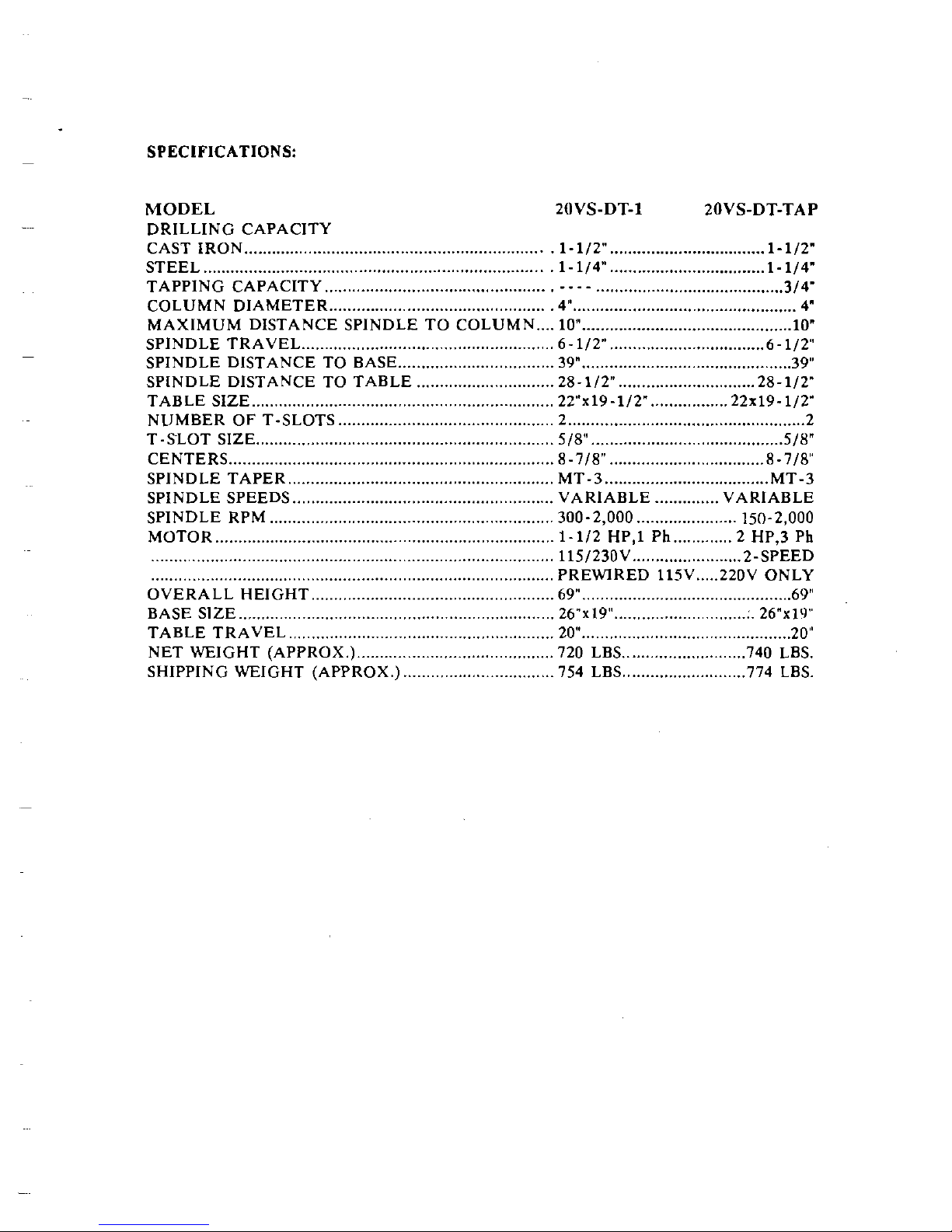

1.

Loosen table lock

(A).

Fig.

1

2.

Cut a

2"x4" approximately

16"

in length.

Raise table (B) and place

2"x4 between

table and head

(C)

as close to the column

(D)

as possible. Caution: do not place Z"x4"

under lock collar

(E).

3.

Using table lift crank (F), raise head to

the point where head bore and column are

flush. Caution: Do not raise head any

farther or it may fall off column!

A

ladder will be needed to observe the

column through the top of the belt cover.

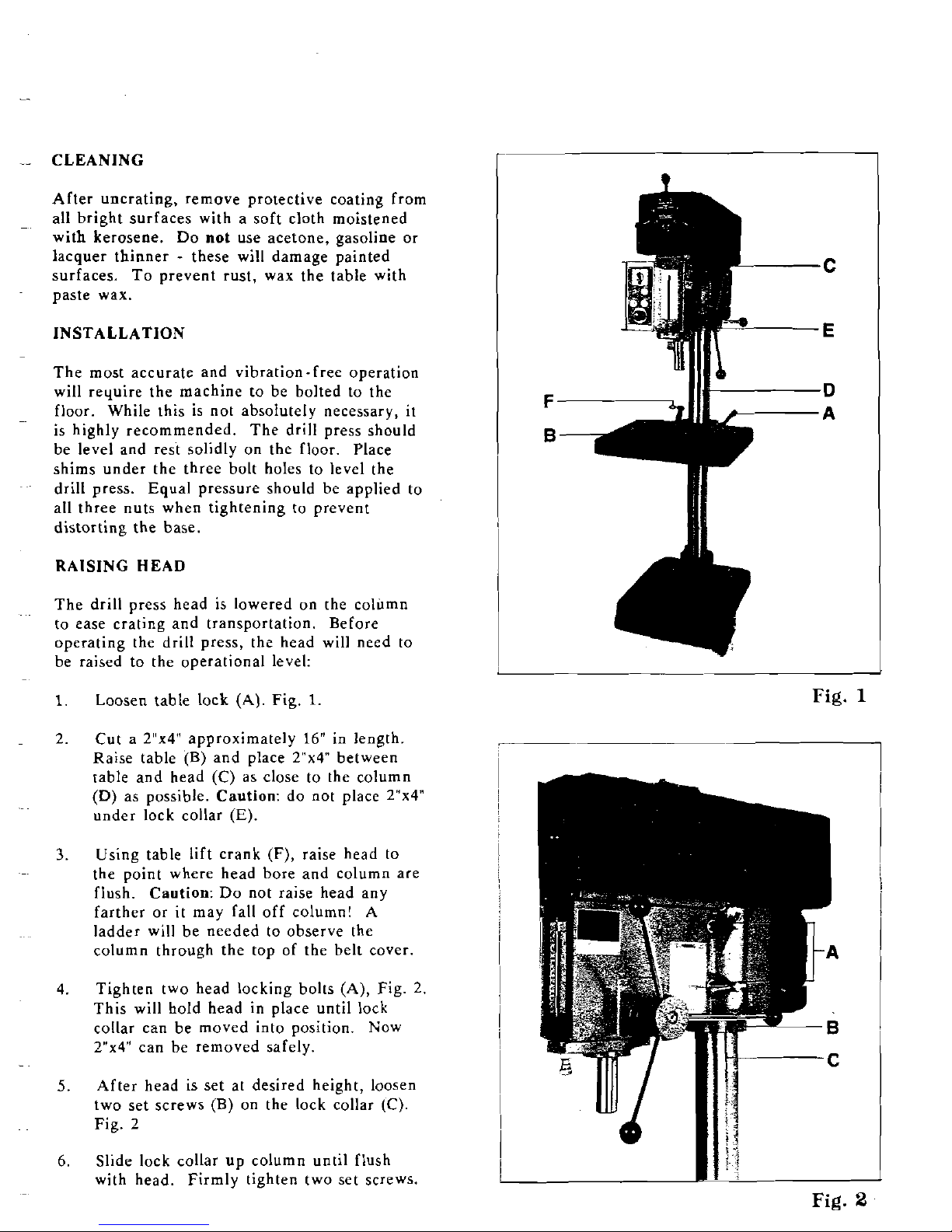

4.

Tighten two head locking bolts (A), Fig. 2.

This will hold head in place until lock

collar can be moved into position. Now

Z"x4" can be removed safely.

5.

After head is set at desired height, loosen

two set screws (B) on the lock collar

(C).

Fig. 2

6.

Slide lock collar up column until flush

with head.

Firmly tighten two set

scrcws.

1

Fig.

Fig.

Loading...

Loading...