Kason 1830000016 User Manual

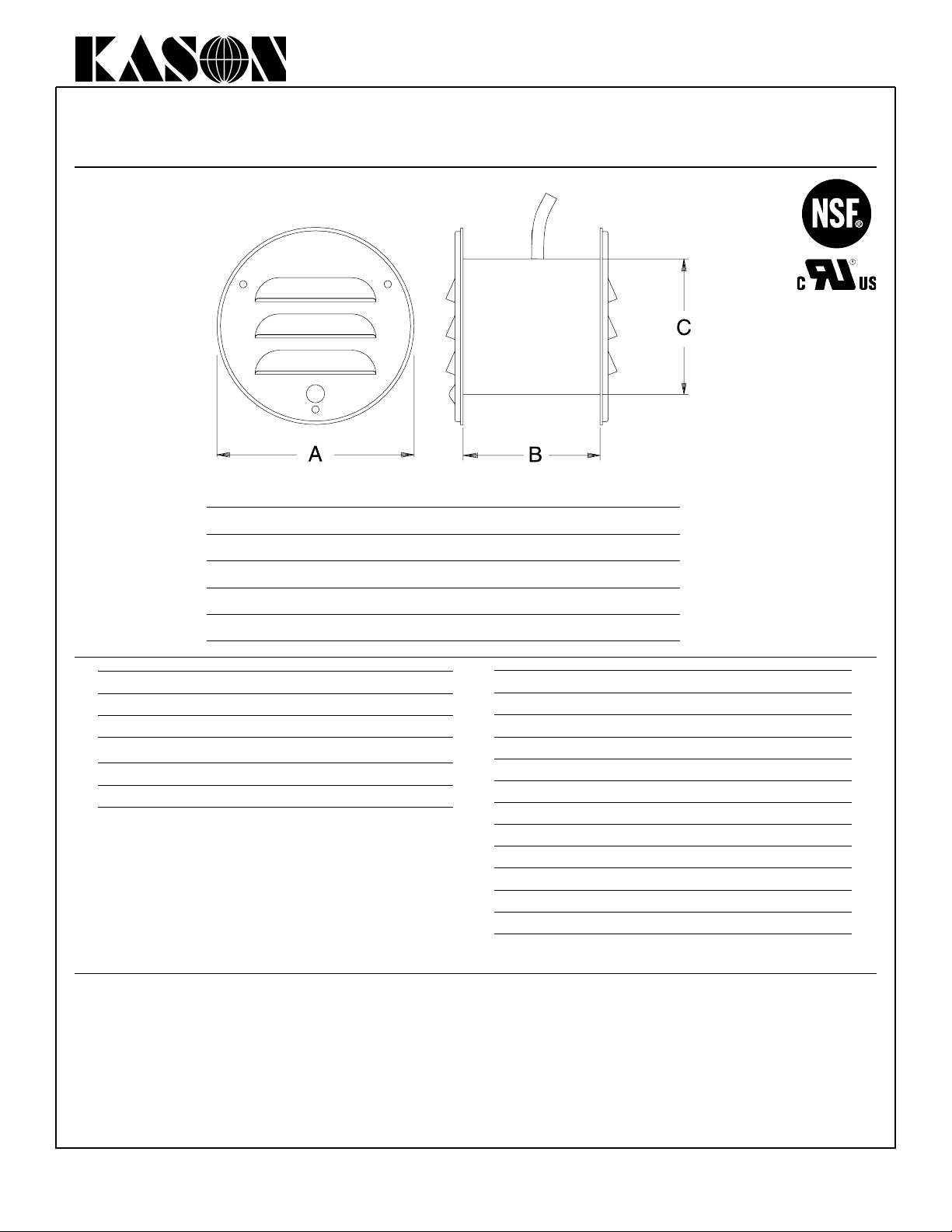

1830 SERIES VENTILATOR PORTS

A B* C

1830

1834

1832

1836

*Other lengths available. Please specify.

5-3/32" (129.4 mm) 4" (101.6 mm) 3-1/2" (88.9 mm)

5-3/32" (129.4 mm) 4" (101.6 mm) 3-1/2" (88.9 mm)

6-1/4" (165.1 mm) 4" (101.6 mm) 4-5/8" (117.5 mm)

6-1/4" (165.1 mm) 4" (101.6 mm) 4-5/8" (117.5 mm)

WALK-IN

STANDARD VENTILATOR PORTS

Model No. Item

1830000004 Heated Vent, 23W, .2 amp @ 120 VAC

1830000008 Heated Vent, 23W, .1 amp @ 240 VAC

1830000016 Heated Vent, 20W, .8 amp @ 24 VAC

1834000004 Non-heated Vent

Model No. Item

1832000004 Heated Vent, 23W, .2 amp @ 120 VAC

1832000008 Heated Vent, 23W, .1 amp @ 240 VAC

1832000016 Heated Vent, 20W, .8 amp @ 24 VAC

1832SA0004 Heated Vent w/Sq. Aluminum Louver, 120 VAC

1832SS0004 Heated Vent w/Sq. Stainless Steel Louver, 120 VAC

1832SA0001 Sq. Aluminum Louver for 1832 Vent

1832SS0001 Sq. Stainless Steel Louver for 1832 Vent

1836000004 Non-heated Vent

1836SA0001 Non-heated w/Sq. Aluminum Louver

1836SS0001 Non-heated w/Sq. Stainless Steel Louver

HIGH-FLOW VENTILATOR PORTS

NOTE

All 1830 Series ventilators are for a 4" (101.6mm) thick wall. When other length is required, specify exact wall thickness. Kason will convert

your individual requirement into our part number.

QUANTITY SELECTOR ON FOLLOWING PAGE

KASON INDUSTRIES, INC.* 57 AMLAJACK BLVD.*NEWNAN*GEORGIA*30265 1.800.93KASON WWW.KASONIND.COM

© 2009 Kason Industries, Inc.

WALK-IN

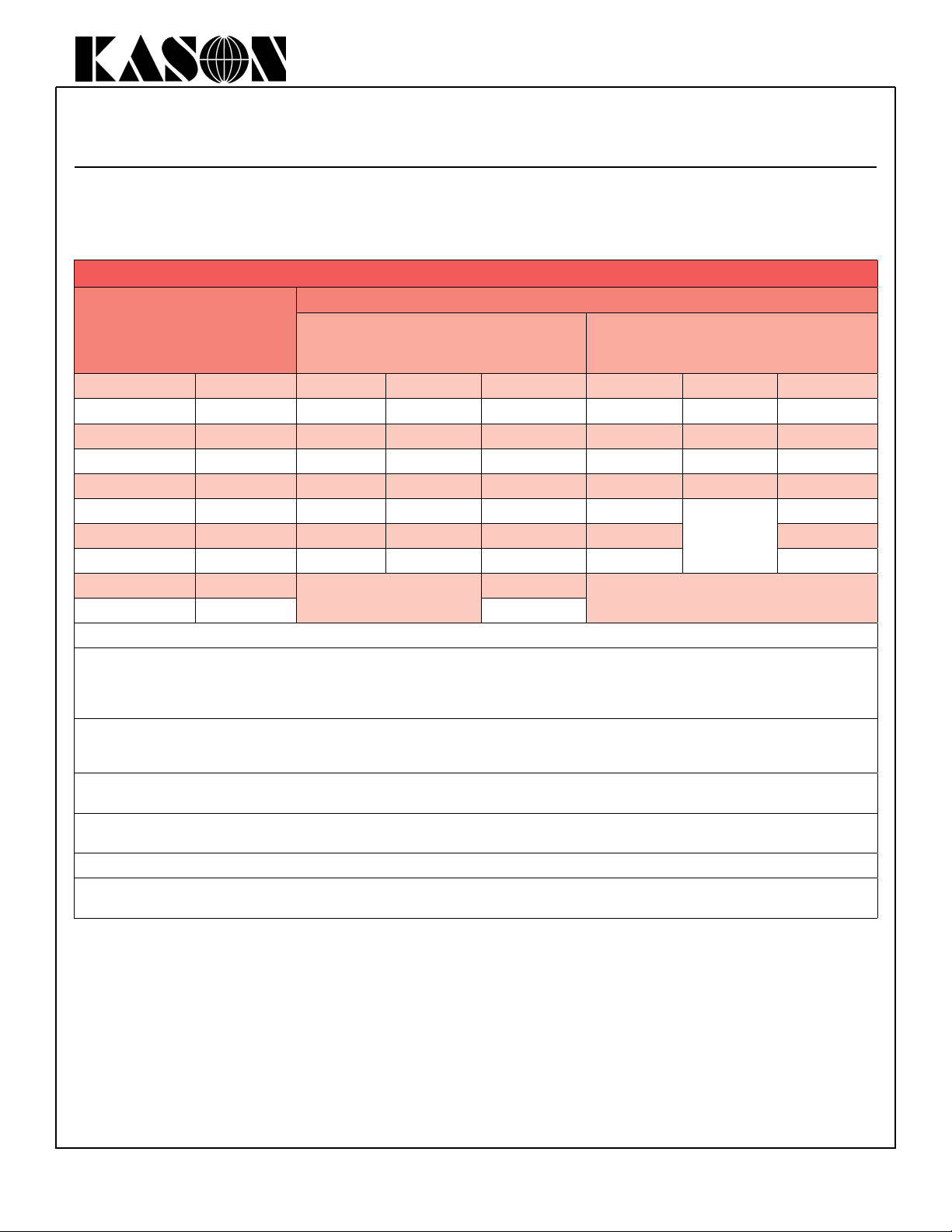

1830 SERIES VENTILATOR QUALITY SELECTOR

1825, 1830 & 1832 VENTILATOR QUANTITY SELECTOR

Quantity of Ventilators Required (See Notes)

Volume of Cooler or Freezer

3

Ft

2,000 (57) 1 1 1 1 1 1

3,000 (85) 1 1 1 1 2 1

4,000 (113) 1 1 1 2 3 1

6,000 (170) 1 2 1 2 4 2

8,000 (226) 2 2 1 3 See Note 3 2

12,000 (340) 2 3 1 3 3

16,000 (453) 3 4 2 4 4

20,000 (566)

24,000 (679) 2

NOTES:

(1) The table above should be used as a general guideline only. Kason does not guarantee these numbers, as many factors beyond those assumed can affect the amount of ventilation required in a refrigerated space. Some of these factors include, but are not limited to: the number

of doors in the enclosure, air-tightness of the enclosure, refrigeration load (how quickly the temperature drops), strength of panel construction,

etc.

(2) Vent quantities are calculated based on actual measured flow rates at an assumed allowable pressure differential for given temperature

change rate: 1825 = 13 ft3/min @ .6in H

sure.

(3) For box temperature less than -20F and/or when humid conditions exist outside box, add one 1830 for each 2000 cf above 6000 - or use 1832LT.

(4) Model 1832LT is recommended over the 1832 for box temperatures between -20F and -40F. Use model 1845 for boxes this size and

larger if box temperature is -20F or greater.

(5) Minimum use temperatures: 1825 -20F, 1830 & 1832 -30F, 1832LT -40F.

(6) Opening pressures: 1825 opens at the lowest pressure (0.1 in. H

in. H

O).

2

(m3) 1825 1830 1832 (4) 1825 1830 1832 (4)

10oF (5.6

Use 1832

O pressure, 1830 = 5 ft3/min @ .8 in H2O pressure, 1832 = 14 ft3/min @ .6 in. H2O pres-

2

Cooler

o

C) Change / 20 min

(0.5o F/min)

O), 1832 at 0.3 in. H2O, and 1830 opens at the highest pressure (0.7

2

30o F (16.8o C) Change / 20 min

2

Freezer

(1.5o F/min)

See Note 4

KASON INDUSTRIES, INC.* 57 AMLAJACK BLVD.*NEWNAN*GEORGIA*30265 1.800.93KASON WWW.KASONIND.COM

© 2009 Kason Industries, Inc.

Loading...

Loading...