Page 1

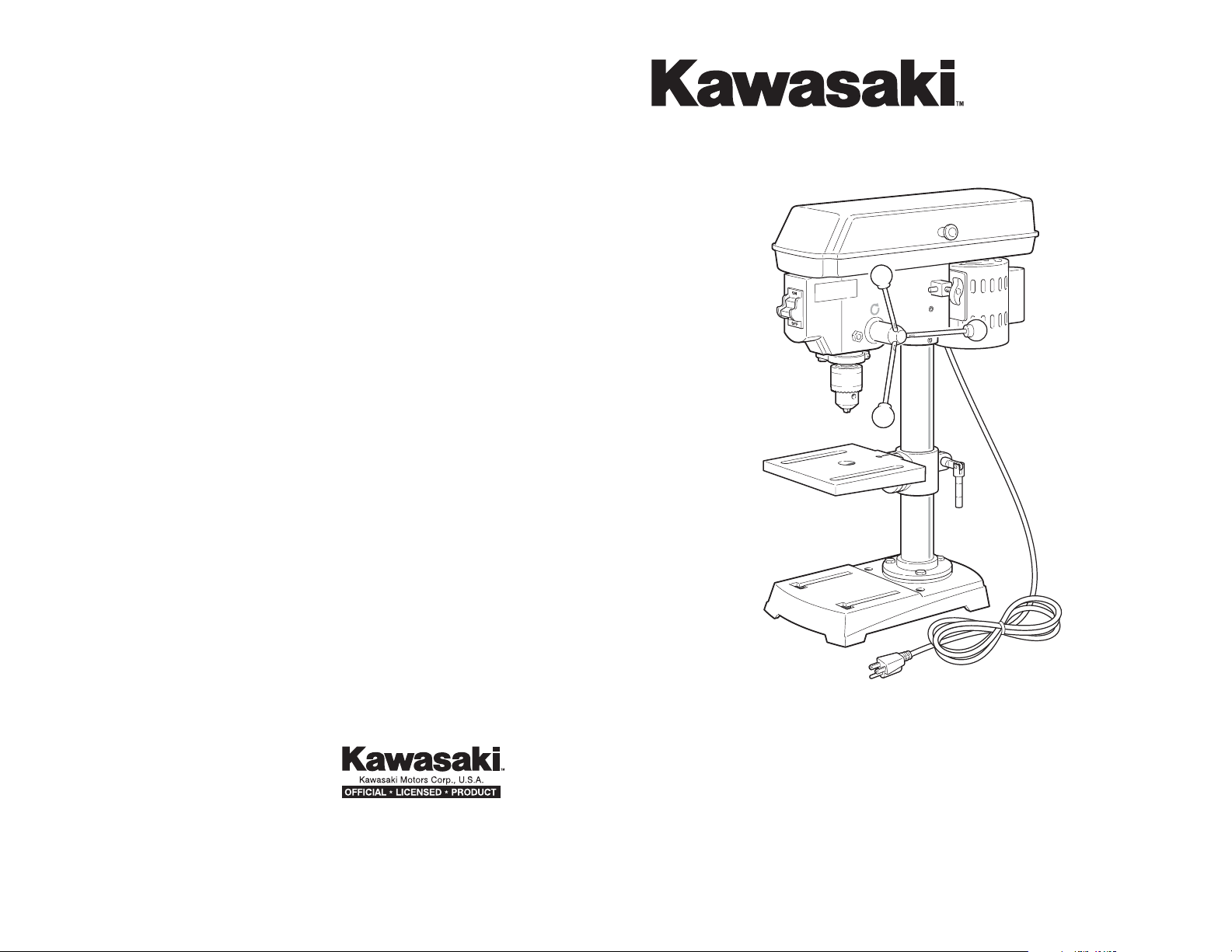

8" BENCH DRILL PRESS

INSTRUCTION MANUAL

FOR CUSTOMER SERVICE

POUR LE SERVICE APRÉS VENTE

OU DU CONSOMMATEUR

PARA EL SERVICIO

PARA EL CONSUMIDOR

1-800-590-3723

Printed in China

KAWASAKI™ IS A TRADEMARK LICENSED BY KAWASAKI™

MOTORS CORP., U.S.A., WHICH DOES NOT MANUFACTURE OR

DISTRIBUTE THIS PRODUCT. CONSUMER INQUIRES SHOULD BE

DIRECTED TO:

©COPYRIGHT 2005 ALLTRADE TOOLS, LLC.

1431 VIA PLATA

LONG BEACH, CA 90810-1462 USA

840116 – 8" Bench Drill Press_Rev 11/13/06

MODEL

#840116

THIS MANUAL CONTAINS IMPORTANT INFORMATION REGARDING SAFETY, OPERATION,

MAINTENANCE AND STORAGE OF THIS PRODUCT. BEFORE USE, READ CAREFULLY AND

UNDERSTAND ALL CAUTIONS, WARNINGS, INSTRUCTIONS AND PRODUCT LABELS. FAILURE TO DO

SO COULD RESULT IN SERIOUS PERSONAL INJURY AND/OR PROPERTY DAMAGE.

IF YOU SHOULD HAVE ANY QUESTIONS OR EXPERIENCE A PROBLEM WITH YOUR ALLTRADE

PRODUCT, DO NOT RETURN THIS PRODUCT TO THE STORE. PLEASE CALL OUR CUSTOMER SERVICE

DEPARTMENT AT 1-800-590-3723. BEFORE YOU CALL, HAVE THE FOLLOWING INFORMATION

AVAILABLE: MODEL No., DATE PURCHASED AND STORE LOCATION. AN ALLTRADE

REPRESENTATIVE CAN RESOLVE YOUR PROBLEM OVER THE PHONE. IF YOU WOULD LIKE TO MAKE

A SUGGESTION OR COMMENT, GIVE US A CALL OR EMAIL US AT: INFO@ALLTRADETOOLS.COM.

YOUR FEEDBACK IS VITAL TO US.

87-1904-60957

Page 2

SECTION FOUR

MAINTENANCE AND CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25-26

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

OTHER CONSUMER DO-IT-YOURSELF (DIY) TOOLS . . . . . . . . . . . . . . 27

SECTION FIVE

2 YEAR LIMITED WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-30

CONGRATULATIONS!

Thanks for choosing this product. At Alltrade, our aim is to provide you with quality

products at an affordable price, and we want you to be totally satisfied with your

product and our Customer Service. If any help and advice is needed, please

contact us at 1-800-590-3723. Properly cared for, this product will give you many

years of satisfaction.

INTENDED USE

This product is intended for consumer use only. This tool is not designed for professional use. The power cord should only be used in approved electrical outlets as

described in this manual. Failure to use the proper power cords and/or extension

cords may result in fire or possible damage to the drill press.

RECOGNIZE SAFETY SYMBOLS, WORDS AND LABELS

READ AND UNDERSTAND ALL INSTRUCTIONS. Failure to

follow all instructions in this manual may result severe in personal injury or

death. Keep this manual and refer to it for Safety Instructions, Operating

Procedures and Warranty.

The safety instructions provided in this manual are not intended to cover all possible conditions and practices that may occur when operating, maintaining and cleaning power tools.

Always use common sense and pay particular attention to all the DANGER,

WARNING, CAUTION and NOTE statements of this manual.

This is the safety alert symbol. It is used to alert

you to potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid

possible injury or death.

DANGER indicates an imminently hazardous

situation which, if not avoided, will result in death

or serious injury.

TABLE OF CONTENTS

CONGRATULATIONS! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

INTENDED USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SECTION ONE

RECOGNIZE SAFETY SYMBOLS, WORDS AND LABELS . . . . . . . . . . . . 2-3

IMPORTANT SAFEGUARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SECTION TWO

GENERAL SAFETY RULES – FOR ALL ELECTRIC POWER TOOLS . . . . 4-5

GROUNDING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

EXTENSION CORD USAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

IMPORTANT SAFETY RULES FOR DRILL PRESSES . . . . . . . . . . . . . . . 7-10

SYMBOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

SECTION THREE

FUNCTIONAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-16

INSTALLING THE COLUMN ASSEMBLY TO THE BASE . . . . . . . . . 13

INSTALLING THE WORK TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

INSTALLING THE DRILL PRESS HEAD . . . . . . . . . . . . . . . . . . . . . 13

INSTALLING HANDLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

INSTALLING DRILL CHUCK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-15

REMOVING AND INSTALLING DRILL BITS . . . . . . . . . . . . . . . . . . 15

MOUNTING THE DRILL PRESS . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

LASER GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-18

LASER SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-17

OPERATING THE LASER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-18

OPERATING THE DRILL PRESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-25

OPERATING THE ON/OFF SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . 19

ADJUSTING THE WORKTABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

TILTING THE WORKTABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

ADJUSTING THE DRILL PRESS SPINDLE SPEED . . . . . . . . . . . . . 21-22

DRILLING HOLES TO SPECIFIED DEPTHS . . . . . . . . . . . . . . . . . . . 22-23

ADJUSTING THE SPINDLE RETURN SPRING . . . . . . . . . . . . . . . . 23-24

CORRECT DRILLING SPEEDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

WORKING WITH WOOD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

DRILLING METAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1 2

Page 3

GENERAL SAFETY RULES – FOR ALL ELECTRIC POWER TOOLS

READ AND UNDERSTAND ALL INSTRUCTIONS. Failure to follow all instructions

listed below may result in electric shock, fire and/or serious personal injury.

KEEP GUARDS IN PLACE AND IN WORKING ORDER.

REMOVE ADJUSTING KEYS AND WRENCHES. Form a habit of checking to see

that keys and adjusting wrenches are removed from the tool before turning it on.

KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

DO NOT USE TOOL IN A DANGEROUS ENVIRONMENT. Do not use power tools

in damp or wet locations, or expose them to rain. Keep work area well lit.

KEEP CHILDREN AWAY. All visitors should be kept a safe distance from the

work area.

MAKE YOUR WORKSHOP CHILD PROOF, with padlocks, master switches, or

by removing starter keys.

DO NOT FORCE TOOL. The correct tool will do the job better and safer at the

rate for which it is designed.

USE THE CORRECT TOOL FOR YOUR APPLICATION. Do not force tool or

attachment to do a job for which it was not designed.

ALWAYS USE SAFETY GLASSES. Also use a face mask or dusk mask if cutting

operation is dusty. Everyday eyeglasses only have impact lenses, they are NOT

safety glasses.

SECURE WORK. Use clamps or other practical ways to secure and support the

workpiece to a stable platform. Holding the work by hand or against your body

is unstable and may lead to loss of control.

DO NOT OVERREACH. Keep proper footing and balance at all times. Proper

footing and balance enables better control of the power tool in unexpected situations.

MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating and changing accessories.

NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don’t leave

tool until it comes to a complete stop.

DISCONNECT TOOLS before servicing and when changing accessories, such as

blades, bits, cutters and the like.

3

4

WARNING indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

CAUTION indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury.

CAUTION used without the safety alert symbol

indicates a potentially hazardous situation which,

if not avoided, may result in property damage.

NOTE provides additional information that is useful

for proper use and maintenance of this tool. If a

NOTE is indicated make sure it is fully understood.

IMPORTANT SAFEGUARDS

People with electronic devices, such as pacemakers, should consult their

physician(s) before using this product. Operation of electrical equipment in

close proximity to a heart pacemaker could cause interference or failure of

the pacemaker.

WARNING: Some dust created by power sanding, sawing, grinding, drilling and

other construction activities contains chemicals known to the State of California

to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks and cement and other masonry products,

and arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type

of work. To reduce your exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, such as dust masks that are

specially designed to filter out microscopic particles.

WARNING: Handling the power cord on corded products may expose you to

lead, a chemical known to the State of California to cause cancer and birth

defects or other reproductive harm.

Wash hands after handling.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

Page 4

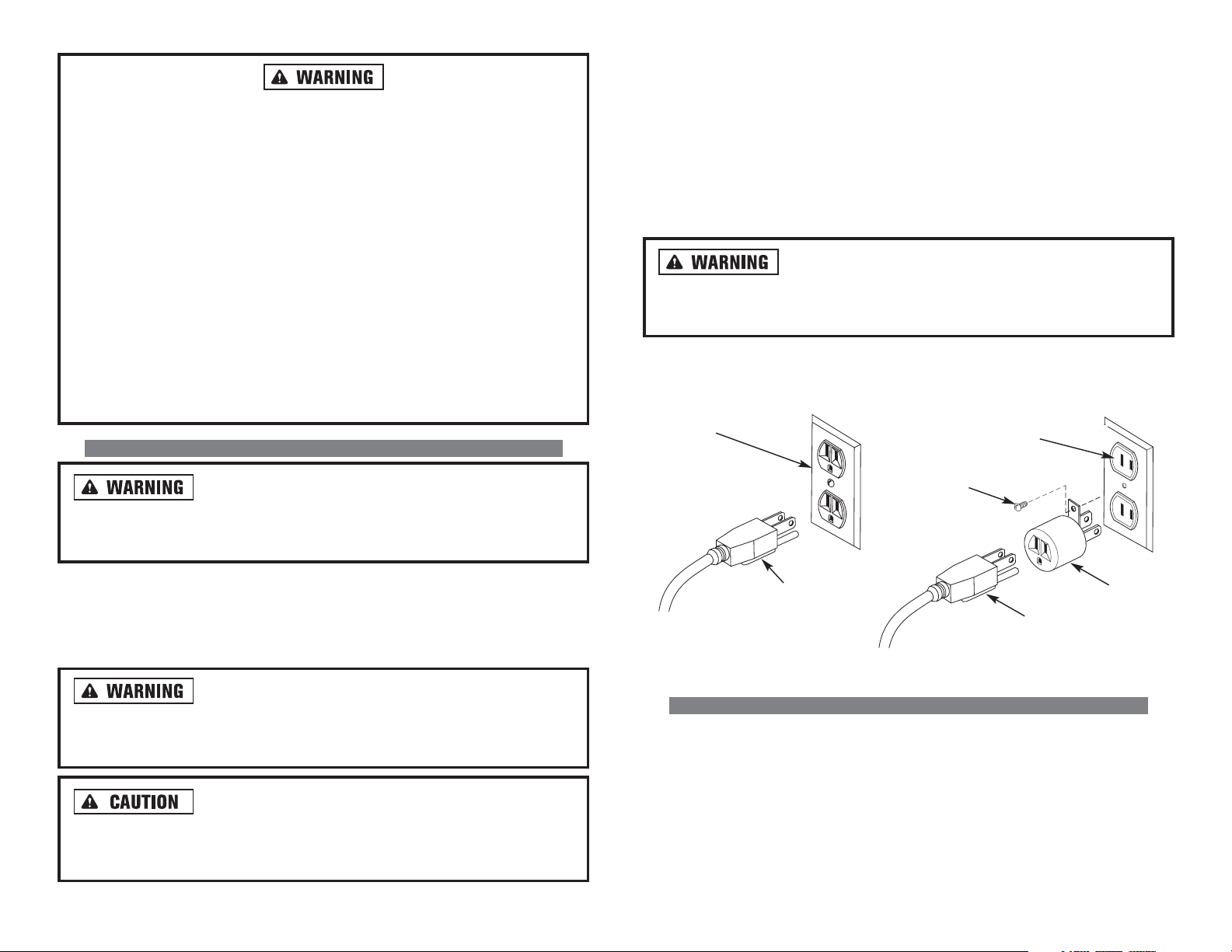

This drill press is equipped with a grounded 3-wire power cord with a 3-prong plug.

If the power cord will not fit into the wall plug, an approved adapter can be used as

long as it is connected to the center screw in the wall plate. See Figure 1 and the

steps below to use an AC grounding adapter:

1. Remove the cover plate mounting screw.

2. Insert the AC grounding adapter into the bottom receptacle so the green

grounding lug fits over the screw hole.

3. Install the mounting screw back into the cover plate securely affixing the

adapter to the receptacle.

Never modify the electrical adapter by cutting off the

grounding prong so it will fit into unapproved, un-grounded electrical receptacles. Failure to follow this procedure could result in burns, severe electrical shock, or even death.

If you have questions about connecting the drill press, contact a certified electrician

to install the proper circuitry needed for this and other power tools you use.

Repair or replace any damaged electrical wiring IMMEDIATELY.

EXTENSION CORD USAGE

Extension cords are not recommended for use with this drill press. Extension cords, if

used, must be properly grounded with a 3-prong plug on one and a 3-hole receptacle on

the other. DO NOT use grounding adapters with an extension cord. Extension cords

must be UL listed and use a minimum of 18 A.W.G. wiring. Extension cords should never

exceed 25 feet in length. Extension cords, that are too long, cause a voltage drop over the

extra distance causing the grinder motor to run slower with the possibility of causing

damage to the motor. Using extension cords with smaller than the recommended wire

gauge run the risk of getting too hot, melting, and/or causing fires. See table, “Extension

Cord Specifications”, on page 25-26.

REDUCE THE RISK OF UNINTENTIONAL STARTING. Be sure switch is in the

“OFF” position before plugging in.

USE RECOMMENDED ACCESSORIES. Consult the owners manual for recommended accessories. The use of improper accessories may cause cause risk of

injury.

NEVER STAND ON TOOL. Serious injury could occur if the tool is tipped or if

the cutting tool is unintentionally contacted.

CHECK DAMAGED PARTS. Before further use of the tool, a guard or other part

that is damaged should be carefully checked to determine that it will operate

properly and perform its intended function. Check for alignment of moving

parts, binding of moving parts, breakage of parts, mounting and any other conditions that may affect its operation. A guard or other part that is damaged

should be properly repaired or replaced.

DIRECTION OF FEED. Only feed work into a blade or cutter against the direction of rotation of the blade or cutter.

GROUNDING INSTRUCTIONS

NEVER use appliances or equipment that have motors

with automatic reset overload protective devices. These protective devices

can cause unexpected startups that can cause property damage, severe personal injury, or death.

The electrical power source for this drill press MUST be grounded in order to prevent

possible electric shock or even death should the tool malfunction or break down.

Grounding provides a path of least resistance for electric current thus reducing the

risk of electrical shock. The power source must also use a minimum 20A service.

Multiple power tools should never be used on the same circuit at the same time.

Failure to properly ground this drill press could result in

burns, severe electrical shock, and even death. This is especially true if used in

damp or wet locations or near metallic plumbing. The reaction from electrical

shock could possibly cause your hands to make contact with the cutting tools.

Not all outlets are properly grounded, regardless of the

type of receptacle they have. If you are not sure if the receptacle is properly

grounded or not, consult a certified electrician. The AC receptacle must be

protected by a dual element time delay or a circuit breaker.

5

UNGROUNDED AC RECEPTACLE

GROUNDED RECEPTACLE

GROUNDING ADAPTER

DRILL PRESS POWER CORD

DRILL PRESS POWER CORD

COVERPLATE

MOUNTING SCREW

FIGURE 1. CONNECTING THE DRILL PRESS TO THE AC POWER RECEPTACLE

Page 5

USE ONLY DRILL BITS, SANDING DRUMS, AND OTHER ACCESSORIES that

are designed for the various speeds of this drill press. The drill bits, sanding

drums and other accessories should have a shank size 1/2" OR SMALLER.

Unsuitable drill bits can break without warning throwing fragments outward at

high speeds possibly causing severe injuries. Contact Alltrade Customer

Service at 1-800-590-3723 (toll free) for authorized drill bit specifications.

USE RECOMMENDED SPEED for drill accessory and workpiece material.

DO NOT FORCE THE TOOL. The drill press will do a better job and be safer if

drilling operations are performed at the proper speeds as expressed in this

manual.

USE ONLY THE CHUCK KEY THAT IS PROVIDED with the drill press or a

duplicate of it to reliably secure the drill bit inside the chuck.

REMOVE CHUCK KEYS AND OTHER ADJUSTMENT TOOLS from the areas

around the drill press before turning the power switch to the “ON” position.

DO NOT USE A DRILL BIT THAT WOBBLES OR VIBRATES. Visually inspect the

drill bits before they contact the work piece ensuring there are no side-to-side

movements. Should the drill bit wobble from side-to-side or if the tip appears

broken, replace them immediately. If the vibration still exists, check the bearings and the motor shaft and repair or replace them as soon as possible.

EXCESSIVE VIBRATION can cause severe damage to both the work piece and

the drill press.

ADJUST THE TOOL TABLE BEFORE EACH USE. The tool table should be tightened and placed at the proper angle for the drilling job before the drill press is

put into use. If not properly adjusted, the work piece can unexpectedly move

causing the drill bit to seize resulting in damage to it or possible severe injury

to the operator.

DO NOT STAND DIRECTLY IN FRONT OF THE DRILL PRESS when it is first

turned on. Loose fragments could fly off at high speeds possibly causing injury.

PROPERLY SUPPORT EXTRA LONG OR EXTRA WIDE WORK PIECES. Work

pieces that are too long or tool wide can tip and cause the drill bit to seize

resulting in a sudden whipping motion resulting in damage to the work piece

and drill press as well as possible severe injury to the operator.

NEVER START THE DRILL PRESS WITH THE WORK PIECE IN CONTACT WITH

THE DRILL BIT. The sudden start-up of the drill bit could cause it to seize result-

ing in a sudden, rapid spinning motion that could damage the work piece, the

drill press, and/or serious injury to the operator.

8

IMPORTANT SAFETY RULES FOR DRILL PRESSES

READ AND UNDERSTAND ALL INSTRUCTIONS. If there are instructions in this

manual that are not completely understood, seek the advice of a trained professional or contact Alltrade Customer Service at 1-800-590-3723 before attempting to perform the procedures. Failure to follow all instructions listed in this

manual may result in property damage, damage to the tool, or serious personal injury or even death.

DO NOT OPERATE THIS DRILL PRESS until it is completely assembled according to the instructions in this manual. Failure to adhere to these instructions

could result in serious and/or permanent injury to the operator.

FOLLOW ALL WIRING CODES. Use only properly grounded three-hole grounded receptacles. DO NOT cut the third prong off the power cord. When using an

extension cord, use only UL Listed extension cords with minimum 16 AWG

wiring and a maximum length of 25 feet. See ELECTRICAL SAFETY section in

this manual.

MAKE SURE APPROVED EYE PROTECTION IS BEING WORN and properly

adjusted and secured at all times the drill press is in use. Everyday eyeglasses

only have impact resistant lenses and ARE NOT safety glasses. Safety glasses

must conform to ANSI Z87.1 requirements. Approved safety glasses and

goggles will have Z87 printed or stamped on them.

KEEP BYSTANDERS, CHILDREN, AND VISITORS at a safe distance from the

drill press while it is in operation. Distractions can cause inadvertent misuse

resulting in possible injury to the bystanders or to the operator.

WEAR PROPER APPAREL. Do not wear loose clothing, gloves, neckties, rings,

bracelets, or other apparel that could possibly become caught in the moving

parts of the drill press. When working in a shop environment around power

tools, wear nonslip footwear. Use protective hair covering to contain long hair.

KEEP THE WORK AREA CLEAN AT ALL TIMES. Cluttered areas around the drill

press can cause unexpected accidents if the debris comes in contact with the

moving parts of the drill press.

MAINTAIN A PROPER WORK ENVIRONMENT. Do not operate the drill press in

damp or wet locations or expose it to rain. Water can cause the electrical

components to malfunction resulting in damage to the drill press and/or

serious injury or death to the operator.

ALWAYS USE APPROVED TABLE CLAMPS AND VICES to clamp work pieces to

the drill press table to prevent breakage, damage to the drill press, the work

piece, and possible severe injury to the operator. Contact Alltrade Customer

Service at 1-800-590-3723 (toll free) for authorized accessories.

Page 6

SECURE THE ELECTRICAL POWER CORD when the drill press is not in use to

prevent unauthorized use of the tool and/or to prevent children from accidentally turning it on.

ADDITIONAL INFORMATION about the proper use of bench-mounted drill

presses is available from the Power Tool Institute, 1300 Sumner Avenue,

Cleveland, OH 44115-2851 (www.powertoolinstitute.com). Information is also

available from the National Safety Council, 1121 Spring Lake Drive, Itasca, IL

60143-3201. Additionally, you can refer to the American National Standards

Institute (ANSI) 01.1 Safety Requirements for Woodworking Machines and the

U.S. Department of Labor OSHA 1910.213 Regulations.

USE COMMON SENSE WHEN OPERATING THIS DRILL PRESS OR OTHER

POWER TOOLS. Never try to perform drilling operations on work pieces that are

too large to be clamped to the worktable or vises. Keep this manual and refer to it

often to ensure proper operation and prevent unnecessary accidents or injuries.

SYMBOLS

IMPORTANT: Some of the following symbols may be used on your tool. Please

study them and learn their meaning. Proper interpretation of these symbols will

allow you to operate the tool better and safer.

SYMBOL NAME EXPLANATION

V Volts Voltage (Potential)

A Amperes Current

Hz Hertz Frequency (Cycles per Second)

W Watt Power

Kg Kilograms Weight

Alternating Current Type of Current

Direct Current Type of Current

Alternating or Direct Current Type of Current

Earthing Terminal Grounding Terminal

Class II Construction Denotes Double Insulation

min Minutes Time

s Seconds Time

! Diameter Size of Drill Bits,

Grinding Wheels, etc.

No load speed No-load Rotational Speed

.../min Revolutions per Minute Revolutions, Surface Speed,

Strokes, etc. per Minute

1,2,3, … Ring Selector Settings Speed, Torque or Position Settings

9

DISCONNECT THE DRILL PRESS POWER CORD FROM THE AC OUTLET before

making adjustments to the worktable, clamps, vises, work pieces, changing drill

bits, or changing the speed of the drill motor preventing the tool from accidentally turning on. Failure to adhere to this step could result in

damage to both the work piece and the drill press as well as possible severe

injury to the operator.

THOROUGHLY CLEAN THE DRILL PRESS before changing types of work

pieces. Combining wood and metal dust can result in an explosion or fire. CON-

SULT EXPERT advice before drilling in work pieces made of magnesium. The

friction generated by the drill bit could the magnesium to ignite resulting in a

very intense fire that could cause severe burns to the operator and/or

seriously damage the drill press.

NEVER PERFORM DRILLING OPERATIONS NEAR FLAMMABLE GAS OR

LIQUIDS. The resulting fire and/or explosion could cause permanent serious

injuries to the operator and damage to the drill press and surrounding work area.

ALWAYS KEEP ARMS, HANDS, AND FINGERS away from the work piece while

it is on the table and the drill press is turned on. Severe injury could result.

ALWAYS CLAMP THE WORK PIECE FIRMLY AGAINST THE WORK TABLE.

Never attempt to hold the workpiece by hand. The drill bit can seize in the work

piece causing it to spin rapidly. This will cause loss of control of the work piece

resulting in severe injuries or damage to the work piece and drill press.

NEVER APPLY A COOLANT directly to the work piece while it is in contact with

the drill bit. Coolant can weaken the makeup of the drill bits causing them to fail.

NEVER PERFORM LAYOUT OR ASSEMBLY to work pieces in front of the drill

press while it is still running. A sudden slip could bring hands in contact with

the moving parts of the drill press resulting in injury to the operator.

REDUCE THE RISK OF UNINTENTIONAL STARTING. Ensure the “ON/OFF” switch

is set to the “OFF” position before plugging the power cord into the AC outlet.

TURN THE ON/OFF SWITCH on the drill press to the “OFF” position and unplug

the power cord from the electrical receptacle when the drilling operations are

finished. Thoroughly clean the area surrounding the drill press making it ready

for the next use.

NEVER LEAVE THE DRILL PRESS RUNNING UNATTENDED. when finished with

a drilling operation, turn “off” the drill press and wait until it comes to a

complete stop.

Page 7

FUNCTIONAL DESCRIPTION

CONTROLS AND COMPONENTS:

1. Drill Bit

2. Column Assembly

3. Feed Handles

4. Chuck Key

5. Drill Chuck

5. Head Assembly

6. Knob (and mtg Hardware)

7. Work Table

ASSEMBLY

Do not begin assembly of Bench-mounted Drill Press if the AC power cord is

plugged into an AC power receptacle.

Do not begin assembly of Bench-mounted Drill Press if power switch on the

front of the base is switched to the “ON” position.

INSPECTION: Carefully inspect each individual part of the drill press to ensure there

are no cracked, broken, or bent components.

1. Carefully choose a location for the bench-mounted drill press. If mounted on a

workbench, ensure there is adequate room all around the drill press for safe

operation. The area must be level and clear of other power tools and/or power

tool cords that could interfere with operation of the drill press.

2. If the drill press is installed on a universal tool stand (available at larger hardware stores), ensure there is plenty of unobstructed space around the drill

press as not to interfere with safe operation on the tool.

3. Use clamps or a vise to hold workpiece securely in place.

4. The drill press should be installed in a place that is away from outside elements

and close to an approved power receptacle so that an extension cord will not be

needed. Should an extension cord be needed, refer to Page 25 in this manual

for choosing the proper length and wire gauge needed for safe operation of the

drill press.

5. Do not assemble and/or use the drill press in an area that may be contaminated

with oily rags. Keep flammable materials such as gasoline, paint thinner or solvents. Sparks from normal drilling operations can ignite these compounds

resulting in moderate to severe burns to the operator.

1211

8. Table Support Lock

Assembly

9. Work Table Clamp

10. Column Base

11. Grounded Power Cord

12. Hex Wrenches

13. Column Assembly mtg Hardware

3

5

2

1

4

10

7

13

6

8

9

5

11

12

Page 8

Ensure the spindle taper (Q) and the tapered hole in the

drill chuck (R) are clean and free of any grease, lacquer, or rust preventative

coatings. These compounds can cause the drill chuck (R ) to seize when

installed on the spindle shaft (Q).

INSTALLING THE DRILL CHUCK

1. Open the jaws of the drill

chuck (1) as wide as possible

by turning the chuck sleeve (2).

2. Holding the drill chuck (1) on

the tapered end of the spindle

shaft, use a soft tip (rubber)

hammer (3) or a block of wood

and a hammer.

3. Tap the drill chuck (1) onto the

spindle shaft. See Figure 6.

1413

INSTALLING THE COLUMN ASSEMBLY

TO THE BASE

1. Place the base (1) on a firm level surface.

2. Secure the column assembly (2) to the base (A)

using the three hex-head screws (3) provided.

See Figure 2.

INSTALLING THE DRILL PRESS

HEAD

1. Place the drill press head (1) onto

the column assembly (2). Press

the drill press head (1) downward

on the column assembly (2) as far

as it will go.

2. Align the drill press head (1) with

the worktable (3) and the base.

3. Tighten the two head locking

screws (4) as shown in Figure 4,

with the hex-wrench (5) supplied.

INSTALLING THE WORK TABLE

1. Slide the worktable (1) and table clamp

bracket (2) onto the column assembly (3).

2. Install the support lock handle (4) into the

clamp bracket (2).

3. Position the worktable to the desired height

and tighten the support lock handle (4).

1

2

3

2

3

FIGURE 2.

ATTACHING THE COLUMN

ASSEMBLY

FIGURE 3.

INSTALLING THE WORK TABLE

INSTALLING HANDLES

1. Insert the three drill press feed handles (2) into the tapped holes on the

pinion shaft (1). See Figure 5.

2. Using a Phillips screwdriver, insert

screw (4) into knob (3) and install it

on the drill press cover.

1

2

3

1

2

5

FIGURE 4.

INSTALLING THE DRILL PRESS

AND MOTOR

FIGURE 5.

INSTALLING HANDLES

4

2

3

4

1

2

1

3

FIGURE 6.

INSTALLING THE DRILL CHUCK

Page 9

LASER GUIDE

Use of controls or procedures, or performance of procedures other then those specified herein may result in hazardous radiation

exposure.

LASER SAFETY

NEVER LOOK INTO THE LASER BEAM. Any contact with the eyes by the beam

could cause injury. Do not use the laser when cutting reflective materials.

DO NOT AIM THE LASER BEAM AT ANYONE OR AT REFLECTIVE SURFACES.

CLASS 2M LASER PRODUCT. Any contact with the eyes by the beam could

cause injury. Ensure the laser beam is turned on only when the tool is on a nonreflective workpiece and as such it is aimed only at the work surface. Metals and

other materials like steel which can be highly reflective should only be cut without the use of the laser.

To avoid damage to the drill chuck and the spindle shaft,

do not drive the chuck onto the spindle shaft with a metal hammer. Damage

to the Drill Chuck will occur.

REMOVING AND INSTALLING DRILL BITS

Disconnect drill press from AC power source and ensure

the “ON/OFF” switch is in the “OFF” position. Failure to adhere to this warning could cause severe, permanent injury to the operator.

Use only the chuck key provided by the manufacturer

with the drill press.

1. Use the chuck key (1) to

loosen the drill chuck (2).

See Figure 7.

2. Insert the smooth end of

the drill bit (3) into the drill

chuck (2) as far as it will

go.

3. Back the drill bit (3) out

approximately 1/16" or up

to the flutes for smaller

bits.

4. Ensure the drill bit (3) is

centered in the drill chuck

jaws before tightening.

5. Use the chuck key (1) and

tighten the drill chuck (2)

locking the drill bit (3) in place.

IMPORTANT: Lock all three jaws in the drill chuck bit to ensure proper tightening and

so it doesn’t slip while drilling.

6. Ensure the check key (1) is removed from the drill chuck BEFORE applying

power to the drill press.

7. The chuck key is equipped with a self-ejecting pin (4) that helps minimize the

hazard of the key being inadvertently left in the drill chuck.

15

MOUNTING THE DRILL PRESS

During operation of the drill press,

there may be instances where the tool

could tip over, slide, or walk on the

supporting surface. To secure the drill

press:

1. Place the drill press (1) on the

workbench (2) as desired.

2. Secure the drill press (1) to the

workbench (2) using two carriage

bolts (3), flat washers (4), and

nuts (5) through the holes in the

drill press base. See Figure 8.

2

1

3

4

5

FIGURE 8.

MOUNTING THE DRILL PRESS

3

1

3

2

4

FIGURE 7.

INSTALLING DRILL BITS

Page 10

17 18

STORE OUT OF REACH OF CHILDREN. Equipment should be in a high location

or locked up to keep out of reach of children. It is not a toy.

DO NOT TAMPER WITH THE LASER OUTPUT. Changing the performance of the

laser to increase its output is prohibited. Any claim for damages or injuries

resulting from not following these instructions will be refused.

OPERATION ACCESSIBLE FIELDS:

Wavelength 636-660nm

Laser Power for Classification <1mW CW

NEVER OPERATE LASER IF THE UNIT IS DEFECTIVE OR THE COVER OR SEAL

IS DAMAGED.

DO NOT SERVICE LASER. The laser unit must be returned to the factory for any

service or repair. Service or repair must be handled by authorized factory

trained technicians.

Do not open the laser unit except to change batteries.

REMOVE BATTERIES IF THE LEVEL IS TO BE STORED FOR ANY LENGTH OF

TIME. Batteries may leak and damage the laser if it is stored idle for more than

3 months.

Be careful with this tool. Striking or jarring it, especially on the laser housing,

can affect its accuracy.

Other than batteries, there are no user-serviceable parts in the laser device.

OPERATING THE LASER

Do not stare directly into the Laser beam, aperture or

into a reflection from a mirror-like surface.

The laser runs on two AAA batteries which are located beneath the “ON/OFF” switch.

When the laser light begins to dim, change both batteries. NEVER mix old batteries

with new.

TO CHANGE LASER BATTERIES:

1. Turn off the laser.

2. Press the tab (1) located below the laser

switch (2) and lift up the laser switch

cover.

3. Insert two “AAA” batteries in the laser

battery compartment (3).

4. Close the laser switch cover.

USING THE LASER LIGHT:

1. Place the workpiece on the table.

2. Turn the laser switch to the ON position.

3. Lower the drill bit to meet the workpiece. The two laser lines should cross

where the drill meets the workpiece.

4. If the drill needs to be adjusted:

• Using a 3mm hex key, turn the laser

adjustment set keys counter-clockwise.

• Rotate the laser light housing until

the two laser lines intersect where

the drill meets the workpiece. DO

NOT stare directly at the laser lines.

5. Re-tighten the adjustment set screws.

1

(ON/OFF SWITCH)

(LASER APERTURES)

3

2

FIGURE 9.

INSTALLING LASER BATTERIES

CAUTION LABEL

CAUTION LABEL

LASER RADIATION

CAUTION LABEL

FIGURE 10. USING THE LASER LIGHT

SER LIGHT

LA

Y WITH OPTICAL

IRECTL

T VIEW D

DO NO

CLASSIFIEDS

AV

O

LAS

E

MITTE

D

FR

INSTR

CLASS 2M

635-66

ID

EX

P

ER

LIGH

O

M TH

NTS (MA

UME

LASER PR

0nm, <1mW

IEC 60825-1, Ed.

PER

O

S

U

R

E -

T IS

IS APE

R

TU

)

NIFIERS

G

T

ODUC

CW

.2, 2001-08

1

R

E

.

”

A

V

O

I

D

E

X

P

O

S

U

R

E

C

A

U

T

I

O

N

L

A

S

E

R

R

A

D

I

A

T

I

O

N

A

V

O

I

D

E

X

P

O

S

U

R

E

C

A

U

T

I

O

N

L

A

S

E

R

R

A

D

I

A

T

I

O

N

A

V

O

I

D

E

X

P

O

S

U

R

E

C

A

U

T

I

O

N

L

A

S

E

R

R

A

D

I

A

T

I

O

N

Page 11

Ensure that the switch toggle, when removed, is kept in

a secure place. Once removed, the drill press will not start without it.

ADJUSTING THE WORK TABLE

1. The worktable (1) can be raised or lowered on the drill press column (2) by

loosening the table clamp (3). See

Figure 12.

2. After the table is positioned at the

desire height, LOCK the table in place

by tightening the table clamp (3). NOTE:

Final positioning of the table should

always be made from the bottom to the

up position.

3. The worktable (1) can be rotated 360

degrees around the column (2) by loosening the table clamp (3). Rotate the

table to the desired position and LOCK

the table in place by tightening the table

clamp (3). See Figure 12.

2019

OPERATING THE DRILL PRESS

The drill press is designed to use drill bits with a shank of 1/2" or less. The following will give the inexperienced operator practice with common drilling operations.

Always use scrap material and do test procedures before working on the actual

workpiece. These test runs will decrease as experience and confidence with the drill

press increase.

When the workpiece is long enough, place it on the

worktable so that one end rests against the drill press column. This is

usually the left side as you look to the rear of the drill press. In case the drill

bit seizes in the workpiece, the drill press support will prevent the workpiece

from spinning out of control. FAILURE to adhere to this step could result in

possible severe injury to the operator.

OPERATING THE ON/OFF SWITCH

The drill press “ON/OFF” switch is located on the front of the drill press head. To

turn the drill press “ON,” move the rocker-style switch up to the “ON” position. To

turn the drill press “OFF,” move the rocker-style switch down to the “OFF” position.

Ensure the “ON/OFF” switch is in the “OFF” position

before plugging the power cord into the AC power source. Ensure there are

no tools or work pieces in contact with the drill bits, cutting tools, or sanding drum when the drill press is turned “ON.” Failure to observe these procedures could result in damage to the drill press, tools, work pieces, and/or

serious personal injury to the operator or bystanders.

LOCKING THE “ON/OFF” SWITCH IN THE “OFF” POSITION

1

FIGURE 11.

LOCKING THE “ON/OFF” SWITCH

1

2

3

FIGURE 12. ADJUSTING THE WORK TABLE

2

Anytime the drill press is not being

used, the “ON/OFF” should be

locked to prevent any unauthorized use.

1. To LOCK the “ON/OFF” switch,

grasp the switch toggle (1) and

remove it from the “ON/OFF”

switch (2). See Figure 11.

Page 12

1. Lift up the pulley cover (1).

2. Release the belt tension by loosening the tension lock knob (2) located

on the side of the drill press head.

Loosen the tension lock knob (2) by

turning it counterclockwise.

3. Pivot the motor (3) towards the

front of the drill press.

4. While holding the motor pivoted to

the front of the drill press, position

the belt (4) on the desired step of

the motor pulley (5) and the spindle

pulley (6). See Figure 14.

5. After attaining the desired spindle

speed, pivot the motor (3) to the

rear of the drill press and securely

tighten the tension lock knob (2) by

turning it clockwise.

6. The belt (4) should be tight enough

to prevent any slippage. If the belt is

overtightened, the life of the belt will

be noticeably reduced.

7. Close the pulley cover (1).

DRILLING HOLES TO SPECIFIED DEPTHS

Disconnect drill press from AC power source and ensure

the “ON/OFF” switch is in the “OFF” position. Failure to adhere to this warning could cause severe, permanent injury to the operator.

A depth stop (1) is provided on the pinion shaft, allowing multiple holes to be

drilled to a specific depth. See Figure 15.

2221

TILTING THE WORKTABLE

ADJUSTING THE DRILL PRESS SPINDLE SPEED

A spindle speed and pulley/belt arrangement chart is posted inside the pulley cover.

See the chart below. Refer to this chart whenever spindle speeds need to be

changed.

Disconnect drill press from AC power source and ensure

the “on/off” switch is in the “OFF” position. Failure to adhere to this warning could cause severe, permanent injury to the operator.

1

5

4

6

2

3

FIGURE 14.

ADJUSTING DRILL PRESS SPEED

3

2

1

4

FIGURE 13.

TILTING THE WORK TABLE

1. The worktable (1) can be tilted to the left

or right by loosening the pivot bolt (4)

mounted beneath the worktable. See

Figure 13.

2. Tilt the worktable (1) to the desired position and tighten the pivot bolt (4).

3. When returning the table to the level

position, line up the register mark on the

table with the tilt scale. This ensures the

table surface is positioned 90 degrees to

the spindle.

4. A tilt scale (K) is provided on the table

bracket casting (L) to indicate the degree

of tilt.

5. A witness line and zero mark (1) are provided on the table to ensure proper

alignment with the tilt scale (2).

620 1100

1720

2340 3100

Page 13

3. Turn the spring housing (5) counterclockwise to increase the spring tension or clockwise to decrease the

spring tension.

4. Turn nut (4 - inside) until it contacts

the spring housing (5). Back nut (4)

out 1/4 turn and tighten it against

nut (3 - outside) to hold the spring

housing in place.

5. IMPORTANT: The inside nut (4)

should not touch the spring housing

(5) after it has been tightened.

CORRECT DRILLING SPEEDS

The correct drilling speed is determined by type of material being drilled, the size of

the hole, the type of the drill bit or cutter, and the desired quality of the hole.

Always use the recommended speed for the drill bit and

for the type of materials the workpiece is made of. If you have any questions

as to the proper speeds or types of materials, contact Alltrade customer

service at 1-800-590-3723.

WORKING WITH WOOD

Twist drills, although designed for drilling metal, can also be use for drilling wood.

However, it is recommended that machine spur bits or wood-boring bits be used for

wood projects. These bits cut a flat bottom hole and are designed to remove to easily remove wood chips. DO NOT USE hand bits designed for a hand-operated drill

brace. These bits have screw tips and at the speeds used by the drill press, they

would rapidly engage the workpiece and spin it around violently.

For through boring, line up the spot where the hole is to drilled with the hole in the

worktable. This permits the drill bit to pass cleanly through the workpiece without

damaging the worktable. Scribe a vertical line on the front of the column and matching marks on the table bracket and the drill press head so that the table and drill

press can be clamped in the center position at any height.

To prevent splintering on the bottom of the workpiece, clamp a scrap piece of wood

beneath the workpiece and allow the drill bit to enter it resulting in a clean hole on

the workpiece. This also protects the point of the drill bit.

23

1. Insert drill bit (2) into drill chuck.

2. Lower the spindle (3) until the pointer

(4) is in line with the mark on the

scale (5).

3. Tighten the lock screw (6).

4. Return the spindle (3) to the up position.

5. Place the workpiece on the drill press

table and securely clamp it in place.

6. Raise the drill press table until the

workpiece just touches the end of the

drill bit (2).

7. Drill a test hole and check the depth.

Make any adjustments as necessary.

ADJUSTING THE SPINDLE RETURN SPRING

Disconnect drill press from AC power source and ensure

the “ON/OFF” switch is in the “OFF” position. Failure to adhere to this warning could cause severe, permanent injury to the operator.

The spindle return spring (1) is automatically returned to its upper position when

the pinion shaft handles (2) are released. It is recommended that the pinion shaft

handles (B) be allowed to return to the upper position slowly. DO NOT LET GO OF

THE HANDLES after the hole has been drilled. This action will cause excessive wear

and tear on spindle return spring. To adjust the spindle return spring, See Figure 15

and follow the steps below:

1. Loosen the two nuts (3 and 4). Ensure the housing stays engaged with the

head casting.

2. While firmly holding the spring housing (5), pull out the housing until the boss

is engaged with the next notch on the housing.

1

5

2

3

4

FIGURE 16.

ADJUSTING SPINDLE

RETURN SPRING

FIGURE 15.

DRILLING HOLES TO SPECIFIED DEPTHS

6

1

4

5

3

2

Page 14

Always attach grounded (3-prong) extension cords to grounded (3-hole) outlets.

If the drill press must be used outside, use an extension cord labeled “W-A” or “W.”

These extension cords are rated for outdoor use and reduce the chances of electrical shock.

If you must use an extension cord, be sure that the gauge is large enough to carry

the amount of current necessary for your power tool. If not, your tool may experi-

ence a loss of power, excessive voltage drop or overheating. The smaller the gauge

number, the heavier the cord (see table below).

RECOMMENDED SIZES OF EXTENSION CORDS 120 VOLT AC 60 HZ TOOLS

TOOL CURRENT RATING CONDUCTOR SIZE IN A.W.G

AMPERE 10FT. 25FT. 50FT. 100FT.

3-6 18 18 18 18

6-8 18 18 18 16

8-10 18 18 18 14

10-12 16 16 14 14

12-16 14 12 12 16-20 12 12 12 -

SPECIFICATIONS

SPECIFICATIONS

Voltage 120V 60 Hz

Rated Current 1.8 A

No-Load Speed (motor) 1700 RPM

Max. Distance

From Spindle Axis

To Surface Of Column: 4 1/8" (105mm)

Max. Distance

From Spindle End

To Surface Of Table: 7" (178mm)

Distance:

Spindle axis to column 4.0" (102mm)

Spindle Travel: 2" (51mm)

Chuck Capacity 1/2" (13mm)

Range of Spindle Speeds

(60Hz) 620-3100 RPM

Laser Beam Class II, Diode Laser

Laser Beam Maximum

Power 1mw

Laser Beam Wavelength 650nm

26

DRILLING METAL

Always use clamps or a vise when drilling metal. The

workpiece should never be held in place by hand.

The drill bit could seize in the metal at any time, especially when breaking through

the backside of the workpiece. This could cause the workpiece to spin out of the

operator’s hand. The drill bit will be broken when the workpiece strikes the column.

Failure to observe this precaution could result in damage to the workpiece, the drill

press, and severe or permanent injury to the operator.

CONSULT EXPERT ADVICE BEFORE DRILLING IN WORK PIECES MADE OF MAGNESIUM. The friction generated by the drill bit could cause the magnesium to ignite

resulting in a very intense fire that could cause severe burns to the operator and/or

seriously damage the drill press.

The workpiece must be clamped firmly while drilling. Tilting, twisting, or shifting not

only results in a rough-drilled hole, but increases the risk of breaking the drill bit.

For flat work, place the workpiece on a piece of scrap wood and clamp tightly to the

worktable to prevent it from turning. If the shape of the workpiece is irregular and

cannot be placed flat on the table, it should be securely blocked and clamped before

attempting to use the drill press.

MAINTENANCE AND CLEANING

LASER MAINTENANCE

For the best laser performance, perform the following maintenance regularly:

1. Disconnect machine from power source.

2. Carefully clean sawdust from each laser lens. Do not use solvents of any kind

since they may damage the lens. Dust build-up can block the laser and prevent

it from accurately indicating the line of drilling.

ACCESSORIES

Optional accessories for the drill press can include wire-brush wheels that can be

used for cleaning and layered cloth wheels that can be used for polishing and buffing. Contact ALLTRADE Customer Service at 1-800-590-3723 (toll free) to find out

what accessories are available for the drill press.

Only use accessories that are designed to fit your particular drill press. These accessories should be specifically labeled to match

the speed and arbor size of the drill. Failure to use the proper accessories

could result in property damage, damage to the grinder, and serious personal injury to the operator.

Page 15

Warranty Performance

By purchasing the product, purchaser expressly acknowledges and agrees that their

sole and exclusive remedy under this warranty shall be strictly limited to the repair

or replacement of any covered nonconforming items or parts thereof provided that

any such nonconforming item and/or part is promptly returned to Alltrade’s facility

postage pre-paid and insured (address: ALLTRADE Warranty Claims & Repair,

1431 Via Plata, Long Beach, CA 90810, Attn: Customer Service #1-800-590-3723)

within the applicable warranty period, with a written request by purchaser that

Alltrade repair and/or replace the nonconforming item and/or part. We recommend

that you keep the original product packaging in the event you need to ship the unit.

We suggest the package be insured against loss or in transit damage. When

sending your product include your name, address, phone number, dated proof

of purchase (or copy), and a statement about the nature of problem. Warranty

coverage is conditioned upon purchaser furnishing Alltrade with adequate written

proof that they are the original purchaser and of the original purchase date. Parts

returned, freight prepaid and insured, to Alltrade’s facility (see above address) will

be inspected and, at Alltrade’s option, repaired and/or replaced free of charge if

found to be defective and subject to warranty. Alltrade retains the sole discretion

to determine whether any item or part is nonconforming and, if so, whether the

item and/or part will be repaired and/or replaced. If the unit is repaired, new or

reconditioned replacement parts may be used. If Alltrade chooses to replace

the product, it may replace it with a new or reconditioned one of the same or

comparable design. The repaired or replaced unit will be warranted under the terms

of the remainder of the warranty period. Typically, a defective product that is

returned within the first 30 days after the purchase date will be replaced; for items

returned after the first 30 days and within the warranty period, covered defective

parts not subject to normal wear and tear or other exclusions will be repaired or

replaced, at Alltrade’s option. During the warranty period, Alltrade will be responsible for the return shipping charges. Alltrade’s repair and/or replacement of any nonconforming item and/or part thereof shall constitute fulfillment of all

obligations to the purchaser. Alltrade shall not be responsible or liable for any

expense, including freight charges, or repairs made outside Alltrade’s facility, unless

expressly agreed to by Alltrade in writing. Under no circumstances shall Alltrade

bear any responsibility for loss of the unit, loss of time or rental, inconvenience,

commercial loss or consequential damages.

Exclusions

This warranty does not cover parts damaged due to normal wear, abnormal

conditions, misapplication, misuse, abuse, accidents, operation at other than

recommended pressures or temperatures, improper storage or freight damage.

Parts damaged or worn by operation in dusty environments are not warranted.

Failure to follow recommended operating and maintenance procedures also

voids warranty.

28

OTHER CONSUMER DO-IT-YOURSELF (DIY) TOOLS

Alltrade offers a full range of Kawasaki™ tools that make DIY jobs easy. If you would

like further information on the following products, please contact Alltrade Customer

Service Department at 1-800-590-3723.

Cordless Drills/Screwdrivers

Impact Wrenches

Sanders

Jigsaws

Circular Saws

Angle Grinders

Reciprocating Saws

Routers

Rotary Tools

Corded and Cordless Multi-Purpose Tools

Wide Range of Accessories and more

2 YEAR LIMITED HOME USE WARRANTY

Express and Exclusive Limited Home Use Warranty to Original Retail Buyer

Alltrade Tools LLC (hereinafter "Alltrade") expressly warrants to the original retail

purchaser of the accompanying KAWASAKI™ portable power tool and no one else

all parts of the product (except those parts referred to below which are specifically

excluded from such warranty (see Exclusions)) to be free from defects in materials

and workmanship for a period of two years from original date of purchase.

SPECIAL WARRANTY NOTE TO CONTRACTORS AND COMMERCIAL USERS: This

Kawasaki™ portable power tool is offered as a home use tool and carries a HOME

USE WARRANTY. This tool is made for home use in the execution of

projects and repairs in and around the home. Use of the tool for COMMERCIAL

PURPOSES OR ON A JOBSITE is not covered under this warranty.

The date of purchase shall be the date of shipment to the original purchaser, or the

date the original purchaser took possession, custody or control of the product,

whichever occurred first. This warranty shall be null and void if the product or any

component thereof is modified, altered or used for any commercial purpose or on

a jobsite. This warranty does not apply to any other product and/or component

thereof manufactured or distributed by Alltrade, and does not apply to products

and/or components thereof designed, manufactured and/or assembled by others,

for which Alltrade makes no warranties whatsoever. THERE ARE NO WARRANTIES

WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF.

27

Page 16

ALLTRADE AND/OR ITS REPRESENTATIVE(S), OR THE PURCHASER, INCLUDING

BUT NOT LIMITED TO THE IMPLIED WARRANTY OF MERCHANTABILITY AND THE

WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE, ARE HEREBY EXPRESSLY

EXCLUDED AND DISCLAIMED BY ALLTRADE AND/OR ITS REPRESENTATIVES.

PURCHASER KNOWINGLY AND WILLINGLY WAIVES ANY AND ALL SUCH

WARRANTIES AND RIGHTS, CLAIMS AND/OR CAUSES OF ACTION ARISING

THEREFROM OR BASED THEREON. PURCHASER’S SOLE AND EXCLUSIVE

REMEDY IS AS STATED ABOVE.

Limitation Of Liability

IN NO EVENT SHALL ALLTRADE AND/OR ITS REPRESENTATIVE(S) BE LIABLE FOR

INDIRECT, INCIDENTAL, SPECIAL AND/OR CONSEQUENTIAL DAMAGES OF ANY

KIND ARISING OUT OF OR RELATED TO, DIRECTLY OR INDIRECTLY, ANY BREACH

OF ANY PROVISION OF ANY AGREEMENT BETWEEN ALLTRADE AND/OR ITS

REPRESENTATIVE(S) AND PURCHASER, ANY WARRANTY HEREUNDER,

AND/OR THE EXISTENCE, DESIGN, MANUFACTURE, PURCHASE, USE AND/OR

OPERATION OF ANY ITEM(S) SOLD HEREUNDER EVEN IF ALLTRADE AND/OR ITS

REPRESENTATIVE(S) HAS BEEN ADVISED OF THE POSSIBILITY OF ANY SUCH

DAMAGES. IN NO EVENT, WHETHER AS A RESULT OF A BREACH OF CONTRACT,

WARRANTY, TORT (INCLUDING NEGLIGENCE) OR OTHERWISE, SHALL

ALLTRADE’S AND/OR ITS REPRESENTATIVE(S)’ LIABILITY EXCEED THE PRICE OF

THE PRODUCT. ANY AND ALL LIABILITY CONNECTED WITH THE USE OF

THIS PRODUCT SHALL TERMINATE UPON THE EXPIRATION OF THE WARRANTY

PERIODS SPECIFIED ABOVE.

Limitations on Warranty Disclaimers

Some states do not allow limitations on how long an implied warranty lasts

and some states do not allow the exclusion or limitation of the incidental or

consequential damages, so part or all of the above limitations or exclusions may not

apply to you. This warranty gives you specific legal rights, and you may also have

other rights which vary from state to state.

If your product is not covered by this warranty, please call our Customer Service

Department toll free at 1-800-590-3723 for general repair information and charges.

30

This limited warranty does not apply to accessory items such as drill bits,

screwdriving bits, circular saw blades, jigsaw blades, grinding wheels, sanding

sheets and other related items.

DAMAGE TO THE PRODUCT RESULTING FROM TAMPERING, ACCIDENT, ABUSE,

NEGLIGENCE, FAILURE TO FOLLOW INSTRUCTIONS, UNAUTHORIZED REPAIRS

OR ALTERATIONS, DAMAGE WHILE IN TRANSIT TO OUR SERVICE FACILITY,

USE OF UNAPPROVED OR IMPROPER ATTACHMENTS OR ACCESSORIES,

COMMERCIAL AND RENTAL APPLICATIONS OR OTHER CAUSES UNRELATED TO

PROBLEMS WITH MATERIAL OR WORKMANSHIP ARE NOT COVERED BY THIS

WARRANTY.

Alltrade will not be liable for the following: labor charges, loss or damage resulting

from improper operation, maintenance or repairs made by other persons;

pre-delivery services such as assembly, oil or lubricants, and adjustment;

maintenance services that are normally required to maintain the product.

The use of other than genuine Alltrade Repair Parts will void warranty.

Warranty Disclaimers

EXCLUSION AND DISCLAIMER OF ALL OTHER EXPRESS WARRANTIES,

GUARANTIES AND/OR REPRESENTATIONS. EXCEPT FOR THE LIMITED WARRANTY

PROVIDED ABOVE, ALL OTHER EXPRESS WARRANTIES, GUARANTIES AND/OR

REPRESENTATIONS BY ALLTRADE AND/OR ITS REPRESENTATIVE(S) REGARDING

THE DESIGN, MANUFACTURE, PURCHASE, USE AND/OR OPERATION OF THE

PRODUCT OR ANY COMPONENT THEREOF SOLD HEREUNDER, REGARDLESS OF

WHETHER ANY SUCH WARRANTY, GUARANTY AND/OR REPRESENTATION,

WRITTEN OR ORAL, ARISES BY OPERATION OF LAW AND/OR EQUITY AND/OR BY

ANY ACT OR OMISSION OF ALLTRADE AND/OR ITS REPRESENTATIVE(S), OR THE

BUYER, ARE HEREBY EXPRESSLY EXCLUDED AND DISCLAIMED BY ALLTRADE

AND/OR ITS REPRESENTATIVES. PURCHASER KNOWINGLY AND WILLINGLY

WAIVES ANY AND ALL SUCH WARRANTIES AND RIGHTS, CLAIMS AND/OR

CAUSES OF ACTION ARISING THEREFROM OR BASED THEREON. PURCHASER’S

SOLE AND EXCLUSIVE REMEDY IS AS STATED ABOVE.

EXCLUSION AND DISCLAIMER OF ALL IMPLIED WARRANTIES, INCLUDING THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. NO WARRANTY, ORAL OR WRITTEN, OTHER THAN THE ABOVE

WARRANTY IS MADE WITH REGARD TO THIS PRODUCT. ALL EXPRESS AND/OR

IMPLIED WARRANTIES, GUARANTIES AND/OR REPRESENTATIONS BY ALLTRADE

AND/OR ITS REPRESENTATIVE(S) REGARDING THE DESIGN, MANUFACTURE,

PURCHASE, USE AND/OR OPERATION OF THE PRODUCT OR ANY COMPONENT

THEREOF SOLD HEREUNDER, REGARDLESS OF WHETHER ANY SUCH WARRANTY,

GUARANTY AND/OR REPRESENTATION, WRITTEN OR ORAL, ARISES BY

OPERATION OF LAW AND/OR EQUITY AND/OR BY ANY ACT OR OMISSION OF

29

Loading...

Loading...