Page 1

Extended Ethernet

EE2CL

User Manual

Page 2

Extended Ethernet User Manual

TABLE OF CONTENTS

1 OVERVIEW ................................................................................. 3

1.1 I

1.2 T

NTRODUCTION

1.1.1 EE2CL ............................................................................................... 3

ECHNICAL SPECIFICATION

1.2.1 Data Throughput over Cable Length ...................................................... 5

1.2.2 Power Supplied over Cable Length

............................................................................................ 3

.............................................................................. 4

(1)

(PSE = 48V) ................................... 5

2 INSTALLATION ............................................................................. 6

2.1 P

2.2 C

2.3 I

2.4 C

2.5 E

2.6 P

2.7 LED S

ACKAGE CONTENTS

ONFIGURATIONS

2.2.1 Physical Connections ........................................................................... 8

NSTALLATION METHOD

2.3.1 Compact ............................................................................................ 9

2.3.2 Rack-mount ..................................................................................... 11

OAXIAL CABLE CONNECTION

THERNET CABLE CONNECTION

OWER CONNECTIONS

TATUS

............................................................................................. 13

...................................................................................... 6

......................................................................................... 7

................................................................................... 9

......................................................................... 12

....................................................................... 12

.................................................................................. 12

3 TROUBLESHOOTING .................................................................... 14

4 SYSTEM EXAMPLE ....................................................................... 15

5 DIMENSIONS ............................................................................. 16

6 WARRANTY .............................................................................. 17

6.1 W

6.2 C

6.3 FCC ....................................................................................................... 18

ARRANTY INFORMATION

LASS A

ITE ............................................................................................ 18

.............................................................................. 17

7 INSTRUCTION OF DISASSEMBLY ...................................................... 18

Manual-EE2CL_Series-Rev1304.docx

Copyright © KBC Networks Ltd. 2013 Page 2 of 19 www.kbcnetworks.com

Page 3

Extended Ethernet User Manual

1 Overview

1.1 Introduction

This manual covers the EE2CL series. These units make it possible to upgrade

installed analogue cameras to high-quality digital IP cameras without the

expense of replacing existing coaxial cabling. Units are available in an extended

temperature range, compact wall-mount format that fits inside most camera

housings and can also be mounted into a 19” rack unit.

1.1.1 EE2CL

The KBC EE2CL series is a 10/100, IEEE 802.3 af/at PoE compliant, Ethernet line

driver providing excellent repeatable performance for today’s CCTV systems. The

line driver provides connectivity for up to four, 10/100Mbps IEEE standard twisted

pair copper port over a 75 Ω coaxial cable interface allowing new IP technology to

pass over existing legacy cable up to a distance of 1.5km

Play’ and are automatically configured for straight forward installation. Maximum

data rates of up to 100Mbps are achievable.

(1)

. The units are ‘Plug and

1. Transmission distances are for indication purposes only. Actual achievable transmission distances on site will depend on cable

type installed, quality and age of installation

Manual-EE2CL_Series-Rev1304.docx

Copyright © KBC Networks Ltd. 2013 Page 3 of 19 www.kbcnetworks.com

Page 4

Extended Ethernet User Manual

(1)

1.2 Technical Specification

Standards

IEEE Standard IEEE 802.3 10BASE-T

IEEE 802.3u 100BASE-TX

IEEE 802.3x Full Duplex

IEEE 802.3af/at

RJ45 Port (Ethernet)

Data Format Ethernet

Data Rate 10/100Mbps half / full duplex auto negotiation

Coax

Transmission Distance

Cable Type RG59 or similar

Cable Impedance 75Ω

1.5km / 5000ft

Electromagnetic compatibility

Interference

Class A

Power

Input voltage

Output 48Vdc / 0.8A / Optional 0.8 – 1.3A

Power Consumption 25W

100 – 240Vac, 50 – 60Hz

Mechanical

Dimensions (Compact W x H x D)

Weight 0.12Kg / 4.2oz

75mm x 45mm x 45mm

2.95” x 1.57” x 1.57”

Environmental

Operating temperature -40°C ~ +74°C / -40° ~ +165°F

Storage temperature -40°C ~ +74°C / -40° ~ +165°F

Relative humidity 0% ~ 85% non-condensing

Mean Time Between Failure >100,000 hours

Connectors

10/100 Electrical 1 x RJ45

Coax 1 x BNC, 75Ω coaxial

Power Jack socket, 2.5mm

Manual-EE2CL_Series-Rev1304.docx

Copyright © KBC Networks Ltd. 2013 Page 4 of 19 www.kbcnetworks.com

Page 5

Extended Ethernet User Manual

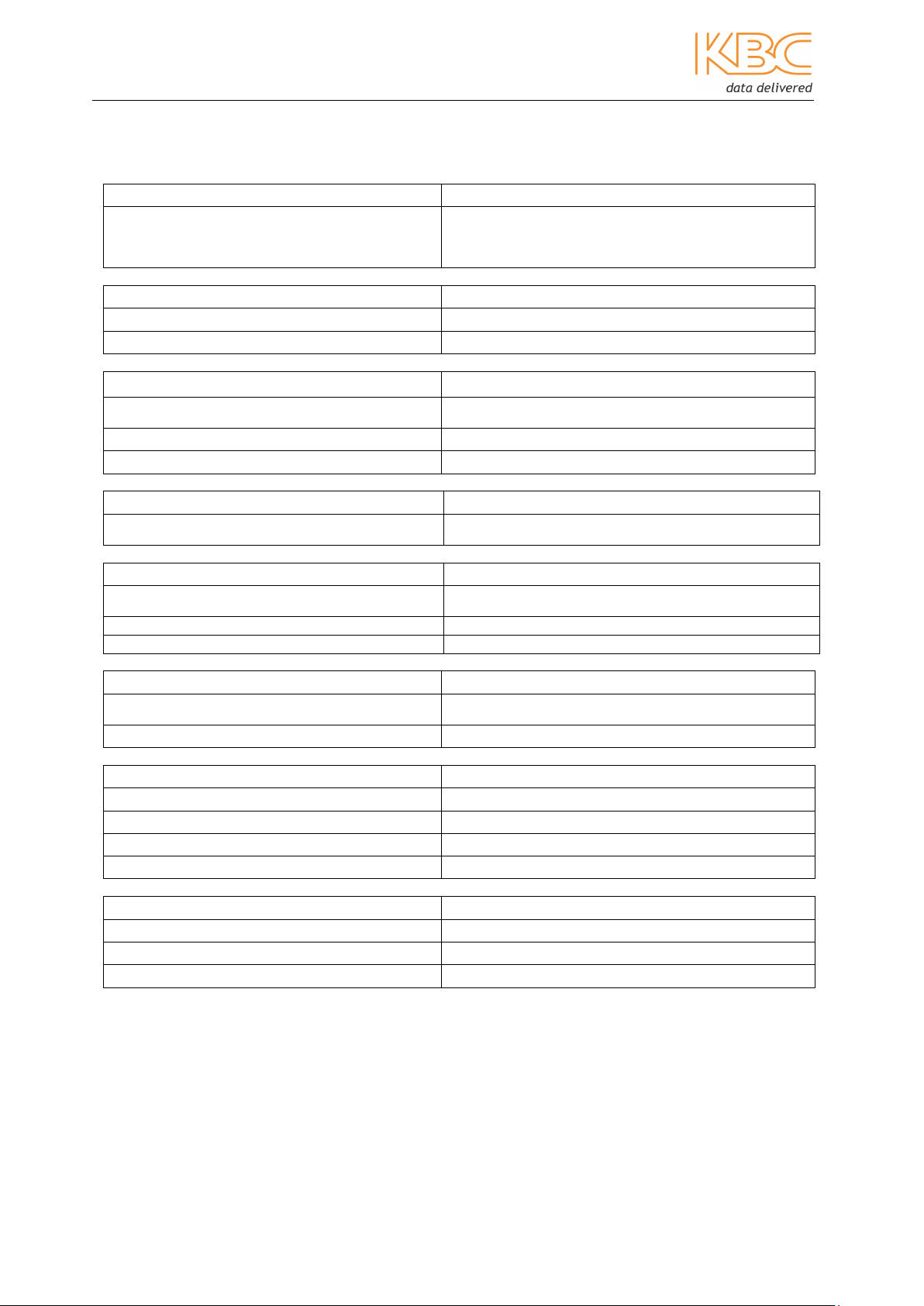

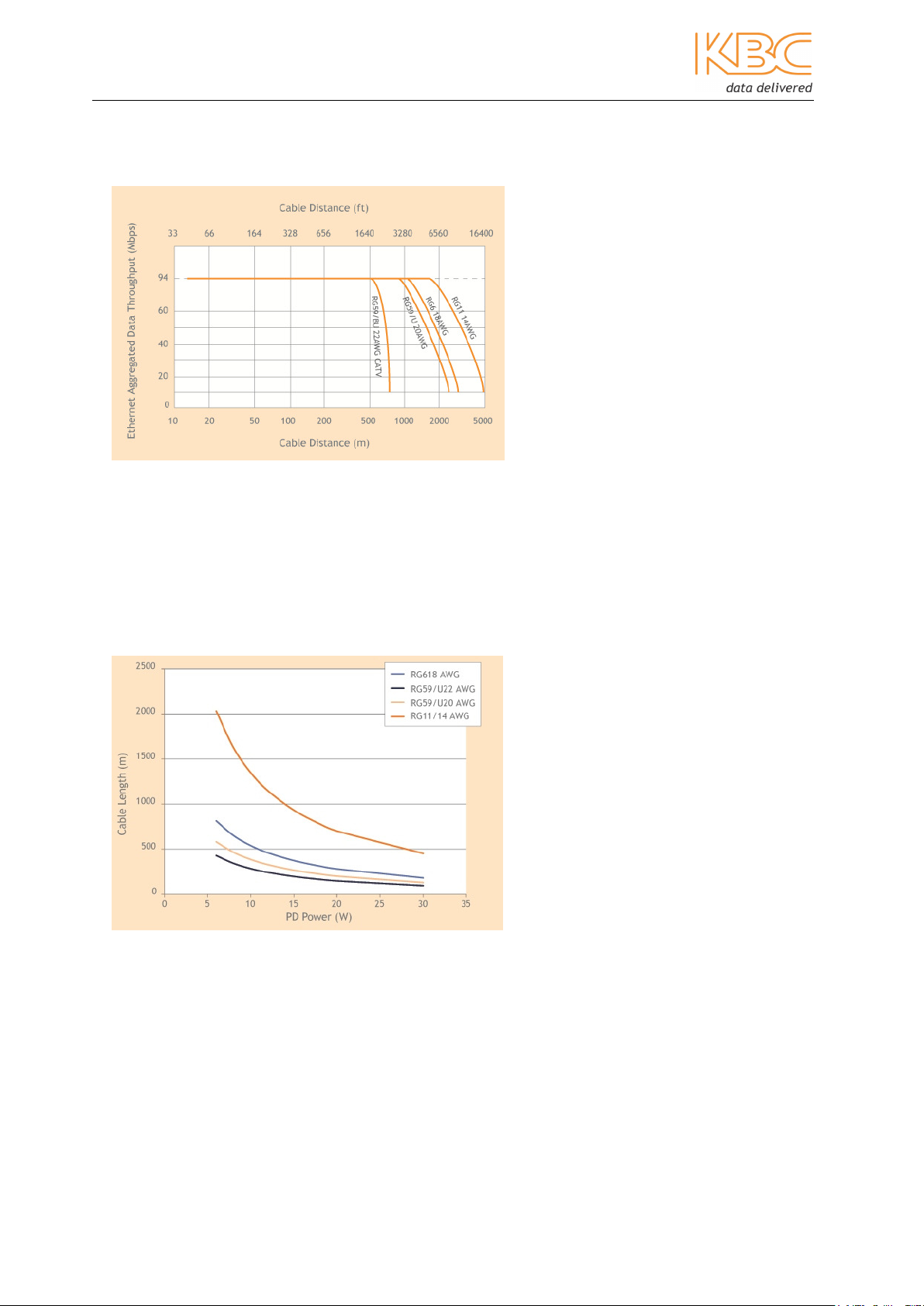

1. Transmission distances supplied are for indication

purposes only. Actual achievable transmission distances on site will depend on cable type installed

, quality

1.2.1 Data Throughput over Cable Length

1.2.2 Power Supplied over Cable Length

(1)

(PSE = 48V)

and age of installation.

Manual-EE2CL_Series-Rev1304.docx

Copyright © KBC Networks Ltd. 2013 Page 5 of 19 www.kbcnetworks.com

Page 6

Extended Ethernet User Manual

2 Installation

2.1 Package Contents

EE2CL-1KT

• 2 x Extended Ethernet units

• 1 x 48Vdc, 1.25A PoE Power Supply Unit

• Quick Start Guide

EE2CL-2KT

• 3 x Extended Ethernet units

• 1 x 48Vdc, 1.25A PoE Power Supply Unit

• 1 x BNC-T Splitter Adaptor

• Quick Start Guide

EE2CL-3KT

• 4 x Extended Ethernet units

• 1 x 48Vdc, 1.25A PoE Power Supply Unit

• 1 x 1:4 BNC Splitter Adaptor

• Quick Start Guide

EE2CL-4KT

• 5 x Extended Ethernet units

• 1 x 48Vdc, 1.25A PoE Power Supply Unit

• 1 x 1:4 BNC Splitter Adaptor

• Quick Start Guide

Manual-EE2CL_Series-Rev1304.docx

Copyright © KBC Networks Ltd. 2013 Page 6 of 19 www.kbcnetworks.com

Page 7

Extended Ethernet User Manual

The following units are also available as individual units:

EE2CL-1 Extended Ethernet unit

GS60A-48-P1J 48Vdc, 1.25A PoE power supply unit

EE2CL-RK 19” high density rack system

EE-BNC4 1:4 BNC Splitter Adaptor

EE-BNC2 BNC T-Splitter

Please contact you dealer or distributor if a part is missing or damaged within 10 days of

receiving products.

2.2 Configurations

Products are available in either compact or wall-mount packages, with the following

configurations:

Product Type Compact

EE2CL

Manual-EE2CL_Series-Rev1304.docx

Copyright © KBC Networks Ltd. 2013 Page 7 of 19 www.kbcnetworks.com

Page 8

Extended Ethernet User Manual

2.2.1 Physical Connections

Extended Ethernet 200 Series

EE2CL

www.kbcnetworks.com

BNC PoE

Coax Data

Power

(no analog video)

Manual-EE2CL_Series-Rev1304.docx

Copyright © KBC Networks Ltd. 2013 Page 8 of 19 www.kbcnetworks.com

Page 9

Extended Ethernet User Manual

2.3 Installation Method

2.3.1 Compact

Basic configuration

• Remove all the packaging materials and labels.

• Choose a Master EE2CL unit; this can be any of the units purchased.

• Connect the 48Vdc power supply to the Master EE2CL unit.

• Check that the blue LEDs on both EE2CL units are lit.

Connecting the EE2CL to the camera

• Mount the EE2CL near to the IP camera.

• Connect an RJ45 cable between the camera and the RJ45 connector on the

EE2CL unit.

• Connect the coaxial cable to the BNC connector on the EE2CL unit.

• If multiple camera units connect to a single Master unit then the 1:4 BNC

Splitter Adaptor or BNC-T adapter will be required.

Note: Depending on power requirements and cable distances power for both the Master

and Slave EE2CL units and the IP cameras can be supplied from the PSU located at the

Master EE2CL unit. For high power or long distance systems, multiple PSU units will be

required; see Section 2.6.

Connecting the Master EE2CL unit at the Control Room

• Mount the Master EE2CL unit in the Control Room.

• Connect the coaxial cable to the BNC connector on the EE2CL unit.

• Connect the supplied 48Vdc PSU to the EE2CL unit

• Connect the RJ45 cable from the EE2CL unit to the Control Room

equipment.

• The green LEDs will light when a network link is established and flash to

show when data traffic is being passed.

See section 2.7 for LED status.

Note:

If two or more Master EE2CL units are connected to the same switch within a

network, the units will need to be ‘joined’ to each other. You will need a small paperclip partially straightened to join EE2CL units; this is provided with the unit.

Manual-EE2CL_Series-Rev1304.docx

Copyright © KBC Networks Ltd. 2013 Page 9 of 19 www.kbcnetworks.com

Page 10

Extended Ethernet User Manual

Joining EE2CL units

• Remove all the packaging materials and labels.

• Choose an EE2CL unit (unit ‘A’); this can be any of the units purchased.

• Using a coaxial jumper lead, connect the chosen EE2CL unit (unit ‘A’) to one

of the other units (unit ‘B’) by attaching one EE2CL unit to each end of the

coaxial cable.

• Connect the 48Vdc power supply to the EE2CL unit ‘A’.

• Check that the blue LEDs on both EE2CL units are lit.

• Wait 20 seconds. Check that the green BNC LEDs on both EE2CL are ‘off’.

Note: If either of the green BNC LEDs remains ‘on’ then that unit has already been

‘joined’ to another EE2CL unit in a different group and will need to be ‘un-joined’ before

being ‘joined’ to the new unit. See the ‘un-joining’ instructions below.

• On the EE2CL unit ‘A’ (which is connected to the PSU) use the straightened

paper-clip to depress the push button for 2 seconds. This button can be

found slightly above the PoE LED.

• The blue Power LED will flash.

• Depress the same push-button on the EE2CL unit ‘B’ for 2 seconds.

• Wait for 10 seconds. The two units will now try to establish an encrypted

communication.

• Once the blue Power LEDs return to a steady condition the units have been

joined.

• If more EE2CL units need to be ‘joined’, disconnect EE2CL unit ‘B’ from

EE2CL unit ‘A’. Connect the new ‘un-joined’ EE2CL unit ‘C’ to EE2CL unit ‘A’.

• Repeat the joining instructions until all units in the group are ‘joined’ to the

EE2CL unit ‘A’.

Un-joining EE2CL units

• Disconnect the EE2CL unit from the old network.

• Connect a 48vdc PSU to the unit.

• Wait until the green BNC LED lights.

• Using the straightened paper-clip press the small push-button located

behind and slightly above the RJ45 LED.

• Wait until the blue LED turns off.

• Release the paper-clip.

• The green BNC and RJ45 LEDs will flash and then turn off.

• The green BNC LED will then switch on for 10 seconds and then switch off.

• The units are now un-joined.

Manual-EE2CL_Series-Rev1304.docx

Copyright © KBC Networks Ltd. 2013 Page 10 of 19 www.kbcnetworks.com

Page 11

Extended Ethernet User Manual

2.3.2 Rack-mount

• Remove all packaging material.

• For each of the 1:4 BNC Splitter Adaptors, push the BNC connectors through

the holes in the front panel of the rack and secure into place. Ensure that

the BNC connectors are properly positioned so that they do not have contact

with the metal rack, before clamping into place.

• Position the PSUs into the internal PSU brackets, they do not need to be

secured in place, ensure that the slot in the front is lined up with the PSU

mains pins.

• Position the EE2CL units into the internal brackets and secure with the nuts

and bolts provided with the rack.

• Attach the 1:4 BNC Splitter Adaptor to the connector on the EE2CL unit.

• Connect the kettle lead through the front panel into the PSUs.

• Switch the power on.

See section 2.7 for LED status.

Manual-EE2CL_Series-Rev1304.docx

Copyright © KBC Networks Ltd. 2013 Page 11 of 19 www.kbcnetworks.com

Page 12

Extended Ethernet User Manual

2.4 Coaxial Cable Connection

Connect the unit’s BNC socket to the coaxial cable. When a physical link over coaxial

cable is established and the units are powered up, the green BNC LED will light to show

that the unit has detected another unit and then flash to indicate there is link activity.

See section 2.7 for complete details of LED status.

2.5 Ethernet Cable Connection

The RJ45 port is adaptive and supports auto MDI/MDI-X connection. It can be connected

by straight through or cross-over type Cat5 or Cat 6 cables. The green RJ45 LED will

light to indicate a link connection and flash to show when data traffic is being passed.

See section 2.7 for complete details of LED status.

2.6 Power Connections

This EE2CL unit must be powered by the +48Vdc, 1.25A PoE power supply, this is

supplied with the unit and is connected using a 2.1mm barrel connector.

Note: For higher power or longer distance applications please contact KBC Networks.

Depending on power requirements and cable distances, power for both the Master and

Slave EE2CL units and the IP cameras can be supplied from the PSU located at the

Master EE2CL unit.

Manual-EE2CL_Series-Rev1304.docx

Copyright © KBC Networks Ltd. 2013 Page 12 of 19 www.kbcnetworks.com

Page 13

Extended Ethernet User Manual

For long distance systems up to two PSU units can be used as shown below:

2.7 LED Status

LED Status Description

Power

BNC

PoE

ON

OFF

ON

FLASH

OFF

ON

FLASH

Power is supplied to the unit

No power to the unit

Another EE2CL unit has been detected

Link activity

No link established

Link active

Ethernet activity and joining function

OFF

No link established

Manual-EE2CL_Series-Rev1304.docx

Copyright © KBC Networks Ltd. 2013 Page 13 of 19 www.kbcnetworks.com

Page 14

Extended Ethernet User Manual

3 Troubleshooting

When the device is powered on, the blue Power LEDs will light to indicate the

presence of power. If the power LEDs flash then the power supply is cycling on and

off due to overload conditions please check to see whether there are any of the

following:

• Wiring faults

• Excessive loading

If the BNC LED does not light after a wire is connected between two EE2CL units

please check the following:

• Verify that the cable connecting the two units is not greater than 1500m in

length

If the PoE LED does not light after a cable is connected to the port please check the

following:

• Verify that the cable being used is Cat5, 5e or 6

• Check that the power to both the EE2CL and the connected device are

switched on

• Check that all cables are firmly seated

• Check that the power adaptors are all functioning

If there is no video being passed through the system, please check that you are

using a managed Ethernet switch. The EE2CL unit will block unknown multicast

packets and hence the video will be blocked. IGMP is required for a properly

configured multi-cast network.

Manual-EE2CL_Series-Rev1304.docx

Copyright © KBC Networks Ltd. 2013 Page 14 of 19 www.kbcnetworks.com

Page 15

Extended Ethernet User Manual

4 System Example

Figure 4.1 EE2CL Typical System Application

Manual-EE2CL_Series-Rev1304.docx

Copyright © KBC Networks Ltd. 2013 Page 15 of 19 www.kbcnetworks.com

Page 16

Extended Ethernet User Manual

5 Dimensions

75mm

35mm

Extended Ethernet 200 Series

EE2CL

www.kbcnetworks.com

103mm

BNC PoE

Coax Data

(no analog video)

Power

14mm

45mm

45mm

28mm

Manual-EE2CL_Series-Rev1304.docx

Copyright © KBC Networks Ltd. 2013 Page 16 of 19 www.kbcnetworks.com

Page 17

Extended Ethernet User Manual

6 Warranty

6.1 Warranty Information

KBC extends the following LIMITED WARRANTY to the original owner/purchaser of this

product as follows:

- Five years from the date of initial sale for Ethernet switches & Extended Ethernet

products.

- Two years from the date of initial sale for all wireless and other network products.

- Five years from the date of initial sale for all fiber products.

1) If, within the specified warranty period, this product, or any part or portion thereof,

shall prove upon examination by KBC, to be defective in material or workmanship,

KBC will repair or replace such part or portion at KBC’s option. The warranty period

on the repaired or replaced part or portion of this product shall be limited to the

unexpired term of the original warranty. The buyer shall be responsible for all

shipping and transportation of the product to KBC for any performance under this

warranty.

2) Conditions and Exceptions:

a) Any accident to this product, any misuse or abuse, alternation, use in modified

form, or any attempt to repair this product shall void this warranty. These

conditions to the warranty include, but are not limited to, incorrect power

connections, physical damage due to mechanical shock, exposure to moisture,

and circuit modification.

b) SHOULD THIS PRODUCT PROVE DEFECTIVE FOLLOWING PURCHASE, THE BUYER,

NOT THE MANUFACTURER, DISTRIBUTOR, OR RETAILER, ASSUMES THE ENTIRE

COST OF ALL SERVICING OR REPAIR, EXCEPT AS OTHERWISE PROVIDED BY THE

TERMS OF THIS WARRANTY.

c) FOR BREACH OF ANY WRITTEN OR IMPLIED WARRANTY ON THIS PRODUCT, THE

BUYER IS LIMITED TO THE FOLLOWING DAMAGES. (1) THE COST OF LABOR TO

REPAIR OR REPLACE DEFECTIVE PARTS OR PORTIONS OF THIS PRODUCT, AND

(2) THE COST OF THE REPAIRED OR REPLACE PARTS OR PORTIONS OF THIS

PRODUCT.

d) NO OTHER EXPRESSED OR IMPLIED WARRANTIES HAVE BEEN MADE OR WILL BE

MADE ON BEHALF OF KBC WITH RESPECT TO THE SALE, REPAIR, INSTALLATION,

OPERATION, OR REPLACEMENT OF THIS PRODUCT. KBC DISCLAIMS ANY

IMPLIED WARRANTY OF MERCHANTABILITY OF THIS PRODUCT OR ITS FITNESS

FOR ANY PURPOSE, AND THE BUYER AGREES THAT THIS PRODUCT IS SOLD “AS

IS” AND THAT THE ENTIRE RISK OF QUALITY AND PERFORMANCE OF THIS

PRODUCT IS WITH THE BUYER, EXCEPT AS OTHERWISE PROVIDED BY THE

TERMS OF THIS WARRANTY.

e) Some states/jurisdictions do not allow exclusions or limitations of incidental or

consequential damages, or limitations on how long an implied warranty lasts, so

the above exclusions or limitations may not apply to you.

f) If you do not wish to be bound by any of the provisions in this warranty, please

return the product(s) immediately.

3) Contact your dealer regarding return authorizations for out of warranty repairs and

any further product information.

This warranty does not apply in Australia.

Manual-EE2CL_Series-Rev1304.docx

Copyright © KBC Networks Ltd. 2013 Page 17 of 19 www.kbcnetworks.com

Page 18

Extended Ethernet User Manual

6.2 Class A ITE

This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

6.3 FCC

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful Interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at this own expense.

7 Instruction of Disassembly

Instruction of Disassembly of KBC Product

(For EU Directive 2002/95/EEC-WEEE)

Tools required:

• No. 1 Phillips screwdriver

• No. 2 Phillips screwdriver

Steps for disassembly:

1. Remove tightening screws of box cover.

2. Remove cover plate.

3. Remove tightening screws for printed circuit board (PCB).

4. Take out all PCBs.

Notice: When a product reaches the end of its life – return to KBC.

Manual-EE2CL_Series-Rev1304.docx

Copyright © KBC Networks Ltd. 2013 Page 18 of 19 www.kbcnetworks.com

Page 19

data delivered

KBC Networks

25691 Atlantic Ocean Drive

Suite 3B

Lake Forest, CA 92630

U.S.A

Americas

Phone: 1-949-297-4930

Fax: 1-949-297-4933

KBC Networks Ltd., EMEA

KBC Networks Ltd.

Barham Court

Teston, Maidstone

Kent, ME18 5BZ

United Kingdom

Phone: +44(0)1622 618787

Fax: +44(0)20 7100 8147

Email:

Web: www.kbcnetworks.com

info@kbcnetworks.com

Loading...

Loading...