Page 1

Page 2

Utility Vehicle

Owner's Manual

ENGLISH

Original instructions

Page 3

Page 4

Quick Reference Guide

GENERAL INFORMATION

This Quick Reference Guide will assist you in

finding the information you're looking for.

BREAK-IN

HOW TO OPERATE

SAFE OPERATION

MAINTENANCE AND ADJUSTMENT

TRANSPORTING AND STORAGE

TROUBLESHOOTING GUIDE

A Table of Contents is included after the Foreword.

Page 5

Page 6

Whenever you see the symbols shown below,

heed their instructions! Always follow safe operating

and maintenance practices.

DANGER

DANGER indicates a hazardous situation

which, if not avoided, will result in death or

serious injury.

WARNING

WARNING indicates a hazardous situation

which, if not avoided, could result in death or

serious injury.

NOTICE

NOTICE is used to address practices not related to personal injury.

NOTE

NOTE indicates information that may help or

○

guide you in the operation or service of the ve-

hicle.

Page 7

BASIC SAFE DRIVING

Knowing and following these rules for safe operation will increase your satisfaction with your new Kawasaki v ehicle.

Perform the Daily Checks

Refer to the Daily Checks section for a list of items

to check each day before use. Habitual performance of these checks will help to insure safer, more

reliable usage. Be sure that any irregularities found

during these checks are corrected before operating

the vehicle.

Drive Carefully and with Good Judgement

We want you to be satisfied with your new Kawasaki vehicle, so drive carefully, safely, and exercise

good judgement. Practice basic maneuvers so you

can drive confidently and safely.

Improper use of this vehicle can be hazardous.

Never operate at speeds too fast for your skills or

conditions. Handling charac teristics of this vehicle

change depending upon cargo load and driving

modes.

Read the Owner's Manual

Read and understand this Owner's Manual. This

is especially important for inexperienced operators.

Refer to this Owner's Manual if you have any questions.

Off-Highway Use Only

This vehicle is not an all-terrain vehicle; it is designed and equipped to be a multiuse utility vehicle

for off-highway use only. Use of this veh icle on public roads and paved surfaces is hazardous. Do not

operate this vehicle on public roads or paved surfaces.

Occupant Capacity

Make sure operators are 16 years or older with a

valid driver's license.

Each occupant must be able to sit with back

against seat, feet flat on floor, and hands on steering

wheel or handgrip.

The operator should be tall enough to wear the

seat belt properly and reach all controls.

Passenger should also be tall enough for the seat

belt to fit properly and to be able to brace themselves, as necessary, by placing both feet firmly on

the floor while gripping the handgrip. Stay completely inside the vehicle.

Never Drink and Drive

Alcohol and drugs impair your judgement and

slow your reactions. Even drugs prescribed by a

physician can be dangerous. Check with your doctor.

Use Proper Riding Gear

Proper protective gear can reduce the severity of

injury in the event of an accident.

Choose a helmet most appropriate for your use of

this utility vehicle. A helmet can reduce the risk of

Page 8

head injuries. Wear appropriate eye protection and

protective clothing.

Wearing Seat Belts

Both the operator and passenger should always

wear their seat belts pro perly. Seat belts cannot

completely protect you in every accident, but in

many cases a seat belt can reduce the risk of serious injury. Also, to avoid injury, do not put any part

of your body outside of the vehicle for any reason.

Close the Doors

Be sure all doors are securely closed during operation and never remove a door.

The doors prevent branches, gravel, and debris

from getting inside the passenger compartment.

Before Starting the Engine

Three “musts” before starting the engine are:

1. Apply the parking brake,

2. Put the gear shift lever in the “N” (neutral) posi-

tion,

3. Check the throttle pedal for proper operation. It

should return to its rest position when released.

Use the Parking Brake

Always apply the parking brake before getting out

of your vehicle.

Obey Local Laws

Know and obey all laws and regulations governing

the use of off-highway vehicles in your area. Respect private property. Always try to preserve nature

and the environment.

Refueling

Before refueling the vehicle, shut the engine off

and make sure the area is well ventilated and free of

any source of flame or sparks. Diesel fuel is very

flammable.

Tire Air Pressure

Tire inflation and type can affect the vehicle's handling characteristics. Check the tire pressure frequently. Use only the recommended tires for

replacement.

Maximum Seating Capacity

Do not exceed seating capacity: 2 occupants.

Occupants shall only ride in designated seating

positions and with maximum 2 persons in the seat.

Do not carry small children on lap.

Reduce Speed When Carrying Cargo, Passenger, and/or Pulling a Trailer

Carrying cargo, passenger and/or pulling a trailer

can make the vehicle difficult to steer and may affect

vehicle handling in an unpredictable manner.

Braking distance is increased when carrying cargo, passenger, and/or pulling a trailer. Reduce

speed and allow greater dist ance for braking when

carrying cargo, passenger, and/or pulling a trailer.

Use extreme caution when climbing and descending hills, and traversing slopes.

Page 9

FOREWORD

Congratulations on your purchase of a new Kawasaki Mule. It is the result of Kawasaki's engineering exper-

tise and a tradition of manufacturing high-quality consumer products.

Please read this Owner's Manual carefully before starting your new Mule so that you will be thoroughly

familiar with the proper operation of your vehicle's controls, its features, capabilities, and limitations.

To ensure a long, trouble–free life for your Mule, give it the proper care and maintenance described in this

manual.

For those who would like more detailed information on their Mule, a Service Manual is available for purchase

from any authorized Kawasaki Mule dealer. The Service Manual con tains detailed disassembly and maintenance information. Those who plan to do their own work should, of course, be competent mechanics and possess the special tools described in the Service Manual.

Keep this Owner's Manual aboard your Mule at all times so that you can refer to it whenever you need information.

This manual should be considered a permanent part of the Mule and should remain with the Mule when it is

sold.

All rights reserved. No part of this publication may be reproduced without our prior written permission.

This publication includes the latest information available at the time of printing. However, there may be minor

differences betw een the actual product and illustrations and text in this manual.

All products are subject to change without prior notice or obligation.

KAWASAKI HEAVY INDUSTRIES, LTD.

Motorcycle & Engine Company

© 2015 Kawasaki Heavy Industries, Ltd. Oct. 9, 2015. (1)

Page 10

Page 11

TABLE OF CONTENTS

SPECIFICATIONS .............................................. 13

DECLARATION OF CONFORMITY ................... 17

SERIAL NUMBER LOCATIONS ........................ 19

LOCATION OF PARTS ....................................... 20

LOCATION OF LABELS .................................... 23

LOADING INFORMATION ................................. 34

GENERAL INFORMATION ................................ 36

Multifunction Meter ........................................... 36

Speedometer ................................................. 37

Fuel Level Gauge .......................................... 38

Clock .............................................................. 38

Odometer ...................................................... 39

Trip Meters (Trip Meter A/B) .......................... 39

Hour Meter ..................................................... 40

2WD/4WD Indicator Symbol ......................... 40

Amber Glow Plug Indicator Light ................... 41

Red EPS Warning Indicator Light .................. 42

Red Parking Brake Indicator Light ................ 42

Red Reverse Indicator Light .......................... 42

Green Neutral Indicator Light ........................ 42

Red Seat-Belt Use Reminder ........................ 42

Red Coolant Temperature Warning Indicator

Light ............................................................

Red Oil Pressure Warning Indicator Light ..... 43

Lighting/Electrical Accessory Socket ............... 43

Light Switches .................................................. 44

Steering Wheel ................................................. 45

Brake Pedal ...................................................... 47

Cargo Bed ........................................................ 47

Tailgate .......................................................... 47

Lifting and Lowering the Cargo Bed .............. 48

42

Loading Cargo Bed ....................................... 50

Fuel ................................................................... 51

Diesel Fuel Requirements ............................. 51

Cold Weather Information ............................. 51

Using Biodiesel Fuel ..................................... 52

Filling the Fuel tank ....................................... 52

Glove Compartment/Tool Kit ............................ 54

Cupholders ................................................ ....... 55

Front Acc ess Cover .......................................... 55

Horn Switch ...................................................... 57

Main Switch ...................................................... 57

Gear Shift Lever ............................................... 58

Selectable 2WD/4WD Shift Switch .................. 60

Selectable DIFF-LOCK Shift Switch ................ 61

Belt Drive Transmission ................................... 62

Parking Brake Lever ......................................... 62

Doors ................................................................ 63

Seat .................................................................. 64

Seat Belts ......................................................... 65

Throttle Pedal ................................................... 67

Trailer Hitch Bracket ......................................... 68

BREAK-IN ........................................................... 69

HOW TO OPERATE ........................................... 70

Daily Checks .................................................... 70

Starting the Engine ........................................... 73

Cold Weather Starting ............... ....................... 74

Jump Starting ................................................... 75

Moving Off ........................................................ 77

Braking ............................................................. 78

Stopping the Engine ......................................... 78

Parking the Mule .............................................. 79

Page 12

Shifting Gears .................................................... 80

2WD/4WD Shifting ............................................ 81

Shifting the Differential ...................................... 82

When Stuck ....................................................... 83

SAFE OPERATION ............................................. 84

Unfamiliar Terrain .............................................. 84

Driving in Reverse ............................................. 85

Driving in “4WD” ................................................ 85

Turning the Vehicle ............................................ 86

Hills .................................................................... 86

Climbing Hills ......................... ............................ 87

Descending Hills ............................................... 88

Traversing Hillsides ........................................... 89

Sliding and Skidding .......................................... 89

Driving through Water ....................................... 90

Operator and Passenger Requirements ........... 91

NOISE AND VIBRATION CONTROL INFORMA-

TION ..................................................................

92

Control Information ............................................ 92

MAINTENANCE AND ADJUSTMENT ................ 93

Periodic Maintenance Chart .............................. 94

Engine Oil .......................................................... 98

Front Final Gear Case Oil .................................102

Transmission Case Oil ......................................105

Cooling System .................................................108

Valve Clearance .................... ............................ 111

Engine Air Cleaner ............................................ 111

Spark Arrester ................................................... 114

Throttle Pedal ....................................................116

Idle Adjustment ..................................................117

Fuel Hose .......................................................... 11 8

Fuel Filter ........................................................... 11 8

Water Separator ................................................ 119

Fuel Tank Vent ...................................................120

Belt Drive Transmission (CVT) ..........................120

Brakes ...............................................................122

Brake Pedal ....................................................122

Brake Disc and Brake Pad .............................124

Brake Light Switch .............................................125

Parking Brake ....................................................126

Steering Wheel ..................................................127

Power Steering System .................................. 127

Wheels ..............................................................128

Rims ...............................................................128

Wheel Nuts .....................................................128

Tires ................................................................128

Joint Boots .........................................................130

Suspension ........................................................131

Seat Belts ..........................................................133

Cargo Bed Latches ............................................134

Headlight Beam .................................................134

Battery ...............................................................135

Fuse ...................................................................143

Breaker ..............................................................149

General Lubrication ...........................................150

Cleaning ............................................................150

General Precautions ......................................150

Where to be Careful .......................................152

Washing Your Vehicle ....................................152

Bolt and Nut Tightening .....................................153

TRANSPORTING AND STORAGE ....................154

Transporting the Vehicle ....................................154

Storage ..............................................................155

Preparation for Storage ..................................155

Engine Care during Long Storage ..................156

Removal from Storage ...................................157

Before Starting Engine after Long Storage ....157

TROUBLESHOOTING GUIDE ............................159

Page 13

ENVIRONMENTAL PROTECTION ....................161

MAINTENANCE RECORD ................................. 162

Page 14

SPECIFICATIONS 13

SPECIFICATIONS

PERFORMANCE

Maximum Torque 52 N·m (5.3 kgf·m, 38 ft·lb) @2 400 r/min (rpm)

Minimum Turning Radius Differential Mode 4.8 m (15.7 ft)

Seating Capacity 2 persons

DIMENSIONS

Overall Length 3 385 mm (133.3 in.)

Overall Width 1 625 mm (63.98 in.)

Overall Height 1 965 mm (77.36 in.)

Wheelbase 2 345 mm (92.32 in.)

Tread: Front 1 385 mm (54.53 in.)

Rear 1 315 mm (51.77 in.)

Ground Clearance 265 mm (10.4 in.)

Curb Mass 828 kg (1 826 lb)

Cargo Bed (L × W × H) 1 375 × 1 355 × 280 mm (54.13 × 53.35 × 11.02 in.)

ENGINE

Type Diesel, OHV, 3-cylinder, 4-stroke, liquid-cooled

Displacement

Bore × Stroke

Compression Ratio

Starting System Electric starter

Cylinder Numbering Method

Firing Order

993 cm³ (60.6 cu in.)

74.0 × 77.0 mm (2.91 × 3.03 in.)

23.5:1

Left to right, 1-2-3

1-3-2

Page 15

14 SPECIFICATIONS

Injection Pump Bosch in-line type

Lubrication System Forced lubrication (wet sump)

Engine Oil: Type API CD, CF, CF-4, CI-4 or CJ-4 *

*: When using CJ-4 oil (low ash oil) in your engine, use

fuel with less than 0.05% sulfur content to avoid engine oil deterioration.

Viscosity SAE 10W-40

Capacity 2.4 L (2.5 US qt)

Coolant Capacity 6.1 L (6.4 US qt)

DRIVE TRAIN

Driving Type: Primary Belt drive torque converter (CVT)

Final 2WD/4WD system with drive shafts

Transmission Type 2-speed & reverse, automatic

Primary Reduction Ratio 3.334 ~ 0.756 (Belt drive torque converter)

Final Reduction Ratio: Front 6.382

Rear 6.245

Overall Drive Ratio: Forward

12.192 (High)

24.205 (Low)

Reverse

Transmission Gear Ratio: Forward

18.794

1.952 (High)

3.876 (Lo w)

Reverse

3.009

Front Final Gear Case Oil API GL-5 Hypoid gear oil

SAE 90 [above 5°C (41°F)]

SAE 80 [below 5°C (41°F)]

Page 16

SPECIFICATIONS 15

Front Final Gear Case Oil Capacity 0.43 L (0.45 US qt)

Transmission Case Oil API GL-5 Hypoid gear oil

SAE 90 [above 5°C (41°F)]

SAE 80 [below 5°C (41°F)]

Transmission Case Oil Capacity 2.00 L (2.1 US qt)

FRAME

Type Steel tube, ladder type

Steering Rack and pinion with Electric Power Steering (EPS) system

Caster 4.4°

Tire Size: Front 26 × 9.00-12 4PR

Rear 26 × 11.00-12 4PR

Rim Size:

Front

Rear

12 × 7.0AT

12 × 8.0AT

Fuel Tank Capacity 30 L (7.9 US gal)

ELECTRICAL EQUIPMENT

Battery 12 V 540CCA @0°F RC80

Headlight:

High Beam 12 V 60 W × 2, LED × 2

Low Beam 12 V 55 W × 2, LED × 2

Brake/Tail Light 12 V 21/5 W × 2

Reverse Light 12 V 10 W

LOAD CAPACITY

Maximum Vehicle Load (Including occupants,

733 kg (1 616 lb)

cargo and accessories)

Maximum Cargo Bed Load 453 kg (1 000 lb)

Page 17

16 SPECIFICATIONS

Specifications are subject to change without notice.

Page 18

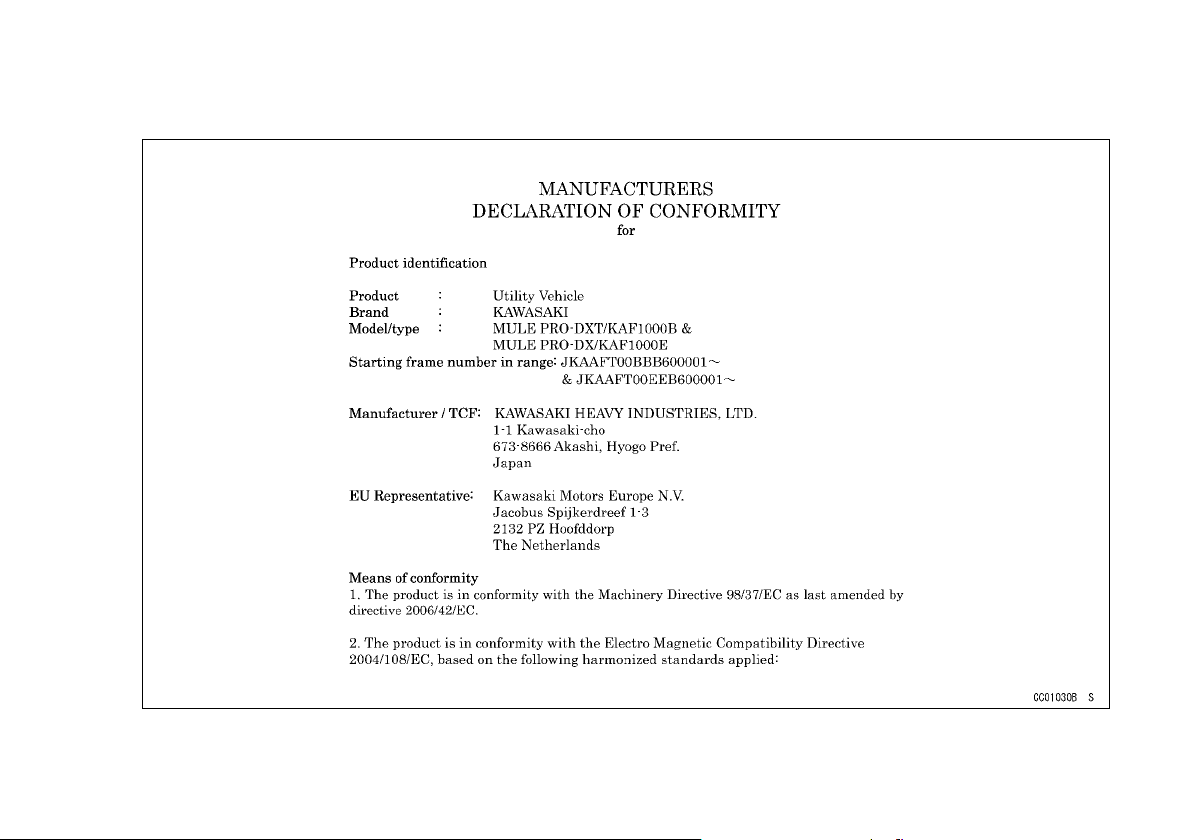

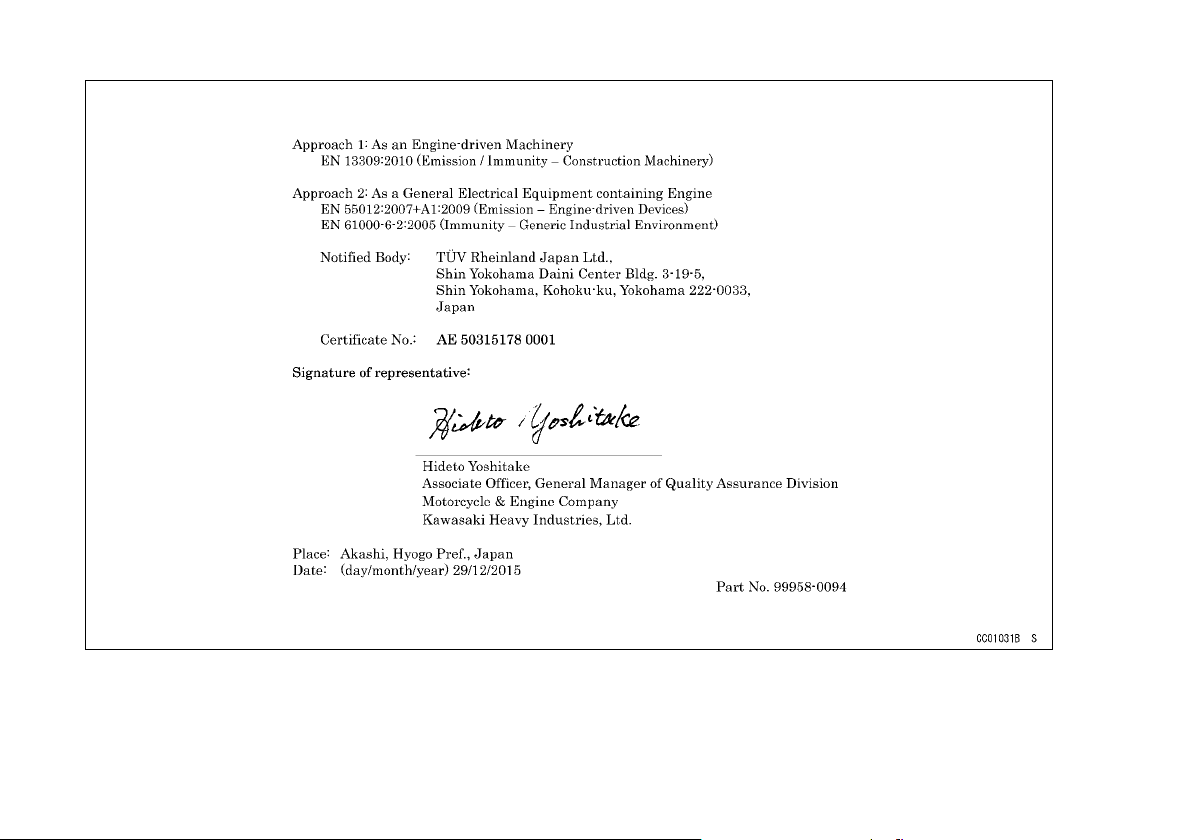

DECLARATION OF CONFORMITY 17

DECLARATION OF CONFORMITY

Page 19

18 DECLARATION OF CONFORMITY

Page 20

SERIAL NUMBER LOCATIONS 19

SERIAL NUMBER LOCATIONS

The engine and frame serial numbers are used to register the vehicle. They are the only means of identifying

your particular machine from others of the same model type. These serial numbers may be needed by your

dealer when ordering parts. In the event of theft, the investigating authorities will require both numbers as well

as the model type and any peculiar features of your machine that can help them identify it.

Frame No.

A. Frame Number

B. Right Front Axle

Engine No.

A. Engine Number

Page 21

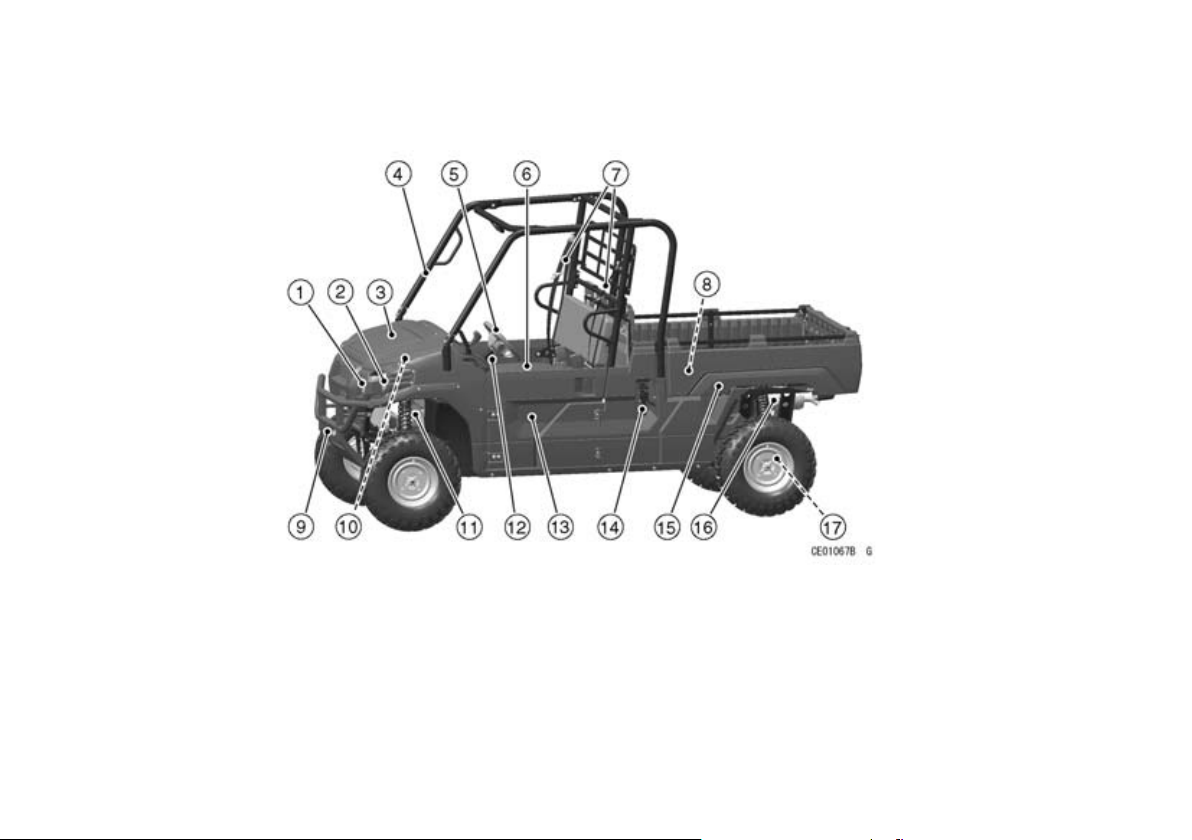

20 LOCATION OF PARTS

LOCATION OF PARTS

1. LED Sub Headlights

2. Headlights

3. Front Access Cover

4. ROPS (Roll Over Protective

Structure)

5. Steering Wheel

6. Seat

7. Seat Belts

8. Cargo Bed

9. Front Guard

10. Coolant Reserve Tank

11. Brake Fluid Reservoir

12. Steering Wheel Tilt Lock Lever

13. Door

14. Cargo Bed Latch

15. Cargo Bed Handgrip

16. Muffler (Spark Arrester)

17. Trailer Hitch Bracket

Page 22

LOCATION OF PARTS 21

1. Tailgate Latch Handle

2. Tailgate

3. Screen

4. Handgrip for Right Seat Passenger

5. Tail/Brake Light

6. Rear Shock Absorber

7. Air Cleaner

8. Battery

9. Fuel Tank Cap

10. Dashboard

11. Front Shock Absorber

12. Radiator

Page 23

22 LOCATION OF PARTS

1. Parking Brake Lever

2. Horn Switch

3. Selectable DIFF-LOCK Shift

Switch

4. Selectable 2WD/4WD Shift

Switch

5. Headlight Switch

6. LED Sub Headlight Switch

7. Multifunction Meter

8. Power Outlet Sockets

9. Glove Compartment

10. Cupholders

11. Main Switch

12. Brake Pedal

13. Throttle Pedal

14. Gear Shift Lever

15. Tool Kit

Page 24

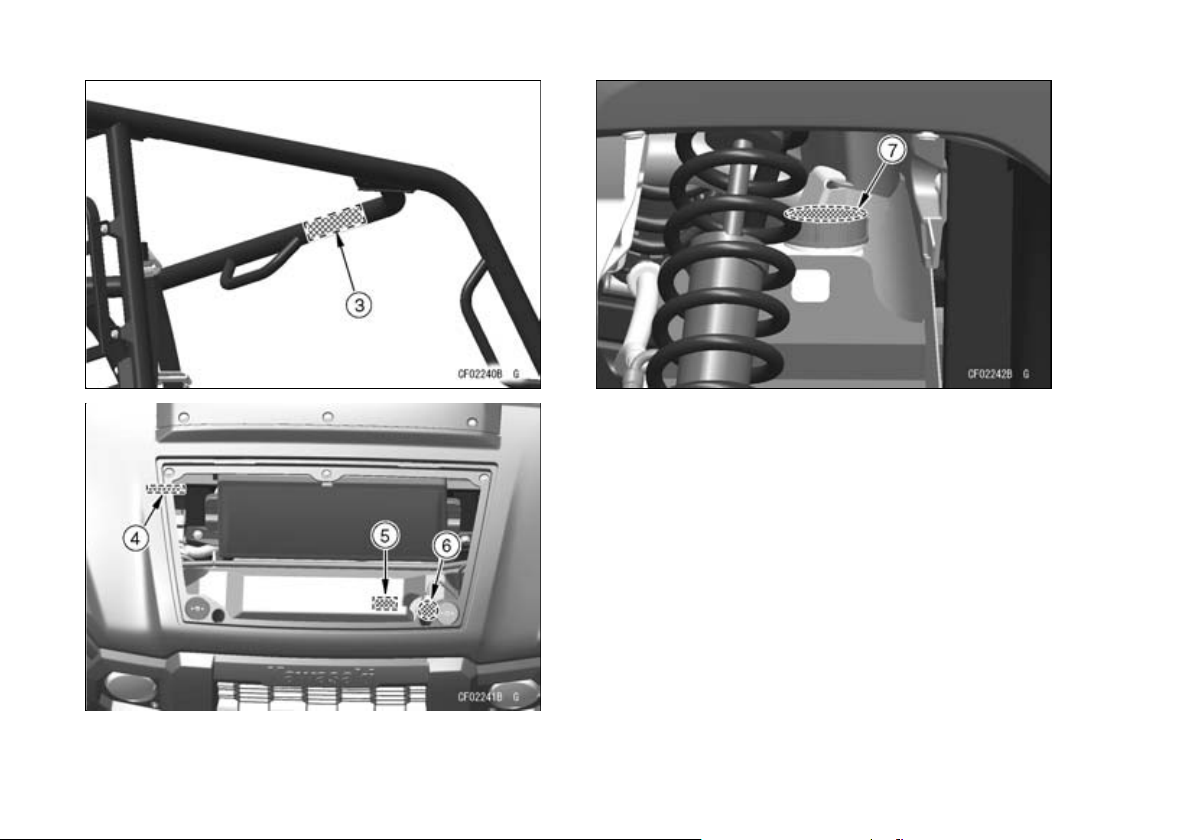

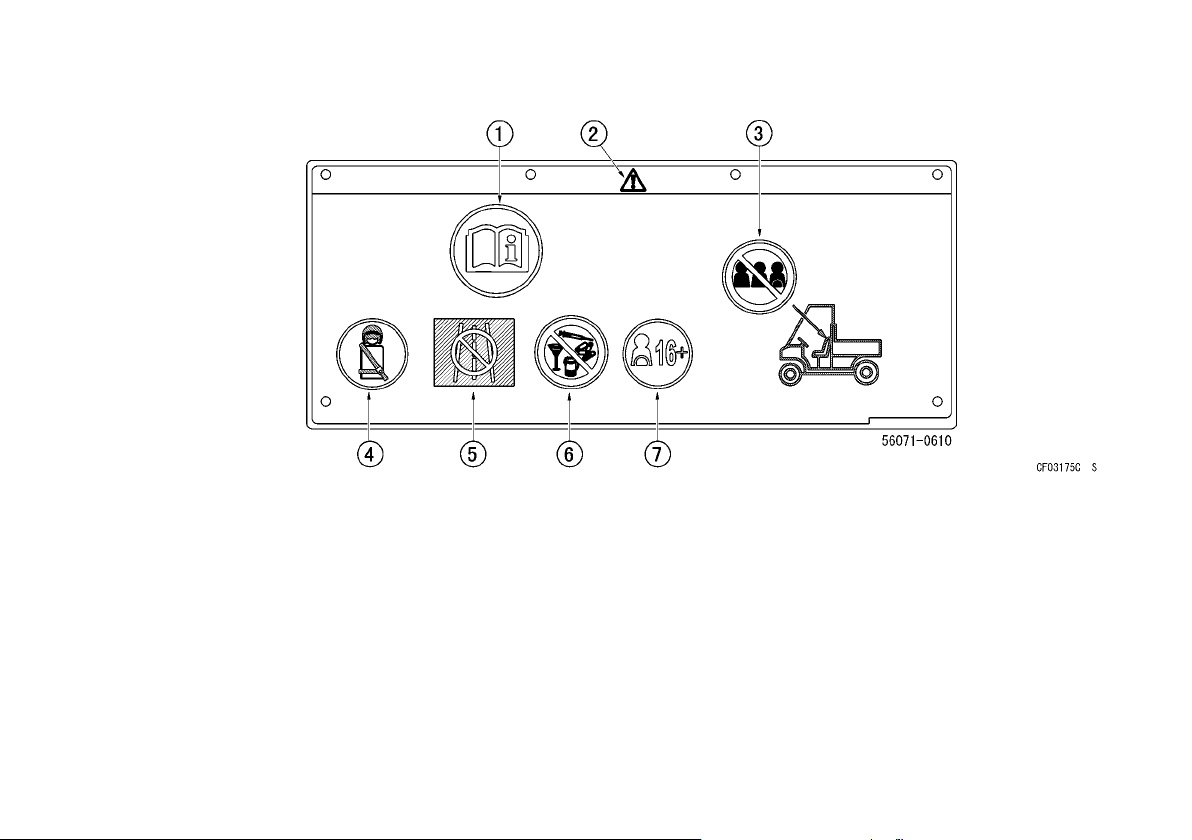

LOCATION OF LABELS

All warning labels which are on your vehicle are

repeated here. Read labels on your vehicle and

understand them thoroughly. They contain information which is important for your safety and the safety

of anyone else who may operate your vehicle.

Therefore, it is very important that all warning labels

be on your vehicle in the locations shown. If any label is missing, damaged, or worn, get a replacement

from your Kawasaki dealer and install it in the correct position.

NOTE

The sample warning labels in this section have

○

part numbers to help you and your dealer obtain

the correct replacem ent.

Refer to the actual vehicle label for model specific

○

data grayed out in the illustration.

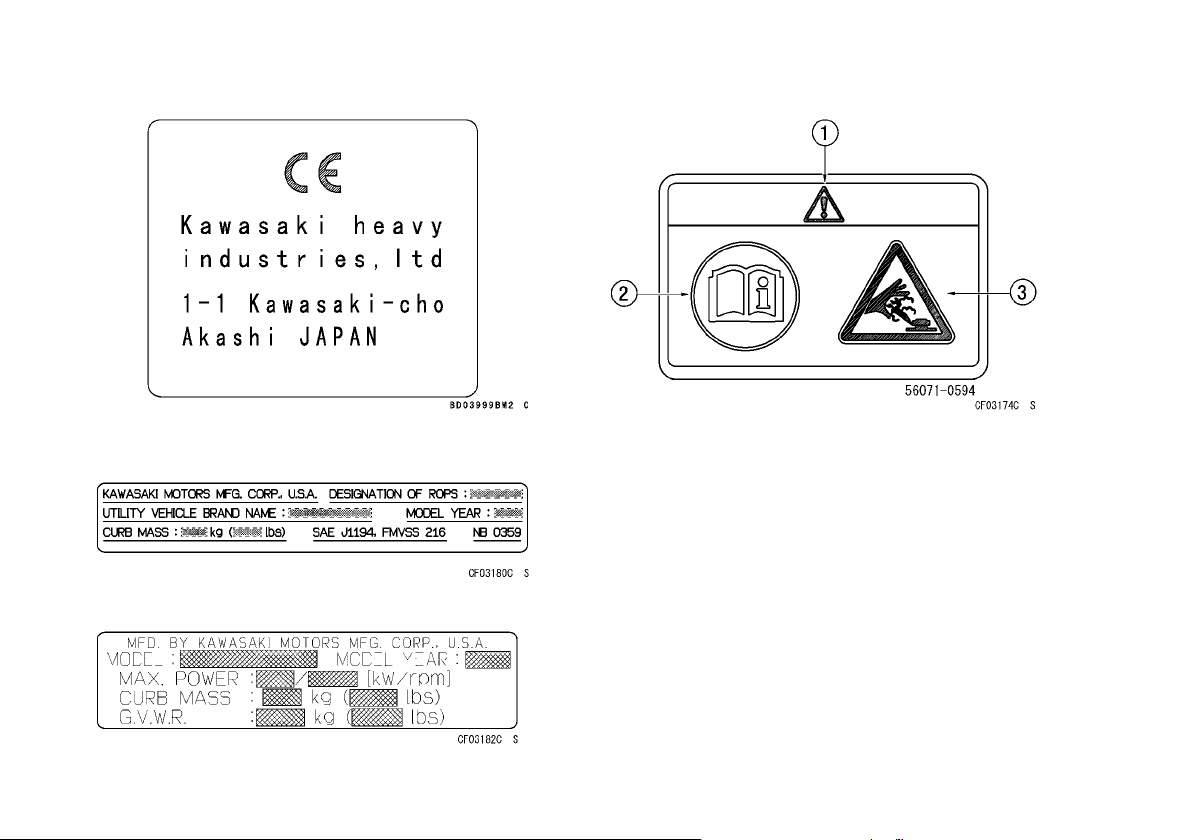

LOCATION OF LABELS 23

1. Warning (General)

2. CE Mark

Page 25

24 LOCATION OF LABELS

3. Specification (ROPS)

4. Specification (Model)

5. Danger (Radiator Cap)

6. Danger (Radiator Cap)

7. Warning (Brake Fluid)

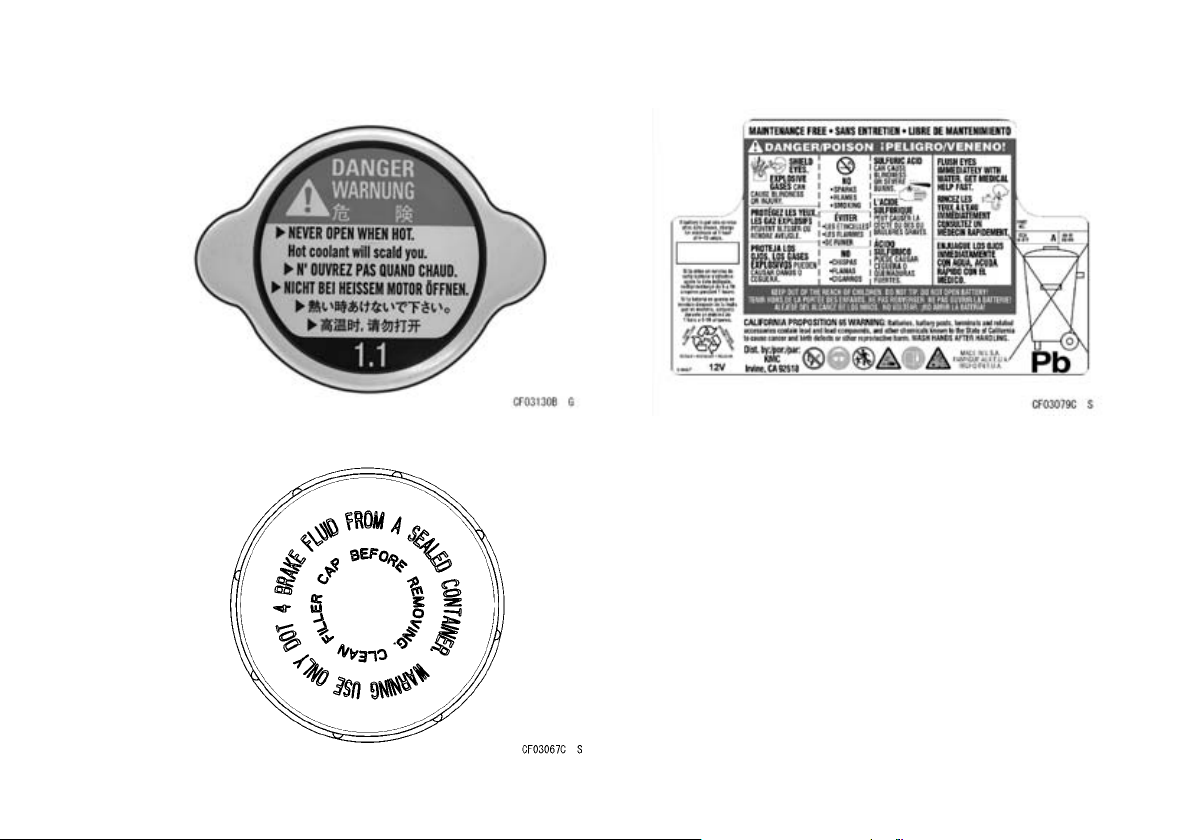

Page 26

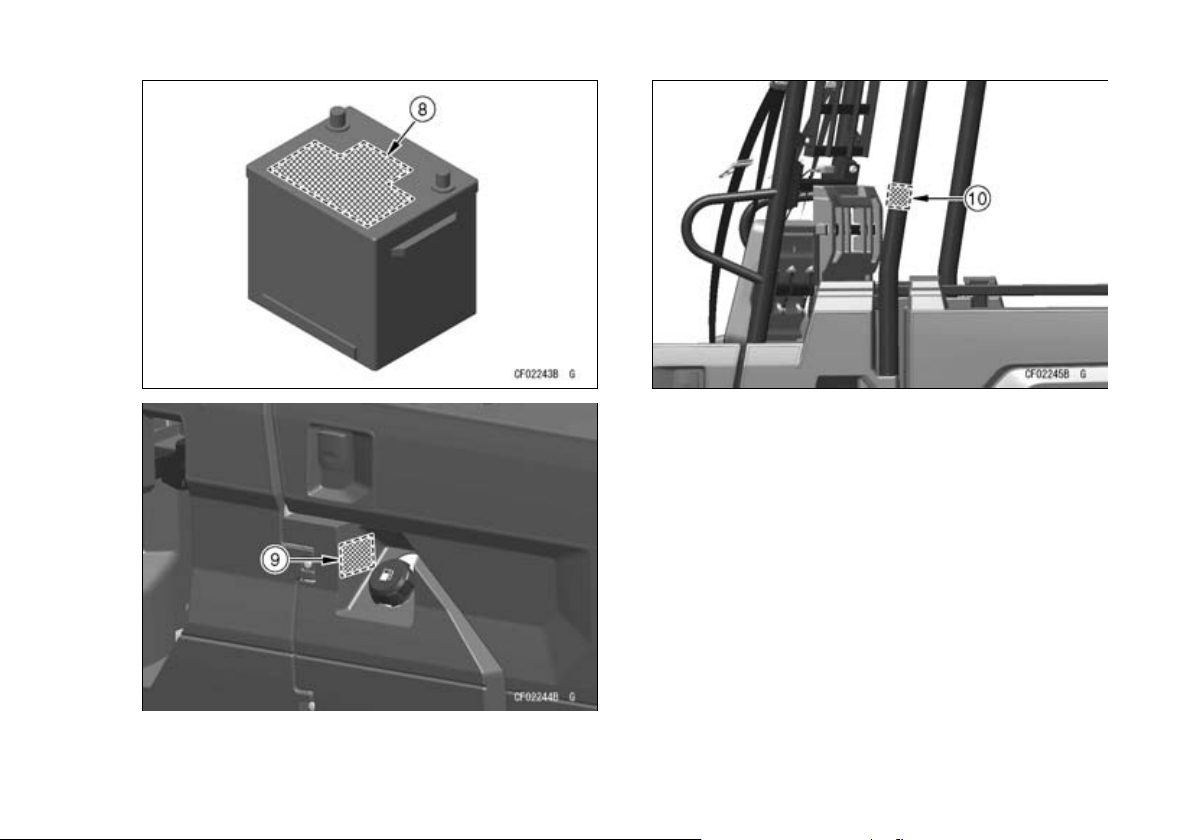

LOCATION OF LABELS 25

8. Danger/Poison (Battery)

9. Warning (Refueling)

10. Warning (Cargo Bed Lifting: both sides)

Page 27

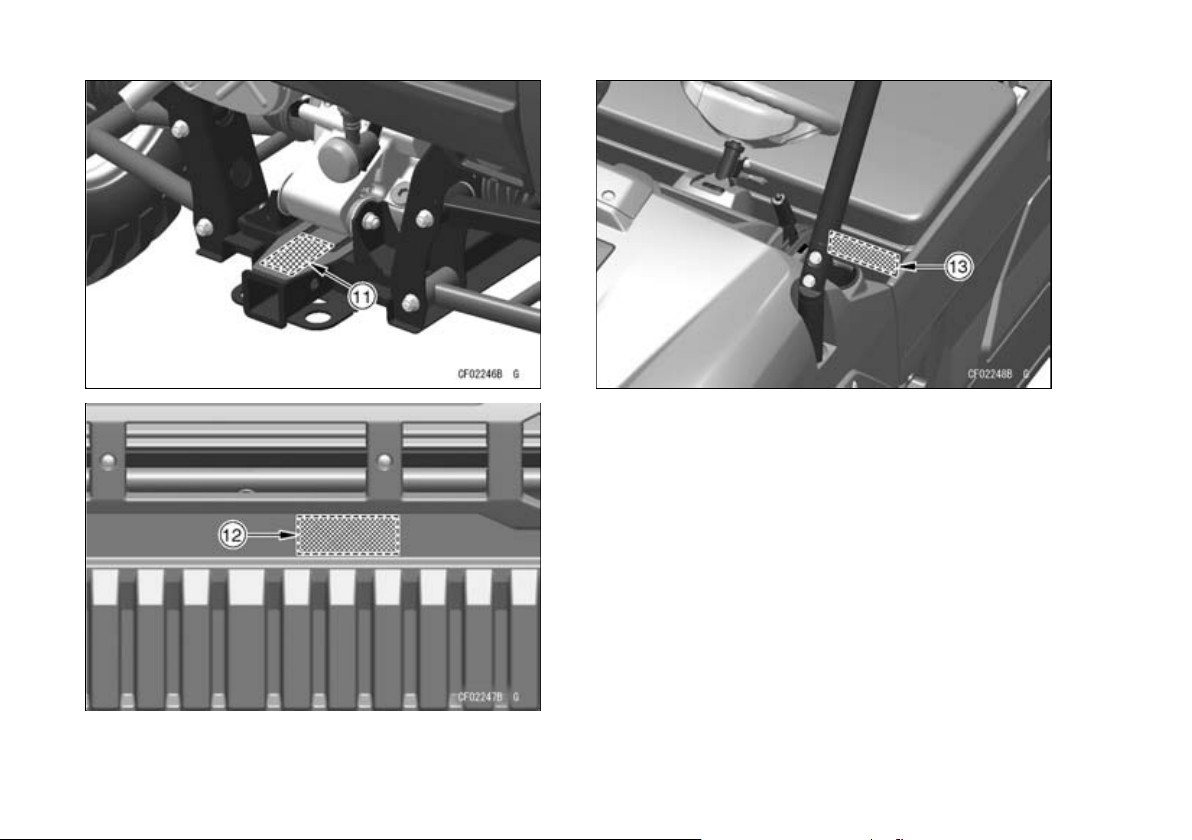

26 LOCATION OF LABELS

11. Warning (Trailer Towing)

12. Warning (Cargo Bed Loading)

13. Important Information (Tires/Max. Load)

Page 28

(1)

1. Read Owner’s Manual

2. Safety alert symbol

3. Maximum seating capacity: 2 persons, see

“BASIC SAFE DRIVING” section

4. Fasten seat belts. Wear an approved helmet

and protective gear, see “BASIC SAFE DRIVING” section

5. Never use on public roads, see “BASIC SAFE

DRIVING” section

6. Never use with drugs or alcohol, see “BASIC

SAFE DRIVING” section

7. Make sure operators are 16 years or older with

a valid driver’s license, see “BASIC SAFE

DRIVING” section

LOCATION OF LABELS 27

Page 29

28 LOCATION OF LABELS

(2)

(3)

(4)

(5)

1. Safety alert symbol

2. Read Owner’s Manual

3. Hot liquid. Never open when engine is hot, see

page 108

Page 30

LOCATION OF LABELS 29

(6)

(7)

(8)

Page 31

30 LOCATION OF LABELS

(9)

1. Read Owner’s Manual

2. Use diesel fuel only, see page 51

(10)

1. Safety alert symbol

2. Read Owner’s Manual

3. Hand crush, see page 48

Page 32

LOCATION OF LABELS 31

(11)

1. Safety alert symbol

2. Read Owner’s Manual

3. Maximum arm length

4. Vertical force limitation, see page 68

5. Horizontal force limitation, see page 68

Page 33

32 LOCATION OF LABELS

(12)

1. Safety alert symbol

2. Read Owner’s Manual

3. Maximum cargo bed load, see page 35

4. Never carry passengers in cargo bed, see page

51

Page 34

(13)

1. Read Owner’s Manual

2. Tire pressure, see page 128

3. Safety alert symbol

4. Load condition (including occupants and cargo), see page 128

5. Front tire size, see page 128

6. Rear tire size, see page 128

LOCATION OF LABELS 33

Page 35

34 LOADING INFORMATION

LOADING INFORMATION

WARNING

Incorrect loading, improper installation or use

of accessories, or modification of your vehicle may result in an unsafe operating condition. Before you operate it, make sure that the

vehicle is not overloaded and that you have

followed these instructions.

With the exception of genuine Kawasaki Parts

and Accessories, Kawasaki has no control over the

design or application of accessories. In some cases,

improper installation or use of accessories, or vehicle modifications, will void the utility vehicle warranty. In selecting and using accessories, and in

loading the vehicle, you are personally responsible

for your own safety and the safety of other person

involved.

NOTE

Kawasaki Parts and Accessories have been spe-

○

cially designed for us e on Kawasaki utility ve-

hicles. We strongly recommend that all parts and

accessories you add to your vehicle be genuine

Kawasaki components.

Because any vehicle is sensitive to increases in

weight and change s in weight distribution, you must

take ca re in carrying cargo. Always follow these precautions:

Carrying cargo, passenger and/or pulling a trailer

•

can make the vehicle difficult to steer and may affect vehicle handling in an unpredictable manner.

Use extreme caution when climbing and descending hills, and traversing slopes.

Braking distance is increased when carrying car-

•

go, passenger, and/or pulling a trailer. Reduce

speed and allow greater distance for braking.

All cargo should be carried as low as possible to

•

reduce the effect on the vehicle’s center of gravity.

Cargo weight should be equally distributed from

side to side. This helps maintain stability by centralizing weight. Avoid carrying cargo that extends

beyond the rear of the vehicle. Do not carry cargo

on top of the ROPS.

Cargo should be securely anchored. Make sure

•

the cargo will not move around while the vehicle is

moving. Recheck cargo security as often as possible (while the vehicle is stopped) and adjust as

necessary.

NOTICE

The front body work and fenders are not designed to carry cargo or to support weight.

Do not place cargo, lean or sit on them, or

they may break.

This vehicle is not designed to carry passengers

•

in the cargo bed. Installing additional passen ger

Page 36

seating or carrying passengers in the cargo bed

can cause changes in vehicle handling.

WARNING

Passengers transported in the cargo bed can

be tossed about or even thrown out causing

serious injury or death. Do not install seating

or trans port passengers in the cargo bed.

(Maximum Cargo Bed Load) Do not carry more

•

than maxi mum cargo bed load as specified below.

Maximum Cargo Bed Load: 453 kg (1 000 lb)

(Maximum Vehicle Load) Weight of operator, pas-

•

senger, cargo, accessories, and trailer tongue

must not exceed following limits.

Maximum Vehicle Load: 733 kg (1 616 lb)

Do not operate this vehicle faster than 16 km/h

•

(10 mph) when pulling a trailer. Refer to the

“Trailer Hitch Bracket” section in the “GENERAL

INFORMATION” chapter.

LOADING INFORMATION 35

Page 37

36 GENERAL INFORMATION

GENERAL INFORMATION

Multifunction Meter

1. Amber Glow Plug Indicator Light

2. Red EPS Warning Indicator Light

3. Speedometer

4. Fuel Level Gauge

5. Red Parking Brake Indicator Light

6. Red Reverse Indicator Light

7. Green Neutral Indicator Light

8. Right Button

9. Odometer/Trip Meters (Trip Meter A and B)/Hour

Meter

10.Clock

11. Left Button

12.“2WD” Indicator Symbol

13.Red Seat-Belt Use Reminder

14.Red Coolant Temperature Warning Indicator

Light

15.Red Oil Pressure Warning Indicator Light

16.“4WD” Indicator Symbol

Pushing the left button shifts the display in the

odometer/trip meters/hour meter through the 4

modes; odometer, trip meter A and B, and hour meter.

When the main switch is turned on, all the “LCD”

segments and “LED” lights are displayed for a second, then the clock and meters operate normally depending on the mode selected.

Page 38

GENERAL INFORMATION 37

Speedometer

The speed ometer shows the speed of the vehicle.

A. Speedometer

mph·km/h Display:

mph·km/h display can alternate between English

and metric modes (mph and km/h) in the digital meter. Make sure that mph or km/h is correctly displayed according to local regulations before driving.

Shift the mph·km/h display in the digital meter as follows.

The mph·km/h display shifts by pushing and hold-

•

ing the left button and pushing the right button

within two seconds.

A. mph·km/h Display

B. Left Button

C. Right Button

The mph·km/h display shifts as follows.

•

NOTE

Do not operate the vehicle with the digital meter

○

displaying in the wrong unit (mph or km/h).

Display the odometer in the digital meter.

•

NOTE

The data is maintained even if the battery is dis-

○

connected.

Page 39

38 GENERAL INFORMATION

Fuel Level Gauge

The fuel in the fuel tank is shown in segments. All

6 segments are displayed when the fuel tank is full.

As fuel is consumed the segments go out accordingly. When the bottom segment is reached, it will

begin blinking to warn of a low fuel level.

When it begins blinking, 6.6 liters (1.7 US gal) of

fuel remains. Fill the fuel tank as soon as possible

because there is no reserve tank in this vehicle (see

Fuel section).

A. Hour Display

B. Minute Display

Push the right button. The hour display only

•

blinks. Push the left button to advance the hours.

A. Blinking to warn of a low fuel level

Clock

To adjust hours and minutes:

Turn the main switch on.

•

The odometer is displayed.

•

Push the right button for more than two seconds.

•

Both the hour and minute displays start blinking.

A. Hour Display

Push the right button. The hour display stops

•

blinking and the minute display starts blinking.

Push the left button to advance the minutes.

Page 40

A. Minute Display

Push the right button. Both the hour and minute

•

displays start blinking again.

Push the left button. The displays stop blinking

•

and the clock starts working.

GENERAL INFORMATION 39

NOTE

When the figures come to 999999, they are

○

stopped and locked.

A. Odometer

NOTE

Pushing the left button momentarily advances the

○

hour or minute step by step. Pushing and holding

the button advances the hour or minute continuously.

The clock works normally from the back-up power

○

while the main switch is turned off.

When the battery is disconnected, the clock re-

○

sets to 1:00, and starts working again when the

battery is connected.

Odometer

The odometer shows the total distance in kilometers or miles that the vehicle has been driven.

The meter cannot be reset.

Trip Meters (Trip Meter A/B)

The trip meter shows the distance in kilometers or

miles traveled since it was last reset to zero.

To reset the trip meter:

Push the left button to display the trip meter A or

•

B.

Push the right button and hold it in.

•

After two seconds, the figure display turns to 0.0,

•

and then starts counting when the vehicle is oper-

ated. The meter counts until it is next reset.

NOTE

When the trip meter reaches 9999.9 when the ve-

○

hicle is running, it turns back to 0.0 and starts

counting again.

Page 41

40 GENERAL INFORMATION

A. Trip Meter A

Hour Meter

The hour meter shows the total hours that the vehicle has been operated. This meter cannot be reset.

NOTE

When the figures come to 99999.9, they are

○

stopped and locked.

A. Hour Meter

2WD/4WD Indicator Symbol

This vehicle can be driven in either “2WD” or

“4WD.”

When the selectable 2WD/4WD shift switch is in

“4WD,” the “4WD” indicator symbol will appear.

After shifting there is a momentary delay before

the indicator symbols change.

Page 42

GENERAL INFORMATION 41

A. “2WD” Indicator Symbol

B. “4WD” Indicator Symbol

A. Amber Glow Plug Indicator Light

B. Red EPS Warning Indicator Light

C. Red Parking Brake Indicator Light

D. Red Reverse Indicator Light

E. Green Neutral Indicator Light

F. Red Seat-Belt Use Reminder

G. Red Coolant Temperature Warning Indicator

Light

H. Red Oil Pressure Warning Indicator Light

Amber Glow Plug Indicator Light

The glow plug indicator light goes on for 4 seconds when the main switch key is turned to the “ON”

position. The indicator light also goes on whenever

the key is in the “START” position. The indicator light

goes off after the plug is fully heated. If it does not

go on or go off, have the glow plug and related system checked by an authorized Kawasaki dealer.

Page 43

42 GENERAL INFORMATION

Refer to the “Starting the Engine” section in the

“HOW TO OPERATE” chapter for detailed informa-

tion.

Red EPS Warning Indicator Light

The EPS warning indicator light will momentarily

illuminate when the engine starts, then go off in a

second if the system is in order. If this warning indicator light illuminates any other time, it indicates the

ECU or actuator has malfunctioned, or the wiring

harness has become disconnected. Stop driving immediately and contact an authorized Kawasaki

dealer to have the system checked.

NOTE

If this warning indicator light does not go on when

○

the main switch is turned on, there may be a prob-

lem with the light itself. Contact an authorized Ka-

wasaki dealer for inspection.

Red Parking Brake Indicator Light

When the parking brake is applied with the main

switch in the “ON” position, the parking brake indicator light illuminates.

Red Reverse Indicator Light

When the transmission is in reverse gear, the reverse indicator light illuminates.

Green Neutral Indicator Light

When the transmission is in neutral, the neutral indicator light illuminates.

Red Seat-Belt Use Reminder

When the main switch is turned on, the seat-belt

use reminder will illuminate and stay on for approximately 8 seconds, even if the operator's belt is

buckled. The light is a reminder to the operator to

make sure that passengers have buckled their seat

belts.

Red Coolant Temperature Warning Indicator

Light

The coolant temperature warning indicator light illuminates whenever the coolant temperature rises

too high while the vehicle is in operation. If it stays

on, stop the engine and check the coolant level in

the coolant reserve tank after the engine cools

down.

Be sure to check that the radiator fan is free from

mud and other obstacles. Refer to the “Breaker”

section in the “MAINTENANCE AND ADJUSTMENT” chapter.

NOTICE

Do not continue running the engine with the

temperature warning indicator light continuously illuminated. Prolonged engine operation can result in engine damage from

overheating.

NOTE

When you touch the fan, be sure to disconnect

○

the negative ( –) battery cable, since the fan can

Page 44

GENERAL INFORMATION 43

operate automatically even with the main switch

off.

Red Oil Pressure Warning Indicator Light

The oil pressure warning indicator light blinks to

warn the oper ator whenever the oil pressure is dangerously low or the main switch is in the “ON” position with the engine not running, and goes off when

the proper engine oil pressure is reached. Refer to

the “MAINTENANCE AND ADJUSTMENT” chapter

for more detailed engine oil information.

Lighting/Electrical Accessory Socket

The lighting/electrical accessory 12 volt sockets

are located on the dashboard.

An auxiliary light or an accessory may be con-

nected to these connectors.

A. Power Outlet Sockets

NOTICE

Do not connect a light or load of more than

120 watts on one or both sockets, or the battery may rapidly discharge.

Page 45

44 GENERAL INFORMATION

Light Switches

The light switches are 3-position type with an indi-

cator.

The headlights can be turned on by pushing the

headlight switch to the “

when the main switch is in the “ON” position.

: Low Beam

: High Beam

When the headlights are on high beam, the high

beam indicator light in the switch goes on as a reminder. The headlights go off when the headlight

switch is pushed in “OFF” position.

” or “ ” position

A. High Beam Position

B. Low Beam Position

C. OFF Position

D. High Beam Indicator Lights

E. Headlight Switch

F. LED Sub Headlight Switch

This vehicle is equipped with LED sub headlights.

The operation of the LED sub headlight switch is

similar with the headlight switch.

Page 46

A. Headlights

B. LED Sub Headlights

GENERAL INFORMATION 45

Steering Wheel

This vehicle is equipped with an electric power

steering system. The system does not require regular maintenance by users. Do not tamper with the

electronic control unit (ECU) or loosen the fittings of

steering actuator, or the neutral position setting of

the steering will be adversely affected and will

cause serious driving problems. If such components

need service, contact an authorized Kawasaki dealer.

If the steering becomes more difficult than usual

or you feel a steering problem, refer to the “Steering

Wheel” section in the “MAINTENANCE AND ADJUSTMENT” chapter.

A. Steering Wheel

Page 47

46 GENERAL INFORMATION

NOTE

The power steering system functions only when

○

engine is running.

If you install wireless equipment on board, contact

○

an authorized Kawasaki dealer. Installing such

equipment improperly may affect the ECU.

Steering Position Adjustment

The steering wheel position can be adjusted to

suit the operator.

Make any steering wheel adjustment before start-

ing the vehicle.

WARNING

Adjusting the steering wheel position while

driving could cause loss of control and an accident resulting in serious injury or death. To

prevent loss of control, do not adjust the

steering wheel position unless the vehicle is

stopped.

Move the steering wheel up or down while pulling

•

up the tilt lock lever under the steering wheel.

Release the tilt lock lever to lock the steering

•

wheel in position.

A. Tilt Lock Lever

B. Pull up.

C. Steering Wheel

D. Adjusting Direction

NOTE

Make sure you have securely locked the steering

○

wheel in place by moving it up and down.

Page 48

GENERAL INFORMATION 47

Brake Pedal

The brake pedal is the left pedal on the floorboard.

Depress the pedal to slow or stop the vehicle.

A. Brake Pedal

B. Floorboard

Cargo Bed

Tailgate

The tailgate of the cargo bed can be lowered. Before lowering the tailgate, park on a firm level surface and set the parking brake.

To open the tailgate, release the latches and lower

the tailgate. Cables hold the tailgate level with the

cargo bed.

A. Tailgate

B. Latch Handle (Both Sides)

To close the tailgate, lift to the upright position and

secure firmly with the latches.

Push the tailgate latch handles forward to make

sure the latches stay securely closed. Do not drive

the vehicle with the tailgate lowered.

Page 49

48 GENERAL INFORMATION

A. Tailgate

B. Cable

Lifting and Lowering the Cargo Bed

WARNING

Reduced clearance between the cargo bed

and the cargo screen ma y trap and seriously

injure an arm while lifting or lowering the cargo bed. To avoid possible injury, do not place

hands on any part of the cargo screen when

lifting or lowering the cargo bed.

The cargo bed can be tilted by releasing the

latches on each side, and then lifting the bed with

the handgr ips.

A. Cargo Bed Latch (Both Sides)

B. Handgrip (Both Sides)

Lifting the Cargo Bed

Before tilting the cargo bed, park on a firm level

•

surface and set the parking brake.

Empty the cargo bed prior to raising the cargo

•

bed.

Lift the bed with the handgrips. The supporting

•

damper under the cargo bed helps lifting the bed.

Pull the supporting rod out of its mounting clip on

•

the front of the cargo bed.

Page 50

GENERAL INFORMATION 49

A. Supporting Rod

B. Pull here to free rod from clip.

C. Cargo Bed

D. Clip

E. Forward

With the cargo bed at the highest position, hook

•

the ring of the supporting rod on the stopper pin of

the bottom horizont al bar of the screen.

A. Supporting Damper

B. Cargo Bed (Tilted Position)

C. Supporting Rod

D. Ring of the supporting rod

E. Screen

F. Stopper Pin

WARNING

Using only the bed supporting damper for

cargo bed support may allow the cargo bed to

suddenly lower. To prevent injury caused by

sudden lowering of the cargo bed, support

the cargo bed with the support rod whenever

lifting the cargo bed.

Page 51

50 GENERAL INFORMATION

Lowering the Cargo Bed

Before lowering the bed, check to be sure the

•

area under it is clear.

Return the supporting rod to its original position

•

and secure it with the clip.

To lower the cargo bed pus h down the side rail of

•

the cargo bed. And then hold the handgrip with

another hand and carefully lower the bed in place.

Latch both latches and check that the bed is prop-

•

erly locked into place. Do not leave the cargo bed

unlatched.

A. Cargo Bed Latch (Locked Position)

B. Side Rail

Do not drive the vehicle with the front end of the

•

cargo bed raised or unlatched.

WARNING

The front of the cargo bed becomes heavier

as it lowers into position and can suddenly

lower, trapping arms between the bed and

frame causing serious injury. To prevent the

bed from suddenly lowering, use the handgrips to properly support the bed when lowering or lifting the bed.

Loading Cargo Bed

NOTICE

Do not carry more than 453 kg (1 000 lb) in the

cargo bed.

Page 52

GENERAL INFORMATION 51

WARNING

Overloading, failure to properly secure car-

•

go, or improper use of the cargo bed can

cause changes in handling which can lead

to an accident. Follow guidelines provided

in the “LOADING INFORMATION” chapter.

Passengers transported in the cargo bed

•

can be tossed about or even thrown out

causing serious injury or death. Do not install seating or transport passengers in the

cargo bed.

Driving with the cargo bed tilted may be

•

hazardous. Failure to lower and lock the

bed into place may cause serious injury or

death. Al ways lower and latch the bed after

tilting.

Fuel

Diesel Fuel Requirements

Kawasaki recommends diesel fuels that meet the

following requirements for use in this vehicle. Use

clean, fresh diesel fuel to maintain performance and

life from the engine.

Fuel Specification and Cetane Number

(1) The diesel fuel must meet the European EN590

specification.

(2) Use diesel fuel with a cetane number equal to

or higher than that shown below. If available in

your area, a high cetane “premium” diesel fuel

may offer improved cold-starting and warm-up

performance.

Fuel type: Diesel fuel for vehicle

Minimum cetane number: 45

Lower Sulfur

A sulfur content less than 0.05% by volume is recommended. To avoid engine corrosion, and engine

oil contamination, do not use fuel with more than

0.5% sulfur content.

When using CJ-4 oil (low ash oil) in your engine,

use fuel with less than 0.05% sulfur content to avoid

engine oil deterioration.

Cold Weather Information

In cold weather, diesel fuel may thicken enough to

clog the fuel filter. This is usually caused by naturally-occurring paraffin in diesel fuel turning to wax

Page 53

52 GENERAL INFORMATION

as it gets colder. If the engine starts but stalls after a

short time and will not restart, the fuel filter may be

clogged. For best results in cold weather use winter

diesel fuel.

WARNING

Starting fluids such as ether are explosive

and may cause severe injury. Do not use

starting fluids containing ether in the air intake system.

NOTICE

Do not add gasoline, gasohol, alcohol or

aftermarket cetane improver additives to diesel fuel. Damage to the fuel injection system

may result.

NOTICE

Wax flakes in the fuel tank could damage the

fuel level sensor. At temperatures below –10°

C (14 °F), use winter diesel fuel to prevent the

diesel fuel from turning to wax.

Using Biodiesel Fuel

Biodiesel fuels blended with diesel fuel may be

used in this vehicle only if the blended fuel meets

the following conditions:

(1) Biodiesel fuel concentration must not exceed

7% by volume (B7).

(2) The petroleum diesel fuel base must meet the

European EN590 specification. The pure biodiesel base must meet the European Standard

EN14214. Raw pressed vegetable oils are NOT

acceptable for use in any concentration.

Precautions when Using Biodiesel Fuels

(1) Cranking time when engine starting in cold

weather will be prolonged.

(2) Biodiesel blended fuel attracts mois ture and

may contain higher water content than conventional diesel fuels. Keep storage and vehicle

tanks as full as possible and ensure all caps

and covers are installed properly to prevent

water from entering and collecting in the fuel

system.

(3) Clean up any spilled fuel immediately to prevent

damage to painted surfaces.

(4) To avoid damage caused by fuel degrada tion,

biodiesel blended fuel should not be used if it

has been stored for more than 3 months. If an

engine is going to be placed in storage, the biodiesel blended fuel should be flushed out by operating the engine for at least 30 minutes on

conventional diesel fuel after replacing biodiesel

fuel in the vehicle fuel tank with petroleumbased diesel fuel.

Filling the Fuel tank

The fuel tank is mounted under the right side of

the seat. Use only fresh diesel fuel with the recommended cetane number from an uncontaminated

Page 54

source to ensure proper running of your vehicle.

Avoid filling the tank in the rain or where heavy dust

is blowing so that the fuel does not get contaminated.

GENERAL INFORMATION 53

A. Filler Neck

B. Fuel Top Level (Bottom of Filler Neck)

C. Fuel Tank

A. Fuel Tank Cap

Never fill the tank completely to the top. After refueling, make sure the fuel tank cap is closed securely.

NOTICE

Always clean dirt/mud/debris/water from the

fuel tank cap and surrounding area prior to

filling the tank to prevent dirt/mud/debris/water from entering the fuel tank. Accumulation of moisture or sediment in the fuel

system can restrict the flow of fuel and cause

fuel system and/or engine damage.

Page 55

54 GENERAL INFORMATION

WARNING

Diesel fuel is extremely flammable and can

ignite under certain conditions. To avoid the

potential for burns or other injuries when refueling, turn the main switch key off. Do not

smoke. Make sure the area is well ventilated

and free from any source of flame or sparks;

this includes any appliance with a pilot light.

Never fill the tank completely to the top. After

refueling, make sur e the fuel tank cap is

closed securely. If diesel fuel is spilled on the

fuel tank, wipe it off immediately.

Glove Compartment/Tool Kit

A glove compartment is provided at the right side

of the dashboard. Store only light items to avoid

damage to the inside of the compartment. Do not

store items which must not get wet or dirty.

The tool kit is located at the inside of the glove

compartment.

A. Glove Compartment

B. Tool Kit

Page 56

GENERAL INFORMATION 55

Cupholders

Cupholders are provided at the left and right sides

of the dashboard.

A. Cupholder (Both Sides)

Front Access Cover

The front access cover can be removed for main-

tenance such as a coolant level inspection.

NOTICE

Do not store items under the front access

cover. This area is not designed for storage.

Cover Opening

Turn the knobs counterclockwise 90° to release

•

the locks.

Pull the front of the front access cover up and

•

open the cover.

A. Front Access Cover

B. Knobs

Page 57

56 GENERAL INFORMATION

Pull the front access cover forward to disengage

•

the tabs from the slits of the front hood.

A. Front Access Cover

B. Tabs

C. Slits

Cover Closing

Insert the tabs on the front access cover to the

•

slits of the front hood.

Lower the front access cover and turn the knobs

•

clockwise until they stop to lock the front access

cover.

A. Front Access Cover

B. Knob (Both Sides)

Pull up the front ends of the front access cover to

•

make su re the cover is locked securely.

WARNING

An open front access cover can distract or

impair visibility of the operator, causing loss

of vehicle control and potential serious injury

or death.

Lock the front access cover securely before

operating the vehicle.

Page 58

GENERAL INFORMATION 57

Horn Switch

Push the horn switch to sound the horn.

A. Horn Switch

Main Switch

This is a three-position, key-operated switch. The

key can be removed from the switch only when it is

in the “OFF” position.

A. Main Switch

B. “OFF” Position

C. “ON” Position

D. “START” Position

Page 59

58 GENERAL INFORMATION

OFF Engine off. All electrical circuits off.

ON

START

All electrical equipment can be used.

Hour meter works.

Electric starter is engaged by holding

main swi tch key in this position, only

when gear shift lever is in “N” (neutral)

position or applying brake pedal. Upon

release, key will return to “ON” position.

NOTICE

Do not operate the starter continuously for

more than 5 seconds, or the starter will overheat and the battery power will drop temporarily. Wait 15 seconds between each operation

of the starter to let it cool and for the battery

to recover power.

Do not turn the main switch key to the

“START” position with the engine running, or

damage to the starter can result.

NOTE

The vehicle is equipped with a starter lockout sys-

○

tem. This system prevents the electric starter from

operating when the gear shift lever is in the “H”

(High), “L” (Low) or “R” (Reverse) position, unless

the brake is applied.

Blank keys are available at your Kawasaki dealer.

Ask your dealer to make any additional spare keys

you need, using your original key as a master.

Gear Shift Lever

The gear shift lever is located on the dashboard,

to the right side of the steering wheel. The gear shift

lever has four positions: “L” (Low), “H” (High), “N”

(Neutral), and “R” (Reverse).

Make certain that the vehicle is completely

stopped and the engine is idling before shifting from

“H” (High) or “L” (Low) to “R” (Reverse) or vice versa. Move the gear shift lever up or down as indicated on the embossed mark next to the gear shift

lever.

Refer to the “Shifting Gears” section in the “HOW

TO OPERATE” chapter.

Page 60

A. Gear Shift Lever

B. “L” (Low) Position

C. “H” (High) Position

D. “N” (Neutral) Position

E. “R” (Reverse) Position

NOTICE

Do not shift from “H” (High) or “L” (Low) to

“R” (Reverse) and vice versa when the ve-

hicle is moving or with the engine running

above idling speed, or the transmission could

be damag ed.

GENERAL INFORMATION 59

range for ordinary off-highway use. Stop the vehicle

before moving the gear shift lever.

NOTICE

Use of the high range for heavy loads, climbing hills, and pulling a trailer can lead to premature wear of the torque converter belt and

pulleys. Use low range for these conditions.

Refer to the “Shifting Gears” section in the “HOW

TO OPERATE” chapter.

This vehicle is equipped with a sub-transmission

to allow maximum transmission efficiency. Use the

low gearing for maximum torque at low speeds, for

climbing hills, pulling a trailer, or keeping constant

low sp eeds. The high gearing raises the speed

Page 61

60 GENERAL INFORMATION

Selectable 2WD/4WD Shift Switch

You can select “2WD” or “4WD” to suit various

driving conditions. The selectable 2WD/4WD shift

switch is located on the dashboard.

A. Selectable 2WD/4WD Shift Switch

B. “2WD” Position

C. “4WD” Position

The current operating condition is indicated with

the 2WD/4WD indicator symbols in the multifunction

meter.

A. “2WD” Indicator Symbol

B. “4WD” Indicator Symbol

Refer to the “Multifunction Meter” section in this

chapter, together with the “2WD/4WD Shifting” section in the “HOW TO OPERATE” chapter.

WARNING

The handling characteristics of this vehicle

differs between “2WD” and “4WD” according

to terrain. Changing the operating mode while

moving can cause sudden changes in handling performance which can cause the operator to lose control and have an accident.

Always stop the vehicle before changing from

“2WD” to “4WD” and vice versa.

Page 62

GENERAL INFORMATION 61

NOTICE

Shifting from “2WD” to “4WD” (or “4WD ” to

“2WD”) when the vehicle is in motion could

cause drive train damage.

Selectable DIFF-LOCK Shift Switch

You can select differential “LOCK” (locked-rear

axle) or “UNLOCK” (unlocked-rear axle) modes to

suit various driving conditions. The selectable DIFFLOCK shift switch is located on the dashboard.

A. Selectable DIFF-LOCK Shift Switch

B. “LOCK” Position (Locked-Rear Axle Mode)

C. “UNLOCK” Position (Unlocked-Rear Axle Mode)

D. DIFF-LOCK Indicator Light

The “LOCK” (locked-rear axle) condition is indicated by a light in the switch as a reminder. Refer to

the “Shifting the Differential” section in the “HOW

TO OPERATE” chapter.

Page 63

62 GENERAL INFORMATION

Belt Drive Transmission

This vehicle is equipped with a belt-driven Continuously Variable Transmission (CVT). This automatic

drive system , although simple to operate, does require periodic inspection. Refer to the “MAINTENANCE AND ADJUSTMENT” chapter.

Parking Brake Lever

The parking brake lever is located at the left side

of the steering wheel. Pull the lever rearward to apply the parking brake.

To release, push in and hold the knob on the end

of the lever and push the lever all the way forward.

Spring pressure helps return the lever to the released pos ition.

Be sure to release the parking brake before driving off. Failure to do so may result in poor performance and premature wearing of the rear brakes and

belt converter system.

The alarm buzzer will sound if the vehicle is running with the parking brake applied. Stop the vehicle

and release the parking brake.

A. Parking Brake Lever

B. Knob

Page 64

GENERAL INFORMATION 63

WARNING

If the vehicle should move after it is parked, it

might be damag ed or cause injury. Be sure to

apply the parking brake before leaving the vehicle.

Doors

Pull the door handle outward to open the door.

Push or pull the door inward until the latch clicks

to close the door. After closing the door, be sure to

check that the latch is securely locked. If a door is

damaged or does not close securely, contact an authorized Kawasaki dealer for repair or replacement.

A. Door Handle

B. Door

C. Latch

NOTE

Make su re that the all doors are properly closed

○

before starting the vehicle.

Page 65

64 GENERAL INFORMATION

NOTICE

The doors are not designed to bear weight.

Never lean on or place excessive weight on

the doors or they will be damaged.

Seat

The seat can be removed for vehicle maintenance

and adjustment.

Seat Removal

Pull up the right and left ends of the seat to clear

•

the projections.

Remove the seat.

•

A. Seat

B. Projections

C. Pull up.

Seat Installation

Make su re that grommets are in position.

•

Insert the projections of the seat into the grom-

•

mets.

Page 66

A. Seat

B. Projection (Both Sides)

C. Grommet (Both Sides)

GENERAL INFORMATION 65

Seat Belts

The vehicle is equipped with retractable threepoint seat belts for all occupants - operator and passenger. Always wear the seat belts when operating

and riding in the vehicle.

A. Seat Belt

B. Latch Plate

C. Buckle

WARNING

Not wearing a seat belt, or wearing one improperly can result in serious injury or death

in the event of an accident. Make certain the

operator and passenger always wear their

seat belts properly.

Page 67

66 GENERAL INFORMATION

WARNING

Operator and passenger must be able to

place both feet flat on the floorboards while

seated upright with their backs against the

seatbacks.

To wear the seat belt properly, follow this proce-

dure:

1. Place the belt across your lap and chest taking

care that the belt is not twisted.

2. Push the latch plate into the buckle until it clicks.

Pull up on the latch plate to make sure it is secure.

3. Put the lap portion of the belt low on your hips.

Push down on the buckle end of the belt as you

pull up on the shoulder part so the belt is snug

across yo ur hips.

4. Place the shoulder belt over your shoulder and

across your chest. The shoulder belt should fit

against your chest. If it is loose, pull the belt out

all the way and then let it retract.

A. Lap Portion of Belt

B. Shoulder Belt

5. To unfasten the belt, press the red button in the

buckle.

A. Seat Belt

B. Latch Plate

C. Buckle

D. Red Button

WARNING

Too much seat belt slack could reduce its protection effectiveness in an accident. Always

verify that the belt is at a SNUG FIT.

Page 68

GENERAL INFORMATION 67

The seat belt is equipped with a dual mode latch

plate. Under normal driving conditions the belt will

self adjust to the seat occupant so that it is snug

around both the occupant's waist and shoulder.

Under rough driving situations the dual mode latch

plate will lock the seat belt in place.

To release the lock:

Move the slider in the direction of the arrow mark.

•

A. Slider

B. Arrow Marks

Throttle Pedal

The throttle pedal is the right pedal on the floorboard. Push the pedal down to increase engine

speed. Spring pressure returns the pedal to the rest

position when released. Always check that the throttle pedal returns normally before starting the engine.

In addition, there must be adequate throttle pedal

play and correct throttle stop position adjustment.

Refer to the “MAINTENANCE AND ADJUSTMENT”

chapter for the throttle pedal adjustment procedure.

A. Throttle Pedal

B. Floorboard

Page 69

68 GENERAL INFORMATION

Trailer Hitch Bracket

This vehicle is equipped with a bracket for a trailer

hitch. Trailer towing equipment is not supplied with

this vehicle.

To avoid injury and property damage, observe the

following precautions:

WARNING

Improper towing of a loaded trailer could

cause an accident resulting in serious injury

or death.

Never carry a passenger in a trailer.

•

Never load more than 68.1 kg (150 lb)

•

tongue weight on the towing bracket.

Do not operate the vehicle faster than 16

•

km/h (10 mph) when towing. Remember that

towing a trailer increases braking distance.

Do not tow more than 907 kg (2 000 lb)

•

trailer weight (trailer plus cargo weight).

Attach a trailer to the trailer hitch bracket

•

only. Do not attach a trailer to any other location or you may lose control of the vehicle and have an accident.

A. Trailer Hitch Bracket

Page 70

BREAK-IN

The first 20 hours or 200 km (120 mile) of vehicle

operation is designated as the break-in period. Do

not exceed 1/2 throttle during the break-in period. If

the vehicle is not used carefully during this period,

you may end up with a “broken down” instead of

“broken in” vehicle.

Break-in period Maximum throttle position

First 20 hours or

200 km (120 mile)

Do not start moving or race the engine immedi-

○

ately after starting it, even if the engine is already

warm.

Do not race the engine while the transmission is

○

in neutral.

It is important to perform the initial service after

○

the first 20 hours or 200 km (120 mile) of opera-

tion as described in this manual and the service

manual for this vehicle. See the “Periodic Mainte-

nance Chart” in the “MAINTENANCE AND AD-

JUSTMENT” chapter.

1/2 throttle

NOTE

BREAK-IN 69

Page 71

70 HOW TO OPERATE

HOW TO OPERATE

Daily Checks

Check the following items each day before operation. The time required is minimal, and habitual performance

of these checks will help ensure safe, reliable operation.

If any irregularities are found during these checks, refer to the “MAINTENANCE AND ADJUSTMENT” chapter, see your dealer, or refer to the Service Manual for the action required to return the vehicle to a safe operating condition.

WARNING

Failure to perform these checks before operation may result in serious damage or an accident. Always per form daily checks before operation.

DANGER

Exhaust gas contains carbon monoxide, a colorless, odorless poisonous gas. Inhaling carbon monoxide can cause serious brain injury or death. DO NOT run the engine in enclosed areas. Operate only in a well-ventilated area.

Fuel ................................................... Enough fuel in tank, no leaks.

Fuel Filter .......................................... Check filter element for contamination.

Water Separator ............................... Check for water accumulation and filter element contamination.

Engine Oil ......................................... Oil level between Full and Low holes on the dipstick (when engine is

cold), no leaks.

Tires .................................................. Air pressure (when cold):

Page 72

HOW TO OPERATE 71

Tire Load Cold Tire Pressure

Front Up to 733 kg (1 616 lb) 78.4 kPa (0.80 kgf/cm², 11.4 psi)

Rear

Up to 590 kg (1 300 lb) 110 kPa (1.12 kgf/cm², 16.0 psi)

590 ~ 733 kg (1 300 ~ 1 616 lb)

130 kPa (1.33 kgf/cm², 18.9 psi)

Check for cuts, cracks, damage, or excessive wear. Check for any im-

bedded stones or other foreign particles in tread.

Front Final Gear Case Oil ................. Oil level come to the bottom of the filler opening, no leaks.

Transmission Case Oil ...................... Oil level between high and low levels on the rib in the oil filler opening,

no leaks.

Coolant ............................................. Coolant level between level lines (when engine is cold), no leaks.

Air Cleaner Element .......................... Check for dirt; clean or replace as required.

Screen at Belt Drive Transmission

(CVT) Air Duct .............................. Check and clean the screen for obstruction by insects, mud or foreign

object.

Throttle .............................................. Throttle pedal free play 2 ~ 10 mm (0.08 ~ 0.39 in.). Throttle pedal op-

erates smoothly and returns to rest position when released.

Steering ............................................ Steering wheel free play 0 ~ 20 mm (0 ~ 0.79 in.). Action smooth with-

out exce ssive play, rough spots, or strange noises.

Brakes ............................................... Check for braking effectiveness (while test running). Brake pedal free

play 2 ~ 10 mm (0.08 ~ 0.39 in.). Brake fluid level between level lines,

no leaks. Parking brake: Stops vehicle completely. Visually check the

return springs for damage.

Parking Brake Indicator .................... Make sure the parking brake indicator light illuminates when the park-

ing brake is applied with the main switch in the “ON” position.

Electrical Equipment ......................... All lights work. Check for dirt on or damage to lights.

ROPS ............................ .................... Make sure there is no damage to the structure or loose bolts.

Seat Belts ......................................... Make sure that all seat belts are in good condition and operate prop-

erly. The belt should pull smoothly and retract when released. The latch

plate should click securely with the buckle and release when the re-

lease button is pushed firmly.

Page 73

72 HOW TO OPERATE

Doors ................................................ Make sure there is no damage to the structure or loose bolts and all

doors are latched securely they are closed.

Page 74

HOW TO OPERATE 73

Starting the Engine

DANGER

Exhaust gas contains carbon monoxide, a

colorless, odorless poisonous gas. Inhaling

carbon monoxide can cause serious brain injury or death. DO NOT run the engine in enclosed areas. Operate only in a wellventilated area.

Close all doors.

•

Wear the seat belts (for an operator and passen-

•

ger).

Make su re the parking brake is applied.

•

Put the gear shift lever in the “N” (neutral) posi-

•

tion.

Put the main switch key in the main switch.

•

Turn the main switch key to the “ON” position. The

•

glow plug system is designed so that the glow

plug indicator light goes on at that time, and turn

off after 4 seconds.

After the glow plug indicator light turns off, turn the

•

main switch key to the “START” position to acti-

vate the electric starter. Repeat until the engine

starts.

NOTICE

Do not operate the electric starter continuously for more than 5 seconds, or the starter

may overheat and the battery power will drop

temporarily. Wait 15 seconds between each

operation of the starter to let it cool and for

battery power to recover.

NOTE

The vehicle is equipped with a starter lockout sys-

○

tem. This system prevents the electric starter from

operating when the gear shift lever is in the “H”

(High) , “L” (Low) or “R” (Reverse) position, unless

the brake is applied.

High-Altitude Injection Control Device

This vehicle has a high-altitude injection control

device installed. It suppresses black smoke when

operating at high altitudes and at the same time

aims to control particulate matter.

The control device measures the atmospheric

pressure just after the engine has started. If at this

time the control device determines that the altitude

is 800 m (2 600 ft) or more, it reduces the fuel injection amount and thus controls the occurrence of

black smoke.

Because of this reduction in the injection amount,

the engine output decreases.

Page 75

74 HOW TO OPERATE

NOTE

The high-altitude injection control device does not

○

actuate during engine operation. Therefore, when

the machine is moved to a high altitude or to a low

altitude during operation, turn the main switch key

to the “OFF” position. This resets the control device. After re-starting the engine, the necessity for

injection control is again determined.

Cold Weather Starting

Idling speed may not be stable and/or the engine

could stall when it is started in cold weather. However this is not engine failure.

If the ambient temperature is 0°C (32°F) or lower,

use the following starting procedure to make idling

speed steady.

Close all doors.

•

Wear the seat belts (for an operator and passen-

•

ger).

Make su re the parking brake is applied.

•

Put the gear shift lever in the “N” (neutral) posi-

•

tion.

Put the main switch key in the main switch.

•

Turn the main switch key to the “ON” position.

•

The glow plug indicator goes on for 4 seconds.

•

When the glow plug indicator goes off, push down

•

the throttle pedal partially, and turn the main

switch key to the “START” position. The glow plug

indicator goes on again, and the engine starts run-

ning.

Return the main switch key to the “ON” position.

•

The glow plug indicator goes off.

After the engine is started, keep the throttle pedal

•

partially pushed down for one minute maximum

until idling speed becomes steady.

After idling speed is steady, release the throttle

•

pedal.

Page 76

Jump Starting

If your vehicle's battery is “run down,” it should be

removed and charged. If this is not practical, a 12

volt booster battery and jumper cables may be used

to start the engine.

DANGER

Battery acid generates hydrogen gas which is

flammable and explosive under certain conditions. It is present within a battery at all times,

even in a discharged condition. Keep all

flames and sparks (cigarettes) away from the

battery. Wear eye protection when working

with a battery. In the event of battery acid contact with skin, eyes, or clothing, wash the affected areas immediately with water for at

least 5 minutes. Seek medical attention.

Connecting Jumper Cables

Make su re the main switch is turned off.

•

Remove the battery cover located under the front

•

right side of the cargo bed. Refer to the “Battery”

section in the “MAINTENANCE AND ADJUST-

MENT” chapter.

HOW TO OPERATE 75

A. Battery Cover

Lift the cargo bed and support it with the support-

•

ing rod. Refer to the “Cargo Bed” section in the

“GENERAL INFORMATION” chapter.

Connect a jumper cable from the positive (+) ter-

•

minal of the booster battery to the positive (+) terminal of the vehicle battery.

Page 77

76 HOW TO OPERATE

A. Vehicle Battery Positive (+) Terminal

B. From Booster Battery Positive (+) Terminal

C. From Booster Battery Negative (–) Terminal

D. Bracket

Connect another jumper cable from the negative

•

(–) terminal of the booster battery to the bracket.

NOTICE

Do not connect the booster battery to the following portions as a ground.

Battery negative ( –) terminal

•

Electrical components or leads

•

Fuel line or fuel relative components

•

DANGER

Batteries contain sulfuric acid that can cause

burns and produce hydrogen gas which is

highly explosive.

Do not make this last connection at the fuel

•

system or battery.

Take care not to touch the positive and neg-

•

ative cables together, and do not lean over

the battery when making this last connection.

Do not connect to a frozen battery. It could

•

explode.

Do not reverse polarity by connecting posi-

•

tive (+) to negative (–), or a battery explosion and serious damage to the electrical

system may occur.

Follow the standard engine starting procedure.

•

NOTICE

Do not operate the starter continuously for

more than 5 seconds, or the starter overheat

and the battery power will drop temporarily.

Wait 15 seconds between each operation of

the starter to let it cool and for the battery to

recover power.

After the engine starts, disconnect the jumper ca-

•

bles. Disconnect the negative (–) cable from the

vehicle first.

Page 78

Reinstall the battery cover. Refer to the “Battery”

•

section in the “MAINTENANCE AND ADJUST-

MENT” chapter.

Lower the cargo bed and secure it with the

•

latches. Refer to the “Cargo Bed” section in the

“GENERAL INFORMATION” chapter.

HOW TO OPERATE 77

Moving Off

Make su re that all doors are properly closed.

•

Depress the brake pedal.

•

Put the gear shift lever into the “H” (High) or “L”

•

(Low) position.

Release the parking brake.

•

Gradually increase engine speed by pressing on

•

the throttle pedal.

NOTE

Practice starting and stopping (using the brakes)

○

until you are familiar with the controls.

Page 79

78 HOW TO OPERATE

Braking

NOTE

When the throttle pedal is released completely

○

and the engine speed drops near an idle, the vehicle has no engine braking. This is caused by the

vehicle's automatic transmission which releases

the engine at very low speed to prevent it from

stalling. Employ the brakes to control the vehicle's

speed.

Release the throttle pedal completely.

•

Press on the brake pedal evenly and firmly.

•

WARNING

Carrying cargo or towing a trailer will increase braking distances. Failure to allow for

increased braking distance may result in accident and injury. Always allow more distance

to stop when carrying cargo or towing a

trailer.

Stopping the Engine

Release the throttle pedal completely.

•

Put the gear shift lever into the “N” (neutral) posi-

•

tion.

Apply the parking brake to help prevent the ve-

•

hicle from rolling.

Turn the main switch key to the “OFF” position.

•

Page 80

Parking the Mule

WARNING

Operating or parking the vehicle near flammable materials can cause a fire, and can result

in property damage or severe personal injury.