Page 1

K

a

a

aw

s

k

Kawasaki Robotics (USA), Inc.

K

a

a

aw

s

k

D SERIES CONTROLLER

TROUBLESHOOTING AND

COMPONENT REPLACEMENT

MPVDCONTV113E-3

Page 2

This publication contains proprietary information of Kawasaki Robotics (USA), Inc. and

is furnished solely for customer use only. No other uses are authorized or permitted

without the express written permission of Kawasaki Robotics (USA), Inc. The contents

of this manual cannot be reproduced, nor transmitted by any means, e.g., mechanical,

electrical, photocopy, facsimile, or electronic data media, without the express written

permission of Kawasaki Robotics (USA), Inc.

All Rights Reserved.

Copyright © 2001, Kawasaki Robotics (USA), Inc.

Wixom, Michigan 48393

The descriptions and specifications in this manual were in effect when it was submitted

for publishing. Kawasaki Robotics (USA), Inc. reserves the right to change or discontinue specific robot models and associated hardware and software, designs, descriptions, specifications, or performance parameters at any time and without notice, without

incurring any obligation whatsoever.

This manual presents information specific to the robot model listed on the title page of

this document. Before performing maintenance, operation, or programming procedures,

all personnel are recommended to attend an approved Kawasaki Robotics (USA), Inc.

training course.

KAWASAKI ROBOTICS (USA), INC. TRAINING

Training courses covering operation, programming, electrical maintenance, and mechanical maintenance are available from Kawasaki Robotics (USA), Inc. These courses

are conducted at our training facility in Wixom, Michigan, or on-site at the customer’s

location.

For additional information contact:

Kawasaki Robotics (USA), Inc.

Training and Documentation Dept.

28059 Center Oaks Court

Wixom, Michigan 48393

Page 3

TROUBLESHOOTING AND COMPONENT REPLACEMENT

K

a

a

aw

s

k

noisiveR

rebmuN

esaeleR

etaDegnahCfonoitpircseDslaitinI

0-30/02/11ypoctnirpfo0-.veRnodesab,esaelerFDPlaitinIBC

/BC

1-40/72/4ypoctnirpfo1-.veRnodesab,1noisiveRBC/BC

3-50/60/9ypoctnirpfo3-.veRnodesab,3noisiveRBC/BC

REVISION HISTORY

D SERIES CONTROLLER

Page 4

D SERIES CONTROLLER

K

a

a

aw

s

k

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

1.0 TROUBLESHOOTING ................................................................................... 1-2

1.1 Error Recovery ............................................................................................... 1-2

1.2 Preliminary Troubleshooting ........................................................................... 1-5

1.2.1 Troubleshooting Common Failures ................................................................. 1-5

1.2.1.1 Controller Power Cannot Be Set to ON .......................................................... 1-6

1.2.1.2 Teach Pendant Is Inoperable ......................................................................... 1-8

1.2.1.3 Motor Power Cannot Be Enabled ................................................................. 1-10

1.2.1.4 Robot Does Not Move.................................................................................. 1-11

1.3 Error Codes ................................................................................................. 1-12

1.3.1 Error Display ................................................................................................ 1-13

1.3.2 Error List ...................................................................................................... 1-13

1.3.2.1 DXXXX Fatal Error Codes............................................................................ 1-14

1.3.2.2 EXXXX Non-Fatal Error Codes .................................................................... 1-59

1.3.2.3 PXXXX Operation Error Codes .................................................................. 1-159

1.3.2.4 WXXXX Mechanical/Control Warning Error Codes .................................... 1-200

1.4 Troubleshooting Flowcharts ....................................................................... 1-210

1-1August 9, 2005

Page 5

D SERIES CONTROLLER

K

a

a

aw

s

k

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

1.0 TROUBLESHOOTING

This unit provides error recovery flowcharts, error code information, and error code

troubleshooting flow charts. In addition, typical causes and remedies for the errors are

also provided.

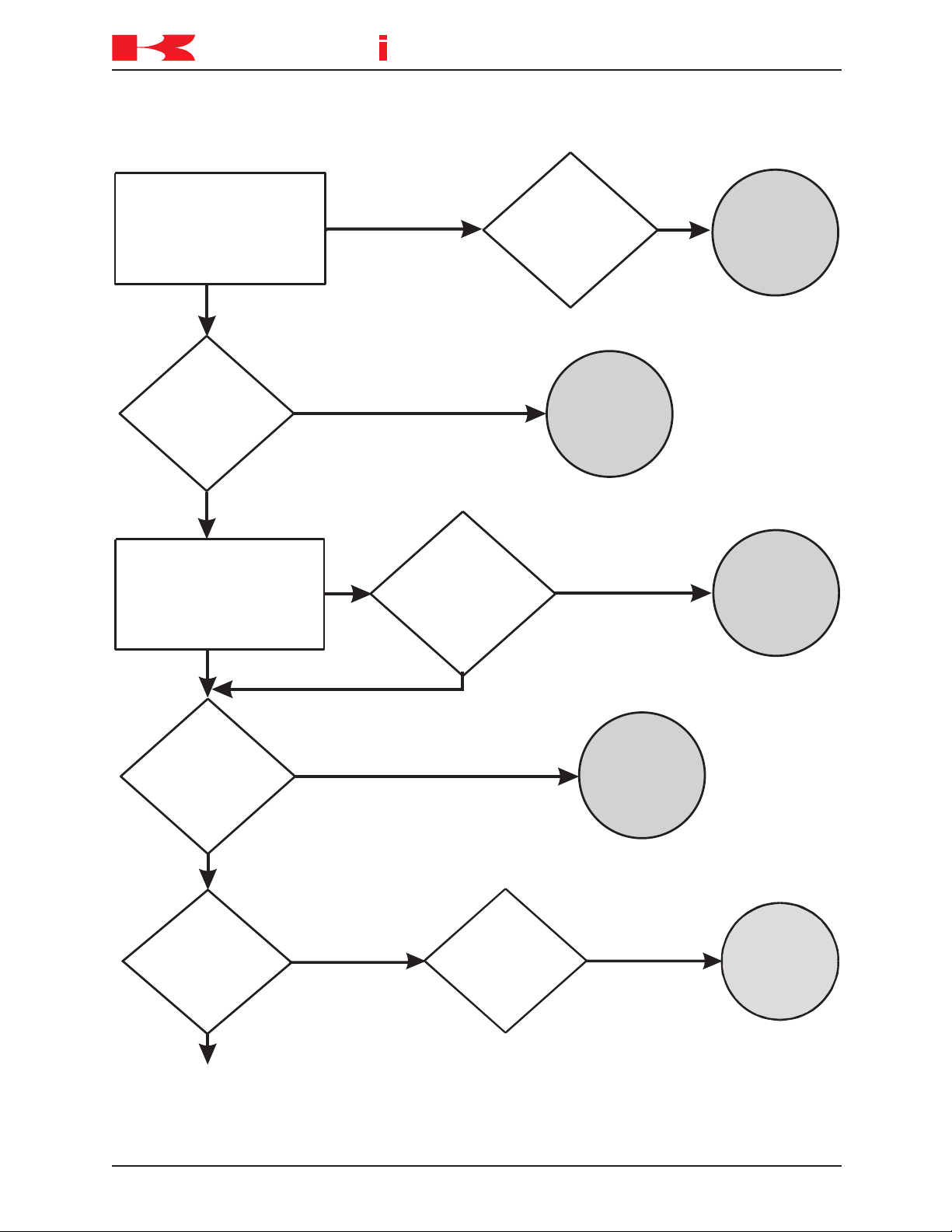

1.1 ERROR RECOVERY

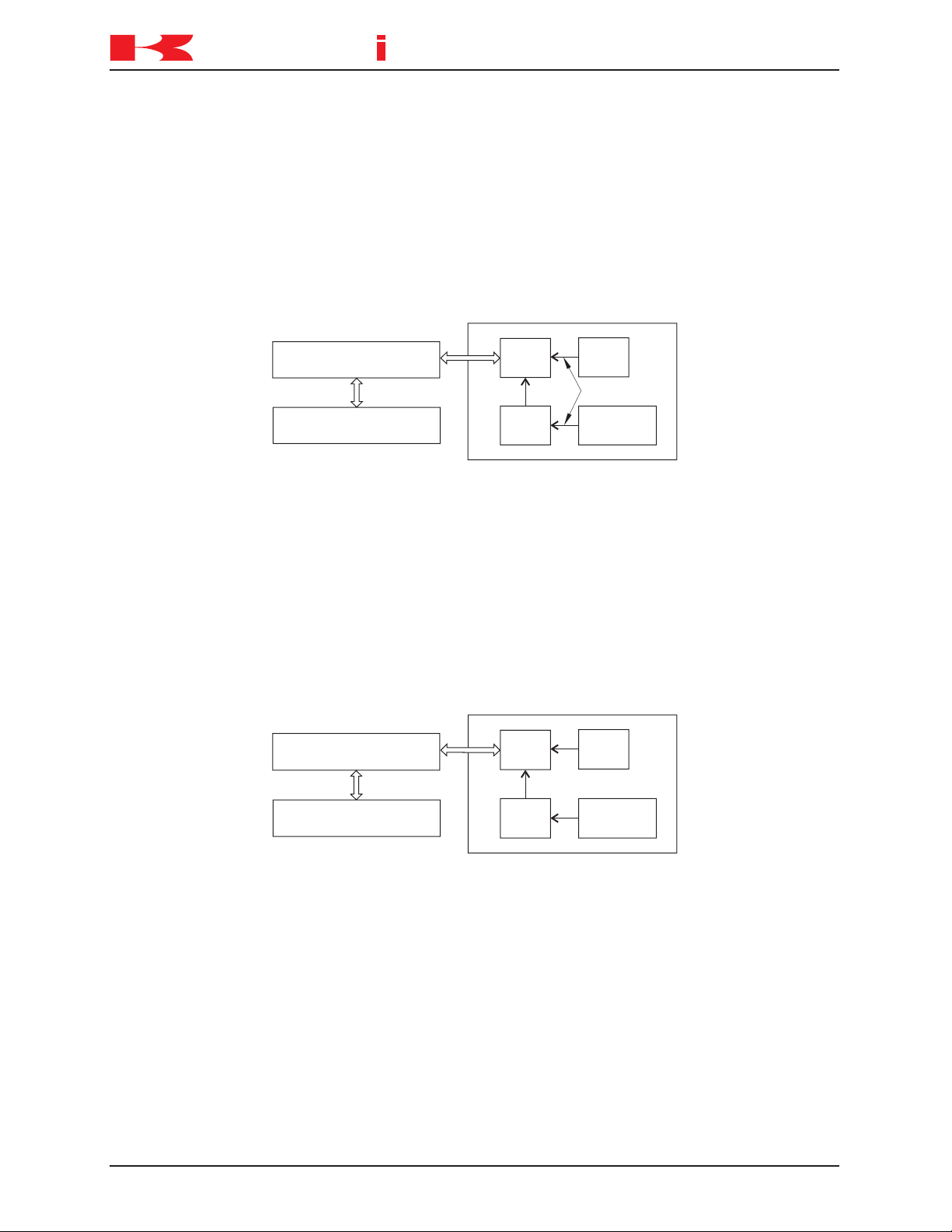

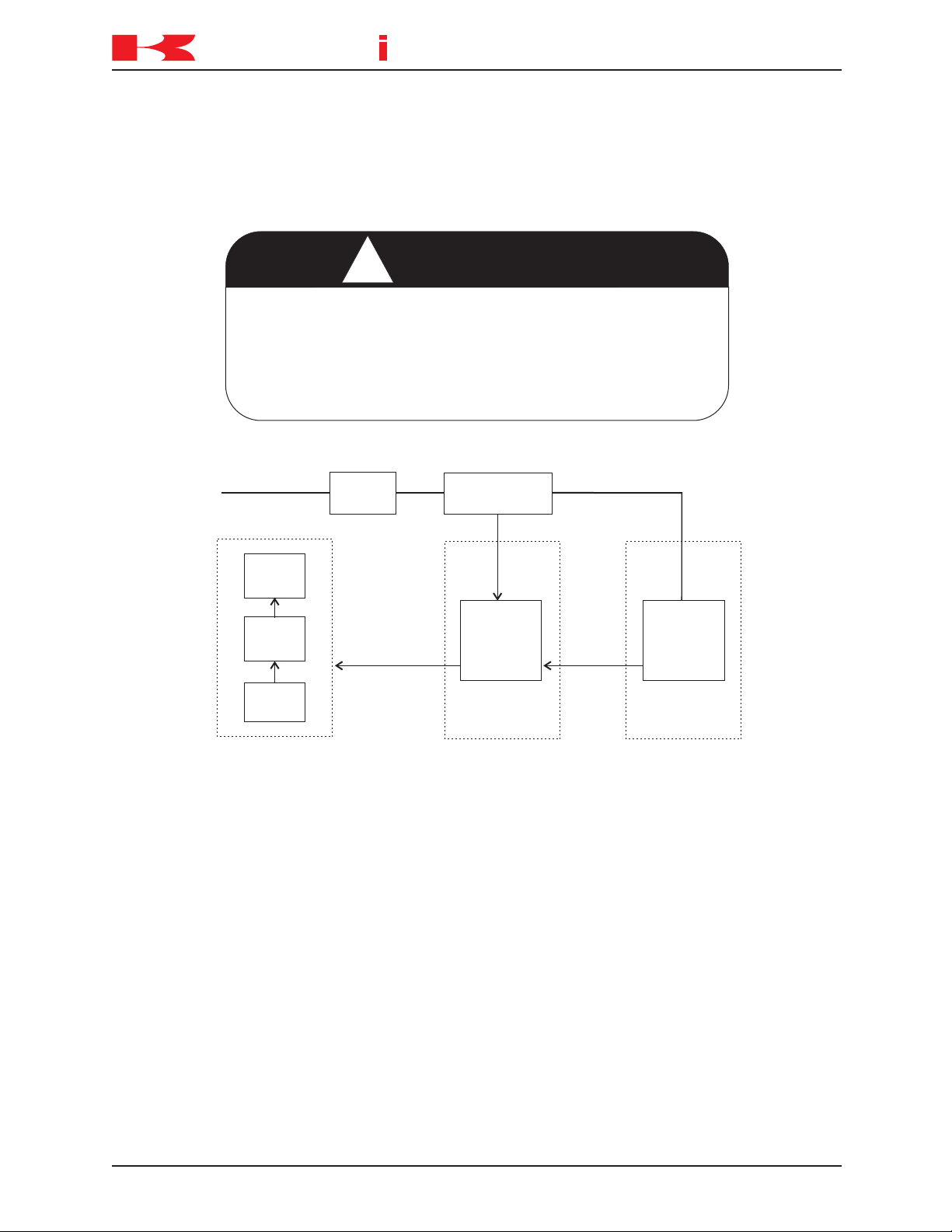

Figures 1-1 and 1-2 show troubleshooting processes that may be helpful if the controller

becomes unresponsive to commands or an error code has been encountered that

cannot be cleared. Troubleshooting should begin with confirmation of basic integrity of

the system: ensure that the power supply is on and meeting supply requirements, all

cables are correctly attached, all circuit boards are properly installed and fully seated, all

peripheral equipment is wired correctly, software is properly configured, etc.

1-2 August 9, 2005

Page 6

TROUBLESHOOTING AND COMPONENT REPLACEMENT

K

a

a

aw

s

k

Source of error known

Locate error on the error

table and determine the

characteristics and possible

causes of the error

Source of error unknown

Press the yellow

reset button on the

controller panel

Error will not clear or

machine is in a “locked” mode

Error cleared and robot

runs normally

Error clears and robot

runs normally

to monitor

and continue

Run Program

Run Program

and continue

to monitor

Troubleshoot

and correct

source of

error

Ye s

Ensure the robot

system data, all

components, signals,

and programs are

compatible

agrees with program, etc.

removed, signal interface

components added or

internal parts, interface

made to system? New

beenchangesanyHave

No

Cycle the

controller power

OFF and ON

Run Program

and continue

to monitor

Error or “locked”

condition cleared

Error still present

Continued on next page

to monitor

and continue

Run Program

Create

backup information

files and initialize the

system

Run program

and continue

to monitor

Error or “locked”

condition cleared

Reset

system settings not

set to defaults after

initialization

TROUBLESHOOTING

D SERIES CONTROLLER

Figure 1-1 Troubleshooting Process

1-3August 9, 2005

Page 7

TROUBLESHOOTING AND COMPONENT REPLACEMENT

K

a

a

aw

s

k

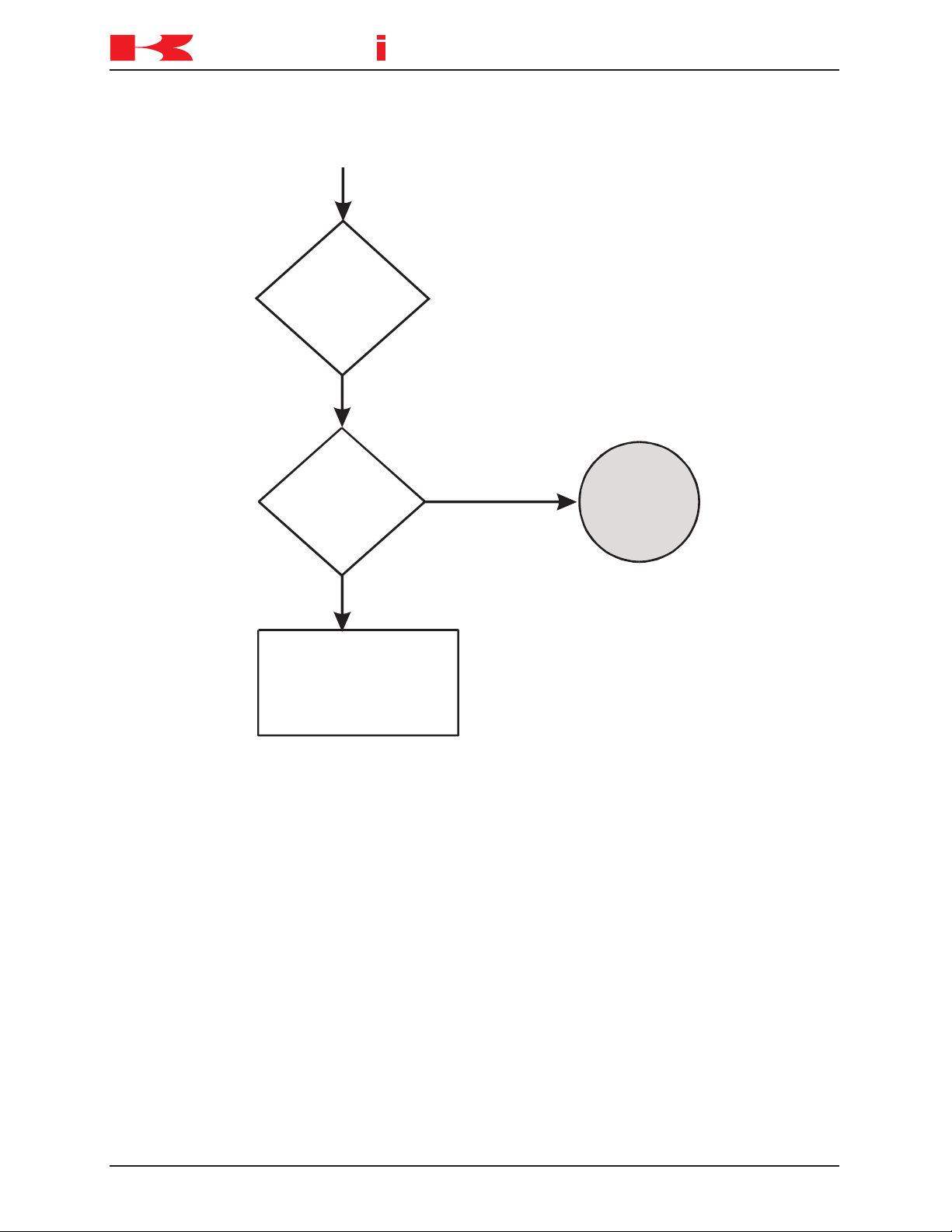

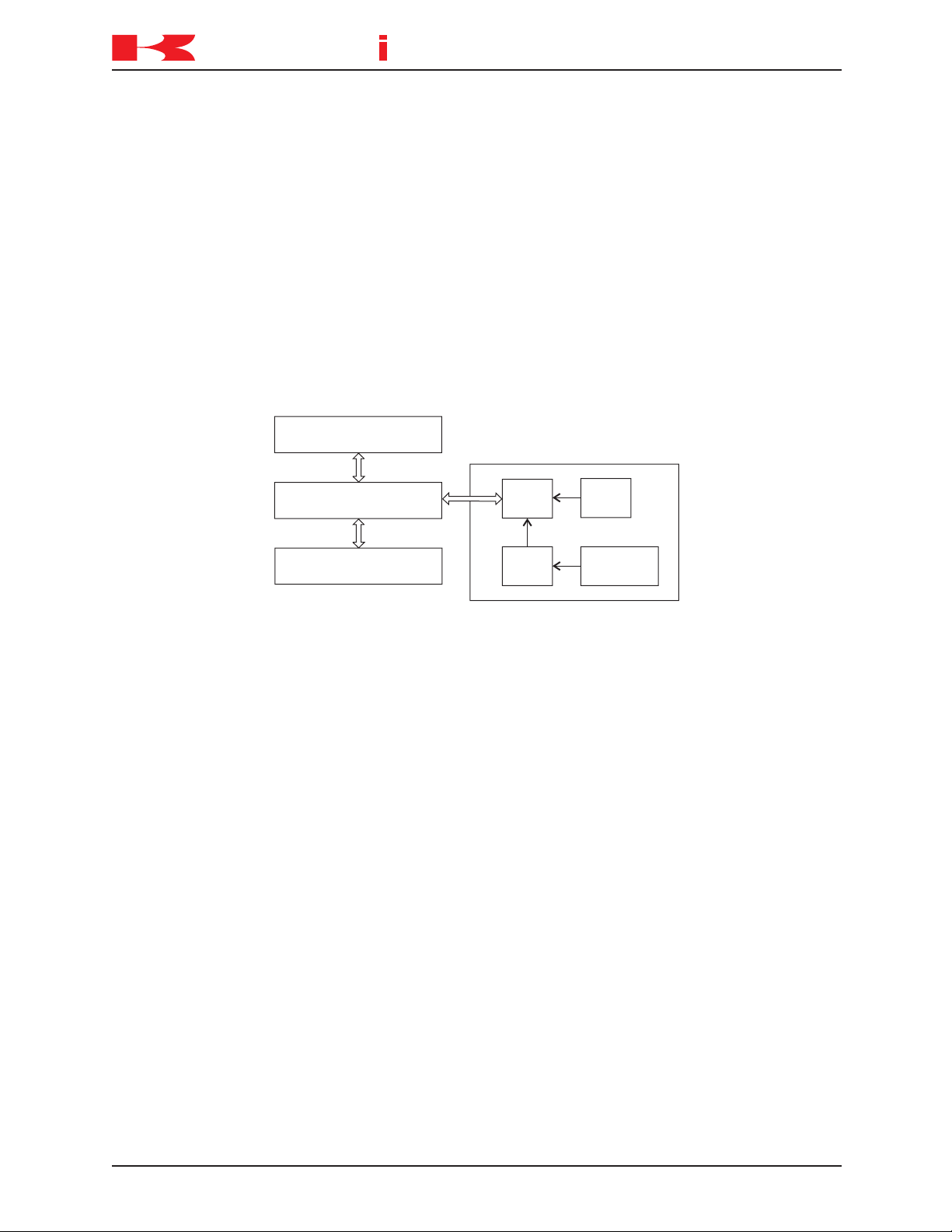

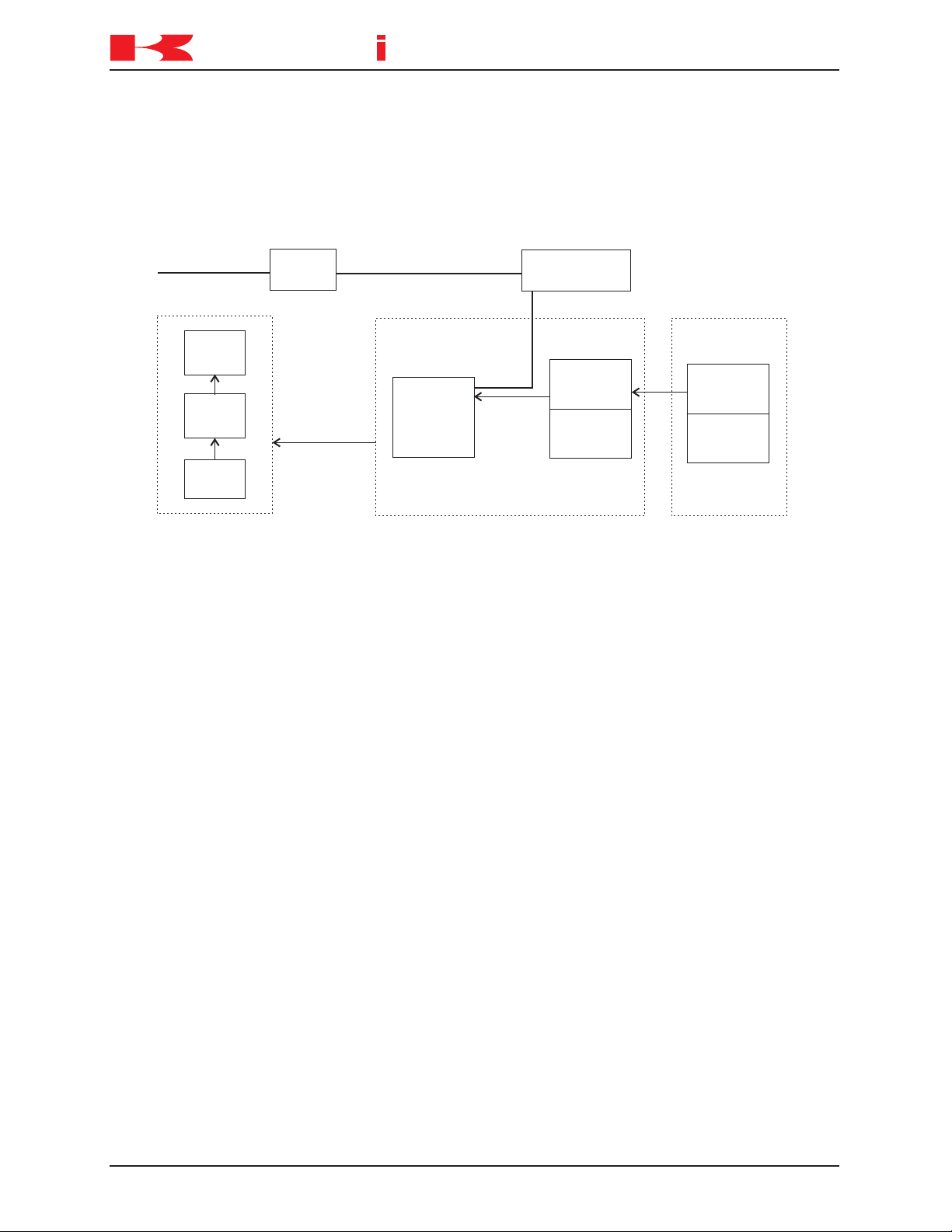

Continued from previous pg

Error still present

Remove the

1KA board from the

rack and allow RAM

memory to deplete

Reinstall

1KA board,

initialize the

system, zero

Error clears and robot

runs normally

Run program

and continue

to monitor

Begin electrical

troubleshooting and repair if

qualified; call service

technician for further

assistance

TROUBLESHOOTING

D SERIES CONTROLLER

Figure 1-2 Troubleshooting Process (Continued)

1-4 August 9, 2005

Page 8

D SERIES CONTROLLER

K

a

a

aw

s

k

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

1.2 PRELIMINARY TROUBLESHOOTING

Prior to following error code troubleshooting procedures, ensure preliminary troubleshooting steps are completed.

1. Ensure proper 460 VAC three-phase power is available at the input and output side

of the controller main disconnect (circuit breaker F1).

2. Ensure circuit breakers F2, F3, F4, and F5 are

3. Ensure proper +5 VDC, +12 VDC, -12 VDC and +24 VDC are available from the

AVR power supply.

4. Observe the state of LEDs and refer to the appropriate section of the

Controller Electrical Maintenance Manual

these conditions are

5. Check for loose connection at circuits boards and cable connections.

6. Ensure all circuit boards are properly seated in the card rack (where applicable).

7. Ensure the F1 and F2 fuses on the 1KP board are

1.2.1 TROUBLESHOOTING COMMON FAILURES

This section describes some common failures, possible causes, and corrective actions.

1.2.1.1 Controller Power Cannot Be Set ON

not normal, correct the cause of abnormal LED indications.

for conditions indicated by the LEDs. If

not tripped.

D Series

not open.

1.2.1.2 Teach Pendant is Inoperable

1.2.1.3 Motor Power Cannot Be Set ON

1.2.1.4 Robot Does Not Move

1-5August 9, 2005

Page 9

D SERIES CONTROLLER

K

a

a

aw

s

k

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

1.2.1.1 CONTROLLER POWER CANNOT BE SET TO ON

This failure occurs when the controller does not power-up when the controller main

disconnect is set to ON.

Failure 1: When the controller main disconnect is set to ON, circuit breaker F1 is tripped

immediately.

Main causes include:

1. The AC power line is short-circuited in the controller, and circuit breaker F1 detects

overcurrent and is tripped.

2. Defective F1 circuit breaker.

⇒

Interrupt the 460 VAC to the main disconnect (circuit breaker F1) set the controller

main disconnect to ON. Using an ohm meter check for a short circuit between these

points:

R and S, S and T, T and R, R and FG, S and FG, T and FG (FG=frame ground)

If a short circuit is detected replace components as necessary (wiring, transformer

T1, circuit breaker F1, etc.).

Failure 2: When the main disconnect is set to ON, the control power lamp does not

illuminate (circuit breaker F1 does not trip).

This failure occurs when the controller does not activate properly because of an abnormality in the primary power supplied to the controller or in the power supply circuit in the

controller.

Main causes include:

1. The primary power voltage supplied to the controller is not within specifications, the

primary power cable is disconnected or damaged, or the primary power is not

supplied.

2. Power is not supplied to the 1KQ/1NR board, or the 1KQ/1NR board is defective.

3. Power is not supplied to the AVR power supply.

4. Power is not supplied to the control power lamp due to a defective AVR power

supply, 1KX/1NR board, 1LS/1NS board or control power lamp.

5. Disconnected or short-circuited wiring in the controller.

1-6 August 9, 2005

Page 10

D SERIES CONTROLLER

K

a

a

aw

s

k

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

⇒

Ensure primary power supply is within specifications. Ensure primary power supply

cable is properly connected and is not damaged.

⇒

Ensure connectors at the 1KQ/1NR board are properly installed and not damaged.

⇒

Ensure the 1KP board fuses F1 and F2 are not open.

⇒

Replace the 1KQ/1NR board.

⇒

Ensure the power supplied to the AVR power supply is within specifications. Ensure

the power connector at the AVR power supply is properly connected and not damaged.

⇒

Ensure to output voltages from the AVR power supply are within specifications.

⇒

Ensure the control power lamp is properly installed and is not defective.

⇒

Repair or replace disconnected or short-circuited wiring in the controller.

1-7August 9, 2005

Page 11

D SERIES CONTROLLER

K

a

a

aw

s

k

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

1.2.1.2 TEACH PENDANT IS INOPERABLE

The teach pendant is in operable with the controller main disconnect set to ON and the

control power lamp is illuminated.

Failure 1: The control power lamp is illuminated and the teach pendant is inoperable

(the back light is not illuminated).

DC power is supplied to the controller, but power is not supplied to the teach pendant to

illuminate the display or back light.

Main causes include:

1. +12 VDC is not supplied to the teach pendant.

2. Defective LCD panel, circuit board, or other internal teach pendant components.

3. Disconnected or short-circuited teach pendant cable.

⇒

Ensure the teach pendant cable is properly connected to the controller.

⇒

Replace the teach pendant.

⇒

Replace the teach pendant cable.

Failure 2: The back light is illuminated, but the screen is not displayed.

When the teach pendant back light is illuminated this indicates power is supplied to the

teach pendant. If the teach pendant is operating normally the initial screen is displayed

regardless of the 1KA board condition.

Main causes include:

1. Defective LCD panel, circuit board, or other internal teach pendant components.

⇒

Replace the teach pendant.

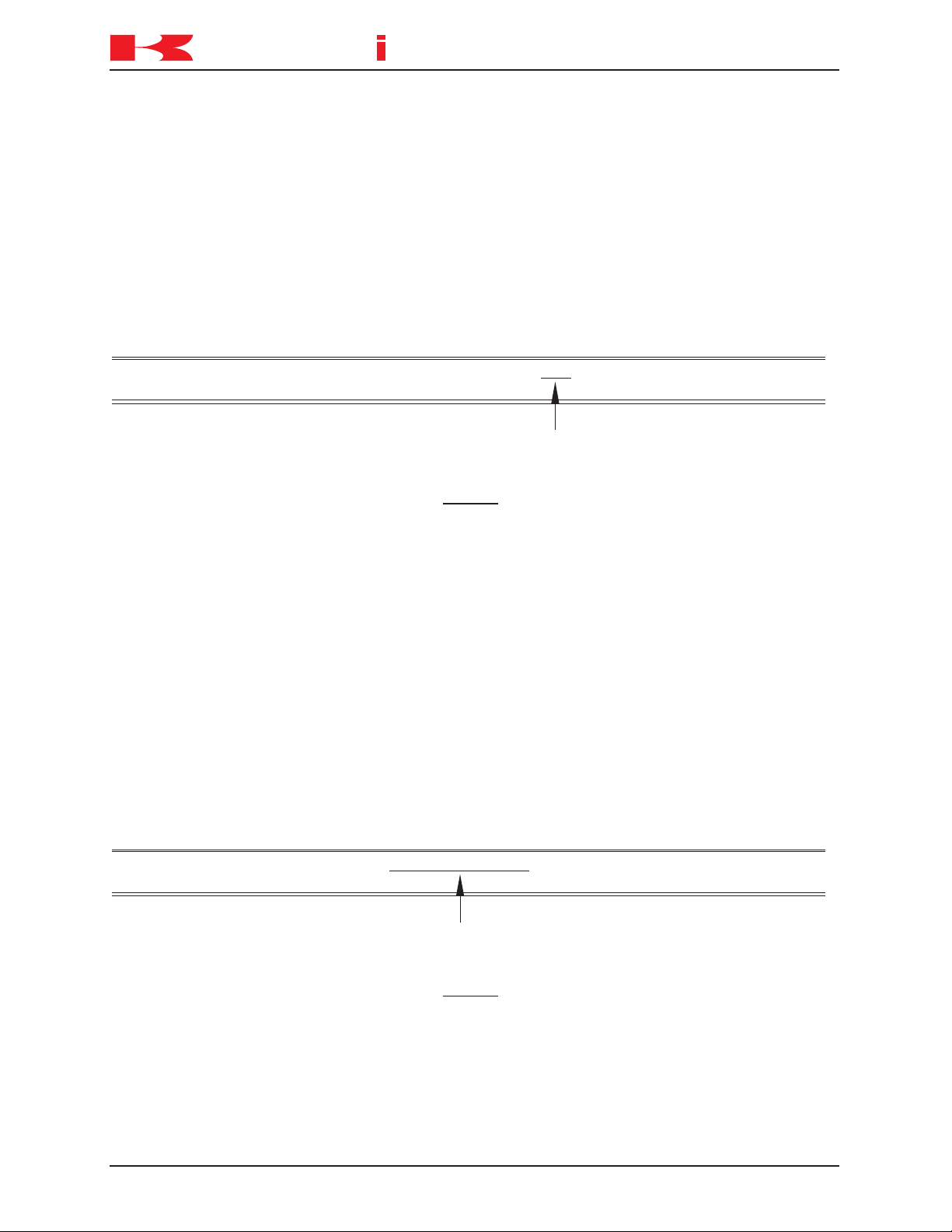

Failure 3: The teach pendant screen is displayed and the back light is illuminated, but

key input and AS Language commands are not possible.

This condition occurs when key input and AS Language commands do not reach the

1KA board or data from the 1KA board does not reach the teach pendant.

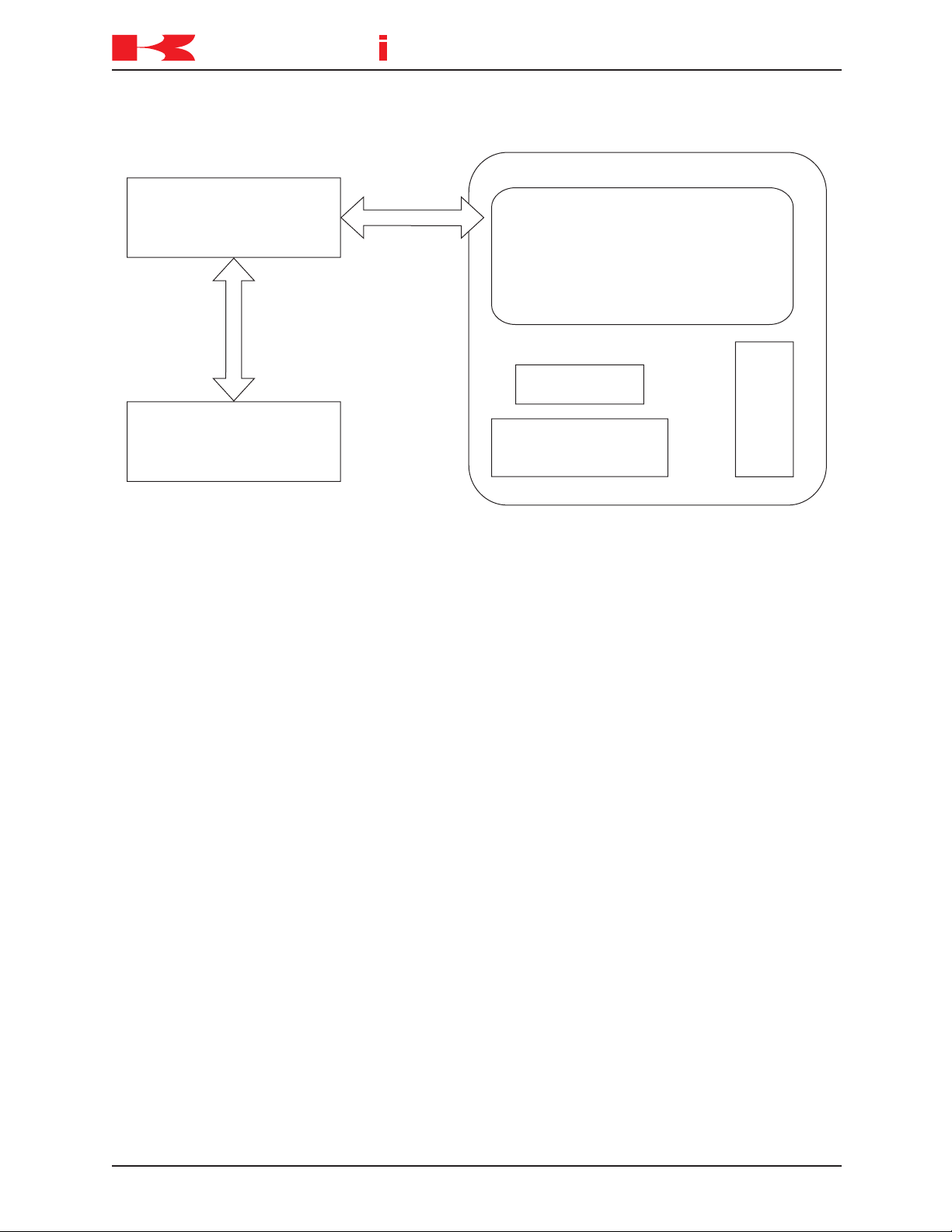

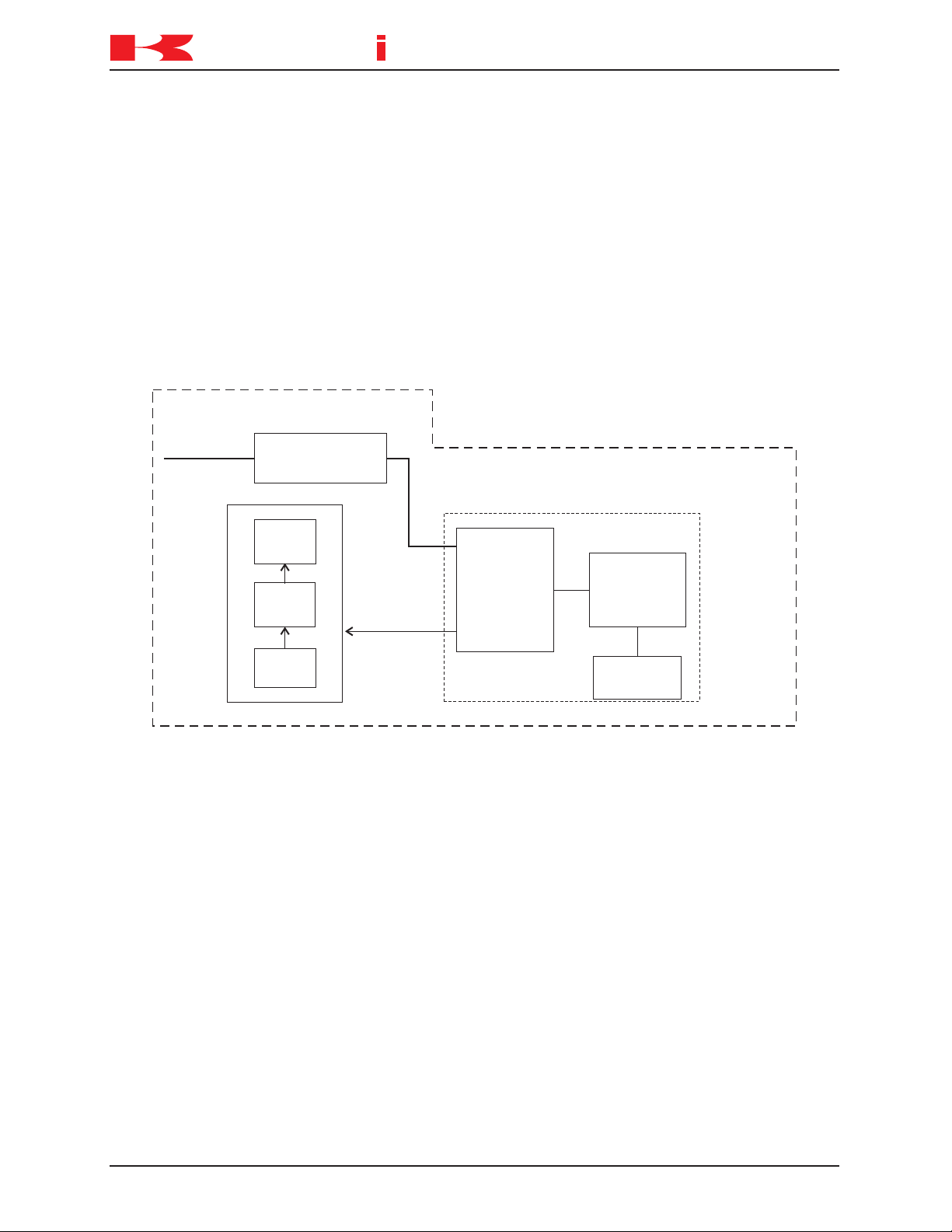

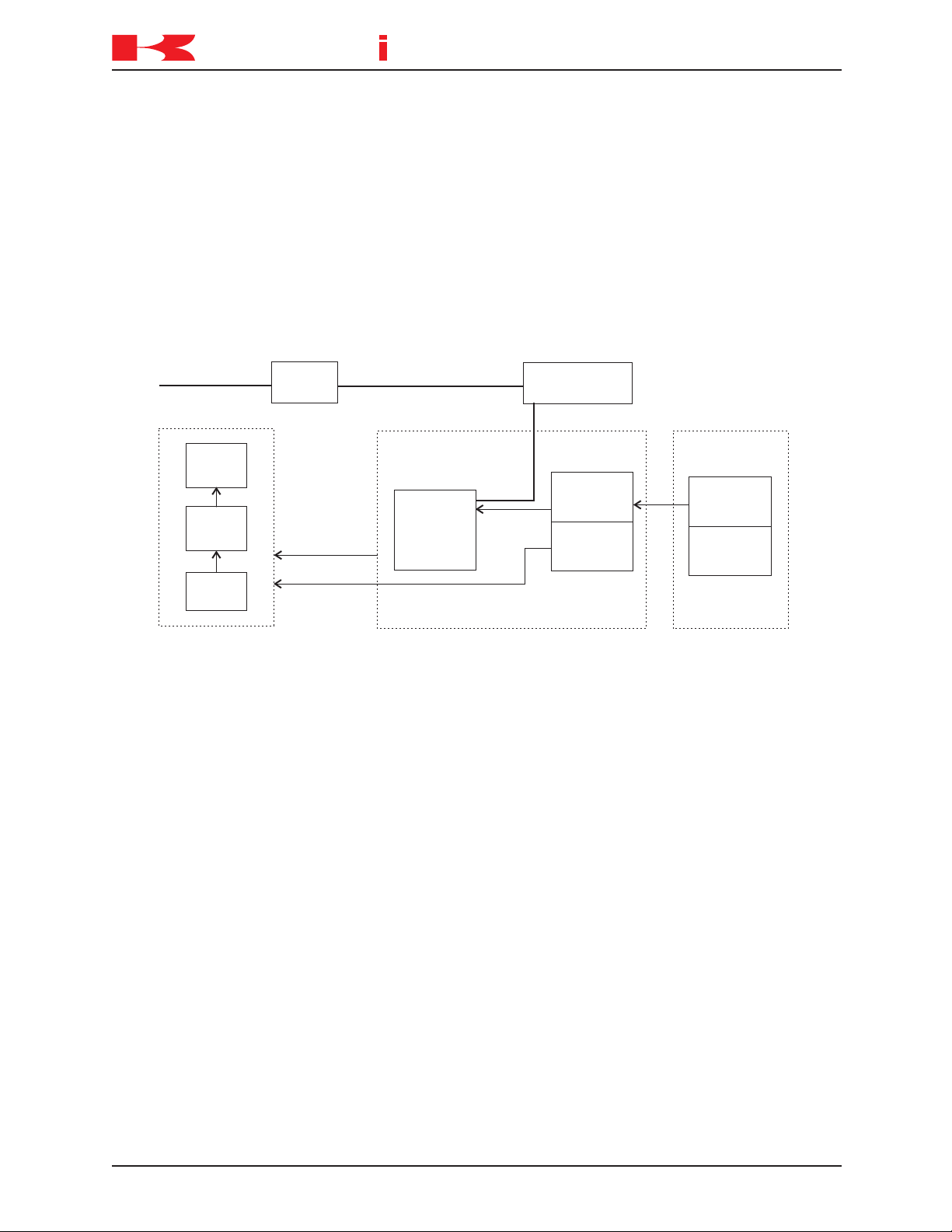

Data is transmitted between the 1KA board and the teach pendant as shown in figure 1-

3.

1-8 August 9, 2005

Page 12

TROUBLESHOOTING AND COMPONENT REPLACEMENT

K

a

a

aw

s

k

1KX/1NX Mother Board

1KA Main CPU Board

Display Device

Teach Pendant

Input

Keys

TROUBLESHOOTING

D SERIES CONTROLLER

Main causes include:

1. Interruption in data communication between the teach pendant and the 1KA board.

2. Defective LCD panel, circuit board, or other internal teach pendant components.

3. Defective 1KA or 1KX/1NX boards.

4. Disconnected or short-circuited teach pendant cable.

⇒

Ensure the teach pendant cable is properly connected to the controller.

⇒

Replace the teach pendant cable.

⇒

Replace the teach pendant.

⇒

Replace the 1KA or 1KX/1NX boards.

Figure 1-3 1KA/Teach Pendant Communication

1-9August 9, 2005

Page 13

D SERIES CONTROLLER

K

a

a

aw

s

k

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

1.2.1.3 MOTOR POWER CANNOT BE ENABLED

This condition exists when motor power does not engage when the MOTOR POWER

switch is pressed.

Main causes include:

1. An error condition exists.

2. K1, K2, or K3 are not engaged due to a defective 1KQ/1NR board, MC unit, teach

pendant, software, eternal signals etc.

3. Emergency stop condition exists.

4. Defective power block.

5. Disconnected or short-circuited motor power supply harness.

6. Motor temperature or controller internal temperature exceeds limits

⇒

If the operation panel error lamp is illuminated or an error message is displayed on

the teach pendant LCD, take appropriate measures to release the error condition

according to the error message.

⇒

Check and repair any abnormalities in the motor power supply circuit.

⇒

Ensure all EMERGENCY STOP switches are released.

⇒

Replace the power block.

⇒

Replace the motor power supply harness.

⇒

Ensure motor temperature and controller internal temperature does not exceed limits.

1-10 August 9, 2005

Page 14

D SERIES CONTROLLER

K

a

a

aw

s

k

! WARNING

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

1.2.1.4 ROBOT DOES NOT MOVE

This condition exists when the robot does not move when conditions are set for teach or

repeat mode.

Main causes include:

1. External hold condition exists.

2. An error condition exists.

3. Operation panel switches set incorrectly.

4. Motor brakes are not released.

5. If the check mode is selected, ensure an enabling device is engaged and the GO

(step forward) key is pressed.

6. Robot is waiting for input signals in repeat mode (cycle start, step forward, program

change, WX, JUMP, etc.)

⇒

Release external hold condition.

⇒

If the operation panel error lamp is illuminated or an error message is displayed on

the teach pendant LCD, take appropriate measures to release the error condition

according to the error message.

⇒

Ensure the operation panel switches are set correctly for robot operation.

⇒

Ensure proper brake voltage is available to the brake release circuit. Check and

repair poor connections, disconnected connectors, open wiring, short circuited wiring,

or any abnormalities in the brake circuits. Ensure the 1KP board, 1KQ/1NR board,

AVR power supply, MC unit, 1KQ/1NR board, servo motor, and controller internal

brake harnesses are in serviceable condition.

⇒

When check mode is selected, ensure an enabling device is engaged and the GO

(step forward) key is pressed.

⇒

In repeat mode, ensure input signals are received to release a wait condition.

The robot may move suddenly when a wait condition is

released. Do not approach the robot when it appears to

be stopped.

1-11August 9, 2005

Page 15

D SERIES CONTROLLER

K

a

a

aw

s

k

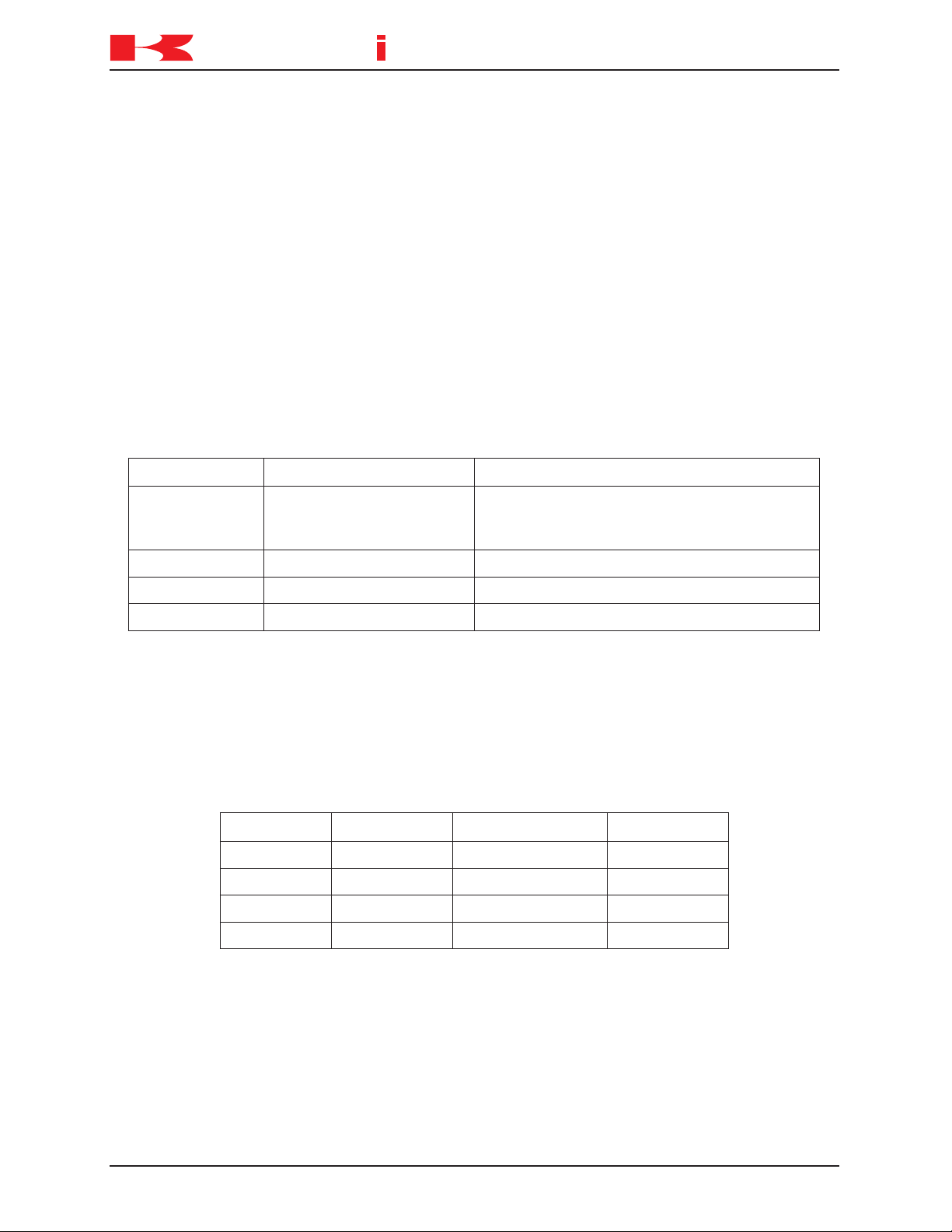

edoCgoLrorrEnoitpircseDtnemmoC

DrorrelataF .rorreecivedlarehpirepro,erawtfos,erawdraH

ebtsumrewoplortnocdet

cerrocsirorrenehW

.NOdnaFFOdelcyc

Erorrelataf-noN.teserrorresserp,detcerrocsirorrenehW

ProrrenoitarepO.noito

mtobortceffatonseoD

Wgninrawlortnoc/lacinahceM.detcerroctonfirorrenaesuacyaM

epyTrorrEpmaLrorrEpmaLtratSelcyCrewoProtoM

PFFONONO

W

1

FFOroNO

1

FFOroNO

1

FFOroNO

ENOFFO

1

FFOroNO

DNOFFOFFO

1

tnetnocrorreehtnognidnepeD

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

1.3 ERROR CODES

This unit provides information about the error codes that are displayed on the teach

pendant or other user interfaces that provide display screen information. The error

codes are listed in numerical order by prefix and code number with the message that is

displayed on the teach pendant. An expanded explanation of the message is provided

along with possible methods to clear or prevent the specific error. Troubleshooting

information is preceded by an ⇒

symbol.

Table 1-1 provides an explanation of the error code prefixes.

Table 1-1 Error Code Prefix Descriptions

Table 1-2 describes the controller state for each type of error.

Table 1-2 Controller Error State

1-12 August 9, 2005

Page 16

D SERIES CONTROLLER

K

a

a

aw

s

k

Pro ramg

[Comment ]

Step

PC

Status

03-01-31 11:55

90%

RPS

Pro ram aborted. No = 1g

Error

p6g

[

1

[

]

0.000 0.000 0.000 0.000 0.000 0.000

JT 1 JT 2 JT 3 JT 4 JT 5 JT 6

(E0100) 02-11-08(Fri) 16:33:20

Abnormal comment statement exists.

T

C

R

]

!

1 pcpr 1g

Reset

Close

JOINT

System Message Area

Error Pop-up Screen

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

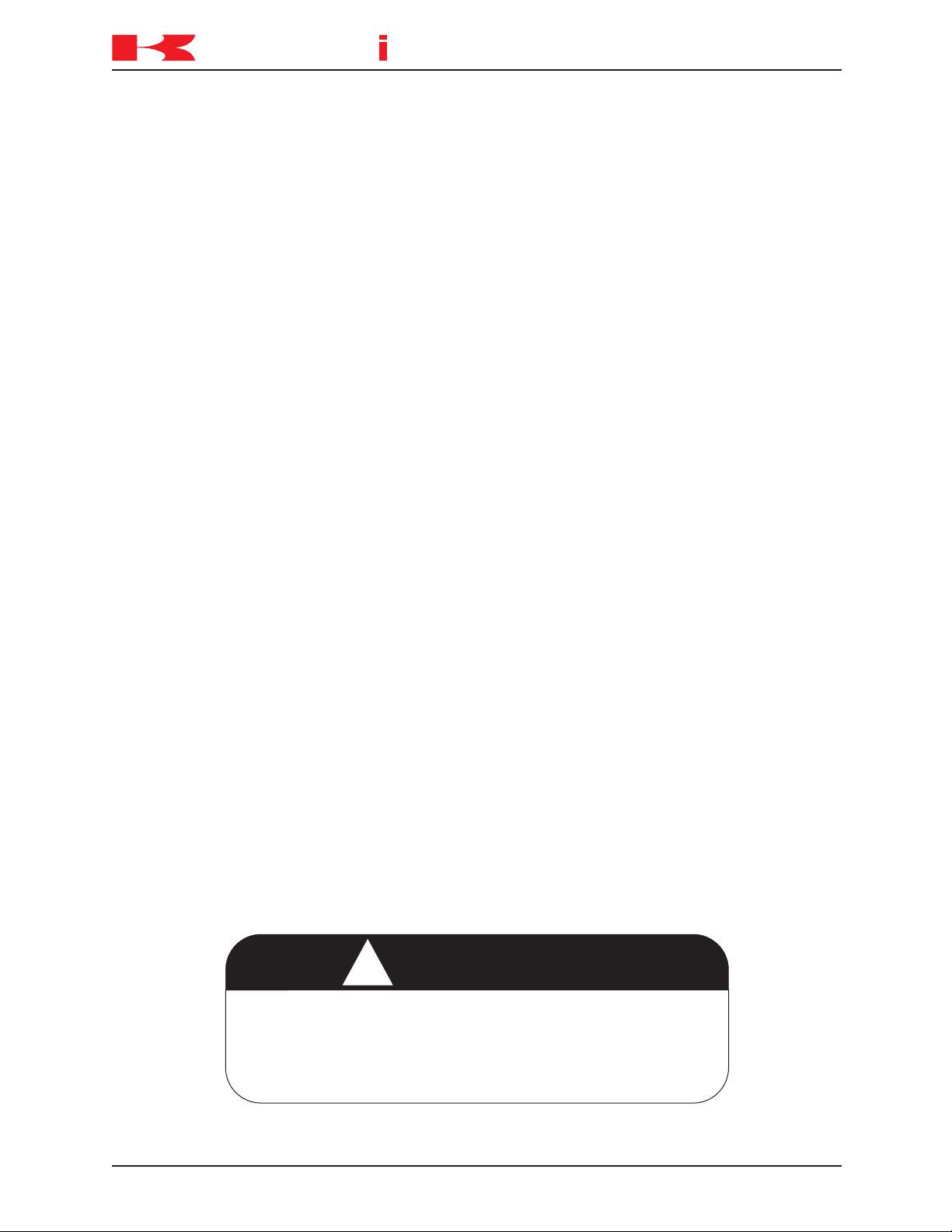

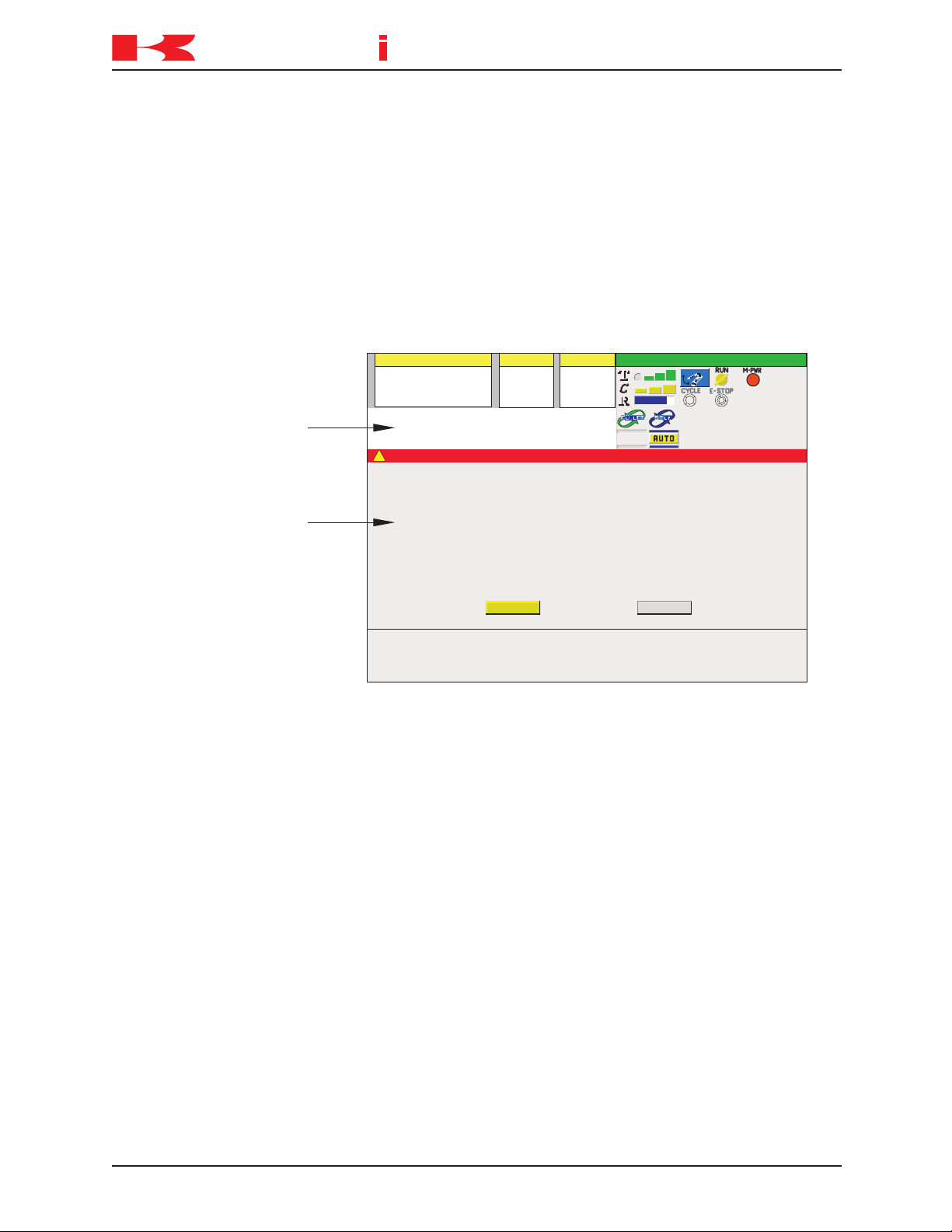

1.3.1 ERROR DISPLAY

Error messages are displayed on the teach pendant LCD screen and/or a PC interfaced

with the controller using KRterm/KCWIN32 terminal software.

The teach pendant LCD screen displays operation errors (P errors) in the system message area and other error messages are shown in a pop-up screen display (Figure 1-4).

1.3.2 ERROR LIST

Refer to the following sections for errors and descriptions:

1.3.2.1 DXXXX Fatal Error Codes

1.3.2.2 EXXXX Non-Fatal Error Codes

1.3.2.3 PXXXX Operation Error Codes

1.3.2.4 WXXXX Mechanical/Control Warning Error Codes

Figure 1-4 Teach Pendant Error Screen Display

1-13August 9, 2005

Page 17

D SERIES CONTROLLER

K

a

a

aw

s

k

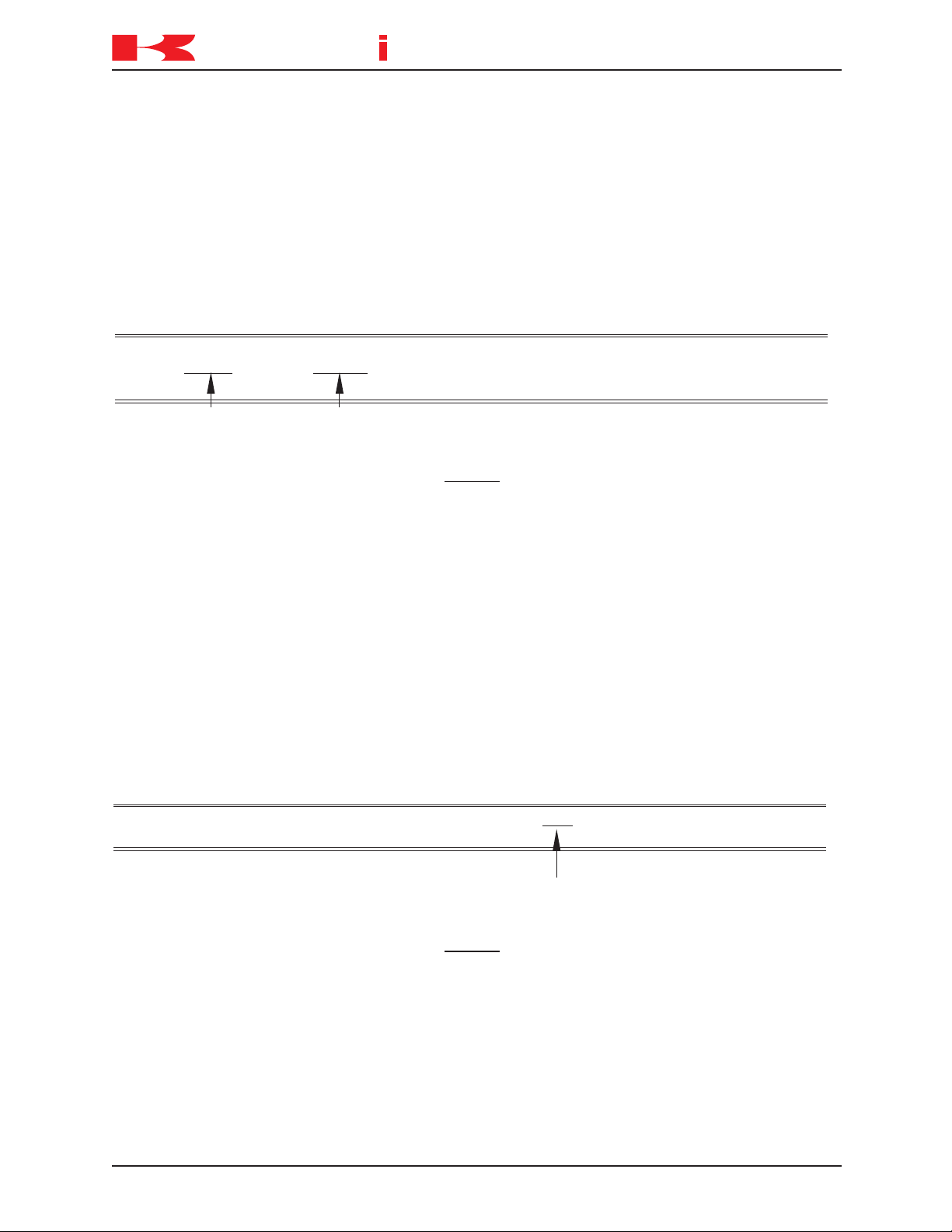

PC Error Display Example:

Error (D0001) CPU error Code=1

Task (Pc01) Stop SIG=00070004 [FAULT (PARALLEL)] PC=*****

Indicates the place the error occurred

PC Error Display Example:

Error (D0002) CPU BUS error Code=1

Task (Pc01) Stop SIG=00070004 [NMI ] PC=*****(VME BUS ERROR)

Indicates the place the error occurred

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

1.3.2.1 DXXXX FATAL ERROR CODES

ERROR CODE D0001 CPU Error. (PC=XX)

The 1KA board CPU has stopped (detected by the AS software). This error is caused

by defective AS or servo software, defective hardware, or noise related malfunction.

⇒

Refer to the error message displayed on a PC interfaced with the controller.

⇒

Cycle controller power OFF and ON. Do not initialize the controller. If a message for

initialization is displayed, select “NO”.

⇒

If the error does not reset when power is cycled, initialize the system and reload

program data.

⇒

Replace the 1KA board.

⇒

If the above steps do not correct the error, contact KRI customer service

_____________________________________________________________________

.

ERROR CODE D0002 Main CPU BUS error. (PC=XX)

A 1KA board bus error occurs (in the VME bus line, detected by AS software); data

processing is not completed normally. This error is caused by defective AS software,

defective 1KA board, or noise related malfunction.

⇒

Refer to the error message displayed on a PC interfaced with the controller.

⇒

Cycle controller power OFF and ON. Do not initialize the controller. If a message for

initialization is displayed, select “NO”.

⇒

If the error does not reset when power is cycled, initialize the system and reload

program data.

⇒

Replace the 1KA board.

⇒

If the above steps do not correct the error, contact KRI customer service

_____________________________________________________________________

.

1-14 August 9, 2005

Page 18

D SERIES CONTROLLER

K

a

a

aw

s

k

PC Error Display Example:

Error (D0003) VME bus error Code=1

Task (Pc01) Stop SIG=00070004 [NMI(VME BUS ERROR)] PC=*****

bus-read= bus-write=******** *********

Indicates the place the error occurred

PC Error Display Example:

Error (D0004) [ARM CONTROL BOARD] CPU error Code=1

Task (Pc01) Stop SIG=00070004 [FAULT (PARALLEL)] PC=*****

Indicates the place the error occurred

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

ERROR CODE D0003 VME BUS error. (PC=XX)

This error occurs when the CPU does not receive a response from one of the I/O bus

devices within a specific time. This error is caused by defective AS software, defective

1KA board, or noise related malfunction.

⇒

Refer to the error message displayed on a PC interfaced with the controller.

⇒

Cycle controller power OFF and ON. Do not initialize the controller. If a message for

initialization is displayed, select “NO”.

⇒

If the error does not reset when power is cycled, initialize the system and reload

program data.

⇒

Replace the 1KA board.

⇒

If the above steps do not correct the error, contact KRI customer service

_____________________________________________________________________

.

ERROR CODE D0004 [ARM CONTROL BOARD] CPU error. (PC=XX)

The 1KB board CPU is stopped (detected by the AS software). This error is caused by

defective AS or servo software, defective hardware, or noise related malfunction.

⇒

Refer to the error message displayed on a PC interfaced with the controller.

⇒

Cycle controller power OFF and ON. Do not initialize the controller. If a message for

initialization is displayed, select “NO”.

⇒

Ensure the correct 1KB board software is loaded into the 1KA board.

⇒

Replace the 1KB board.

⇒

If the above steps do not correct the error, contact KRI customer service

_____________________________________________________________________

.

1-15August 9, 2005

Page 19

D SERIES CONTROLLER

K

a

a

aw

s

k

PC Error Display Example:

Error (D0005) [ARM CONTROL BOARD] CPU BUS error Code=1

Task (Pc01) Stop SIG=00070004 [NMI( )] PC=*****VME BUS ERROR

Indicates the place the error occurred

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

ERROR CODE D0005 [ARM CONTROL BOARD] CPU BUS error. (PC=XX)

On the 1KB board, a bus error occurs (in the VME bus line, detected by AS software);

data processing is not completed normally. This error is caused by defective AS software, defective 1KB board, or noise related malfunction.

⇒

Refer to the error message displayed on a PC interfaced with the controller.

⇒

Cycle controller power OFF and ON. Do not initialize the controller. If a message for

initialization is displayed, select “NO”.

⇒

Ensure the correct 1KB board software is loaded into the 1KA board.

⇒

Replace the 1KB board.

⇒

If the above steps do not correct the error, contact KRI customer service

_____________________________________________________________________

.

ERROR CODE D0900 Teach data is broken.

The program storage area of the system memory is damaged and is not linking data

correctly.

Main causes include:

1. Loss of memory battery back-up.

2. Noise related malfunction.

3. Defective 1KA board.

⇒

Set the 1KA board switch SW2-8 to ON and initialize the memory, do not use AUX

0805 or SYSINIT command. Reload the robot program data.

⇒

Check the memory backup battery. Replace if necessary (3.3 VDC or less). When

battery voltage drops to 3.3 VDC, or less, error W1010 is displayed.

⇒

Replace the 1KA board if the error recurs.

_____________________________________________________________________

1-16 August 9, 2005

Page 20

D SERIES CONTROLLER

K

a

a

aw

s

k

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

ERROR CODE D0901 AS Flash memory sum check error.

A check sum error occurrs in AS software, in flash memory on the 1KA board, when the

controller is powered-up. The check sum data is created when the FCHK command is

executed and is recorded in flash memory during AS software download.

Main causes include:

1. When the AS software is downloaded, the FCHK command is not executed.

2. The addressing of the FCHK command is wrong.

3. The flash memory and 1KA board are defective.

4. The system data in the flash memory is corrupt.

⇒

Confirm the content of the command as_load.cmd file on the PC card. If error occurs

immediately after downloading the AS software, download AS software again. If error

continues after download, replace the 1KA board.

_____________________________________________________________________

ERROR CODE D0902 Servo flash memory sum check error.

A check sum error of the servo software in flash memory on the 1KA board occurrs

when the controller is powered-up. The check sum data is created when the FCHK

command is executed and is recorded in flash memory during software download.

Main causes include:

1. When the servo software is downloaded, the FCHK command is not executed.

2. The addressing of the FCHK command is wrong.

3. The flash memory and 1KA board are defective.

4. The system data in flash memory is corrupt.

⇒

If the error occurs immediately after servo software download, confirm the content of

sv_load.cmd on the PC card and download servo software again. If the error reoccurs, replace the 1KA board.

_____________________________________________________________________

ERROR CODE D0903 IP board memory error. (Code)

This error occurs when the flash ROM on the 1GS board is corrupt (check sum error).

Code 2: flash ROM SAM error.

Code 3: DPRAM write and read error.

Code 4: SRAM write and read error.

⇒

Replace the 1GS board.

_____________________________________________________________________

1-17August 9, 2005

Page 21

D SERIES CONTROLLER

K

a

a

aw

s

k

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

ERROR CODE D0904 Memory is locked due to AC_FAIL.

The memory is accessed during the controller shut down due to a power supply abnormality (ACFAIL) (AVR +5 V, +12 V, -12 V, +24 V).

⇒

Cycle the controller power OFF and ON.

⇒

Check for proper AVR voltage supply (+5 V, +12 V, -12 V, +24 V) and related circuitry.

_____________________________________________________________________

ERROR CODE D1000 Read error of servo control software.

Main causes include:

1. Servo control software (armsc.mb) not found at controller power-up or software is

corrupt.

2. Defective 1KJ/1QJ board.

⇒

Download servo control software (armsc.mb)

Replace 1KJ/1QJ board.

⇒

_____________________________________________________________________

ERROR CODE D1001 Download error of servo control software.

Servo control software (armsc.mb) download failure at controller power-up.

Main causes include:

1. Incorrect servo control software.

2. Defective 1KJ/1QJ board.

2. Defective 1KA and or 1KB board.

⇒

Ensure the correct servo software is loaded into the 1KA board

⇒

Replace the 1KJ/1QJ board.

⇒

Replace the 1KA and or 1KB board.

_____________________________________________________________________

.

.

1-18 August 9, 2005

Page 22

TROUBLESHOOTING AND COMPONENT REPLACEMENT

K

a

a

aw

s

k

TROUBLESHOOTING

ERROR CODE D1002 Init. error of servo software.

D SERIES CONTROLLER

Servo software

Main causes include:

1. Servo software is not installed correctly or is corrupt.

2. Incompatibility between the AS and servo software.

3. Defective 1KA and or 1KB board.

⇒

Reinstall servo software.

⇒

Check compatibility of AS and servo software and reinstall software as needed.

⇒

Replace the 1KA and or 1KB boards.

_____________________________________________________________________

ERROR CODE D1003 Init. error of servo control software.

Servo software

Main causes include:

1. Servo software is not installed correctly or is corrupt.

2. Incompatibility between the AS and servo software.

3. Defective 1KA and or 1KB board.

(armsc.mb)

(armsv.abs)

initialization failure at controller power-up.

initialization failure at controller power-up.

⇒

Reinstall servo software.

⇒

Check compatibility of AS and servo software and reinstall software as needed.

⇒

Replace the 1KA and or 1KB boards.

_____________________________________________________________________

1-19August 9, 2005

Page 23

D SERIES CONTROLLER

K

a

a

aw

s

k

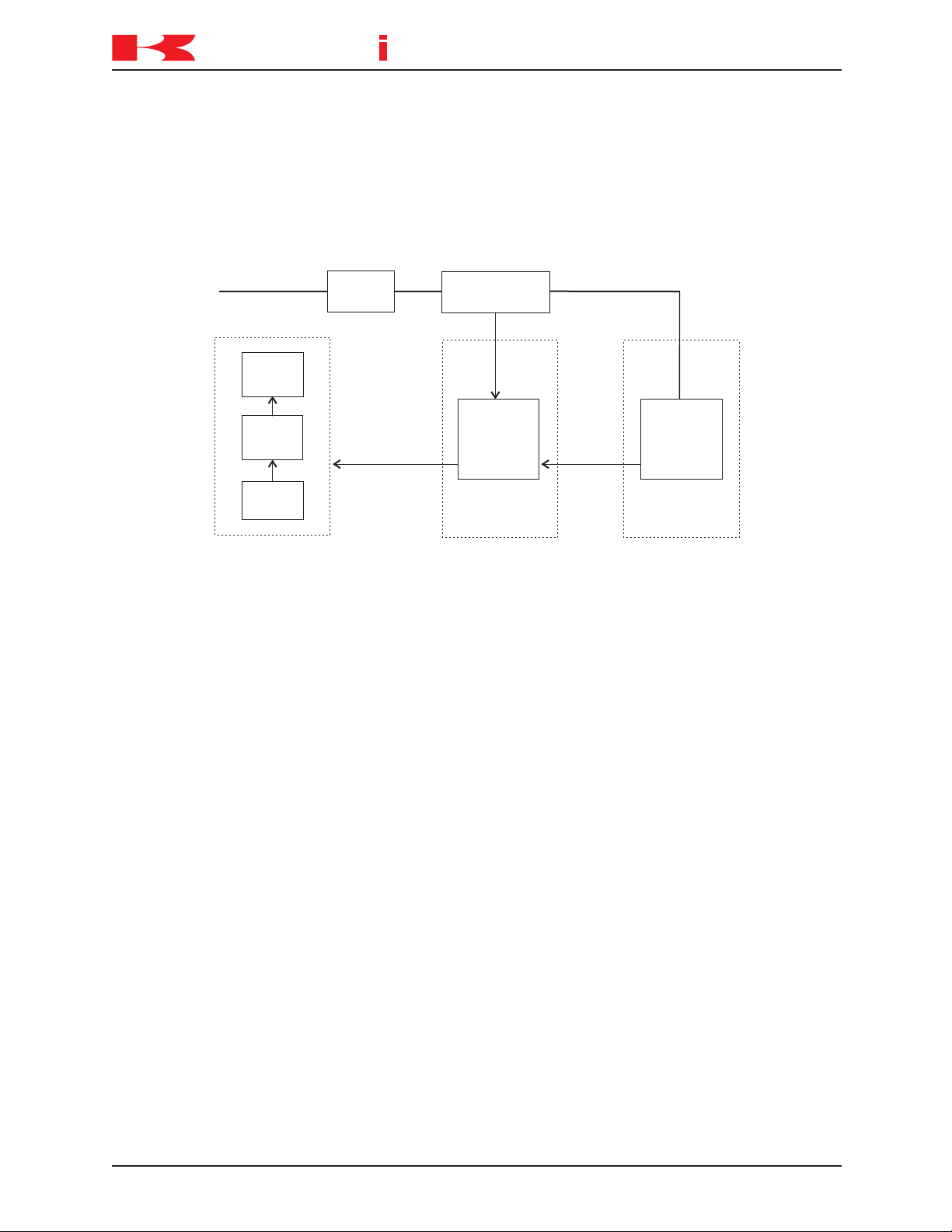

Gate Array

ELPD

Servo

Control

CPU

Interface

CPU

1KX (Mother Board)

1KA (Main CPU Board)

1KB (Servo CPU Board)

Watch Dog

Error Signal

Gate Array

ELPD

Servo

Control

CPU

Interface

CPU

1KX (Mother Board)

1KA (Main CPU Board)

1KB (Servo CPU Board)

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

ERROR CODE D1004 [ARM CTRL BOARD] watch dog error of servo control

software.

The watch dog circuit on the 1KA board or 1KB board has detected a software problem.

This is caused by a defective 1KA main CPU board or 1KB servo CPU board or a problem with the servo software.

⇒

Replace the AS or servo software.

⇒

Replace the 1KA or 1KB board.

_____________________________________________________________________

ERROR CODE D1005 Servo board command error. (xx)

Servo software returned an error code, other than a servo system error, to the AS software after receiving an unrecognized command from the 1KA board.

Main causes include:

1. Corrupt servo or AS software.

2. Noise malfunction.

3. Defective 1KB servo board or 1KA main CPU board.

4. Versions of servo and AS software incompatible.

⇒

Install correct versions of servo and AS software.

⇒

Replace the 1KA or 1KB board.

_____________________________________________________________________

1-20 August 9, 2005

Page 24

D SERIES CONTROLLER

K

a

a

aw

s

k

Gate Array

ELPD

Servo

Control

CPU

Interface

CPU

1KX (Mother Board)

1KA (Main CPU Board)

1KB (Servo CPU Board)

1KP (Power Sequence Board)

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

ERROR CODE D1006 AMP power unit error.

General servo system error. This error indicates that a servo system error has occurred.

Refer to any other servo system errors which occurred at the same time.

When a servo error signal (SVER) is sent from the 1KB board (servo CPU board) to the

1KP board (power sequence board) motor power is shut down. The error notification is

sent to the AS software via the EPLD. The error information from the 1KB board is sent

through the command line and the corresponding error code(s) is/are displayed after

D1006.

⇒

Check the servo error codes that follow this error for additional information. Ensure

that the 1KP board and 1KB board are properly seated.

_____________________________________________________________________

1-21August 9, 2005

Page 25

D SERIES CONTROLLER

K

a

a

aw

s

k

Regenerative

signal

1KB board

Controller

P-N power

voltage

monitoring

circuit/

Regeneration

controlling

circuit

Drive circuit

1KC: IGBT

1KD: IGBT

1KL/1KR: FET

Regenerative

resistor

Motor power

(P-N power

voltage)

Motor power circuit

Motor power

Power block

Gate Array

Servo

CPU

Interface

CPU

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

ERROR CODE D1007 Regenerative time over [XX].

This error occurs when current is sent to regenerative resistors for six or more consecutive seconds.

When the robot decelerates, the motors enter the power generation state to absorb the

inertia energy from the arm. When the P-N power voltage exceeds the rated value (390

VDC), the current is split from the power block to the regenerative resistor. When the

voltage drops to a safe level (365 VDC) the resistor is removed from the circuit.

Main causes include:

1. Abrupt direction changes at high speed.

2. Burned out regenerative resistors in the power block.

3. Defective power block.

4. Defective servo board (1KB board).

5. Loose or disconnected harness between 1KX board (mother board) connector X211

or X212 and the 1KB board (servo CPU board) connector X501 or X502.

6. Defective/incorrect optional second regenerative resistance unit (when used).

⇒

Avoid abrupt high speed direction changes. Change accuracy, speed, add points.

⇒

Replace defective regenerative resistor.

⇒

Install/replace optional second regenerative resistance unit.

⇒

Replace defective 1KB board.

⇒

Replace defective power block.

⇒

Check connections described in item 5 and repair as necessary.

_____________________________________________________________________

1-22 August 9, 2005

Page 26

D SERIES CONTROLLER

K

a

a

aw

s

k

! WARNING

1KB board

1KP board

P-N power low

voltage error

MC unit

(1KQ/1NQ board)

Primary power

Power block

Gate Array

Servo

CPU

Interface

CPU

P-N power

voltage

monitoring

circuit

Main

disconnect

EPLD

K3 STATUS

Motor power

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

ERROR CODE D1008 P-N low voltage [XX].

The voltage between P-N supplied to the power block is 60 VDC or less at servo on.

Because motor power is not supplied, when low voltage

occurs, the arm will fall until the error is detected. As a

result, other errors may be generated (abnormal speed,

deviation error, etc.).

Main causes include:

1. Motor power circuit connector detached or loose.

2. Three phase (U, V, W) control power circuit breaker set to OFF.

3. Defective 1KB/1KP/1KQ/1NQ boards.

4. Defective power block.

5. Defective MC unit or harness.

⇒

Ensure the motor power circuit connector is properly attached.

⇒

Ensure control power circuit breaker is set to ON.

⇒

Replace the 1KB/1KP/1KQ /1NQ boards.

⇒

Replace the power block.

⇒

Replace the MC unit or harness.

_____________________________________________________________________

1-23August 9, 2005

Page 27

D SERIES CONTROLLER

K

a

a

aw

s

k

1KB board

Additional regenerative

resistor (option)

P-N power high

voltage error

MC unit

(1KQ/1NQ board)

Primary power

Power block

Gate Array

Servo

CPU

Interface

CPU

P-N power

voltage

monitoring

circuit

Main

disconnect

Motor power

Regenerative

resistor

Thermal

(140° C)

Additional

regenerative

resistor

Thermal

(140° C)

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

ERROR CODE D1009 P-N- high voltage [XX].

The voltage between P-N supplied to the power block exceeded 410 VDC.

Main causes include:

1. High inertia loads due to excessive tool weight or incorrect program data.

2. Defective regenerative resistance control circuit, overheat failure of regenerative

resistance unit, defective voltage monitoring circuit, or defective power block.

3. Defective servo board (1KB board) or harness.

4. Defective additional regenerative resistance unit.

⇒

Reteach program steps to eliminate sudden high speed direction changes (dynamic

shock).

⇒

Replace the regenerative unit.

⇒

Replace the 1KB board, power block or harness.

⇒

Replace the additional regenerative resistor unit.

_____________________________________________________________________

1-24 August 9, 2005

Page 28

D SERIES CONTROLLER

K

a

a

aw

s

k

1KB board

Additional regenerative

resistor (option)

P-N power high

voltage error

MC unit

(1KQ/1NQ board)

Primary power

Power block

Gate Array

Servo

CPU

Interface

CPU

P-N power

voltage

monitoring

circuit

Main

disconnect

Motor power

Regenerative

resistor

Thermal

(140° C)

Additional

regenerative

resistor

Thermal

(140° C)

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

ERROR CODE D1010 Regenerative resistor over-heat [XX].

The thermal switch for the power block regenerative resistor unit, or the optional regenerative resistor unit reached 140° C (284°F), or the heat sink thermal switch reached

90° C (194°F), or the controller cabinet thermal switch reached 70° C (158° F). The

thermal switches are wired in series and the AS software cannot distinguish which

thermal switch is activated. For D7X controller, if the heat exchange fan is inoperative

(X207 disconnected) this error is generated.

Main causes include:

1. High inertia loads due to excessive tool weight or incorrect program data.

2. Defective cooling fans.

3. Insufficient clearance for air circulation.

4. High ambient controller temperature.

5. Defective power block.

6. Disconnected or defective harness between the 1KC/1KD board and the additional

regenerative resistor unit.

7. Defective regenerative resistor unit.

8. Defective additional regenerative resistor unit.

9. Defective 1KB board.

10. Disconnected or defective harness between X211 or X212 on the 1KX/1NX board

and X501 or X502 on the power block.

1-25August 9, 2005

Page 29

D SERIES CONTROLLER

K

a

a

aw

s

k

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

⇒

Reteach program steps to eliminate sudden high speed direction changes (dynamic

shock).

⇒

Ensure cooling fans are in proper working condition.

⇒

Reduce controller ambient temperature.

⇒

Replace defective thermal switch(es).

⇒

Repair or replace disconnected or defective harness(es).

⇒

Replace the regenerative unit.

⇒

Replace the 1KB board, power block or harness.

⇒

Replace the additional regenerative resistor unit.

⇒

Connect or repair D7X power supply connection for heat exchange fan (X207).

_____________________________________________________________________

ERROR CODE D1011 AS or servo software is not compatible with the robot

model.

This error occurs when the servo software does not match the robot specifications.

⇒

Load the correct AS and servo software.

_____________________________________________________________________

ERROR CODE D1012 Servo type mismatch. Check the settings.

Servo type set for the robot and servo software do not match.

⇒

Change the robot servo type setting

⇒

Install servo software that matches the robot setting.

_____________________________________________________________________

.

1-26 August 9, 2005

Page 30

D SERIES CONTROLLER

K

a

a

aw

s

k

1KB board

1KP board

P-N capacitor

discharge error

MC unit

(1KQ/1NQ board)

Primary power

Power block

Gate Array

Servo

CPU

Interface

CPU

P-N power

voltage

monitoring

circuit

Main

disconnect

EPLD

K3 STATUS

Motor power

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

ERROR CODE D1013 P-N capacitor is not discharged.

This error occurs when motor power is OFF for a period of time and the P-N power

voltage does not decrease to 60 VDC or less.

Main causes include:

1. Defective 1KB/1KP/1KQ/1NQ boards.

2. Defective power block.

3. Defective MC unit or harness between the MC unit and the power block.

⇒

Replace the 1KB/1KP/1KQ/1NQ boards

⇒

Replace the power block.

⇒

Replace the MC unit or harness between the MC unit and the power block.

.

_____________________________________________________________________

ERROR CODE D1014 Servo system error. (Code=XX)

An unrecognized error occurred in the 1KB board.

⇒

Contact KRI customer service (include operating conditions/settings at the time the

error occurred)

_____________________________________________________________________

ERROR CODE D1015 The servo data file does not exist.

.

This error occurs when the servo data file is not found.

⇒

Contact KRI customer service (include operating conditions/settings at the time the

error occurred)

.

_____________________________________________________________________

1-27August 9, 2005

Page 31

D SERIES CONTROLLER

K

a

a

aw

s

k

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

ERROR CODE D1016 Data applicable to the robot model not in servo servo data

file.

This error occurs when the installed robot model file is not found in the servo data file.

⇒

Contact KRI customer service (include operating conditions/settings at the time the

error occurred)

_____________________________________________________________________

ERROR CODE D1017 Error of download of servo data.

Servo data could not be downloaded from the servo software at controller power-up.

⇒

Ensure the correct servo software is installed.

⇒

Ensure the 1KA and 1KB boards are properly installed

_____________________________________________________________________

.

.

1-28 August 9, 2005

Page 32

D SERIES CONTROLLER

K

a

a

aw

s

k

Encoder I/F

1KB board

Encoder power supply +12 V

Controller

Robot

Power circuit

Battery

Encoder

Encoder

1FG/1HG board

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

ERROR CODE D1500 Encoder misread error JtXX.

Immediately after control power on, steady encoder data is not able to be read. This

error is caused by a disconnected encoder signal line or a short circuit, or a defect in the

main body of the encoder.

Main causes include:

1. Defective encoder or encoder harness.

2. Defective servo weld gun encoder (detected at controller power-up/power-down with

gun connected.

3. Servo weld gun is not connected.

4. Defective 1KB board.

5. Defective 1FG/1HG board.

⇒

Check for disconnection or short circuit in encoder signal line.

⇒

Replace the encoder or encoder harness.

⇒

Replace the 1KB servo board.

⇒

Replace the 1FG/1HG board.

⇒

Release the servo weld gun axis in teach mode and cycle controller power OFF and

ON.

_____________________________________________________________________

1-29August 9, 2005

Page 33

D SERIES CONTROLLER

K

a

a

aw

s

k

Robot

Motors

Current

sensor

1GM board

I/V

converter

HIC

(Over current

detection)

Gate

Array

IPM

Controller

Power block

PWM

Over current

error signal

Current

feedback

1KB Board

U, V, W

earth

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

ERROR CODE D1501 Defective gun changer connection or encoder comm. error.

This error occurs when the servo weld gun is connected and encoder data is not read

normally within the specified time.

Main causes include:

1. Improper connection at the tool changer.

2. Defective encoder or encoder communication line.

⇒

Check tool changer connection and repair as necessary

⇒

Check encoder and encoder harness and replace as necessary.

.

_____________________________________________________________________

ERROR CODE D1502 Amp over current JtXX.

The feedback current from a current sensor in the power block exceeded 150% of the

maximum instantaneous motor current rating.

Main causes include:

1. Short in the U, V, W from the power block to motor and ground wire.

2. Defective motor.

3. Defective power block.

4. Defective 1KB servo board, harness, etc.

⇒

⇒

Check the connection for the U, V, W and ground line to the power block. Replace the

separation harness if necessary.

Replace the motor, 1KB board, power block, or harness.

_____________________________________________________________________

1-30 August 9, 2005

Page 34

D SERIES CONTROLLER

K

a

a

aw

s

k

HCnoitacinummoCoT

ecneuqeSrewoPotyaleR

)draoBCPPK1(draoB

AtinUAdraoBCPBK1tsriFretsaM

BtinUBdraoBCPBK1tsriFrets

aM

CtinUCdraoBCPBK1tsriFevalS

ro

tinUAdraoBCPBK1dnoceS

ro

reifilpmAsixAenO

D

tinUBdraoBCPBK1dnoceS

evalS

ro

reifi

lpmAsixAenO

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

ERROR CODE D1503 Current detector type (XX) mismatch!

When the control power supply is turned ON, the ID code data of the 1GM (1KV) board

and the AS software installed on the 1KB board do not correspond. The unit name of

the servo board displayed at (XX) in the error message corresponds to the CH column

in the table below.

Main causes include:

1. 1GM (1KV) board is not suitable for the AS software (robot model).

2. The AS software does not correspond to the 1GM (1KV) board.

⇒

Ensure the correct AS software is loaded.

⇒

Replace the 1GM (1KV) board.

_____________________________________________________________________

1-31August 9, 2005

Page 35

D SERIES CONTROLLER

K

a

a

aw

s

k

Robot

Motors

Current

sensor

1GM board

I/V

converter

Servo CPU

IPM

Controller

Power block

Current

feedback

1KB Board

U, V, W

earth

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

ERROR CODE D1504 Abn. curr. feedback Jt XX. (Amp fail, pwr harness discon-

nect).

This error occurs if the current feedback value is near 0 from the time the servo is turned

ON until the brake is released, even if the commanded current value meets or exceeds

the expected current.

Main causes:

1. Motor power line U, V, and/or W phase are disconnected.

2. Improper power harness line connection.

3. Defective power block

⇒

Check the power line wiring and repair or replace as necessary.

⇒

Replace the power block.

_____________________________________________________________________

1-32 August 9, 2005

Page 36

D SERIES CONTROLLER

K

a

a

aw

s

k

1KB board

Gate Array

Servo

CPU

Interface

CPU

1KQ/1NR board

Controller

Photo coupler

Upper arm

Rotor trunk

Thermal switch

Thermal switch

Thermal line

(TH)

Robot

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

ERROR CODE D1505 Motor harness disconnected or over heat. (XX)

Motor thermal circuit is open due to motor overheat or harness problem. Not all robot

models utilize thermal switches in the motors. Some robot models may have multiple

thermal switches connected in series (see diagram below). The FS03/06/10/20 robot

models have the thermal switch mounted near JT1 motor. The FS03 model is calibrated

to 55° C and FS06/10/20 models are calibrated to 65° C

Main causes include:

1. Disconnected thermal line.

2. Defective connection in the separation harness.

3. Defective 1KB servo board.

4. Defective 1KQ/1NR board.

5. When the motor thermal switch is used:

– The robot rated weight capacity is exceeded.

– The ambient temperature exceeds limits for use.

– Excessive execution of abrupt high speed direction changes.

– Defective controller cooling fan or cooling air purge system.

– Servo system holding the robot arm in high load position for extended periods.

– Defective thermal switch.

⇒

When the thermal switch opens, error cannot be reset until cooling is complete.

⇒

Confirm continuity of thermal line.

⇒

Replace the harness or the 1KB servo board as necessary.

⇒

⇒

Replace the 1KQ/1NR board.

Use the auto servo off function, AUX 0808, to prevent the servo system holding a

high load arm position for extended periods.

_____________________________________________________________________

1-33August 9, 2005

Page 37

D SERIES CONTROLLER

K

a

a

aw

s

k

1KB board

IPM error signal

Power block

Gate Array

Servo

CPU

Interface

CPU

PWM signal

Controller

HIC

IPM

Motor

Robot

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

ERROR CODE D1506 Power module error JtXX.

An error signal from the IPM module in the power block is detected by the 1KB board.

Main causes include:

1. U, V, and W phase short-circuited or short-circuited to ground wire.

2. Payload weight exceeds rating.

3. Defective cooling fan in the power block.

4. Ambient temperature above normal operating limits.

5. Constant execution of abrupt high speed direction changes.

6. Defective 1KB board.

7. Disconnected or defective harness between the 1KB board and the power block.

8. Disconnection or poor connection in the thermal line at the separate harness and/or

controller harness.

9. Defective thermal switch in the controller or servo motors (if used).

10. Defective power block.

⇒

Check and repair cause of U, V, and W phase short-circuited or short-circuited to

ground wire.

⇒

Ensure payload does not exceed rating.

⇒

Reduce ambient temperature.

⇒

Ensure cooling fans are in proper working condition.

⇒

Correct abrupt high speed direction changes in the robot program.

⇒

Replace the 1KB board.

⇒

Repair or replace the harness between the 1KB board and the power block.

⇒

Check the thermal line in the separate harness and controller harness, and repair or

replace as necessary.

⇒

Replace the power block.

_____________________________________________________________________

1-34 August 9, 2005

Page 38

D SERIES CONTROLLER

K

a

a

aw

s

k

Mother Board

1KP board

1KB board

1KX board

EPLD

AVR

output

cut

AVR for

control power

Main

disconnect

Primary

power

Control

power

210 VAC

AC error

signal

REMOTE

Local

bus

F1

T1 F3

1KQ/1NQ board

Transformer

Circuit

breaker

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

ERROR CODE D1507 AC primary power OFF.

This error occurs when there is an instantaneous decrease in the primary power to the

AVR for control power supply (130–145 VAC or less for 20–30 msec).

Main causes include:

1. The primary power is below the specified rating, or an instantaneous power decrease

occurred.

2. The non-fuseable breaker (NFB) F1 for the control power supply is turned OFF or

tripped due to a short-circuit.

3. An instantaneous decrease in the 210 VAC supply to AVR for the control power

supply.

4. Circuit breaker F3 is OFF or tripped due to a short circuit.

5. Defective AVR.

6. Defect in the primary power supply.

7. Defective 1KP board.

8. Defective 1KQ/1NQ board.

⇒

It is normal for this error to occur when NFB F1 is set OFF and back ON.

⇒

Check power supply circuit through NFB F1 and repair as necessary.

⇒

Check power supply circuit to the AVR through the circuit breaker F3 and repair as

necessary.

⇒

Confirm that primary power is supplied according to specifications.

⇒

Replace the 1KP board.

⇒

Replace the 1KQ/1NQ board.

⇒

Replace the AVR.

_____________________________________________________________________

1-35August 9, 2005

Page 39

D SERIES CONTROLLER

K

a

a

aw

s

k

Mother Board

1KP board

1KB board

1KX board

EPLD

24 VDC

monitor

AVR for

control power

Main

disconnect

Primary

power

Control

power

210 VAC

DC error

signal

Local

bus

F1

T1

F3

1KQ/1NQ board

Transformer

Circuit

breaker

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

ERROR CODE D1508 24VDC power source is too low.

24 VDC to the power sequence board has dropped to +21.6 VDC or less.

Main causes include:

1. Defective AVR for control power supply.

2. Defective 1KP board.

3. Defective 1KQ/1NQ board.

4. Short circuit in the motor power on circuitry, the EMERGENCY STOP switch, or axis

restriction limit switch circuits.

5. Short in machine valve and sensor circuits.

⇒

Check the power supply, machine valve, and the sensor circuits for short circuits.

⇒

Ensure the 24 VDC load does not exceed the power supply capacity.

⇒

Check the AVR, the 1KP power sequence board, and the 1KQ/1NQ relay board and

replace as necessary.

_____________________________________________________________________

1-36 August 9, 2005

Page 40

D SERIES CONTROLLER

K

a

a

aw

s

k

Mother Board

1KP board

1KX board

EPLD

AVR

output

cut

AVR for

control power

Main

disconnect

Primary

power

Control

power

210 VAC

AC error

signal

Local

bus

F1

T1 F3

1KQ/1NQ board

Transformer

Circuit

breaker

REMOTE

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

ERROR CODE D1509 Primary power source is too high.

Voltage level of the AVR for the control power supply is too high (267-277 VAC or more

for 1-2 sec.).

Main causes include:

1. Primary power exceeds the specified rating.

2. Defective AVR.

3. Defective 1KP power sequence board.

4. Defective 1KQ/1NQ relay board.

5. Power supply circuit problem.

⇒

Ensure the power supply to the controller is within ratings.

⇒

Check power supply circuit to the AVR.

⇒

Confirm the supply power is within specifications.

⇒

Replace the 1KP board.

⇒

Replace the 1KQ/1NQ board.

⇒

Replace the AVR.

_____________________________________________________________________

1-37August 9, 2005

Page 41

D SERIES CONTROLLER

K

a

a

aw

s

k

Mother Board

1KP board

1KB board

1KX board

EPLD

AVR for

control power

Main

disconnect

Primary

power

Control

power

210 VAC

AC error

signal

Local

bus

F1

T1 F3

1KQ/1NQ board

Transformer

Circuit

breaker

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

ERROR CODE D1510 Primary power source is too low.

Voltage level of the AVR primary power supply is too low (150-158 VAC or less for 1-2

sec.).

Main causes include:

1. Drop in the primary power supply voltage.

2. Defective AVR.

3. Defective NFB F1.

4. Defective 1KP power sequence board.

5. Defective 1KQ/1NQ relay board.

6. Power supply circuit problem.

⇒

Verify the power supply to the controller is within ratings.

⇒

Check the AVR and NFB F1 and replace as necessary.

⇒

Confirm supply power is within specifications.

⇒

⇒

Replace the 1KP board.

Replace the 1KQ/1NQ board.

_____________________________________________________________________

1-38 August 9, 2005

Page 42

TROUBLESHOOTING AND COMPONENT REPLACEMENT

K

a

a

aw

s

k

TROUBLESHOOTING

ERROR CODE D1511 +12VDC or -12VDC is abnormal.

+/-12 VDC supplied to the 1KA board is out of specifications.

+12 VDC: +10.75 VDC or less.

-12 VDC: -10.4 VDC or more.

Main causes include:

1. Defective AVR.

2. Defective 1KA, 1KB, or 1KP board.

3. Power supply contacts in the motherboard are damaged.

5. Defective power block.

6. Defective 1FG/1HG board.

7. Short in the harness between the servo unit and the 1FG board.

8. Short in the optional circuit boards, i.e., vision, etc.

9. Insufficient DC power supply capacity to support optional boards.

D SERIES CONTROLLER

⇒

Adjust the AVR output voltage.

⇒

Replace the AVR and each board for the control power supply.

⇒

Check for short circuits in the operation panel and separation harness and replace as

necessary.

_____________________________________________________________________

1-39August 9, 2005

Page 43

D SERIES CONTROLLER

K

a

a

aw

s

k

Transformer Circuit breaker

MOSFET

Voltage

monitoring

1KP board

Motor

1KB board

Robot

Controller

Safety circuit

Brake power supply error signal

Brake release signal

Brake line error signal

1KQ/1NR board

+24 VDC

Brake power supply D3X

Brake power supply D7X

Motor brake line

Motor power

Servo control

Brake release

ON

START

RELEASE

Disconnection

detected

Short-circuit

detected

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

ERROR CODE D1512 Brake line error for JtXX.

This error occurs when the 1KB board detects an error signal sent from the brake release control MOSFET on the 1KQ/1NR board.

Brake line errors are not detected during motor power OFF. Brake line disconnection is

not detected during automatic operation. Brake line error detection timing is shown in

the diagram below.

Main causes include:

1. Disconnection/short-circuit/ground fault/poor connection at the brake line axis motor

harness.

2. Defective connection for the brake power line.

3. Defective connection or harness between the 1KB and 1KQ/1NR boards.

4. Defective connection or harness between the 1KB and 1KX/1NX boards.

5. Defective connection or harness between the 1NR and 1NX boards.

6. Incorrect 1KP board safety circuit setting.

7. Defective 1KB or 1KQ/1NR board.

⇒

Check for disconnection or short-circuit in the motor harness, and repair or replace as

1-40 August 9, 2005

Page 44

D SERIES CONTROLLER

K

a

a

aw

s

k

Transformer Circuit breaker

MOSFET

Voltage

monitoring

1KP board

Motor

1KB board

Robot

Controller

Safety circuit

Brake power supply error signal

Brake release signal

Brake line error signal

1KQ/1NR board

+24 VDC

Brake power supply D3X

Brake power supply D7X

Motor brake line

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

necessary.

⇒

Check and repair brake power line and connections as necessary

⇒

Check and repair connections between 1KB and 1KQ/1NR, 1KB and 1KX/1NX, and

.

1NR and 1NX as necessary.

⇒

Ensure the 1KB board is properly seated in the card rack.

⇒

Ensure the 1KP board safety circuit setting is correct.

⇒

Replace the 1KB and or the 1KQ/1NR.

_____________________________________________________________________

ERROR CODE D1513 Brake power is abnormal. (XX)

This error occurs when the 1KB board detects an error signal sent from the brake power

supply, voltage monitoring circuit, on the 1KQ/1NR board.

Main causes include:

1. Defective transformer winding for brake power supply.

2. Short or open in wiring from transformer to brake power supply circuit.

3. Disconnected or defective harness between the 1KB board and the 1KQ/1NR board.

4. 1KB board not properly seated in the 1KX/1NX board.

5. 1NR board not properly seated in the 1NX board.

6. Defective circuit breaker F4 or F4 tripped.

7. Defective MC unit (1KQ board).

8. Defective 1NR board.

⇒

Check transformer winding and wiring and repair or replace as necessary

⇒

Repair or replace harness between the 1KB and 1KQ/1NR board.

⇒

Ensure the 1NR and or the 1KB boards are properly seated in the 1KX/1NX board.

⇒

Replace MC unit.

⇒

Reset or replace circuit protector F4 as necessary.

⇒

Replace the 1KB and or 1KQ/1NR boards as necessary.

_____________________________________________________________________

.

1-41August 9, 2005

Page 45

D SERIES CONTROLLER

K

a

a

aw

s

k

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

ERROR CODE D1514 I/O 24V fuse is open.

Fuse F2 on the 1KP board is open.

Main causes include:

1. Solenoid valve or diode polarity reversed.

2. Current load on the 24 VDC I/O circuit exceeds rating.

3. Short-circuit or ground fault in the 24 VDC I/O harness.

4. Defective 1KP board.

⇒

Check components for proper polarity and repair as necessary

Ensure the load on the 24 VDC I/O circuit is within rating.

⇒

⇒

Check the I/O harness and replace as necessary.

⇒

Replace fuse F2 on the 1KP board (after cheching for short-circuit).

⇒

If the above steps do not correct the problem, replace the 1KP board.

_____________________________________________________________________

.

ERROR CODE D1515 Mismatch in setting of safety circuit as single/double.

Main causes include:

1. Safety circuit setting between the software and hardware do not match.

2. Defective 1KP board.

⇒

Set SW-2 on the 1KP board to ON for a double circuit or OFF for a single circuit

In AUX 2021-2 set [2 Line] ON or [1 Line] OFF.

⇒

⇒

Replace 1KP board.

_____________________________________________________________________

ERROR CODE D1516 Mismatch betw hard/software settings for HOLD backup

time.

Main causes include:

1. The setting that specifies a two second delay before motor power is set OFF when

the RUN/HOLD switch is switched from RUN to HOLD, is not matched between the

software and hardware.

2. Defective 1KP board.

⇒

Set SW-1 on the 1KP board to ON for two second delay or OFF no delay

⇒

In AUX 2021-2 set the delay parameter to [standard] (delay) or [Off] (no delay).

⇒

Replace 1KP board.

_____________________________________________________________________

.

.

1-42 August 9, 2005

Page 46

D SERIES CONTROLLER

K

a

a

aw

s

k

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

ERROR CODE D1517 Blown fuse on safety circuit emergency line.

Fuse F1 on the 1KP board is open.

Main causes include:

1. Incorrect wiring in the emergency line (wiring harness, emergency stop, safety fence,

external trigger, teach pendant, limit switches).

2. Short-circuit in the emergency line (wiring harness, emergency stop, safety fence,

external trigger, teach pendant, limit switches).

3. Defective 1KP board.

⇒

Check wiring and components in the safety circuit emergency line and repair/replace

as necessary

⇒

Replace 1KP board.

⇒

Ensure the controller power is set OFF, when wiring safety circuits. The fuse F1 will

blow if wiring is shorted.

_____________________________________________________________________

.

ERROR CODE D1518 Mismatch in the Emer. Stop condition safety circuit.

Main causes include:

1. When the system is set for double safety circuits, and the circuits at the operation

panel, teach pendant, and/or the external emergency stop switch are wired as single

circuits.

2. Disconnection or ground fault in the emergency stop circuit.

3. Defective 1KP board.

⇒

With the E-STOP switch(es) engaged, check wiring harness and switches in the

circuit and repair or replace as necessary

⇒

Ensure all contacts in the external emergency stop circuit are wired correctly (double

circuits).

⇒

If the above steps do not correct the problem, replace the 1KP board.

_____________________________________________________________________

.

1-43August 9, 2005

Page 47

D SERIES CONTROLLER

K

a

a

aw

s

k

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

ERROR CODE D1519 Mismatch of the safety circuit LS condition.

In a double safety circuit system, conditions set for contacts in the limit switch (LS)

circuit do not match.

Main causes include:

1. Defective harness connection or harness (short-circuit or ground fault in harness).

2. Defective LS override switch.

3. Defective 1KP board

⇒

Replace the controller/separate/machine harness(es).

⇒

Replace the LS override switch.

⇒

Replace the 1KP board.

_____________________________________________________________________

ERROR CODE D1520 Mismatch of the safety circuit TEACH/REPEAT condition.

Main causes include:

1. TEACH/REPEAT switch setting and relay conditions for switching teach/repeat modes

do not match.

2. Contact condition at the TEACH/REPEAT switch does not match between the first

and second safety circuits.

3. Defective 1KP board.

⇒

Check the TEACH/REPEAT switch and relays (RY5 and RY6 on the 1KP board), and

replace as necessary.

⇒

Replace the 1KP board.

_____________________________________________________________________

ERROR CODE D1521 Mismatch in safety circuit safety-fence condition.

In a double safety circuit system, conditions set for contact at the safety fence circuit do

not match.

Main causes include:

1. Incorrect circuit or wiring for safety fence circuit (single circuit wired).

2. Disconnection or ground fault in the safety fence circuit wiring.

3. Defective safety fence switch.

4. Defective 1KP board.

⇒

Inspect contact points at the safety fence circuit and repair or replace as necessary

⇒

Replace the 1KP board.

_____________________________________________________________________

1-44 August 9, 2005

.

Page 48

D SERIES CONTROLLER

K

a

a

aw

s

k

NOTE

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

ERROR CODE D1522 Mismatch in cond. of safety circuit enabling device.

In a double safety circuit system, conditions set for contacts at the TRIGGER switch

circuit do not match.

If the trigger switch is not pressed firmly, only one contact may engage resulting in this error. The trigger

switch has three positions and pressing too firmly may

disengage the trigger circuit.

Replace the teach pendant, teach pendant harness or controller harness to the teach

⇒

pendant connector.

⇒

Replace the 1KP board.

_____________________________________________________________________

ERROR CODE D1523 Mismatch in cond. of safety circuit enabling device.

In a double safety circuit system, conditions set for contacts at the EXTERNAL TRIGGER switch circuit do not match.

⇒

Inspect contacts on the EXT.TRIGGER switch and replace as necessary

⇒

Check for disconnection or short-circuit in external trigger wiring and repair as necessary.

⇒

Replace the 1KP board.

_____________________________________________________________________

ERROR CODE D1524 Incorrect operation of the safety relay.

Safety relay on the 1KQ board did not operate correctly.

Main causes include:

1. Defective controller harness.

2. Defective 1KQ board

3. Defective MC unit.

4. Defective 1KP board.

.

⇒

Replace controller harness.

⇒

Replace the 1KQ board

⇒

Replace the MC unit.

⇒

Replace the 1KP board.

_____________________________________________________________________

.

1-45August 9, 2005

Page 49

D SERIES CONTROLLER

K

a

a

aw

s

k

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

ERROR CODE D1525 Incorrect operation of MC (K1).

Main causes include:

1. Defective controller harness.

2. Defective magnetic contactor K1.

3. Defective MC unit (1KQ/1NQ board).

4. Defective 1KP board.

⇒

Replace controller harness

Replace magnetic contactor K1.

⇒

⇒

Replace MC unit

⇒

Replace 1KP board.

_____________________________________________________________________

ERROR CODE D1526 Incorrect operation of MC (K2).

(1KQ/1NQ board)

.

.

Main causes include:

1. Defective controller harness.

2. Defective magnetic contactor K2.

3. Defective MC unit (1KQ/1NQ board).

4. Defective 1KP board.

⇒

Replace controller harness

⇒

Replace magnetic contactor K2.

⇒

Replace MC unit

⇒

Replace 1KP board.

_____________________________________________________________________

ERROR CODE D1527 Incorrect operation of MC (K3).

Main causes include:

1. Defective controller harness.

2. Defective magnetic contactor K3.

3. Defective MC unit (1KQ/1NQ board).

4. Defective 1KP board.

⇒

Replace controller harness

Replace magnetic contactor K3.

⇒

⇒

Replace MC unit

⇒

Replace 1KP board.

_____________________________________________________________________

(1KQ/1NQ board)

(1KQ/1NQ board)

.

.

.

.

1-46 August 9, 2005

Page 50

D SERIES CONTROLLER

K

a

a

aw

s

k

TROUBLESHOOTING AND COMPONENT REPLACEMENT

TROUBLESHOOTING

ERROR CODE D1528 Controller temperature is out of range.

Temperature inside the controller exceeds specification.

Main causes include:

1. Defective cooling fan(s). For D7X controller, defective heat exchange fan on the left

side of the controller.

2. Ambient temperature above specified rating.

3. Defective 1KP board.

⇒

Inspect cooling fans for proper operation and replace fans and/or fan harness(es) as

necessary

⇒

Ensure air inlet filter is not restricted.

⇒

Lower ambient temperature within specifications.

⇒

Replace the 1KP board.

_____________________________________________________________________

.

ERROR CODE D1529 Signal harness is disconnected or encoder power error.

This error is caused when a communication error occurs for all axes.

Main causes include:

1. Separate harness disconnected or poor connection.

2. Abnormality in encoder power supply.

3. Low battery voltage on the encoder battery board (1FG/1HG).

4. Defective encoder battery board (1FG/1HG).

⇒

Ensure proper connections at the separate harness

⇒

Ensure proper encoder power is supplied.

⇒

Replace batteries on the encoder battery board (1FG/1HG).

⇒

Replace the encoder battery board (1FG/1HG).

_____________________________________________________________________