Publication 350-01001-00, 01/19/2016

Instruction Manual

Installation • Operation • Maintenance

Please read this manual and all included manuals in its entirety

before unpacking, installing, and operating your generator. If your

manual came on a CD, read all the fi les included on the CD.

Kato EngineeringP.O. Box 8447 Mankato, MN USA 56002-8447Tel: 507-625-4011

Fax: 507-345-2798Email:

Copyright © 2015 Kato Engineering, Inc. All rights reserved

KatoEngineering@emerson.com www.kato-eng.com

Standard AC generator

Single or two-bearing

Drive-end air discharge

Copyright © 2012 Kato Engineering, Inc. All rights reserved

Page 1

Notice: Because of rapid changes in

designs and processes and the variability of

Kato Engineering’s products, information in

this manual must not be regarded as binding

and is subject to change without notice.

The image on the front cover is representative only. Several variations are available

within the range of generators covered

within this manual.

Table of Contents

Introduction......................................................... 4

Foreword............................................................................ 4

Safety instructions.............................................................. 4

Ratings/description............................................................ 4

Construction and Operating Principles............ 5

Stator ................................................................................. 5

Rotor.................................................................................. 5

Bearings............................................................................. 5

Connection boxes.............................................................. 6

Excitation system............................................................... 6

Optional PMG system........................................................ 7

Other options..................................................................... 7

Installation........................................................... 8

Receiving inspection.......................................................... 8

Unpacking and moving...................................................... 8

Location............................................................................. 8

Base design....................................................................... 8

Assemble to prime mover, alignment................................ 8

Two-bearing close-coupled alignment.....................9

Two-bearing alignment...........................................14

Single-bearing alignment........................................18

Foot defl ection................................................................. 23

Doweling.......................................................................... 23

Electrical connections...................................................... 23

Space heaters................................................................. 23

Inspection before startup................................................. 23

Operation........................................................... 25

Initial startup: generators w/auto & manual control.......... 25

Initial startup: generators w/auto control only................... 25

Restoring residual magnetism/fi eld fl ashing.....................26

Continuous operation....................................................... 27

Idling................................................................................. 27

Parallel operation.............................................................. 27

Copyright © 2012 Kato Engineering, Inc. All rights reserved

Page 2

Maintenance....................................................... 30

Schedules........................................................................30

Maintenance procedures................................................. 32

Visual inspection methods of windings.................. 33

Cleaning................................................................ 35

Insulation resistance tests at low voltage.............. 35

Dry out procedures............................................... 36

Bearing lubrication................................................ 36

Rectifi er tests........................................................ 37

Disassembly ..................................................................... 39

Overall disassembly............................................... 39

Exciter armature and PMG removal...................... 40

Bearing removal.................................................... 42

Assembly .......................................................................... 43

Bearing installation................................................ 43

Overall assembly................................................... 43

Exciter armature and PMG installation.................. 43

Storage............................................................................ 45

Torque chart..................................................46-47

Troubleshooting Guide..................................... 48

Main part location............................................................. 51

List of equipment required for installation

and maintenance............................................................. 52

Page 3

Copyright © 2012 Kato Engineering, Inc. All rights reserved

WARNING: Shock hazard - Do not

service the generator or other electrical

machinery without de-energizing and

tagging the circuits as out of service.

Dangerous voltages are present, which

could cause serious or fatal shock.

NOTICE: For specifi c lubrication

instructions, always refer to the bearing

lubrication sheet that came with your

manual or the lube plate on the generator.

Unauthorized lubricants may result in a

bearing failure.

Introduction

Foreword

This manual contains instructions for installing, operating and

maintaining Kato Engineering AC brushless revolving fi eld generators.

These generators are manufactured in many sizes and ratings and with

various options.

Lubrication information, electrical connection drawings, dimensional

drawings and parts listings for your model are contained in the manual

package as supplementary information and are the specifi c source of

information for making connections and ordering replacement parts.

Information about optional components of your generator may also be

contained as a supplement.

Please read this manual and all included manuals in its entirety before

unpacking, installing, and operating your generator. If your manual

came on a CD, read all the fi les included on the CD.

Safety instructions

In order to prevent injury or equipment damage, everyone involved in

installation, operating and maintenance of the generator described in this

manual must be qualifi ed and trained in the current safety standards that

govern his or her work.

While “common-sense” prevention of injury or equipment damage

cannot be completely defi ned by any manual (nor built into any piece of

equipment), the following paragraphs defi ne warnings, cautions, Notices

and Important as they are used in this manual:

WARNING: Warnings identify an installation, operating or

maintenance procedure, practice, condition, or statement that, if not

strictly followed, could result in death or serious injury to personnel.

CAUTION: Cautions identify a hazardous situation that if not

avoided could result in minor or moderate injury.

NOTICE: Notices identify an installation, operating or maintenance

procedure, practice, condition, or statement that, if not strictly followed,

could result in destruction of or damage to equipment or serious

impairment of system operation.

IMPORTANT: Important messages are informational only.

Ratings/description

Nameplates, which are located on the side of the generator, include

serial and model number as well as rating information and bearing and

lubrication information.

Copyright © 2012 Kato Engineering, Inc. All rights reserved

Page 4

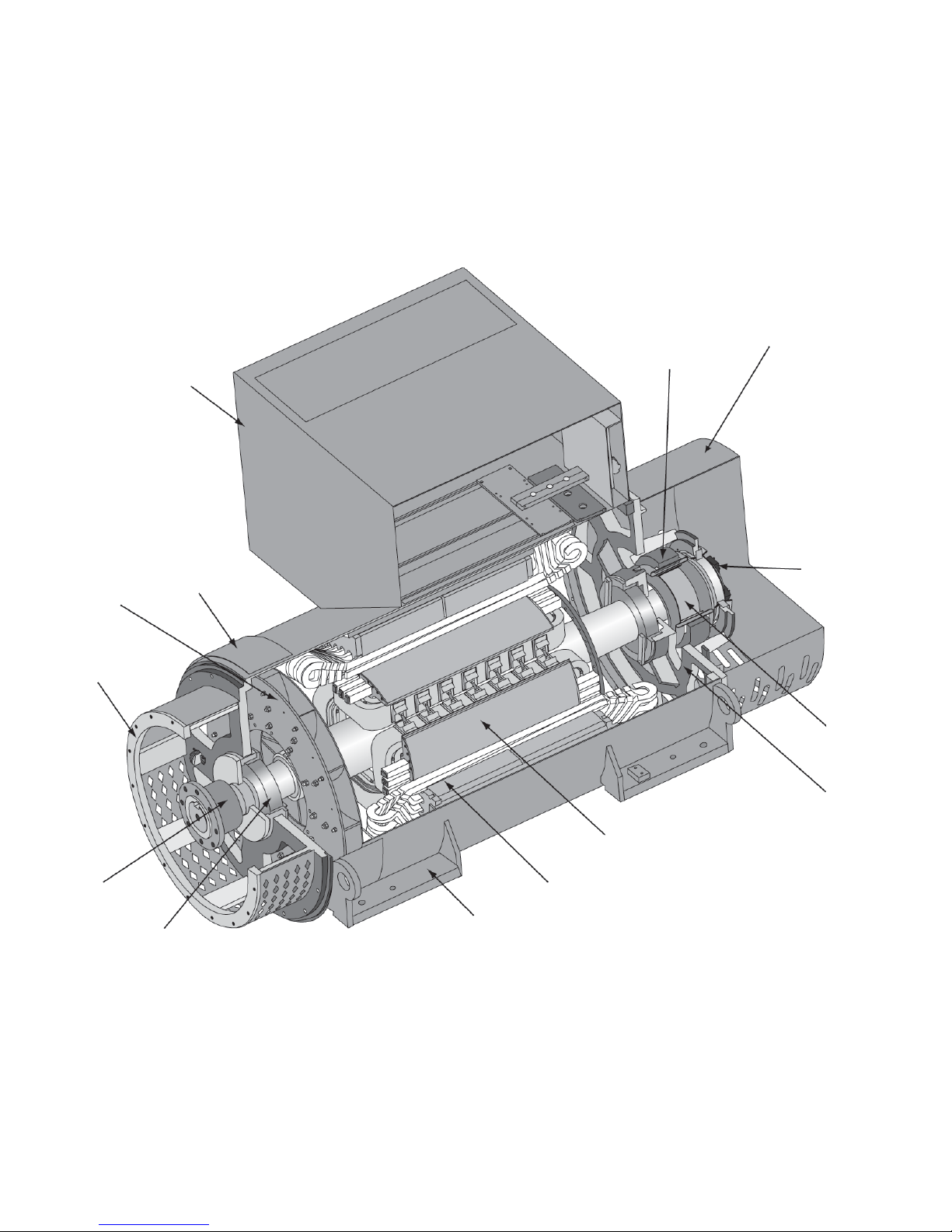

Construction and Operating Principles

Stator

The stator consists of the supporting frame, core, and armature windings.

The stator core is made from laminations, thin sheets of electrical steel,

which are stacked and held in place by steel endrings and support

bars. The rings and bars are welded to or are part of the steel frame.

Base mounting plates are welded to the bottom of the frame. The base

mounting plates allow the assembly to be mounted on the genset base.

The windings (coils) are constructed of layered and insulated copper

wire. The coils are inserted in the core slots, connected together, and

the entire assembly is vacuum-pressure impregnated with resin. Stator

leads terminate in standard connection lug or strap terminals for ease of

connection to the load.

Rotor

The main rotor assembly is the revolving fi eld. It consists of windings

in a core, which is in turn mounted on a steel shaft. The exciter armature

assembly and optional permanent magnet generator (PMG) rotor are also

mounted on the shaft as are the fan(s) and other optional accessories.

The core consists of laminations, thin sheets of electrical steel, which are

stacked together. The core makes the salient poles (four, six, eight or 10).

With six or more poles, the poles are typically attached to a center hub.

The rotor windings consists of insulated magnet wire wound around

each pole. V-blocks between each pole keep the rotor windings in place.

Damper windings consist of copper or aluminum rods that are inserted

through each pole surface and are brazed to copper or aluminum damper

end plates at each end of the lamination stack. The end plates are brazed

to adjacent poles to form a continuous damper winding.

windings are supported with bars or aluminum pole shoes. The rotor

either has resin applied during the winding process or is vacuum-pressure

impregnated with resin.

The ends of the

NOTICE: Generators equipped with sleeve

oil bearings must have oil added to the

bearing prior to rotation. Failure to comply

will result in bearing damage. See the

bearing manual.

The shaft is made from high-strength rolled or forged steel and machined

to accommodate all the rotating generator components. Keyways in

the shaft ensure precise positioning of the rotor, exciter armature, and

optional PMG rotor as well as drive couplings. On the exciter side, the

shaft has a slot or hole in its centerline for running the revolving fi eld

leads to the rectifi er.

Bearings

The generator may contain either one or two bearings. Bearings are

typically ball or roller type and are regreaseable bearings, which contain

fi ll and drain ports for easy lubrication. Sleeve bearings are optional

on some designs. A supplementary instruction will be included in

NOTICE: For specifi c lubrication

instructions, always refer to the bearing

lubrication sheet that came with your

manual or the lube plate on the generator.

Unauthorized lubricants may result in a

bearing failure.

Copyright © 2012 Kato Engineering, Inc. All rights reserved

Page 5

the manual package for sleeve bearings if they are applicable to this

generator. Some smaller generators may use heavy duty double shielded

bearings, which are typically used on smaller generators and are greased

for life.

Connection boxes

The main lead connection box houses the load lead terminals. In

addition, the generator may have auxiliary connection boxes for

connecting temperature detector outputs, space heater connectors, and

sensing outputs.

Excitation system

The excitation system consists of the exciter stator assembly and the

exciter armature assembly:

The exciter stator assembly consists of windings in a core. The core is

made from steel laminations that are stacked and welded together. The

main exciter stator coils are placed in slots in the core and form alternate

north and south poles. The entire assembly is either mounted to the end

bracket or mounted in a frame, which is mounted to the end bracket. The

stator is a stationary fi eld, which is powered by the voltage regulator.

The assembly consists of two subassemblies: the exciter armature and

the rotating rectifi er. The exciter armature assembly contains steel

laminations that are stacked and keyed on the shaft or on to a sleeve,

which is keyed to the generator shaft. A three-phase winding is inserted

into slots in the laminations. The coils are held in place by insulating

wedges. The coil extensions are braced with tape. Output leads from the

winding are connected to the rotating rectifi er assembly.

The rotating rectifi er is a three-phase full wave bridge rectifi er,

converting the AC from the exciter armature to DC, which is transferred

to the revolving fi eld windings. Two aluminum steel plates, each

containing three rotating rectifi er diodes, are mounted on each side of

an insulating hub to form the negative and positive terminals. The plates

also act as heat sinks for the diodes.

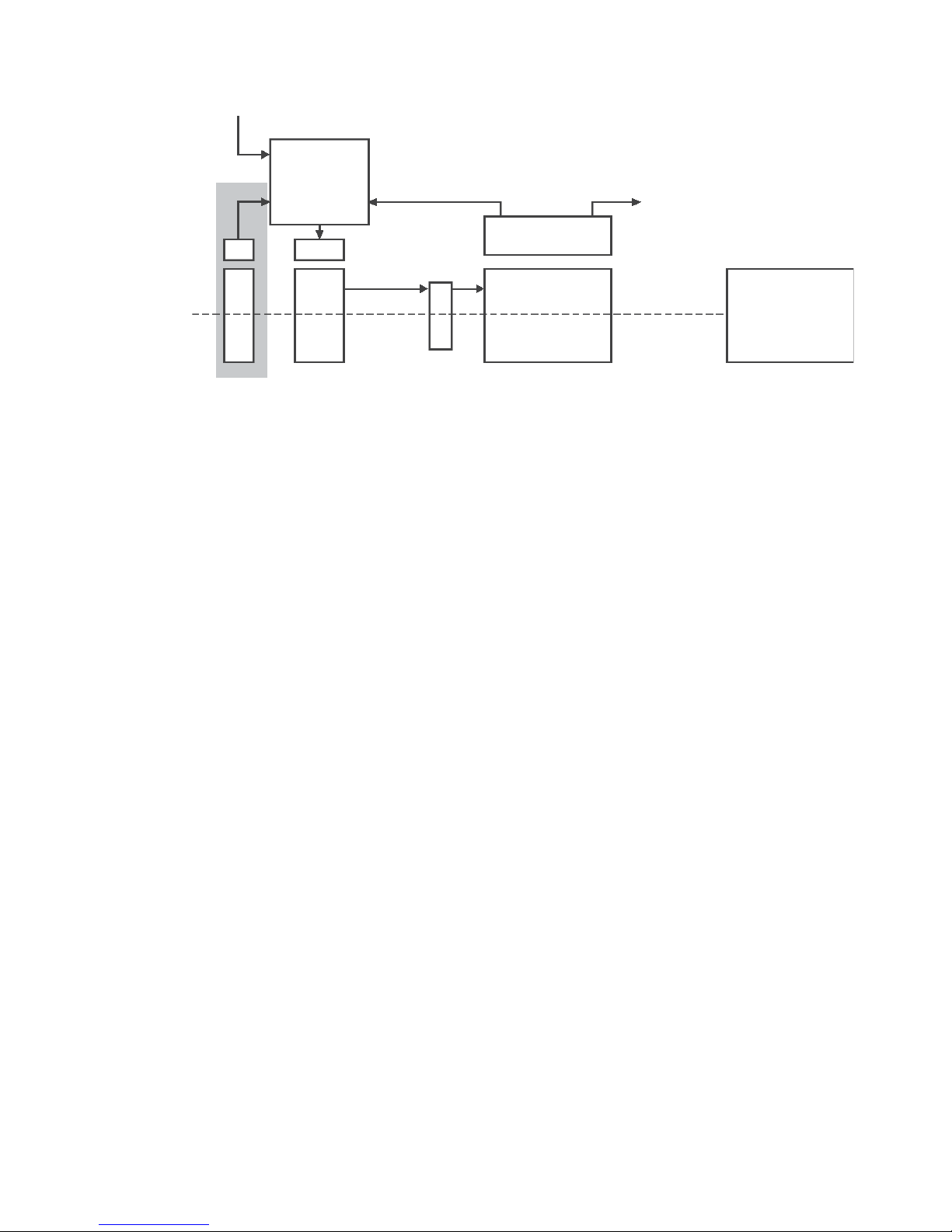

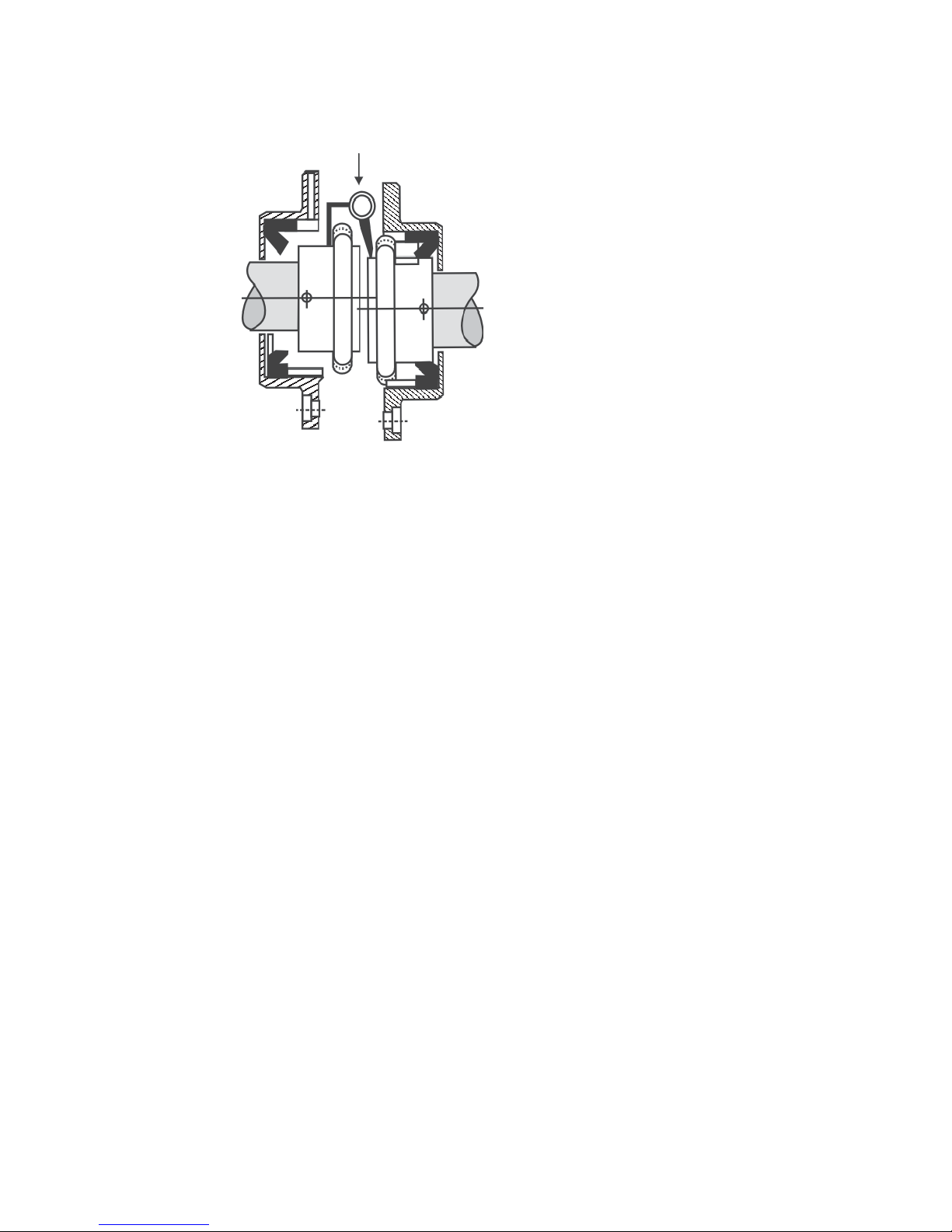

Excitation system functional overview: Exciter fi eld control is

established by the strength of the exciter fi eld current developed by

the voltage regulator system. The DC voltage and current levels of the

exciter fi eld signal from the voltage regulator varies depending upon the

generator output voltage and the loading of the output lines (see Figure

1).

Copyright © 2012 Kato Engineering, Inc. All rights reserved

Page 6

Power input

Voltage

regulator

Output leads

Main stator

PMG stato

(armature)

PMG rotor

(fi eld)

r

Exciter

armature (AC)

Figure 1: Overview of excitation system

(with an optional PMG)

Exciter stato

(fi eld)

r

Rectifi er

(armature)

Main rotor (DC)

Optional PMG system

The permanent magnet generator (PMG) system consists of the PMG

stator and PMG rotor:

The PMG stator is a stationary armature and is located within the stator

assembly that also contains the exciter stator or is a separate stator

mounted next to the exciter stator. The PMG stator consists of steel

laminations. The laminations are held in place by steel compression rings

and are welded to the frame bars of the exciter-PMG frame. The PMG

windings are placed in slots in the laminations. Insulating wedges are

inserted at the top of each slot to hold the coils in position.

Prime mover

Shaft

The PMG rotor consists of rectangular permanent magnets and cast pole

tips secured to a steel hub with nonmagnetic stainless steel bolts. The

PMG rotor is keyed to the shaft and secured with a nut and lock washer.

PMG system overview: The PMG system functions as a pilot exciter,

providing power to the automatic voltage regulator power supply. The

PMG is an AC generator that uses permanent magnets in the rotor instead

of electromagnets to provide the magnetic fi eld (see Figure 1).

Other options

Other options include, but are not limited to, space heaters, fi lters, and

temperature sensing devices.

Page 7

Copyright © 2012 Kato Engineering, Inc. All rights reserved

WARNING: Electric shocks can occur

from faulty ground connections on portable

electrical equipment and failure to ground

stationary equipment which may result in

death or injury. Be alert at all times when

installing, operating and maintaining the

generator. Avoid contact with the uninsulated

metal parts of the generator. Test all portable

devices frequently to prove that a solid

electrical circuit exits from the metal frame

though the grounding conductor, in the

electrical cord, to the grounding contact in

the attachment plug. Do not use electrical

equipment with frayed, burned or damaged

cords.

Always take extreme care when moving the

generator. Be careful to not strike objects or

personnel.

Installation

Receiving inspection

Before accepting a shipment, examine the packaging for any sign of

damage that might have occurred during transit. Report any damage to

the transportation company and Kato Engineering.

Unpacking and moving

If the generator is received during cold weather, reduce condensation on

cold surfaces and failure due to wet windings by allowing the generator

to reach room temperature before removing the protective packing.

Unpack the generator carefully to avoid scratching painted surfaces. Do

not remove the protecting lubricant from the shaft end or drive plates.

Inspect for loosely mounted components and the presence of moisture.

Inspect to make certain foreign material, such as crating nails, loose

bolts or packing material, which may have fallen into the machine during

unpacking, is removed. If damage is Noticed, determine the extent of

damage and immediately notify the transportation company claims offi ce

and Kato Engineering. Be sure to give complete and accurate details

when reporting damage.

WARNING: Apply lifting force to

structural points specifi cally provided for

lifting. Do not use the enclosure lifting holes

to lift the whole unit. Use lifting means

adequate for the weight. Observe lifting

notices attached to the generator. Failure

to observe these instructions can result in

injury, death and damage to the generator.

NOTICE: Do not attempt to transport a

single-bearing generator without maintaining

proper rotor support and with the exciter

rotor assembly removed. Failure to observe

this warning can result in equipment

damage.

NOTICE: Blocking or restriction of normal air

fl ow into or out of the generator may cause

damage to the electrical windings.

Move the generator by attaching an overhead hoist to the eyebolts

installed on the generator frame or by lifting the generator from

underneath the skid with a forklift.

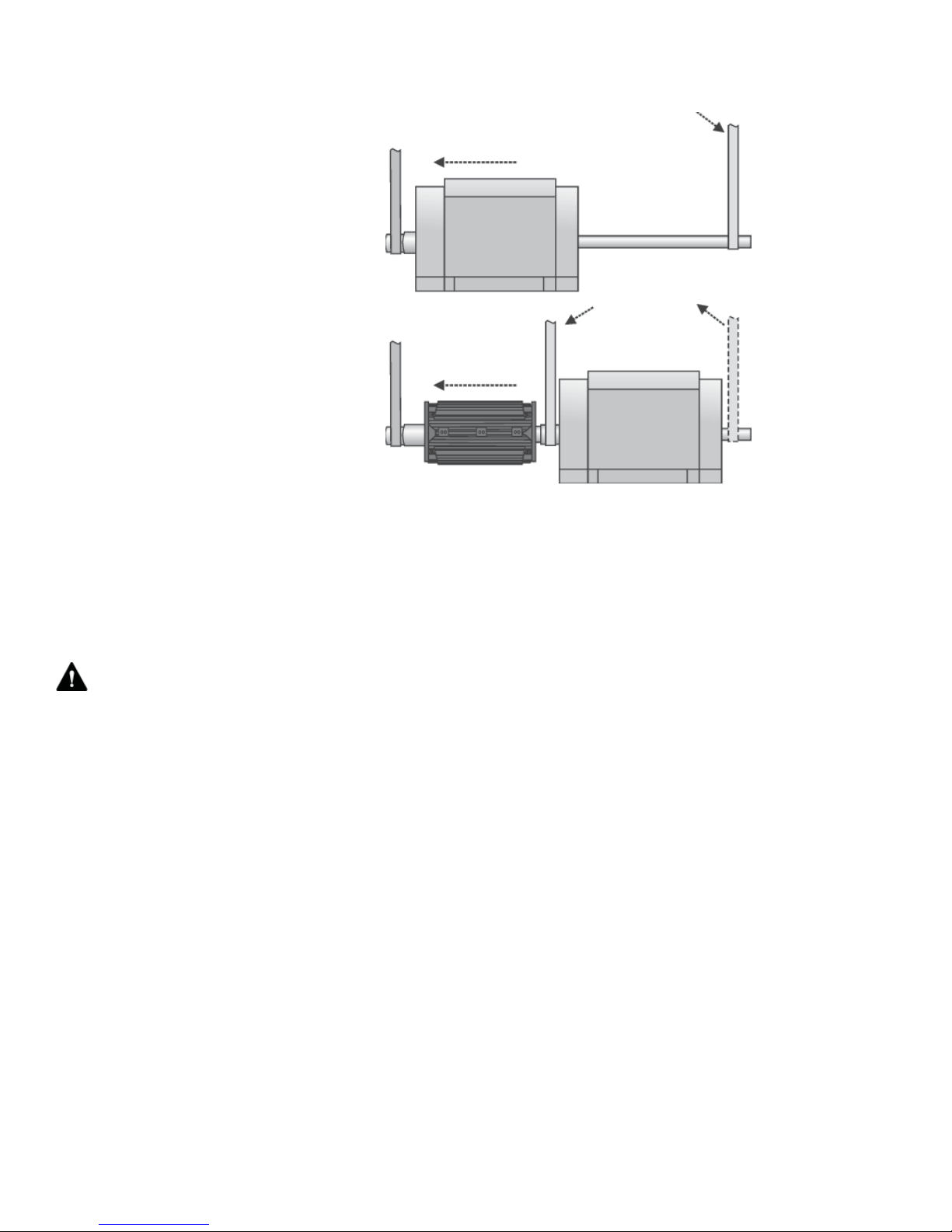

Single-bearing generators are shipped with the exciter rotor assembly

removed from the shaft and a support mounted across the drive discs to

support the rotor.

Location

Install the generator in an area so it complies with all local and industrial

regulations. Locate it in a clean, dry, well-vented area or area that is

suitable for the generator enclosure. Make sure it is easily accessible for

inspection and maintenance.

Check winding insulation resistance before placing the generator in

operation (see the maintenance section).

Protect generators operating intermittently in very damp locations with

space heaters. Slowly warm generators placed in operation after being

subjected to very low temperatures to prevent excessive condensation.

Base design

The type of base to be used will depend upon the nature of the

installation site. However, the generator base must be rigid, level, and

free from vibration. Mounting holes must be larger than the fasteners to

allow for alignment.

Copyright © 2012 Kato Engineering, Inc. All rights reserved

Page 8

Assemble to prime mover, alignment

Follow either the two-bearing alignment (if your generator model has

two bearings but no adapter to bolt to an engine fl ywheel housing),

two-bearing close-coupled alignment (if your generator model has two

bearings and an adapter for bolting to a fl ywheel housing), or single-

bearing alignment (if your generator has one bearing and drive plates).

Consult the factory for belt or gear drive alignment).

Two-bearing close-coupled alignment

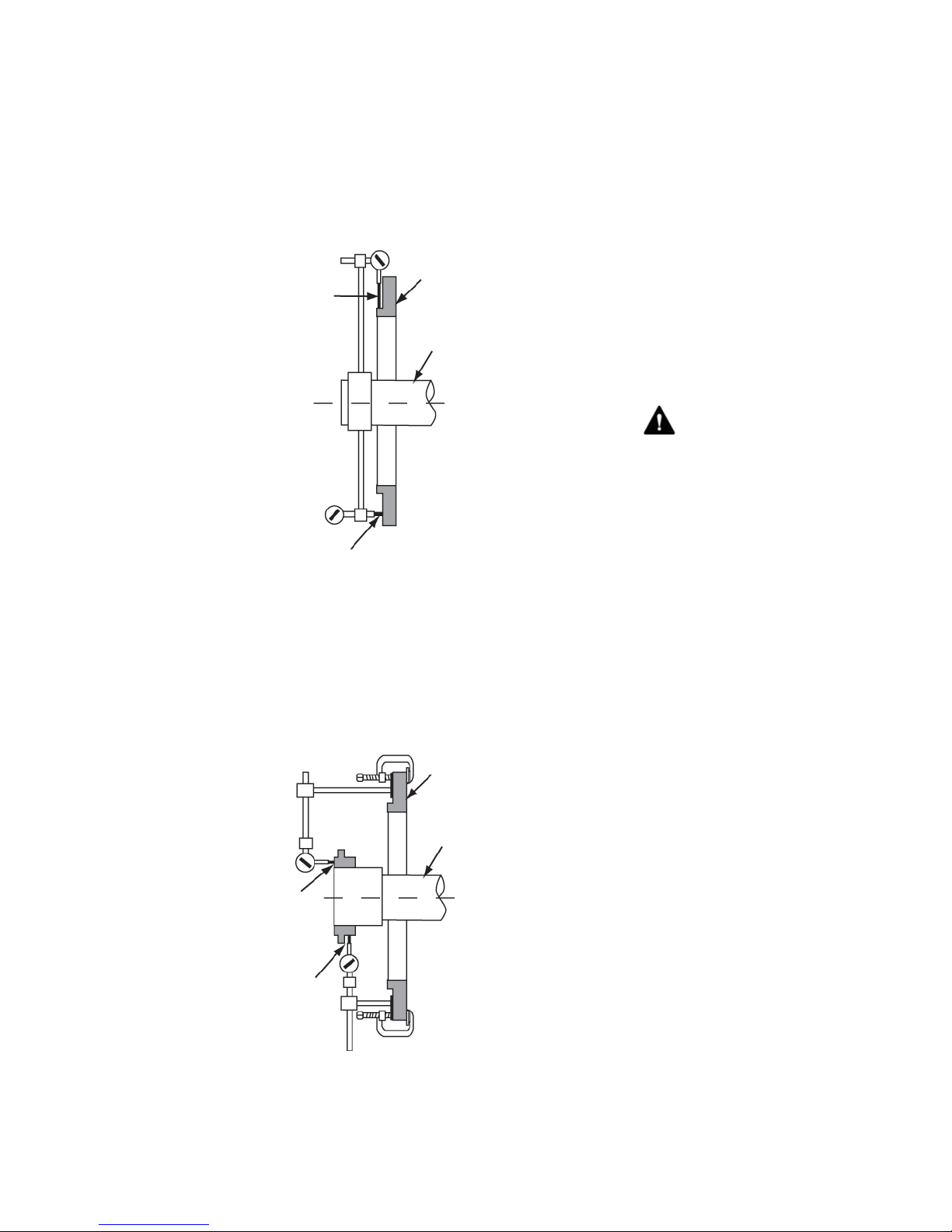

Check the engine fl ywheel housing pilot’s radial and face runout by

mounting a dial indicator and measuring the fl ywheel to the fl ywheel

housing as shown in Figure 2. See Table 1 for maximum allowable

runout.

Flywheel

Dial indicator

pointer for radial

runout

Dial indicator pointer for

face runout

Figure 2: Flywheel housing check

Flywheel housing

NOTICES:

Mounting of the indicators must allow

complete rotation of the prime mover.

Shaft

Use dial indicators that are rigid so indicator

sag won’t be a factor. Using the shortest

offset distance of the indicator bracket will

reduce the effects of indicator droop or sag.

During alignment, you may also need to

compensate for engine expansion due to

heating. Generator expansion is generally

not considered a factor.

If the genset is moved to a different

location, check alignment before startup.

WARNING: Do not pry on the

generator fan blades. The blades can

weaken, which could result in serious injury

or death from fl ying debris.

Page 9

Copyright © 2012 Kato Engineering, Inc. All rights reserved

SAE housing

number

Housing inside

dia.

Allowable

runout (TIR)

NOTICE: TIR = Total indicated runout

6

5

4

3

2

1

0.5

0

00

10.500

12.375

14.250

16.125

17.625

20.125

23.000

25.500

31.000

0.002

0.003

0.003

0.004

0.004

0.005

0.005

0.006

0.007

Table 1: Maximum allowable

fl ywheel housing runout (inches)

Check the engine fl ywheel’s radial and face runout by mounting a dial

indicator and measuring the fl ywheel housing to the fl ywheel as shown

in Figure 3. The maximum allowable fl ywheel runout is .0005” per inch

of radius with a maximum of .010”.

Flywheel

NOTICE:

Compensation for engine

thermal growth must be taken into

account on this measurement.

Dial indicator pointer

for radial runout

Dial indicator

pointer for face

runou

t

Figure 3: Flywheel check

Flywheel housing

Shaft

Copyright © 2012 Kato Engineering, Inc. All rights reserved

Page 10

Check the generator adapter’s radial and face runout by mounting a

dial indicator on the generator shaft or coupling as shown in Figure 4.

The maximum radial and face runout on the generator adaptor must not

exceed 0.010 inch.

NOTICES: Mounting of the indicators must

allow complete rotation of the prime mover.

Use dial indicators that are rigid so indicator

sag won’t be a factor. Using the shortest

offset distance of the indicator bracket will

reduce the effects of indicator droop or sag.

Dial indicator pointer

Adapter

for radial runout

Shaft

Dial indicator

pointer for face

runout

Figure 4: Generator adapter check

Check the generator coupling’s radial and face runout by mounting

a dial indicator to the generator adapter as shown in Figure 5. The

maximum radial and face runout on the coupling must not exceed 0.003

inch.

During alignment, you may also need to

compensate for engine expansion due to

heating. Generator expansion is generally

not considered a factor.

If the genset is moved to a different

location, check alignment before startup.

WARNING: Do not pry on the

generator fan blades. Blades can weaken

which could result in serious injury or death

from fl ying debris.

NOTICE: Generators equipped with sleeve

oil bearings must have oil added to the

bearing prior to rotation. Failure to comply

will result in bearing damage. See the

bearing manual.

Dial indicator

pointer for face

runout

Dial indicator

pointer for radial

runout

Figure 5: Generator coupling check

Adapter

Shaft

Copyright © 2012 Kato Engineering, Inc. All rights reserved

Page 11

Install the portion of the coupling that fi ts into the engine fl ywheel

following the manufacturer’s recommended procedures and in accordance with engine manufacturer’s specifi cations. Check the coupling’s

radial and face runout by mounting a dial indicator to the engine

fl ywheel housing as shown in Figure 6. The maximum radial and face

runout on the coupling must not exceed 0.004 inch.

Measure and record the engine crank shaft endplay Set the engine

endplay at a position of one half of the measured distance.

Measure the generator endplay. Compare the measured endplay to the

factory recorded endplay located on the Generator Warranty/Test Tag.

Once this is verifi ed, thrust the generator shaft all the way to the engine,

then back off that location .020”, or .508mm. This will allow for the

thermal growth of the shaft.

Flywheel

IMPORTANT: The maximum allowable

fl ywheel runout is .0005” per inch of radius

with a maximum of .010”.

Flywheel housing

Dial indicator

pointer for face

runout

Dial indicator pointer

for radial runout

Figure 6: Engine coupling check

Shaft

Mount the generator on the skid, and move the generator to within 0.010

inch of the engine. Place two 0.010-inch shims in the horizontal

(9 o’clock and 3 o’clock) positions between the generator adapter

and the engine fl ywheel housing. Raising the rear, exciter end of the

generator as necessary, place two 0.010-inch shims in the vertical (6

o’clock and 12 o’clock) positions between the generator adapter and

the engine fl ywheel housing. This will give a good starting point for

alignment. Remove the vertical shims at this time. (If necessary, mark

holes to be drilled on the base, and remove the generator at this time.)

Mount a dial indicator on the generator shaft or half coupling to the

fl ywheel radial surface for parallel alignment as shown in Figure 7.

Copyright © 2012 Kato Engineering, Inc. All rights reserved

Page 12

Mount a dial indicator on the fl ywheel coupling to the face of the

generator half coupling for angular alignment as shown in Figure 7.

Align the engine by rotating the prime mover in 90-degree incre ments

and measuring total indicator runout. Tighten the generator to the base

before taking each set of readings. Raise or lower the generator by

adding or removing shims under the machined feet.

Flywheel

Dial indicator pointer

for parallel alignment

Flywheel housing

Shaft

Dial indicator pointer

for angular alignment

Figure 7: Alignment check

Following the fi nal generator adjustment and runout check, remove

the horizontal shims from the adaptor fl ywheel housing, and move the

generator all the way to the adaptor. Then tighten the fasteners.

Recheck alignment. Make sure angularity (face) total indicated runout

does not exceed 0.005 inch per inch of generator coupling diameter and

parallel (radial) total indicated runout does not exceed 0.005” TIR.

IMPORTANT: Clearances between the

adaptor pilot and the fl ywheel housing

recess are designed to meet the tolerance

of 0.001 to 0.015 inches.

Torque the fasteners to the value shown in Table 3.

Page 13

Copyright © 2012 Kato Engineering, Inc. All rights reserved

Two-bearing alignment

Follow the tolerances specifi ed by the coupling manufacturer when they

are less than described in this manual.

Use shims, if necessary, between the mounting pad and the base to

properly level and align the generator to the prime mover.

Install the coupling(s) on the generator and engine drive shafts in

accordance with coupling manufacturer installation procedures. Check

the generator coupling’s radial and face runout by mounting a dial

indicator to the generator adapter as shown in Figure 8. The maximum

radial and face runout on the coupling must not exceed 0.003 inch.

Adapter

Shaft

Dial indicator

pointer for face

runout

Dial indicator

pointer for radial

runout

Figure 8: Generator coupling check

Install the portion of the coupling that fi ts into the engine fl ywheel

following the manufacturer’s recommended procedures and in accordance with engine manufacturer’s specifi cations. Check the coupling’s

radial and face runout by mounting a dial indicator to the engine

fl ywheel housing as shown in Figure 9. The maximum radial and face

runout on the coupling must not exceed 0.004 inch. Measure and record

the engine crank shaft endplay Set the engine endplay at a position of

one half of the measured distance.

Measure the generator endplay. Compare the measured endplay to the

factory recorded endplay located on the Generator Warranty/Test Tag.

Once this is verifi ed, thrust the generator shaft all the way to the engine,

then back off that location .020”, or .508mm. This will allow for the

thermal growth of the shaft.

Copyright © 2012 Kato Engineering, Inc. All rights reserved

If the generator has “fl oating bearings”, align the face of the outer seat

with the groove in the shaft (electrical center).

Page 14

Dial indicator

pointer for face

runout

Dial indicator pointer

for radial runout

Figure 9: Engine coupling check

Flywheel

Flywheel housing

Shaft

Use a straight edge and a thickness gauge for rough alignment as shown

in Figure 10. Check for angular and parallel alignment as follows:

Straight edge

Thickness gauge

Figure 10: Rough alignment

Page 15

Copyright © 2012 Kato Engineering, Inc. All rights reserved

Angular alignment: Fasten a dial indicator to one of the coupling halves,

and scribe the position of the dial button on the face of the opposite

coupling half as shown in Figure 11. Rotate both shafts simultaneously,

keeping the fi nger or button on the indicator at the reference mark on the

coupling hub. Notice the reading on the indicator dial at each one quarter

revolution.

A variation of readings at different positions will indicate how the

machine needs to be adjusted to obtain a maximum misalignment of

0.005 inch for each inch of the coupling hub’s radius, total indicator

runout. Place or remove slotted shims from under the front or rear engine

or generator mounting pads and/or shift the front or back half of one

component from side to side until the components are properly aligned.

Tighten the mounting bolts, and recheck alignment.

Dial indicator

Copyright © 2012 Kato Engineering, Inc. All rights reserved

Figure 11: Angular alignment

Parallel alignment: Fasten a dial indicator to one of the coupling halves,

and scribe the position of the dial button on the top of the opposite

coupling half as shown in Figure 12. Rotate both shafts simultaneously,

keeping the fi nger or button on the indicator at the reference mark on the

coupling hub. Notice the reading on the indicator dial at each one quarter

revolution. A variation of readings at different positions will indicate how

the machine needs to be adjusted to obtain a maximum misalignment of

0.005 TIR. Compensation for engine thermal growth must be taken into

account on this measurement. Place or remove slotted shims from under

all of the engine or generator mounting pads and/or shift one component

from side to side until the components are properly aligned. Tighten the

mounting bolts, and recheck alignment.

Page 16

Dial indicator

Figure 12: Parallel alignment

Page 17

Copyright © 2012 Kato Engineering, Inc. All rights reserved

NOTICES: Mounting of the indicators must

allow complete rotation of the prime mover.

Use dial indicators that are rigid so indicator

sag won’t be a factor. Using the shortest

offset distance of the indicator bracket will

reduce the effects of indicator droop or sag.

During alignment, you may also need to

compensate for engine expansion due to

heating.

If the genset is moved to a different

location, check alignment before startup.

WARNING: Do not pry on the

generator fan blades. Blades can weaken

which could result in serious injury or death

from fl ying debris.

Single-bearing alignment

Before assembling the generator to the prime mover, remove the exciter

cover and adapter cover. Remove the blocking holding the drive discs to

the adapter. Also make sure the generator bearing end clearance is not

less than the total engine crankshaft axial movement plus 1/16 inch. The

generator is shipped from the factory with 1/8-inch minimum bearing

end clearance. (This dimension is recorded on the Factory Recorded

Dimensions sheet, packaged with the generator.)

Measure the distance from the end of the exciter shaft extension to the

bearing housing on the endbracket (dimension A in Figure 13). This

dimension is recorded on the Factory Recorded Dimensions sheet,

packaged with the generator. If the dimensions do not match, move the

rotor axially relative to the stator until the dimensions are equal.

Endbracket

Bearing

Exciter fi eld

A

Shaft extension

Figure 13: Generator coupling check

Check the engine fl ywheel housing pilots’s radial and face runout by

mounting a dial indicator and measuring the fl ywheel to the fl ywheel

housing as shown in Figure 5. See Table 1 for maximum allowable

runout.

Check the engine fl ywheel’s radial and face runout by mounting a dial

indicator and measuring the fl ywheel housing to the fl ywheel as shown

in Figure 3. See Table 2 for maximum allowable runout.

Copyright © 2012 Kato Engineering, Inc. All rights reserved

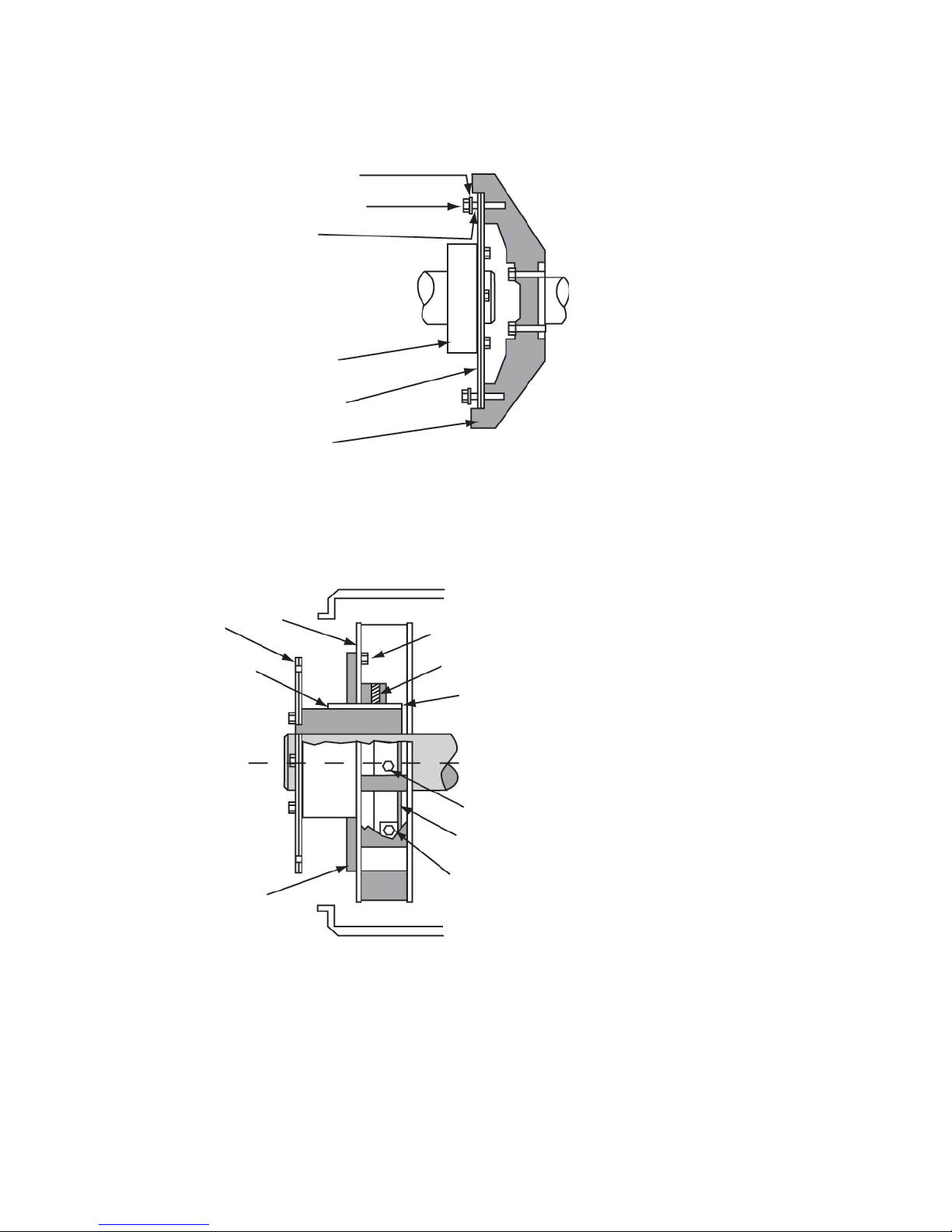

Measure the generator drive plate diameter (dimension S of Figure 14)

and fl ywheel bore diameter (dimension B of Figure 15). Drive plate

diameter must not be greater than the fl ywheel bore diameter. Also check

to make sure the hole centers match (dimension W of Figure 14 and

dimension C of Figure 15).

Page 18

Measure the axial distance from the surface on the generator adapter

to the outside surface on the drive disc coupling plates (dimension Y

in Figure 14). This dimension is recorded on the Factory Recorded

Dimensions sheet, which was packaged with the generator. If the

dimensions do not match, move the rotor axially relative to the stator

until the dimensions are equal.

Measure the axial distance from the machined surface on the engine

fl ywheel housing the bottom of the fl ywheel drive disc recess

(dimension G in Figure 15). Make sure the difference between

dimensions Y (of Figure 14) and G are less than 1/32 inch. If G is

more than Y, install additional spacers between the drive discs and the

generator hub. If Y is more than G, remove spacers between the drive

discs and generator hub.

Adaptor

Drive

plates

Y

Fan

WARNING: Never grind the OD

of drive discs or attempt to drill out the

holes. If the dive discs do not fi t properly ,

use different discs or a different fl ywheel.

The number and thickness of drive discs

are specifi ed for torque requirements. Do

not remove drive discs to compensate

for spacing Drive disc modifi cations may

result in drive disc failure and debris

ejected from the generator.

S

A

W

Bolt holes

Figure 14: Single bearing generator drive plate

and adaptor

Shaft

Page 19

Copyright © 2012 Kato Engineering, Inc. All rights reserved

Tapped

bolt holes

B

Flywheel

Figure 15: SAE fl ywheel and adapter

G

C

Install the generator to the engine. Make sure the drive discs seat in

the recess of the fl ywheel housing. Secure the generator to the engine

(drive discs to fl ywheel, adapter to fl ywheel housing), and the base. Use

lock washers on all bolts. Torque the adapter and drive discs in a crisscross pattern to the values in Table 3.

Ensure that the bolts in the fl ywheel do not bottom out. If they are too

long or cannot be tightened with a socket or box wrench, use 1/4 to 3/8inch long spacers inserted in the bolts as shown in Figure 16 to increase

the clearance between the bolt head and the fl ywheel.

Occasionally, there is insuffi cient clearance to install the bolts that

fasten the drive discs to the engine fl ywheel, and the fan will have to be

temporarily moved to accommodate this. This situation will typically

occur with several types of generators:

• With the three-frame units that have an aluminum fan, loosen the fan

hub bolts to move the fan. After installing the drive disc-to-fl ywheel

bolts, move the fan back so the rotor-side edge is fl ush with the air

opening and the minimum distance between the windings and the

fan is 3/8 inch. Torque the fan hub bolts to 75 ft-lbs.

Copyright © 2012 Kato Engineering, Inc. All rights reserved

• With sheet metal fans with cast hubs that are in turn mounted on the

drive hub, mark the drive hub as closes as possible to the fan hub.

Loosen the two set screws, the fan clamping bolt, and the fan bolts.

Wedge the fan open, and move it out of the way (See Figure 17).

After attaching the drive discs-to-fl y wheel bolts, align the fan hub

to the mark to move the fan back to its original position. Ensure

the key is fully in place under the fan hub and positioned so the set

screw will press on the key. Tighten the fan hub clamping bolt and

the set screws. Install the fan bolts and torque them according to

Table 3.

Page 20

Drive discs

Keyway

Lock washer

Bolt

Spacer

Drive hub

Drive plates

Flywheel

Figure 16: Disc-to-fl ywheel installation

Fan

Fan bolts

Set screw

Key

IMPORTANT: The generator with sheet

metal fans and cast fan hubs is shipped

from the factory with the fan 1/2 to 3/4 inch

from the fan baffl e and clear of the inside

adaptor for optimum air fl ow through the

exhaust screen.

Fan hub

Figure 17: Moving sheet metal fans

Bolt holes

Alignment mark on

drive hub

Fan hub bolt

Copyright © 2012 Kato Engineering, Inc. All rights reserved

Page 21

After installing the drive disc-to-fl ywheel bolts, check the runout of the

generator shaft by placing the base of a dial indicator on the generator

frame and positioning of the probe on the shaft as shown in Figure 18.

If the total indicated runout exceeds 0.003 inch, remove the drive discs

bolts, and rotate the generator relative to the engine fl ywheel. Reinstall

the bolts, and check the runout again.

Recheck the shaft-end-to-bearing-housing distance (dimension A in

Figure 13).

Mount the brushless exciter armature assembly to the generator shaft

(as described in the assembly procedures below).

Adapter

Fan

Dial indicator pointer

Shaft

Copyright © 2012 Kato Engineering, Inc. All rights reserved

Drive plates

Drive hub

Figure 18 Runout check

Page 22

Foot defl ection

After alignment, check for foot defl ection or “soft foot” condition on

each shim location to eliminate distortion of the generator frame. Do

this by loosing one mounting bolt at a time and checking defl ection

after retightening. Defl ection at the shim location from shims under

compression to a loosened condition must not exceed 0.003 inch.

Doweling

In case the mounting bolts loosen during operation, doweling will

prevent movement of the generator. Dowel as follows:

Check the alignment after the generator has been in operation for at least

48 hours. If alignment is not satisfactory, realign.

Drill holes through the footpads and into the base in two mounting pads

opposite each other. Drill the holes slightly smaller than the dowel pin.

Ream the holes to the proper diameter for the pin. Clean out chips, and

install the pins.

Electrical connections

If the generator was subjected to a rapid change in temperature, freezing

or wet conditions during shipment or storage, measure the insulation

resistance of each winding and dry the generator, if necessary, as

described in the maintenance section below.

Make all electrical connections (main load, temperature monitoring

device, space heater, AVR) in accordance with local regulations and

national/international electrical code requirements. Check the electrical

diagrams provided with the generator or manual. The main terminals

need to be properly spaced for the load connections. Refer to Table 3 for

the proper torque values for the connections.

NOTICE: Alternator current machines are

intended for continuous operation with

the neutral at or near ground potential.

Operation with one line at ground potential

should be done only for infrequent periods

of short duration, for example, as required

for normal fault clearance.

On larger generators grounding points are provided for properly

grounding the system to the generator frame. The grounding wire must

be sized to national/international code requirements.

Space heaters

When the generator has optional space heaters to prevent water

condensation during long periods of downtime, connect the space heaters

so they start when the generator is turned off and stop when the generator

is switched on. Some generators with space heaters have thermostats.

The thermostat should be set above the dewpoint. Refer to the electrical

diagrams for the space heater characteristics.

CAUTION: The space heaters

are designed to be energized when the

generator is shut down. They are hot

enough to cause skin burns. Terminals for

power at the space heaters are live during

operation. Disconnect power to the space

heaters before removing the generator

covers.

Copyright © 2012 Kato Engineering, Inc. All rights reserved

Page 23

WARNING: Do not pry on the

generator fan blades. Blades can weaken

which could result in serious injury or death

from fl ying debris.

Inspection before startup

After electrical connections have been made, perform the following

checks:

• Check all the connections to the electrical diagrams provided.

• Secure all covers and guards.

• Turn the rotor slowly with the appropriate starting mechanism (bar

the engine or fl ywheel) through one revolution to see if the rotor

turns freely.

NOTICE: For specifi c lubrication

instructions, always refer to the bearing

lubrication sheet that came with your

manual or the lube plate on the generator.

Unauthorized lubricants may result in a

bearing failure

• Check the bearings to see they are properly lubricated.

• Determine the direction of the engine rotation, and make sure that it

matches the rotation of the generator.

• Make sure the power requirements comply with the data on the

generator nameplate.

• Make sure that the engine-generator set is protected with an adequate

engine governor and against excessive overspeed.

• Make sure the output of the generator is protected with an overload

protection device, such as circuit breakers or fuses, sized in

accordance with national/international electrical code and local

electrical code standards. Fuses need to be sized using the lowest

possible current rating above the full-load current rating (115% of

rated current is commonly recommended).

Remove tools and other items from the vicinity of the generator.

Copyright © 2012 Kato Engineering, Inc. All rights reserved

Page 24

Operation

Initial startup: generators with both automatic and

manual voltage control

1. Disconnect the generator output from the load by opening the main

circuit breaker.

2. Turn the manual voltage adjust rheostat fully counterclockwise.

3. Put the auto-manual switch in the manual position.

4. Start the prime mover, and bring the set to rated speed. Turn the

manual voltage adjust rheostat to reach rated voltage. Close the

output circuit breaker, and apply load in steps until the rated load is

reached. Adjust the manual adjust rheostat as necessary to obtain the

desired output voltage.

5. Gradually reduce load, and adjust the rheostat accordingly until no

load is reached. Open the circuit breaker, and stop the prime mover.

6. Actuate the auto voltage rheostat. Then start the genset, and bring it

to rated speed. Adjust the voltage to the desired value.

NOTICE: Do not actuate the auto-manual

switch with the full load applied to the

generator. Generator over voltage will

result which may cause damage to the

generator control and protection equipment.

Whenever possible, stop the generator

before switching to assure full load is not

applied.

7. Close the output circuit breaker. Then check the generator voltage

and voltage regulation. Apply load in steps until the rated load is

reached.

8. Check for vibration levels at no load and rated load. A slight increase

is normal. As the load is maintained for 2-3 hours, the vibration

levels will gradually increase and reach a fi nal level.

Initial startup: Generators with automatic voltage control

only (generator has an automatic voltage regulator (AVR)

with no auto-manual switch)

1. Disconnect the generator output from the load by opening the main

circuit breaker.

2. Turn the voltage adjust rheostat fully counterclockwise. Start the

prime mover, and bring the set to rated speed. Turn the voltage adjust

rheostat to obtain the desired voltage.

3. Close the output circuit breaker, and apply load in gradual steps

until the rated load is reach. Notice the voltage regulation with the

changes in load steps.

4. Check for vibration levels at no load and rated load. A slight increase

is normal. As the load is maintained for 2-3 hours, the vibration

levels will gradually increase and reach a fi nal level.

Page 25

Copyright © 2012 Kato Engineering, Inc. All rights reserved

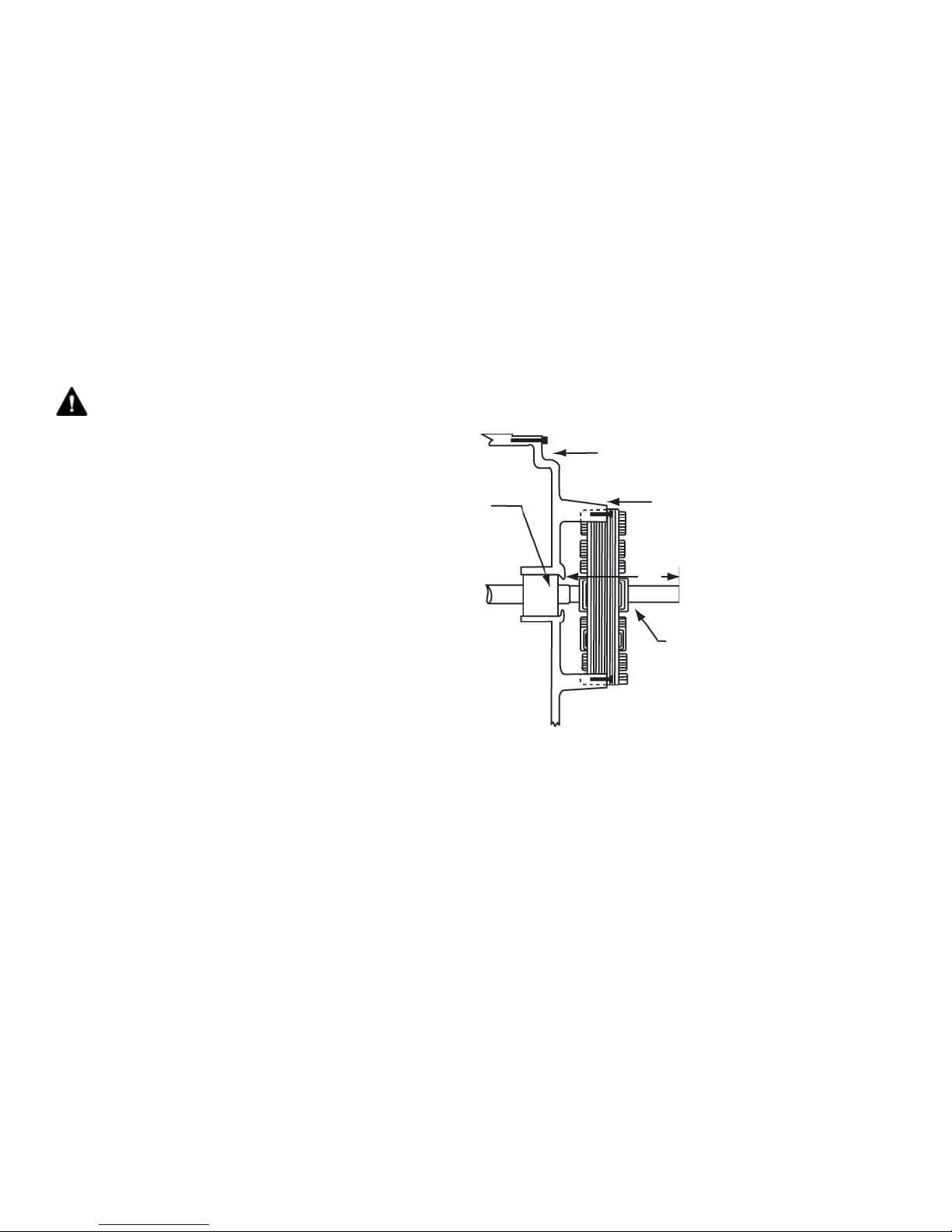

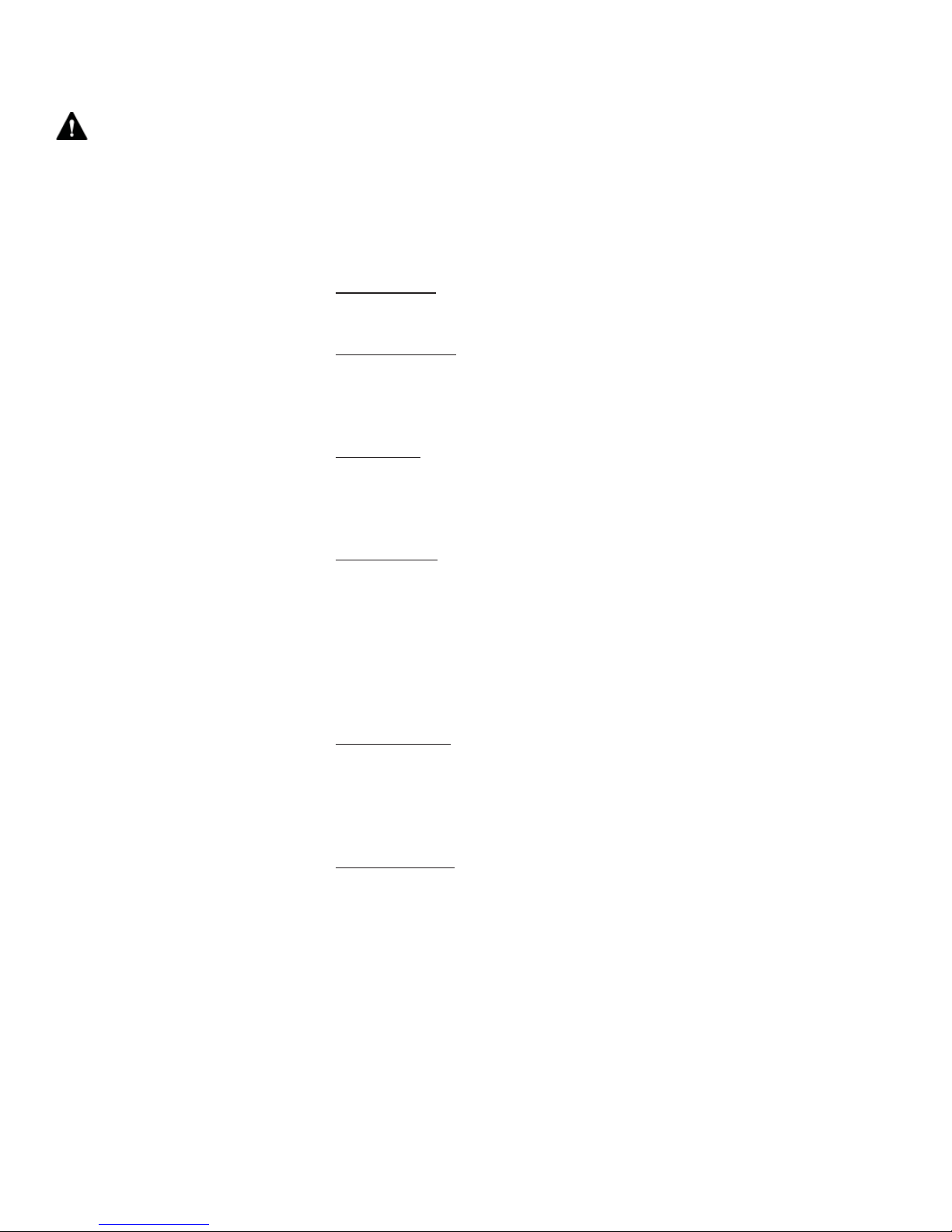

Restoring residual magnetism/fi eld fl ashing

The direct current necessary to magnetize the revolving fi eld is obtained

from the exciter. Upon starting the generator, current and voltage is

induced into the exciter by the magnetic lines of force set up by residual

magnetism of the exciter fi eld poles. Residual magnetism of the exciter

fi eld poles may be lost or weakened by a momentary reversal of the fi eld

connection, a strong neutralizing magnetic fi eld from any source, or non-

operation for a long time. If the generator fails to generate voltage after

it has come up to rated speed, it may be necessary to restore residual

magnetism.

To restore the small amount of residual magnetism necessary to begin the

voltage build up, connect a 12 or 24-volt battery to the exciter fi eld coil

circuit and fl ash as follows:

1. Open the output circuit breaker, and stop the engine.

2. Disconnect the exciter fi eld coil wires EF1 at the terminal EF1 and

EF2 at the terminal EF2, and connect the battery positive lead to the

fi eld coil lead EF1.

3. Flash the fi eld by touching the battery lead to the fi eld coil circuit

terminal EF2.

4. Disconnect the battery leads.

5. Reconnect the fi eld coil lead EF1 to terminal EF1, and reconnect the

fi eld coil lead EF2 to terminal EF2.

6. Start the generator, and check for voltage build up. Refl ash if

the generator output voltage does not build up, or fl ash with the

generator running, the fi eld coil wires connected to the regulator, and

a 3-amp or larger diode off the positive terminal of the battery per

Figure 19.

-

12 or 24 V

battery

+

3 amp or

larger diode

FF+

Voltage

regulator

Copyright © 2012 Kato Engineering, Inc. All rights reserved

EF2

Figure 19: Field fl ashing setup with the fi eld wires

connected to the regulator

Page 26

EF1

Continuous operation

Operate the generator within the nameplate values . If the generator is

operated below the rated power factor and voltage, decrease the kVA to

prevent overheating of the fi eld and stator windings. Consult the factory

for derating factors if the application requires the unit to be operated

beyond nameplate values.

Rotor overheating may occur when the generator is carrying excessive

unbalanced loads. Negative sequence currents fl owing in the fi eld pole

face cause the rotor heating. For a general guide to the allowable phase

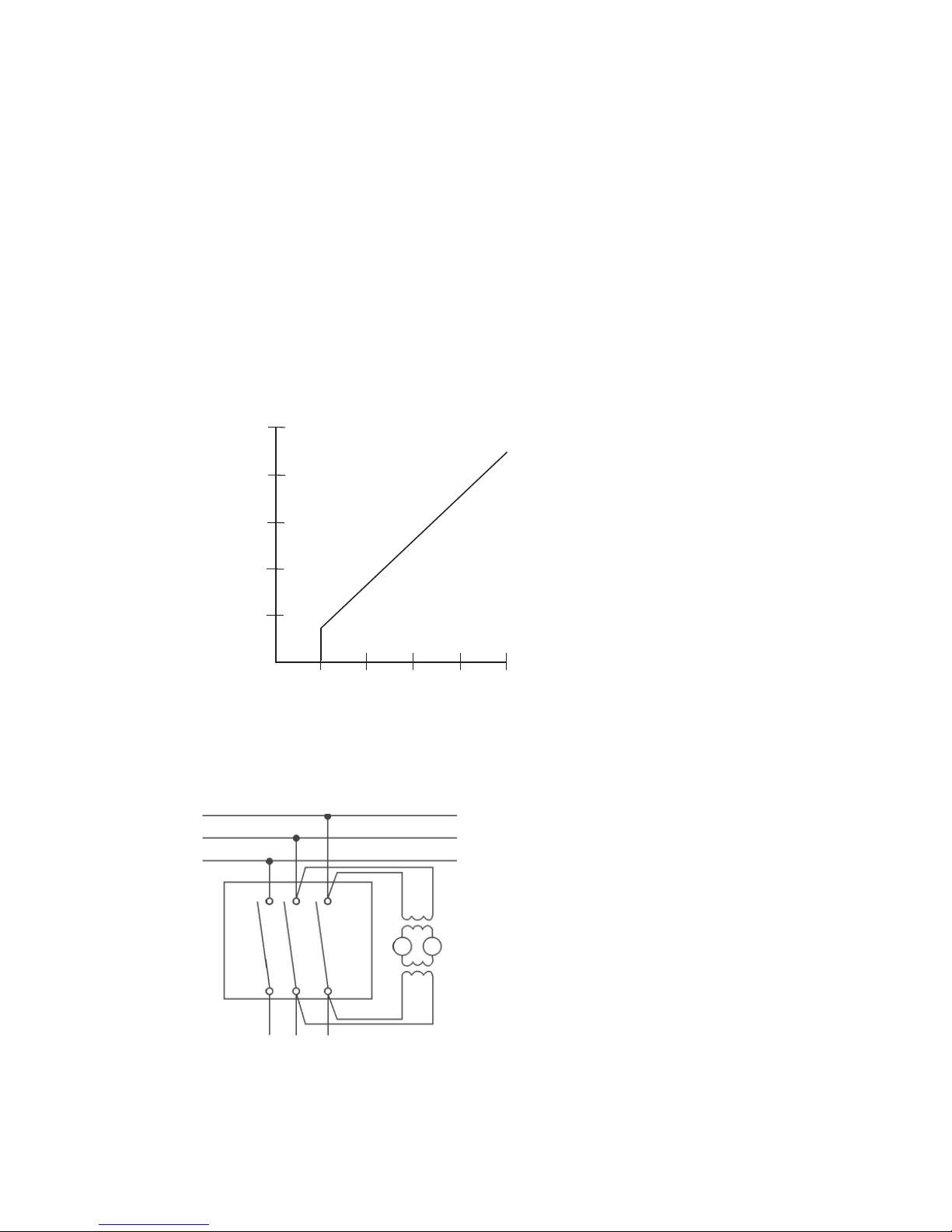

unbalance, see Figure 20, Guide to allowable phase unbalance (which is

based on a 10% equivalent negative sequence current).

The guide is used in the following manner: Find the point where the

vertical line (determined by the maximum current in any of the phases

and expressed in percent of rated current) crosses the horizontal line

(determined by the minimum current in any of the phases and expressed

in percent of rated current). Ensure the point where these two lines

intersect is within the permissible allowable unbalance region for safe

operation of the generator.

Loss of fi eld excitation can result in the unit operating out of

synchronization with the system when operating is parallel. This has the

effect of producing high currents in the rotor, which will cause damage

very quickly. Protective relays should be considered to open the circuit

breaker.

NOTICE: Operating the unit beyond name-

plate values may cause equipment damage

or failure.

Idling

Unless the voltage regulator has V/Hz protection built in, having the

generator set in operating mode while idling the engine can cause

permanent equipment damage. If engine adjustments require that

the engine be run at idle speed and the regulator does not have V/Hz

protection, make the generator regulating system inoperative during

idling by one of the following methods:

When the generator is provided with a voltage shutdown switch, be sure

the switch is set to the idle position while the engine is running at idle

speed.

Where the generator set is provided with fi eld circuit breakers, set the

circuit breaker to the off position while the generator is running at idle

speed.

Where the generator set is provided with an automatic/manual control

switch that has an off position, switch it to off while the engine is

running at idle speed.

Where the generator set does not have any of the above options, remove

the wires from the voltage regulator input power terminals when the

engine is running at less than rated speed.

Page 27

Copyright © 2012 Kato Engineering, Inc. All rights reserved

IMPORTANT: If the polarity of the exciter

is reversed by fl ashing the fi eld, it may be

corrected by interchanging the battery leads.

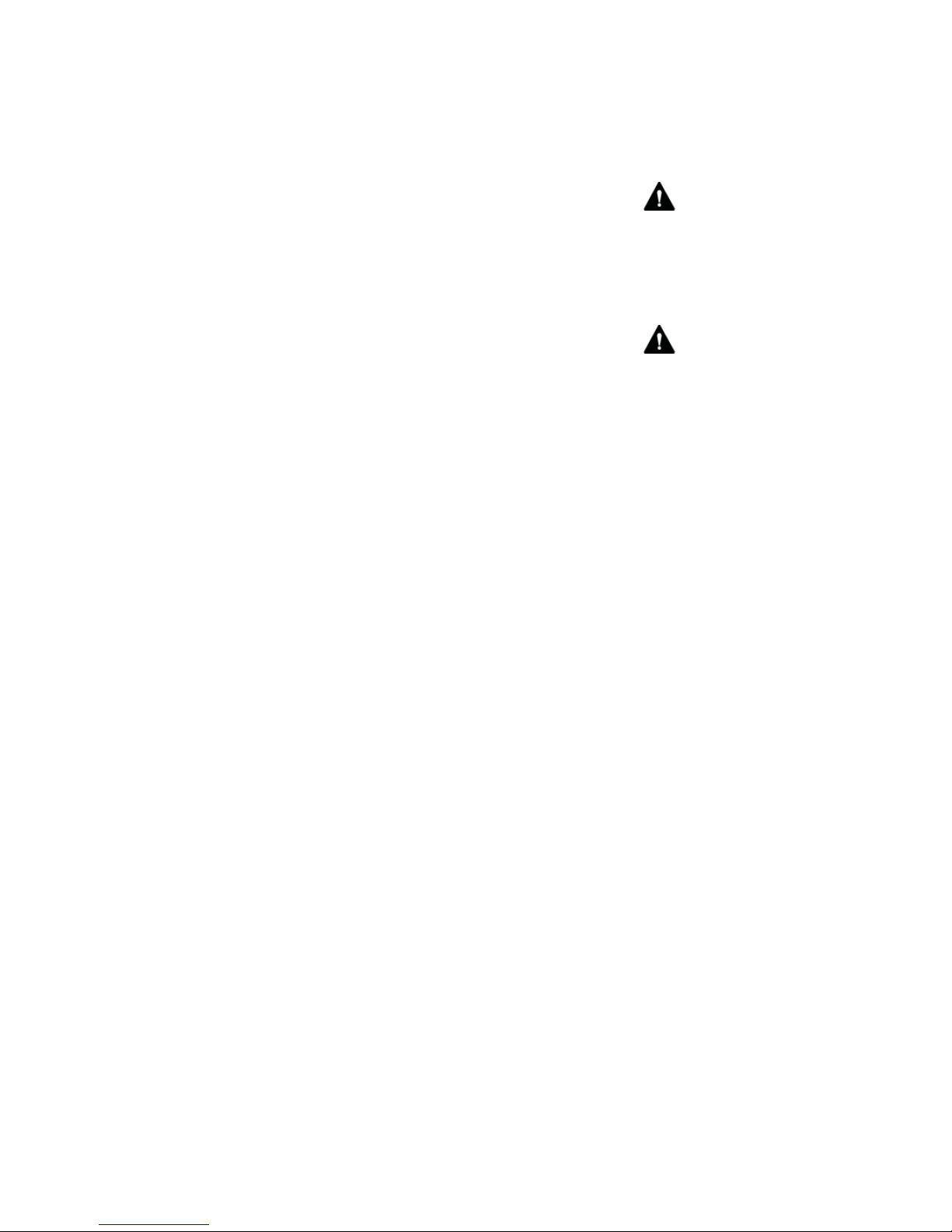

Parallel operation

For the generator to operate in parallel with a system in operation, the

phase sequence of the generator must be the same as that of the system.

Use transformers to reduce the voltage to an acceptable level, and then

use a phase rotation meter or incandescent lamp method, described in

electrical machinery handbooks, for a phase sequence check.

The output voltage at the paralleling point must be the same as each

instant, which requires that the two voltages be of the same frequency,

same magnitude, same rotation, and in coincidence with each other.

Voltmeters indicate whether the voltage magnitude is the same, and

frequency meters indicate whether the frequencies are the same. Whether

the voltages are in phase and exactly at the same frequency is indicated

by a synchroscope or by synchronizing lamps.

A synchroscope can be used to indicate the difference in phase angle

between the incoming machine and the system. The generator can be

paralleled by using incandescent lamps connected as shown in Figure 21.

The voltage rating of the series lamps must equal the voltage rating of the

transformer-low voltage winding.

WARNING: Shock hazard - Do

not make connections or otherwise make

contact with the generator leads or other

devices connected to them unless the

genset is stopped and the phase leads are

grounded. A rotating generator is always

producing some voltage and contact with

the leads or other devices connected may

result in serious injury or death

NOTICE: Refer to the voltage regulator

manual for complete details and possible

additional instructions. Damage to the rotating diodes, generator, and voltage regulator

can be caused if the regulator is operated

improperly.

Each prime mover in the system must have the same speed regulating

characteristics, and the governors must be adjusted to give the same

speed regulation as determined by applying load that is proportional to

the full load rating of the generator.

The voltage regulator must include paralleling circuitry. In addition, the

voltage, droop settings and the V/Hz regulation characteristics must be

the same for all the voltage regulators. This will allow the generators to

properly share reactive loads.

If cross-current compensation is used, paralleling current transformers

must give the same secondary current.

Current transformer secondary windings provide reactive kVA droop

signal to the voltage regulator. Accidental reversal of this electrical

wiring will cause the voltage to attempt to rise with load rather than

droop. If this occurs during paralleling, stop the unit and reverse the

wires at the voltage regulator terminals.

If the set is provided with a unit/parallel switch, set the switch to the

parallel position on the unit being synchronized.

Copyright © 2012 Kato Engineering, Inc. All rights reserved

Synchronize the generator by adjusting the speed (frequency) slightly

higher than the system. Observe the synchroscope or the lamps. The

lamps should fl uctuate from bright to dark at the rate of one cycle every

2 to 3 seconds. When the generator is in phase (the lights will be dark),

close the circuit breaker. Immediately after closing the breaker, measure

Page 28

the line current kVAR of the generator. The readings must be within

the rating of the unit. A high ammeter reading accompanied by a large

kW reading indicates faulty governor control. A high ammeter reading

accompanied by a large kVAR unbalance indicates problems with the

voltage regulator. Adjusting the cross current or voltage droop rheostat

should improve the sharing of kVAR.

To shut down the generator operating in parallel, gradually reduce the

kW load by using the governor to reduce speed. When kW load and

line current approach 0, open the generator circuit breaker. Operate

the generator unloaded for several minutes to dissipate the heat in the

windings. Refer to the prime mover manual for shutdown and cool-down

procedures.

100

80

Allowable

unbalance

60

Excessive

40

20

Min. current in any phase (% of rated)

020406080

Max. current in any phase (% of rated)

unbalance

Figure 20: Guide to allowable phase unbalance

System bus

Load

switch

100

Synchronizing

lamps

Load lines from the incoming generator

Figure 21: Synchronizing paralleled generators with test lamps

Page 29

Copyright © 2012 Kato Engineering, Inc. All rights reserved

Maintenance

Schedules

A regular preventive maintenance schedule will ensure peak

performance, minimize breakdowns and maximize generator life. The

schedule listed below is a guide for operating under standard conditions.

Specifi c operating conditions may require reduced or increased

maintenance intervals. Also, if there is a different or more specifi c

schedule for your generator than the schedule provided below, it will be

included as a supplement to the manual package.

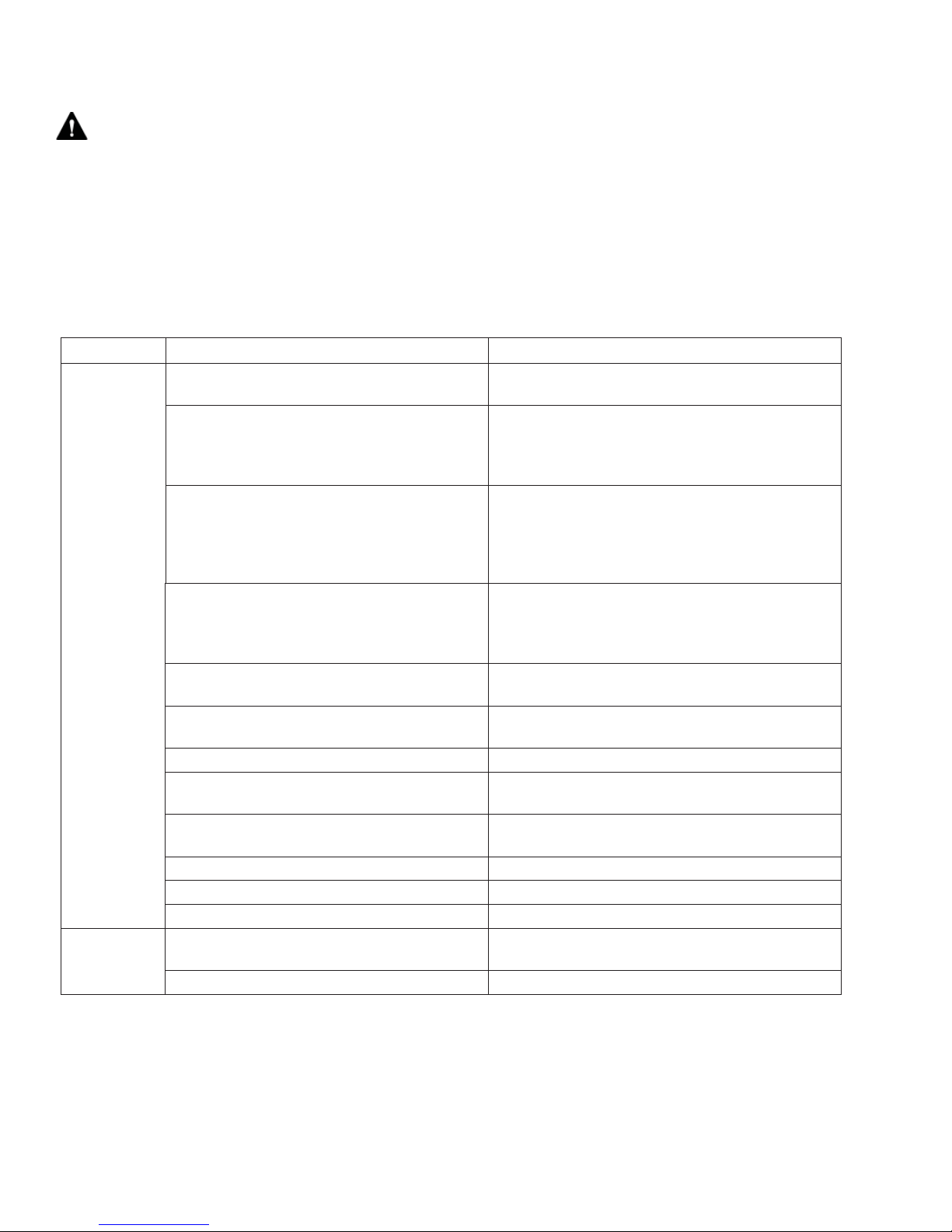

Every day

Visually check generator bearing housings for any sign of oil seepage.

Check the operating temperatures of the generator stator windings.

Check the control panel voltmeter for proper stability and voltage output.

Monitor the power factor and generator loading during operation.

With generators that have sleeve oil bearings, check the operating

temperatures and sight glass levels (if applicable).

Every week

Visually inspect the bearing exterior for dirt, and clean if necessary.

Inspect any generator air fi lters for build up of contaminants, and clean or

replace as required

Every 2000 Hours or 6 months of operation

Remove generator outlet box cover. Visually inspect the stator output

leads and insulation for cracking or damage. Check all exposed electrical

connections for tightness. Check transformers, fuses, capacitors, and

lightning arrestors for loose mounting or physical damage. Check all lead

wires and electrical connections for proper clearance and spacing.

Clean the inside of the outlet box, air screens, bearing housings, and air

baffl es with compressed air and electrical solvent if needed.

Copyright © 2012 Kato Engineering, Inc. All rights reserved

Page 30

With generators that have ball or roller bearings, check machine

vibrations and bearing condition with a spectrum analyzer or shock

pulse.

Regrease the regreaseable-type bearings. With generators that have

sleeve oil bearings, inspect bearing oil for proper levels and clarity.

Every 8000 hours or 1 year of operation

Check insulation resistance to ground on all generator windings,

including the main rotating assembly, the main stator assembly, the

exciter fi eld and armature assemblies, and the optional PMG assembly.

Check the space heaters for proper operation.

Check the rotating rectifi er connection tightness.

With generators that have sleeve oil bearings, replace the bearing oil.

Every 20,000 hours or 3 years of operation

With generators that have sleeve oil bearings, perform a sleeve bearing

inspection to include the removal of the upper bearing housing and

bearing liner to inspect the liner, shaft journal, and seal surfaces for wear

or scoring.

Remove the endbrackets, and visually inspect the generator end windings

for oil or dirt contamination. Excessive contamination may necessitate

surface cleaning with compressed air and electrical solvent.

Inspect the fan and fan hub for damage.

Every 30,000 hours or 5 years of operation

(Contact Kato Engineering for assistance)

Disassemble generator.

Clean the generator windings using either (depending upon the severity

of contamination) 1) compressed air and electrical solvent or 2) degreaser and high pressure hot water wash. Dry the windings to acceptable

resistance levels (see the dry out procedure).

Inspect the rotor shaft bearing journals for wear or scoring.

With generators that have ball or roller bearings, replace the bearings.

With generators that have sleeve bearings, replace the bearing liners and

oil seals.

NOTICE: Rotor removal should be

performed only as necessary and based

on the level of contamination and / or a low

Insulation Resistance value.

Page 31

Copyright © 2012 Kato Engineering, Inc. All rights reserved

WARNING: Shock hazard - Do not

service the generator or other electrical

machinery without de-energizing and

tagging the circuits as out of service.

Dangerous voltages are present, which

could cause serious or fatal shock.

NOTICE: For specifi c lubrication

instructions, always refer to the bearing

lubrication sheet that came with your manual

or the lube plate on the generator.

Maintenance procedures

Visual inspection methods of windings

Electric machines and their insulation systems are subjected to

mechanical, electrical, thermal and environmental stresses that give rise

to many deteriorating infl uences. The most signifi cant of these are the

following:

Thermal aging: This is the normal service temperature deteriorating

infl uence on insulation.

Over temperature: This is the unusually high temperature of operation

caused by conditions such as overload, high ambient temperature,

restricted ventilation, foreign materials deposited on windings, and

winding faults.

Overvoltage: This is an abnormal voltage higher than the normal service

voltage, such as caused by switching or lightning surges or non-linear

loads. Operating above rated nameplate voltage will reduce insulation

life.

Contamination: This deteriorates electrical insulation by 1) conducting

current over insulated surfaces 2) by attacking the material to reduce

electrical insulation quality or physical strength, or by 3) thermally

insulating the material so the generator operates at higher than normal

temperatures. Such contaminants include water or extreme humidity, oil

or grease including unstable anti-wear and extreme pressure lubricants,

conducting and non-conducting dusts and particles, industrial chemicals

such as acids, solvents, and cleaning solutions.

Copyright © 2012 Kato Engineering, Inc. All rights reserved

Physical damage: This contributes to electrical insulation failure by

opening leakage paths through the insulation. Physical damages can be

caused by physical shock, vibration, over-speed, short-circuit forces or

line starting, out-of-phase paralleling, erosion by foreign matter, damage

by foreign objects and thermal cycling.

Ionization effects: Ionization (corona), which may occur at higher

operating voltages, is accompanied by several undesirable effects such as

chemical action, heating, and erosion.

To achieve maximum effectiveness, a direct visual inspection program

initially to those areas that are prone to damage or degradation caused

by the infl uences listed above. The most suspect areas for deterioration

or damage are 1) ground insulation, which is insulation intended to

isolate the current carrying components from the non-current bearing

components, and 2) support insulation, which includes blocks and slot

wedges and are usually made from compressed laminates of fi brous

materials, polyester, or similar felt pads impregnated with various types

of bonding agents. Check for the following:

Page 32

Deterioration or degradation of insulation from thermal aging:

Examination of coils reveal general puffi ness, swelling into ventilation

ducts, or a lack of fi rmness of the insulation, suggesting a loss of bond

with consequent separation of the insulation layers from themselves or

from the winding conductors or turns.

Abrasion: Abrasion or contamination from other sources, such as

chemicals and abrasive or conducting substances, may damage coil and

connection surfaces.

Cracking: Cracking or abrasion of insulation may result from prolonged

or abnormal mechanical stress. In stator windings, looseness of the

bracing structure is a certain sign of such phenomena and can itself cause

further mechanical or electrical damage if allowed to go unchecked.

Erosion: Foreign substances impinging against coil insulation surfaces

may cause erosion.

Cleaning

Exterior: Wipe loose dirt from the exterior with a clean, lint-free cloth.

Remove stubborn accumulations of dirt with a detergent or solvent

that won’t damage the paint or metal surfaces. Use a vacuum to clean

ventilating ports.

Windings, assembled machines: Where cleaning is required at the

installation site and complete disassembly of the machine is unnecessary

or not feasible, pick up dry dirt, dust or carbon with a vacuum cleaner to

prevent the redistribution of the contaminant. A small non-conducting

nozzle or tube connected to the vacuum cleaner may be required to reach

dusty surfaces or to enter into narrow openings. After most of the dust

has been removed, a small brush can be affi xed to the vacuum nozzle to

loosen and allow removal of dirt that is more fi rmly attached.

WARNING: When using cleaning

solvents, ensure adequate ventilation and

user protection. Inhaling vapors may impair

breathing and/or cause damage to internal

organs.

After the initial cleaning with a vacuum, compressed air may be used to

remove the remaining dust and dirt. Compressed air used for cleaning

must be clean and free of moisture or oil. Air pressure or velocity must

be adequately controlled to prevent mechanical damage to the insulation.

Disassembly of the machine and more effective cleaning by a qualifi ed

Kato technician may be required if the above described fi eld service

cleaning procedures do not yield effective results.

Windings, disassembled machines: Take an initial insulation resistance

reading on the machine to check electrical integrity. The high pressure

hot water wash method of cleaning, which sprays a high velocity jet of

hot water and water containing a mild detergent, is normally effective

in cleaning windings, including those subjected to fl ooding or salt

contamination.

Page 33

Copyright © 2012 Kato Engineering, Inc. All rights reserved

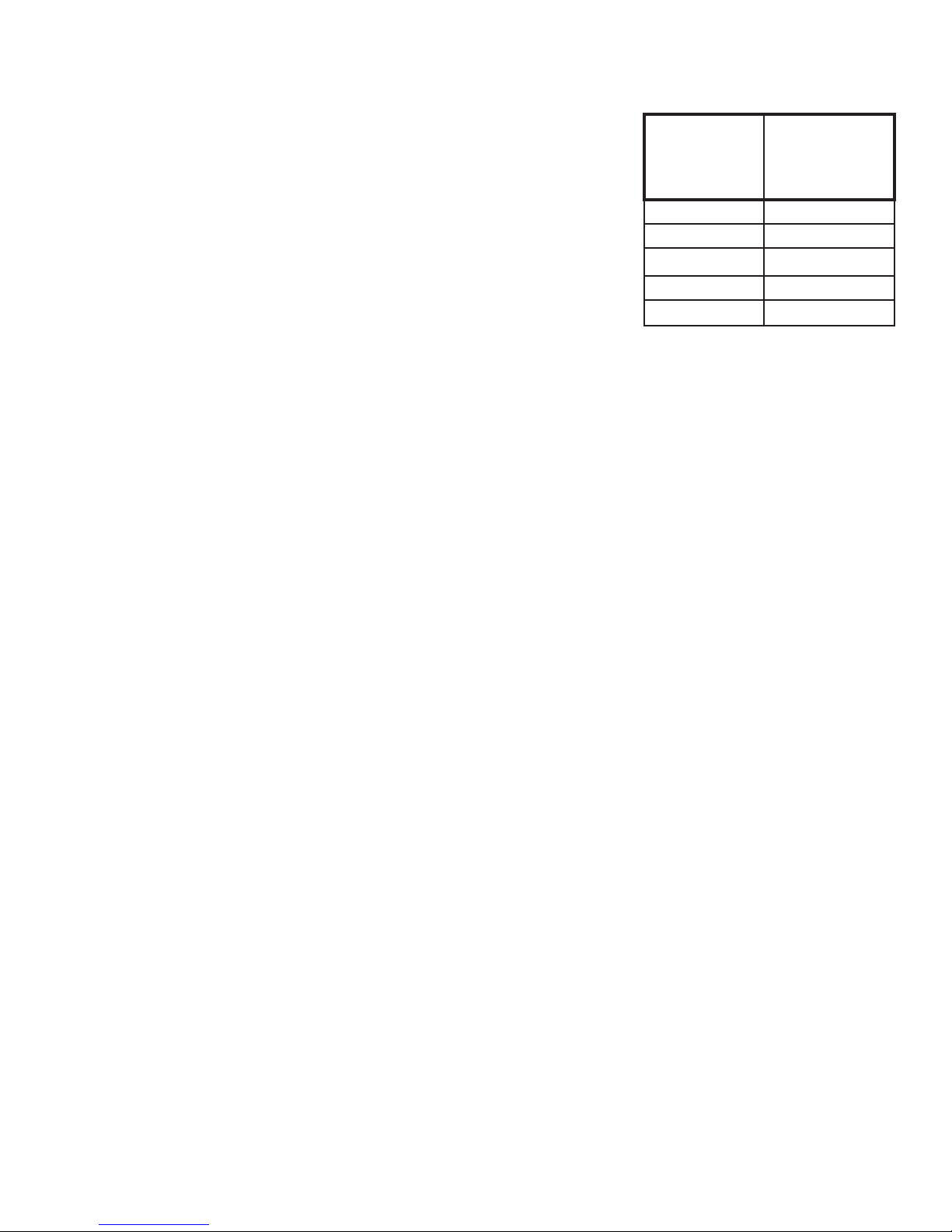

IMPORTANT: The insulation resistance

tests are usually made on all or parts

of an armature or fi eld circuit to ground.

They primarily indicate the degree of

contamination of the insulating surfaces

or solid insulation by moisture and other

conducting infl uences and will not usually

reveal complete or uncontaminated

ruptures.

IMPORTANT: The insulation resistance

value increases with de creasing winding

temperatures. All readings must be

corrected to winding temperatures. Use

Table 4 for converting megger readings to

other temperatures (e.g., 100 megohms at

50º C is converted to 170 megohms: 1.7 x

100).

Winding

Temp

(ºC)

10

20

30

40

50

60

70

80

90

100

110

120

Conversion

factor

0.23

0.37

0.6

1

1.7

2.7

4.5

7.5

14

23

38

61

Table 4: Temperature conversion

factor for resistance readings

NOTICE: Never apply the megger to the

rotating rectifi er, the voltage regulator, or

generator accessories (e.g., temperature

detectors, space heaters) These devices

can be damaged by the applied voltage.

IMPORTANT: New generators should

measure about 100 megohms minimum

of insulation resistance when meggered.

Generators that read 50 megohms or less

should be dried out according to the dry out

procedures here. Generators with insulation

resistance readings of 10 megohms or less

should be investigated.

Use multiple sprays with clean water to remove or dilute the detergent

following the detergent spray. Dry the machine until acceptable

insulation resistance values are obtained at room

temperature. See the insulation resistance procedures below for minimum

recommended values.

Electrical contacts: Clean electrical contacts, switch contacts and

terminals with an approved contact cleaner. Do not fi le contacts.

Insulation resistance tests at low voltage

Insulation tests are conducted for two reasons: to discern existing

weakness or faults or to give some indication of expected service

reliability. Insulation resistance tests are based on determining the current

through the insulation and across the surface when a DC voltage is

applied. The leakage current is dependent upon the voltage and time of

application, the area and thickness of the insulation, and the temperature

and humidity conditions during the test.

Refer to the following electrical measurement procedures for testing

detail. Contact Kato Engineering or refer to IEEE Standard. 432-1992

when more extensive insulation tests are required

When checking insulation resistance with a megger, fi rst verify the

ground path. Connect one test lead to a ground point. Then connect

the second test lead to another ground location to prove the ground

connection. Once the ground path has been proven, the second test lead

can be connected to the leads of the component to be tested.

Exciter fi eld (stator) and PMG armature (stator)

1. Disconnect the exciter leads from the terminals in the ter minal box or

the voltage regulator.

2. Connect exciter leads to one clamp of 500-volt megger, and connect

the other clamp to the exciter fi eld frame.

3. Apply 500 V from the megger, and measure the resistance reading

after 1 minute. The reading must be a minimum of 50 megohm. If it

is not, refer to the cleaning or dry out procedures.

4. Ground the exciter fi eld leads to the exciter fi eld frame for several

minutes after the megger has been disconnected. This will allow the

voltage build up to be properly discharged.

5. Repeat steps 1-4 for the PMG armature (stator).

Copyright © 2012 Kato Engineering, Inc. All rights reserved

Page 34

Exciter armature

1. Disconnect the exciter armature leads from the rotating rec tifi ers.

2. Connect the leads of the exciter armature to one clamp of a 500-volt

megger, and connect the other clamp to a suitable connection on

exciter sleeve or shaft.

3. Apply 500 V from the megger, and measure the resistance reading

after 1 minute. The reading must be a minimum of 50 megohms. If it

is not, refer to the cleaning or dry out procedures.

4. Ground the exciter leads to the exciter sleeve or shaft after

disconnecting the megger. This will allow the voltage build up to be

properly discharged.

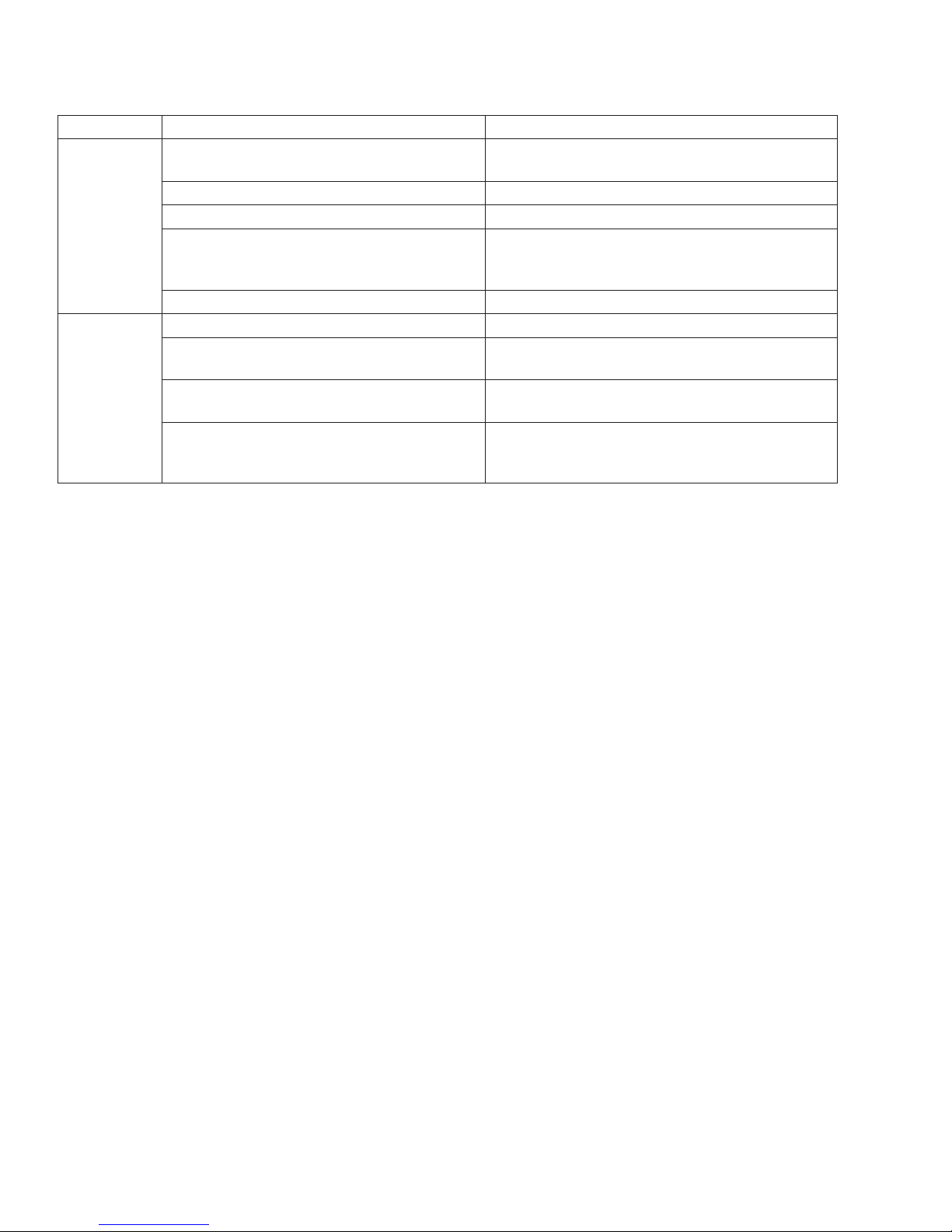

Winding rated

voltage (V)

*

Insulation

resistance test

direct voltage

(V)

<1000 500

1000-2500 500-1000

2501-5000 1000-2500

5001-12000 2500-5000

>12000 5000-10000

Table 5

Guidelines for DC voltages to be

applied during insulation resistance

tests

Main rotor

1. Disconnect the generator fi eld leads from the posi tive and negative

terminals of the rotating rectifi er assembly.

2. Connect the positive and negative leads to one clamp of the megger,

and connect the other clamp to the shaft.

3. Apply voltage from the megger, and measure the resistance reading

after 1 minute. The reading must be a minimum of 50 megohms. If it

is not, refer to the cleaning or dry out procedures. (See Table 5).

4. Ground the fi eld leads to the shaft after disconnecting the megger for

a minimum of 1 minute. This will allow the voltage build up to be

properly discharged.

Main stator

1. Disconnect power connections and all control appara tus from the

generator terminals.

2. Measure insulation resistance of each phase separately with the two

other phases shorted to the frame.

*

Rated line-line voltage for three-phase

ac machines, and line-to-ground voltage

for single-phase machines, and rated

direct voltage for dc machines or fi eld

windings.

3. Use a megger connected between the lead(s) of the phase to be

measured and generator frame. The minimum 1-minute insulation

resistance must not be less than 50 megohms. (See Table 5).

4. Ground the leads to the frame after the 1-minute megger test. This

will allow the voltage build up to be properly discharged.

Page 35

Copyright © 2012 Kato Engineering, Inc. All rights reserved

NOTICE: Do not apply heat too rapidly. It

could damage the windings.

Dry out procedures

If the insulation resistance readings are below the recommended minimum values specifi ed previously, use one of the dry out procedures

described below. Select the procedure based on the size and location

of the unit, available equipment, and experience of personnel. Before

drying, remove the voltage regulator, and cover all inlet and discharge

openings. Provide an opening at the top of the machine, preferably at the

fan end, for moisture to evaporate.

Drying with external heat: Place heat lamps, space heaters (in addition

to the ones already supplied) or a steam pipe near the windings. Monitor

winding temperatures. Raise winding temperature gradual ly at a rate

of 10-20° F (-12° to -6°

C) per hour up to 200° F (93° C). Measure

insulation resistance at 1-hour intervals. Typically the insulation

resistance will slowly drop while the temperature is coming up, and then

gradual ly increase and level out.

Drying with AC current in the armature: Short circuit the generator

terminals. Provide DC excitation to the brushless exciter fi eld winding.

Insert a current transformer and an ammeter to read full load current.

Run the generator at rated speed. Apply excitation to the exciter fi eld

until rated current is developed. Monitor winding temperatures until they

stabilize. Continue running until insulation resistance values level off.

Monitor winding temperatures. Raise winding temperature gradually at a

rate of 10-20° F (-12° to -6°

C) per hour up to 200° F (93° C). Measure

insulation resistance at 1-hour intervals. Typically, the insulation

resistance will slowly drop while the temperature is coming up and then

gradually increase and level out.

NOTICE: For specifi c lubrication

instructions, always refer to the bearing

lubrication sheet that came with your manual

or the lube plate on the generator.

Copyright © 2012 Kato Engineering, Inc. All rights reserved

Bearing lubrication

Shielded or sealed ball bearings: Shielded or sealed ball bearings are

factory packed with lubricants and generally can be operated several

years without requiring replenishment or change of the grease. If

repacking the grease is necessary, disassemble the machine, clean the

bearings, and repack the bearings about 1/2 full using a high quality ball

bearing grease, which must be capable of lubricating satisfactorily over a

temperature range of the lowest ambient temperature to 250º F (121

o

C).

Regreaseable ball or roller bearings: In applications where regreaseable

bearings are used, grease fi ll fi ttings and relief valves are incorporated

into the bearing housing. Lubricate the bearings in accordance with the

lubricating instructions attached to the generator.

Sleeve bearings: Lubricate the bearings in accordance with the

lubricating instructions attached to the generator and the bearing

lubrication instructions, which are provided in the manual package as

supplementary material.

Page 36

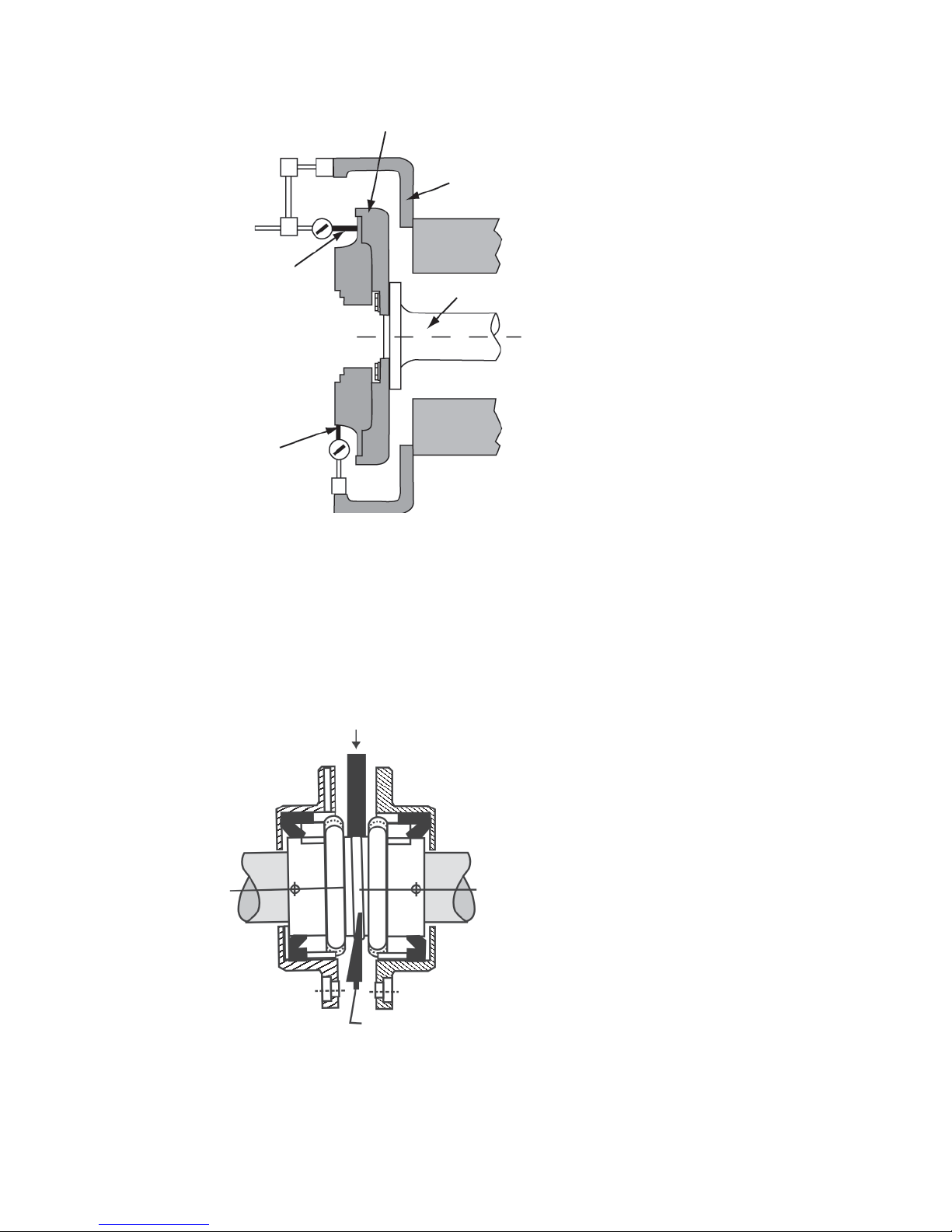

Rectifi er tests

If a failure of a rectifi er is suspected, remove the exciter cover. Remove

the nut and washer holding the rectifi er in the heat sink, and remove the

diode lead wire. Lift the rectifi er from the heat sink (see fi gure 22 for

an overview). Test the entire rectifi er with an ohmmeter or test lamp as

follows:

Negative

Positive

Positive

Figure 22: Rectifi er