Page 1

K

a

a

aw

s

k

Kawasaki Robotics (USA), Inc.

k

aw

s

a

C SERIES CONTROLLER

AS LANGUAGE REFERENCE MANUAL

MPPCCONTO11E-2

a

K

Page 2

This publication contains proprietary information of Kawasaki Robotics (USA), Inc. and

is furnished solely for customer use only. No other uses are authorized or permitted

without the express written permission of Kawasaki Robotics (USA), Inc. The contents

of this manual cannot be reproduced, nor transmitted by any means, e.g., mechanical,

electrical, photocopy, facsimile, or electronic data media, without the express written

permission of Kawasaki Robotics (USA), Inc.

All Rights Reserved.

Copyright © 2001, Kawasaki Robotics (USA), Inc.

Wixom, Michigan 48393

The descriptions and specifications in this manual were in effect when it was submitted

for publishing. Kawasaki Robotics (USA), Inc. reserves the right to change or discontinue specific robot models and associated hardware and software, designs, descriptions, specifications, or perfor mance parameters at any time and without notice, without

incurring any obligation whatsoever.

This manual presents information specific to the robot model listed on the title page of

this document. Before performing maintenance, operation, or programming procedures,

all personnel are recommended to attend an approved Kawasaki Robotics (USA), Inc.

training course.

KAWASAKI ROBOTICS (USA), INC. TRAINING

Training courses covering operation, programming, electr ical maintenance, and mechanical maintenance are available from Kawasaki Robotics (USA), Inc. These courses

are conducted at our training facility in Wixom, Michigan, or on-site at the customer’s

location.

For additional information contact:

Kawasaki Robotics (USA), Inc.

Training and Documentation Dept.

28059 Center Oaks Court

Wixom, Michigan 48393

Page 3

K

a

a

s

C SERIES CONTROLLER

aw

k

REVISION HISTORY

AS LANGUAGE REFERENCE MANUAL

Revision

Number

-0 6/ 7/99 In itial PD F r e l ea se B F

-1 9/22/00 Revisio n 1 , bas ed on revi s i on 1 o f print copy CB

-2 1/15/01 Revision 2, based on revision 2 of print copy CB

Release

Date

D escription of Change Init ial s

Page 4

C SERIES CONTROLLER

K

a

I.0 INTRODUCTION..................................................................................................... I-2

I.1 Robot Controller Design Specifications................................................................... I-3

a

s

aw

k

INTRODUCTION

AS LANGUAGE REFERENCE MANUAL

November 20, 1998

I-1

Page 5

C SERIES CONTROLLER

K

a

I.0 INTRODUCTION

The

AS Language Reference Manual

responsibility includes programming and operating Kawasaki industrial robots on a daily

basis. AS Language is a computer control language designed specifically for use with

Kawasaki robot controllers. This text provides information on creating programs, running

programs, and editing programs using AS Language commands. AS Language is relatively easy to learn with many keywords, syntax sequences, and interface commands

being intuitive.

AS Language provides the programmer with the ability to precisely define the task a

robot is to perform. Programming the robot with a computer control language (AS) also

provides the ability to integrate peripheral components into the program. Typical component interfacing with AS Language programs includes: programmable logic controllers

(PLCs), lasers, weld controllers, gray scale vision, and remote sensing systems.

a

s

aw

k

INTRODUCTION

is designed to assist the user whose primary

AS LANGUAGE REFERENCE MANUAL

AS Language programs provide outstanding perfor mance in terms of robot trajectory

control. Program location points can be stored and played back as either joint angles

representing the manipulator configuration (precision points) or geometrically defined

locations in the work envelope (transformations). Transformation locations can also be

defined based on their relative position to one another (compound transformations).

These capabilities allow program locations to be shifted and moved based on parameters and variables identified in the AS Language program.

I-2

November 20, 1998

Page 6

K

a

I.1 ROBOT CONTROLLER DESIGN SPECIFICATIONS

Control System: 32 bit RISC main CPU

Number of Axes: 6 standard; 7th optional

Motion Control: Teach mode - Joint

a

aw

k

s

INTRODUCTION

32 bit RISC CPU for multi function panel unit

32 bit RISC servo CPU controller (one per 3 axes)

Software controlled AC servo drive system using pulse width

modulation (PWM) circuitry

Base

Tool

Repeat mode - Joint move

Linear move

Circular move (optional)

FLIN move (optional)

C SERIES CONTROLLER

AS LANGUAGE REFERENCE MANUAL

Memory: CMOS RAM

Memory Capacity: Standard - 1024 KB (approximately 4,000 steps)

Optional - 4096 KB (approximately 34,000 steps)

Accuracy: Adjustable in increments of 0.0001 mm within the ranges

below:

F-series

Adjustable between 0.1 mm - 5,000 mm

UX/UT-series

Adjustable between 0.5 mm - 5,000 mm

UZ-series

Adjustable between 0.3 mm - 5,000 mm

Z-series

Adjustable between 0.3 mm - 5,000 mm

September 15, 2000

I-3

Page 7

C SERIES CONTROLLER

K

a

Speed: Proportional speed - percentage of maximum joint or TCP

Data Editing: Step insertion and deletion, and rewriting of auxiliary and

Software Features: Continuous path motion control - CP ON/OFF

a

aw

k

s

INTRODUCTION

speed. Adjustable in increments of 0.0001 up to 100%

(rounding occurs as necessary).

Absolute speed - speed of TCP in mm/s. Adjustable in

increments of 0.0001 mm/s up to maximum robot TCP speed

(rounding occurs as necessary).

positional data.

Time delays

Coordinate modification

Process control programs (3)

Peripheral equipment control

Interrupt signal control

Error interrupt control

Input of real, string, and integer variables

Local variables

Subroutine calls with arguments (maximum stack = 20)

Program weld schedules

Servo shutdown timer

Auto start function

AS LANGUAGE REFERENCE MANUAL

I/O Signals: 1GW I/O board 32 inputs/32 outputs (256 maximum)

(including dedicated signals)

1FS RI/O board (optional)

Robot I/O 256 I/O (including dedicated signals)

Robot internal 256

Relay circuit 32 I/O

A-B PLC 64 I/O

Weld controller 32 I/O

Non-retentive 128 I/O

Retentive 16 I/0

Timers 16 I/0

Counters 16 I/0

Message display 64 I/0

Slogic status 16 I/0

Control Net (option)

I-4

September 15, 2000

Page 8

K

a

Dedicated Signals: Outputs - Motor power ON

Dedicated Signals: Inputs - Ext. motor power ON,

a

s

aw

k

INTRODUCTION

Error occurrence

Automatic

CYCLE_START

Teach mode

HOME1

HOME2

Power ON

RGSO

Ext. program select (RPS) enabled

Ext. error reset

Ext. cycle start

Ext. program

Select start (JUMP)

JUMP_ON

JUMP_OFF

JUMP_ST

Ext. program select start (RPS)

RPS_ON

RPS_ST

Number of RPS code signal

First signal number of RPS code

Program reset

Ext. hold (EXT_IT)

Ext. condition wait (EXT_WAIT)

Ext. slow repeat mode

AS LANGUAGE REFERENCE MANUAL

C SERIES CONTROLLER

Error Messages: Error code messages, self-diagnosis, error logging, operation

logging

Special Features: Program check mode

Adjustable restriction of JT1

Terminal box on robot arm (optional)

Robot application interface panel (optional)

Overtravel limit switch - JT1 (JT2, JT3 optional)

Power lockout

Ethernet (optional)

November 20, 1998

I-5

Page 9

C SERIES CONTROLLER

K

a

Multi Function Panel: Deadman safety switches

(optional) 7.2 inch color LCD

Teac h Pendant: Deadman safety switches

(optional) Teach-lock function

Supplemental

Data Storage: PC flash RAM memory card 8 MB, PCMCIA 2.1 slot

a

aw

k

s

INTRODUCTION

Touch panel

Teach-lock function

Emergency stop switch

Pen for touch panel

PC card insertion section

Emergency stop switch

Membrane switch keypad

Alphanumeric LCD

Floppy disk drive (optional)

Personal computer (optional)

AS LANGUAGE REFERENCE MANUAL

Power Requirements: Standard Spec.: 3-phase 200/220 VAC

North Am Spec.: 3-phase 400/440/460/480/515/575 VAC

European Spec.: 3-phase 380/400/415/440/460/480 VAC

Tolerance: +/- 10%

Frequency: 50/60 Hz

Rated Load: 10.5 kVA

Ground: less than 100 ohm ground line separated

from welder power ground

Dimensions: Standard Spec.: W x D x H, 460.8mm x 430mm x

1240mm

(inches) (18.1 x 16.9 x 48.8)

North Am. Spec.: W x D x H, 550mm x 500mm x 1150mm

(inches) (21.7 x 19.7 x 45.3)

European Spec.: W x D x H, 550mm x 500mm x 1150mm

(inches) (21.7 x 19.7 x 45.3)

Weight: Standard Spec.: approx. 80 kg (176 lbs)

North Am. Spec.: 250 kg (550 lbs)

European Spec.: 250 kg (550 lbs)

I-6

September 15, 2000

Page 10

C SERIES CONTROLLER

K

a

1.0 SYSTEM OVERVIEW ........................................................................................1-2

1.1 AS System Status .............................................................................................. 1-2

1.2 Notations and Conventions ................................................................................ 1-6

1.3 Displaying with the Ter minal ............................................................................... 1-7

1.4 Location Information........................................................................................... 1-8

1.4.1 Precision Location.............................................................................................. 1-8

1.4.2 Transformation Location ..................................................................................... 1-8

1.4.3 Compound Transformation Location (Relative Transformation)........................ 1-10

1.5 Numeric Information......................................................................................... 1-12

1.5.1 Integers ............................................................................................................ 1-12

1.5.2 Real Numbers .................................................................................................. 1-12

1.5.3 Logical V alues.................................................................................................. 1-12

1.5.4 ASCII V alues.................................................................................................... 1-13

1.6 Var iable Names................................................................................................ 1-13

1.6.1 Location V ariab les............................................................................................ 1-14

1.6.2 Real Variables .................................................................................................. 1-14

1.6.3 Character String Variables ............................................................................... 1-15

1.7 Numerical Expression ...................................................................................... 1-17

1.7.1 Operators ......................................................................................................... 1-17

1.8 Monitor Commands.......................................................................................... 1-20

1.8.1 Program Instructions ........................................................................................ 1-21

a

s

aw

k

SYSTEM OVERVIEW

AS LANGUAGE REFERENCE MANUAL

November 14, 2000

1-1

Page 11

C SERIES CONTROLLER

K

a

1.0 SYSTEM OVERVIEW

AS Language for the C controller is a software based control system and high-level

language used to interface with the robot controller and control robot motion. The AS

software is permanently stored in the robot controller’s memory and is activated as soon

as controller power is turned on. It continuously generates robot control commands and

can simultaneously interact with a programmer, permitting on-line program generation

and modification. The multi function panel and/or a personal computer is used to access AS Language.

1.1 AS SYSTEM STATUS

The AS system consists of the monitor mode, the editor mode, and the playback mode.

• Monitor Mode: This is the basic mode in the AS system. Monitor commands are

executed in this mode. The editor or playback modes are accessed from this mode.

a

s

aw

k

SYSTEM OVERVIEW

AS LANGUAGE REFERENCE MANUAL

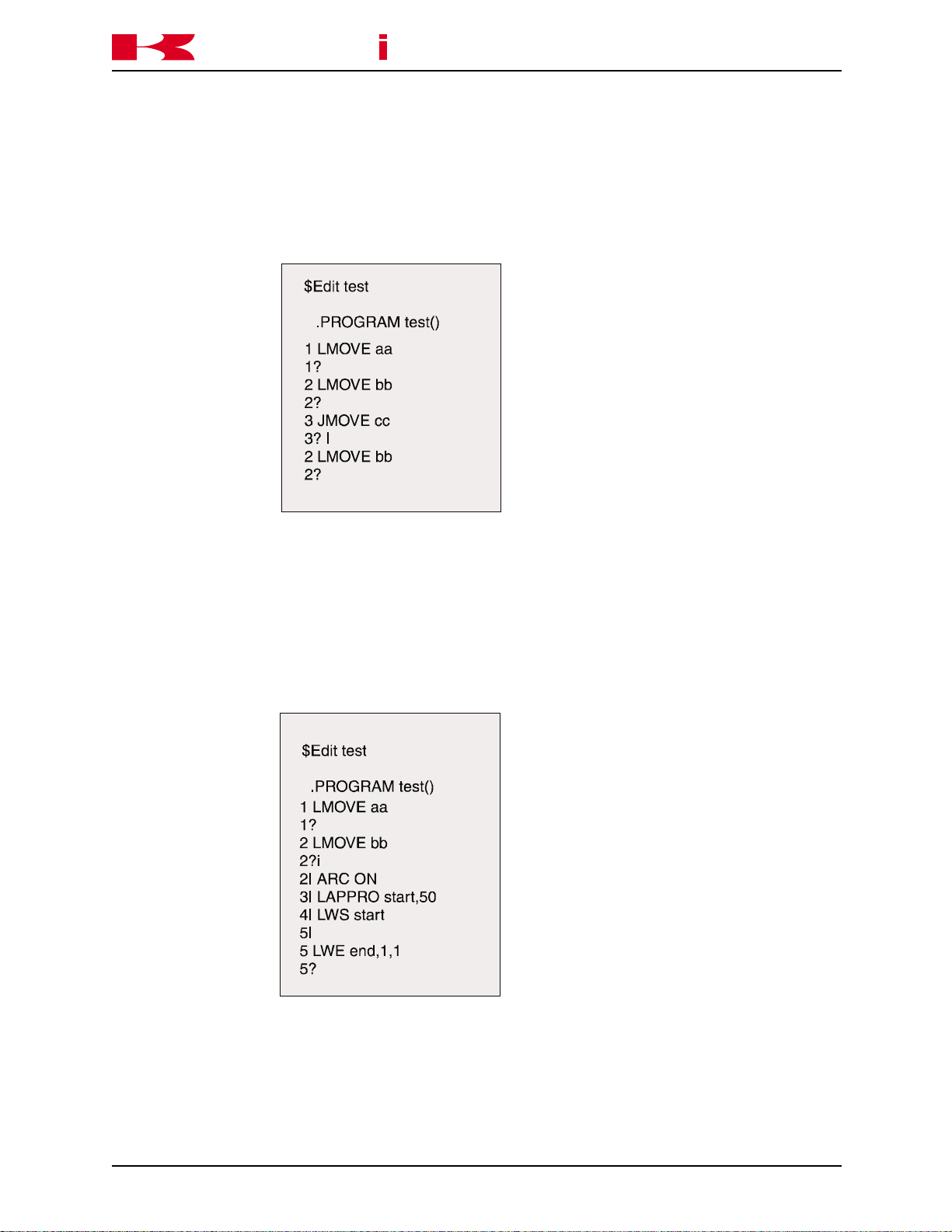

• Editor Mode: This mode enables the user to create a new program or modify an

existing program. Only editor commands are accepted by the system in this mode.

• Playback Mode: The system is in the playback mode during program execution.

Computations for robot motion control are performed and commands entered from

the terminal are processed during unoccupied CPU time. Some monitor commands

cannot be executed in playback mode. Refer to unit 4, Monitor and Editor Commands for details.

The

AS

system is controlled by the following system switches:

• CHECK.HOLD

This switch is used with the AS Language commands EXECUTE, DO, STEP,

MSTEP and CONTINUE. When the CHECK.HOLD switch is ON these commands

are available only if the HOLD/RUN switch is in the HOLD position. The controller

accepts these commands with the HOLD/RUN switch in the HOLD position but

robot motion is not initiated until the switch is manually placed in the RUN position.

Default setting is OFF.

1-2 November 14, 2000

Page 12

C SERIES CONTROLLER

K

a

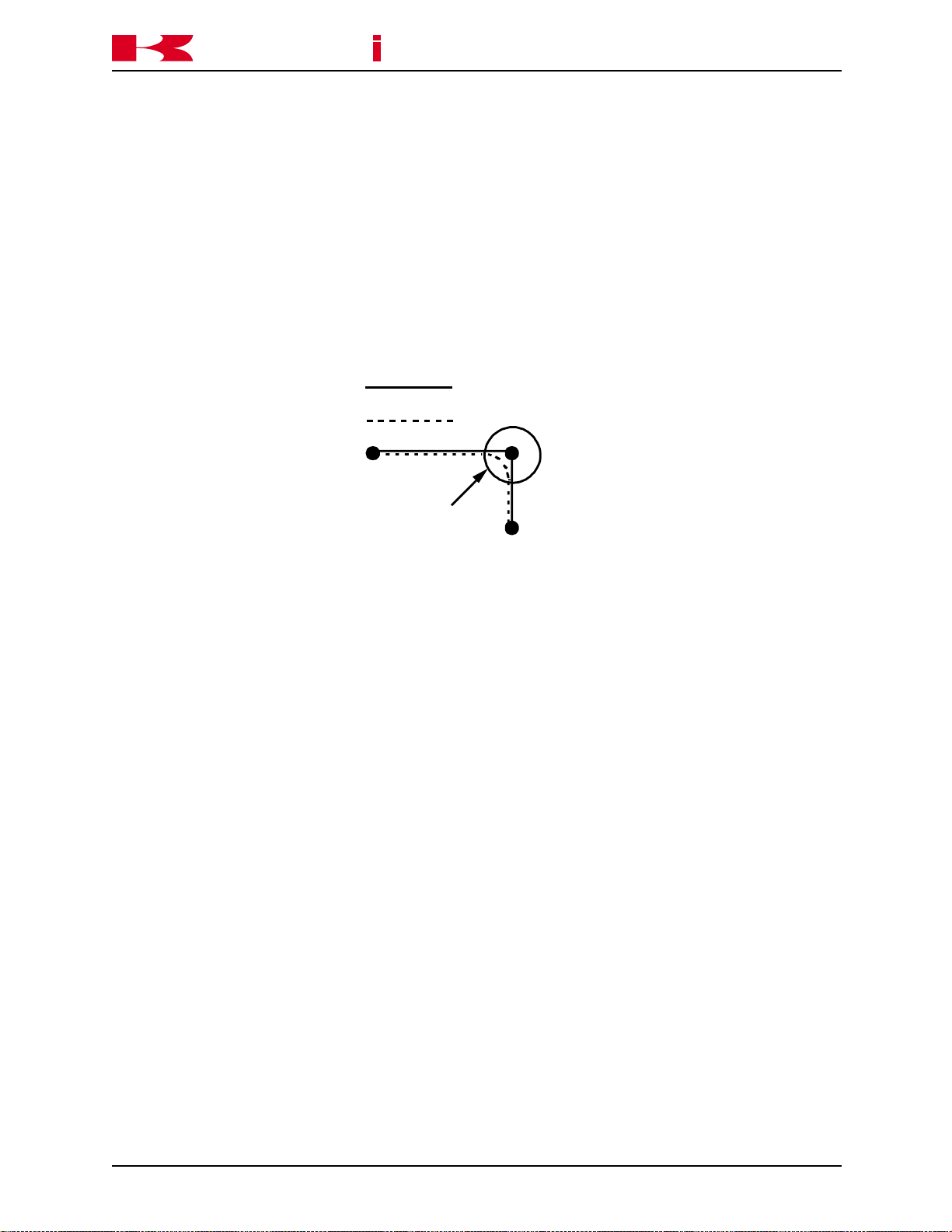

• CP

The CP switch is used to enable or disable the continuous path function. When the

switch is ON, the robot makes smooth transitions between motion segments within

the accuracy ranges set. When the switch is OFF, the robot decelerates and stops

at the end of each motion segment regardless of accuracy.

Default setting is ON

a

s

aw

k

SYSTEM OVERVIEW

Robot Path Switch Setting

AS LANGUAGE REFERENCE MANUAL

OFF

ON

Accuracy Range

Figure 1-1 CP Switch

• CYCLE.STOP

This switch is used in conjunction with an external input signal to stop the motion of

the robot. With the switch ON, when the input signal is received the robot stops and

the cycle start light turns OFF. When the program is started again it starts at the

beginning. If the program is called from another program, the program restarts at

the beginning of the main program. With the switch OFF, when the input signal is

received the robot stops and the cycle start light remains ON. The robot is in a hold

condition and when the program is started again, it continues at the point in the

cycle where it was stopped.

Default setting is OFF.

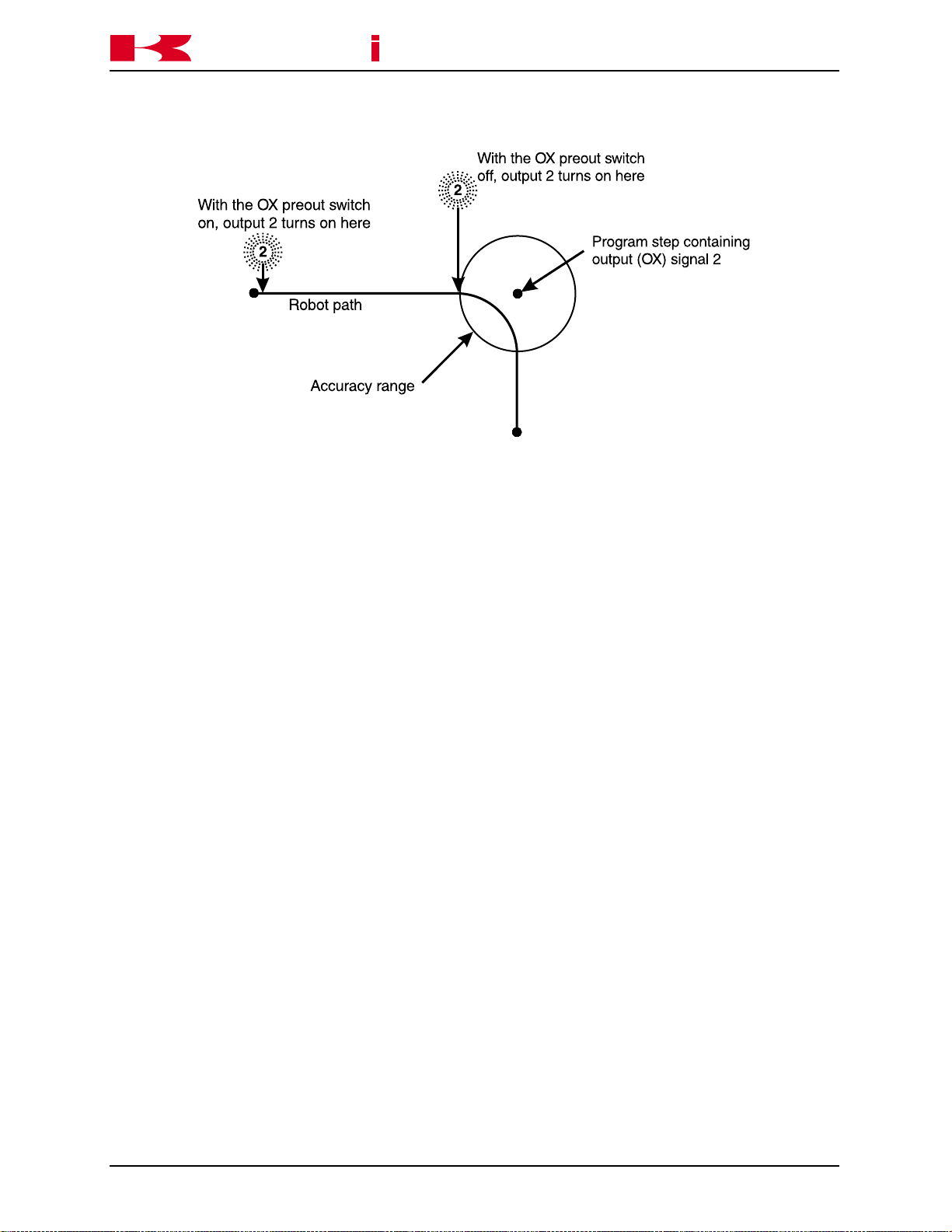

• OX.PREOUT

This switch affects the timing of output signal generation in block step programs.

When the switch is ON, an output programmed for a given point is turned ON when

the robot begins motion to the point. With the O X. PREOUT switch OFF, an output

programmed for a given point is not turned ON until the robot reaches the accuracy

range of the point. Figure 1-2 shows the effects the OX.PREOUT switch on signal

timing.

Default setting is ON.

November 14, 2000

1-3

Page 13

K

a

a

aw

k

s

SYSTEM OVERVIEW

Figure 1-2 OX.PREOUT Switch

C SERIES CONTROLLER

AS LANGUAGE REFERENCE MANUAL

• PREFETCH.SIGINS

This switch is used in conjunction with AS Language instructions and has the same

effect on signal timing as the OX.PREOUT switch has with blockstep instructions.

Default setting ON. The AS Language instructions affected are; SWAIT, TWAIT,

SIGNAL, PULSE, DLYSIG, RUNMASK, RESET and BITS.

• QTOOL

This switch allows the user to identify tools to use in block step or AS Language

programming. When the QTOOL switch is ON, nine tools are available for programming and jogging. The tool dimensions are recorded and assigned a tool number

using auxiliary function 48. When the QTOOL switch is ON, the selected tool dimensions are in effect for jogging and linear playback of block step programs.

When the QTOOL switch is OFF, the tool identified with AS Language instructions

is used.

Default setting is ON.

• REP_ONCE (Repeat Once)

When this switch is ON, programs run one time. With the switch OFF, the program

runs continuously.

Default setting is OFF.

1-4 November 14, 2000

Page 14

C SERIES CONTROLLER

K

a

• STP_ONCE (Step Once)

When this switch is ON, the repeat condition function of progressing through a

program one step at a time is active. The step forward key is used to step through a

program. When the switch is OFF, programs run continuously.

Default setting is OFF.

• AFTER.WAIT.TIMER

When this switch is ON, timers begin timing for a specified step when all wait condi-

tions are satisfied. With the switch OFF, timers begin timing when the robot reaches

coincidence of the taught point.

Default setting is OFF.

• AUTOSTART.PC

a

s

aw

k

SYSTEM OVERVIEW

AS LANGUAGE REFERENCE MANUAL

The AUTOSTART.PC, AUTOSTART2.PC, and AUTOSTART3.PC switches automatically start the associated PC program when controller power is turned on.

Default setting is OFF.

• ERRSTART.PC

When this switch is ON and specified errors (assigned dedicated signals) occur, a

PC program is run as soon as the error is detected.

Default setting is OFF.

• MESSAGES

Enables or disables message output (PRINT or TYPE) to the keyboard screen.

Default setting is ON

• RPS (Random Program Selection)

This switch enables or disables the random selection of programs based on binary

status of dedicated inputs.

Default setting is OFF

• SCREEN

This switch enables or disables scrolling of the screen when information is too large

to fit on one screen.

Default setting is ON

November 14, 2000

1-5

Page 15

C SERIES CONTROLLER

K

a

• DISPIO_01

This switch allows the user to select the type of display for viewing the status of

inputs and outputs. If the switch is ON, 1s and 0s are displayed to identify the

signal state of individual signals. A 1 represents an ON signal, while a 0 represents

an OFF signal. If the switch is off, an ON signal is represented by an O, while an X

represents a OFF signal. Dedicated signals are represented by uppercase Xs and

Os.

Default setting is OFF.

1.2 NOTATIONS AND CONVENTIONS

A mixture of uppercase and lowercase words is used throughout this manual, all key

words are shown in uppercase and all elements freely specified by the user are shown

in lowercase.

a

s

aw

k

SYSTEM OVERVIEW

AS LANGUAGE REFERENCE MANUAL

Abbreviated notations are used as well. For example, the EXECUTE command can be

abbreviated as EX.

At least one space (blank) or tab is necessary as a delimiter between the instruction (or

command) name and its arguments. The excess spaces or tabs are ignored by the

system.

Monitor commands and program instructions are processed by pressing the ENTER

key.

Many instructions or commands have arguments which can be omitted. If there is a

comma following the optional argument, the comma should be retained even if the

argument is omitted. If all successive arguments are omitted, commas may also be

omitted.

In this manual, values are expressed in decimal notations, unless noted otherwise.

Some instructions and commands require several types of arguments. Mathematical

expressions can be used to designate the value as arguments. The acceptable value

may be restricted. The following r ules show how the values are interpreted in various

cases.

• The AS

Code for Infor mation Interchange (ASCII). An ASCII character is specified by prefixing a character with an apostrophe (‘). For example, ddd = ‘A assigns 65 to ddd.

• All numerical expressions evaluated by the system result in a real value.

1-6 November 14, 2000

Language follows the conventions established by the American Standard

Page 16

C SERIES CONTROLLER

K

a

• DISTANCE is used to define the position to which the robot moves. The unit for

distance is millimeters, although units are not required to be entered with values.

Values entered for distances can be positive or negative, with their magnitudes

limited by a number representing the maximum reach of the robot. For example,

> DO DRAW 50,100,-50 moves the robot 50 mm in X, 100 mm in Y, and 50 mm in

the Z Cartesian direction.

• ANGLES in degrees are entered to define and modify orientations the robot as-

sumes at named locations, and to describe angular positions of robot joints. The

values can be positive or negative, with their magnitudes limited by 180 degrees or

360 degrees depending on the context. For example,

> DO DRIVE 2,45,75 moves joint 2 of the robot 45° at 75% of the repeat speed.

a

s

aw

k

SYSTEM OVERVIEW

AS LANGUAGE REFERENCE MANUAL

• JOINT NUMBER is an integer value from one to the number of joints available on

the robot, including a servo-controlled external axes.

• SIGNAL NUMBER is used to identify binary (on/off) signals. The value is an integer

in the range of 1-256 (output signals), 1001-1256 (input signals) depending on the

number of I/O signals available in the controller. Negative signal numbers indicate

an OFF state.

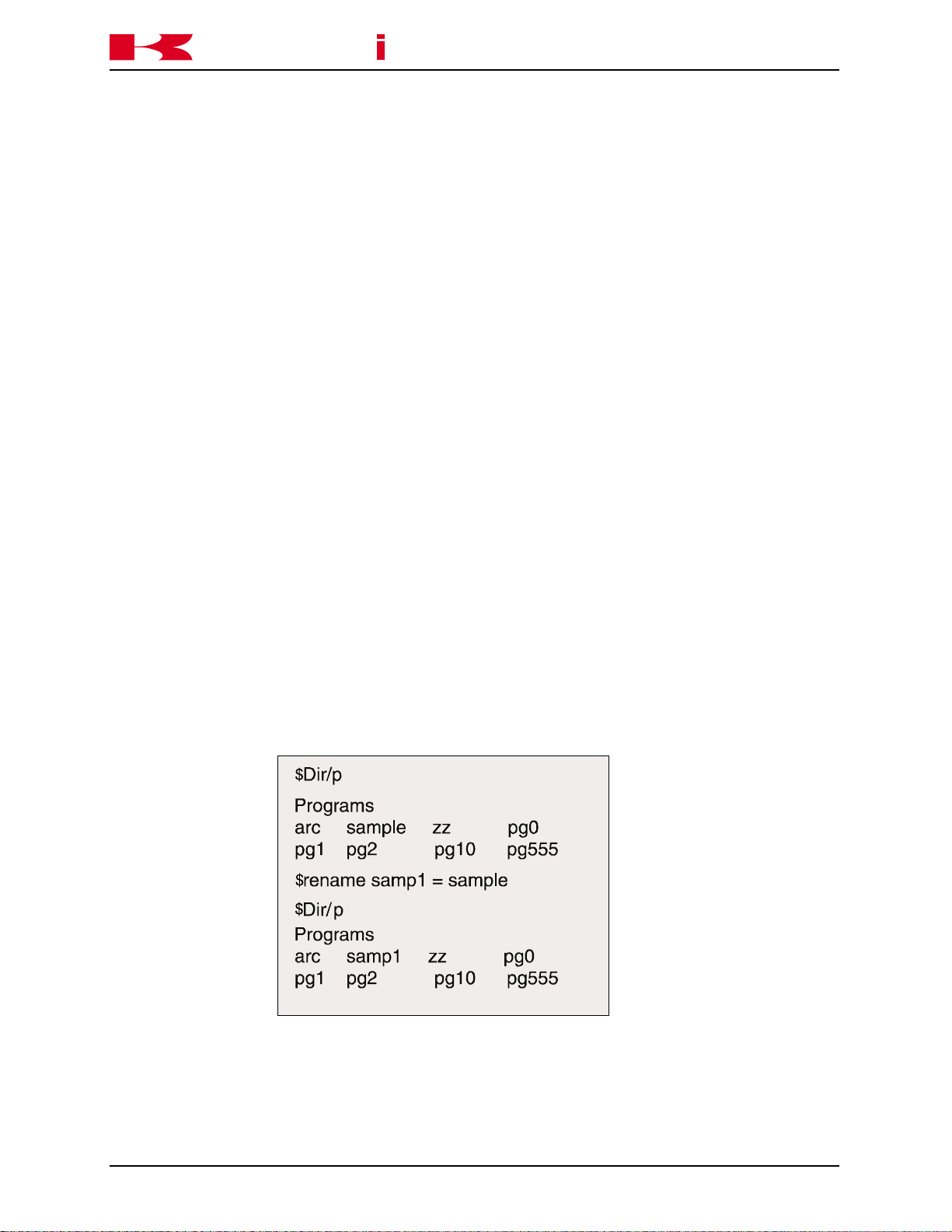

• Whenever an existing program is saved, or renamed, the new name is entered first,

followed by the old name. The above also holds true for the POINT command. For

example:

Command New Name = Old Name

SAVE Right_Side = Fender3

RENAME test = test.tmp

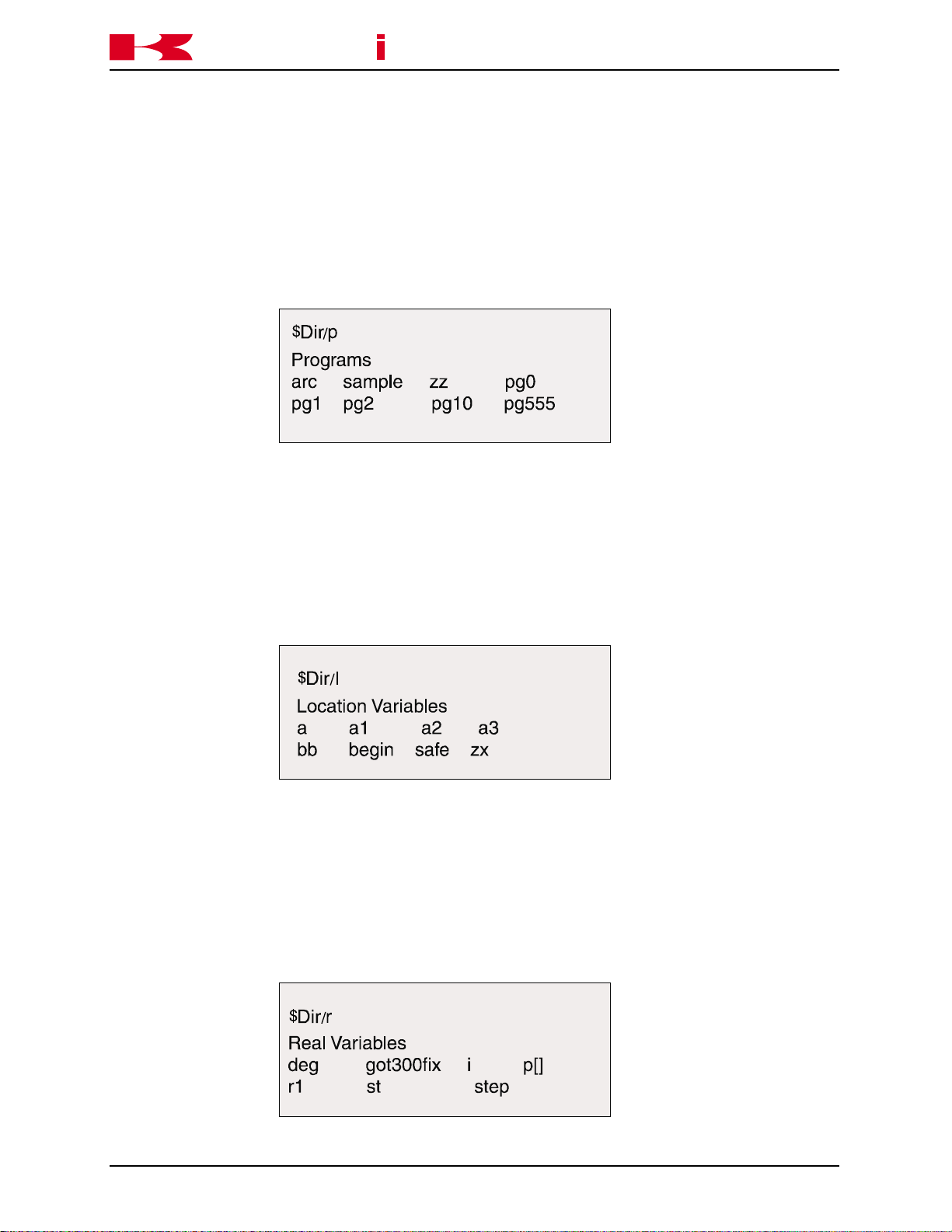

1.3 DISPLAYING WITH THE TERMINAL

The operator can display various types of information in the monitor mode or playback

mode. Directories and listings of programs, locations, variable data, and weld conditions

are displayed by entering specific monitor commands. For additional information, refer

to section 4.2, Program and Data Control Commands.

November 14, 2000

1-7

Page 17

C SERIES CONTROLLER

K

a

1.4 LOCATION INFORMATION

Locations recorded in the controller’s memory are comprised of values which designate

destinations for robot motion. The values recorded in memory are either Cartesian

coordinates or robot joint angles. A Car tesian coordinate represents a point in the robot

workspace with a tool center point orientation at that point. A location recorded with

joint angles specifies a robot arm configuration at that point. When the robot is directed

to move to a Cartesian location, two actions occur simultaneously: the robot is moved

so the tool center point moves to the specified point, and the tool is rotated to the prescribed orientation. When the robot is directed to move to a location recorded with joint

angles, the processor calculates a motion path based on the encoder values of the

recorded point, then moves the arm until all encoder values match those of the recorded

point. There are two types of location information, transformation locations (Cartesian

coordinates) and precision locations (joint angles).

a

s

aw

k

SYSTEM OVERVIEW

AS LANGUAGE REFERENCE MANUAL

1.4.1 PRECISION LOCATION

A precision location’s value is represented by the exact position of the individual robot

joints in degrees. There are several characteristics of precision locations that should be

considered. These characteristics result from joint angles being recorded.

Advantages of precision locations: Playback precision is achieved and there is no

ambiguity about robot configuration at a location.

Disadvantages of precision locations: The values recorded can be used by any model

of robot, however the tool center point location is different when used by a robot of

different physical size. Precision locations cannot be easily modified to compensate for

location changes in the robot workspace, because a change requires complete knowledge of the relationship between the positions of all robot joints and the locations in the

robot workspace.

1.4.2 TRANSFORMATION LOCATION

A transformation location is represented by defining the location in terms of a Cartesian

(XYZ) reference frame fixed to the base of the robot. The position of the tool center

point is defined with X, Y, and Z coordinates, and the tool orientation is defined by three

angles measured from the coordinate axes.

1-8 November 14, 2000

Page 18

C SERIES CONTROLLER

K

a

Advantages of transfor mation locations: A value defined for use with one robot can be

used with a different robot having a similar work envelope because the value is defined

in terms of workspace coordinates. Transformations are easily modified to change a

location within the robot workspace. A powerful feature of transformation locations is

the ability to define locations as combinations of values. This is called compound or

relative transfor mation. Such values are used to define the location of a part relative to

its fixturing.

Disadvantages of transfor mation locations: Since a transformation location defines the

location of the tool center point in terms of coordinates in the workspace, no information

is provided about the specific robot configuration at the location. Whenever a transformation is used to define the destination of a robot motion, the AS

the transformation location into an equivalent precision location so it knows how to move

the individual joints. This conversion can introduce small location errors. Despite these

disadvantages, transformation locations are generally much more convenient than

precision locations.

a

s

aw

k

SYSTEM OVERVIEW

AS LANGUAGE REFERENCE MANUAL

system must convert

November 14, 2000

1-9

Page 19

C SERIES CONTROLLER

K

a

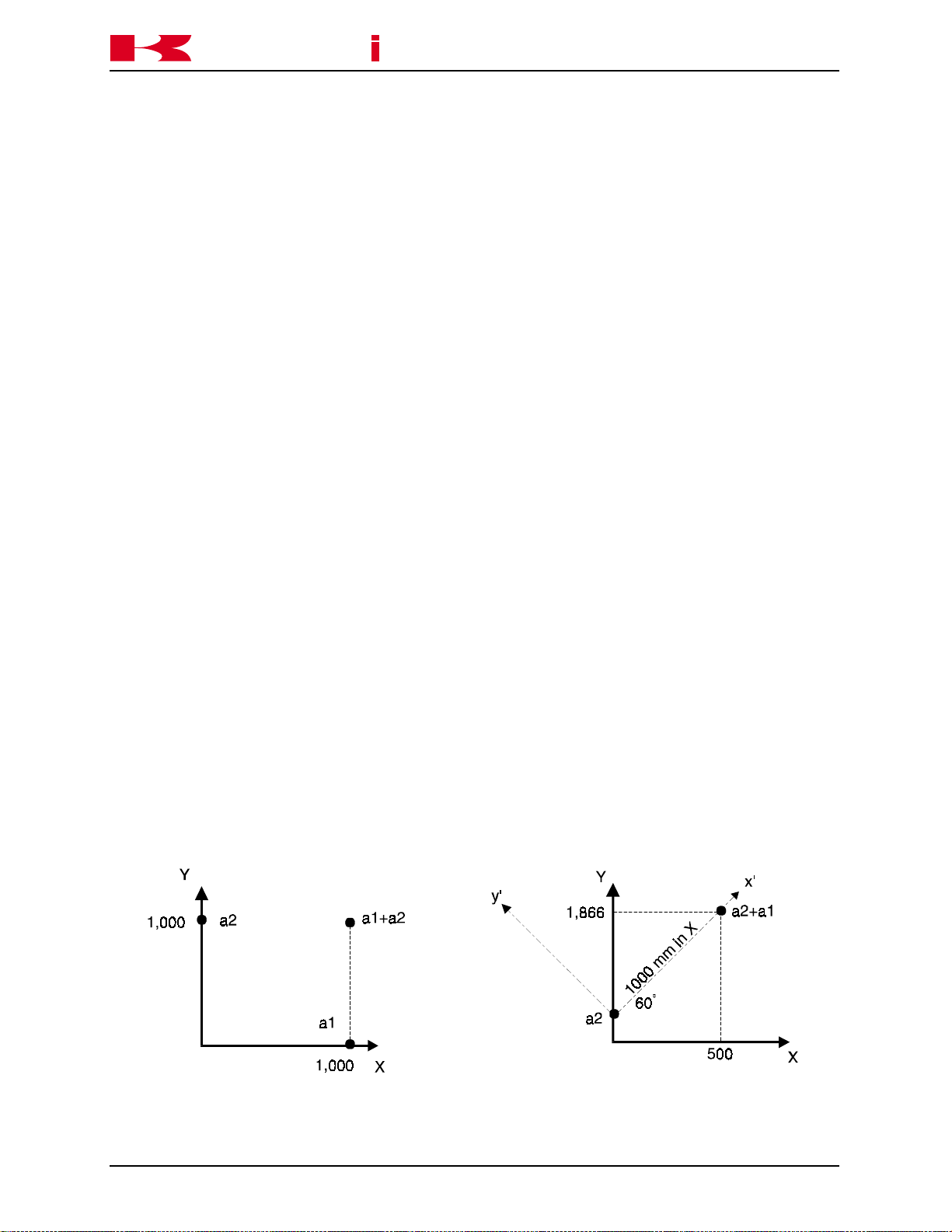

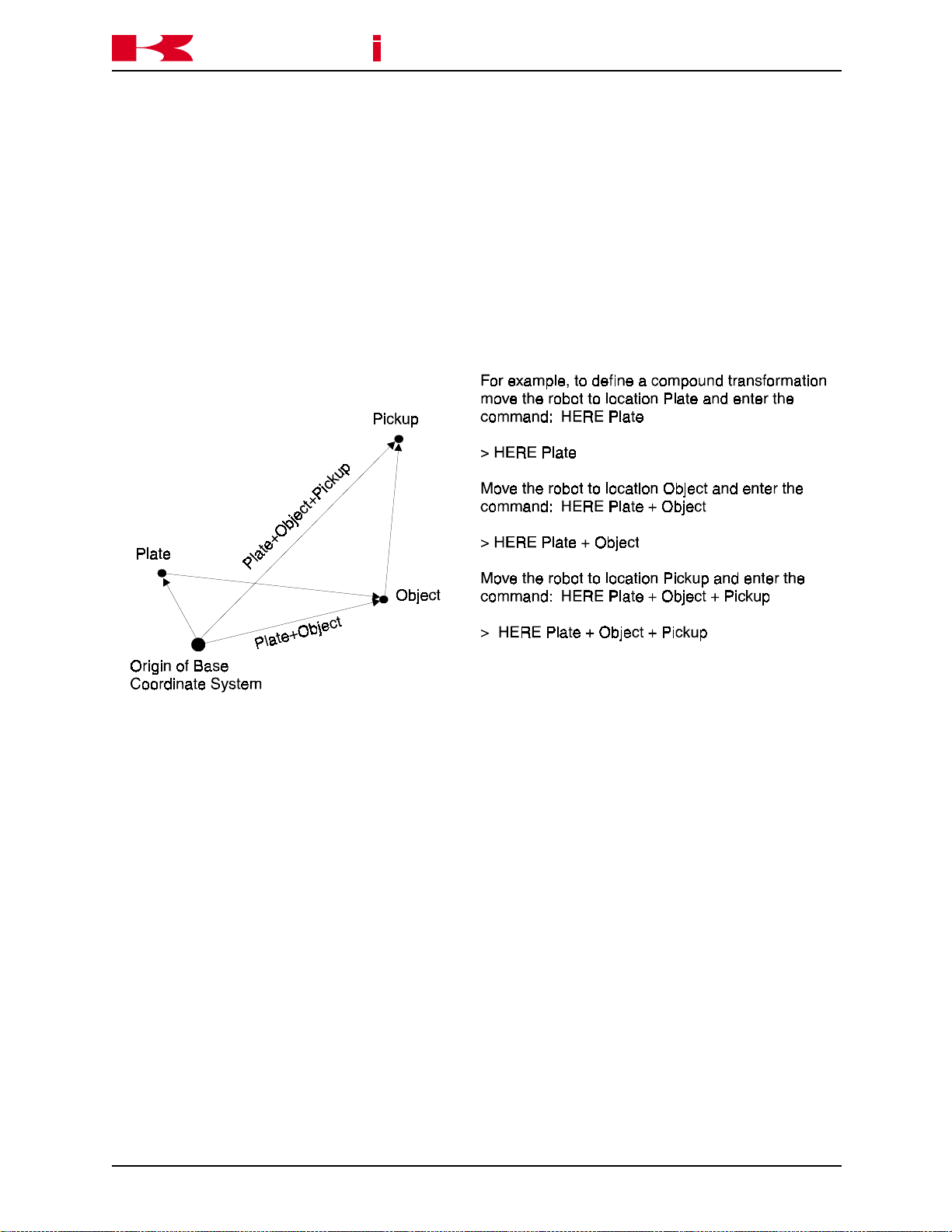

1.4.3 COMPOUND TRANSFORMATION LOCATION (RELATIVE TRANSFORMATION)

Compound transformations are defined by a combination of transformation locations,

used to create a location or locations that are relative to the first transfor mation value, in

the compound transformation (Figure 1-3).

transformation_value+transformation_value....

The last component of the compound transformation value, defines the actual location.

If the transformations are subtracted an inverse value results.

transformation - transformation

This is useful when several locations are defined relative to a reference location.

a

s

aw

k

SYSTEM OVERVIEW

AS LANGUAGE REFERENCE MANUAL

To change the location points defined relative to a reference location, only the transformation location of the reference must be updated. All locations defined relative to the

reference point are automatically changed to reflect the change.

Unlike usual addition or subtraction, the commutative law does not hold true for the

transformation operation. The compound expression “loc.a + loc.b” does not necessarily

equal “loc.b + loc.a” because the turning angles O,A,T are taken into consideration. An

example of this is shown below.

Assuming: a1 = (1000, 0, 0 , 0, 0, 0)

a2 = ( 0, 1000, 0, 60, 0, 0)

a1 + a2 = (1000, 1000, 0 , 60, 0, 0)

a2 + a1 = ( 500, 1866, 0, 60, 0, 0)

1-10 November 14, 2000

Page 20

C SERIES CONTROLLER

K

a

For example, “Plate” is the name of the transformation location representing the location

of a base plate relative to the origin of the base coordinate system of the robot. “Object”

is the relative transformation for the location of an object relative to the location of the

plate. The compound transformation “Plate+Object” defines the location of the object

relative to the origin of the base coordinate system of the robot. If the transformation

location “Pickup” represents the final location relative to “Plate+Object”, the compound

transformation “Plate+Object+Pickup” defines the location of pickup relative to the origin

of the base coordinate system.

a

s

aw

k

SYSTEM OVERVIEW

AS LANGUAGE REFERENCE MANUAL

Figure 1-3 Compound Transformation

As indicated in the example above, the compound transformation is defined by a combination of several transformation values separated by “+”.

November 14, 2000

1-11

Page 21

C SERIES CONTROLLER

K

a

1.5 NUMERIC INFORMATION

Numeric information is a combination of numerals, variables, operators, and functions

which return numeric values. Numeric expressions are used not only for mathematical

calculations, but also as arguments for monitor commands or program instructions.

Numeric values used in the AS system are divided into the four types described below:

1.5.1 INTEGERS

Integers are values without fractional parts (whole numbers). Values with full precision

ranges are from -16,777,216 to +16,777,216. Values that exceed this range are

rounded to seven significant digits. Integer values are usually entered as decimal numbers, however, it may be more convenient to enter them in binary or hexadecimal notations.

a

s

aw

k

SYSTEM OVERVIEW

AS LANGUAGE REFERENCE MANUAL

1.5.2 REAL NUMBERS

Real numbers have both the integer part and a fractional part which can range from

-3.4E +38 ~ 3.4E +38. Like integers, real values are positive, zero or negative. They

can be represented in scientific notation. Real values are stored with an accuracy of

approximately seven digits, but actual values may have less precision caused by a

calculation error.

1.5.3 LOGICAL VALUES

Logical values have only two states, ON or OFF. These two states are also referred to

as TRUE and FALSE respectively. A value of negative one (-1) is assigned for the TRUE

or ON state and a value of zero (0) is assigned for the FALSE or OFF state.

NOTE

ON, OFF, TRUE, and FALSE are AS Language keywords.

> AA = ON Stores a value of -1 in variable AA

> BB = FALSE Stores a value of 0 in variable BB

> CC = -TRUE Stores a value of 1 in variable CC

1-12 November 14, 2000

Page 22

C SERIES CONTROLLER

K

a

1.5.4 ASCII VALUES

An ASCII value is the numeric value of one ASCII character. An ASCII value is specified

by prefixing the character with an apostrophe (‘).

> X = ‘A Stores a value of 65 in variable X

> X = ‘a Stores a value of 97 in variable X

1.6 VARIABLE NAMES

Variable names must start with an alphabetic character and can contain only letters,

numbers, periods, and underlines. The letters used in variable names can be entered

either in lowercase or uppercase. The length of a name is limited to fifteen characters.

AS Language

variable names because they cause ambiguity with the AS system keywords, but their

abbreviations can be used. For example, the following names cannot be used:

commands should not be used and in some cases cannot be used as

a

s

aw

k

SYSTEM OVERVIEW

AS LANGUAGE REFERENCE MANUAL

3P (first character is not alphabetic)

part#2 (“#” prefix for precision location name)

random (AS keyword)

Precision location names must be preceded by the symbol “#” to differentiate them from

transformation location names. String variables must be preceded by the symbol “$” to

differentiate them from real and transfor mation variables.

pick (transformation or real variable value)

#pick (precision value)

$count (string variable)

A transformation location and precision location may have the same name, however, the

same name may not be used for transformation values and real values. A defined

variable may be used by any program in the system.

Array variables can be used for any type of information. Arrays consist of several values

under the same name and these values are distinguished from each other by their index

value. In order to designate array elements, attach an element number (index) enclosed

by brackets to the array name. For example, “part[7]” indicates the seventh element of

the array “part”. Indexes should be integers within the range 0 to 9999.

Location, real, string, and array are four types of var iables within the AS system. These

four variable types are explained on the following pages.

November 14, 2000

1-13

Page 23

C SERIES CONTROLLER

K

a

1.6.1 LOCATION VARIABLES

A location variable (precision or transfor mation) is automatically defined when a value is

assigned for the first time. Prior to this, the location name is undefined. If a program

uses an undefined variable, an error occurs. The user defines location variables by

using monitor commands or program instructions. The following are examples of location variable values:

Precision location value: name with joint angles

#weld 90.000° 145.056° -95.098° 90.000 °45.000° 0.000°

Transformation location value: name with joint angles and turning angles

a

aw

k

s

SYSTEM OVERVIEW

JT1 JT2 JT3 JT4 JT5 JT6

AS LANGUAGE REFERENCE MANUAL

XYZOAT

weld 60.000 mm 145.050 mm -95.098 mm 90.000° 45.000° 0.000°

1.6.2 REAL VARIABLES

Real variables are defined using the assignment instruction (=). The format for assigning a real variable is:

Variable_name = numeric_value

a = 6

b = 7

c = a + b

The variable on the left side may be either a scalar variable (i.e.,“count”) or an array

element (i.e., “x [2]”). A variable is defined automatically the first time it is assigned a

value. If a program uses an undefined variable, an error occurs. The numeric value on

the right side may be a constant, a variable, or a numer ic expression. When an assignment instruction is processed, the value on the right side of the assignment instruction is

first computed, then the value is assigned to the variable on the left side.

For example, the assigned value “x=3” assigns the value 3 to the variable “x”. If a vari-

able on the left side has never been used it is defined automatically, and if it has already

been assigned a value, its current value is replaced by a new assigned value. The

above example is read as “assign 3 to x” and not “x is equal to 3”. The following ex-

ample shows this difference: x = x + 1.

1-14 November 14, 2000

Page 24

C SERIES CONTROLLER

K

a

If the example is a general equation, it is read as “x is equal to x plus 1”, which does not

make sense mathematically. It must be read as “assign the value of x plus 1 to x”. In

this case, the sum of the current value of “x” and 1 is calculated. In the next step, that

value is assigned to “x” as a new value. Therefore, the result of the above assignment

instruction is to increase the value of x by 1. In this example, the variable “x” should

have been previously defined.

x = 3

x = x + 1

In the case above, the resulting value of “x” is 4.

1.6.3 CHARACTER STRING VARIABLES

a

s

aw

k

SYSTEM OVERVIEW

AS LANGUAGE REFERENCE MANUAL

The character information referred to in the AS

characters enclosed by quotation marks (“). Since the quotation mar ks indicate the

beginning and end of a character string, they cannot be included in the string. ASCII

control characters (CTRL, CR, LF, etc.) also cannot be included in the string. For example, a command for printing (displaying on the screen) would be entered as:

PRINT “Kawasaki”

Character strings are defined by using the assignment instruction (=). The format for

assigning a character variable is :

$string_variable = string_value

(name of variable) (string expression)

The string variable on the left side may be either a scalar variable (ie., “$name”) or an

array element (ie., “$line [2]”). A variable is defined automatically the first time it is

assigned a value. If a program uses an undefined variable, an error occurs. The character string on the right side may be a constant, a string variable, or a string expression.

When an assignment instruction is processed, the value on the right side is first computed, then the value is assigned to the variable on the left side. If the var iable on the

left side has never been used, it is defined automatically, and if it has already been

used, its current value is replaced by a new assigned value.

system is indicated as a string of ASCII

November 14, 2000

1-15

Page 25

C SERIES CONTROLLER

K

a

The following is an example of string variable assignment:

In the above example, the string variable $Name is assigned the sum of $First, $Last,

and the character string “Inc.”. The command PRINT or TYPE $Name returns the string

value: Kawasaki Robotics Inc.

1.6.4 Arrays

An array is a group of values that share a single name. Location variables can be scalars or arrays. A location scalar is a single location value. Each value in an array is

called an element of the array. An element of a location array is specified in exactly the

same way as an element of a numeric array by appending an index enclosed in brackets

to the array name. For example, “part[7]” refers to element 7 of the array “part.” Indexes

must be integers in the range of 0 ~ 9999. Three examples of arrays are described

below:

a

aw

k

s

SYSTEM OVERVIEW

$First = “Kawasaki”

$Last = “ Robotics”

$Name = $First + $Last + “ Inc.”

AS LANGUAGE REFERENCE MANUAL

Example 1:

PROGRAM OUTPUT

HERE edge edge[1]=120.456

DECOMPOSE edge[1]=edge edge[2]=145.670

FOR i=1 to 6 edge[3]=-95.432

TYPE “edge[“I1,i,”]=“,/D,edge[i] edge[4]=90.456

END edge[5]=45.000

edge[6]=10.018

In the above example, the current location of the robot is defined as “edge”. The DECOMPOSE instruction extracts component values of edge (XYZOAT) consecutively (1

through 6). The program instructions between the FOR and END statements are executed repeatedly and the TYPE instruction displays the component values of edge

individually.

1-16 November 14, 2000

Page 26

C SERIES CONTROLLER

K

a

Example 2:

In the above example, the robot moves 100 mm in the X direction, a calculated amount

(10 * i + 7) mm in the Y direction, and 50 mm in the Z direction, and define the location

as weld[i].

The FOR statement, in this example increments the value of “i” in increments of two, for

example:

a

aw

k

s

SYSTEM OVERVIEW

FOR i = 2 to 6 STEP 2

DRAW 100, 10 * i + 7, 50

HERE weld[i]

END

i = 2, i = 4, i = 6.

AS LANGUAGE REFERENCE MANUAL

Example 3:

PROGRAM SUBPROGRAM OUTPUT

Main() Pg10() Corner 1

$POINT[1]=”Corner1” FOR i=1to3 edge

$POINT[2]=”edge” JMOVE weld[i] Corner2

$POINT[3]=”Corner2” TYPE$POINT[i]

CALL pg10 END

In the above example, the array is used as a string array. Each move of the robot displays the strings assigned in the main program.

1.7 NUMERICAL EXPRESSION

The numerical expression is a combination of numeric values and variables combined

together with operators. The expressions are completed by the addition of functional

modifiers to the numeric values and variables. All numerical expressions evaluated by

the system result in a real value. The interpretation of the value depends on the context

in which the expression appears. For example, an expression specified for an array

index is interpreted as yielding an integer value.

1.7.1 OPERATORS

For describing expressions, ar ithmetic, logical, and binary, operators are provided. All of

these operators combine two values to obtain a single resulting value, except three: the

two operators (NOT and COM) operate on a single value and the operator (-) operates

on one or two values. The operators are described on the following page.

November 14, 2000

1-17

Page 27

K

a

Arithmetic Operators: + addition

Relational Operator: < less than

a

s

aw

k

SYSTEM OVERVIEW

- subtraction or negation

* multiplication

/ division

^ power (if a

x=(-2)^2 results in an error

x= -2^2 assigns -4 to x

MOD remainder

x=5 MOD 2 assigns the remainder of 5/2 (1

in this case) to x

<=, (=<) less than or equal to

== equal to

<> not equal to

>=, (=>) greater than or equal to

> greater than

C SERIES CONTROLLER

AS LANGUAGE REFERENCE MANUAL

b

, a<0 results in error)

Logical Operator: AND logical AND

NOT logical complement

OR logical OR

XOR exclusive logical OR

The logical operators are used in Boolean operations such as logical OR (0+1=1,

1+1=1, 0+0=0), logical AND (0x1=0, 1x1=1, 0x0=0), and logical XOR (0+1=1, 1+1=0,

0+0=0). The logical operators are not used for calculating numeric values, but for determining the logical state (TRUE or FALSE) of the conditional expression. If a numeric

value is zero (0), it is considered to be FALSE (0). All nonzero values are considered to

be TRUE(-1).

OPERATION RESULT

0 AND 0 0 (FALSE)

1 AND 1 -1 (TRUE)

1 OR 0 -1 (TRUE)

1-18 November 14, 2000

Page 28

C SERIES CONTROLLER

K

a

Binary Operator: BAND Binary AND

The binary logical operators perform logical operations for each respective bit of two

numeric values.

OPERATION RESULT

5 BOR 3 7

0101 BOR 0011 0111

5 BAND 9 1

0101 BAND 1001 0001

a

aw

k

s

SYSTEM OVERVIEW

BOR Binary OR

BXOR Binary XOR

COM Binary Complement

AS LANGUAGE REFERENCE MANUAL

Expressions are evaluated according to a sequence of pr iorities. Parentheses can be

used to group the components of an expression and to control the order in which the

operations are performed. When expressions containing parentheses are evaluated, the

expression within the innermost pair is evaluated first, then the system works toward the

outermost pair. Within parentheses, expressions are evaluated in the following order:

1. Evaluate functions and arrays.

2. Process power operator “ ^ ”.

3. Process unary operators “ - ” (single component).

4. Process multiplication “ * ” and division “ / ” operators from left to right.

5. Calculate remainders (MOD operators) from left to right.

6. Process addition “ + ” and subtraction “ - ” operators from left to right.

7. Process relational operators from left to right.

8. Process COM operators from left to right.

9. Process BAND operators from left to right.

10. Process BOR operators from left to r ight.

11. Process BXOR operators from left to r ight.

12. Process NOT operators from left to right.

13. Process AND operators from left to r ight.

14. Process OR operators from left to r ight.

15. Process XOR operators from left to r ight.

The logical expressions result in a logical value TRUE or FALSE. A logical expression

can be used as a condition in which the execution of a program or program steps is

performed. When evaluating logical expressions, the value zero is considered FALSE

and all nonzero values are considered TRUE. Therefore, all real values or real value

expressions can be used as a logical value.

November 14, 2000

1-19

Page 29

C SERIES CONTROLLER

K

a

For example, the following two statements have the same meaning, but the second

statement is easier to understand.

IF x GOTO 10 (If the value of x is true, goto label 10 in the program)

IF x <> 0 GOTO 10 (If the value of x is not equal to 0, goto label 10 in the program)

1.8 MONITOR COMMANDS

TEACH location variable name

The TEACH command is used in conjunction with the small teach pendant. With the

small teach pendant connected, the TEACH command is entered at the monitor prompt.

The small teach pendant is used to jog the robot to the locations used in the specified

program. When the RECORD key on the teach pendant is pressed, the location is

placed into the system memory with the specified location variable name

0. Each time the RECORD key is pressed the number following the location variable

name is increased by one.

a

s

aw

k

SYSTEM OVERVIEW

AS LANGUAGE REFERENCE MANUAL

followed by a

For example, the command TEACH loc is entered at the monitor prompt, the first time

the RECORD key on the small teach pendant is pressed, a location with the name loc0

is stored in the system memory. The next time the RECORD key of the small teach

pendant is pressed, the location stored in system memory is loc1

The TEACH command allows the programmer to record transfor mation locations without

having to exit the work cell for each new location.

The HERE command stores the current robot location in the specified precision or

transformation variable.

HERE #pallet

The POINT command defines the named location variable using an existing location

variable. Component values may also be entered from the keyboard.

POINT a = b

Assigns component values of location var iable b into location variable a.

POINT #a

.

Displays the current component of location variable #a. If the location variable is not

defined, zeros are displayed.

1-20 November 14, 2000

Page 30

C SERIES CONTROLLER

K

a

1.8.1 PROGRAM INSTRUCTIONS

The commands HERE and POINT may also be used in a program as program instr uctions. For example,

JMOVE loc1

POINT loc2=loc1

DRAW 347.28, ,479.0

HERE loc3

In the above example, the robot moves to loc1. The POINT command then assigns

component values of loc1 to loc2. The DRAW command moves the robot 347.28 mm in

X, and 479 mm in the Z direction. Finally, loc3 is defined by the HERE command.

a

s

aw

k

SYSTEM OVERVIEW

AS LANGUAGE REFERENCE MANUAL

November 14, 2000

1-21

Page 31

C SERIES CONTROLLER

K

a

2.0 SAFETY ........................................................................................................... 2-2

2.1 Introduction....................................................................................................... 2-2

2.2 Safety Conventions and Symbology................................................................. 2-3

2.2.1 Warning/Caution Symbols ................................................................................ 2-3

2.3 Safety Categories............................................................................................. 2-4

2.3.1 Personal Safety ................................................................................................ 2-4

2.3.2 Safety During Operation ................................................................................... 2-6

2.3.3 Safety During Programming ............................................................................. 2-7

2.3.4 Safety During Inspection and Maintenance...................................................... 2-8

2.4 Safety Features ................................................................................................ 2-9

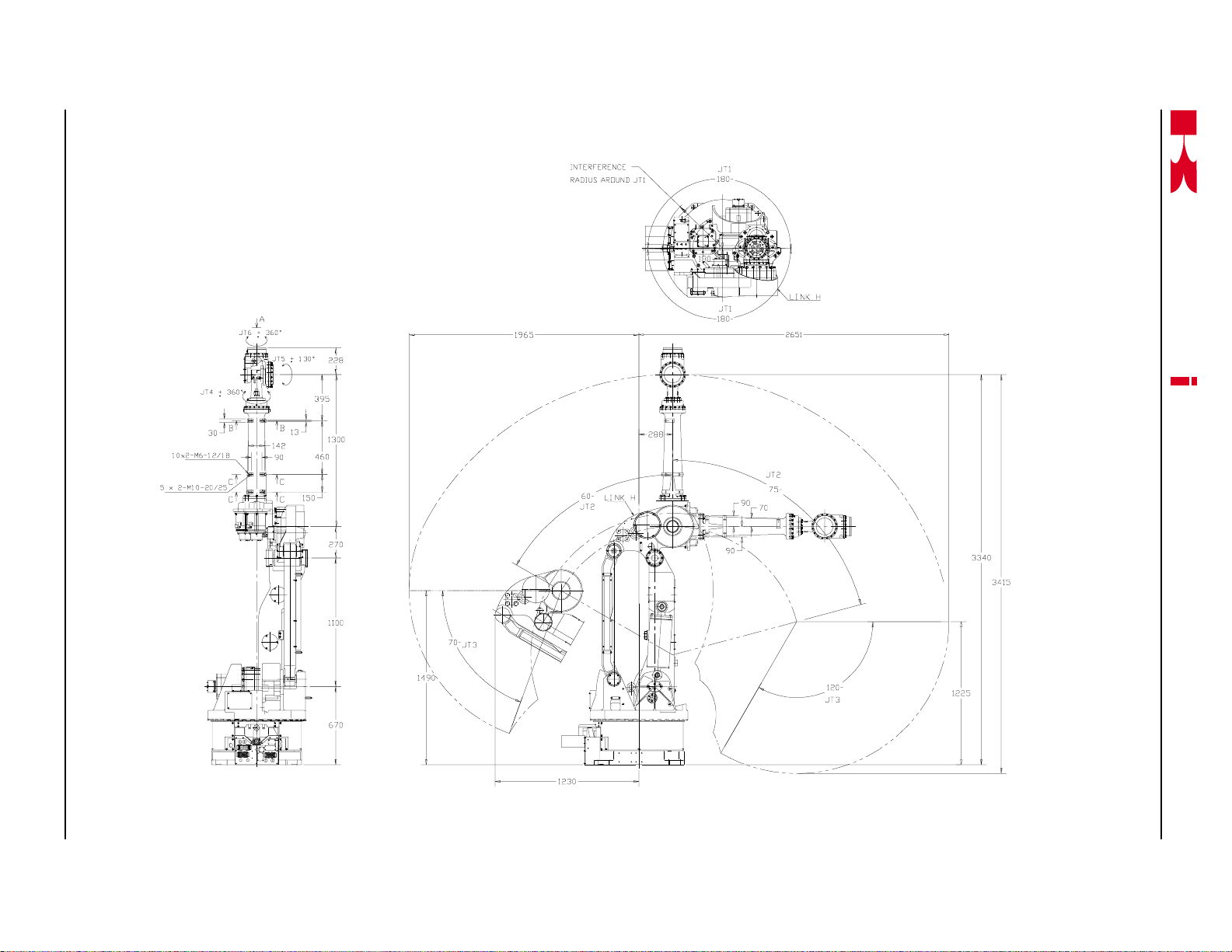

2.5 Work Envelope Drawings ............................................................................... 2-10

2.5.1 FS02N/FS03N................................................................................................ 2-10

2.5.2 FS06L............................................................................................................. 2-11

2.5.3 FC06N/FS06N/FW06N/FS10C....................................................................... 2-12

2.5.4 FS10N ............................................................................................................ 2-13

2.5.5 FS10E ............................................................................................................ 2-14

2.5.6 FS10L............................................................................................................. 2-15

2.5.7 FS20C ............................................................................................................ 2-16

2.5.8 FS20N ............................................................................................................ 2-17

2.5.9 FS30L............................................................................................................. 2-18

2.5.10 FS30N/FS45C ................................................................................................ 2-19

2.5.11 FS45N ............................................................................................................ 2-20

2.5.12 UB150 ............................................................................................................ 2-21

2.5.13 UT100/150/200............................................................................................... 2-22

2.5.14 UX70 .............................................................................................................. 2-23

2.5.15 UX100/120/150 .............................................................................................. 2-24

2.5.16 UX200 ............................................................................................................ 2-25

2.5.17 UX300 ............................................................................................................ 2-26

2.5.18 UZ100/120/150............................................................................................... 2-27

2.5.19 ZD130............................................................................................................. 2-28

2.5.20 ZX130L........................................................................................................... 2-29

2.5.21 ZX130U .......................................................................................................... 2-30

2.5.22 ZX165U .......................................................................................................... 2-31

2.5.23 ZX200S .......................................................................................................... 2-32

2.5.24 ZX200U .......................................................................................................... 2-33

2.5.25 ZX300S .......................................................................................................... 2-34

a

s

aw

k

SAFETY

AS LANGUAGE REFERENCE MANUAL

November 14, 2000

2-1

Page 32

C SERIES CONTROLLER

K

a

2.0 SAFETY

2.1 INTRODUCTION

Safety is an important consideration in the use of automated and robotic equipment in

the industrial environment. All operators, maintenance personnel, and programmers

must be aware of all automated equipment, peripheral and robotic equipment that

occupies the work cell, and their associated operational and maintenance procedures.

For this reason it is recommended that all personnel who operate, maintain, and

program Kawasaki robots, attend a Kawasaki approved training course that would be

pertinent to each employee’s specific job responsibilities.

The following safety sections in this text are designed to support and augment existing

safety guidelines that may be in use in your plant, and/or are provided by municipal,

state, or federal governments, but are NOT designed to supplant or supersede any

existing rules, regulations, or guidelines that may be in use. Because safety is the

primary responsibility of the user, owner, and/or employer, Kawasaki recommends that

specific safety guidelines and recommendations be adopted from groups or individuals

that are professionals in safety design and implementation.

a

s

aw

k

SAFETY

AS LANGUAGE REFERENCE MANUAL

Two recommended sources for national and federal safety laws and regulations are:

1. OCCUPATIONAL SAFETY AND HEALTH STANDARDS, available from:

U.S. Department of Labor

Occupational Safety & Health Administration

Office of Public Affairs - Room N3647

200 Constitution Avenue

Washington, DC 20210

http://www.osha-slc.gov/SLTC/robotics/index.html

2. AMERICAN NATIONAL STANDARD FOR INDUSTRIAL ROBOTS AND ROBOT

SYSTEMS-SAFETY REQUIREMENTS (ANSI/RIA R15.06-1992), available from:

American National Standards Institute

11 West 42nd Street

New York, NY 10036

http://www.ansi.org/

All safety related issues and descriptions, either presented in written or oral form from

any representative of Kawasaki Robotics (USA), Inc., are intended to provide general

safety precautions and procedures and, therefore, are not intended to provide all safety

measures necessary for the protection of all personnel in the work environment.

2-2 November 14, 2000

Page 33

C SERIES CONTROLLER

K

a

Kawasaki robots are considered safe for use in industrial environments when all safety

guidelines are adhered to. Adherence to the safety guidelines for safe robot operation

and the protection of personnel and equipment is the responsibility of the end user.

2.2 SAFETY CONVENTIONS AND SYMBOLOGY

2.2.1 WARNING/CAUTION SYMBOLS

The following symbol is present in all Kawasaki Robotics (USA), Inc. documentation to

signify to the user that proper guidelines, as set forth in the text, are designed to provide

pertinent information for the protection of personnel:

a

s

aw

k

SAFETY

AS LANGUAGE REFERENCE MANUAL

! WARNING

This warning symbology is used in all Kawasaki Robotics (USA), Inc. documentation to identify processes or

procedures, that if not followed properly, may result in

serious injury or death to personnel.

The following symbol is present in all Kawasaki Robotics (USA), Inc. documentation to

signify to the user that proper guidelines as set forth, are designed to provide pertinent

information for the protection of robotic related equipment:

! CAUTION

This caution symbology is used in all Kawasaki Robotics (USA), Inc. documentation to identify processes or

procedures, that if not followed properly, may result in

damage to robotic or peripheral equipment.

November 14, 2000

2-3

Page 34

K

a

2.3 SAFETY CATEGORIES

Personnel safety can be described in one of four categories:

• Personal safety

• Safety during operation

• Safety during programming

• Safety during inspection and maintenance

A description of each follows in this section.

2.3.1 PERSONAL SAFETY

a

s

aw

k

SAFETY

AS LANGUAGE REFERENCE MANUAL

C SERIES CONTROLLER

Safety procedures must be an integral part of operational procedures for the operator,

programmer, and maintenance person. These procedures must be followed explicitly

and on a regular basis. Safety procedures are followed on a daily basis, they should

become a regular part of everyday operational procedures, which are designed to

protect the user. Some guidelines are presented in brief in the following section:

• Before operating or maintaining the robot or robot controller, be sure you fully

understand and comprehend ALL maintenance, operating, and programming

procedures, and ensure that ALL safety related precautions are taken and complied

with before these procedures are attempted.

• AVOID wearing loose clothing, scarves, wrist watches, rings, and jewelry when

working on the controller and robot. It is also recommended that if ties must be

worn in your shop environment that they be the clip-on var iety rather than tied ties.

• ALWAYS wear safety glasses or goggles and approved safety shoes for your shop

conditions. Follow all applicable OSHA, NIOSHA, MSHA, local, state, federal, and

plant safety specifications and procedures.

• Know the ENTIRE work cell or area that the robot occupies.

• Be aware of the ENTIRE work envelope of the robot and any peripheral devices.

• Locate ALL emergency stop buttons or switches.

• AVOID trap points in which personnel could become trapped between a moving

device and any stationary devices.

2-4 November 14, 2000

Page 35

C SERIES CONTROLLER

K

a

• Personnel should NEVER enter the work envelope during automatic operations.

• Ensure that ALL personnel are clear of the work envelope before initiating any

motion commands for the robot.

• Before initiating any motion commands, KNOW beforehand how the robot will

perform when that command is given.

• Be sure that the ENTIRE work area is free of any debris, tools, fixturing, lubricants,

and cleaning equipment before operation of the robot is attempted.

• If any personnel observe unsafe working conditions, report them IMMEDIATELY to

your supervisor or plant safety coordinator.

• ALL personnel should identify by name and function ALL switches, indicators, and

control signals that could initiate robot motion.

a

s

aw

k

SAFETY

AS LANGUAGE REFERENCE MANUAL

• NEVER defeat, render useless, jumper out, or bypass any safety related device,

whether mechanical or electrical in design.

• ALL safety devices approved for use in your plant must be properly installed and

maintained to ensure personnel safety.

• NEVER attempt to stop or brake the robot during operation with your body or person.

• ONLY utilize E-stops to stop robot motion in emergency situations.

November 14, 2000

2-5

Page 36

C SERIES CONTROLLER

K

a

2.3.2 SAFETY DURING OPERATION

• During operation of the robot, identify the maximum reach of the robot in ALL

directions, which is referred to as the work envelope.

• ALWAYS keep your work area clean and free of any debris which includes, but

is not limited to, oil, water, tool, fixturing, electronic test equipment, etc.

• During operations that involve the teach pendant, the ONLY person allowed in

the work envelope is the teacher, or the person operating the teach pendant.

The teach pendant has provisions to protect the operator. These safety

provisions include an E-stop, trigger switch, and deadman switch.

• NEVER block the operator’s path of retreat.

a

s

aw

k

SAFETY

AS LANGUAGE REFERENCE MANUAL

• During the teach operation of the robot ALWAYS have a path of retreat planned.

• AVOID pinch points.

2-6 November 14, 2000

Page 37

C SERIES CONTROLLER

K

a

2.3.3 SAFETY DURING PROGRAMMING

• During operation of the robot, be sure you are able to identify the maximum

reach of the robot in ALL directions, which is referred to as the work envelope.

• During teach operations the ONLY person allowed in the work envelope is the

teacher, or the person operating the teach pendant. The teach pendant has

provisions to protect the operator including E-stop, trigger switch, and deadman

switch.

• AVOID pinch points.

• During point-to-point playback operations, be aware that the robot is ONLY

cognizant of its present location and the next point it is requested to move to.

It will execute this move with total disregard to what may lie in its path when

the move is executed.

a

s

aw

k

SAFETY

AS LANGUAGE REFERENCE MANUAL

• Playback accuracy and speed can affect the geometry of the path coordinates.

Therefore, when changing accuracy or speed, ALWAYS test run the program at

a slow speed or point-to-point mode before attempting the continuous path

operation in the repeat mode.

• ALWAYS test run a new path program at a reduced speed or in point-to-point

mode prior to attempting a high-speed playback operation in the repeat mode.

November 14, 2000

2-7

Page 38

C SERIES CONTROLLER

K

a

2.3.4 SAFETY DURING INSPECTION AND MAINTENANCE

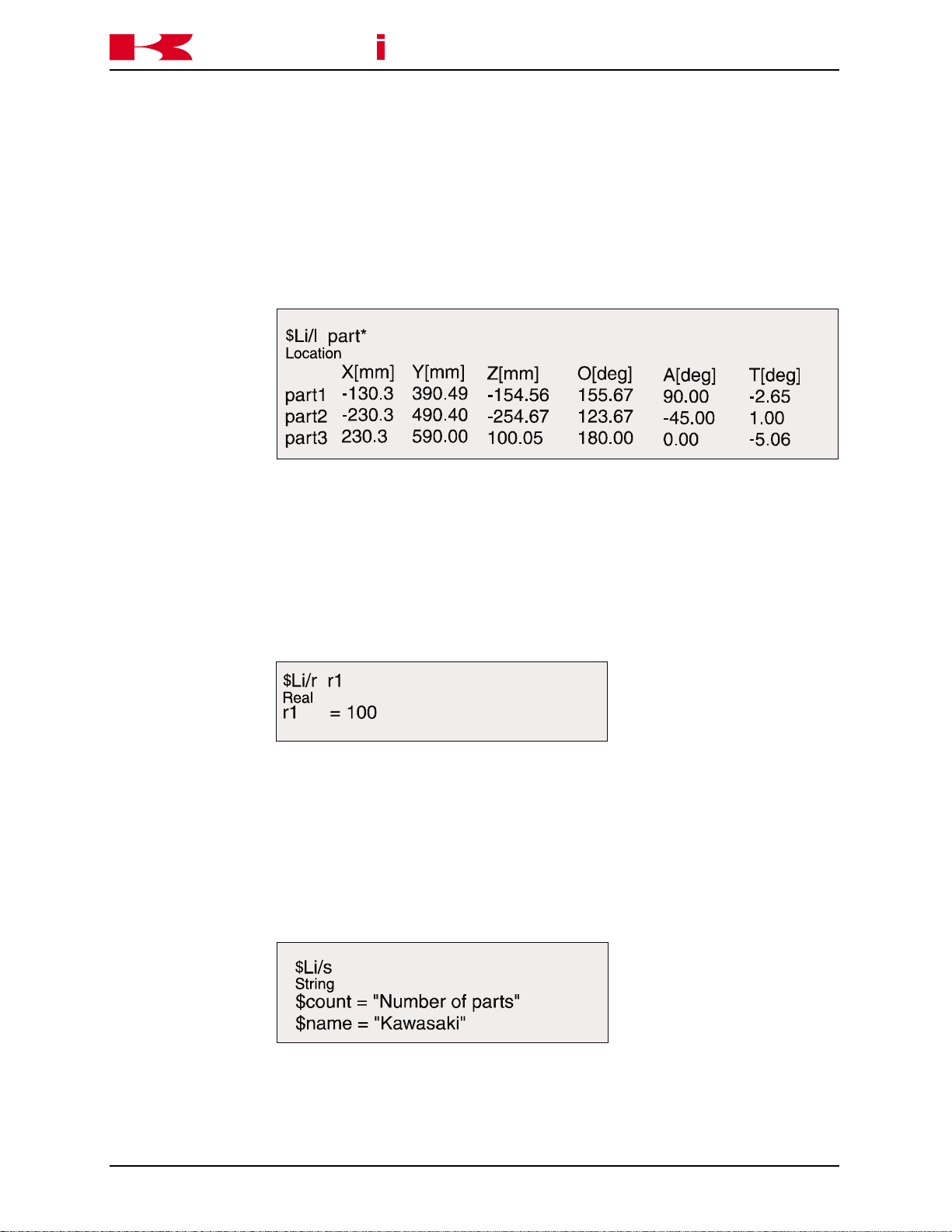

Before entering the work envelope to perform either inspection or maintenance

procedures, turn off 3-phase power on the disconnect and tag and lockout the

disconnect switch.

a

s

aw

k

SAFETY

AS LANGUAGE REFERENCE MANUAL

! WARNING

The input side (top) of the controller disconnect may still

be live when the controller disconnect is turned OFF. If

work is to be performed at the controller disconnect

switch, turn OFF the 3-phase power at the source, and

tag and lockout the source disconnect.

• When removing an axis motor, be aware that the axis WILL fall if left unsupported.

The brake assembly is in the servo drive motor, therefore, the axis of the robot will

be unsupported if removed.

• When using the axis brake release switches in the controller, be aware that the axis

MAY fall if left unsupported.

• Before working on pneumatic or high pressure water supplies, turn off supply

pressure and purge ALL lines to remove any residual pressure.

• Assign ONLY qualified personnel to perform all maintenance procedures.

• Consult ALL available documentation before attempting any repair or service

procedures.

• Use ONLY replacement parts approved by Kawasaki Robotics (USA), Inc.

• BEFORE attempting to adjust or repair a device in the robot controller that may

have yellow interlock control circuit wires attached, locate the source of the power

and remove it by disconnecting the appropriate disconnect at its source.

• During inspection and maintenance procedures, if your installation is equipped

with safety fences and safety plugs, REMOVE and HOLD the safety plug while

performing these operations. In addition, the safety procedures outlined above

should be adhered to.

2-8 November 14, 2000

Page 39

C SERIES CONTROLLER

K

a

2.4 SAFETY FEATURES

To safeguard the user, the Kawasaki robot system is equipped with many safety

features. These safety items include:

• All E-stops are hard-wired.

• The multi function panel, small teach pendant, and operation panel are equipped

with red mushroom-type detented E-stop push buttons. If an optional interface

panel is installed, the E-stop from the operation panel is relocated to the optional

interface panel.

• All robot axes are monitored by the robot controller for velocity and deviation errors.

• Robot velocities are constantly monitored by software. Should an over-velocity

condition be detected, the robot will fault in a velocity error condition.

a

s

aw

k

SAFETY

AS LANGUAGE REFERENCE MANUAL

• Teach velocities and check mode velocities are limited to a maximum of 250

mm/sec (9.843 in/sec).

• All robot axes have software limits.

• JT1 is equipped with overtravel limit switches (JT2 and JT3 are optional).

• All F-series, U-series, and Z-series mechanical units have overtravel hardstops on

the JT1, JT2, JT3, and JT5 axes.

• All robot axes are equipped with 24 VDC electromechanical brakes. Should the

robot lose line power, the robot arm will not drop because the brakes are engaged

when power is OFF at the robot controller.

November 14, 2000

2-9

Page 40

K

a

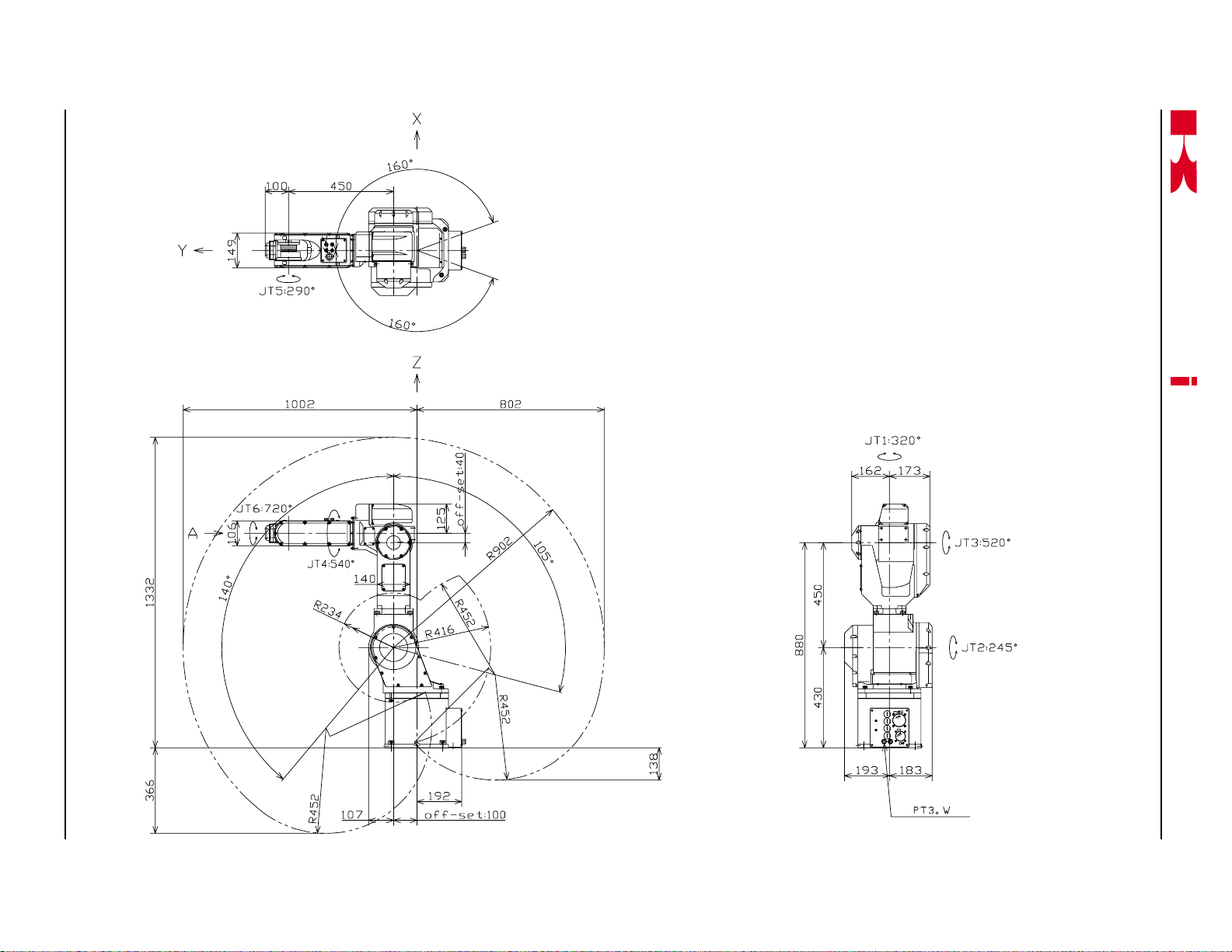

2.5 WORK ENVELOPE DRAWINGS

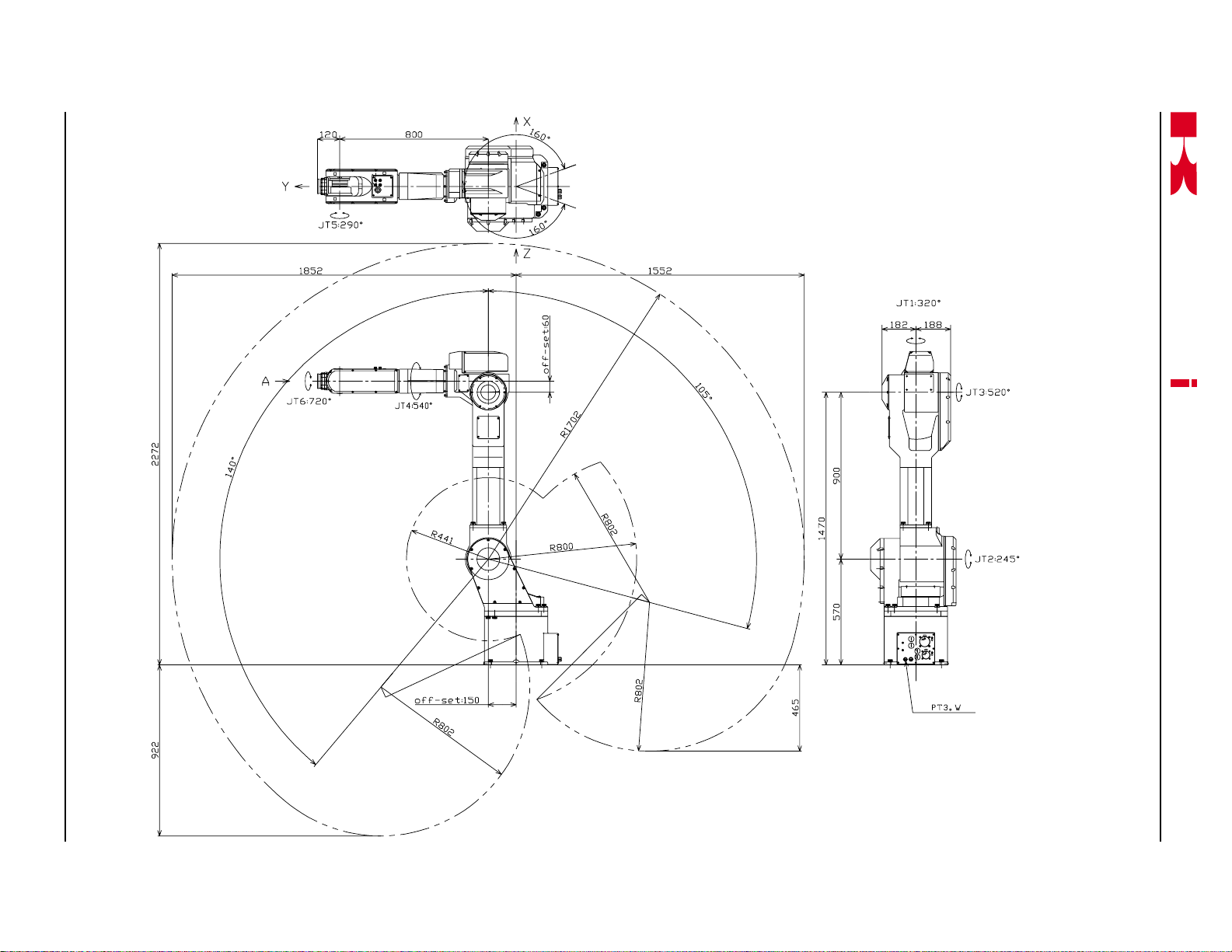

2.5.1 FS02N/FS03N

a

s

aw

k

C SERIES CONTROLLER

AS LANGUAGE REFERENCE MANUAL

SAFETY

Figure 2-1 FS02N/FS03N Work Envelope

2-10 November 14, 2000

Page 41

November 14, 2000

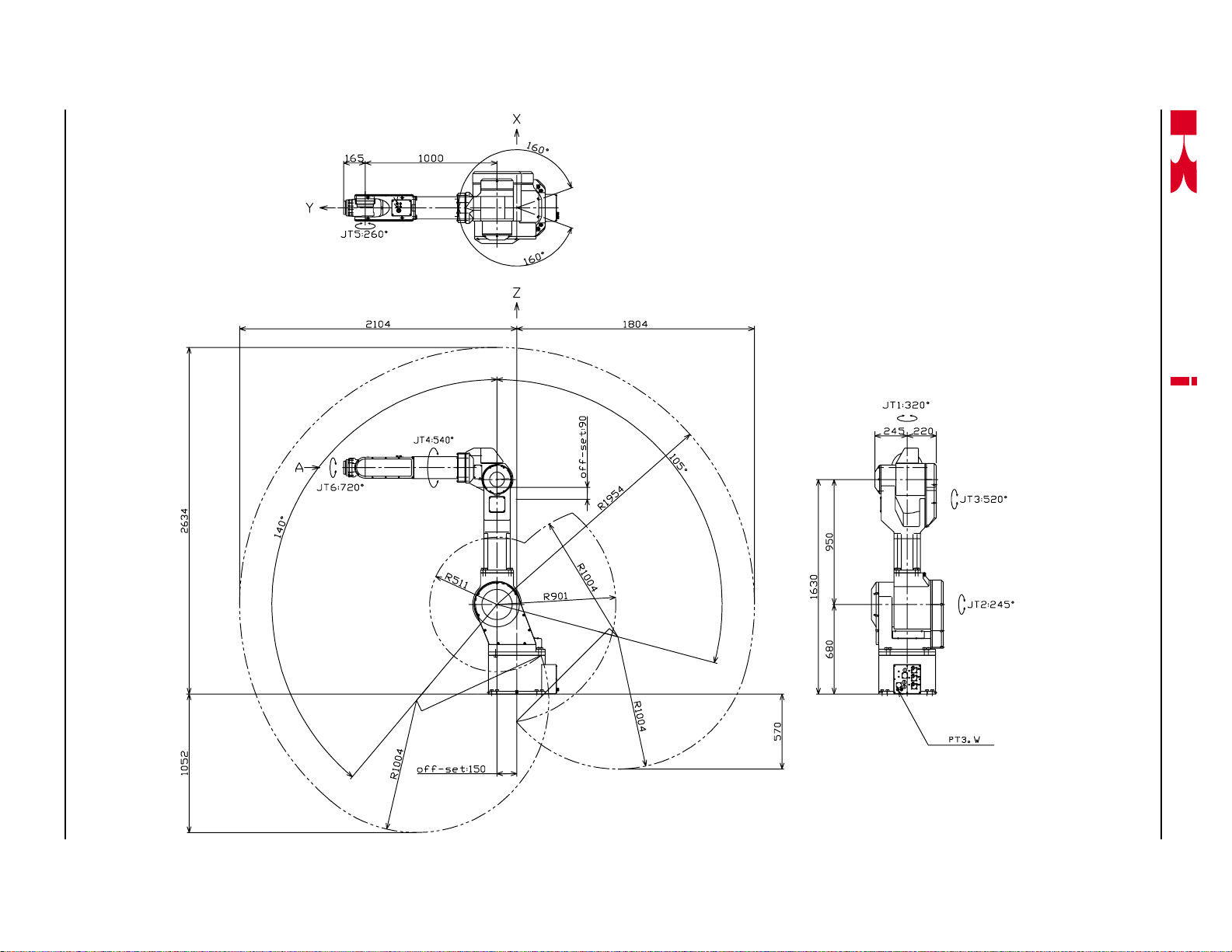

Figure 2-2 FS06L Work Envelope

2.5.2 FS06L

K

a

a

s

aw

k

SAFETY

2-11

AS LANGUAGE REFERENCE MANUAL

C SERIES CONTROLLER

Page 42

2-12 November 14, 2000

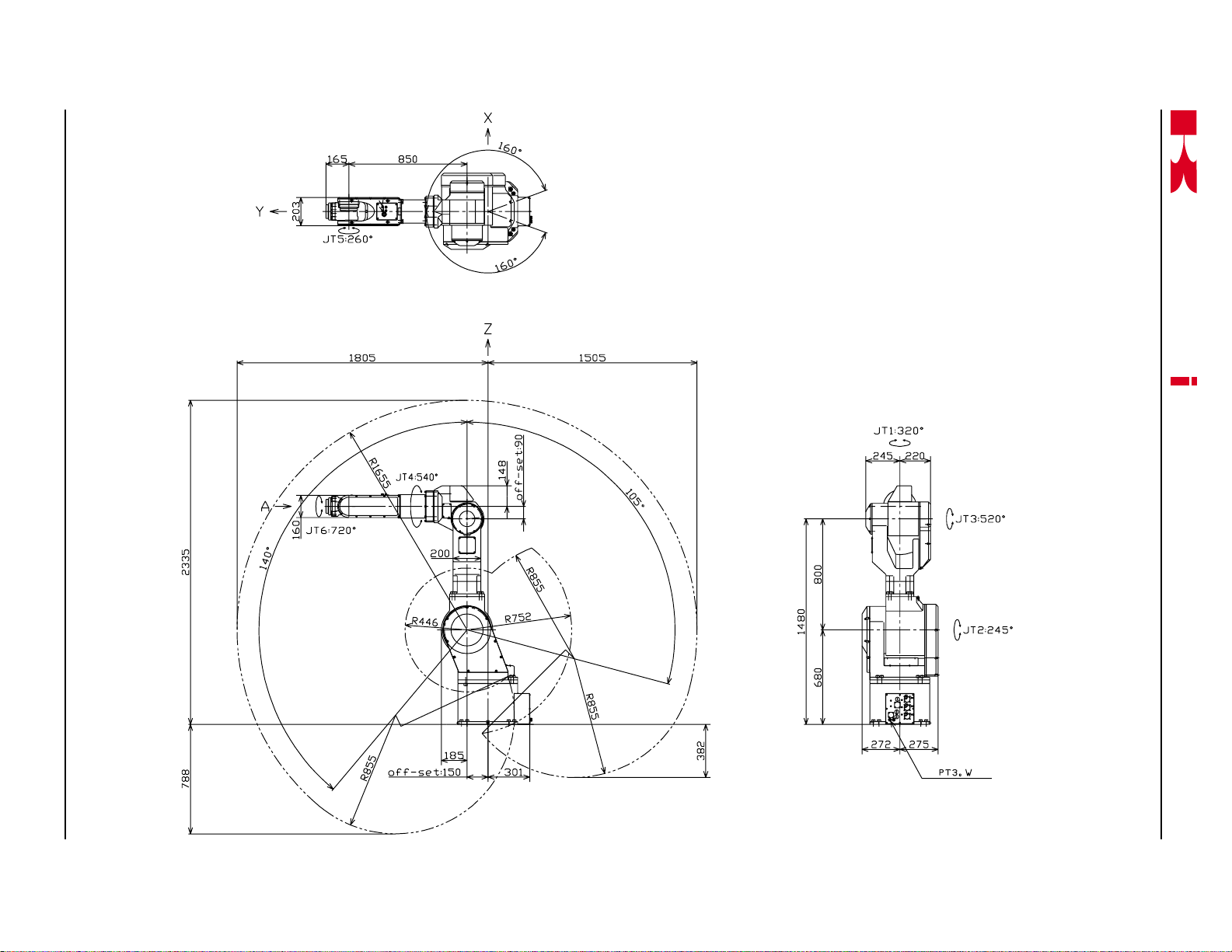

2.5.3 FC06N/FS06N/FW06N/FS10C

K

Figure 2-3 FC06N/FS06N/FW06N/FS10C Work Envelope

a

a

s

aw

k

SAFETY

AS LANGUAGE REFERENCE MANUAL

C SERIES CONTROLLER

Page 43

November 14, 2000

Figure 2-4 FS10N Wor k Envelope

2.5.4 FS10N

K

a

a

s

aw

k

SAFETY

2-13

AS LANGUAGE REFERENCE MANUAL

C SERIES CONTROLLER

Page 44

2-14 November 14, 2000

Figure 2-5 FS10E Wor k Envelope

2.5.5 FS10E

K

a

a

s

aw

k

SAFETY

AS LANGUAGE REFERENCE MANUAL

C SERIES CONTROLLER

Page 45

November 14, 2000

Figure 2-6 FS10L Work Envelope

2.5.6 FS10L

K

a

a

s

aw

k

SAFETY

2-15

AS LANGUAGE REFERENCE MANUAL

C SERIES CONTROLLER

Page 46

2-16 November 14, 2000

Figure 2-7 FS20C Work Envelope

2.5.7 FS20C

K

a

a

s

aw

k

SAFETY

AS LANGUAGE REFERENCE MANUAL

C SERIES CONTROLLER

Page 47

November 14, 2000

Figure 2-8 FS20N Wor k Envelope

2.5.8 FS20N

K

a

a

s

aw

k

SAFETY

2-17

AS LANGUAGE REFERENCE MANUAL

C SERIES CONTROLLER

Page 48

2-18 November 14, 2000

Figure 2-9 FS30L Work Envelope

2.5.9 FS30L

K

a

a

s

aw

k

SAFETY

AS LANGUAGE REFERENCE MANUAL

C SERIES CONTROLLER

Page 49

November 14, 2000

2.5.10 FS30N/FS45C

K

a

Figure 2-10 FS30N/FS45C Work Envelope

a

s

aw

k

SAFETY

AS LANGUAGE REFERENCE MANUAL

C SERIES CONTROLLER

2-19

Page 50

2-20 November 14, 2000

Figure 2-11 FS45N Work Envelope

2.5.11 FS45N

K

a

a

s

aw

k

SAFETY

AS LANGUAGE REFERENCE MANUAL

C SERIES CONTROLLER

Page 51

K

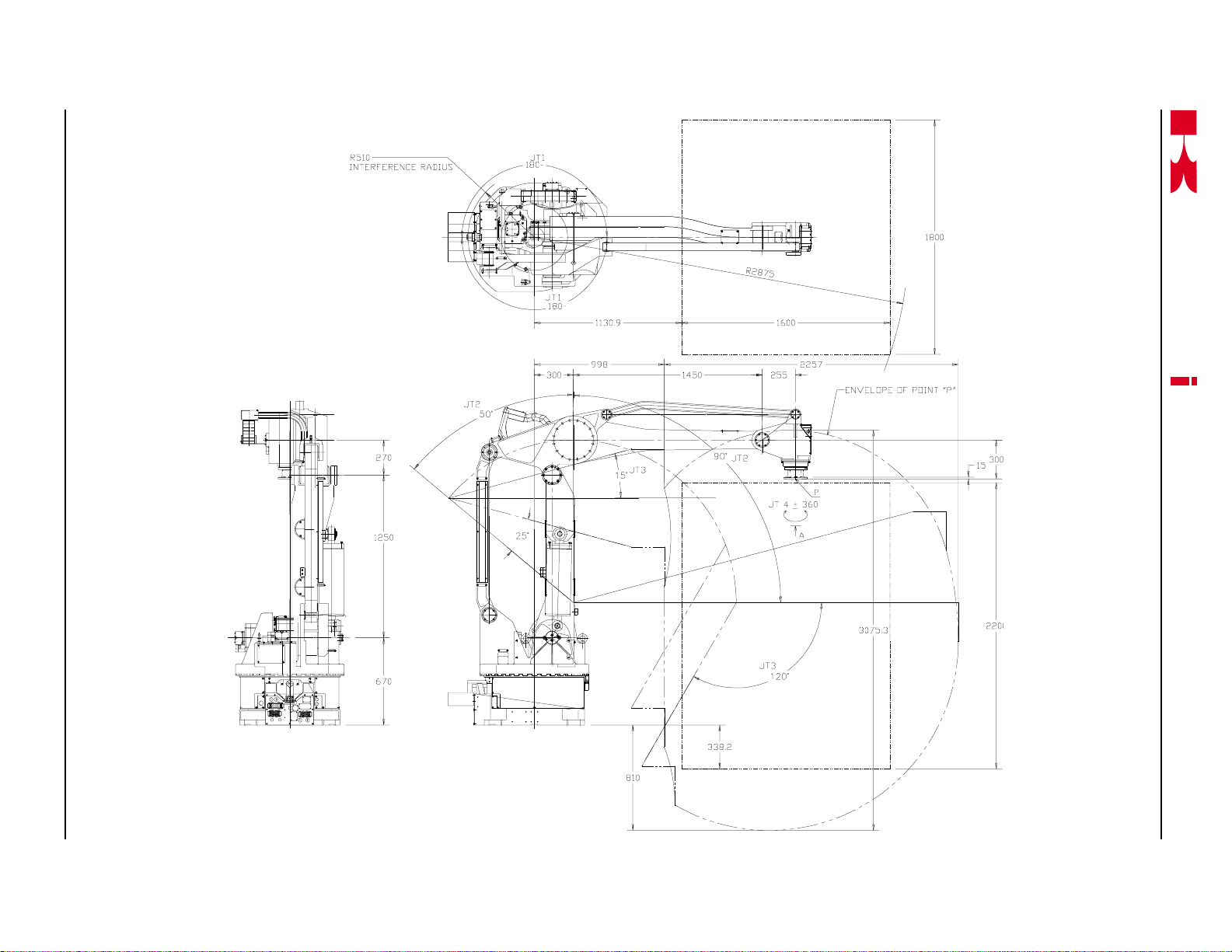

2.5.12 UB150

a

a

s

C SERIES CONTROLLER

aw

k

SAFETY

AS LANGUAGE REFERENCE MANUAL

November 14, 2000

Figure 2-12 UB150 Work Envelope

2-21

Page 52

K

a

2.5.13 UT100/150/200

a

s

C SERIES CONTROLLER

aw

k

SAFETY

AS LANGUAGE REFERENCE MANUAL

Figure 2-13 UT100/120/150 Work Envelope

2-22 November 14, 2000

Page 53

November 14, 2000

Figure 2-14 UX70 Work Envelope

2.5.14 UX70

K

a

a

s

aw

k

SAFETY

2-23

AS LANGUAGE REFERENCE MANUAL

C SERIES CONTROLLER

Page 54

2-24 November 14, 2000

2.5.15 UX100/120/150

K

a

Figure 2-15 UX100/120/150 Work Envelope

a

s

aw

k

SAFETY

AS LANGUAGE REFERENCE MANUAL

C SERIES CONTROLLER

Page 55

November 14, 2000

Figure 2-16 UX200 Work Envelope

2.5.16 UX200

K

a

a

s

aw

k

SAFETY

2-25

AS LANGUAGE REFERENCE MANUAL

C SERIES CONTROLLER

Page 56

2-26 November 14, 2000

Figure 2-17 UX300 Work Envelope

2.5.17 UX300

K

a

a

s

aw

k

SAFETY

AS LANGUAGE REFERENCE MANUAL

C SERIES CONTROLLER

Page 57

November 14, 2000

2.5.18 UZ100/120/150

K

a

Figure 2-18 UZ100/120/150 Wor k Envelope

a

s

aw

k

SAFETY

AS LANGUAGE REFERENCE MANUAL

C SERIES CONTROLLER

2-27

Page 58

2-28 November 14, 2000

Figure 2-19 ZD130 Work Envelope

2.5.19 ZD130

K

a

a

s

aw

k

SAFETY

AS LANGUAGE REFERENCE MANUAL

C SERIES CONTROLLER

Page 59

November 14, 2000

Figure 2-20 ZX130L Work Envelope

2.5.20 ZX130L

K

a

a

s

aw

k

SAFETY

2-29

AS LANGUAGE REFERENCE MANUAL

C SERIES CONTROLLER

Page 60

2-30 November 14, 2000

Figure 2-21 ZX130U Work Envelope

2.5.21 ZX130U

K

a

a

s

aw

k

SAFETY

AS LANGUAGE REFERENCE MANUAL

C SERIES CONTROLLER

Page 61

November 14, 2000

Figure 2-22 ZX165U Work Envelope

2.5.22 ZX165U

K

a

a

s

aw

k

SAFETY

2-31

AS LANGUAGE REFERENCE MANUAL

C SERIES CONTROLLER

Page 62

2-32 November 14, 2000

Figure 2-23 ZX200S Work Envelope

2.5.23 ZX200S

K

a

a

s

aw

k

SAFETY

AS LANGUAGE REFERENCE MANUAL

C SERIES CONTROLLER

Page 63

November 14, 2000

Figure 2-24 ZX200U Work Envelope

2.5.24 ZX200U

K

a

a

s

aw

k

SAFETY

2-33

AS LANGUAGE REFERENCE MANUAL

C SERIES CONTROLLER

Page 64

2-34 November 14, 2000

Figure 2-25 ZX300S Work Envelope

2.5.25 ZX300S

K

a

a

s

aw

k

SAFETY

AS LANGUAGE REFERENCE MANUAL

C SERIES CONTROLLER

Page 65

C SERIES CONTROLLER

K

a

3.0 POWER ON/OFF PROCEDURES ..................................................................... 3-2

3.1 Controller Power On/Off Procedures.................................................................. 3-2

3.1.1 Controller Power On Procedures ....................................................................... 3-2

3.1.2 Controller Power Off Procedures ....................................................................... 3-2

3.2 Servo Motor Power-On Procedures ................................................................... 3-7

3.2.1 Servo Motor Power-On in the Repeat Mode ...................................................... 3-7

3.2.2 Servo Motor Power-On in the Teach Mode......................................................... 3-7

3.3 Methods for Stopping the Robot ........................................................................ 3-8

3.3.1 Emergency Stop Switch..................................................................................... 3-8

3.3.2 HOLD/RUN Switch............................................................................................. 3-8

3.3.3 TEACH/REPEAT Switch .................................................................................... 3-8

a

aw

k

s

POWER ON/OFF PROCEDURES

AS LANGUAGE REFERENCE MANUAL

November 20, 1998

3-1

Page 66

C SERIES CONTROLLER

K

a

3.0 POWER ON/OFF PROCEDURES

This unit provides the power ON/OFF procedures for the robot controller and servo

motors. Refer to figures 3-1 through 3-7 during these procedures.

3.1 CONTROLLER POWER ON/OFF PROCEDURES

3.1.1 CONTROLLER POWER ON PROCEDURES

1. Ensure all personal are clear of the work cell and all safety devices are in place and

operational.

2. Turn the HOLD/RUN switch to the HOLD position.

3. Place the controller main disconnect switch in the ON position. At this time the

CONTROL POWER indicator lamp illuminates.

a

aw

k

s

POWER ON/OFF PROCEDURES

AS LANGUAGE REFERENCE MANUAL

3.1.2 CONTROLLER POWER OFF PROCEDURES

1. Turn the HOLD/RUN switch to the HOLD position; the robot decelerates to a stop

and the MOTOR POWER lamp turns off.

2. Press the EMERGENCY STOP switch. At this time the CYCLE START lamp turns

off.

3. Place the controller main disconnect switch in the OFF position.

3-2

November 14, 2000

Page 67

K

t

a

Control Power

Indicator

a

aw

k

s

POWER ON/OFF PROCEDURES

C SERIES CONTROLLER

AS LANGUAGE REFERENCE MANUAL

Main Disconnec

Switch

November 20, 1998

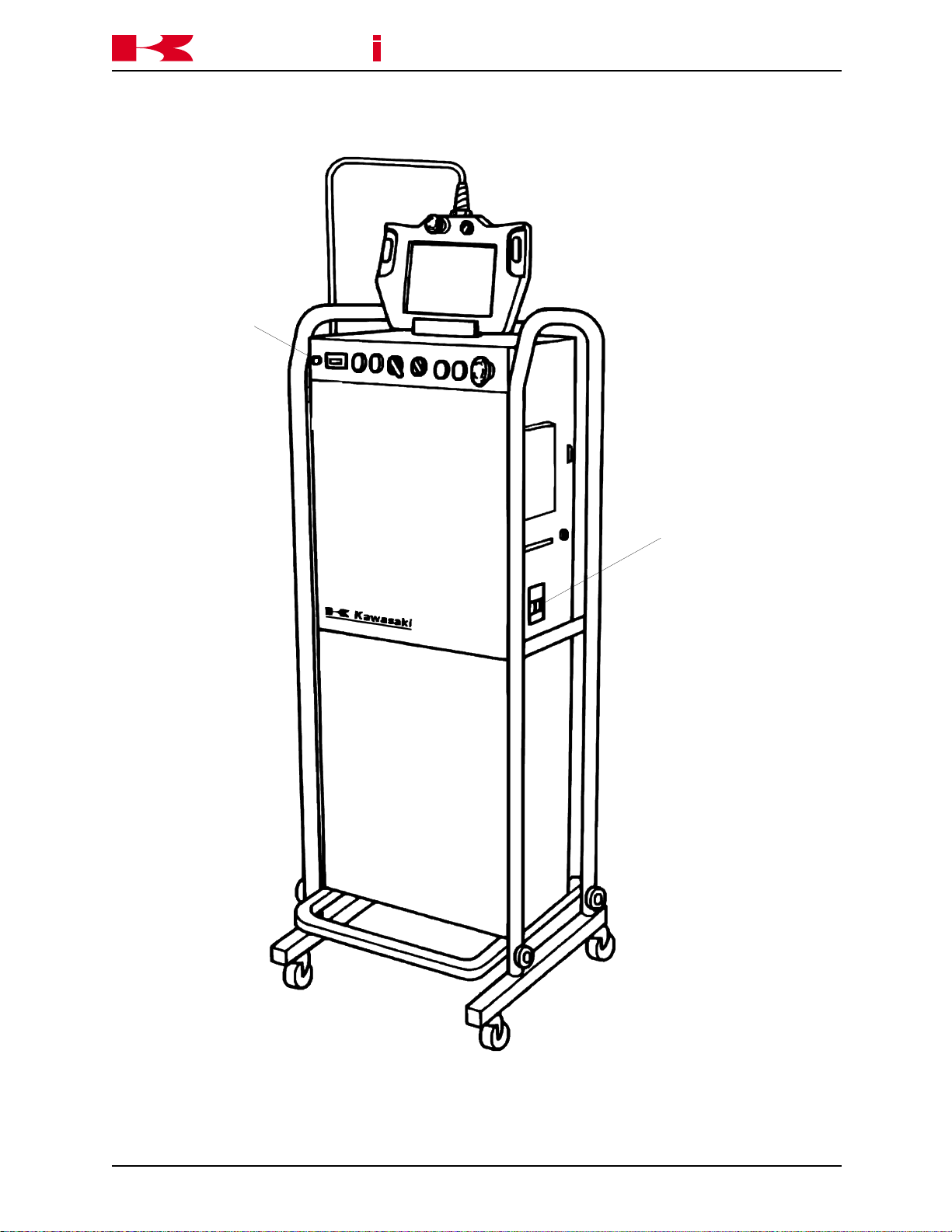

Figure 3-1 Standard C Controller

3-3

Page 68

K

a

a

aw

k

s

POWER ON/OFF PROCEDURES

C SERIES CONTROLLER

AS LANGUAGE REFERENCE MANUAL

3-4

Figure 3-2 North American C Controller

November 20, 1998

Page 69

K

a

a

aw

k

s

POWER ON/OFF PROCEDURES

C SERIES CONTROLLER

AS LANGUAGE REFERENCE MANUAL

November 20, 1998

Figure 3-3 European C Controller

3-5

Page 70

K

a

a

aw

k

s

POWER ON/OFF PROCEDURES

EMERGENCY STOP

MOTOR POWERERROR

CYCLE STARTERROR RESET

C SERIES CONTROLLER

AS LANGUAGE REFERENCE MANUAL

TEACH REPEAT

HOLD RUN

Figure 3-4 North American and European C Controller Switch Panel

CONTROL

POWER

HOUR METER

HOLD RUN

TEACH REPEAT

CYCLE STARTERROR RESET

MOTOR POWERERROR

Figure 3-5 Standard C Controller Switch Panel

EMERGENCY STOP

3-6

November 20, 1998

Page 71

C SERIES CONTROLLER

K

a

3.2 SERVO MOTOR POWER-ON PROCEDURES

3.2.1 SERVO MOTOR POWER-ON IN THE REPEAT MODE

1. Place the TEACH LOCK switch on the multi function panel in the OFF position.

2. Place the TEACH/REPEAT switch in the REPEAT position.

3. Press the MOTOR POWER push button. The MOTOR POWER lamp illuminates.

4. Place the HOLD/RUN switch in the RUN position.

5. The robot is now ready to execute a program.

3.2.2 SERVO MOTOR POWER-ON IN THE TEACH MODE

a

aw

k

s

POWER ON/OFF PROCEDURES

AS LANGUAGE REFERENCE MANUAL

1. Place the TEACH/REPEAT switch in the TEACH position.

2. Place the TEACH LOCK switch on the multi function panel in the ON position.

3. At the BLOCK TEACHING screen, press and hold one of the trigger (deadman)

switches and press the MOTOR POWER push button. At this time the MOTOR

POWER lamp illuminates.

Emergency Stop

Switch

ON OFF

TEACH LOCK

Teach Lock

Trig ger (Dea dman)

Switches

November 14, 2000

Figure 3-6 Multi Function Panel

3-7

Page 72

C SERIES CONTROLLER

K

a

3.3 METHODS FOR STOPPING THE ROBOT

One of three methods are used to stop robot motion. Each of these methods is described in the following sections.

3.3.1 EMERGENCY STOP SWITCH

When the EMERGENCY STOP switch is pressed, motor power is turned off and the

brakes are applied stopping the robot immediately. This places very high loads upon the

robot and is only recommended for emergency situations. To stop the robot during nonemergency situations refer to section 3.3.2, HOLD/RUN SWITCH.

3.3.2 HOLD/RUN SWITCH

When the HOLD/RUN switch is turned to the HOLD position the robot decelerates