Page 1

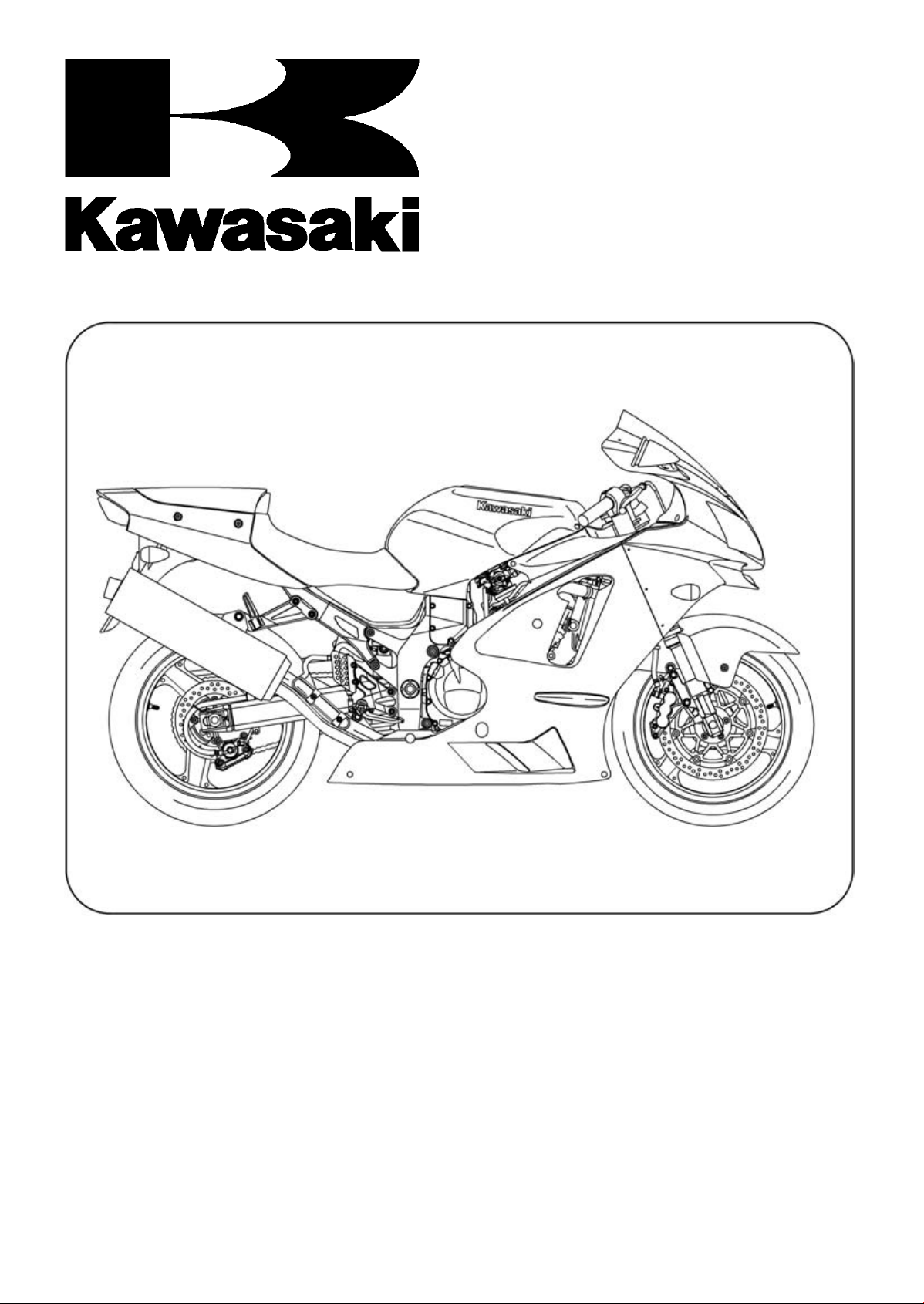

Ninja ZX-12R

Motorcycle

Service Manual

Page 2

Page 3

Quick R eference Guide

General Information 1 j

Periodic Maintenance 2 j

Fuel System (DFI) 3 j

Cooling System 4 j

Engine Top End 5 j

Clutch 6 j

Engine Lubrication System 7 j

Engine Removal/Installation 8 j

This quick reference guide will assist

you in locating a desired topic or procedure.

•Bend the pages back to match the

black tab of the desired chapter number with the black tab on the edge at

each table of contents page.

•Refer to the sectional table of contents

for the exact pages to locate the specific topic required.

Crankshaft/Transmission 9 j

Wheels/Tires 10 j

Final Drive 11 j

Brakes 12 j

Suspension 13 j

Steering 14 j

Frame 15 j

Electrical System 16 j

Troubleshooting 17 j

Page 4

Page 5

Ninja ZX-12R

Motorcycle

Service Manual

All r ights reserved. No parts of this publication may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means, electronic mechanical photocopying, recording or otherwise,

without the prior written permission of Quality Assurance Department/Consumer Products & Machinery

Company/Kawasaki Heavy Industries, Ltd., Japan.

No liability can be accepted for any inaccuracies or omissions in this publication, although every possible

care has been taken to make it as complete and accurate as possible.

The right is reserved to make changes at any time without prior notice and without incurring an obligation

to make such changes to products manufactured previously. See your Motorcycle dealer for the latest

information on product improvements incorporated after this publication.

All information contained in this publication is based on the latest product information available at the time

of publication. Illustrations and photographs in this publication are intended for reference use only and may

not depict actual model component parts.

© 2002 Kawasaki Heavy Industries, Ltd. Fourth Edition (1) : Mar. 5, 2004 (K)

Page 6

LIST OF ABBREVIATIONS

A

ABDC after bottom dead center

AC alternating current min minute(s)

ATDC after top dead center N newton(s)

BBDC before bottom dead center Pa pascal(s)

BDC bottom dead center PS horsepower

BTDC before top dead center psi pound(s) per square inch

°C degree(s) Celsius r revolution

DC direct current rpm revolution(s) per minute

F farad(s) TDC top dead center

°F degree(s) Fahrenheit TIR total indicator reading

ft foot, feet V volt(s)

g gram(s) W watt(s)

h hour(s) Ω ohm(s)

L liter(s)

ampere(s)

lb

m

pound(s)

meter(s)

Read OWNER’S MANUAL before operating.

Page 7

EMISSION CONTROL INFORMATION

To protect the environment in which we all live, Kawasaki has incorporated crankcase emission (1) and exhaust emission (2) control systems in compliance with applicable regulations of

the United States Environmental Protection Agency and California Air Resources Board. Additionally, Kawasaki has incorporated an evaporative emission control system (3) in compliance

with applicable regulations of the California Air Resources Board on vehicles sold in California

only.

1. Crankcase Emission Control System

This system eliminates the release of cranckcase vapors into the atmosphere. Instead, the

vapors are routed through an oil separator to the inlet side of the engine. W hile the engine is

operating, the vapors are drawn into combustion chamber, where they are burned along with the

fuel and air supplied by the fuel injection system.

2. Exhaust Emission Control System

This system reduces the amount of pollutants discharged into the atmosphere by the exhaust

of this motorcycle. The fuel, ignition, and exhaust systems of this motorcycle have been carefully

designed and constructed to ensure an efficient engine with low exhaust pollutant levels.

The exhaust system of this model motorcycle manufactured primarily for sale in California in-

cludes a catalytic converter system.

3. Evaporative Emission Control System

Vapors caused by fuel evaporation in the fuel system are not vented into the atmosphere. In-

stead, fuel vapors are routed into the running engine to be burned, or stored in a canister when

the engine is stopped. Liquid fuel is caught by a vapor separator and returned to the fuel tank.

The Clean Air Act, which is the Federal law covering motor vehicle pollution, contains what is

commonly referred to as the Act’s " tampering provisions."

"Sec. 203(a) The following acts and the causing thereof are prohibited...

(3)(A) for any person to remove or render inoperative any device or element of design installed

on or in a motor vehicle or motor vehicle engine in compliance with regulations under this

title prior to its sale and delivery to the ultimate purchaser, or for any manufacturer or dealer

knowingly to remove or render inoperative any such device or element of design after such

sale and delivery to the ultimate purchaser.

(3)(B) for any person engaged in the business of repairing, servicing, selling, leasing, or trading

motor vehicles or motor vehicle engines, or who operates a f leet of m otor vehicles knowingly to remove or render inoperative any device or element of design installed on or in a

motor vehicle or motor vehicle engine in compliance with regulations under this title following its sale and delivery to the ultimate purchaser..."

NOTE

The phrase "remove or render inoperative any device or element of design" has been generally

○

interpreted a s follows :

1. Tampering does not include the temporary removal or rendering inoperative of devices or elements of design in o rder to perform maintenance.

2. Tampering could include:

a.Maladjustment of vehicle components such that the emission standards are ex-

ceeded.

b.Use of replacement parts or accessories which adversely affect the performance

or durability of the motorcycle.

c.Addition of components or accessories that result in the vehicle exceeding the stan-

dards.

d.Permanently removing, disconnecting, or rendering inoperative any component or

element of design of the emission control systems.

Page 8

WE RECOMMEND THAT ALL DEALERS OBSERVE THESE PROVISIONS OF FEDERAL LAW,

THEVIOLATIONOFWHICHISPUNISHABLEBYCIVILPENALTIESNOTEXCEEDING

$10,000 PER VIOLATION.

TAMPERING WITH NOISE CONTROL SYSTEM PROHIBITED

Federal law prohibits the following acts or the causing thereof: (1) The removal or rendering

inoperative by any person other than for purposes of maintenance, repair, or replacement, of any

device or element of design incorporated into any new vehicle for the purpose of noise control

prior to its sale or delivery to the ultimate purchaser or while it is in use, or (2) the use of the

vehicle after such device or element of design has been removed or rendered inoperative by

any person.

Among those acts presumed to constitute tampering are the acts listed below:

Replacement of the original exhaust system or muffler with a component not in compliance

•

with Federal regulations.

Removal of the muffler(s) or any internal portion of the muffler(s).

•

Removal of the air box or air box cover.

•

Modifications to the muffler(s) or air inlet system by cutting, drilling, or other means if such

•

modifications result in increased noise levels.

Page 9

Foreword

This manual is designed primarily for use by

trained mechanics in a properly equipped shop.

However, it contains enough detail and basic information to make it useful t o the owner who desires to perform his own basic maintenance and

repair work. A basic knowledge of mechanics,

the proper use of tools, and workshop procedures must be understood in order to carry out

maintenance and repair satisfactorily. Whenever the owner has insufficient experience or

doubts his ability to do the work, all adjustments, maintenance, and repair should be carried out only by qualified mechanics.

In order to perform the work efficiently and

to avoid costly mistakes, read the text, thoroughly familiarize yourself with the procedures

before starting work, and then do the work carefully in a clean area. Whenever special tools or

equipment are specified, do not use makeshift

tools or equipment. Precision measurements

can only be made if the proper instruments are

used, and the use of substitute tools may adversely affect safe operation.

For the duration of the warranty period,

we recommend that all repairs and scheduled

maintenance be performed in accordance with

this service manual. Any owner maintenance or

repair procedure not performed in accordance

with this manual may void the warranty.

To get the longest life out of your vehicle:

Follow the Periodic M aintenance Chart in the

•

Service Manual.

Be alert for problems and non-scheduled

•

maintenance.

Use proper tools and genuine Kawasaki Mo-

•

torcycle parts. Special tools, gauges, and

testers that are necessary when servicing

Kawasaki motorcycles are introduced by the

Special Tool Catalog or Manual. Genuine

parts provided as spare parts are listed in the

Parts Catalog.

Follow the procedures in this manual care-

•

fully. Don’t take shortcuts.

Remember to keep complete records of main-

•

tenance and repair with dates and any new

parts installed.

How to Use This Manual

In this manual, the product is divited into its

major systems and these systems make up

the manual’s chapters. The Quick Reference

Guide shows you all of the product’s system

and assists in locating their chapters. Each

chapter in turn has its own comprehensive

Table of Contents.

For example, if you want ignition coil information, use the Quick Reference Guide to locate

the Electrical System chapter. Then, use the

Table of Contents on the first page of the chapter to find the Ignition Coil section.

Whenever you see these WARNING and

CAUTION symbols, heed their instructions!

Always follow safe operating and maintenance

practices.

WARNING

This warning symbol identifies special

instructions or procedures which, if not

correctly followed, could result in per-

sonal injury, or loss of life.

CAUTION

This caution sym bol identifies special

instructions or procedures which, if not

strictly observed, could result in dam-

age to or destruction of equipment.

This m anual contains four more symbols (in

addition to WARNING and CAUTION) which will

help you distinguish different types of information.

NOTE

This note symbol indicates points of par-

○

ticular interest for more efficient and con-

venient operation.

Indicates a procedural step or work to be

•

done.

Indicates a procedural sub-step or how to do

○

the work of the procedural step it follows. It

also precedes the text of a NOTE.

Indicates a conditional step or what action to

take based on the results of the test or inspec-

tion in the procedural step or sub-step it fol-

lows.

In most chapters an exploded view illustration

of the system components follows the Table of

Contents. In these illustrations you will find the

instructions indicating which parts require specified tightening torque, oil, grease or a locking

agent during assembly.

Page 10

Page 11

GENERAL INFORMATION 1-1

General Information

Table of Contents

Before Servicing ..................................................................................................................... 1-2

Model Identification................................................................................................................. 1-5

General Specifications............................................................................................................ 1-6

Technical Information – KAWASAKI LOW EXHAUST EMISSION SYSTEM ......................... 1-9

Technical Information – Monocoque Frame . .......................................................................... 1-12

Technical Information – Spark Plug ........................................................................................ 1-13

Technical Information – Immobilizer System (ZX1200-B3)..................................................... 1-14

Torque and Locking Agent...................................................................................................... 1-17

Special Tools and Sealant ...................................................................................................... 1-22

Cable, W ire, and Hose Routing (ZX1200-B1/B2) ................................................................... 1-29

Cable, W ire, and Hose Routing (ZX1200-B3) ........................................................................ 1-46

Unit Conversion Table ............................................................................................................ 1-60

1

Page 12

1-2 GENERAL INFORMATION

Before Servicing

Before starting to service a motorcycle, careful reading of the applicable section is recommended to

eliminate unnecessary work. Photographs, diagrams, notes, cautions, warnings, and detailed descriptions have been included wherever necessary. Nevertheless, even a detailed account has limitations,

a certain amount of basic knowledge is also required for successful work.

Especially note the following:

(1) Dirt

Before removal and disassembly, clean the motorcycle. Any dirt entering the engine or other

parts will work as an abrasive and shorten the life of the motorcycle. For the same reason, before

installing a new part, clean off any dust or metal filings.

(2) Battery Cables

Disconnect the ground (–) cable f rom the battery before performing any disassembly operations

on the motorcycle. This prevents the engine from accidentally turning over while work is being

carried out, sparks from being generated while disconnecting the leads from electrical parts, as

well as damage to the electrical parts themselves. For reinstallation, first connect the positive

cable to the positive (+) terminal of the battery.

(3) Installation, Assembly

Generally, installation or assembly is the reverse of removal or disassembly. But if this Service

Manual has installation or assembly procedures, follow them. Note parts locations and cable,

lead, and hose routing during removal or disassembly so they can be installed or assembled in

the same way. It is preferable to mark and record the locations and routing as much as possible.

(4) Tightening Sequence

Generally, when installing a part with several bolts, nuts, or screws, start them all in their holes

and tighten them to a snug fit. Then tighten them evenly in a cross pattern. This is to avoid

distortion of the part and/or causing gas or oil leakage. Conversely when loosening the bolts,

nuts, or screws, first loosen all of them by about a quarter turn and then remove them. Where

there is a tightening sequence indication in this Service Manual, the bolts, nuts, or screws must

be tightened in the order and method indicated.

(5) Torque

When torque values are given in this Service Manual, use them. Either too little or too much

torque may lead to serious damage. Use a good quality, reliable torque wrench.

(6) Force

Common sense should dictate how much force is necessary in assembly and disassembly. If

a part seems especially difficult to remove or install, stop and examine what m ay be causing the

problem. Whenever tapping is necessary, tap lightly using a wooden or plastic-faced mallet. Use

an impact driver for screws (particularly for the removal of screws held by a locking agent) in order

to avoid damaging the screw heads.

(7) Edges

Watch for sharp edges, especially during major engine disassembly and assembly. Protect your

hands with gloves or a piece of thick cloth when lifting the engine or turning it over.

(8) High-Flash Point Solvent

A high-flash point solvent is recommended to reduce fire danger. A commercial solvent commonly available in North America is Stoddard solvent (generic name). Always follow manufacturer

and container directions regarding the use of any solvent.

(9) Gasket, O-ring

Do not reuse a gasket or O-ring once it has been in service. The mating surfaces around the

gasket should be free of foreign matter and perfectly smooth to avoid oil or compression leakage.

(10)Liquid Gasket, Non-Permanent Locking Agent

Follow manufacturer’s directions for cleaning and preparing surfaces where these compounds

will be used. Apply sparingly. Excessive amounts may block engine oil passages and cause serious damage. An example of non-permanent locking agent commonly available in North America

is Loctite Lock’n Seal (Blue).

(11) Press

A part installed using a press or driver, such as a wheel bearing, should first be coated with oil

on its outer or inner circumference so that it will go into place smoothly.

Page 13

GENERAL INFORMATION 1-3

Before Servicing

(12)Ball Bearing and Needle Bearing

Do not remove a ball bearing or a needle bearing unless it is absolutely necessary. Replace

any ball or needle bearings that were removed with new ones, as removal generally damages

bearings. Install bearings with the marked side facing out applying pressure evenly with a suitable

driver. Only press on the race that forms the press fit with the base component to avoid damaging

the bearings. This prevents severe stress on the balls or needles and races, and prevent races

and balls or needles from being dented. Press a ball bearing until it stops at the stopper in the

hole or on the shaft.

(13)Oil Seal and Grease Seal

Replace any oil or grease seals that were removed with new ones, as removal generally damages seals. When pressing in a seal which has manufacturer’s marks, press it in with the marks

facing out. Seals should be pressed into place using a suitable driver, which contacts evenly with

the side of seal, until the face of the seal is even w ith the end of the hole. Before a shaft passes

through a seal, apply little high temperature grease on the lips to reduce rubber to metal friction.

(14)Circlip, Retaining Ring, and Cotter Pin

Replace any circlips and retaining rings, and cotter pins that were removed with new ones, as

removal weakens and deforms them. When installing circlips and retaining rings, take care to

compress or expand them only enough to install them and no more.

(15)Lubrication

Engine wear is generally at its maximum while the engine is warming up and before all the

rubbing surfaces have an adequate lubricative film. During assembly, oil or grease (whichever

is more suitable) should be applied to any rubbing surface which has lost its lubricative film. Old

grease and dirty oil should be cleaned off. Deteriorated grease has lost its lubricative quality and

may contain abrasive foreign particles.

Don’t use just any oil or grease. Some oils and greases in particular should be used only in

certain applications and may be harmful if used in an application for which they are not intended.

This manual makes reference to molybdenum disulfide grease (MoS

oil in the assembly of certain engine and chassis parts. The molybdenum disulfide oil is a mixture

of engine oil and molybdenum disulfide grease with a weight ratio (10 : 1), which can be made in

your work shop. Always check manufacturer recommendations before using such special lubricants.

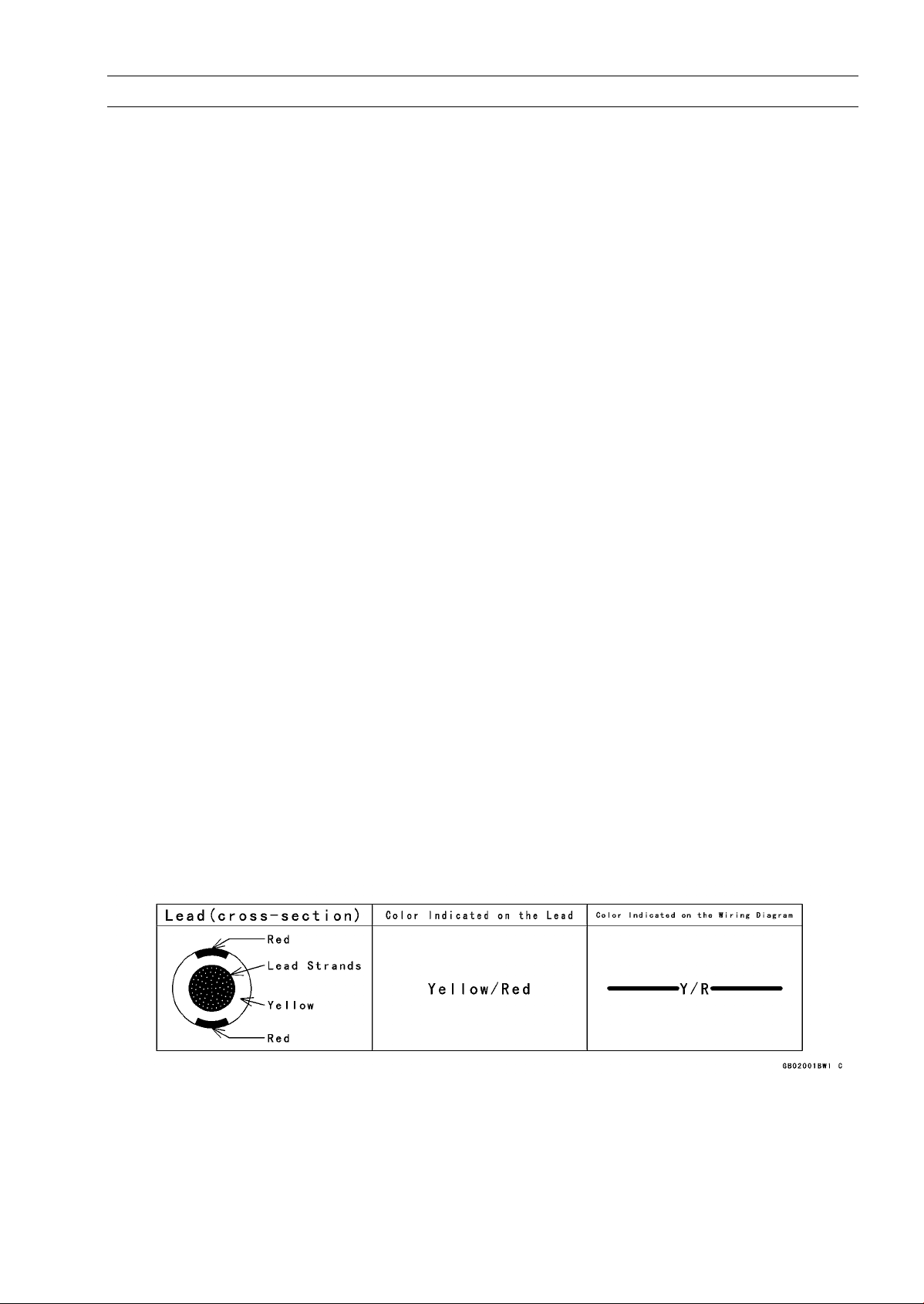

(16)Electrical Leads

All the electrical leads are either single-color or two-color and, with only a few exceptions, must

be connected to leads of the same color. On any of the two-color leads there is a greater amount

of one color and a lesser amount of a second color, so a two-color lead is identified by first the

primary color and then the secondary color. For example, a yellow lead with thin red stripes is

referred to as a "yellow/red" lead; it would be a "red/yellow" lead if the colors were reversed to

make red the main color .

2) and molybdenum disulfide

(17)Replacement Parts

When there is a replacement instruction, replace these parts with new ones every time they are

removed. These replacement parts will be damaged or lose their original function once removed.

Page 14

1-4 GENERAL INFORMATION

Before Servicing

(18)Inspection

When parts have been disassembled, visually inspect these parts for the following conditions

or other damage. If there is any doubt as to the condition of them, replace them with new ones.

Abrasion Crack Hardening Warp

Bent Dent Scratch Wear

Color change Deterioration Seizure

(19)Specifications

Specification terms are defined as follows:

"Standards" show dimensions or performances which brand-new parts or systems have.

"Service Limits" indicate the usable limits. If the measurement shows excessive wear or dete-

riorated performance, replace the damaged parts.

(20)Instrument

Use a meter that has enough accuracy for an accurate measurement.

Read the manufacturer’s instructions thoroughly before using the meter.

Incorrect values may lead to improper adjustments.

Page 15

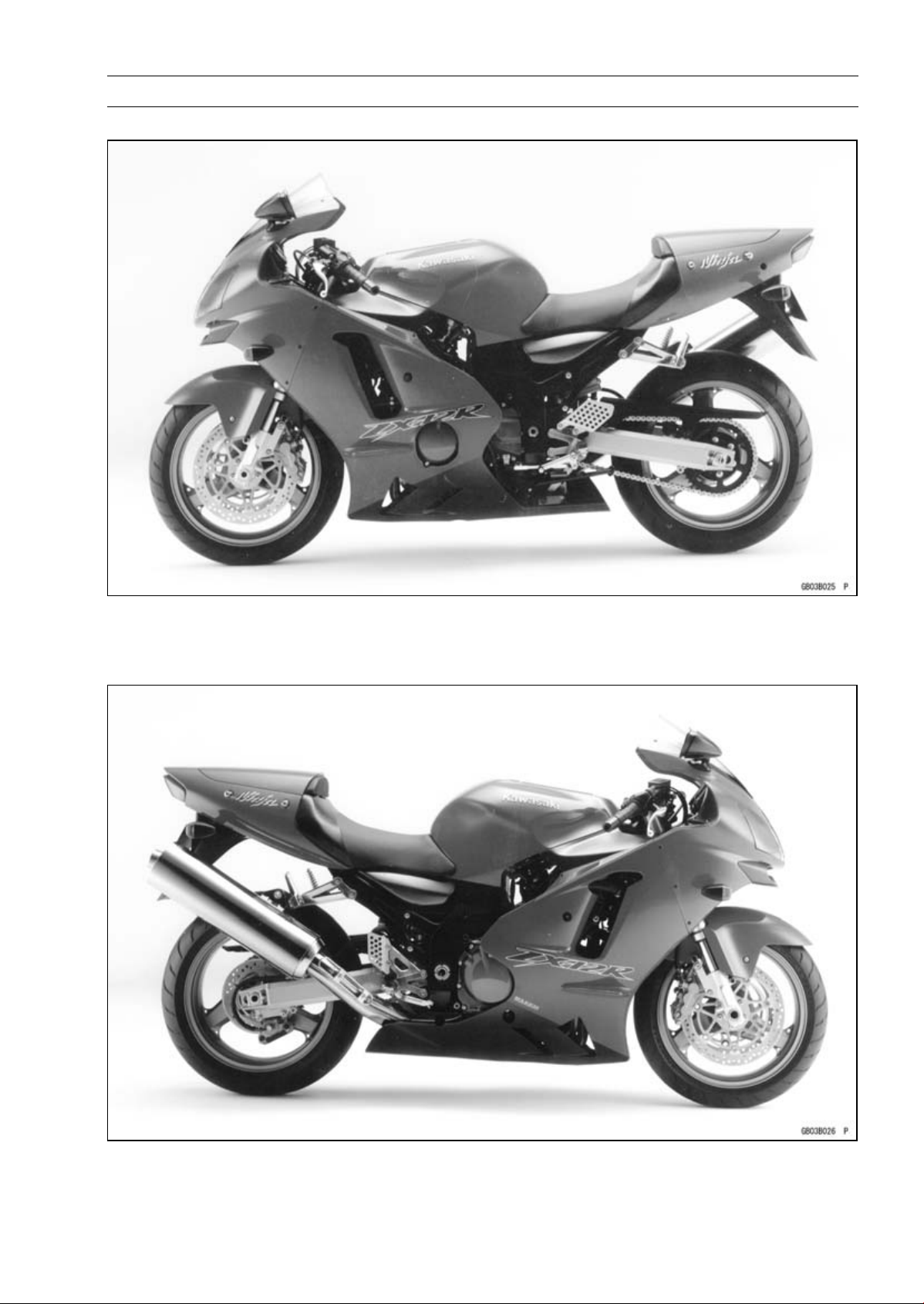

Model Identification

ZX1200-B1 Left Side View

GENERAL INFORMATION 1-5

ZX1200-B1 Right Side View

Page 16

1-6 GENERAL INFORMATION

General Specifications

Items ZX1200-B1 ∼ B3

Dimensions

Overall Length 2 085 mm (82.09 in.)

Overall Width 740 mm (29.13 in.)

Overall Height 1 200 mm (47.24 in.)

Wheelbase 1 450 mm (57.09 in.)

Road Clearance 120 mm (4.72 in.)

Seat Height 820 mm (32.28 in.)

Dry Mass 210 kg (463 lb)

Curb Mass:

Front 125 kg (276 lb)

Rear 121 kg (267 lb)

Fuel Tank Capacity 19.0 L (5.0 US gal)

Performance

Minimum Turning Radius 3.0 m (9.8 ft)

Engine

Type 4-stroke, DOHC, 4-cylinder

Cooling System Liquid-cooled

Bore and Stroke 83.0 × 55.4 mm (3.27 × 2.18 in.)

Displacement 1 199 mL (73.16 cu in.)

Compression Ratio 12.2

Maximum Horsepower (H) 131 kW (178 PS) @9 500 r/min (rpm),

(AU) ZX1200-B1/B2: 130 kW (177 PS) @10 500 r/min (rpm),

(AU) ZX1200-B3: 131 kW (178 PS) @10 500 r/min (rpm),

(HR) 78.2 kW (106.4 PS) @8 500 r/min (rpm),

(MY) ZX1200-B1/B2: 131 kW (178 PS) @ 9 500 r/min ( rpm),

(MY) ZX1200-B3: 128 kW (174 PS) @9 500 r/min (rpm)

(US), (CA) – – –

Maximum Torque (H, AU) 134 N·m (13.7 kgf·m, 99 ft·lb) @7 500 r/min (rpm),

(MY) ZX1200-B1/B2: 134 N·m (13.7 kgf·m, 99 ft·lb) @7 500

r/min (rpm),

(MY) ZX1200-B3: 130 N·m ( 13.3 kgf·m, 96 ft·lb) @7 500 r/min

(rpm),

(HR) 111 N·m (11.3 kgf·m, 82 ft·lb) @5 000 r/min (rpm),

(US), (CA) – – –

Carburetion System FI (Fuel Injection), ZX1200-B1/B2: MIKUNI 46 EIS × 4

ZX1200-B3: KEIHIN ( 46 × 4)

Starting System Electric starter

Ignition System Battery and coil (transistorized)

Timing Advance Electronically advanced (digital igniter in ECU)

Ignition Timing 10° BTDC @1 000 r/min (rpm)

Spark Plugs NGK CR9EKPA

Cylinder Numbering Method Left to right, 1-2-3-4

Firing Order 1-2-4-3

Page 17

GENERAL INFORMATION 1-7

General Specifications

Items ZX1200-B1 ∼ B3

Valve Timing:

Inlet:

Open 46° BTDC

Close 74° ABDC

Duration 300°

Exhaust:

Open 69° BBDC

Close 45° ATDC

Duration 294°

Lubrication System Forced lubrication (wet sump with cooler)

Engine Oil:

Grade API SE, SF or SG

API SH or SJ with JASO MA

Viscosity

Capacity 3.6 L (3.8 US qt)

Drive Train

Primary Reduction System:

Type Gear

Reduction Ratio 1.596 (83/52)

Clutch Type Wet, multi disc

Transmission:

Type 6-speed, constant mesh, return shift

Gear Ratios:

1st 2.429 (34/14)

2nd

3rd

4th

5th 1.130 (26/23)

6th 1.033 (31/30)

Final Drive System:

Type Chain drive

Reduction Ratio 2.556 (46/18)

Overall Drive Ratio 4.215 @Top gear

Frame

Type Press backbone

Caster (Rake Angle) 23.5°

Trail

Front Tire:

Type Tubeless

Size 120/70 ZR17 M/C (58W)

Rear Tire:

Type Tubeless

Size 200/50 ZR17 M/C (75W)

SAE 10W-40

1.824 (31/17)

1.440 (36/25)

1.250 (30/24)

98 mm (3.86 in.)

Page 18

1-8 GENERAL INFORMATION

General Specifications

Items ZX1200-B1 ∼ B3

Front Suspension:

Type

Wheel Travel

Rear Suspension:

Type Swingarm (uni-trak)

Wheel Travel 140 mm (5.51 in.)

Brake Type:

Front Dual discs

Rear Single disc

Electrical Equipment

Battery 12 V 12 Ah

Headlight:

Type Semi-sealed beam

Bulb 12 V 60/55 W (quartz-halogen) × 2

Tail/Brake Light 12 V 5/21 W × 2

Alternator:

Type Three-phase AC

Rated Output 31 A/14 V @ 5 000 r/min (rpm)

Telescopic fork (upside-down)

120 mm (4.72 in.)

Specifications are subject to change without notice, and may not apply to every country.

AU: Australian Model

US: U.S.A. Model

CA: Canadian Model

MY: Malaysian Model

HR: WVTA Approval Model, Honeycomb Catalytic Converter (Restricted Power)

H: WVTA Approval Model, Honeycomb Catalytic Converter

Page 19

GENERAL INFORMATION 1-9

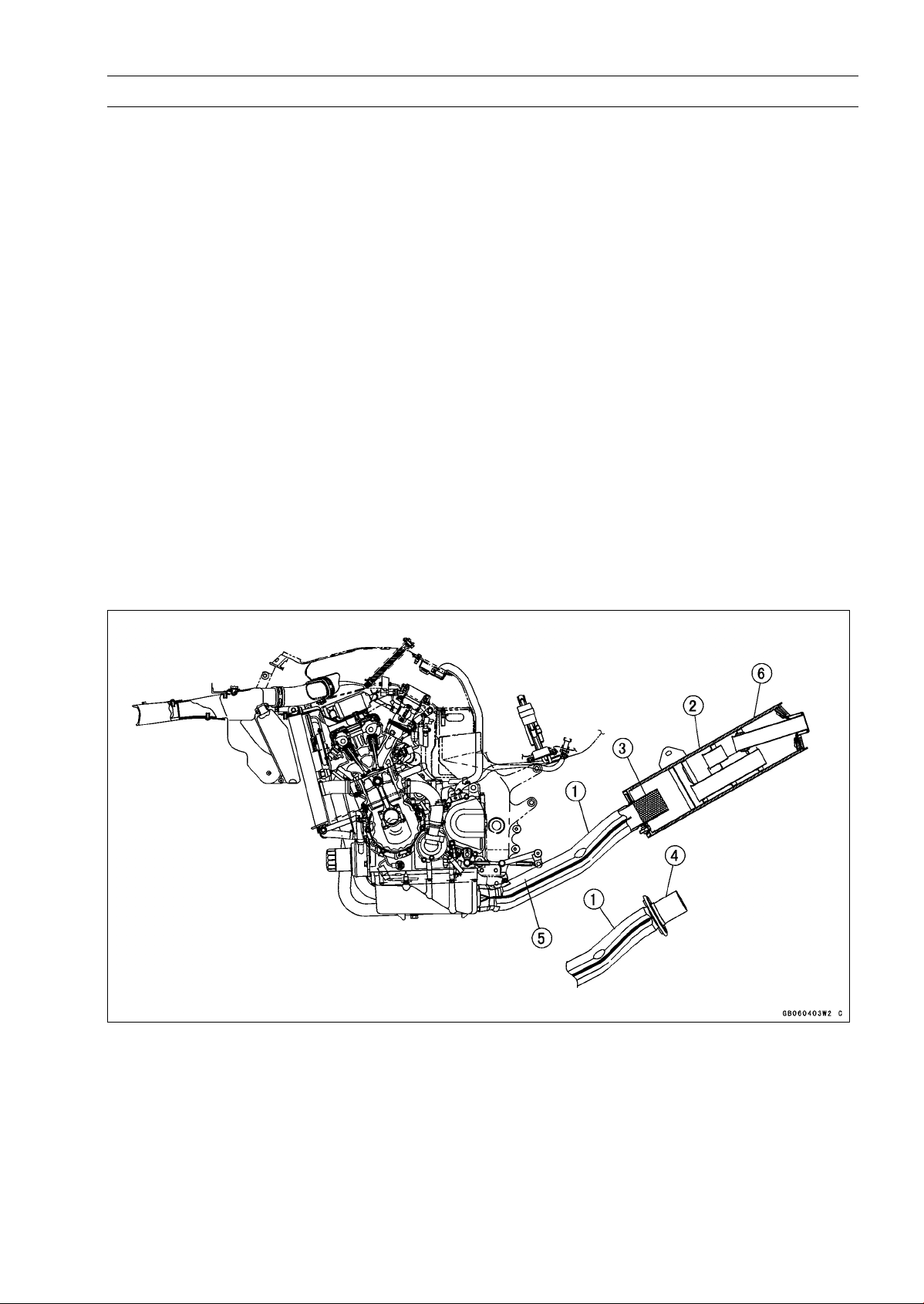

Technical Information – KAWASAKI LOW EXHAUST EMISSION SYS TEM

Since the emission regulations become more severe, Kawasaki has adopted a type of simplified

KAWASAKI LOW EX HAUST EMISSION SYSTEM (KLEEN), which have no catalyst protection system, according to each regulation of different countries.

The muffler with built-in catalyst has the same durability as the conventional muffler, however, do

not use leaded gasoline and do not coast with the ignition system OFF. Running the engine without

ignition damages catalyst.

Refer to the ZX900E Service Manual (Part No. 99924-1255) for more information about the KLEEN

(theory, maintenance, and handling precautions), including the secondary air injection system.

Honeycomb Type Catalytic Converter

The converter is a three-way catalytic converter, and its surface is covered with alumina upon which

○

platinum and rhodium are applied, and has a cylindrical metalic honeycomb structure made by bend-

ing a corrugated sheet and a flat sheet of stainless steel into a spiral of increasing diameter. The

honeycomb structure is convenient for the catalytic converter because it has a large surface area

but small size to react effectively and has low exhaust resistance. In addition, its inherent strength

helps resist vibration, and has simple structure welded directly on the silencer.

Generally, the temperature of t he exhaust gas must be higher than activation temperature, so the

○

converters are installed in the exhaust manifold rear end where the temperature of exhaust gas is

still high. And, the converters will be activated even under low load conditions.

After the exhaust gas is diluted with the secondary air injection, the catalytic converter works well

○

because of rich oxygen to reduce CO, HC, and NO

emission within regulation.

This type of converter works more efficiently as a three-way catalytic converter to reduce CO, HC,

○

and NO

x than the pipe type catalytic converter because of its more and denser catalysts.

x. Accordingly, we can keep the exhaust gas

1. Manifold

2. Silencer

3. Honeycomb Type Catalyst

4. Non-Catalyst

5. Mark for Manifold

6. Mark for Silencer

Page 20

1-10 GENERAL INFORMATION

Technical Information – KAWASAKI LOW EXHAUST EMISSION SYSTEM

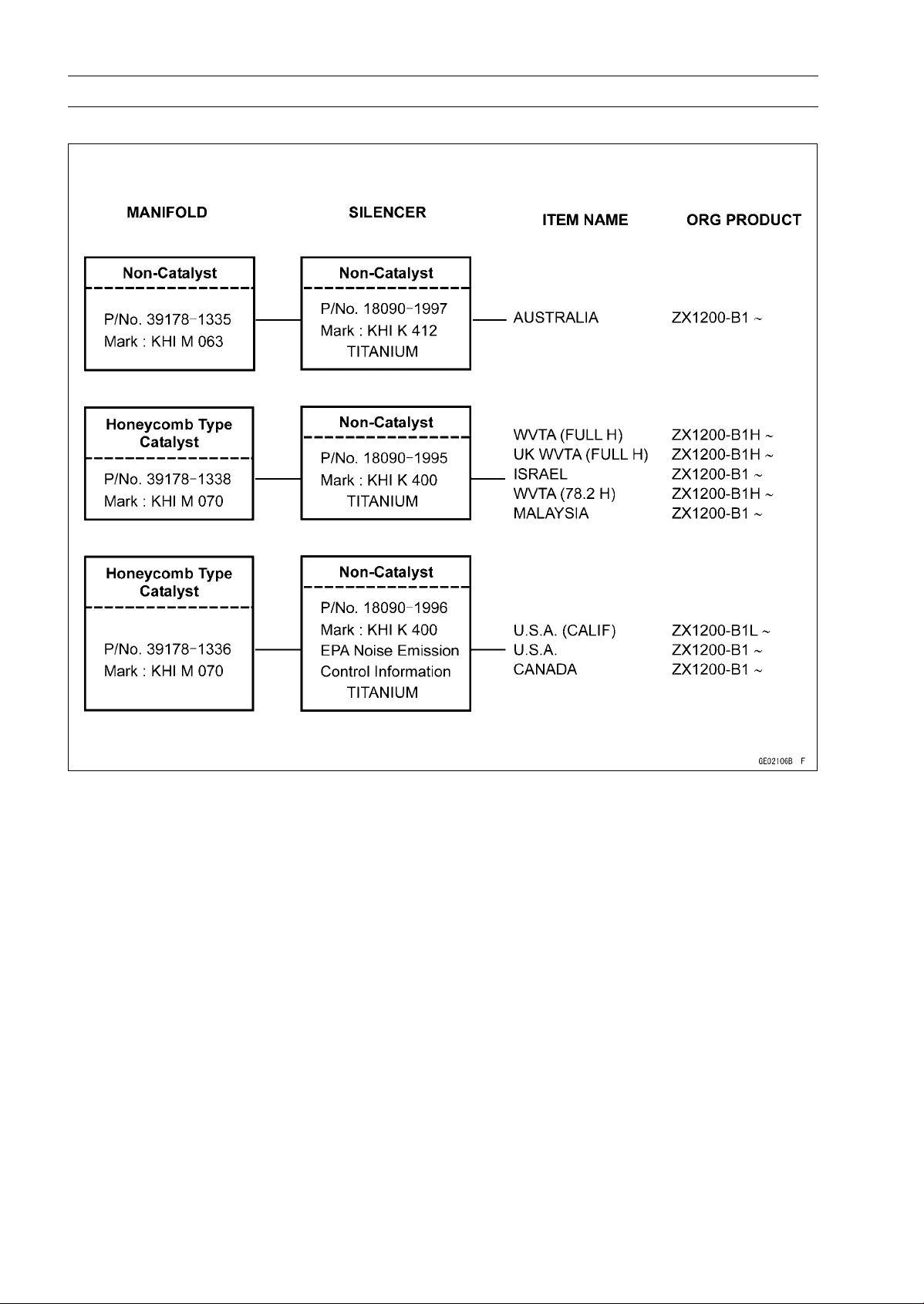

Exhaust System (ZX1200-B1/B2)

78.2: Horsepower 78.2 kW (106.3 ps)

Full: Full Power

H: Honeycomb Type Catalyst

UK: United Kingdom Model

Page 21

GENERAL INFORMATION 1-11

Technical Information – KAWASAKI LOW EXHAUST EMISSION SYS TEM

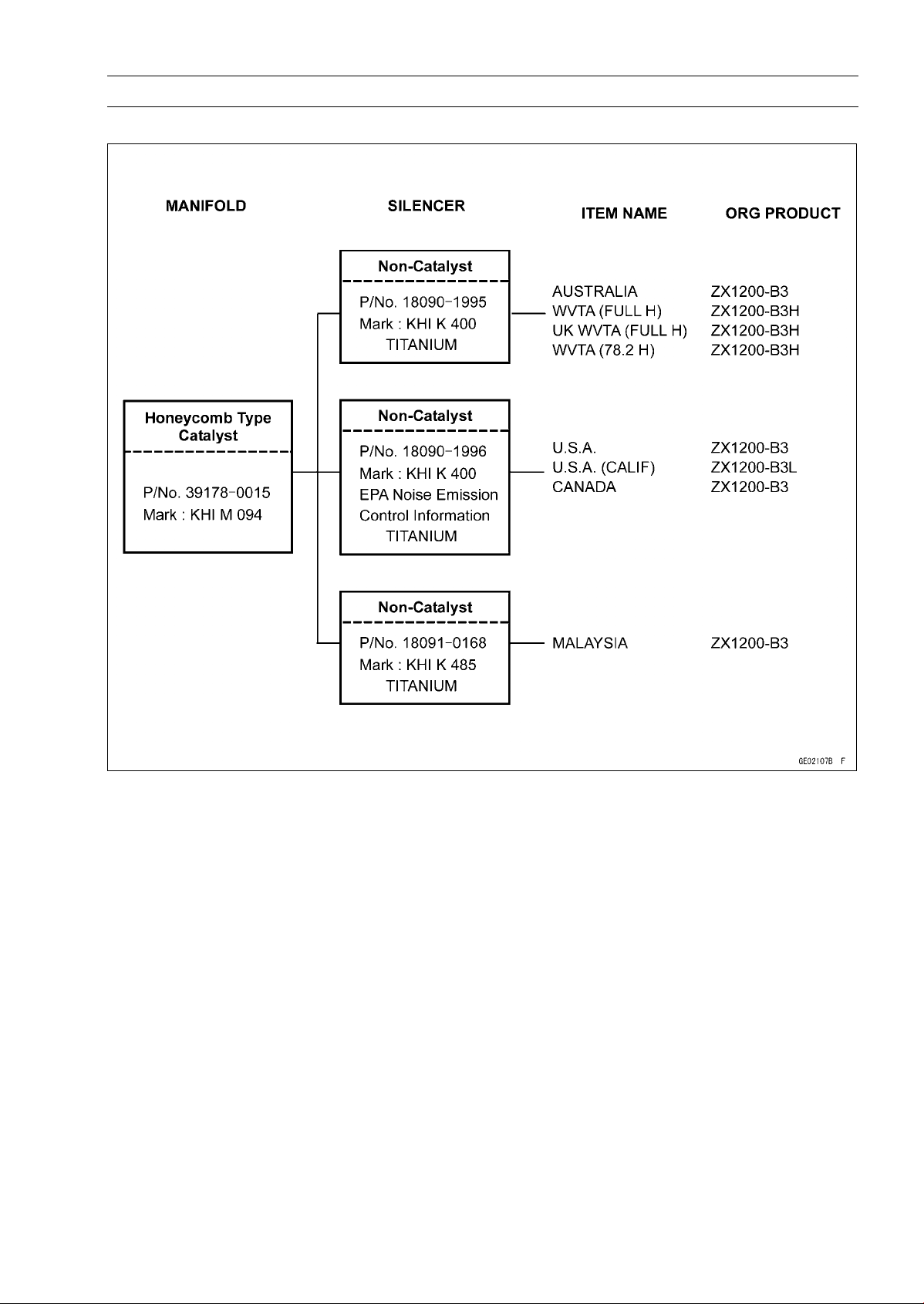

Exhaust System (ZX1200-B3)

78.2: Horsepower 78.2 kW (106.3 ps)

Full: Full Power

H: Honeycomb Type Catalyst

UK: United Kingdom Model

Page 22

1-12 GENERAL INFORMATION

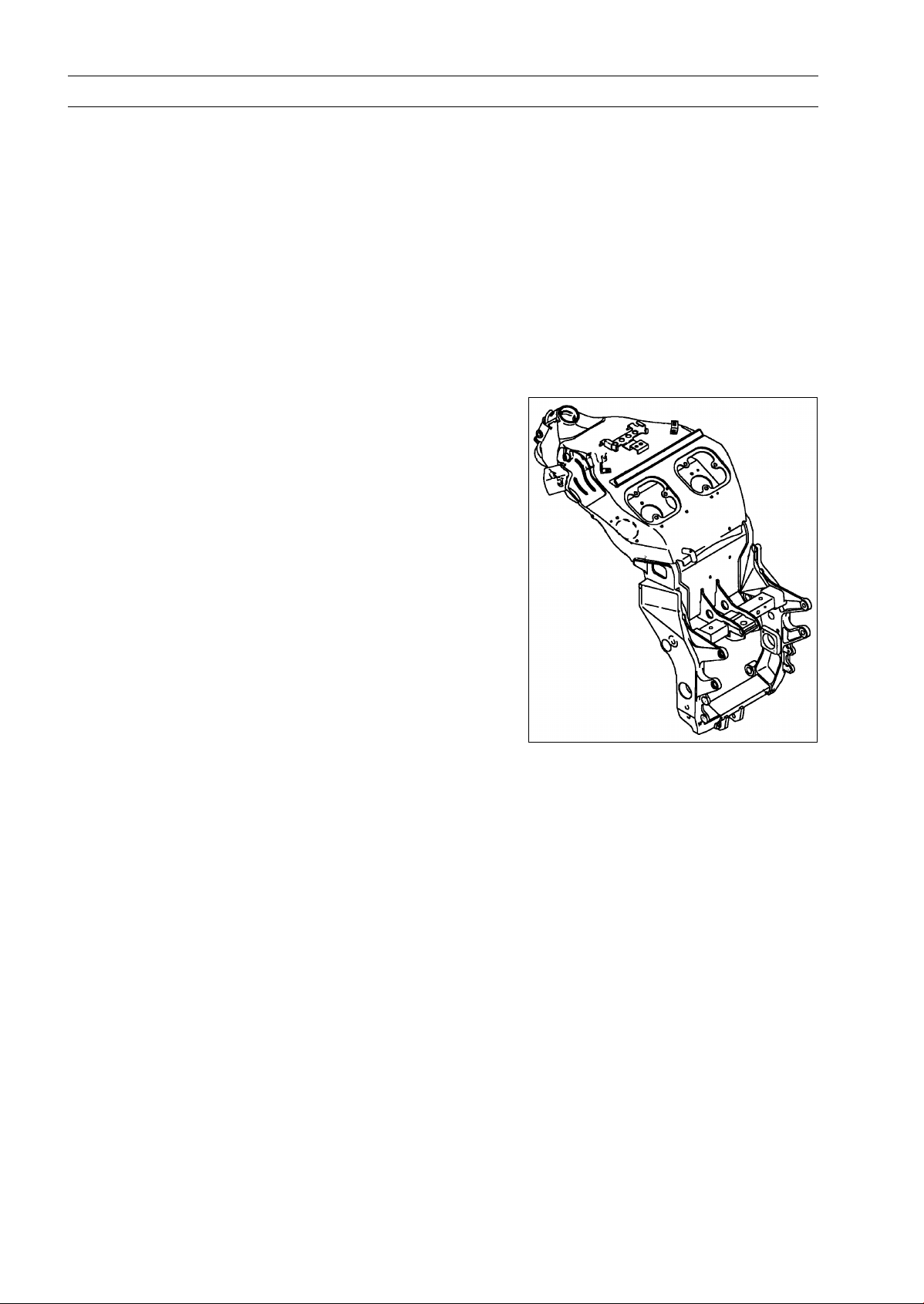

Technical Information – Monocoque Frame

Why a monocoque? Like all breakthrough innovations, the choice appears quite obvious after the

fact. When large-section aluminium spars are wrapped around an already wide, large-displacement

in-line Four engine, the resulting package must of necessity be wide. The ZX-12R’s all-aluminium box

-section monocoque chassis eliminates these perimeter spars in favor of a large box section running

over the top of the engine.

This frame design surpasses the levels of chassis stiffness and strength associated with conventional aluminium twin-beam frames, but with considerably less breadth. Without the twin beams or

other frame elements running around the side of the engine, the fairing can be much narrower, resulting in a much slimmer overall package and significantly better aerodynamics. Further, in a radical

departure, the hollow structure also doubles as an airbox for the Ram Air system, eliminating the need

for a space-consuming, conventional airbox.

And ultimately, it is the synergy of combining a compact, massively powerful engine with this super

stiff and slim chassis structure that explains much of the ZX-12R’s superlative high-speed performance.

All-new frame-integrated Ram Air system adds consider-

•

able horsepower in the higher speed ranges.

Monocoque frame allows for the use of perfectly straight,

•

highly efficient inlet ports.

Using the frame backbone as an airbox saves space and

•

creates a very efficient airbox.

Battery mounts inside the frame and the battery cover is

•

a structural element.

Revolutionary new all-aluminum monocoque frame for

•

high rigidity and lightweight.

Huge box section and heat-freated cast steering

•

head/swingarm pivot areas realize an extremely

stiff structure and contribute to the ZX-12R’s superb

high-speed stability and nimble, s uper sport handling

performance.

By eliminating the dual large-section beams of conven-

•

tional aluminum frames, this frame design makes possi-

ble a much narrower and more compact overall package

and greatly improves aerodynamics.

Page 23

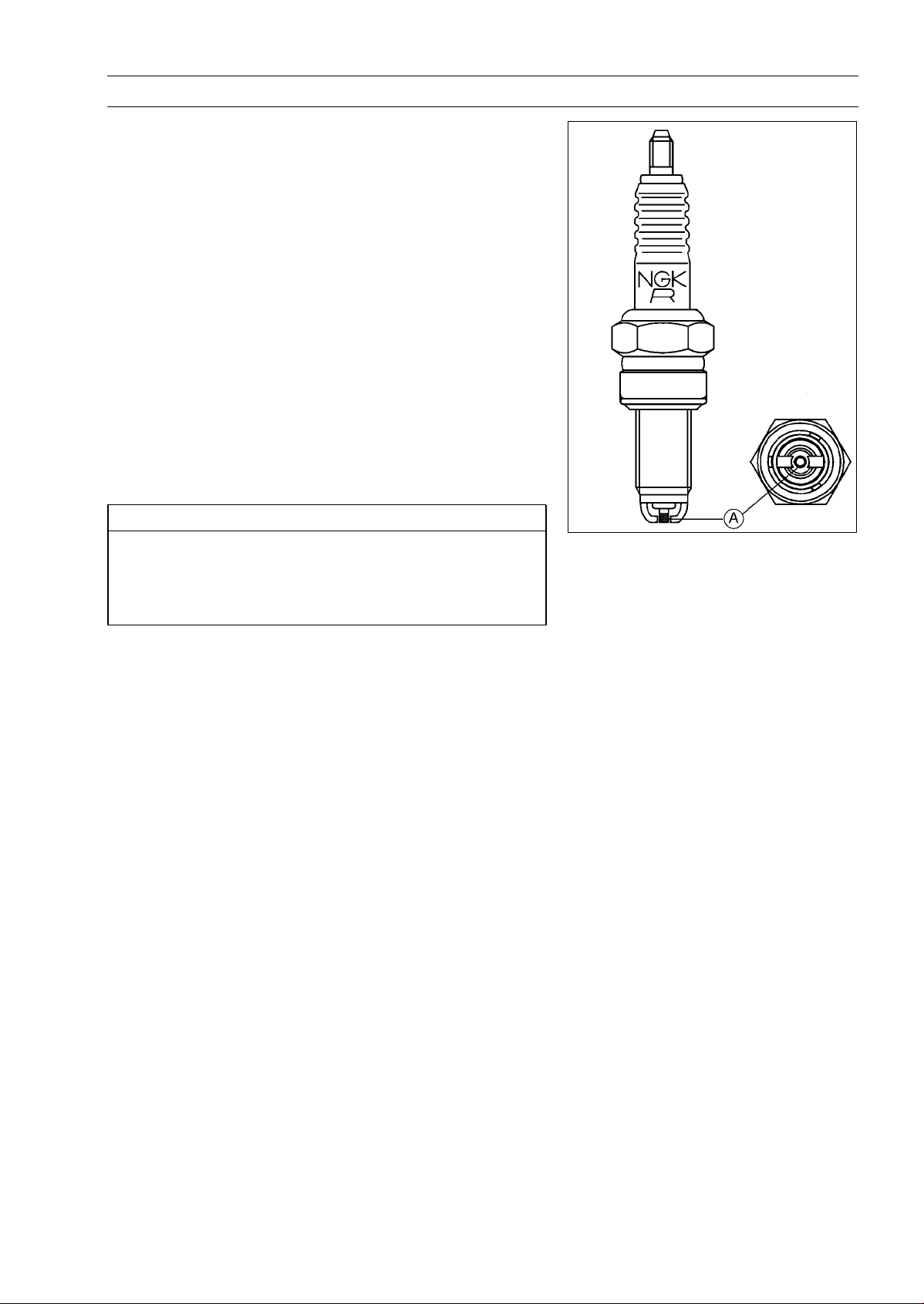

Technical Information – Spark Plug

ZX1200-B1 is equipped with the Kawasaki recommended

spark plug (NGK CR9EKPA). By using the Kawasaki recommended spark plug, the i dling stability, the fuel consumption improvement, and the maintenance free spark plug is

planed.

This spark plug is calculated 3 or 4 times as durable as

the usual one (NGK CR9EK).

Feature

1. This spark plug is more superior t o the usual one with

the ignition for the ignition point protruding.

2. Further, this spark plug is superior to the usual one with

the endurance for the Pt alloy [A] covering around the

center electrode and for the opposed area improvement

of the side electrodes.

Specification

1. Standard Spark Plug CR9EKPA, two side electrodes,

M10 threads

2. Hotter Spark Plug CR8EKPA, two side electrodes, M10

threads

GENERAL INFORMATION 1-13

CAUTION

Use only the recommender spark plug. Do not use

other spark plug, even though it may fit, because it

could cause the engine failure of the idling stability,

etc.

Page 24

1-14 GENERAL INFORMATION

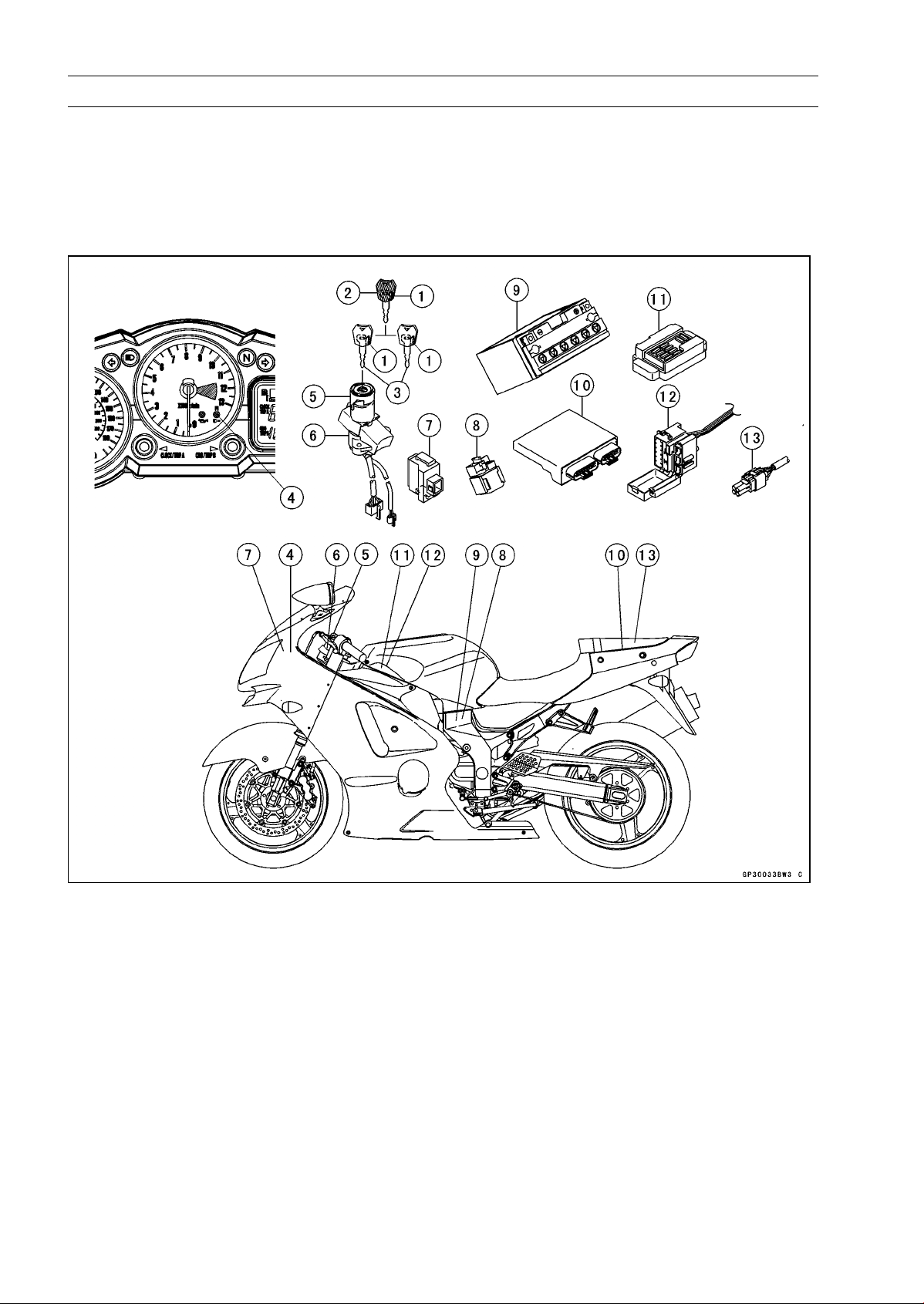

Technical Information – Immobilizer System (ZX1200-B3)

Overview

This system provides a theft proof device by means of matching a code between the inbuilt key

transponder and the ECU (Electronic Control Unit). If t his code does not match, the fuel pump, injectors, ignition system and sub-throttle valve actuator will not operate and the engine will not start.

Related Parts and Function

1. Transponder (Inside Keys)

2. Master Key

3. User Keys

4. FI Indicator Light

5. Immobilizer Antenna

6. Ignition Switch

7. Immobilizer Amplifier

Master Key (1 piece)

The master key (colored red) has an inbuilt transponder, containing a master key code. These

codes are unique to each key. This code and an additional two user key codes must be registered

in the ECU for the system to operate. The master key is necessary when registering user keys and

should not be used as the main key to start the motorcycle except in emergencies (loss or damage of

user keys). It should be kept in a safe place.

8. Starter Relay

9. Battery

10. Electronic Control Unit (ECU)

11. J unction Box

12. Fuse Box

13. Immobilizer/Kawasaki Diagnostic System

Connector

Page 25

GENERAL INFORMATION 1-15

Technical Information – Immobilizer System (ZX1200-B3)

Transponder (in Keys)

The transponder (made by Texas Instruments, Inc.) has an integrated circuit with a unique code

that also calculates data sent by the ECU. When the ignition switch is turned ON, the transponder

is excited by the radio wave transmitted from the antenna and then transmits a unique code to the

antenna.

User Key (2 pieces)

The user keys (colored black) should be used when riding the motorcycle. These keys have unique

codes which differ from the master key. Up to a maximum of five user key codes can be stored by

the ECU at any one time. These codes can not be registered to the ECU without firstly registering the

master key c ode.

Antenna

The antenna transmits a radio wave to excite the transponder, receives the code from the t ransponder and then transmits the code to the ECU through the amplifier.

Ignition Switch

The ignition switch turns the main circuit ON and OFF.

Amplifier

The amplifier (which is approximately the same size as a match box), amplifies signals from the

antenna and the ECU.

ECU

The ECU has the capacity to store a maximum of six key code memories (one master and five user

keys). The owner can have a total of five user keys at any one time. The master key memory can not

be rewritten after initial registration, whereas the user key memories can be rewritten as necessary.

When the ECU communicates with the transponder, a cipher generator changes the code every time

it is used to avoid cloning.

FI Indicator Light

The condition or the failure of the immobilizer system is indicated by various patterns of the FI indicator light blinking.

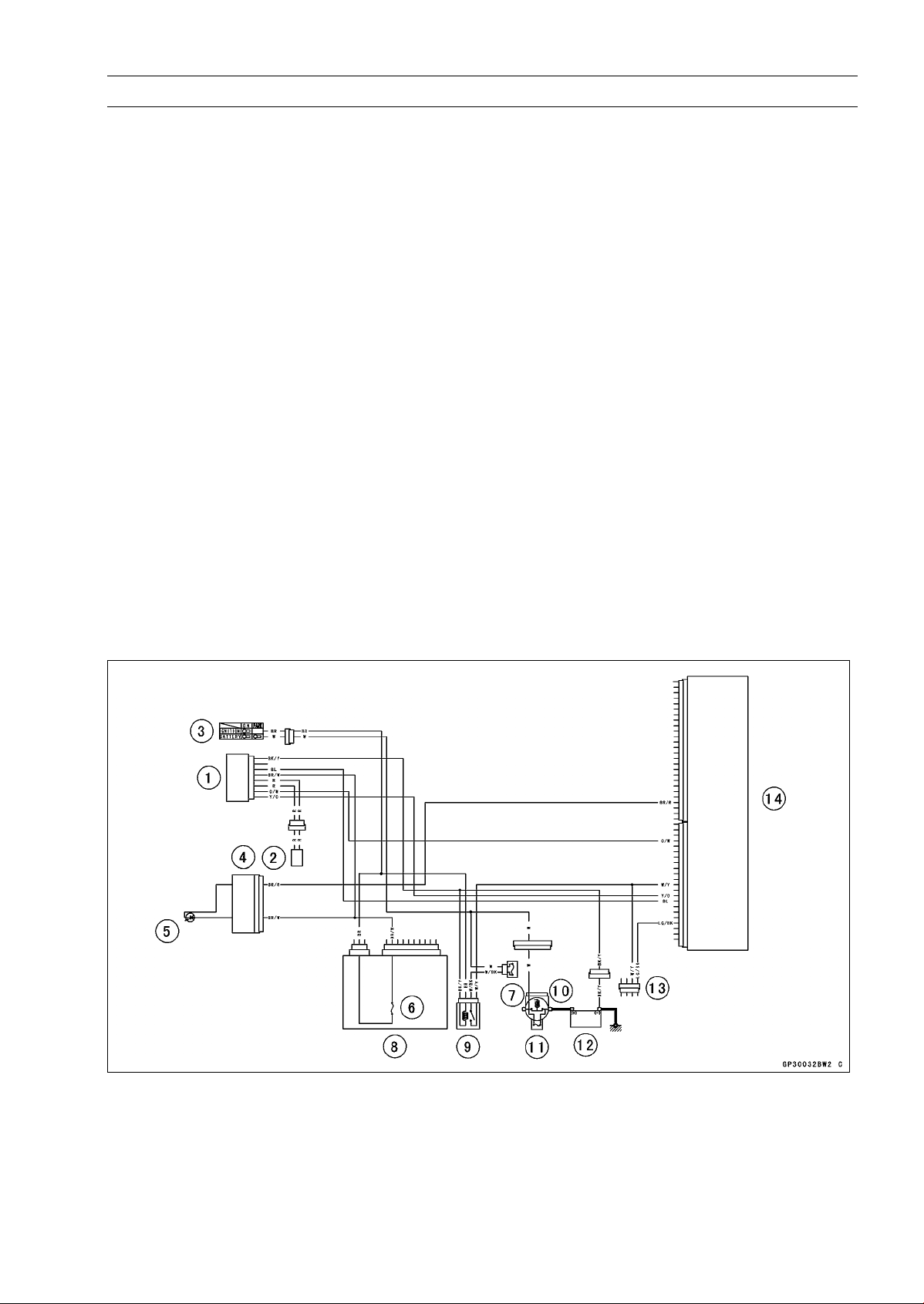

1. Immobilizer Amplifier

2. Immobilizer Antenna

3. Ignition Switch

4. Meter Unit

5. FI Indicator Light

6. Ignition Fuse 10 A

7. ECU Fuse 15 A

8. Junction Box

9. ECU Main Relay

10. Starter Relay

11. Main Fuse 30 A

12. Battery 12 V 12 Ah

13. Immobilizer/Kawasaki Diagnostic System

Connector

14. Electronic Control Unit (ECU)

Page 26

1-16 GENERAL INFORMATION

Technical Information – Immobilizer System (ZX1200-B3)

Sequence of Operation

1. Turn ON the ignition switch, the ECU, amplifier and antenna start working, and the meter assembly

FI indicator lights up.

2. The transponder excited by radio waves transmitted from the antenna receives the ciphered code

from the ECU.

3. The transponder transmits the calculated result from the key’s unique code to the ECU.

4. The ECU com pares this with its memorized code, and if they match the engine can start. At this

time, the FI indicator in the meter assembly is switched off.

Page 27

GENERAL INFORMATION 1-17

Torque and Lo cking Agent

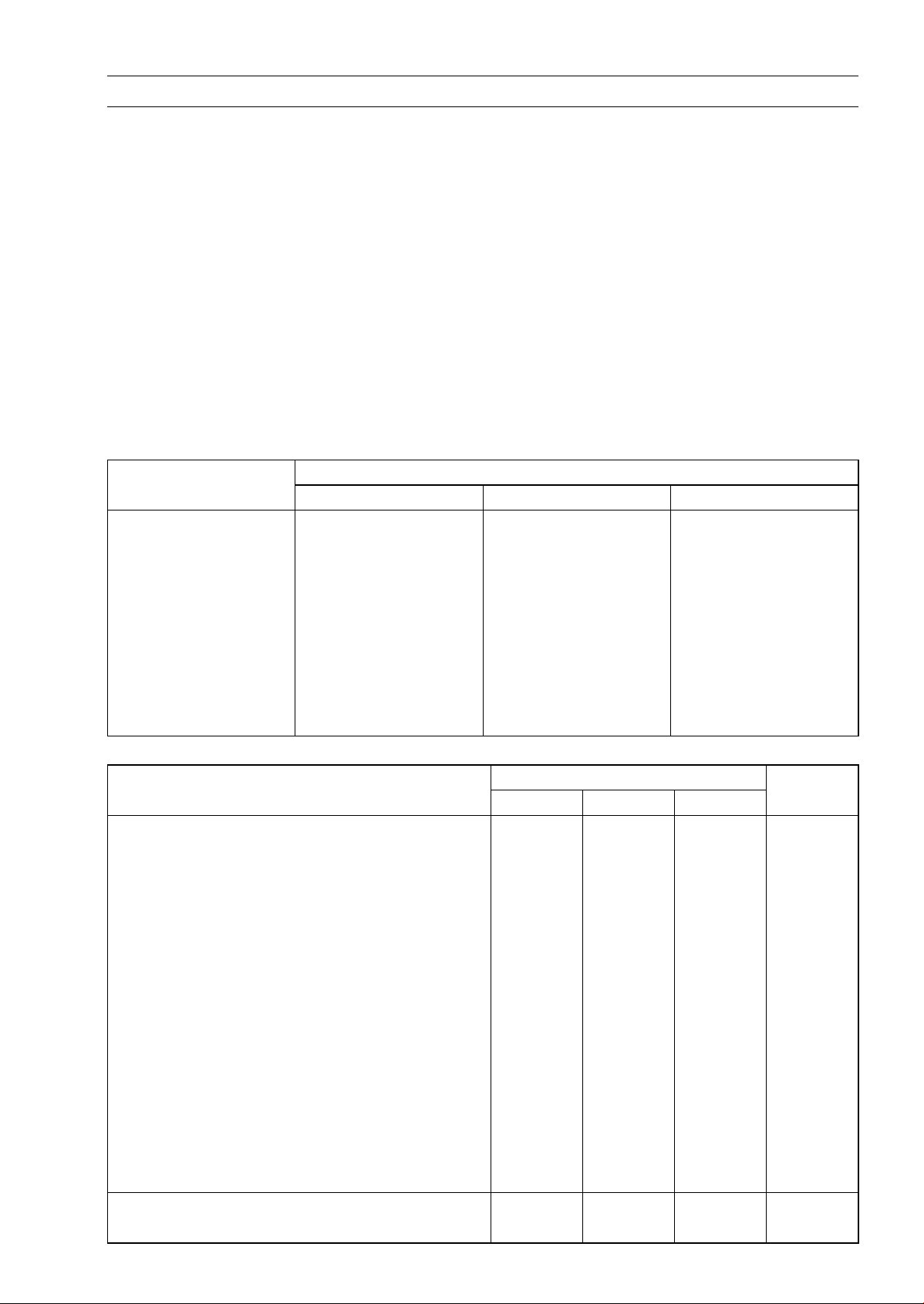

The following tables list the tightening torque for the major fasteners requiring use of a

non-permanent locking agent or liquid gasket.

Letters used in the “Remarks” column mean:

L: Apply a non-permanent locking agent to the threads.

M: Apply molybdenum disulfide grease.

MO: Apply molybdenum disulfide oil solution.

O: Apply oil to the threads and seating surface.

S: Tighten the fasteners following the specified sequence.

SS: Apply silicone sealant.

St: Stake the fasteners to prevent loosening.

R: Replacement Parts

The table below, relating tightening torque to thread diameter, lists the basic torque for the bolts and

nuts. Use this table for only the bolts and nuts which do not require a specific torque value. All of the

values are for use with dry solvent-cleaned threads.

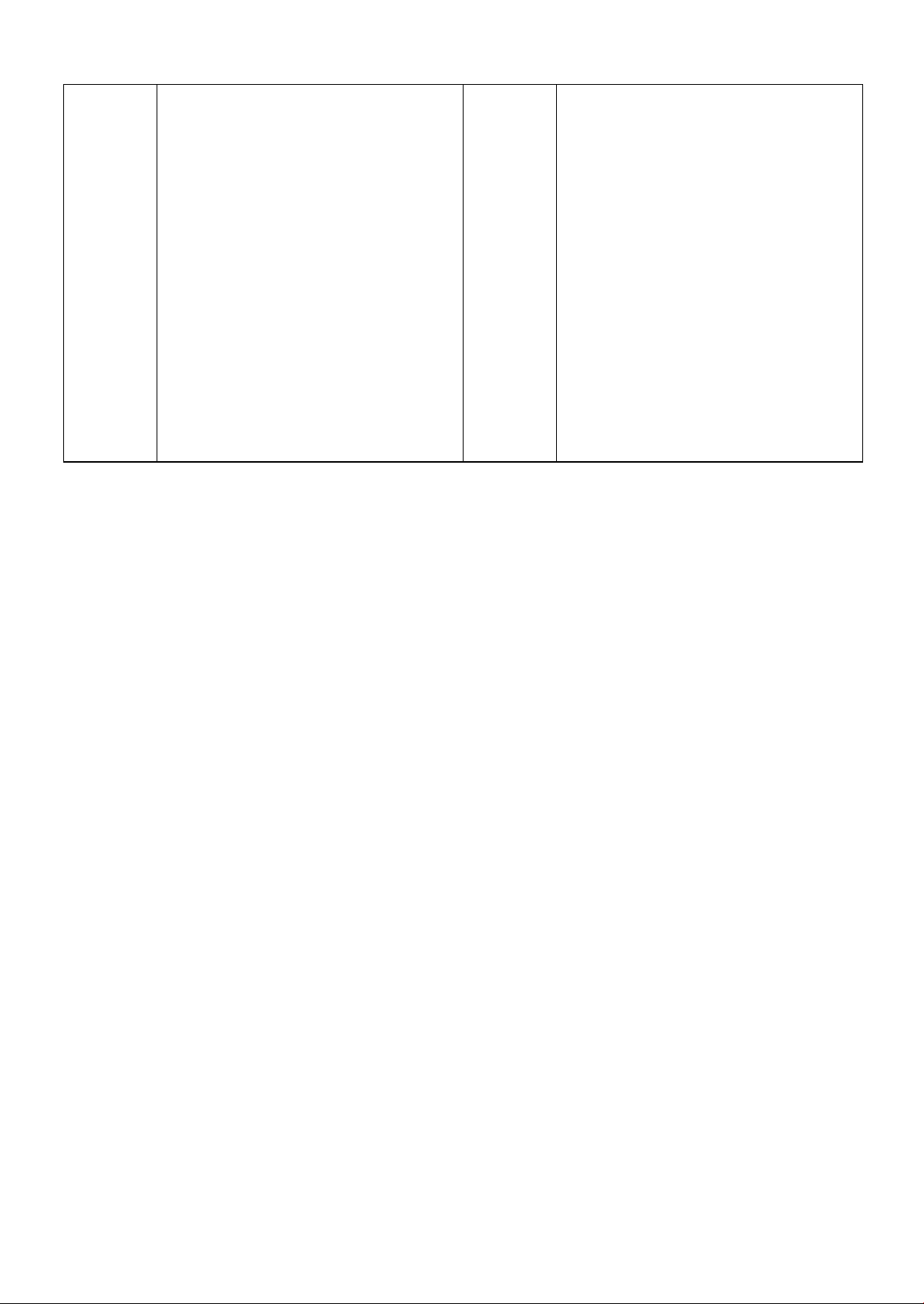

Basic Torque for General Fasteners

Threads Tor qu e

dia.(mm)

5 3.4 ∼ 4.9 0.35 ∼ 0.50 30 ∼ 43 in·lb

6 5.9 ∼ 7.8 0.60 ∼ 0.80 52 ∼ 69 in·lb

8 14 ∼ 19 1.4 ∼ 1.9 10.0 ∼ 13.5

10 25 ∼ 34 2.6 ∼ 3.5 19.0 ∼ 25

12 44 ∼ 61 4.5 ∼ 6.2 33 ∼ 45

14 73 ∼ 98 7.4 ∼ 10.0 54 ∼ 72

16 115 ∼ 155 11. 5 ∼ 16.0 83 ∼ 115

18 165 ∼ 225 17.0 ∼ 23.0 125 ∼ 165

20 225 ∼ 325 23 ∼ 33 165 ∼ 240

N·m

kgf·m ft·lb

Fastener

N·m kgf·m ft·lb

Fuel System (DFI)

Fuel Level Sensor Bolts 6.9 0.70 61 in·lb L

Fuel Pump Bolts 6.9 0.70 61 in·lb L, S

Fuel Hose Clamp Bolts 1.5 0.15 13 in·lb

Inlet Air Pressure Sensor Bolt 12 1.2 106 in·lb

Inlet Air Pressure Sensor Bracket Nut 12 1.2 106 in·lb

Inlet Air Temperature Sensor 7.8 0.80 69 in·lb

Atmospheric Pressure Sensor Bolts 12 1.2 106 in·lb

Gear Position Switch Screws 4.0 0.40 35 in·lb L

Crankshaft Sensor Bolts 6.0 0.60 53 in·lb

Camshaft Position Sensor Bolt 12 1.2 106 in·lb

Crankshaft Position Sensor Rotor Bolt 12 1.2 106 in·lb L

Delivery Pipe Screws (ZX1200-B1/B2) 5.0 0.50 44 in·lb

Delivery Pipe Screws (ZX1200-B3) 3.4 0.35 30 in·lb

Nipple Assy Screws 3.5 0.35 31 in·lb

Cooling System

Coolant Hose Clamp Screws 2.0 0.20 18 in·lb

Torque

Remarks

Page 28

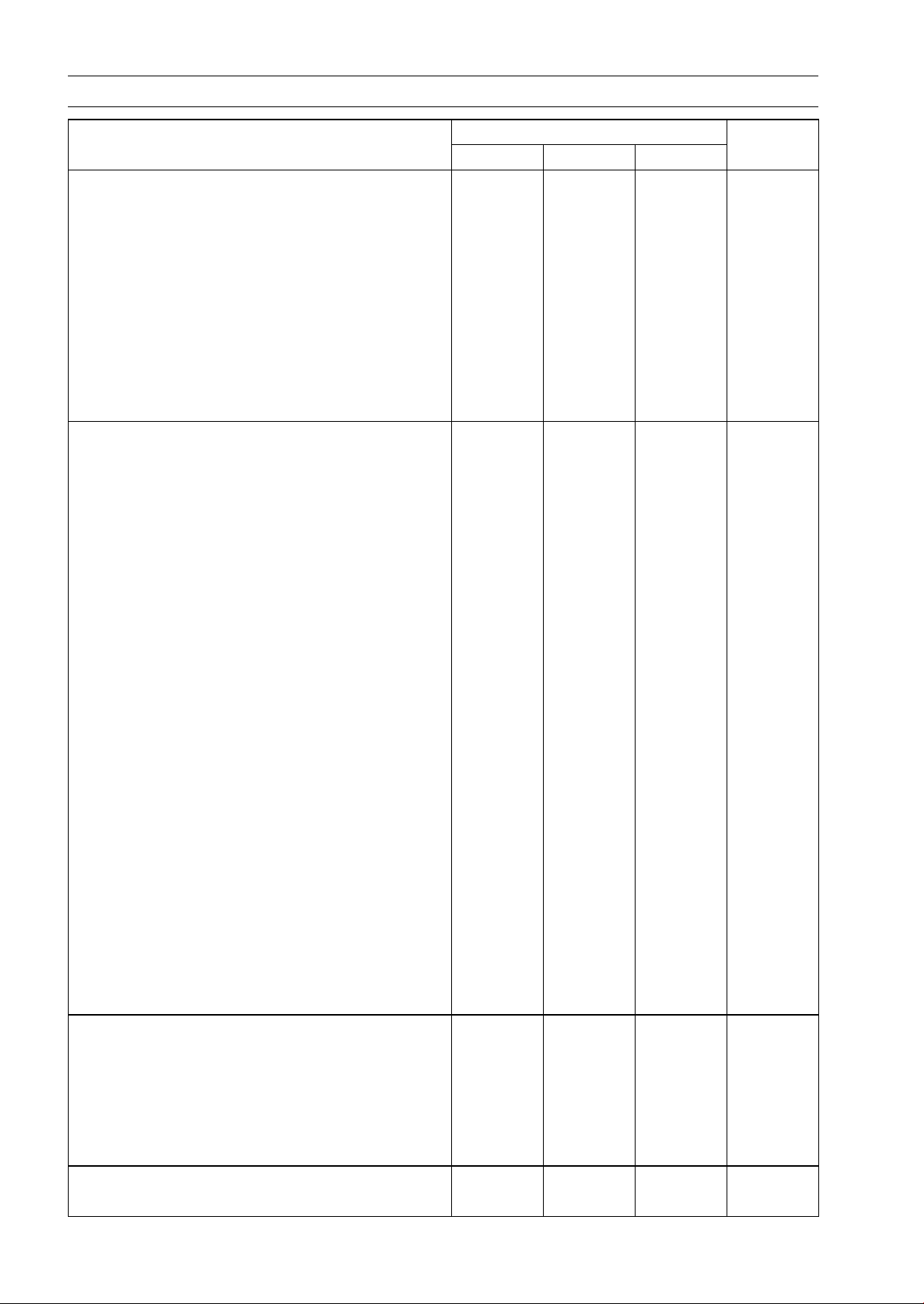

1-18 GENERAL INFORMATION

Torque and Locki ng Agent

Fastener

Coolant Fitting Nozzle (ZX1200-B1/B2)

Coolant Drain Plug (Water Pump)

Coolant Drain Plug (Cylinder) 10 1.0 89 in·lb

Radiator Fan Switch 18 1.8 13

Water Temperature Sensor 25 2.5 18 SS

Water Pum p Impeller Bolt 10 1.0 89 in·lb

Water Pum p Cover Bolts 12 1.2 106 in·lb

Coolant Pipe Bolt 12 1.2 106 in·lb

Thermostat Housing Cover Bolts 8.0 0.80 71 in·lb L

Fitting Bolts 12 1.2 106 in·lb

Engine Top End

Spark Plugs 13 1.3 115 in·lb

Air Suction Valve Cover Bolts 12 1.2 106 in·lb

Baffle Plate Bolts 10 1.0 89 in·lb

Cylinder Head Cover Bolts 10 1.0 89 in·lb

Crankshaft Sensor Cover Bolts 15 1.5 11 L

Camshaft Chain Tensioner Mounting Bolts 10 1.0 89 in·lb L

Camshaft Cap Bolts 12 1.2 106 in·lb

Upper Camshaft Chain Guide Bolts 12 1.2 106 in·lb

Front Camshaft Chain Guide Bolt (Upper) 25 2.5 18

Front Camshaft Chain Guide Bolt (Lower) 12 1.2 106 in·lb

Rear Camshaft Chain Guide Bolt 25 2.5 18

Camshaft Position Sensor Bolt 12 1.2 106 in·lb

Camshaft Position Sensor Rotor Bolt 12 1.2 106 in·lb L

Cylinder Head Bolts: M11 First Tighten 23 2.3 17 MO, S

Cylinder Head Bolts: M11 Final Tighten 59 6.0 44 MO, S

Cylinder Head Bolts: M7 20 2.0 15 S

Cylinder Head Jacket Plugs 22 2.2 16 L

Throttle Body Holder Bolts 12 1.2 106 in·lb

Muffler Body Connection Nuts 34 3.5 25

Guard Mounting Bolts 12 1.2 106 in·lb

Exhaust Pipe Holder Studs – – – (Stopped)

Clutch

Clutch Lever Clamp Bolts 7.8 0.80 69 in·lb S

Clutch Cover Bolts 15 1.5 11 L(2)

Clutch Cover Damper Plate Bolts 7.0 0.70 62 in·lb L

Clutch Spring Bolts 8.8 0.90 78 in·lb

Clutch Hub Nut 135 14 100 R

Engine Lubrication System

Oil Level Gauge Bolts

N·m

12 1.2 106 in·lb L

12 1.2 106 in·lb

12 1.2 106 in·lb

Torque

Remarks

kgf·m ft·lb

(Washer)

(Washer)

Page 29

Torque and Lo cking Agent

GENERAL INFORMATION 1-19

Fastener

Oil Filler Plug 1.5 or

Engine Oil Drain Plug 20 2.0 15

Oil Filter (Cartridge Type) 31 3.2 23 EO, R

Oil Cooler Passage Bolt 78 7.8 58 EO

Oil Cooler Mounting Bolts 25 2.5 18 L

Oil Pan Bolts 15 1.5 11 L(1)

Oil Pipe Holder Bolts 12 1.2 106 in·lb L

Oil Pressure Relief Valve 15 1.5 11 L

Oil Pressure Switch 15 1.5 11 SS

Oil Pressure Switch Terminal Screw 1.5 0.15 13 in·lb

Water Pump Impeller Bolt 10 1.0 89 in·lb

Engine Removal/Installation

Engine Mounting Bolts and Nuts: M12 59 6.0 44

Engine Mounting Bolts and Nuts: M8 25 2.5 18

Upper Engine Mounting Bracket Bolt: M12 59 6.0 44

Lower Engine Mounting Bracket Bolt: M10 44 4.5 32

Adjusting Collars 25 2.5 18

Crankshaft/Transmission

Breather Plate Bolts 10 1.0 89 in·lb L

Breather Tube Bracket Bolts 12 1.2 106 in·lb

Crankcase Bolts: M10 50 5.0 37 MO, S

Upper Crankcase Bolts: M8, L85

Upper Crankcase Bolts: M7

Lower Crankcase Bolts: M8, L99

Lower Crankcase Bolts: M7 20 2.0 15 S

Oil Passage Plugs (Each Side) 20 2.0 15 L

Connecting Rod Big End Nuts in the text ← ← ←

Timing Rotor Bolt 39 4.0 29

Starter Torque Limiter Cover Bolts 12 1.2 106 in·lb L

Oil Pressure Switch 15 1.5 11 SS

Gear Positioning Lever Bolt 10 1.0 89 in·lb L

Shift Shaft Return Spring Pin (Bolt) 30 3.0 22 L

Speed Sensor Bolt 12 1.2 106 in·lb L

Shift Drum Bearing Holder Bolt 12 1.2 106 in·lb L

Shift Drum Bearing Holder Screw 5.4 0.55 48 in·lb L

Shift Drum Cam Bolt 12 1.2 106 in·lb L

Balancer Shaft Clamp Lever Bolt 25 2.5 18 L

Balancer Shaft Clamp Bolt 12 1.2 106 in·lb

Oil Pipe Holder Bolts (Crankshaft Pipe) 12 1.2 106 in·lb L

Oil Pipe Holder Bolt (Transmission Pipe)

Oil Nozzle

N·m kgf·m ft·lb

Hand

-Tight

28 2.8 21

25 2.5 18

23 2.3 17

12 1.2 106 in·lb

2.5 0.25 22 in·lb

Torque

0.15 or

Hand

-Tight

Remarks

13 in·lb

or Hand

-Tight

S

S

S

St

Page 30

1-20 GENERAL INFORMATION

Torque and Locki ng Agent

Fastener

Starter Clutch Shaft Bolt

Starter Clutch Shaft Plate Bolt

Wheels/Tires

Front Axle Clamp Bolts 20 2.0 15 AL

Front Axle Nut 125 13 92

Rear Axle Nut 125 13 92

Rear Sprocket Nuts 59 6.0 44

Air Valve Cap 0.15 0.015 1.3 in·lb

Final Drive

Engine Sprocket Nut 127 13 94 MO

Engine Sprocket Cover Bolts 12 1.2 106 in·lb

Chain Guide Bolt 12 1.2 106 in·lb L

Rear Sprocket Nuts 59 6.0 44

Rear Axle Nut 125 13 92

Brakes

Bleed Valves 7.8 0.80 69 in·lb

Brake Hose Banjo Bolts 25 2.5 18

Brake Lever Pivot Bolt 1.2 0.12 11 in·lb Si

Brake Lever Pivot Bolt Locknut 6.0 0.60 52 in·lb

Front Reservoir Cap Screws 1.5 0.15 13 in·lb

Front Brake Light Switch Screw s 1.2 0.12 11 in·lb

Front Master Cylinder Clamp Bolts 8.8 0.90 78 in·lb S

Front Brake Pad Spring Bolts (ZX1200-B1/B2) 3.0 0.30 27 in·lb

Front Caliper Mounting Bolts

Front Caliper Assembly Bolts

Brake Disc Mounting Bolts 27 2.8 20 L

Front Brake Pad Pins (ZX1200-B3) 15 1.5 11

Rear Caliper Mounting Bolts 25 2.5 18

Rear Caliper Assembly Bolts 30 3.0 22

Brake Pedal Mounting Bolt 8.8 0.90 78 in·lb

Rear Master Cylinder Mounting Bolts 25 2.5 18

Rear Master Cylinder Push Rod Locknut 18 1.8 13

Suspension

Front Fork Clamp Bolts (Upper) 20 2.0 15

Front Fork Clamp Bolts (Lower) 20 2.0 15 AL

Front Fork Top Plugs 23 2.3 17

Piston Rod Nut 28 2.8 21

Front Fork Bottom Allen Bolts 40 4.0 30 L

Front Axle Clamp Bolts 20 2.0 15 AL

Rear Shock Absorber Bracket Nut 59 6.0 44

Rear Shock Absorber Nuts (Upper and Lower) 34 3.5 25

Swingarm Pivot Shaft Nut

Swingarm Pivot Shaft Lock Nut

N·m

25 2.5 18 L

12 1.2 106 in·lb L

34 3.5 25

21 2.1 15

125 13 92

98 10 72

Torque

Remarks

kgf·m ft·lb

Page 31

Torque and Lo cking Agent

GENERAL INFORMATION 1-21

Fastener

Uni-Track:

Rocker Arm Nut 34 3.5 25

Tie-rod Nuts 59 6.0 44

Steering

Steering Stem Head Nut (ZX1200-B1/B2) 54 5.5 40

Steering Stem Head Nut (ZX1200-B3) 78 8.0 57

Steering Stem Nut 20 2.0 15

Handlebar Bolts 34 3.5 25 L

Handlebar Weight Bolts – – – L

Handlebar Switch Housing Screws 3.5 0.36 31 in·lb

Frame

Wind Shield Mounting Screws 0.40 0.040 3.5 in·lb

Rear Frame Bolts and Nuts 44 4.5 32

Front Footpeg Holder Bolts 25 2.5 18

Rear Footpeg Holder Bolts 34 3.5 25

Side Stand Bracket Bolts 49 5.0 36

Side Stand Mounting Bolt and Nut 44 4.5 32

Side Stand Switch Bolt 8.8 0.90 78 in·lb L

Electrical System

Spark Plugs 13 1.3 115 in·lb

Alternator Rotor Bolt 110 11 81

Stator Coil Bolts 22 2.2 16 L

Alternator Lead Holding Plate Bolts 8.5 0.87 75 in·lb L

Engine Ground Lead Terminal Bolt 10 1.0 89 in·lb

Alternator Cover Bolts 15 1.5 11

Crankshaft Sensor Cover Bolts 15 1.5 11 L

Crankshaft Sensor Bolts 6.0 0.60 53 in·lb

Camshaft Position Sensor Bolt 12 1.2 106 in·lb

Timing Rotor Bolt 39 4.0 29

Starter Motor Mounting Bolts

Handlebar Switch Housing Screws

Radiator Fan Switch

Water Temperature Sensor 25 2.5 18 SS

Oil Pressure Switch 15 1.5 11 SS

Oil Pressure Switch Terminal Bolt 1.5 0.15 13 in·lb

Gear Position Switch Screws 4.0 0.40 35 in·lb L

Speed Sensor Bolt 10 1.0 89 in·lb

Fuel Level Sensor Bolts 6.9 0.70 61 in·lb

Front Brake Switch Light Screw 12 1.2 106 in·lb

Tail/Brake Light Assy Mounting Nuts 6.0 0.60 53 in·lb

N·m kgf·m ft·lb

12 1.2 106 in·lb

3.5 0.36 31 in·lb

18 1.8 13

Torque

Remarks

Page 32

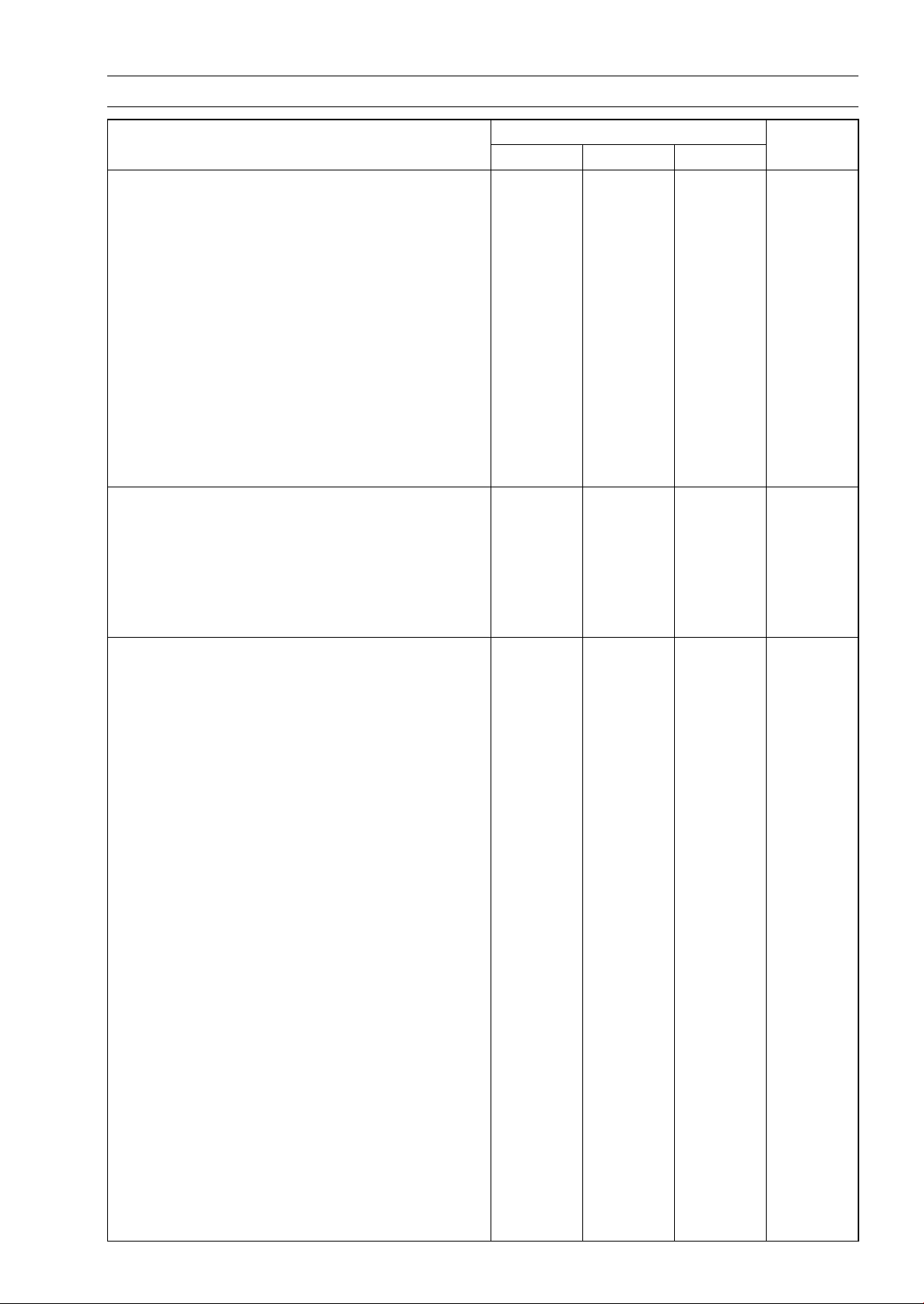

1-22 GENERAL INFORMATION

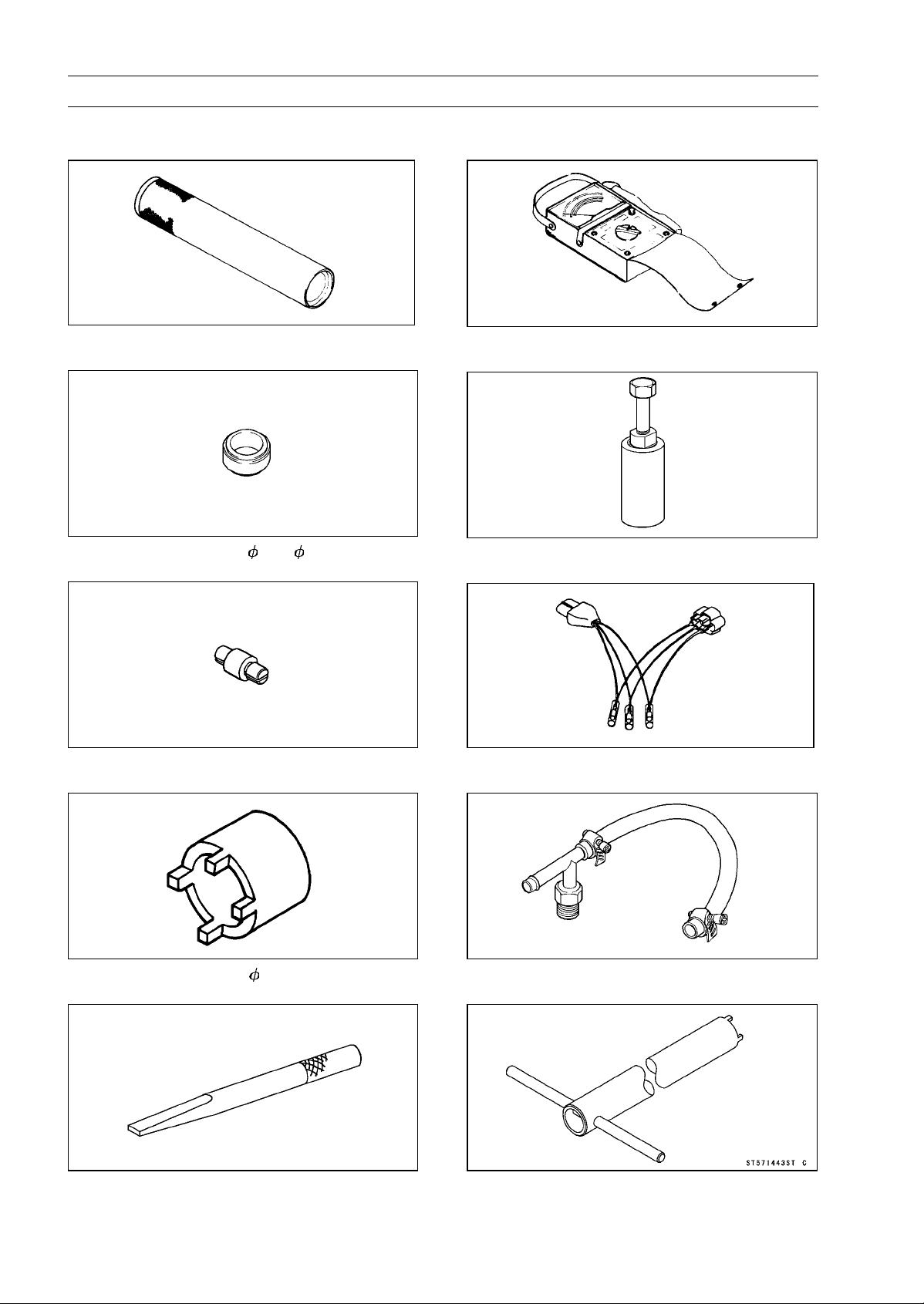

Special Tools a nd Sealant

Oil P ressure Gauge, 5 kgf/cm²:

57001-125

Bearing Puller:

57001-135

Inside Circlip Pliers:

57001-143

Compression Gauge, 20 kgf/cm²:

57001-221

Valve Spring Compressor Assembly:

57001-241

Bearing Puller Adapter:

57001-317

Outside Circlip Pliers:

57001-144

Oil Pressure Gauge, 10 kgf/cm²:

57001-164

Bearing Driver:

57001-382

Piston Pin Puller Assembly:

57001-910

Page 33

Special Tools and Sealant

GENERAL INFORMATION 1-23

Oil Pressure Gauge Adapter, PT 1/8:

57001-1033

Oil Seal & Bearing Remover:

57001-1058

Head Pipe Outer Race Press Shaft:

57001-1075

Head Pipe Outer Race Remover:

57001-1107

Valve Seat Cutter, 45° - 35:

57001-1116

Valve Seat Cutter, 30° - 30:

57001-1120

Piston Ring Compressor Grip:

57001-1095

Steering Stem Nut Wrench:

57001-1100

Valve Seat Cutter, 32° - 35:

57001-1121

Valve Seat Cutter, 60° - 30:

57001-1123

Page 34

1-24 GENERAL INFORMATION

Special Tools a nd Sealant

Valve Seat Cutter Holder Bar:

57001-1128

Bearing Driver Set:

57001-1129

Valve Seat Cutter, 45° - 30:

57001-1187

Valve Guide Reamer, 5:

57001-1204

Valve Seat Cutter Holder, 5:

57001-1208

Rotor Puller, M16/M18/M20/M22 × 1.5:

57001-1216

Valve Spring Compressor Adapter, 22:

57001-1202

Valve Guide Arbor, 5:

57001-1203

Jack:

57001-1238

Clutch Holder:

57001-1243

Page 35

Special Tools and Sealant

GENERAL INFORMATION 1-25

Valve Seat Cutter, 55° - 35:

57001-1247

Oil Filter Wrench:

57001-1249

Carburetor Drain Plug Wrench, Hex 3:

57001-1269

Pilot Screw Adjuster, C:

57001-1292

Flywheel Holder:

57001-1313

Piston Ring Compressor Belt, 80 ∼ 91:

57001-1320

Fork Piston Rod Puller, M12 × 1.25:

57001-1289

Fork Oil Le vel Gauge:

57001-1290

Fork Oil Seal Driver, 43:

57001-1340

Flywheel & Pulley Holder:

57001-1343

Page 36

1-26 GENERAL INFORMATION

Special Tools a nd Sealant

Steering Stem Bearing Driver:

57001-1344

Steering Stem Bearing Driver Adapter:

57001-1345

Bearing Remover Head, 25 × 28:

57001-1346

Hand Tester:

57001-1394

Flywheel Puller Assembly, M38 × 1.5/M35 × 1.5:

57001-1405

Throttle Sensor Setting Adapter #2:

57001-1408

Socket Wrench:

57001-1370

Bearing Remover Shaft, 13:

57001-1377

Fuel Pressure Gauge Adapter:

57001-1417

Fork Cylinder Holder:

57001-1443

Page 37

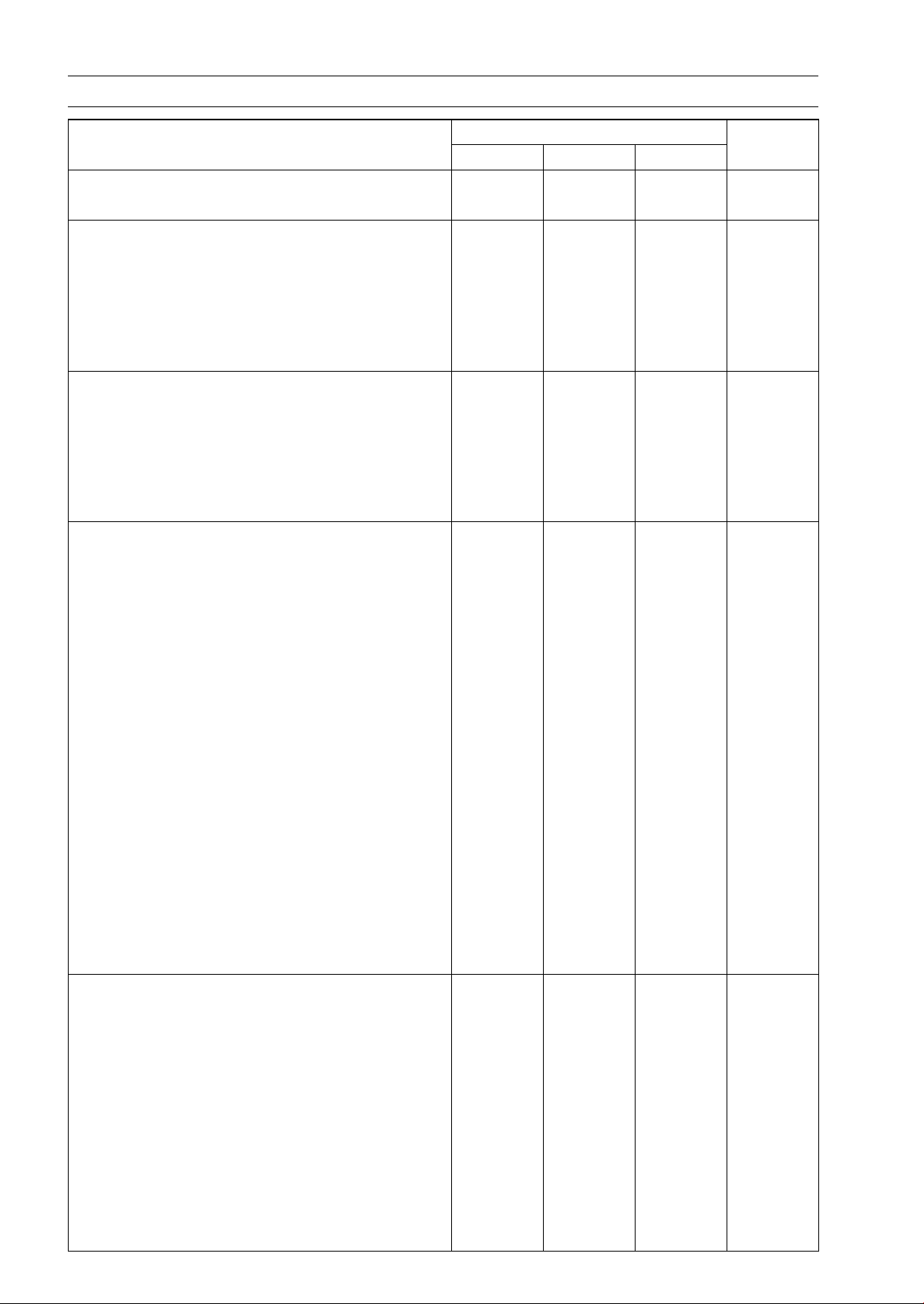

Special Tools and Sealant

GENERAL INFORMATION 1-27

Head Pipe Outer Race Driver:

57001-1446

Head Pipe Outer Race Driver:

57001-1447

Lead Wire - Voltage Regulator Adapter:

57001-1448

Clutch Gear Setting Screw:

57001-1455

Needle Adapter Set:

57001-1457

Compression Gauge Adapter, M10 × 1.0:

57001-1458

Lead Wire - Peak Voltage Adapter:

57001-1449

Fork Spring Compressor Set:

57001-1452

Piston Base, 10:

57001-1459

Hook Wrench:

57001-1522

Page 38

1-28 GENERAL INFORMATION

Special Tools a nd Sealant

Throttle Sensor Setting Adapter:

57001-1538

Key Registration Unit:

57001-1582

Fork Spring Compressor:

57001-1587

Rotor Holder:

57001-1592

Kawasaki Bond (Silicone Sealant):

56019-120

Kawasaki Bond (Liquid Gasket - Black):

92104-1062

Pulley Holder, Grip:

57001-1591

Page 39

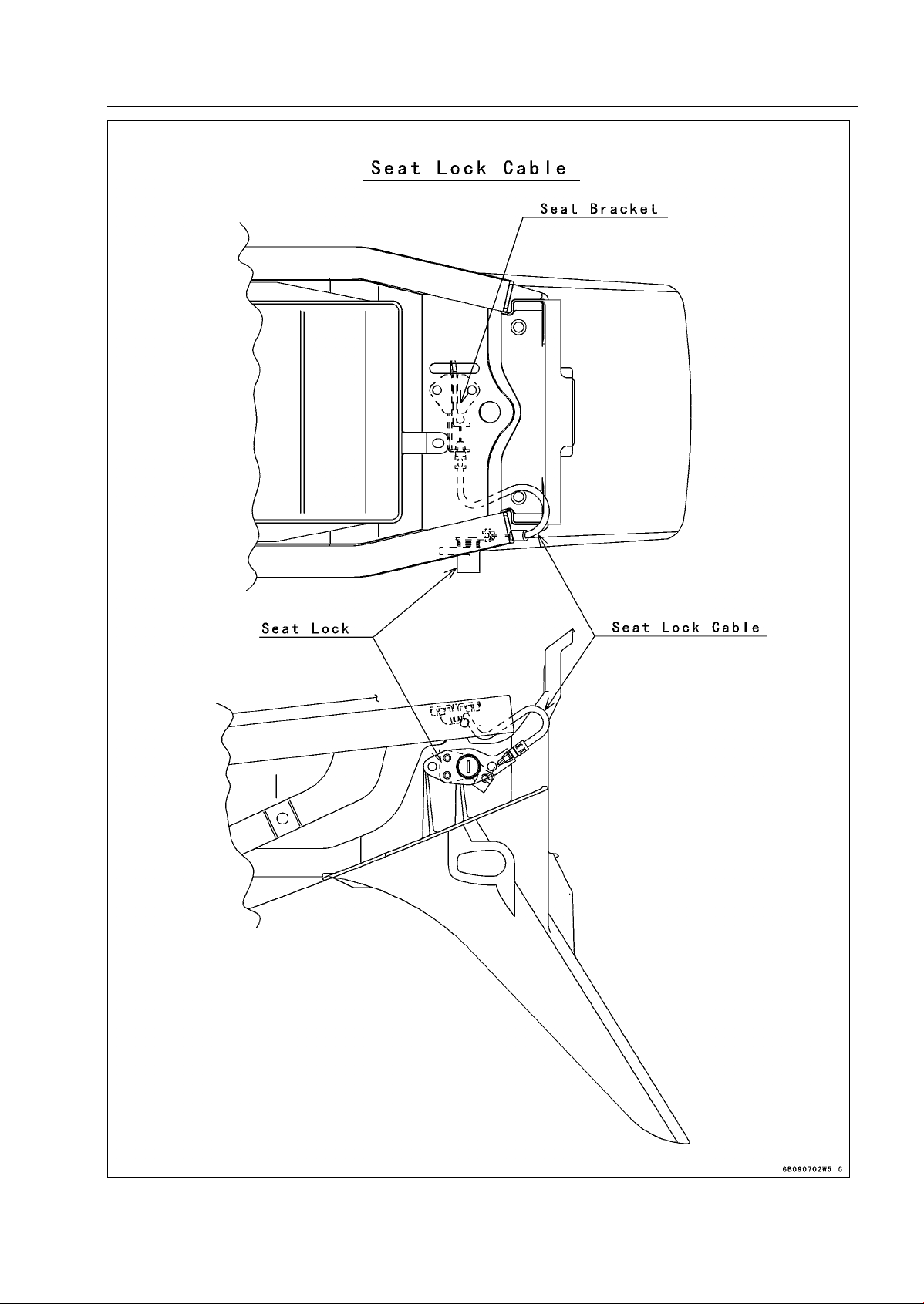

Cable, Wire, and Hose Routing (ZX1200-B1/B2)

GENERAL INFORMATION 1-29

Page 40

1-30 GENERAL INFORMATION

Cable, Wire, and Hose Routing (ZX1200-B1/B2)

Page 41

Cable, Wire, and Hose Routing (ZX1200-B1/B2)

GENERAL INFORMATION 1-31

Page 42

1-32 GENERAL INFORMATION

Cable, Wire, and Hose Routing (ZX1200-B1/B2)

Page 43

Cable, Wire, and Hose Routing (ZX1200-B1/B2)

GENERAL INFORMATION 1-33

Page 44

1-34 GENERAL INFORMATION

Cable, Wire, and Hose Routing (ZX1200-B1/B2)

Page 45

Cable, Wire, and Hose Routing (ZX1200-B1/B2)

GENERAL INFORMATION 1-35

Page 46

1-36 GENERAL INFORMATION

Cable, Wire, and Hose Routing (ZX1200-B1/B2)

Page 47

Cable, Wire, and Hose Routing (ZX1200-B1/B2)

GENERAL INFORMATION 1-37

Page 48

1-38 GENERAL INFORMATION

Cable, Wire, and Hose Routing (ZX1200-B1/B2)

Page 49

Cable, Wire, and Hose Routing (ZX1200-B1/B2)

GENERAL INFORMATION 1-39

Page 50

1-40 GENERAL INFORMATION

Cable, Wire, and Hose Routing (ZX1200-B1/B2)

Page 51

Cable, Wire, and Hose Routing (ZX1200-B1/B2)

GENERAL INFORMATION 1-41

Page 52

1-42 GENERAL INFORMATION

Cable, Wire, and Hose Routing (ZX1200-B1/B2)

Page 53

Cable, Wire, and Hose Routing (ZX1200-B1/B2)

GENERAL INFORMATION 1-43

Page 54

1-44 GENERAL INFORMATION

Cable, Wire, and Hose Routing (ZX1200-B1/B2)

Page 55

Cable, Wire, and Hose Routing (ZX1200-B1/B2)

GENERAL INFORMATION 1-45

Page 56

1-46 GENERAL INFORMATION

Cable, Wire, and Hose Routing (ZX1200-B3)

Page 57

Cable, Wire, and Hose Routing (ZX1200-B3)

1. Clamp

2. To Side Stand Switch

3. Insert the dampers of the ECU into the holes of the fender.

4. ECU

5. Atmospheric P ressure Sensor

6. Regulator/rectifier

7. From Regulator/rectifier

8. From Alternator

GENERAL INFORMATION 1-47

Page 58

1-48 GENERAL INFORMATION

Cable, Wire, and Hose Routing (ZX1200-B3)

Page 59

Cable, Wire, and Hose Routing (ZX1200-B3)

1. Front

2. About 45°

3. Viewed A

4. Clamp

GENERAL INFORMATION 1-49

Page 60

1-50 GENERAL INFORMATION

Cable, Wire, and Hose Routing (ZX1200-B3)

Page 61

GENERAL INFORMATION 1-51

Cable, Wire, and Hose Routing (ZX1200-B3)

1. Run the horn lead between the water hose and water pipe.

2. Clamp

3. Clamp the leads so that the speed sensor lead is outside.

4. Clamp the speed sensor lead, gear position switch lead and sub harness.

5. Section A-A

6. To Horn

7. Radiator Fan Switch

8. Clamp the horn lead and reserve tank hose.

9. Clamp the fan switch lead.

10. Clamp the side stand switch lead.

11. G ear Position Switch Lead

12. Speed Sensor Lead

13. Sub Harness

Page 62

1-52 GENERAL INFORMATION

Cable, Wire, and Hose Routing (ZX1200-B3)

Page 63

GENERAL INFORMATION 1-53

Cable, Wire, and Hose Routing (ZX1200-B3)

1. ECU Guard

2. Clamp

3. Connect the connectors of the fuel pump and fuel gauge leads.

4. To Alternator

5. Install the clamp with air cleaner cap.

6. Insert the harness into the clamps.

7. To Left Switch Housing

8. Immobilizer Antenna

9. Ignition Switch

10. Immobilizer Amplifier

11. View e d A

12. Crankshaft Sensor Lead

13. Engine

14. Right Lower Fairing

15. To R ight Switch Housing

16. To Battery Tray

17. Put the harness into the holes of the clamp.

18. To Rear Brake Light Switch

19. Put the harness into the holes of the fenders.

20. Right Turn S ignal Light Connector

21. Left Turn Signal Light Connector

22. Tail/Brake Light Connector

23. Right Turn Signal Light Lead

24. Diagnosis Connector

25. Self-diagnosis Indicator Terminal

26. Clamp (Fit the clamp to the rear frame.)

27. Atmospheric Pressure Sensor Connector

28. Viewed B

29. Trim (Fit the trim to the rear fender rear.)

Page 64

1-54 GENERAL INFORMATION

Cable, Wire, and Hose Routing (ZX1200-B3)

Page 65

GENERAL INFORMATION 1-55

Cable, Wire, and Hose Routing (ZX1200-B3)

1. To Meter Assembly

2. Sub Harness

3. Headlight Relays

4. Band (Clamp the ignition switch lead on to the upper bracket.)

5. Clamp (Bend inside the tip of the left side clamp.)

6. Left Side (Connect the left switch housing lead connectors and ignition switch lead connectors.)

Right Side (Connect the right switch housing connectors.)

7. Insert the clamp into the hole of the frame.

8. Clamp (Fit the clamp into the rear fender rear.)

9. Frame Ground (Install the ground with the air inlet pressure sensor bracket.)

10. Ignition Switch

11. To Left Switch Housing

12. Main Harness

Page 66

1-56 GENERAL INFORMATION

Cable, Wire, and Hose Routing (ZX1200-B3)

Page 67

Cable, Wire, and Hose Routing (ZX1200-B3)

1. Clamp the vacuum hose and fuel hose.

2. Vacuum Hose

3. Fuel Hose

4. Engine Sub Harness

5. Gear Position Switch Lead

6. Alternator Lead

7. Tube (Air Switching Valve – Canister):California Model Only

8. Clamp

9. Alternator Lead

10. Water Hose

11. View e d A

GENERAL INFORMATION 1-57

Page 68

1-58 GENERAL INFORMATION

Cable, Wire, and Hose Routing (ZX1200-B3)

Page 69

GENERAL INFORMATION 1-59

Cable, Wire, and Hose Routing (ZX1200-B3)

1. Air Switching Valve

2. Fan Leads

3. Run the water hose on the fan leads and fan switch lead.

4. Fan Relay (Signal) Connector

5. To Main Harness

6. Run the engine sub harness outside the lib of the head cover.

7. To Canister

8. Actuator

9. To Separator

10. Run the speed sensor lead back the bolt and under the gear position switch lead for prevention

of the lead lift up.

11. Speed Sensor

12. To Headlight Relay

13. Gear Position Switch Lead Connector

14. Engine Sub Harness Connector

15. Engine Sub Harness Connector

16. Run the starter motor cable under the engine sub harness.

17. Fix the crankshaft sensor lead connector.

18. Viewed A

19. Crankshaft Sensor Lead

20. Fuel Hose

21. Tube (Throttle Body – Separator): California Model Only

22. Alternator Lead

23. Run the alternator lead under the fuel tube.

Page 70

1-60 GENERAL INFORMATION

Unit Conversion Table

Prefixes for Units:

Prefix Symbol Power

mega M × 1 000 000

kilo k × 1 000

centi c ×0.01

milli m × 0.001

micro µ × 0.000001

Units of Mass:

kg × 2.205 = lb

g × 0.03527 = oz

Units of Volume:

L × 0.2642 = gal (US)

L × 0.2200 =

L × 1.057 =

L × 0.8799 = qt (imp)

L × 2.113 = pint (US)

L × 1.816 = pint (imp)

mL × 0.03381 = oz (US)

mL × 0.02816 = oz (imp)

mL × 0.06102 = cu in

gal (imp)

qt (US)

Units of Length:

km × 0.6214 = mile

m × 3.281 = ft

mm × 0.03937 = in

Units of Torque:

N·m × 0.1020 = kgf·m

N·m × 0.7376 = ft·lb

N·m × 8.851 = in·lb

kgf·m × 9.807 = N·m

kgf·m × 7.233 = ft·lb

kgf·m × 86.80 = in·lb

Units of Pressure:

kPa × 0.01020 = kgf/cm²

kPa × 0.1450 = psi

kPa × 0.7501 = cm Hg

kgf/cm² × 98.07 = kPa

kgf/cm² × 14.22 = psi

cmHg×1.333=kPa

Units of Speed:

km/h × 0.6214 = mph

Units of Force:

N × 0.1020 = kg

N × 0.2248 = lb

kg × 9.807 = N

kg × 2.205 = lb

Units of Temperature:

Units of Power:

kW ×1.360=PS

kW ×1.341=HP

PS × 0.7355 = kW

PS × 0.9863 = HP

Page 71

PERIODIC MAINTENANCE 2-1

Periodic Maintenance

Table of Contents

Periodic Maintenance Chart .............. 2-2

Specifications .................................... 2-4

Periodic Maintenance Procedures..... 2-6

Fuel System (DFI)........................... 2-6

Fuel Hose and Connection

Inspection .................................. 2-6

Throttle Control System

Inspection .................................. 2-7

Idle Speed Inspection .................. 2-8

Engine Vacuum Synchronization

Inspection .................................. 2-9

Air Cleaner Element Cleaning

(ZX1200-B1/B2)/Element

Replacement (ZX1200-B3) ....... 2-13

Evaporative Emission Control

System Inspection(CAL) ........... 2-14

Cooling System............................... 2-15

Cooling Hose and Connection

Inspection .................................. 2-15

Coolant Change........................... 2-15

Engine Top End .............................. 2-17

Air Suction Valve Inspection ........ 2-17

Valve Clearance Inspection ......... 2-18

Clutch.............................................. 2-22

Clutch Adjust Inspection .............. 2-22

Engine Lubrication System............. 2-23

Engine Oil Change....................... 2-23

Oil Filter Replace ......................... 2-23

Wheels/Tires................................... 2-24

Tire Wear Inspection .................... 2-24

Final Drive....................................... 2-25

Drive Chain Slack Inspection....... 2-25

Drive Chain Wear Inspection ....... 2-26

2

Drive Chain Lubrication................ 2-28

Brakes............................................. 2-28

Brake Hose, Connection

Inspection.................................. 2-28

Brake Fluid Level Inspection........ 2-29

Brake Fluid Change ..................... 2-29

Front Brake Pad Wear Inspection 2-30

Rear Brake Pad Wear Inspection 2-31

Brake/Master Cylinder Cup and

Dust Seal Replace .................... 2-31

Caliper Piston/Dust Seal Replace 2-31

Front Brake Light Switch

Inspection.................................. 2-31

Rear Brake Light Switch

Inspection/Adjustment............... 2-31

Suspension..................................... 2-32

Front Fork Oil Change ................. 2-32

Front Fork Oil Leak Inspection..... 2-42

Rear Shock Absorber Oil Leak

Inspection.................................. 2-42

Swingarm Pivot Lubrication ......... 2-42

Unit-trak Linkage Lubrication ....... 2-43

Steering .......................................... 2-43

Steering Inspection ...................... 2-43

Steering Stem Bearing

Lubrication................................. 2-45

Electrical System ............................ 2-45

Spark Plug Cleaning and

Inspection.................................. 2-45

General Lubrication ........................ 2-45

Lubrication Perform...................... 2-45

Nut, Bolt, and Fastener Tightness .. 2-47

Tightness Inspection .................... 2-47

Page 72

2-2 PERIODIC MAINTENANCE

Periodic Maintenance Chart

The scheduled maintenance must be done in accordance with this chart to keep the motorcycle in

good running condition. The initial maintenance is vitally important and must not be neglected.

FREQUENCY Whichever

comes

first

1 6 12 18 24 30 36

OPERATION Every (0.6) (4) (7.5) (12) (15) (20) (24)

Steering - inspect †

Steering stem bearing - lubricate

Brake hoses, connections - inspect †

Brake fluid level - inspect † month

Brake fluid - change 2 years

Brake pad wear - inspect † #

Brake master cylinder cup and dust seal

-replace

Caliper piston seal and dust seal - replace 4 years 2-31

Brake light switches - inspect †

Tire wear - inspect †

Front fork oil - change

Front fork oil leak - inspect †

Rear shock absorber oil leak - inspect †

Swingarm pivot, Unit-track linkage lubricate

2 years

4 years 2-31

2 years

• • • • • • •

• • • • • •

• • • • • • •

• • • • • •

• • • • • • •

• • • • • •

• • •

• • •

• • •

*Odometer Reading

× 1000 km

(× 1000 mile)

Refer-

ence

2-43

•

•

•

2-45

2-28

2-29

2-29

2-30

2-31

2-24

2-32

2-42

2-42

2-42

Clutch adjust - inspect †

Drive chain slack - inspect † # 1 000 km 2-25

Drive chain wear - inspect † #

Drive chain roller wear - inspect † #

Drive chain - lubricate # 600 km 2-28

Spark plug (e) - clean and gap †

Fuel hoses, connections - inspect †

Throttle control system (e) - inspect †

Idle speed (e) - inspect †

Engine vacuum sychronization (e) inspect †

Air cleaner element (e) - clean † #

(ZX1200-B1/B2)

Air cleaner element (e) - replace † #

(ZX1200-B3)

Evaporative emission control system (e)

(CAL) - inspect †

Air suction valve (e) - inspect †

Valve clearance (e) - inspect †

Cooling hoses, connections - inspect †

Coolant - change 2 years

• • • • • • •

• • • • • •

• • • • • •

• • • • • •

• • • • • •

• • • • • • •

• • • •

• • •

• • •

•

• • • • • • •

• • • • • •

• • •

•

•

2-22

2-26

2-27

2-45

2-6

2-7

2-8

2-9

2-13

2-13

2-14

2-17

2-18

2-15

2-15

Page 73

Periodic Maintenance Chart

PERIODIC MAINTENANCE 2-3

FREQUENCY Whichever

comes

first

1 6 12 18 24 30 36

OPERATION Every (0.6) (4) (7.5) (12) (15) (20) (24)

Engine oil - change # 6 months

Oil filter - replace

General lubrication - perform

Nuts, bolts, and fasteners tightness inspect †

#: Service more frequently when operating in severe conditions; dusty, wet, muddy, high speed,

or frequent starting/stopping.

*: For higher odometer readings, repeat at the frequency interval established here.

†: Replace, add, adjust, clean, or torque if necessary.

CAL: California model only

e: Emission Related Items

• • • • • • •

• • • •

• • •

• • • •

*Odometer Reading

× 1000 km

(× 1000 mile)

Refer-

ence

2-23

2-23

2-45

2-47

Page 74

2-4 PERIODIC MAINTENANCE

Specifications

Item Standard Service Limit

Fuel System (DFI)

Throttle Grip Free Play 2 ∼ 3 mm (0.08 ∼ 0.12 in.) –––

Idle Speed 1 000 ±50 r/min (rpm) –––

Throttle Body Vacuum 26 ±1.333 kPa (195 ±10 mmHg) –––

Air Cleaner Element:

ZX1200-B1/B2 Polyurethane foam –––

ZX1200-B3 Filter paper –––

Air Cleaner Element Oil SE, SF or SG SAE 30, or High-quality air

filter oil

Cooling System

Coolant:

Type (Recommended) Permanent type antifreeze –––

Color Green –––

Mixed Ratio Soft water 50%, Coolant 50% –––

Freezing Point – 35°C (– 31°F) –––

Total Amount 3.6L(3.8USqt) –––

Engine Top End

Valve Clearance:

Exhaust 0.22 ∼ 0.31 mm (0.0087 ∼ 0.0122 in.) –––

Inlet 0.15 ∼ 0.24 mm (0.0059 ∼ 0.0094 in.) –––

Clutch

Clutch Lever Free Play 2 ∼ 3 mm (0.08 ∼ 0.12 in.) –––

Engine Lubrication System

Engine Oil:

Type API SE, SF or SG –––

API SH or SJ with JASO MA

Viscosity SAE 10W-40 –––

Capacity 2.5 L (2.6 US qt, when filter is not removed) –––

2.8 L (3.0 US qt, when filter is removed) –––

3.6 L (3.8 US qt, when engine is completely

disassembled and dry)

Level

Tires

Tread Depth:

Front: DUNLOP D208FJ 4.0 mm (0.16 in.) 1 mm (0.04 in.)

Rear: DUNLOP D208J 5.4 mm (0.21 in.) 2 mm (0.08 in.)

Between upper and lower level lines (after

idling or running)

1.6 mm (0.063 in.)

–––

–––

–––

(AT, CH, DE):

Up to 130 km/h

(80 mph)

Over 130 km/h

(80 mph)

3 mm (0.12 in.)

Page 75

PERIODIC MAINTENANCE 2-5

Specifications

Item Standard Service Limit

Air Pressure: (when Cold)

Front Up to 182 kg (401 lb) l oad: –––

290 kPa (2.9 kgf/cm², 42 psi)

Rear Up to 182 kg (401 lb) load: –––

290 kPa (2.9 kgf/cm², 42 psi)

Final Drive

DriveChainSlack 25 ∼ 35 mm (0.98 ∼ 1.4 in.) –––

Drive Chain Roller Distance Less than 6 mm (0.236 in.) 6.2 mm (0.244 in.)

Drive Chain 20-link Length 317.5 ∼ 318.2 mm (12.50 ∼ 12.53 in.) 323 mm (12.7 in.)

Brakes

Brake Fuid:

Grade DOT4 –––

Brake Pad Lining Thickness:

Front and Rear 4 mm (0.12 in.) 1 mm (0.04 in.)

Brake Light Timing:

Front Pulled ON –––

Rear ON after about 10 mm (0.39 in.) of pedal

travel

Suspension

Fork Oil:

Viscosity KAYABA KHL15-10 (SAE 0 W) –––

Amount (per Side):

When Changing Oil approx. 420 mL (14.2 US oz) –––

After Disassembly and

490 ±4 mL (16.6 ±0.1 US oz) –––

Completely Dry

Fork Oil Level: 93 ±2 mm (3.66 ±0.08 in.)

(Fully Compressed, without

(from the top of the outer tube)

Spring)

Electrical System

Spark Plug Gap 0.7 ∼ 0.9 mm (0.028 ∼ 0.035 in.) –––

–––

–––

AT: Republic of Austria

CH: Swiss Confederation

DE: Federal Republic of Germany

Special Tools - Steering Stem Nut Wrench: 57001-1100

Jack: 57001-1238

Oil Filter Wrench: 57001-1249

Fork Piston Rod Puller, M12 × 1.25: 57001-1289

Fork Oil Level Gauge: 57001-1290

Pilot Screws Adjuster, C: 57001-1292

Fork Spring Compressor Set: 57001-1452

Fork Spring Compressor: 57001-1587

Page 76

2-6 PERIODIC MAINTENANCE

Periodic Maintenance Procedures

Fuel System (DFI)

Fuel Hose and Connection Inspection

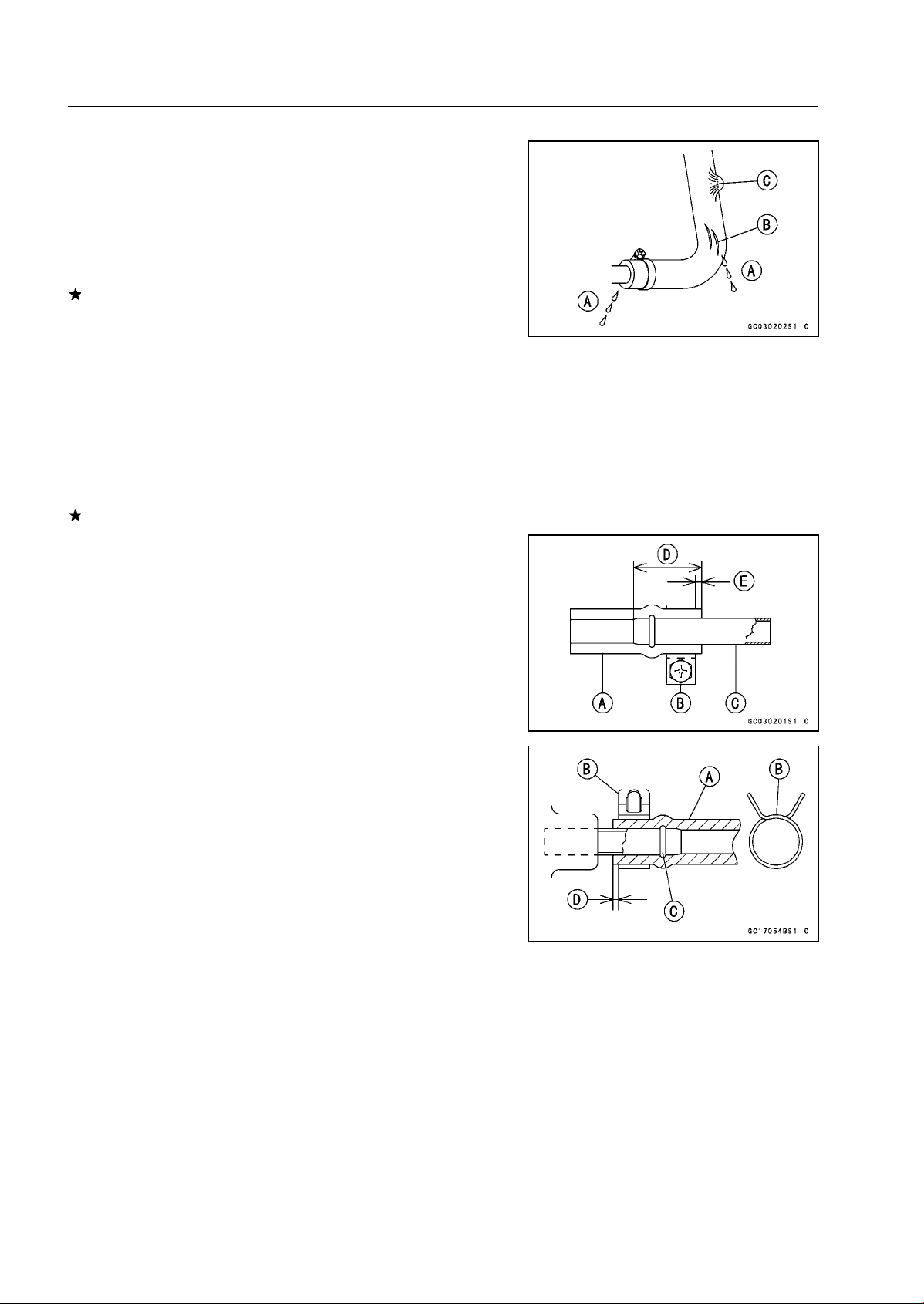

The fuel hoses are designed to be used throughout the

○

motorcycle’s life without any maintenance, however, if the

motorcycle is not properly handled, the high pressure inside the fuel line can cause fuel to leak [A] or the hose

to burst. Remove the fuel tank (see Fuel System (DFI)

chapter) and check the fuel hose.

Replace the fuel hose if any fraying, cracks [B] or bulges

[C] are noticed.

Check that the hoses are securely connected and clamps

•

are tightened correctly.

When installing, route the hoses according to Cable,

•

Wire, and Hose Routing section in the General Information chapter.

When installing the fuel hoses, avoid sharp bending, kink-

•

ing, flattening or twisting, and route the fuel hoses with a

minimum of bending so that the fuel flow will not be obstructed.

Replace the hose if it has been sharply bent or kinked.

Install the hose clamps in the position shown, and se-

•

curely tighten the clamp screws to the specified torque.

Check the fuel system for leaks after hose installation.

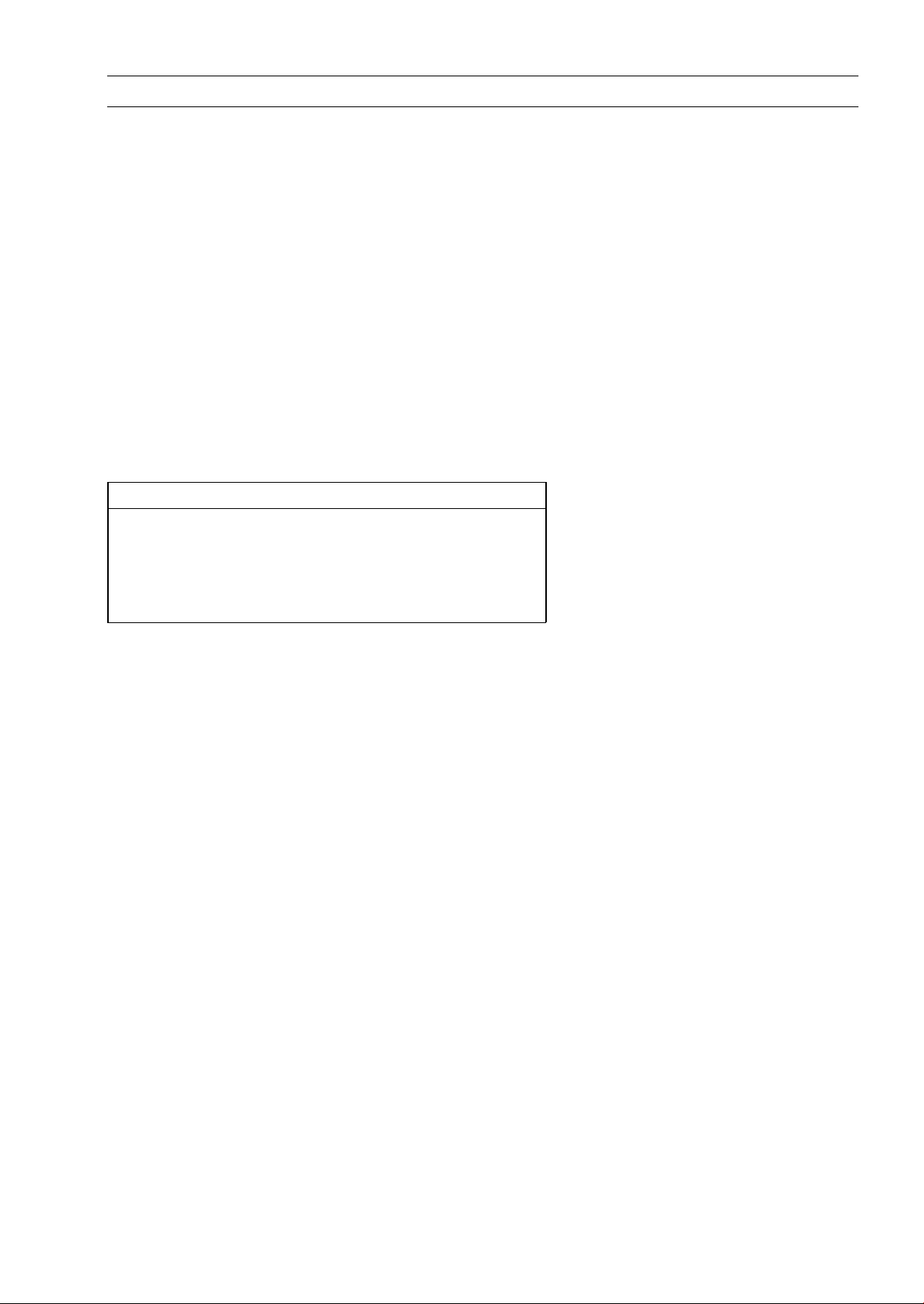

Fuel Hose [A ]

Clamp [B]

Fuel Pipe [C]

18 ∼ 22 mm (0.70 ∼ 0.87 in.) [D]

2 ∼ 3 mm (0.08 ∼ 0.12 in.) [E]

Fit the fuel hose [A] onto the pipe fully and install the plate

•

clamp [B] beyond the raised rib [C].

1 ∼ 2 mm (0.04 ∼ 0.08 in.)

Page 77

Periodic Maintenance Procedures

Throttle Control System Inspection

Check the throttle grip free play [B].

•

If the free play is incorrect, adjust the throttle cables.

Throttle Grip Free Play

Standard: 2 ∼ 3 mm (0.08 ∼ 0.12 in.)

Check that the throttle grip [A] moves smoothly from full

•

open to close, and the throttle closes quickly and completely in all steering position by the return spring.

If the throttle grip does not return properly, check the throttle cables routing, grip free play, and cable damage. Then

lubricate the throttle cable.

Run the engine at the idle speed, and turn the handlebar

•

all the way to the right and left to ensure that the idle speed

does not change.

If the idle speed increase, check the throttle cable free

play and the cables routing.

Remove the right lower inner cover (see Frame chapter).

•

Loosen the locknuts.

•

Screw both throttle cable adjuster to give the throttle grip

•

plenty of play.

Completely close the throttle grip, turn the accelerator

•

cable adjuster [A] to eliminate any cable free play, and

tighten the adjuster locknut [B].

Turn the decelerator cable adjuster [C] to adjust the throt-

•

tlegripfreepalyto2∼ 3 mm (0.08 ∼ 0.12 in.).

Tighten the deaccelerator cable locknut [D] securely.

•

If the free paly cannot be adjusted with the adjusters, replace the cable.

ZX1200-B1/B2 [E]

ZX1200-B3 [F]

PERIODIC MAINTENANCE 2-7

Check the throttle bore for cleanliness as follows:

•

Set up the fuel tank (see Fuel System (DFI) chapter).

○

Disconnect the inlet air temperature sensor connector [A].

○

Remove:

○

Air Cleaner Cap Bolts [B]

Right and Left Air Cleaner Caps [C]

Page 78

2-8 PERIODIC MAINTENANCE

Periodic Maintenance Procedures

In accordance with the Periodic Maintenance Chart,

○

check the throttle bores [A] at the butterfly valves [B] and

around them for carbon deposits by opening the valves.

If any carbon accumulates, wipe the carbon off the throttle

bores around the butterfly valves, using a lint-free cloth

[C] penetrated with high-flash point solvent.

Idle Speed Inspection

Start the engine and warm it up thoroughly.

•

With the engine idling, turn the handlebar to both sides

•

[A].

If handlebar movement changes the idle speed, the

throttle cables may be improperly adjusted or incorrectly

routed, or damaged. Be sure to correct any of these

conditions before riding (see Cable Routing Section in

General Information chapter).

WARNING

Operation with improperly adjusted, incorrectly

routed, or damaged cables could result in an unsafe riding condition.

Check the idle speed.

•

If the idle speed is out of specified range, adjust it.

Idle Speed

Standard: 1 000 ±50 r/min (rpm)

Start the engine and warm it up thoroughly.

•

Turn the adjusting screw [A] until the idle speed is correct.

•

Open and close the throttle a few times to make sure that

○

the idle speed is within the specified range. Readjust if

necessary.

ZX1200-B1/B2 [B]

ZX1200-B3 [C]

Page 79

Periodic Maintenance Procedures

Engine Vacuum Synchronization Inspection

ZX1200-B1/B2

NOTE

These procedures are explained on the assumption that

○

the inlet and exhaust system of the engine are in good

condition.

Remove the lower inner covers (see Frame chapter).

•

Set up the fuel tank (see Fuel System (DFI) chapter).

•

Pull out the vacuum switch valve hose [B] from the air

•

cleaner.

Pull off the three vacuum hoses [A] and rubber cap from

•

the right fittings on the throttle bodies.

CAUTION

Do not remove the atmospheric pressure hose.

Completely close the removed hoses [A] and [B] of the

•

clean air system with the proper plugs.

Completely close the clean air system hole of the air

•

cleaner with the proper plug.

PERIODIC MAINTENANCE 2-9

Start the engine and warm it up thoroughly.

•

Check the engine speed, using the engine revolution

•

tester [A] for high accuracy.

If the engine speed is out of 1 000 rpm, set the engine

speed to

1 000 rpm.

CAUTION

Do not adjust the engine speed by the tachometer

in the meter unit.

Connect the vacuum gauge hoses [A] to the right fittings

•

on the throttle bodies.

Connect the vacuum gauge hoses to the vacuum gauge

•

[B].

Start the engine and left it idle to measure the inlet vac-

•

uum.

If the vacuum is incorrect, adjust the synchronization.

Engine Vacuum

Standard: 26 ±1.333 kPa (195 ±10 mmHg) at Idle

Speed 1 000 ±50 r/min (rpm)

Page 80

2-10 PERIODIC MAINTENANCE

Periodic Maintenance Procedures

Turn the adjusting screw [A] to synchronize the throttle

•

valves.

First synchronize the left two or the right two throttle

○

valves by means of the left and right adjusting screws.

Then synchronize the left two throttle valves and the right

two throttle valves using the center adjusting screw.

If the throttle valves synchronization cannot be obtained

by using the adjusting screws, check for dirt or blockage,

and then check the inlet parts connection.

Special Tool - Pilot Screw Adjuster, C: 57001-1292 [B]

Check the throttle valve synchronization again

•

NOTE

Do not turn the bypass screws [A] carelessly during

○

throttle valve synchronization. You may cause poor running at low engine speed or irregular throttle sensor output voltage.

Remove the vacuum gauge hoses and install the re-

•

moved parts.

Check the idle speed.

•

ZX1200-B3

NOTE

These procedures are explained on the assumption that

○

the inlet and exhaust systems of the engine are in good

condition.

Situate the motorcycle so that it is vertical.

•

Remove the lower inner covers (see Frame chapter).

•

Set up the fuel tank (see Fuel System (DFI) chapter).

•

Pull off the vacuum hoses [A] and rubber cap(s) from the

•

right fittings of each throttle body.

Pull off the air switching valve hose [B] from the air cleaner

•

housing.

CAUTION

Do not remove the atmospheric pressure hose.

Plug:

•

Air Switching Valve Hose [A] and its Air Cleaner H ousing

Hole

Page 81

Periodic Maintenance Procedures

Start the engine and warm it up thoroughly.

•

Check the idle speed.

•

Tachometer [A]

Open and close the throttle.

•

If the idle speed is out of the specified range, adjust it.