Page 1

Service Manual

– GP –

HYBRID PIANO

Manufacturing Start Date 2014/05

KAWAI MUSICAL INSTRUMENTS

MANUFACTURING CO.,LTD.

KPSZ-0804

Date of issue : July 2015

Copyright © 2015 Kawai Musical Instruments Mfg. Co., Ltd. All rights reserved.

Page 2

– 2 –

■CONTENTS

SPECIFICATION 3

〔1〕INFORMATION 4

〔2〕BASICSTRUCTURE 4

【A】OperationofMuteMechanism 4

【B】OverviewofHammerSensor 5

〔3〕ADJUSTMENTS 6

【A】ExtractionofActionUnit 6

【B】AdjustingStopRailHeightandLet-o 9

【C】AdjustingtheSensorHeight 11

【D】AdjustingthePedalSensor 12

【E】AdjustingtheActuator(Transducer) 12

【F】ReplacingandadjustingtheDriveLever(P) 13

〔4〕CHECKANDADJUSTMODES 14

【A】ActivatingtheCheckMode 14

【B】CheckingSwitchesandPedalSensors 14

【C】CheckingtheLCD 15

【D】CheckingKeyboardandMIDI 16

【E】CheckingtheSoundSource 16

【F】CheckingtheL/RChannel 16

【G】CheckingtheHammerSensor 16

【H】AdjustingVolumeInconsistency 17

【I】CheckingSoftwareVersionandCheckSum18

〔5〕TROUBLESHOOTING 19

【A】ProblemswithStarting 19

【B】ProblemswiththeController 19

【C】ProblemswitthePedals 21

【D】ProblemswithemittingSounds 22

【E】ProblemswithMechanicalNoise 23

【F】ProblemswithMutingtheAcousticSound 24

【G】ProblemswithKeyTouch 25

【H】ProblemswithOtherMechanism 25

【I】ProblemswiththeSoundboardSpeaker 26

〔6〕PARTSLIST&ASSEMBLINGINSTRUCTIONS 28

【A】Controller 28

【B】SoundSystemUnit 33

【C】D-SubBox 35

【D】Sensor 36

【E】StopRail 38

【F】StopRailArm 40

【G】Bracket 41

【H】DriveRod 43

【I】DriveLever 44

【J】Action 46

【K】ControllerandMuteLever 50

【L】Speaker 51

【M】Actuator(Transducer) 53

〔7〕ELECTRICPARTSLIST 55

〔8〕BLOCKDIAGRAM 56

〔9〕CABLEWIRINGSPECIFICATION 57

ControlBox 57

PWBChassis 58

SpeakerUnit 58

〔10〕CIRCUITDIAGRAM 60

KEP-539~544 60

KEP-545 62

KEP-503,KEP-267 63

KEP-276 64

KKB-036 65

KKB-037 67

〔11〕PWBASSYSPECIFICATION 69

KEP-339(11) 69

KEP-539~544(1),KEP-545~546(1) 70

KEP-267(2),KEP-503(2),KEP-276(2) 71

KKB-036(1),KKB-037(1) 72

〔12〕SOFTWARE 73

Page 3

– 3 –

Internal Sounds 27 voices

Polyphony max. 256 notes

Keyboard Modes Dual Mode, Split Mode, Four Hands Mode (Volume/Balance adjustable)

Reverb Type: Room, Lounge, Small Hall, Concert Hall, Live Hall, Cathedral

Parameters: Reverb Depth, Reverb Time

Eects Type: Stereo Delay, Ping Delay, Triple Delay, Chorus, Classic Chorus, Tremolo, Classic Tremolo,

Auto Pan, Classic Auto Pan, Phaser, Rotary, Combination eects x 4, Amplied Eects x 3

Parameters: Dry/Wet, Time, Speed, Mono/Stereo, Accel./Rotary Speed – Parameters dependent on eect.

Virtual Technician Touch Curve: Light+, Light, Normal, Heavy, Heavy+, O (Constant), User 1, User 2

Voicing: Normal, Mellow 1, Mellow 2 , Dynamic, Bright 1, Bright 2

Resonance, Noise

& Eects:

Damper Resonance, Damper Noise, String Resonance, Key-o Eect (incl. Key-o Release),

Fall-back Noise, Hammer Delay, Topboard, Decay Time, Soft Pedal Depth

Temperament &

Tuning:

Equal (Piano), Pure Major, Pure minor, Pythagorean, Meantone, Werckmeister, Kirnberger,

Equal (Flat), Equal (Stretch), User Temperament, Key of Temperament

Others: Stretch Tuning, User Tuning, User Key Volume, Half-Pedal Adjust, Minimum Touch

Internal Recorder 10 song, 2 track recorder – approximately 90,000 note memory capacity

USB Functions Playback: MP3, WAV, SMF

Record: MP3, WAV

Others: Load Internal Song, Load User Memory, Save Internal Song, Save SMF Song, Save User Memory,

Rename File, Delete File, Format USB.

Convert Song to Audio, Overdub Audio

Metronome Beat: 1/4, 2/4, 3/4, 4/4, 5/4, 3/8, 6/8, 7/8, 9/8, 12/8 + 100 drum rhythms

Tempo: 10 - 400 bpm (20 - 800 bpm for eighth note rhythms)

Music Menu Demo Songs: 22 songs

Piano Music: 29 or 42 pieces ¹

Lesson Function: Finger exercises + Alfred or Burgmüller, Czerny, Beyer, and Bach lesson books ¹

Other Settings &

Functions

Key Transpose, Song Transpose, Tone Control (incl. User EQ), Speaker Volume*, Phones Volume, Line In Level,

Line Out Volume, Audio Recorder Gain, Wall EQ*, Tuning, Damper Hold, LCD Contrast, User Memory, Factory Reset,

Lower Octave Shift, Lower Pedal On/O, Split Balance, Layer Octave Shift, Layer Dynamics, Dual Balance, MIDI Channel,

Send PGM#, Local Control, Transmit PGM#, Multi-timbral Mode, Channel Mute, Auto Power O

Display 128 x 64 pixel LCD with backlight

Pedals Damper (with half-pedal support), Soft, Sostenuto (switchable from Soft for Upright Piano)

Jacks LINE IN (stereo mini), LINE OUT (stereo mini), Headphones x 2,

MIDI (IN/OUT), USB to Device

Speaker System

(ATX2-f only)

Speakers: 12cm x 2

Soundboard Speaker System

Output Power: 15W + 10W

Power Consumption ATX2: 35W

ATX2-f: 25W

* ATX2-f only. / ¹ depending on market location.

■SPECIFICATION

Page 4

– 4 –

Silent Mode

Mute Lever

Standard

Play Mode

Keybed Right

Down Surface

Wire

to inside of Piano

Figure 1

Standard Play Mode

DRIVE LEVER (A)

*Parts attached to Action

(Action not present in the drawing)

Rod (axis of rotation)

Wire

to Mute Lever

Silent Mode

Stop Rail Arm

Stop Rail

Drive Lever (P)

Figure 2 (Perspective from high tone keys side)

Figure 3 (Perspective from lower tone key side)

〔1〕INFORMATION

This guide describes the basic structure of the Grand Piano ANYTIME X2, and provides instructions on

how to perform adjustments and troubleshooting.

Please refer to this guide for maintenance services.

〔2〕BASIC STRUCTURE

ANYTIME X2 is an hybrid instrument that incorporates an acoustic piano and a digital piano, therefore

it has a unique structure which is different from both acoustic and digital pianos. Also different from the

traditional Anytime series, it adopts a new mechanism which captures the playing information from the

hammer's movement.

【Switching the Modes】

To switch from Standard Play Mode to Silent Mode, use the mute lever located on the high tone keys

side under the keybed as shown in Figure 1.

Then, turn the volume knob of controller to the right to turn on the digital sound generator.

【Internal Behavior】

1. When the mute switching lever is pulled, the wire inside the piano is pulled (Figure 2) and the drive

lever (P) linked with the wire rotates.

2. When the dDrive lever (P) rotates, the lower part of the drive lever (A) attached to the action (shown

in Figure 2) is pushed and pivots on the rod.

3. When the drive lever (A) rotates, the connected stop rail arm turns and goes down, as shown in

Figure 3. In this way, the hammer shank is stopped just before striking the string.

* In GP-ATX2 , adjusting the wire tension will not have any effect on the height of the stop rail.

Since an unnecessary adjustment of the wire tension will cause the following malfunctions, use the

proper screw for adjusting the the stop rail height as indicated in step 〔3〕 .】B【

[Wire Tension]

・Too tense : When the mute lever is pulled, the drive lever (P) might miss the stopper.

・Too loose : In the Standard mode, the drive lever (P) might stand up too much and interfere the

lower part of drive lever (A).

* After exchanging the wire, adjust the wire tension following step 〔3〕 【F-7】.

* If the drive lever (P) is not properly installed, it might cause the following malfunctions.

[DRIVE LEVER (P) - Install position]

・

Too forward : It will make the adjustment difficult to perform as the stop rail goes down too much.

・

Too backward : It will make the adjustment difficult to perform as the stop rail goes up too much.

* For exchanging the drive lever (P), first follow the instruction 〔3〕 【F】, then adjust the stop rail height

as indicated in step 〔3〕 【B】.

Page 5

– 5 –

Strings

46mm

Sensor PWB A-D Assy.

Sensor Mount Rail

Shutter

Sensor Cover

Hammer Shank

(Strings side) (Keyboard side)

PS3 PS2

PS1

Velocity

Key being

depressed

Auxiliary

The GP-ATX2 Hammer Sensing System is composed of three optical sensors to detect the hammer's

movement.The system adopted before AT II was sensinng the keys movements and detecting only two

points in the keys passage.

The New GP-ATX2 Hammer Sensing System remarkably improves the capability of detecting the subtle

key touch and the repeated strokes, and greatly enhances the playability multiplied by the new sound

source.

【B-1】Structure

of detector

Figure 4 shows a simplified cross-section view of the GP-ATX2 Hammer Sensing detector.

All 88 keys are equipped with three pair of light emitter/receiver and are deployed as P1, P2 and P3

from the keyboard side.The PS1 unit detects the key being depressed, the PS2 unit detects the auxiliary

signal of the hammer, and the PS3 detects the velocity of the hammer movement.

【B-2】Explanation

of Behavior

)thgieh liar pot knahs eht gnitsujda rof 】B【 ③ ees ,thgieh rosnes eht gnitsujda rof 】C【 〕3〔 eeS(.tinu noitca eht gnitsujda nehw dnim ni siht peeK .ytilibayalp eht secneuflni yltaerg rettuhs dna rosnes fo noitisop evitaler ehT※

⑧ Detected key being released

PS1 sensor is conducted,

and determines that

the key is released.

The electronic sound ceases.

⑦ Starting releasing key

The hammer shank starts

going down.

PS2, and the PS3 sensors

are blocked.

⑥ Hammer being stopped

The hammer shank collides

against the stop rail.

⑤ Once detection of velocity is completed,

the PS3 sensor is conducted,

and an electronic sound

comes out.

③ Starting to detect the velocity

PS3 sensor is blocked.

② Detecting key being depressed

PS1 sensor is blocked.

① Before key is depressed

String All the sensors are conducted.

④

PS2 sensor is blocked.

Page 6

– 6 –

* The keys are abbreviated in this drawing.

Cleat (Upper)

Binde

Cleat (Lower)

Figure 2 Figure 3 Figure 1

Stop Rail

Pin Block

(Wrest Plank)

Pull it up until

it stops

Set Lever

Sensor

〔3〕ADJUSTMENTS

[Preparation]

・Phillips Screwdriver Large

・Phillips Screwdriver No.2

The action unit of GP-ATX2 is equipped with mute mechanism, sensor units, cables, etc.

Therefore if you try to extract the action unit in the same way of a standard piano, this might damage

the piano components or the ATX2 parts, because these parts might touch against the piano body, or the

cables might be pulled too stronghly and therefore damaged.

The clearance between mute mechanism and piano body (pin block=wrest plank etc.) may be smaller

than on a standard piano.

Before performing regulation and voicing, pull out the action unit and turn sensors and stop rails, always

as indicated in the following steps.

A DVD with a series of of operations is available. To request it, please contact Kawai Japan or your local

distributor.

[Instructions] - Pulling out the Action -

【A-1】 Set back the position of the mute lever located on the high tone keys side under the keybed

to

unlock the Silent Mode.

【A-2】 Remove fall-board, keyblock (wooden parts outer side of keyborad) and keybed.

* A holding screw for the keyblock is a countersunk screw. Use a larger Phillips screwdriver

to

extract it.

【A-3】 Release the binder and remove the upper and lower cleats (indicated with circle), then pull

out

the connector as shown in Figure 1.

【A-4】 Pull up the set lever until it stops, as shown in Figure 2.

* By doing this, the stop rail goes down until a position where the stop rail does not touch

the

pin block, as shown in Figure 3.

【A-5】 Extract the action unit carefully, making sure that the sensors do not touch the pin block and

the

cables do not get entangled.

Page 7

– 7 –

Screw

Screw

Screw

Screw

Screw

Screw

Rotate to this side

Figure 4

Figure 5

[Instructions] - Rotating the Sensor -

【A-6】

Loosen all six screws fully, as shown in Figure 4.

* Loosen each screws by around three rotations in turn, do not loosen the screws fully one by

one.

* The screws will not drop off easily even after fully loosened because they are provided with a

a drop prevention washer.

【A-7】

Lift the sensor unit end and rotate it slowly to this side, as shown in Figure 5.

* The sensor units are independent between the lower tone and medium/high tone areas. You

may need to rotate them separately.

Page 8

– 8 –

Lift the stop rail end

With holding down the set lever

Turn it up until it halts

Figure 7

Bush

Washer Screw

Figure 6

Pin of Drive Rod

This goes off from

the drive rod pin.

Figure 8

Stop Rail Arm

U-Shaped Part

[Instructions] - Turning the Stop Rail -

【A-8】

Pull down the set lever to release the action part from the mount/dismount state.

【A-9】

Remove the washer screw and bush (semitransparent) located on the side of the action unit low tone part, as

shown in Figure 6.

* This screw helps preventing the stop rail from dropping off.

【A-10】

Lift up the end side of the stop rail and turn it to this side until it halts, as shown in figure 7.

* The U-shaped part of stop rail will come off from the screwdriver rod as shown in Figure 8.

* If you lift up the stop rail with pushing the set lever down slantwise, it will smoothly turn.

*

When you get back the stop rail, make it sure that all the five U-shaped part will perfectly fit to the pin of drive rod.

( Alligning the U-shape to the pin, pull the set lever with holding down the stop rail, then it will smoothly fit to

the pin)

By observing the above steps, you can safely extract the action unit of GP-ATX2.

Rotating the sensor units and stop rails will make easier performing regulation and voicing.

For restoring the action unit, perform the above steps in the reversed way.

Do not forget to pull down and set the set lever back, and also to re-connect and fix the cables with the

binders after putting the action back into the piano.

Page 9

– 9 –

Stop rail

Adjust screw

Lock nut

goes down

goes up

[Preparation]

・Phillips Screwdriver Large

・Phillips Screwdriver No.2 (longer shaft)

・8 mm Wrench

・Capstan Pliers

・Let-off measuring jig (if the jig for 4 mm is not available, use the one for 3 mm)

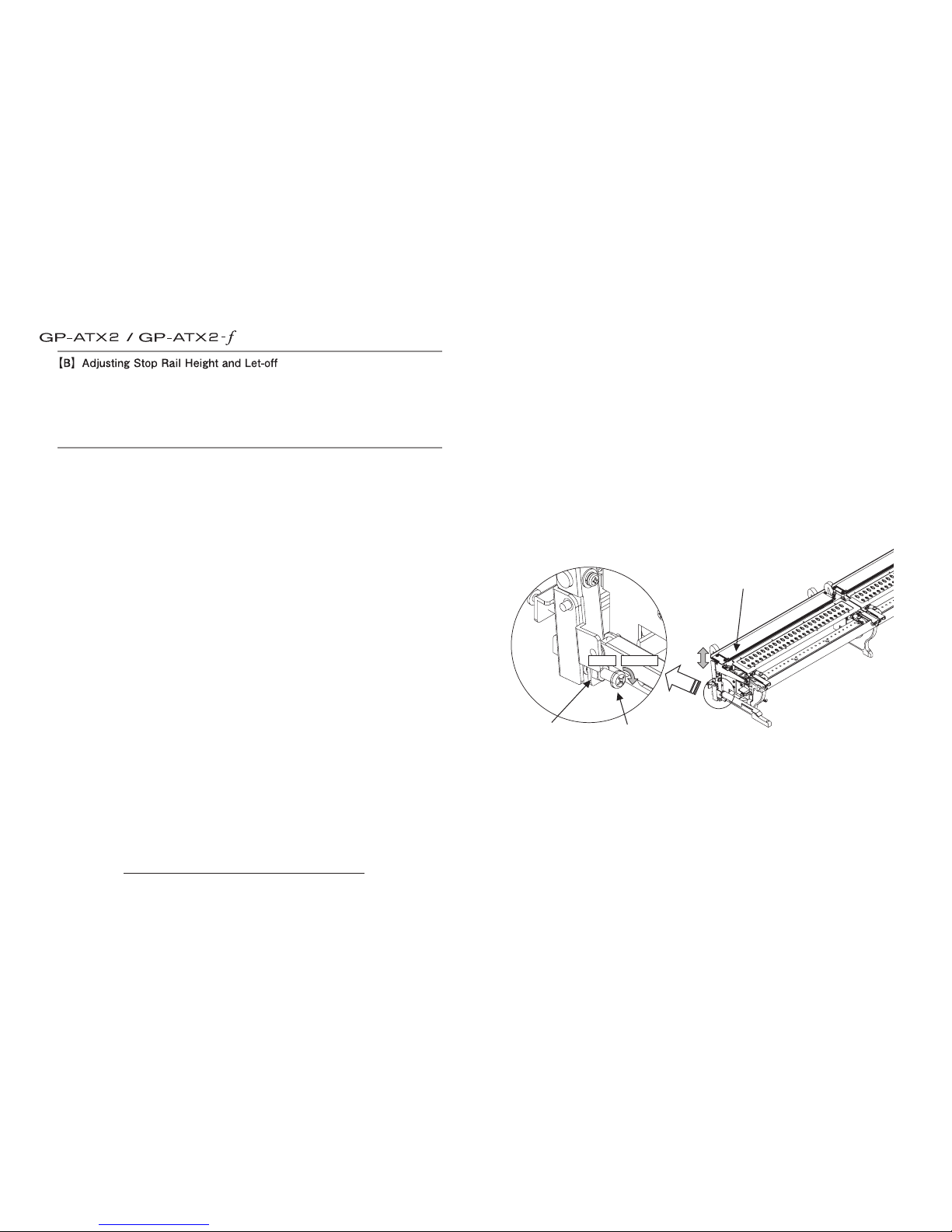

In the GP-ATX2, the hammer shank stops just before the string using the stop rail (let-off is 4 mm) in order to

enhance the pianist’s key touch feel and expression, and to keep the same touch feel even when in silent mode.

For this reason, it is very important to adjust the let-off and the height of the stop rail not only for the key

touch feel but also for the mute function.

These two have mutual relationship, so that you need to adjust them both at one time.

These adjustments also influence the sensing efficiency of the musical performance by the sensor. After

ot woH 】C【 〕3〔 ot refeR( .dedeen fi ti tsujda-er dna thgieh rosnes eht kcehc ,stnemtsujda eseht gnimrofrep

check and adjust)

The adjustments are always rigorously performed at the factory before shipping. If re-adjustment is

needed due to age deterioration or malfunction, please implement the following procedure.

[Work Procedure] - Adjusting the entire stop rail height -

Follow these procedures for adjusting the stop rail height across the board in case the muting functionality

becomes lower throughout all keys.

【B-1】 Pull the mute lever located under the keybed (at the treble side) to switch to the Silent Mode.

【B-2】 Adjust the let-off of No.1 key (or any other keys) by 4 mm using the jig.

* If the 4 mm jig is not available, adjust it by 4 mm by visual judgment using the 3 mm jig

instead.

【B-3】

1 erugiF ni nwohs tun kcol eht ylluf nesool dna noitca eht tuo llup ,】A【 〕3〔 fo pets eht ot gnidroccA

using the 8 mm wrench. After loosening the lock nut, put the action back into the piano and set back the

set lever, then place the keyblock at the bass side. (It is recommended not to tighten the screw fully)

【B-4】 Adjust the height of the stop rail aligning it to the let-off position of the hammer shank for No.1

.)desu fi 】2-B【 ta detsujda yek rehtona ro( yek

* Depress the key slowly several times, rotate the adjust screw (Figure 1), and move the stop

rail as close as possible to the let-off position of the hammer shank.

Rotate clockwise : stop rail lowers, Rotate counterclockwise : stop rail lifts.

* Using a longer Phillips screwdriver No.2 it is possible to perform the adjustment while keeping

the action inside the piano.

* Looking through the interspace of the shank flange makes the work easier.

* In this situation, when the action comes forward, the stop rail lifts and it becomes ready to

emit sound (i.e. to strike the string). In such a case, it is better to work on it while holding

down the reed end of the bass section by hand (For this reason, the keyblock is placed first.)

Caution : Never perform any adjustment using a wire at the mute lever side.

Changing the tension of the wire may produce abnormal noise due to interposition of

the internal parts.

【B-5】 Check the muting state.

* Criteria for judging

・ Hit strongly each section of the keyboard five times in a row with three fingers of your

dominant hand, and make sure that the hammer does not strike the string.

・ If the string was hit during the above, repeat the procedure from 【B-2】 for re-adjusting.

【B-6】 After finishing the adjustment, pull out the action and tighten the lock nut without changing the

adjust screw position.

【B-7】 Put the action back into the piano and re-install keyslip, keyblock and fallboard.

Set back the mute lever if needed.

Figure 1

Page 10

– 10 –

▼ ▼ ▼ ▼▼ ▼▼ ▼

Adjust screw A

Lock nut A

Lock nut B

Lock nut B

Adjust screw B

(Upper)

Adjust screw B

(Lower)

Indicator

(Guideline)

Adjusting

point

Adjusting

point

Adjusting

point

Adjusting

point

Adjusting

point

Read the number on the scale

This indicates “4.5”.

(Longer scale line means 0.5)

Figure 2

Figure 3

Figure 4

Screw for hammer rail

(attached here)

Rail positioning fitting

[Work Procedure] - Adjusting the stop rail height per section -

In the GP, the distance between the keybed and the string undersurfaces may vary depending on the

areas of the piano.

In the GP-ATX, it is possible to adjust the stop rail height per section to follow the variation of this

distance, and make sure that the muting happens at the 4 mm point of let-off.

This procedure should be implemented when the adjustment per section is needed if the muting works

only partially.

【B-8】

Using the jig, adjust by 4 mm the let-off of the keys at both ends of each section (8 keys in total).

* If the 4 mm jig is not available, adjust it by 4 mm by visual judgment using the 3 mm jig

instead.

【B-9】

Switch to the Silent Mode, and write down the value of the scale located at the bass side of the

stop rail, as shown in Figure 2.

【B-10】

Attach the rail positioning fitting on the action as shown in Figure 3.

* The rail positioning fitting is fixed with a screw at the treble side of the rear chambranle

(threshold, Kamachi).

* One screw for the hammer rail is attached at the bass side end of the action.

【B-11】

Loosen the lock nut A (Figure 4) and rotate the adjust screw A so that the scale indicator at the

netsaf ot A tun kcol eht nethgit nehT .】9-B【 ni daer eulav eht ot stniop liar pots eht fo edis ssab

the stop rail.

* By doing this, the height of the stop rail across the board becomes equal to that of when it was

in the piano.

【B-12】

Adjust the height of the stop rail aligning it to the let-off position of both ends of each section.

* There are eight areas to adjust as shown in Figure 2.

* Loosen the lock nut B (Figure 4) and adjust the height using the adjust screw B (Upper).

Rotate clockwise : Lower Rotate counterclockwise : Lift

* Adjust both forward and backward ends to make it parallel to the hammer shank.

Then rotate the adjust screw B (Upper) about one time per turn.

※ Especially for counterclockwise rotation, the adjust screw B (Upper) could drop off from the

adjust screw B (Lower).

If that happens, remove the adjust screw B (Upper) once and apply a slight coat of instant

glue on the screw hole of the adjust screw B (Lower) then tighten the adjust screw B (Upper).

* After completing the adjustment, tighten the lock nut B without changing the adjust position

of the adjust screw B (Lower).

【B-13】

Align the let-off of the remaining keys to the stop rail.

* Move the hammer shank at the let-off position as close as possible to the stop rail.

【B-14】

Remove the rail positioning fitting and fasten the stop rail at the original

position on the rear chambranle (threshold).

【B-15】

Put the action back into the piano and re-install keyslip, keyblock and

fallboard.

【B-16】

Check the muting state.

* Criteria for judging

・ Hit strongly each section of the keyboard five times in

a row with three fingers of your dominant hand, and

make sure that the hammer does not strike the string.

・ If the string was hit during the above, repeat the

.gnitsujda-er rof 】8-B【 morf erudecorp

Page 11

– 11 –

▼ ▼▼ ▼ ▼ ▼

Figure 1

Figure 2

Six points to adjust indicated by circles

Sensor height adjust screw

Shutter

Sensor

[Preparation]

・Phillips Screwdriver No.2

・Flat screwdriver No.2

The height of the sensor is one of the elements that has a direct influence on the emission of the electronic

sound and the muting position.

For instances, if the sensor is located at an extremely high position, the position of emitting sound may be higher

than the position where the hammer stops by the stop rail. In this state, no electronic sound will be emitted.

On the contrary, if the sensor is located too low, this may cause deterioration of the functionality in detecting

consecutive key stroking. This could also cause collision of the shutter (root part of hammer shank) and the assy.

In the following cases an adjustment is needed.

・ No sound is emitted (especially with weak strokes)

> The sensor position is too high

・ When playing in the acoustic mode, the sensor collides

with the shutter by strong stroking (snapping noise)

> The sensor position is too low

・ Poor performance in detecting consecutive key stroking > The sensor position is too low

Also, when the height of the stop rail is lowered or the sensor PWB is replaced, please check and adjust

the functionality according to these procedures. The adjustment can be performed per section.

[Work Procedure]

【C-1】 Extract the action and rotate the sensor following the instruction steps .】7-A【 - 】1-A【 】A【 〕3〔

【C-2】 There are six height adjust screws which are shown in Figure 1.

【C-3】 Adjust upwards and downwards the adjust screw for the sensor height (Figure 2) using a flat

screwdriver.

※ Rotate clockwise : Lower Rotate counterclockwise : Lift

【C-4】 Set the sensor back and fasten with the screw, then put the action back into the piano following

.】1-C【 fo erudecorp esrever eht

【C-5】 Check the height of the sensor .

* Criteria for judging

・ Emits electronic sound by weak stroking at the center and both ends of each section.

・ The sensor does not collide with the shutter by strong stroking (no snapping noise) when

playing in the acoustic mode.

・ If it does not pass the criteria above, repeat the procedure from 【C-1】 for re-adjusting.

* For your information

・ If only the center area of the section does not pass the test, it might be good to correct the

warp of the sensor PWB frame by bending it with your hands.

・ If the sound stops immediately after a strong stroke, adjust the position of the backstop

higher (less than 15 mm high from the strings).

Page 12

– 12 –

Sostenuto Pedal Rod

Soft Pedal Rod

When pressed down

Adjust by tightening

the screw

Loud Pedal Rod

Loosen four screws on both

sides and remove the cover.

[Preparation]

・Phillips Screwdriver No.2

In the GP-ATX2, the sensors sensing the movement of pedals are housed in the box located over the pedal

rods. A type of guard called “push nut” is fixed on the pedal rod, and this drives functionally the volume

(for Loud pedal) and the limit switches (for Soft sensor and Sostenuto sensor) linked with the movement

of the pedal. If the timing of pedal effect for the electronic sound seems odd or it does not work, adjust

these sensors by moving them upwards or downwards.

[Work Procedure]

【D-1】 Loosen and remove the set screws (total 4) from both sides of the cover.

【D-2】 Moving the pedal, check if the positional relationship of push nut, switch and volume is correct.

【D-3】 Loosen the set screws that are fastening the sensor stay on the case, then adjust the sensor by

moving it upwards and downwards.

※ While listening to the sound through the headphone, press down the damper pedal and check

the timing of disengagement of the damper from the string and the effect of the damper on

the electronic sound; then adjust the switch positions accordingly.

【D-4】 If the sensor looks normal but it does not work properly, one of its parts could be faulty.Replace

it accordingly.

[Preparation]

・Phillips Screwdriver No.2

・10 mm Wrench

The GP-ATX2-f is equipped with a soundboard speaker.

The actuator (transducer) must be pushed down with proper force on the soundboard, so that the

soundboard can vibrate efficiently and emit the sound properly.

The adjustments are always rigorously performed at the factory before shipping. If re-adjustment is

needed due to age deterioration or malfunction, please implement the following procedure.

[Work Procedure] - Adjusting the Transducer -

This procedure should be done in case the soundboard speaker emits clipping noise etc.

【E-1】 Turn the power off.

【E-2】 Loosen the four screws ④ that fasten

the transducer (actuator) cover ① to

remove the cover.

【E-3】

Loosen nut ③ using the 10 mm wrench.

【E-4】 Looking at adjust scr ew ④ from

underneath, rotate it clockwise to

loosen once.

Again, looking at adjust

sc rew ④ from underneath, rotat e

it counterclockwise and adju st the

position so that the actuator cushion

⑥

comes in touch with the soundboard

(the torque for ④ becomes heavier).

【E-5】

Rotate adjust screw ④ counterclockwise

one more time (alway s look in g u p

from unde rneath) and push actuator

(transducer) ⑤ down on the soundboard

underface.

【E-6】 Tighten nut ③ to fasten the actuator.

Check if nut ⑦ i s not loose. I f it is

loose, tighten it up using the wrench.

【E-7】 Reinstall the cover of the transducer

with four screws.

*Pass through the

notching of the

actuator cover.

Soundboard

Support

①

②

⑥

⑤

④

③

③

④

⑦

⑤

②

Speaker relay 2

Cable (L)

KPBB-0806

【D】 【E】

Adjusting the Actuator (Transducer)Adjusting the Pedal Sensor

Page 13

– 13 –

Gap :1-2 mm

Figure 4

Length A

Length A

・ GM, GX-1 : 456±1mm

・ GX-2 to 5 : 466±1mm

Stopper rubber

Drive lever (P)

At Silent ModeAt Acoustic Mode

Around 12 degree

forward tilt

[Preparation]

・Phillips Screwdriver No. 2

The install position of the drive lever (P) is very important since it has direct influence on the muting

performance (See 〔2〕 【A】 for details). When replacing the drive lever (P), follow carefully the procedures

below, and install it paying attention to the lengthwise position (Length A) from the keybed front side.

[Work Procedure]

【F-1】

E .1 erugiF ni elcric a yb detacidni si )P( revel evird ehT .】A【 〕3〔 pets ot gnidrocca noitca eht tcartx

【F-2】

Fig. 2 - ① Remove two screws and the wire set fitting.

【F-3】

Fig. 2 - ② Remove the wire.

【F-4】

Fig. 2 - ③ Remove two tapping screws, drive lever (P) assy and spacer.

【F-5】

Fig. 3 - ①

Align the spacer wood with the hollow of the action crosspiece, then place the spacer on it.

* It is advisable l to use double-sided tape for fastening.

【F-6】

Fig. 3 - ② Attach drive lever (P) assy following the reverse procedure of Figure 2.

* Adjust it using the elongate hole of the drive lever (P) assy as the lengthwise position becomes

equal to the Length A in Figure 4.

* Check if the lengthwise position is as shown in Figure 5.

If it exceeds the range of Figure 5, adjust the thickness of the spacer.

【F-7】

Using the adjust screw (white resin) of the shift lever, adjust the wire tension to make it like the

drawing at the top of Figure 4.

* Switch to the Silent mode and adjust to 1-2 mm the gap between the drive lever (P) and the

stopper rubber, then check that the angle is 12 degree inthe Acoustic mode.

Figure 2

= How to install = = How to install =

Figure 1

Figure 3

Action crosspiece

hollow

Align both centers

Off center allowance :

within 2 mm

Roller

Drive lever (A)

Drive lever (P)

Figure 5 View from above

① ①

②

②

③

Drive base (P) assy

Spacer

Wire

Wire set fitting

Screw

Spacer Wood (attached to the spacer)

* Spacer not shown in the drawing.

Page 14

– 14 –

〔4〕 CHECK AND ADJUST MODES

※ This section describes the modes needed for performing checking and adjustments when a problem occurs.

※ Before running these modes, you need to switch to the Silent Mode by pulling the mute lever located

under the keybed (at the treble side).

【A】 Activating the Check Mode

Starting from power-o

Press down and hold the [◀], [▲] and [▶] buttons simultaneously, then turn the power on. When the

message below appears on the LCD display, release the buttons.

Left screen turns to right one after a while.

(* : di ers depending on models and market location.)

※ To exit from the Check Mode, turn the power o .

【B】 Checking Switches and Pedal Sensors

① Press all the buttons in rotation and check if the corresponding button name appears on the LCD display

and “○” at the corresponding position change as follows; ○→●→◦

Also, make sure that the LED light is turning on and o when pressing the buttons except “Value”

buttons [◀], [▲], [▼], [▶]. LED color of REC button is red, and the others are green.

※ If nothing appears on the LCD or the LED does not turn on and o when the button is depressed, the

circuit board inside the switch panel may be defective.

[ 1 ]

[ 2 ]

[ REC ]

Page 15

– 15 –

② Press down each pedal, and check if the following message appears on the LCD for each pedal.

Soft Sostenuto

Damper

XXX : Check if the value varies from 0 to 127 depending on how deeply the damper pedal is

being depressed.

If the LCD display doesn't show the above, the sensing system of pedals need to be adjusted.

③ Adjust the switch position according to 【D】“Adjusting the Pedal Sensor”.

※ If the messages do not appear on the LCD even after adjusting all the Soft, Sostenuto and Damper

switches, check cable and connector of each switch.

【C】 Checking the LCD

Starting from the Check mode of the switch

press [1] and [3] buttons simultaneously.

When the message above appears, press the [EFFECTS] or [REVERB] button.

・Press [EFFECTS] button, and make sure if all the dots turn o .

・Press [REVERB], and make sure if all the dots turn on.

If dots are missing when the [REVERB] button is pressed, the LCD is faulty.

Page 16

– 16 –

【D】 Checking Keyboard and MIDI

From the 【C】“Checking the LCD” state, press the [Play/Stop] button one time.

The following message will appear on the LCD.

Connect MIDI IN with MIDI OUT in a loop using a MIDI cable.

Press any keys and check if the sound is emitted from the headphone (for the -f model, you can use the

speaker instead). If no sound is emitted, the MIDI board may be faulty.

※ Check rst if all the cables are properly connected.

【E】 Checking the Sound Source

From 【D】“Checking Keyboard and MIDI” state, press [▶] button repeatedly until the message below is

shown in the LCD display.

After this message is displayed, check if every key tone is emitted by half-tone from the lowest bass tone.

※ By performing this, it is veried that the sound source is functioning all over the diapason.

※ It is recommended to decrease the volume.

【F】 Checking the L/R Channel

From 【E】“Checking the Sound Source” state, press the [▶] button. LCD display will show as below.

Use the headphone and check that a sound comes out from the L channel when the [EFFECTS] button is

pressed, and that the same happens from the R channel when the [REVERB] button is pressed.

※ It is recommended to decrease the volume since a pure tone will be emitted.

【G】 Checking the Hammer Sensor

From 【F】“Checking the L/R Channel” state, press the [▶] button repeatedly until LCD display shows as

below.

When a key is pressed down, the sound will be emitted at the strongest touch regardless of how strong

you press.

Press down all the keys one by one and check if all of them emit a sound.

※ It is recommended to decrease the volume beforehand since sounds by the strongest touch will be

emitted.

※ If there is a key that does not emit a sound, the sensor may be faulty.

Page 17

– 17 –

【H】 Adjusting Volume Inconsistency

Perform this operation if the sound volume balance is obviously inconsistent when each key is pressed

down with the same strength.

This operation must be performed also after replacing the sound source board.

※ Usually the electronic sound volume is set as at with the balance between the keys. However, the key

touches sometimes are not even because generally smoothness and friction are slightly dierent per

each key on the piano keyboard and action.

This adjustment will be performed for correcting such inconsistency of feel.

From 【A】“Activating the Check Mode” state, press [PIANO] and [MUSIC]

buttons simultaneously. LCD display will show as right.

In this state, check the sound volume consistency.

If the volume of a key is lower or higher than the other keys, press and

hold the key, and then press down the highest (88th) key to increase the

value by 1, or press the second highest (87th) key to decrease by 1.

The example display right shows when Key No.40 is increased its value by 5.

(The value of each piano is adjusted before shipment from our factory, so

each shows adjusted value respectively, however, when the sound source

board is replaced, the value become 0 for all keys.)

If you adjust the value with 87th and 88th keys while pressing and holding some of other keys

simultaneously, the value adjustment will be applied to all the keys being depressed.

If you press 87th and 88th keys without pressing any keys from 1st to 86th, the value adjustment will be

applied to all the 88 keys.

Key: all = down

E.Adjust(REC to Save)

Key: all = up

E.Adjust(REC to Save)

※ 87th and 88th keys are not adjustable since they are dedicated for the volume adjusting operation.

※ By pressing 87th and 88th keys simultaneously, all the value adjustments you set will be cleared.

After nishing the operations, press [REC] button to store the settings.

E.Adjust(REC to Save)

E.Adjust(REC to Save)

※ If you turn the power o without pressing [REC] button, the value adjustment you set will not be stored.

E.Adjust(REC to Save)

Key: xx = xxxx

Key: 040 = +5

E.Adjust(REC to Save)

Page 18

– 18 –

【 I 】 Checking Software Version and Check Sum

Turn the power o .

Press and hold [EFFECTS], [▼], and [REVERB] buttons simultaneously, then turn the power on. When the

message below is shown in the LCD display, release the buttons.

x di ers depending on the model and market area.

y and z di er depending on the software version.

The version of software and the sum value will be shown in the display.

To exit from this mode, turn the power o .

Page 19

– 19 –

●

Does not turn on.

Possible

Cause 1 : The AC adapter may be disconnected or out of order.

Solution 1 : Check the AC adapter connection and the output voltage.

Possible

Cause 2 : The connector may be disconnected.

Solution 1 : dna tinu ecruos dnuos eht fo revoc rotcennoc eht nepo ,】B【 〕6〔 ot gnirrefeR

check if all connectors are firmly inserted.

Solution 2 : srotcennoc lla fi kcehc dna tinu ecruos dnuos eht nepo ,】B【 〕6〔 ot gnirrefeR

are firmly inserted.

Solution 3 : fo rotcennoc eht fi kcehc dna rellortnoc eht elbmessasid 】A【 〕6〔 ot gnirrefeR

panel board is disconnected.

Solution 4 : Check if the cable is broken.

Possible

Cause 3 : The switch board may be faulty.

Solution 1 : Check the analog board inside the sound source unit and the soldering on the

volume board of the controller.

Solution 2 : Replace the analog board inside the sound source unit.

Solution 3 : Replace the volume board inside the controller.

●

The controller turns on and emits electronic sounds but nothing is displayed on the

LCD, and the switch does not work.

Possible

Cause 1 : The connector may be disconnected.

Solution 1 : dna tinu ecruos dnuos eht fo revoc rotcennoc eht nepo ,】B【 〕6〔 ot gnirrefeR

check if all connectors are firmly inserted.

Solution 2 : srotcennoc lla fi kcehc dna tinu ecruos dnuos eht nepo ,】B【 〕6〔 ot gnirrefeR

are firmly inserted.

Solution 3 : fo rotcennoc eht fi kcehc dna rellortnoc eht elbmessasid ,】A【 〕6〔 ot gnirrefeR

panel board is displaced.

Solution 4 : Check if any wire is broken.

Possible

Cause 2 : The switch board may be faulty .

Solution 1 : Check the soldering surfaces on the switch panel board.

Solution 2 : Replace the switch panel board.

Page 20

– 20 –

● Nothing is displayed on the LCD but the switch panel works.

Possible

Cause 1 : The connector may be disconnected.

Solution 1 :

and check if the connector between the panel board and LCD unit is

disconnected.

Possible

Cause 2 : The LCD unit may be out of order.

Solution 1 : Replace the LCD unit.

Possible

Cause 3 : The switch board may be faulty.

Solution 1 : Check the soldering surface on the switch panel board.

Solution 2 : Replace the switch panel board.

●

The panel switch get stuck and does not spring back.

Possible

Cause 1 : A burr on the key top prevents it from springing back.

Solution 1 :

and remove the burr on the key top.

●

No sound comes from LINE OUT.

Possible

Cause 1 : Are the IN and OUT terminals correctly connected?

Solution 1 : Check the connection.

Possible

Cause 2 : The connector may be disconnected.

Solution 1 :

dna tinu ecruos dnuos eht fo revoc rotcennoc eht nepo ,】B【 〕6〔 ot gnirrefeR

check if all connectors are firmly inserted.

Solution 2 :

srotcennoc lla fi kcehc dna tinu ecruos dnuos eht nepo ,】B【 〕6〔 ot gnirrefeR

are firmly inserted.

Solution 3 :

fo rotcennoc eht fi kcehc dna rellortnoc eht elbmessasid ,】A【 〕6〔 ot gnirrefeR

LINE board is displaced.

Solution 4 : Check if the cable is snapped or not.

Possible

Cause 3 : The switch board may be faulty.

Solution 1 : Check the analog board inside the sound source unit and the soldering surfac

e

on the LINE board of the controller.

Solution 2 : Replace the analog board inside the sound source unit.

Solution 3 :

Replace the LINE board inside the controller.

Page 21

– 21 –

● The MIDI does not work.

First, refer to 〔4〕 【D】 and run it in the check mode.

If it functions normally, the problem might be in the MIDI device connected to it.

If it does not function normally, try the following solutions.

Possible

Cause 1 : Are the IN and OUT terminals correctly connected?

Solution 1 : Check the connection.

Possible

Cause 2 : The connector may be disconnected.

Solution 1 : Check all connectors and cables, as well as the LINE board.

Possible

Cause 3: The switch board may be faulty.

Solution 1 : Check the soldering surface of LINE board, as well as the board itself. If

no

clue is found, replace the board.

●

No sound comes from the headphone.

Possible

Cause 1 : Is the headphone plug not fully inserted?

Solution 1 : Plug it in firmly.

Possible

Cause 2 : The headphone may be out of order.

Solution 1 : Try to connect the headphone to another device and recheck.

Solution 2 : Try to use another headphone.

Possible

Cause 3 : The connector may be disconnected.

Solution 1 : Check all connectors and cables as well as the LINE board.

Possible

Cause 4 : The switch board may be faulty.

Solution 1 : Check the soldering surfaces of the LINE board, as well as the board itself.

If

no clue is found, replace the board.

●

The pedal does not work for the electronic sound play.

Possible

Cause 1 : A connector may be disconnected.

Solution 1 : Check the connectors of sound source unit.

Solution 2 :

srotcennoc lla fi kcehc dna tinu ecruos dnuos eht nepo ,】B【 〕6〔 ot gnirrefeR

are firmly inserted.

Possible

Cause 2 : The position adjustment of the pedal sensor may be incorrect.

Solution 1 :

Possible

Cause 3 : The pedal sensor may be faulty.

Solution 1 : Refer to .ylreporp gnikrow si rosnes ladep eht fi kcehc dna ,】B【 〕4〔

Solution 2 : Replace the pedal sensor.

●

The pedal effect carries on for electronic sound.

Possible

Cause 1 : The position adjustment of the pedal sensor may be incorrect.

Solution 1 :

Page 22

– 22 –

●

No acoustic or electronic sound comes out even if a key is depressed.

Possible

Cause 1 : Does the shank stop rail stay at the position where the action goes in and out?

Solution 1 : .revel tes eht kcab tes dna ,】A【 〕3〔 ot refeR

Possible

Cause 2 : If the demo tune is playing normally, the connector of the hammer sensor might be

disconnected.

Solution 1 : Check if the connector of the sensor is disconnected. The connector is

located

inside the side board and at the side of the bass.

Solution 2 :

dna tinu ecruos dnuos eht fo revoc rotcennoc eht nepo ,】B【 〕6〔 ot gnirrefeR

check if all connectors are firmly inserted.

Solution 3 :

srotcennoc lla fi kcehc dna tinu ecruos dnuos eht nepo ,】B【 〕6〔 ot gnirrefeR

are firmly inserted.

Solution 4 :

Check if one of the relay connectors inside the sound source unit is disconnected.

●

No sound comes from any of the 4th keys.

Possible

Cause 1 : The connector is disconnected or the cable is broken.

Solution 1 : If this happens at the second and following sections of the sensor PWB,

check

the cable connectivity between the sensor boards.

Solution 2 : If you cannot solve the problem following Solution 1 or if the error

happens

in the first section, remove the connector cover of the sound source unit and

.】B【 〕6〔 ot gnirrefer ,)2( yaler rosnes eht fo stcatnoc elbac eht kcehc

Solution 3 : Check if the sensor relay (2) is broken.

Possible

Cause 2 : Failure of FPGA board.

Solution 1 : .draob AGPF eht ecalper ,】C【 〕6〔 ot gnirrefeR

●

Only a certain key does not emit sound or it rarely does.

Possible

Cause 1 : The hammer stop position at the mute mechanism is too far from the string. Or the sensor

does not detect it well.

Solution 1 :

Solution 2 :

per key.

Possible

Cause 2 : The shutter is missing or broken.

Solution 1 :

attach the shutter.

Possible

Cause 3 : Something is abnormal with the sensor.

Solution 1 : Replace the board.

Page 23

– 23 –

● No sound is emitted on the consecutive keys on the keyboard.

Possible

Cause 1 : The install position of the sensor PWB assy is floating upwards (too far from the shutter).

Solution 1 :

Possible

Cause 2 : Something abnormal with the sensor board.

Solution 1 :

gnitsujdA“ 】C【 〕3〔 ot gnidrocca ti tsujda dna llatsni ,draob eht gnicalper retfA

●

Volume levels are variable or only strong keystroke makes sound, while a light keystroke does not.

Possible

Cause 1 : The hammer stop position at the mute mechanism is too far from the string. Or the sensor

does not detect it well.

Solution 1 :

Solution 2 :

key by key.

●

No sound occasionally comes out with consecutive keystroking.

Possible

Cause 1 : The sensor malfunctions when the hammer hits strongly by consecutive stroking.

Solution 1 : Bring the sensor closer to the string side.

Solution 2 :

●

Sound was stopped or deadened while depressing the key.

Possible

Cause 1 : The hammer gets back to the sound stop position when it returns to the backstop.

Solution 1 : Adjust the backstop at a position of 15 mm from the string.

●

Noise can be heard before the hammer reach the string or the hammer sticks on it.

Possible

Cause 1 : The shutter and sensor positions are too close in the front-back direction, and the shutter

touches inside the sensor cover.

Solution 1 : Loosen the screws of the sensor PWB frame or the sensor PWB assy,

then

adjust the sensor PWB frame.

Possible

Cause 2 : The shutter and sensor positions are too close vertically and the shutter touches the

bottom of the sensor cover.

Solution 1 :

Referring to〔3〕【C】“Adjusting the Sensor Height”, adjust the height of sensor.

Possible

Cause 3 : The unit width is too long vertically and the pin block (wrest plank) is located too low,

therefore the shutter touches the lower surface of the pin block.

Solution 1 :

Plane the lower surface of the pin block.

Page 24

– 24 –

● Mechanical noise can be heard from a certain key while keystroking.

Possible

Cause 1 : The gluing between the shutter and hammer shank is out of alignment. Or the gluing

dimension is too small. Or its end is detached.

Solution 1 : Apply an additional layer of bonding agent (Cemedine Super X Clear) on it.

Possible

Cause 2 : The gluing between the hammer shank and hammer is out of alignment.

Solution 1 : Apply and additional layer of instant wood glue on it.

Possible

Cause 3 : The damper stop rail locates too high and the damper lever jumps and hits the sustaining

(sostenuto) rod when the key is stroked strongly.

Solution 1 : Adjust the position of the damper stop rail to fasten firmly.

●

Noise can be heard when the soft pedal is released.

Possible

Cause 1 : The sensor PWB frame is touching the "jaw" of the frame.

Solution 1 : Loosen the screws fastening the sensor PWB frame, then move the frame

towards the treble side.

●

Sound is emitted in the entire or certain key area while keystroked strongly.

Possible

Cause 1 : The shank stop rail is too close to the string (too high).

Solution 1 : .liar pots knahs eht fo thgieh eht tsujda dna ,】B【 〕3〔 ot refeR

Possible

Cause 2 : The hammer shank does not knock the shank stop rail in parallel.

Solution 1 : .liar pots knahs eht fo thgieh eht tsujda dna ,】B【 〕3〔 ot refeR

●

When keystroked strongly on the bass area of the second section, a slight sound can be

heard despite the muting mode.

Possible

Cause 1 : Even though the hammer shank is blocked, the damper rubs the string when it goes up.

This emits a slight sound.

Solution 1 : This is as designed.

●

Even when the damper pedal is stepped on, the sound of string does not fade away.

Possible

Cause 1 : Since the damper is detaching from the strings, the sound will not fade away.

Solution 1 :

Because of the piano's structure, this cannot be canceled.

Page 25

– 25 –

●

In the entire key area or in certain keys, there is no feel of smoothness before letting off.

Possible

Cause 1 : The hammer shank is touching the shank stop rail before letting off.

Solution 1 : dnuos gnittime tuohtiw egnar eht ni liar pots eht esiar ,】B【 〕3〔 ot gnirrefeR

when keystroked strongly.

Solution 2 : Expand the let off within 4 mm.

●

The hammer shank collides against the stop rail before letting off.

Possible

Cause 1 : Is the set lever released? (The set lever is used to extract/reinstall the action.)

Solution 1 : .revel tes eht esaeler ,】A【 〕3〔 ot gnirrefeR

●

The feel of key touches differ depending on the sections.

Possible

Cause 1 : The hammer shank touches the cables between the sensor PWB assys.

Solution 1 : eht neewteb selbac eht eldnub dna rosnes eht nepo ,】A【 〕3〔 ot gnirrefeR

boards with a banding band etc.

Possible

Cause 2 : The hammer shank and the stop rail are touching.

Solution 1 : tekcarb eht fo wercs eht nesool neht ,rosnes eht nepo ,】A【 〕3〔 ot gnirrefeR

and adjust the position.

●

The mute lever is heavy or does not return. The terminal of the wire came off.

Possible

Cause 1 : The roller of the drive lever (P) located inside the piano is not rotating.

Solution 1 : )P( revel evird eht ecalper ro 】G【 〕3〔 ni denialpxe sa rellor eht ecalpeR

including the roller.

Solution 2 : Replace the wire whose terminal came off.

●

The action cannot be extracted due to obstacle.

Possible

Cause 1 : The set lever at the left end of action is not pulled up.

Solution 1 : .uoy sdrawot ti gnillup yb revel tes eht tfil ,】A【 〕3〔 ot gnirrefeR

Possible

Cause 2 : The binder of the cables at the left side of the piano body is not released.

Solution 1 : .rednib eht esaeler ,】A【 〕3〔ot gnirrefeR

Possible

Cause 3 : The large connector located at the inner left side of the piano body is not removed.

Solution 1 : dna rewol eht ta detacol sgnittfi tes eriw eht ffo ekat ,】A【 〕3〔 ot gnirrefeR

upper sides of the connectors, then remove the connectors.

Page 26

– 26 –

● The fallboard does not open and close smoothly.

Possible

Cause 1 : The cable touches the fallboard at the inner left side of the piano body.

Solution 1 : Bundle and push backwards the cables using the binder.

●

After releasing the Mute mode, additional keystrokes are needed before the piano starts

emitting sounds.

Possible

Cause 1 : The mute mechanism does not function well.

Solution 1 : Replace the springs of the mute mechanism on the inner side of the piano and

on the action.

Solution 2 : Loosen the screws on the drive part of the entire mute mechanism, and

adjust any distortion of the assembly.

●

No sound comes from the soundboard speaker.

Possible

Cause 1 : The headphone is connected or in use.

Solution 1 : This is as designed.Plug off the headphone from the controller.

Possible

Cause 2 : The connector may be disconnected.

Solution 1 : Check the connectors of the sound source unit.

Possible

Cause 3 : A connector inside the sound source unit is disconnected.

Solution 1 : .srotcennoc eht kcehc dna tinu ecruos dnuos eht nepo ,】B【 〕6〔 ot gnirrefeR

Possible

Cause 4 : There are some problems with the sound system PWB board.

Solution 1 : dnuos eht ecalper dna tinu ecruos dnuos eht nepo ,】B【 〕6〔 ot gnirrefeR

system PWB board.

●

Sound comes out from the supplementary speaker on the pillar, but no sound comes

from the soundboard.

Possible

Cause 1 : Pressing force of the transducer is not properly adjusted.

Solution 1 : Referring to 〔3〕 【E】, adjust the pressing force of the transducer.

Possible

Cause 2:The cable of the transducer (actuator) is disconnected.

Solution 1 :

Referring to 〔3〕 【E】, remove the actuator (transducer) cover and check the

connection of the cables.

Possible

Cause 3 : The transducer (actuator) is faulty.

Solution 1 : .draob )recudsnart( rotautca eht ecalper ,】M【 〕6〔 ot gnirrefeR

●

The transducer is functioning, but no sound comes from the supplementary speaker on

the pillar.

Possible

Cause 1 : The wire inside the speaker box is disconnected.

Solution 1 : .xob rekaeps eht edisni eriw eht kcehc ,】L【 〕6〔 ot gnirrefeR

Possible

Cause 2 : The speaker unit is out of order.

Solution 1 :

.xob rekaeps eht edisni tinu eht ecalper ,】L【 〕6〔 ot gnirrefeR

Page 27

– 27 –

● The soundboard speaker does not sound loud enough.

Possible

Cause 1 : There are some problems with the sound system PWB board.

Solution 1 :

dnuos eht ecalper dna tinu ecruos dnuos eht nepo ,】B【 〕6〔 ot gnirrefeR

system PWB board.

Possible

Cause 2 : This is as designed. (The soundboard speaker is an intermediate means between

headphone and acoustic sound.)

Solution 1 : If you connect the external amplifier and speaker to the LINE OUT o

f

controller, you will hear the sound that the amplifierr can perform.

Page 28

– 28 –

04

03

09

02

08

10

07

06

05

06

06

9

01

〔6〕 PARTS LIST & ASSEMBLING INSTRUCTIONS

【A】 Controller

【A-1】 Control Box

No. Parts Name Code No.

01 Controller Assy. A02245

02 Controller Chassis Assy. —

03 Control Panel Assy. —

04 Slide Rail Assy. —

05 +Binding Head P-Tite 3*8 WHC or BKC 798319

06 +Binding Head S-Tite 3*8 Black 798007

07 Hand grip 953754

08 Knob 812038

09 Cushion 953764

10 Power Switch Button 810031

Page 29

– 29 –

01

02

03

04

05

06

08

07

10

09

〔6〕 PARTS LIST & ASSEMBLING INSTRUCTIONS

【A】 Controller

【A-2】 Control Panel Parts

No. Parts Name Code No.

01 Control Panel 953743

02 M PWB Assy. (KEP-503) —

03 +Binding Head P-Tite 3*6 Black 798528

04 +Binding Head P-Tite 3*8 WHC or BKC 798319

05 E PWB Assy. (KEP-545) 238925

06 Key Top with Lens Black2 (DCRE-0003) 950867

07 Key Top Gray2 (DCRE-0009) UP 950897

08 Key Top Gray4 (DCRE-0009) RIGHT 950898

09 LCD cover 953745

10 Key Top Cushion 953744

Page 30

– 30 –

01

08

02

03

04

05

06

07

09

〔6〕 PARTS LIST & ASSEMBLING INSTRUCTIONS

【A】 Controller

【A-3】 Controller Chassis Parts

No. Parts Name Code No.

01 Controller Chassis 953746

02 PWB Assy. (KEP-546) 238925

03 PWB Assy. (KEP-541) 238923

04 Power Switch, LED, Volume PWB support Assy. —

05 +Binding Head S-Tite 3*8 Black 798007

06 +Binding Head S-Tite 3*8 798030

07 PWB Assy. (KEP-542) 238923

08 +Binding Head P-Tite 3*8 WHC or BKC 798319

09 Binder 721220

Page 31

– 31 –

01

02

03

04

05

06

07

〔6〕 PARTS LIST & ASSEMBLING INSTRUCTIONS

【A】 Controller

【A-4】 Power SW, LED, Volume Unit Parts

No. Parts Name Code No.

01 Power Switch, LED, Volume PWB support Assy. 953747

02 Power Switch 816981

03 PWB Assy. (KEP-540) 238923

04 PWB Assy. (KEP-544) 238923

05 +Binding Head S-Tite 3*8 798030

06 Spacer 953748

07 Nut 812420

Page 32

– 32 –

01

03

02

04

08

05

06

07

09

〔6〕 PARTS LIST & ASSEMBLING INSTRUCTIONS

【A】 Controller

【A-5】 Slide Rail Unit Parts

No. Parts Name Code No.

01 Slide Rail 953750

02 Slide rail board 953751

03 Fixing board 953749

04 +Truss Screw 797854

05 +Countersunk Screw M3*6 798227

06 Ball fastener 953752

07 Spacer 953753

08 +Countersunk Screw M2.6*12 799036

09 Hex Nut 799037

Page 33

– 33 –

2

3

4

5

7

6 8

9

10

11

12

13

1

〔6〕 PARTS LIST & ASSEMBLING INSTRUCTIONS

【B】 Sound System Unit

【B-1】 Sound System Assy.

No. Parts Name Code No.

1 Sound System Assy. A02253

2 PCB chassis assy. A02261

3

Sideboard for sound system

PCB chassis (2)

910031

4

Sideboard for sound system

PCB chassis (1)

910015

5 Protector (1 piece) 952443

6 PWB Assy. (KEP-539) A01621

7 PWB Assy. (KEP-339) A02288

8 +Binding Head S-Tite 3*6 953628

9 +Binding Head S-Tite (Black) 3*6 953610

10 PWB Assy. (KEP-543) A01630

11 PWB Chassis Cover 910082

12 Connector Cover 916986

13 Binder 851108

Page 34

– 34 –

1

3

2

4

〔6〕 PARTS LIST & ASSEMBLING INSTRUCTIONS

【B】 Sound System Unit

【B-2】 Amplier PWB

No. Parts Name Code No.

1 Sound System Assy. A02253

2 +Binding Head S-Tite 3*6 953628

3 PWB Assy. (KEP-276) 918512

4 PWB spacer 918024

Page 35

– 35 –

INSULOK tie T-18R

* Face the bindig part

to this side

FPGA relay(2) cable

Tighten together with ground terminal

Wiring diagram

Sensor relay(1) cable

Assembling

Instruction

1. Fasten SFPGA PWB assy ② on FPGA PWB cover assy ① with four screws ⑤ .

*

Install assy in the direction shown in the drawing.

2. Insert sensor relay (1) into the hole of FPGA PWB cover assy ① , then fasten D-sub connector ③ and

D-sub spring ④ with two screws ⑤ .

3. Connect sensor relay (1) to the two connectors on the FPGA PWB.

4. Connect sensor relay (2) to one connector on the FPGA PWB, then fasten it with INSULOK tie.

No. Description Description Remarks PN

1 FPGA PWB Cover Assy FPGA PWB cover assy 910121

2 FPGA PWB Assy FPGA PWB assy KEP-267 (2) 238361

3

D-sub Socket

(SENSOR Relay (1) Cable)

D-sub socket

(Sensor relay (1) cable)

Sensor relay (1) cable 950669

4 D-sub. Spring D-sub Spring D110277 950683

5

+

BINDING TAPTITE SCREW

S TITE

+

Binding taptite screw S tite

M3 x 6 812255

〔6〕 PARTS LIST & ASSEMBLING INSTRUCTIONS

【C】 D-sub Box

Page 36

– 36 –

1

2

Sensor cover floating

○ ×

Sensor cover and assy adhered

Assembling Instruction

1. Fit sensor cover ② into the hole of sensor PWB ① .

* 【IMPORTANT】 Make sure the sensor cover is pushed deeply, and

does not float. (shown in the drawing left down)

Table1

Name of Sensor PWB A-D assy, Corresponding Sensor PWB, Number of Sensor Cover

Name of Sensor PWB A-D assy

Sensor PWB Number of sensor cover

Sensor PWB (1) assy

KKB-036 A (1)

[KKB-037 A (1)]

30

[26]

Sensor PWB (2) assy

KKB-036 B (1)

[KKB-037 B (1)]

16

[28]

Sensor PWB (3) assy

KKB-036 C (1)

[KKB-037 C (1)]

22

[18]

Sensor PWB (4) assy

KKB-036 D (1)

[KKB-037 D (1)]

20

[16]

Without[ ]=GM,GE,RX-1, with[ ]= RX-2,3,5

No. Description Description Remarks PN

1 Sensor PWB A-D Assy Sensor PWB (A-D assy) See D-2

2 Sensor Cover Sensor cover 909050

〔6〕 PARTS LIST & ASSEMBLING INSTRUCTIONS

【D】 Sensor

【D-1】 Sensor Cover

Page 37

– 37 –

〔6〕 PARTS LIST & ASSEMBLING INSTRUCTIONS

【D】 Sensor

【D-2】 Sensor PWB Frame Assy

Section 1 Section 2 Section 3 Section 4

Assembling

Instruction

1. Fasten sensor PWB (1) assy ③ on sensor PWB frame (1) assy ① with eight screws ⑦ .

2. Fasten sensor PWB (2) (3) (4) assys ④⑤⑥ to sensor PWB frame (2) assy ② with 18 screws ⑦ (50

screws for RX-2, 3, 5).

*

After assembled, make sure that the warp of both assy sides in each section shown in the drawing

below stays within 1 mm.

*

If the warp above mentioned is more than 1 mm, correct it by bending the PWB frame by hands.

No. Description Description Remarks PN

1 Sensor PWB Frame (1) Assy Sensor PWB frame (1) assy 909068 [909122]

2 Sensor PWB Frame (2) Assy Sensor PWB frame (2) assy 909157 [909351]

3 Sensor PWB (1) Assy Sensor PWB (1) assy KKB-036A(1) [KKB-037A(1)] 238359 [238360]

4 Sensor PWB (2) Assy Sensor PWB (2) assy KKB-036B(1) [KKB-037B(1)] 238359 [238360]

5 Sensor PWB (3) Assy Sensor PWB (3) assy

KKB-036C(1) [KKB-037C(1)]

238359 [238360]

6 Sensor PWB (4) Assy Sensor PWB (4) assy

KKB-036D(1) [KKB-037D(1)]

238359 [238360]

7

+ PAN WASHER DOUBLE

SEMS MACHINE SCREW

+ Pan washer double SEMS

machine screw

M3 x 4

798899

Without [ ]= GM,GE,RX-1

With[ ]= RX-2,3,5

Page 38

– 38 –

6

2

1

4

3

5

6

7

22

1

Detail A

Stop rail cushion (1), Stop rail support plate (1) Attaching position

22

Stop rail cushion (1) Attaching position

Align to the edge of R corner

Mating surfaces

Detail A

Mating surfaces

Align to the bend

2

Assembling Instruction

1. Attach two pieces of stop rail cushion (1) ② on shank stop rail (1) ① .

* Observe the attaching position shown in the drawing below.

2. Attach stop rail upper cushion (1) ③ and stop rail support plate (1) ④ on shank stop rail (1) ① .

* Observe the attaching position shown in the drawing below.

3. Insert four screws ⑤ and eight polyslider washers ⑥ into shank stop rail (1) ① .

4. Attach action scale sticker ⑦ on shank stop rail (1) ① .

* Observe the attaching position shown in Detail A.

No. Description Description Remarks PN

1 Shank Stop Rail (1) Shank stop rail (1) 917419 [915769]

2 Stop Rail Cushion (1) Stop rail cushion (1) 917443 [915807]

3 Stop Rail Upper Cushion (1) Stop rail upper cushion (1) 917478 [915874]

4 Stop Rail Board (1) Stop rail board (1) 917451 [915858]

5

+

BINDING WASHER DOUBLE

SEMS MACHINE SCREW

+ Binding washer double

SEMS machine screw

M3 x 6 442569

6 Polyslider Washer Polyslider washer t=0.8

2.85- 7 916382

7 Action Scale Sticker Action scale sticker 915882

Without [ ]=

GM,GE,RX-1

With[ ]= RX-2,3,5

〔6〕 PARTS LIST & ASSEMBLING INSTRUCTIONS

【E】 Stop Rail

【E-1】 Shank Stop Rail (1)

Page 39

– 39 –

5

2

1

4

3

6

2

6

10

1

10

Align to the edge of R corner

Mating surfaces

Stop rail cushion (2) Attaching position

Stop rail cushion (2), Stop rail support plate (2) Attaching position

Assembling Instruction

1. Attach two pieces of stop rail cushion (2) (3) (4) ② on shank stop rail (2) (3) (4) ① .

* Observe the attaching position shown in the drawing below.

2. Attach stop rail upper cushion (2) (3) ③ and stop rail support plate (2) (3) ④ on shank stop rail (2) (3) ① .

* Observe the attaching position shown in the drawing below.

3. Insert four screws ⑤ and eight polyslider washers ⑥ into shank stop rail (2) (3) (4) ① .

No. Description Description Remarks PN

Shank Stop Rail (2) Shank stop rail (2)

917494 [915971]

1 Shank Stop Rail (3) Shank stop rail (3)

917656 [916242]

Shank Stop Rail (4) Shank stop rail (4)

917711 [916358]

Stop Rail Cushion (2) Stop rail cushion (2)

917508 [915980]

2 Stop Rail Cushion (3) Stop rail cushion (3)

917664 [916269]

Stop Rail Cushion (4) Stop rail cushion (4)

916366 [916366]

3

Stop Rail Upper Cushion (2) Stop Rail Upper Cushion (2)

917591 [916021]

Stop Rail Upper Cushion (3) Stop Rail Upper Cushion (3)

917699 [916293]

4

Stop Rail Board (2) Shank Stop Rail Board (2)

917583 [915998]

Stop Rail Board (3) Shank Stop Rail Board (3)

917681 [916277]

5

+

BINDING WASHER DOUBLE

SEMS MACHINE SCREW

+ Binding washer double

SEMS machine screw

M3 x 6 442569

6 Polyslider washer Polyslider Washer t=0.8

2.85- 7 916382

Without [ ]= GM,GE,RX-1

With[ ]= RX-2,3,5

〔6〕 PARTS LIST & ASSEMBLING INSTRUCTIONS

【E】 Stop Rail

【E-2】 Shank Stop Rail (2) (3) (4)

Page 40

– 40 –

Assembling Instruction

1. Insert hexagon nut ⑦ into sensor screw ④ .

2. Insert sensor screw ⑥ into stop rail arm (1) (2) (3) ① until the point shown in the drawing below.

3. Tighten hexagon nuts ⑦ and fasten sensor screws ⑥ .

* Assemble a pair of stop rail arm (1) (2) L&R per unit. (See the drawing below for the configuration)

* Assemble two stop rail arm (3) per unit.

Stop rail arm (1) L/R

Stop rail arm (2) L/R

Stop rail arm (3)

No. Description Description Remarks PN

1 Stop Rail Arm (1) L Stop rail arm (1) L 915360

2 Stop Rail Arm (1) R Stop rail arm (1) R 915386

3 Stop Rail Arm (2) L Stop rail arm (2) L 915424

4 Stop Rail Arm (2) R Stop rail arm (2) R 915459

5 Stop Rail Arm (3) Stop rail arm (3) 915556

6 Sensor Screw Sensor screw CN-14R 914762

7 Nut Hexagon nut M4 917222

〔6〕 PARTS LIST & ASSEMBLING INSTRUCTIONS

【F】 Stop Rail Arm

【F-1】 Stop Rail Arm (1)L/R, (2)L/R, (3)

Page 41

– 41 –

10

6

6

8

11

2

1

7

4

3

5

9

8

12

10

10

13

14

15

Additional processing on muffler arm bush

*Cut at position shown below.

Cutting position

⑬Muffler Arm Bush

(Flange)

Assembling Instruction

1. Fasten spring hook ② on the stop rail bracket (1) ① with two screws ⑧ .

2. Fasten rail arm bearing ③ on the stop rail bracket (1) ① with two screws ⑧ .

3. Insert muffler arm bush ④ into rail arm bearing ③ in the direction shown in the drawing.

4. Fasten adjust base (1) ⑤ on stop rail bracket (1) ① with two screws ⑨ .

5. Insert and fasten sensor screw ⑥ into adjust base (1) ⑤ until the point shown in the drawing below.

* Fasten it perpendicularly

6. Sandwich spring set fittings ⑦ with two polyslider washers ⑩, then fasten it on the stop rail bracket (1

)

① with screw ⑮ .

* Adjust fastening torque of screw ⑮ in order to rotate smoothly the spring set fittings.

7. Keeping the state of step 6 above, fasten nut ⑪ and tighten screw ⑮ .

8. Attach spring hook felt ⑫ on the bent part of spring hook ② .

9. Attach flange ⑬ cut off from muffler arm bush ④ , on spring hook ② with screw ⑭ .

* Assemble one piece per unit.

No. Description Description Remarks PN

1 Stop Rail Bracket (1) Stop rail bracket (1) 921751

2 Spring Hook Spring hook 914584

3 Rail Arm Bearing Rail arm bearing 914282

4 Muffler Arm Bush Muffler arm bush 463400

5 Adjust Base (1) Adjust base (1) 914657

6 Sensor Screw Sensor screw CN-14R 914762

7 Spring Set Ftgs. Spring set Fittings 914614

8 +

BINDING MACHINE SCREW

+ Binding machine screw M3 x 6 Black 878804

9

+

BINDING TAPTITE SCREW

P TITE

+

Binding taptite screw P tite

M3 x 10 Black 914941

10 Polyslider Washer Polyslider washer t=0.5

4.2- 10 914851

11 HEXAGON NUT Nut M4 917222

12 Spring Hook Felt Spring hook felt 914959

13 Muffler Arm Bush (Flange) Muffler arm bush (Flange) 463400

14

+ PAN WASHER DOUBLE

SEMS MACHINE SCREW

+ Pan washer double SEMS

machine screw

M4 x 10

917206

15 + TRUSS MACHINE SCREW + Truss machine screw M4 x 8 878782

〔6〕 PARTS LIST & ASSEMBLING INSTRUCTIONS

【G】 Bracket

【G-1】 Stop Rail Bracket (1)

Page 42

– 42 –

5

6

2

1

3

4

7

3

2

10

5

5

6

2

1

3

4

7

3

2

10

5

6

3

1

2

4

7

5

Assembling Instruction

1. Fasten two rail arm bearings ② on stop rail bracket (2) ① with four screws ⑥ .

3. Insert two muffler arm bushes ③ into rail arm bearing ② in the direction shown in the drawing.

4. Fasten adjust base (2) ④ on stop rail bracket (2) ① with two screws ⑦ .

5. Insert and fasten two sensor screws ⑤ into adjust base (2) ④ until the point shown in the drawing

below.

* Fasten it perpendiculary.

* Assemble one piece per unit.

Assembling Instruction

1. Fasten rail arm bearing ② on rail arm bracket (3) ① with two screws ⑥ .

3. Insert muffler arm bush ③ into rail arm bearing ② in the direction shown in the drawing.

4. Fasten adjust base (3) ④ on stop rail bracket (1) ① with two screws ⑦ .

5. Insert and fasten sensor screw ⑤ into adjust base (1) ④ until the point shown in the drawing below.

* Fasten it perpendicularly.

* Assemble three pieces per unit.

No. Description Description Remarks PN

1 Stop Rail Bracket (2) Stop rail bracket (2) 914169

2 Rail Arm Bearing Rail arm bearing 914282

3 Muffler Arm Bush Muffler arm bush 463400

4 Adjust Base (2) Adjust base (2) 914975

5 Sensor Screw Sensor screw CN-14R 914762

6 +

BINDING MACHINE SCREW + Binding machine screw M3 x 6 Black 878804

7

+

BINDING TAPTITE SCREW

P TITE

+

Binding taptite screw P tite

M3 x 10 Black 914941

No. Description Description Remarks PN

1 Stop Rail Bracket (3) Stop rail bracket (3) 915050

2 Rail Arm Bearing Rail arm bearing 914282

3 Muffler Arm Bush Muffler arm bush 463400

4 Adjust Base (1) Adjust base (1) 914657

5 Sensor Screw Sensor screw CN-14R 914762

6 +

BINDING MACHINE SCREW

+ Binding machine screw M3 x 6 Black 878804

7

+

BINDING TAPTITE SCREW

P TITE

+

Binding taptite screw P tite

M3 x 10 Black 914941

〔6〕 PARTS LIST & ASSEMBLING INSTRUCTIONS

【G】 Bracket

【G-2】 Stop Rail Bracket (2) 【G-3】 Stop Rail Bracket (3)

Page 43

– 43 –

*

Attaching Position of Cushion Felt.

(circumference sketch)

* Attach the cushion felt at the position circled in the drawing below and let it come close to the pin.

Pin

Assembling Instruction

1. Attach Cushion Felt (1) - (4) ② ③ ④ ⑤ on Drive Rod ① at the position shown in the drawing.

* The attaching position in the circumference of circle should be as shown in the drawing left

below.

No. Description Description Remarks PN

1 Drive Rod Drive Rod 917737 [915122]

2 Cushion Felt (1) Cushion felt (1) 3 x 10 x 410 [360] 917753 [915149]

3 Cushion Felt (2) Cushion felt (2) 3 x 10 x 224 [375] 917800 [915190]

4 Cushion Felt (3) Cushion felt (3) 3 x 10 x 290 [236] 917907 [915203]

5 Cushion Felt (4) Cushion felt (4) 3 x 10 x 263 917915

Without [ ]= GM,GE,RX-1

With[ ]= RX-2,3,5

〔6〕 PARTS LIST & ASSEMBLING INSTRUCTIONS

【H】 Drive Rod

Page 44

– 44 –

* Fastening position for screw ⑤

Detail A

Color the top with white

* Use whiteout.

Detail A

Assembling Instruction

1. Insert nut ⑥ into screw ⑤ .

2. Tighten screw ⑤ into drive Lever (A) ① until the point shown in the

drawing

left below, and tighten nut ⑥ to fix it.

3. Insert cap ⑦ on the tip of screw ⑤ .

* Insert the cap deeply.

4. As shown in the drawing left, insert first muffler arm bushes ③ , then

adjust

lever ② into drive Lever (A) ① .

5. As shown in the drawing right, insert first muffler arm bushes ③ , then

spring

set lever ④ into drive lever (A) ① .

6. Color the edge of drive lever (A) ① with white. (See Detail A)

* Use whiteout

No. Description Description Remarks PN

1 Drive Lever (A) Drive Lever (A) 915246

2 Adjust Lever Adjust lever 915254

3 Muffler Arm Bush Muffler arm bush 463400

4 Spring Set Lever Spring set lever 915262

5 + PAN MACHINE SCREW + Pan machine screw M5 x 30 915297

6 HEXAGON NUT Hexagon nut M5 x 30 917303

7 Cap Cap 846988

〔6〕 PARTS LIST & ASSEMBLING INSTRUCTIONS

【 I 】 Drive Lever

【I-1】 Drive Lever (A)

Page 45

– 45 –

4

1

2

11

3

4

11

13

Apply adhesive around

the rod base (G-17)

6

8

12

7

9

10

14

15

16

16

16

17

5

Apply a slight coat of

grease on the rod

Assembling Instruction

【Refer

to Drawing in Left】

1. Fasten muffler arm support ②

on drive lever base ① with two screws ⑪ .

2. Press fit two bushes ④ to drive lever (P) ③ .

3. Insert the bush part of drive lever (P) ③ into drive lever base ① .

4.

Apply the bond (G-17) on the shaft of drive lever base ①, then insert muffler arm stopper rubber ⑥ on it.

5. Hook up muffler spring ⑬ on drive lever base ① and drive lever (P) ③ .

【Refer

to Drawing in Right】

6. Attach lever base spacer ⑭ behind the action crosspiece inside the rim block of piano with doublesided adhesive tape ⑯ .

* Fill up the hollow for installing the action crosspiece with spacer wood ⑮ .

7. Attach the assembled drive lever base ① on the piano with two screws ⑱ .

* The screws ⑱ should touch the rim of the block.

8. Pass control wire assy ⑩ through wire fittings ⑦ , then insert muffler arm bush ⑧ in it.

9. Pass the outer part of control wire assy ⑩ through muffler wire support ② , then insert wire fittings

⑦ into drive lever base ① .

10. Apply grease on the shaft of drive lever (P) ③ , then insert one polyslider washer and roller on it in

the order shown in the drawing.

11. Fasten wire set fittings ⑨ on drive lever (P) ③ with two screws ⑪ .

【Refer

to drawing below】

12. Check if the centers of roller and adjust lever are well aligned by observing from top of piano.

* If there is more than 3 mm gap, exchange, add or remove Lever base spacers ⑭ as needed.

No. Description Description Remarks PN

1 Drive Lever Base Drive lever base 916510

2 Muffler Wire Support Muffler wire support 471798

3 Drive Lever (P) Drive lever (P) 916528

4 Bush

Bush 53449

5 Roller Roller 916820

6 Muffler Arm Stopper Rubber Muffler arm stopper rubber 562653

7 Wire Ftgs. Wire fittings 916838

8 Muffler Arm Bush Muffler arm bush 463400

9 Wire Set Ftgs. Wire set fittings 916854

10 Control Wire Assy Control wire assy 916978

11 + FLAT MACHINE SCREW + Flat machine screw M3x10 917249

12 +

BINDING MACHINE SCREW

+ Binding machine screw M3x6 Black 878804

13 Muffler Spring Muffler Spring 985252

GM, GE, RX-1 t=6 926396