Page 1

APPLICATION:

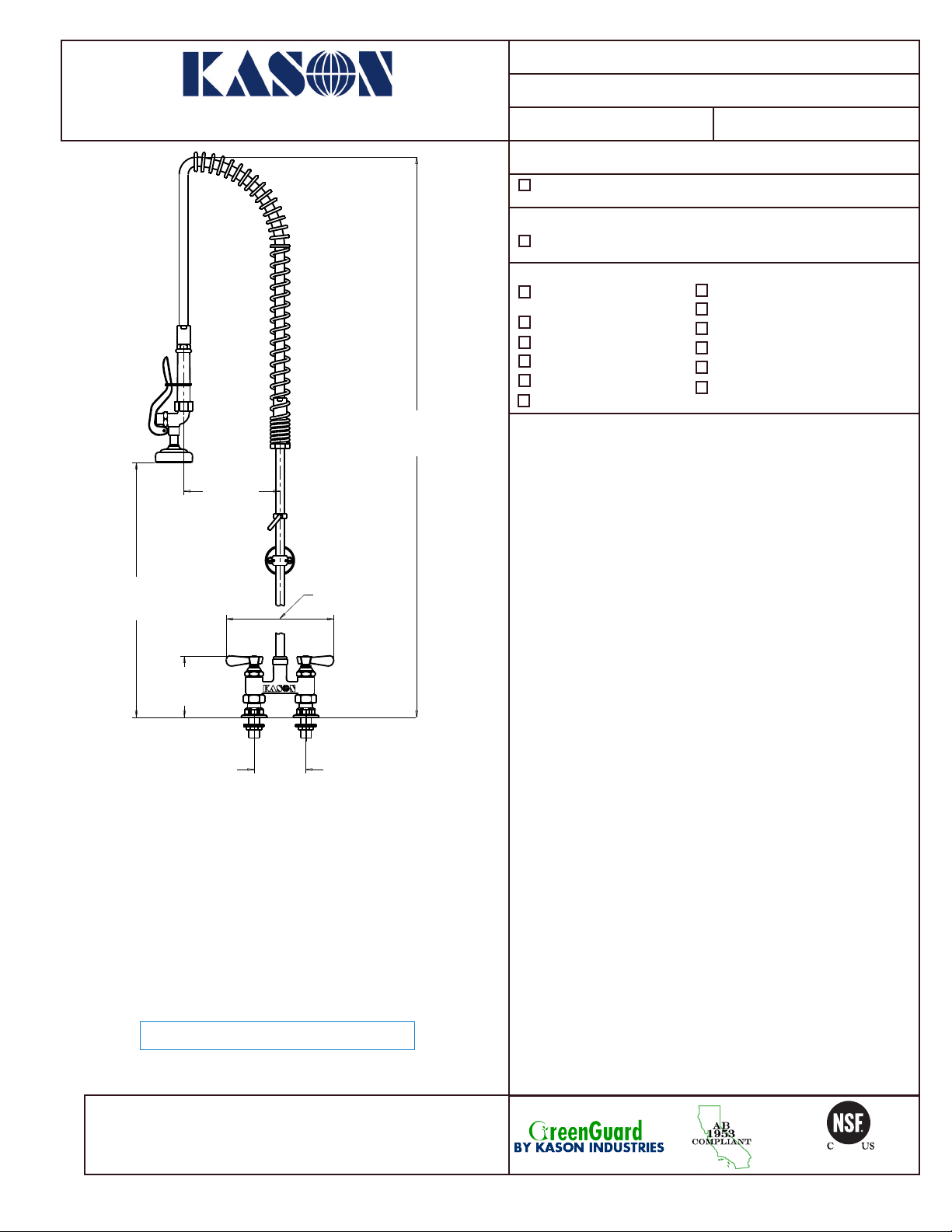

44-3/32

JOB NAME:

KASON FOOD SERVICE 31-A AMLAJACK BLVD. NEWNAN, GA 30265

20-15/32

1-800-935-2766 WWW.KASONIND.COM

7-7/16

[188,8]

8-5/16 MAX

[520]

[1120]

[210,9]

SERVING YOU SINCE 1926

QUANTITY:

SPECIFIER NO:

PRODUCT NAME: 4" DECK MOUNT PRE-RINSE

SPECIAL CONFIGURATION

CHECK BASE MODEL AND OPTIONS

MODEL:

452KL4500 4" DECK MOUNT PRE-RINSE

OPTIONS OR MODIFICATIONS:

SUPPLY LINES (24" OR

36" CIRCLE LENGTH)

INLET KIT

NIPPLES

ELBOWS

HANDLES: CROSS STYLE

CERAMIC CARTRIDGE

VACUUM BREAKER

ADD-ON FAUCET

LONGER HOSE LENGTH _______

RISER LENGTH ________________

OTHER _______________________

HANDLES: WRIST STYLE

FEATURES:

*INSTITUTIONAL QUALITY, HEAVY DUTY PRE-RINSE UNITS.

*RUGGED LOW LEAD BRASS ALLOY BODY WITH TRIPLE CHROME

PLATE FINISH AND STAINLESS STEEL COVERED HOSE FOR LONG LIFE

AND LOW MAINTENANCE.

*LOW LEAD BRASS VALVE STEM AND SEAT USE URETHANE BIBB TYPE

WASHER.

*BRASS INSERT IN HOSE HANDLE.

*PATHOGUARD™ ANTIMICORBIAL TREATMENT PROTECTS GRIP AND

HANDLE FROM DETERIORATION, ODORS OR COLOR CHANGE

CAUSED BY THE GROWTH OF BACTERIA OR MOLDS.¹

*COMPLETE WITH 12" WALL BRACKET.

4-23/32

[119,7]

4 [101,6]

ROUGH-IN: Ø 7/8" HOLES ON Ø 4" CENTERS

¹PATHOGUARD TREATED PRODUCTS HELPS PREVENT ODOR, STAINING, AND DETERIORATION OF

PRODUCT BY NON PUBLIC HEALTH MOLD, BACTERIA, AND FUNGUS. REGULAR CLEANING AND

SANITAZTION PRACTICES ARE REQUIRED IF PUBLIC HEALTH IS A CONCERN.

MATERIALS:

*POLISHED, CHROME PLATED, LOW LEAD BRASS ALLOY FAUCET,

BODY, STEM, AND SPOUT.

*POLISHED CHROME FINISHED HIGH PRESSURE DIE-CAST ZINC

HANDLES WITH STAINLESS STEEL SCREWS.

SPRAY UNIT:

*POLISHED CHROME PLATED BODY, BONNET AND NOZZLE.

*PATHOGUARD™ ANTIMICROBIAL POLYMER GRIP AND HANDLE WITH

BRASS INSERT.¹

*42" FLEXIBLE SANTOPRENE HOSE WITH STAINLESS STEEL COVER.

*STANDARD UNIT INCLUDES 3.3 GPM, 1.6 GPM AND 1.2 GPM SPRAY

HEADS.

MOUNTING:

*1/2"-14 NPT FEMALE ECCENTRIC INLETS

*Ø 7/8" MOUNTING HOLES

*4" CENTERS, ADJUSTABLE ±1/4"

SYSTEM LIMITS:

*TEMP: 40 °F MIN. TO 140 °F MAX

*PRESSURE 200 PSI MAX. STATIC

APPROVALS:

DATE:

ASME A112.18.1/CSA B125.1

NSF-61/9-G

© 2012 Kason Industries, Inc., All Rights Reserved SPEC SHEET REV1 01.2012

Loading...

Loading...