Page 1

Page 2

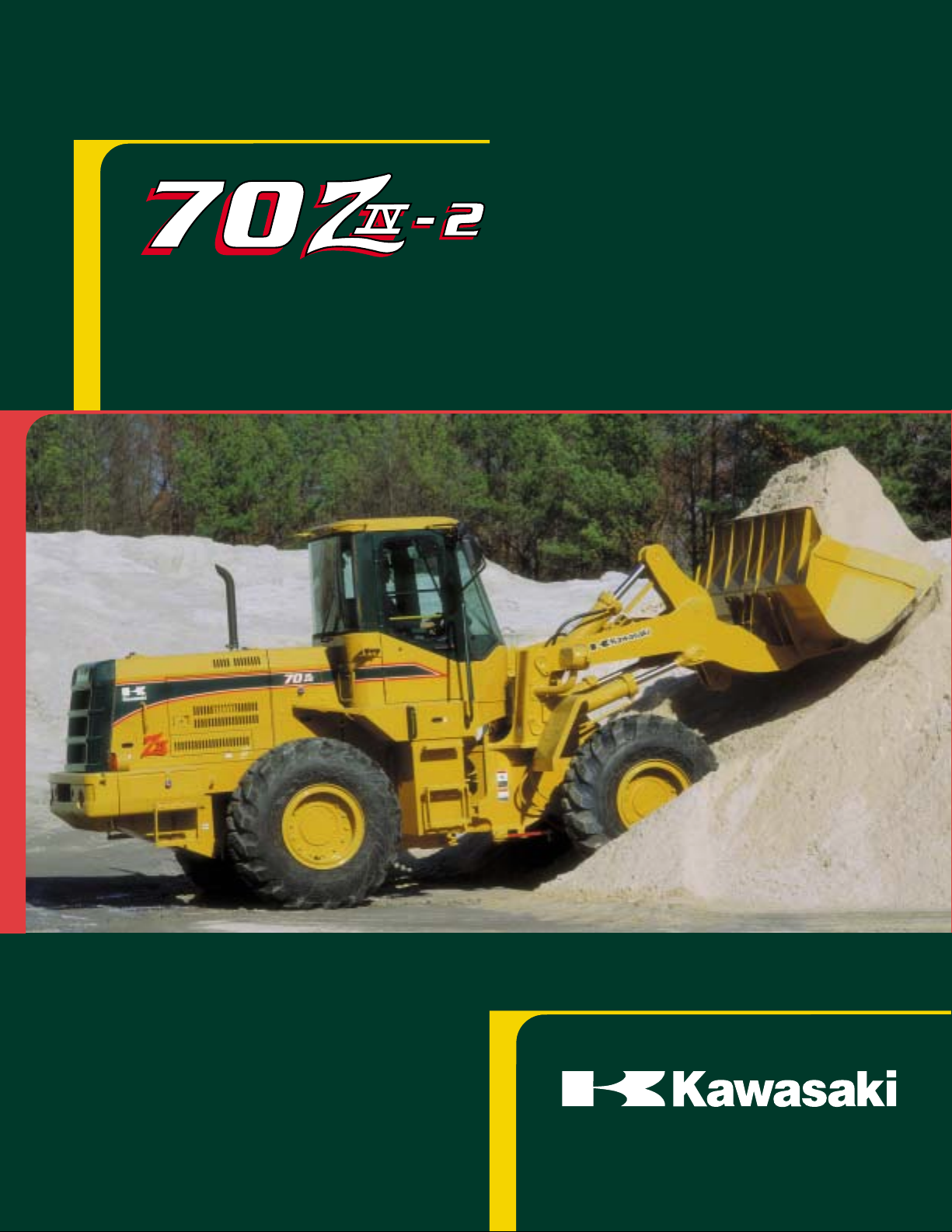

THE POWER TO PERFORM!

The 4 loader is a versatile, high productivity

wheel loader for a wide range of applications from

asphalt and concrete plants to road construction.

Featuring a Cummins B5.9C diesel engine producing

160 flywheel horsepower, a 3.25

cu. yard bucket, a certified ROPS

cab and a host of other features

that provide high operating efficiency,

ease of maintenance and safety,

the 4 is always ready for

the heavy duty jobs.

OPERATOR PRODUCTIVITY

AND SAFETY

The 4 features a completely redesigned

ROPS cab with an operator’s compartment that offers

unmatched comfort and is designed to maximize

efficiency and productivity. The cab is accessible by

ladders on both sides, features a wrap-around tinted

windshield, has front and rear wipers and includes

many other features which contribute to improved

safety, visibility and comfort. The 4 comes

standard with an AM/FM cassette player and can

even be ordered with an optional 25,000 BTU

air conditioner.

THE RUGGED, DEPENDABLE

A COMPLETE

SOLUTION

• Emissions-compliant

160 HP Cummins

diesel

• 3.25 cu. yard bucket

standard

• Accepts a wide assortment of attachments

to handle many jobs

• Redesigned ROPS cab

optimizes productivity

and visibility

• Ride Control option

provides stable

load handling

• Single hydraulic

control option for

easy operation

• Automatic powershift

transmission with

four forward and

reverse speeds

• Outboard-mounted,

four-wheel, dual circuit

sealed wet disc brakes

for reliability and long

service life

• Torque-proportioning

differentials for longer

brake and tire life

• Heavy duty threepiece tire rims for

easy servicing

• Easy access to drains,

filters and fittings

The 4 provides solutions to all your

wheel loader needs from material handling

to road building.

Page 3

PUTTING THE 4 TO WORK

Like all Kawasaki loaders, the 4 has a 35-year

heritage of strength and reliability. Dual lever hydraulic

control with a single lever option and single twist-grip

transmission control offer ease of operation.

The 4 comes equipped with a 3.25 cubic yard

bucket with a bolt-on cutting edge. A third spool valve,

control lever, linkage and line are available to handle

a number of attachments and extend the 4’s

versatility. Other buckets, Quick Couplers and

attachments are also available.

The outboard-mounted, four-wheel sealed wet disk

brakes are designed for long life and easy access and

overhaul. Standard spin-on filters, remote mounted

grease fittings and oil drain simplify maintenance.

The standard 20.5 x 25-12PR (L2) tires and optional

23.5 x 25-12PR (L3) tires use heavy duty three-piece

rims for easy servicing in the field.

UNMATCHED

SUPPORT

Kawasaki maintains

a large inventory of

new components to

ensure outstanding

parts availability and

minimal downtime. In

addition, a predictive

oil analysis program

helps eliminate unnecessary maintenance and helps

find problems before they occur. Kawasaki also stocks

an array of cost-effective rebuilt components.

BUILT TO STAY ON THE JOB

Kawasaki loaders are designed with the durability to

provide years of service. Backed by a dealer network

of heavy equipment experts and a dedicated support

staff in the Kawasaki parts and service organization,

your investment in a Kawasaki loader is an excellent

choice that will pay dividends for years to come.

Kawasaki and their dealer organization

offer comprehensive support and service

programs designed to keep you on the job.

Page 4

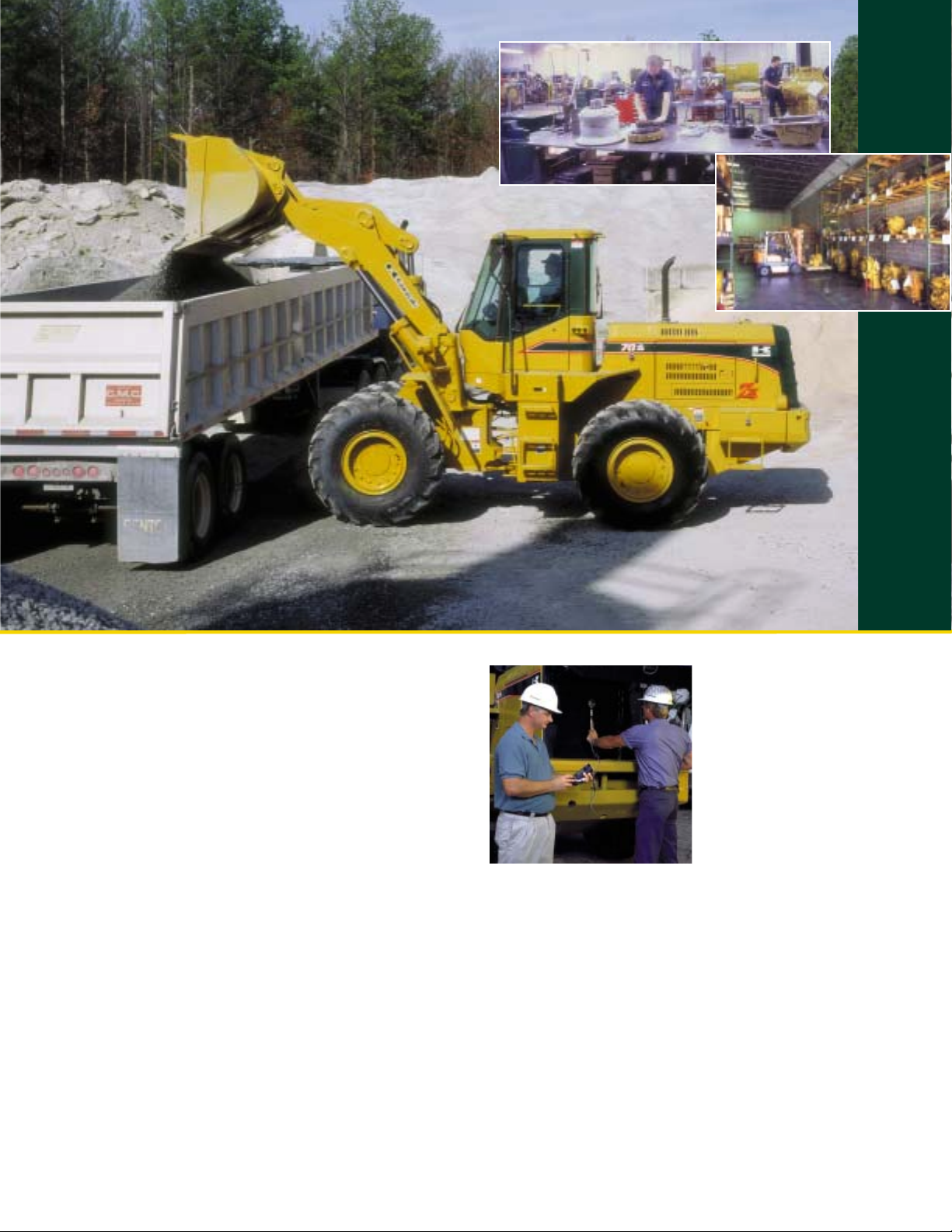

WORLD-CLASS ENGINES

• 160 HP emissions-compliant

Cummins B5.9C diesel

• Complies with tough new emissions

standards for 2001

• Totally reengineered for longer

service life

• Reliable and fuel efficient

• Extensive distribution system

• 24 volt battery system for

reserve power

HIGH EFFICIENCY

HYDRAULIC SYSTEM

• Dry, reliable

• Cast iron gear pump

• Energy efficient, steering circuit

supplements main

• Easy access to two-spool

control valve

• Large oil reservoir keeps oil cooler

POWER AND PERFORMANCE

UNMATCHED PRODUCTIVITY

The Kawasaki 4 means

business. It incorporates the best

in design and technology, giving

your operators the tool they need

to get the job done.

Because Kawasaki specializes

in the design and manufacture of

articulated wheel loaders, you get

a machine with a 35-year heritage

of successful innovations. The

power and productivity that the

4 brings to the job is a

result of that experience.

Steering

Control

Valve

Surplus Flow

PUMPPUMP

TRANSMISSION

• Automatic four-speed transmission

with powershift

• Single lever control

• Left brake pedal activates

transmission declutch switch

• Downshift button speeds cycle times

and reduces operator fatigue

Page 5

AXLES/BRAKES

• Heavy-duty torque proportioning

differential

• 20.5 x 25-12PR (L-2) tires standard

• 20.5 x 25-12PR (L-3)

23.5 x 25-12PR (L-3 and radial)

tires available

• 3-piece rims standard

• Outboard-mounted,four-wheel,

dual-circuit wet disc brakes

• Easy maintenance

• High capacity

• Long life

LIFT ARMS/BUCKETS

• Z-linkage

• High breakout force

• Optional high lift arms available

• 3.25 cu. yard bucket standard

• Easy loading

• Excellent load retention

• Full assortment of edges and teeth

• Complete array of attachments

available

• Heel plates extend bucket life

• Bucket leveler and boom kick-out

standard

PROVIDE

STRONG, RUGGED

BOX FRAME

• Massive center pins and bearings

• High strength loader tower

• Heavy box frame rear chassis

• All pins of the loading system are

fully sealed with grease to provide

dependable service with minimum

maintenance

Page 6

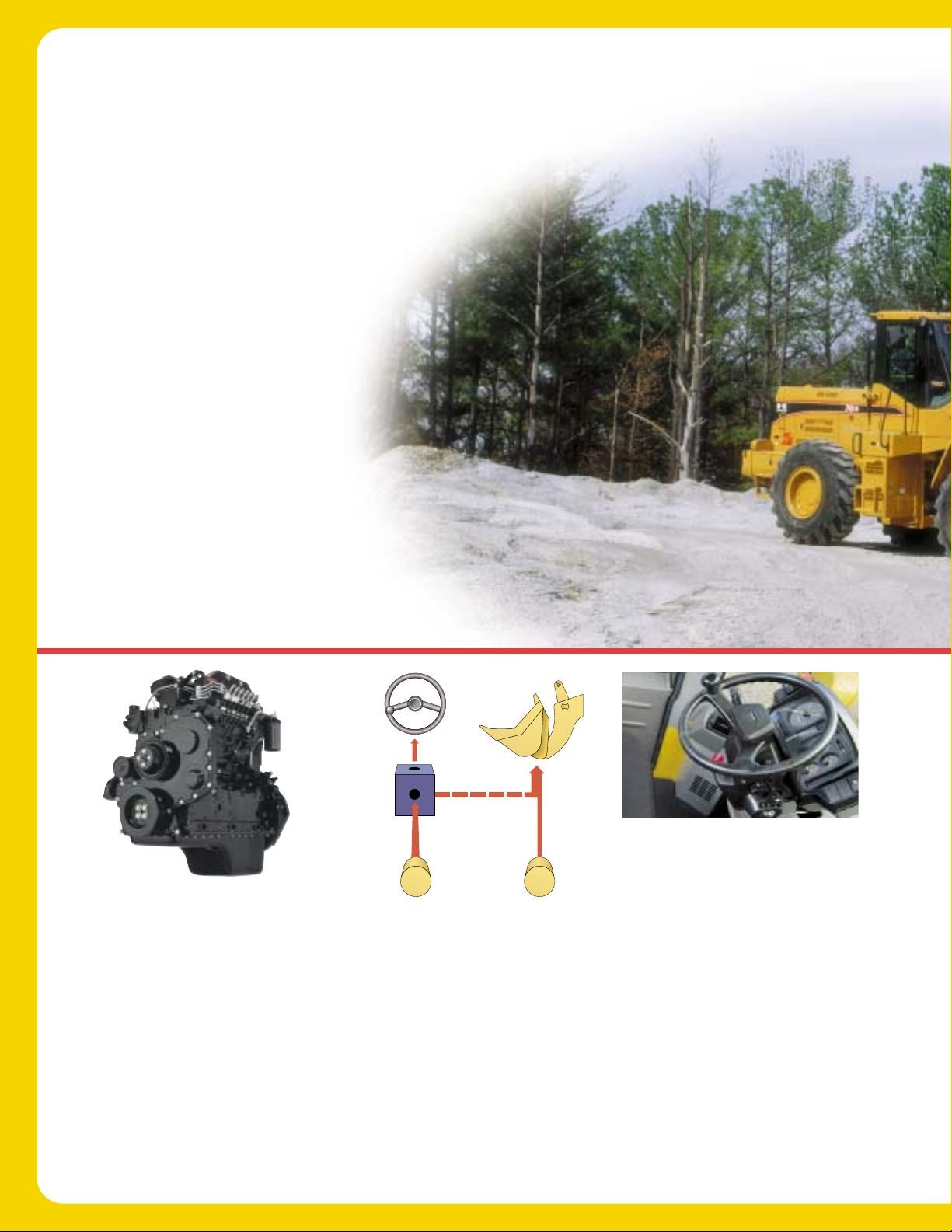

THE COMFORT ZONE

Kawasaki has taken a from-theground-up approach to create a cab

designed with the operator in mind.

The new cab focuses on providing the

ultimate environment for productivity,

comfort and safety. The high visibility,

quiet, temperature controlled cab

offers the operator ideal surroundings

for putting the Kawasaki loader

through its paces.

New Features

• Adjustable tilt steering with

interlocking instrument panel

• Adjustable wrist rest

• AM/FM cassette radio, standard

• Viscous isolation-mounted to

reduce vibration

• Wrap-around tinted windshield

for excellent visibility

• Reduced sound levels

• Personal storage space and

coat hook

• Intermittent front wiper

• Seven-way adjustable seat with

headrest and adjustable arms,

standard

Redesigned Features

• Single twist grip transmission lever

redesigned for easy gripping and

smoother shifting

• All systems monitored with lights

and alarms

• Dual, pilot-assisted hydraulic

controls— fingertip control

• One rearview and two side mirrors

• Rear lights added to ROPS

Standard Features

• Certified ROPS

• Rear cab light

• Doors latch back

• Side windows slide down

• 40,000 BTU heater standard

• Pressurized air control

• Left brake pedal activates

transmission declutch switch

• Front and rear wipers

and washers

• Six-way adjustable seat

with lumbar support

• Heavy duty suspension

Optional Features

• 25,000 BTU air conditioner available

• Single lever hydraulic control,

optional

• Air ride seat

Page 7

EASY ACCESS SIMPLIFIES SERVICING

• Hinged grille makes radiator

cleaning easy

• Engine side covers open wide for

optimum access

• Filters positioned within easy reach

• Easy access to drains, filters

and fittings

• Grease fittings are grouped for

easy lubrication

• Readily available Fleetguard and

Donaldson filters

• Starters and alternators available

through Cummins national

distribution network

• 3-piece wheel rims standard for easy

field service

• Ladders on both sides of the

machine

• Pressurized air control reduces

dust in cab and control boxes

QUICK COUPLER ATTACHMENT

The JRB Quick Coupler, can be used

in conjunction with a variety of

attachments, including:

• General and multi-purpose buckets

• Side dump bucket

• Construction utility forks

• Utility pallet forks

• Extendable boom

• Paddle top clamp forks

• Grapple bucket

• Loader rake and loader rake with

hydraulic clamps

Illustration representative

of similar models.

OPTIONS

RIDE CONTROL

• Stable load handling

• Reduces operator fatigue

• Cuts vibration and equipment wear

• Improves safety and productivity

• Less spillage

• Faster travel

speed

Without Ride Control

With Ride Control

Page 8

BUCKET DATA

General Purpose Material Handling

With Bolt-on Cutting Edge With Teeth With Bolt-on Cutting Edge

Capacity Heaped yd

3

3.25 3.0 3.5

(m3) (2.5) (2.3) (2.7)

Struck yd

3

2.8 2.6 3.1

(m3) (2.1) (2.0) (2.4)

Maximum dumping ft-in 8'101/2" 8'71/8" 8'81/4"

clearance (mm) (2705) (2620) (2650)

Dumping reach (to front ft-in 3'77/8" 3'101/2" 3'10"

of bucket edge or tooth) (mm) (1115) (1180) (1170)

Bucket hinge pin height ft-in 12'43/4" 12'43/4" 12'43/4"

(mm) (3780) (3780) (3780)

Digging depth ft-in 41/2"5

1

/8"4

1

/2"

(mm) (115) (130) (115)

Breakout force lb 27,560 30,210 25,795

(kg) (12,500) (13,700) (11,700)

Bucket tilt- at ground level 43° 43° 43°

back angle at carry position 50° 50° 50°

Overall Length ft-in 24'47/8" 24'97/8" 24'8"

(mm) (7440) (7565) (7520)

Height ft-in 10'115/16" 10'115/16" 10'115/16"

(mm) (3335) (3335) (3335)

Width ft-in 8'53/4" 8'53/4" 8'53/4"

(outside tire) (mm) (2585) (2585) (2585)

Width ft-in 8'91/8" 8'95/8" 8'91/8"

(outside bucket) (mm) (2670) (2680) (2670)

Wheel base ft-in 10'1/8" 10'1/8" 10'1/8"

(mm) (3050) (3050) (3050)

Minimum turning at outside ft-in 19'93/4" 19'11" 19'105/8"

radius bucket (mm) (6040) (6070) (6060)

at center of ft-in 17'13/8" 17'13/8" 17'13/8"

outside tire (mm) (5215) (5215) (5215)

Minimum ground ft-in 1'4" 1'4" 1'4"

clearance (mm) (405) (405) (405)

Full articulation angle degree 40° 40° 40°

Operating weight lb 28,750 28,550 28,860

(with ROPS Cab) (kg) (13,040) (12,950) (13,090)

Static tipping Straight lb 22,024 22,265 21,935

load (kg) (9990) (10100) (9950)

(with ROPS Cab) Full turn lb 18,915 19,160 18,830

(kg) (8580) (8690) (8540)

Measured in accordance with SAE J732C & J742

Materials and specifications are subject to change without notice and without obligation on the part of the manufacturer. The specifications supplied, while

believed to be completely reliable, are not to be taken as warranty for which we assume legal responsibility.

Page 9

OPERATING SPECIFICATIONS

Base Tire 20.5-25-12PR (L-2)

Tread . . . . . . . . . . . . . . . . . .6'83/4" (2050mm)

Width (outside tire) . . . . . . . .8'53/4" (2585mm)

Width (outside bucket) . . . . .8'91/8" (2670mm)

Equipped with GSC bucket with

bolt on cutting edge

20.5-25-12PR (L-2) Tire and ROPS Cab

10' "

1'4"

12'4 "

10' 11 "

45

3'7 "

50

43

3/4

7/8

8'10 "

1/8

24'4 "

4 "

1/2

1/2

7/8

5/16

WEIGHTS AND DIMENSIONS (SUPPLEMENTAL DATA)

Operating Tipping Load Overall Width Tread Vertical Overall

Weight Straight Full Turn (Outside Tire) Dimensions Length

ROPS Canopy lb -440 -330 -310 in

(Instead of ROPS Cab) (kg) (-200) (-150) (-140) (mm)

Remove ROPS Canopy lb -1150 in -10'13/16"

and Cab (for transport only) (kg) (-520) (mm) (-275)

Counterweight lb +500 +1200 +1020 in

(kg) (+225) (+544) (+463) (mm)

Tires: 20.5-25-12PR (L-3) lb +300 +230 +200 in

(kg) (+135) (+105) (+90) (mm)

23.5-25-12PR (L-2) lb +1610 +1235 +1060 in +2 +15/8"+2

3

/8"-2

1

/8"

(kg) (+730) (+560) (+480) (mm) (+50) (+40) (+60) (-55)

23.5-25-12PR (L-2) lb +2030 +1555 +1335 in +2 +15/8"+2

3

/8"-2

1

/8"

(kg) (+920) (+705) (+605) (mm) (+50) (+40) (+60) (-55)

23.5-25-12PR (L-3) lb +1800 +2765 +2370 in

with 75% CaCl

2

(kg) (+815) (+1250) (+1070) (mm)

Air conditioner lb +220 +260 +220 in

(kg) (+100) (+120) (+100) (mm)

Belly Guard (rear frame) lb +130 +120 +100 in

(kg) (+60) (+55) (+45) (mm)

Page 10

OPERATING SPECIFICATIONS

ENGINE

Make/Model/Fuel Type Cummins/B5.9-C/Diesel

Type 4-cycle, watercooled, turbocharged

after-cooled, direct injection

Net flywheel horsepower 160 HP/2400 RPM

Max Torque 490 lb/ft. @ 1500 RPM

Number of cylinders 6

Bore and stroke 4.02" x 4.72" (102mm x 120mm)

Total displacement 359 in3(5883 cm3)

Alternator AC24V– 1.68kw (65amp)

Starting motor 24V – 7.8kw (4 HP)

Battery 12V– 150AH, 2 units

Governor All-speed, mechanical type

TORQUE CONVERTER AND TRANSMISSION

Torque converter 3 elements, single stage

Torque stall ratio 3.65:1

Main clutches Wet hydraulic, multi-disk type

Cooling method Forced circulation type

Transmission Full power shift, 4 forward, 4 reverse with

automatic mode (2nd - 4th) with downshift

switch for 2nd - 1st downshifting

Forward 1st: 4.7 MPH (7.5 km/hr)

2nd: 7.8 MPH (12.5 km/hr)

3rd: 12.7 MPH (20.5 km/hr)

3rd: 23.0 MPH (37.0 km/hr)

Speeds

Reverse 1st: 4.7 MPH (7.5 km/hr)

2nd: 7.8 MPH (12.5 km/hr)

3rd: 12.7 MPH (20.5 km/hr)

3rd: 23.0 MPH (37.0 km/hr)

SERVICE REFILL CAPACITY

LOCATION CAPACITY: Gallons Liters

Engine (coolant) 14.3 (54.0)

Fuel tank (diesel fuel) 58.1 (220.0)

Engine (oil pan) 5.8 (22.0)

Front axle (gear oil) 12.7 (48.0)

Rear axle (gear oil) 13.5 (51.0)

Steering box 0.4 (1.5)

Torque converter and 7.9 (30.0)

transmission (engine oil)

Hydraulic system including 35.7 (135.0)

tank (hydraulic oil)

Brake oil tank (engine oil) 1.3 (4.9)

HYDRAULIC AND STEERING SYSTEM

Steering type Articulated frame steering

Steering mechanism Hydraulic power steering unit,

mechanical follow up

Lift (boom) cylinder Two (2) double-acting piston type:

5.5" x 29.7" (140mm x 754mm)

Tilt (bucket) cylinder One (1) double-acting piston type:

6.3" x 19.8" (160mm x 502mm)

Steering cylinder Two (2) double-acting piston type:

3.1" x 15.0" (80mm x 380mm)

Main oil pump Gear type: 15.9 GPM @ 1800 RPM

(60 LPM @ 1800 RPM)

Steering oil pump Gear type: 37.8 GPM @ 1800 RPM

(143 LPM @ 1800 RPM)

Pilot oil pump Gear type: 10.6 GPM @ 1800 RPM

(40 LPM @ 1800 RPM)

Relief valve Loading 3000 psi (210 kg/cm2)

set pressure Steering 3000 psi (210 kg/cm2)

HYDRAULIC CYCLE TIME*

Lifting time (at full load) 6.2 sec.

Lowering time (empty) 3.1 sec.

Bucket dumping time 1.2 sec.

TOTAL 10.5 sec.

* Measured in accordance with SAE J732C

AXLE SYSTEM

Drive system 4-wheel drive

Front and rear axle Full floating banjo type

Tires Standard 20.5 x 25-12PR (L-2)

Optional 20.5 x 25-12PR (L-3)

23.5 x 25-12PR (L-2)

Reduction and Spiral bevel/gear, 1 stage reduction torque,

differential gear proportioning type

Final reduction gear Outboard mounted. Internal planetary gear

Oscillation angle ±12° (total 24°)

BRAKE SYSTEM

Service brakes 4 wheel air over hydraulic wet disc brake.

Dual circuit.

Parking/Emergency brake Spring applied air released type.

Meets MSHA requirements.

Page 11

EQUIPMENT DATA

STANDARD EQUIPMENT

Adjustable Steering Column

Air Cleaner

(Double Element Donaldson)

Alarms (Audible):

Air Master Overstroke

Air Pressure

Brake Oil Level

Engine Oil Pressure

Alarms (Visual):

Air Filter

Air Master Overstroke

Air Pressure

Battery Discharge

Brake Oil Level

Converter Oil Temperature

Engine Oil Pressure

Engine Coolant Temperature

Parking Brake

Alternator (65 amp)

AM/FM Cassette Radio

Batteries: 12V–150AH (2 units)

Brake Line Protection (Front)

Brake (Parking)

Spring applied;

Air released, Drum type

Brakes (Service)

Air/Oil Actuation

Enclosed Wet Disc

Dual System

Bucket Control Lever

Dual, Pilot Assisted

Bucket Leveler

Boom Kickout

Coat Hook

Cold Start Aid

Cup Holder

Downshift Button

Drawbar

Electrical System (24 volt)

Engine Coolant Expansion Tank

Fan (Blower)

Fenders (Front and Rear)

Gauges:

Air Pressure

Converter Oil Temperature

Engine Coolant Temperature

Fuel Level

Hour Meter

Hydraulic Oil Level

Tachometer

Heater/Pressurizer

(40,000 BTU)

Hoodsides (Hinged)

Horn (Electric)

Hydraulic Oil Cooler

Indicators:

High Beam

Parking Brake

Transmission Declutch

Transmission Shift Monitor

Working Light

Linkage (Z-type, Sealed)

Lights:

4 Front

4 Rear

2 Stop/Tail

2 Backup

Muffler

Neutral Safety Start

Operator’s Manual Box

Radiator: Heavy Duty

Plate Fin Type

Radiator Grille, Hinged

Reverse Alarm

ROPS Cab: Enclosed cab with

sound suppression, front

lights, front and rear wipers

and washers, one rear view

and two side mirrors, tinted

glass, and sliding side

windows

Safety Articulation Locking Bar

Seat (Super Deluxe, Adjustable

Suspension, Headrest and

Adjustable Arm Rests)

Seat Belt, Retractable, 3" wide

Shift Control Unit for

Automatic Shift

Torque Proportioning

Differentials

Transmission Declutch

Selector Switch

Vandalism Protection

Wiper, Front Intermittent

Wrist Rest, Adjustable

OPTIONAL EQUIPMENT

Air Conditioner (R134)

Refrigerant

Air Dryer

Belly Guard, Hinged

Bolt-on Cutting Edge Segments

Bucket Teeth

Counterweight

Cushion Dump Valve

Easy Clean Radiator

Side-by-Side

Emergency Steering

Engine Pre-Cleaner

High Lift Arm

Hydraulic System,

3 Spool Valve

Lighting System

No Spin Differential

Quick Coupler and

Attachments

Ride Control

ROPS Canopy

Single Lever Hydraulic Control

Turn Signal With Four-Way

Flasher

2000

(1187)

2500

(1483)

3000

(1780)

BUCKET SELECTION GUIDE

STANDARD BUCKETS

3.5

(2.7)

3.25

(2.5)

3

(2.3)

Bucket Size yd

3

(m

3

)

2000

(1187)

2500

(1483)

3000

(1780)

BUCKET SELECTION GUIDE

HIGH LIFT BUCKETS

3.5

(2.7)

3.25

(2.5)

3

(2.3)

Bucket Size yd

3

(m

3

)

Material Density lbs/yd3 (kg/m3) Material Density lbs/yd3 (kg/m3)

Page 12

Kawasaki Construction Machinery

Corp. of America, a division of

Kawasaki Heavy Industries, is a

leading supplier of a full range of

high quality wheel loaders. In fact,

Kawasaki is the oldest on-going

manufacturer of rubber-tired wheel

loaders in the world. With over

35 years of proven performance

history, Kawasaki wheel loaders

have continuously evolved to bring

you the best in equipment and

support services, backed by a

carefully selected dealer network.

Kawasaki articulated wheel loaders

incorporate innovative design

features coupled with extensive

knowledge and experience gained

from real-world applications.

Kawasaki pioneered Z-Link design

to provide unmatched utility, high

breakout force and efficiency in

its machines. Powered by proven

emissions-compliant Cummins

diesel engines, durability and

serviceability are designed into

every Kawasaki loader.

Kawasaki loaders are assembled at

the company’s modern facilities in

Newnan, GA. Service and support

operations are headquartered in

Kennesaw, GA.

A state-of-the-art parts distribution

system links dealers with the main

parts warehouse, allowing them

to order parts directly. Qualified

craftsmen rebuild components

for all Kawasaki models at our

fully-equipped rebuild center,

making component exchange

easier and faster. An independent

oil analysis program allows

monitoring of critical systems

to reduce unscheduled downtime.

The independent dealers that

represent and support Kawasaki

loaders are experts in their

markets and are dedicated to

providing you with the best

service available. Together, we

are committed to making your

investment in a Kawasaki loader

a sound business decision that will

pay dividends for years to come.

KAWASAKI LOADERS

More Than A Machine, A Complete Solution

2140 Barrett Park Drive • Suite 101

P.O. Box 1657

Kennesaw, Georgia 30144

Tel: 770-499-7000

Fax: 770-421-6842

www.kawasakiloaders.com

5-00Part #70ZIV-2 Brochure

Loading...

Loading...