Owners Manual

Robust-Aire®

Aquatic Aeration System

Contents

Important Safety Instructions . . . . . .pg2

Unit Specs . . . . . .pg2

Parts Included . . . . . .pg2

Installation Tools & Materials . . . . . .pg2

On Shore Preparation . . . . . .pg3

Diffuser Assembly Installation . . . . . .pg3

Compressor Connections . . . . . .pg4

No Cabinet System Installation Requirements . . . . . .pg5

Base Mount Cabinet Installation . . . . . .pg7

Post Mount Cabinet Installation . . . . . .pg7

Remote Manifold Accessory Installation . . . . . .pg7

Startup Procedure . . . . . .pg9

Winter Warning . . . . . .pg9

Maintenance . . . . . .pg9

Troubleshooting . . . . . .pg10

Warranty . . . . . .pg10

Kasco Marine, Inc.

800 Deere Rd.

Prescott, WI 54021

U.S.A.

PH 00+1+715+262+4488

FAX 00+1+715+262+4487

sales@kascomarine.com

www.kascomarine.com

Rev. 03/19/14

Important Safety Instructions

CAUTION

• Caution should be used when dealing with any

electrical equipment with moving parts.

• Extreme caution should be used around water,

especially cold water, such as in Spring, Fall,

and Winter, which poses a hazard in and of

itself.

• Running the system in freezing conditions may

create open areas of water in the ice at the

diffuser locations and also thin ice around the

area.

• Check your local laws and ordinances as some

areas require warning signs to be posted. The

owner will assume all risks with operating the

Robust-Aire System during winter months.

• Do not use waders in deep ponds/lakes or

ponds/lakes with drop-offs, drastic slopes, or

soft bottom material.

• Do not use boats that tip easily for installation,

such as a canoe, and follow all boating safety

rules and regulations, including wearing a PFD.

(Personal Flotation Device)

• Means for disconnection must be incorporated

inthexedwiringinaccordancewithlocaland

national wiring rules.

• Consultaqualiedelectricianforelectrical

installation.

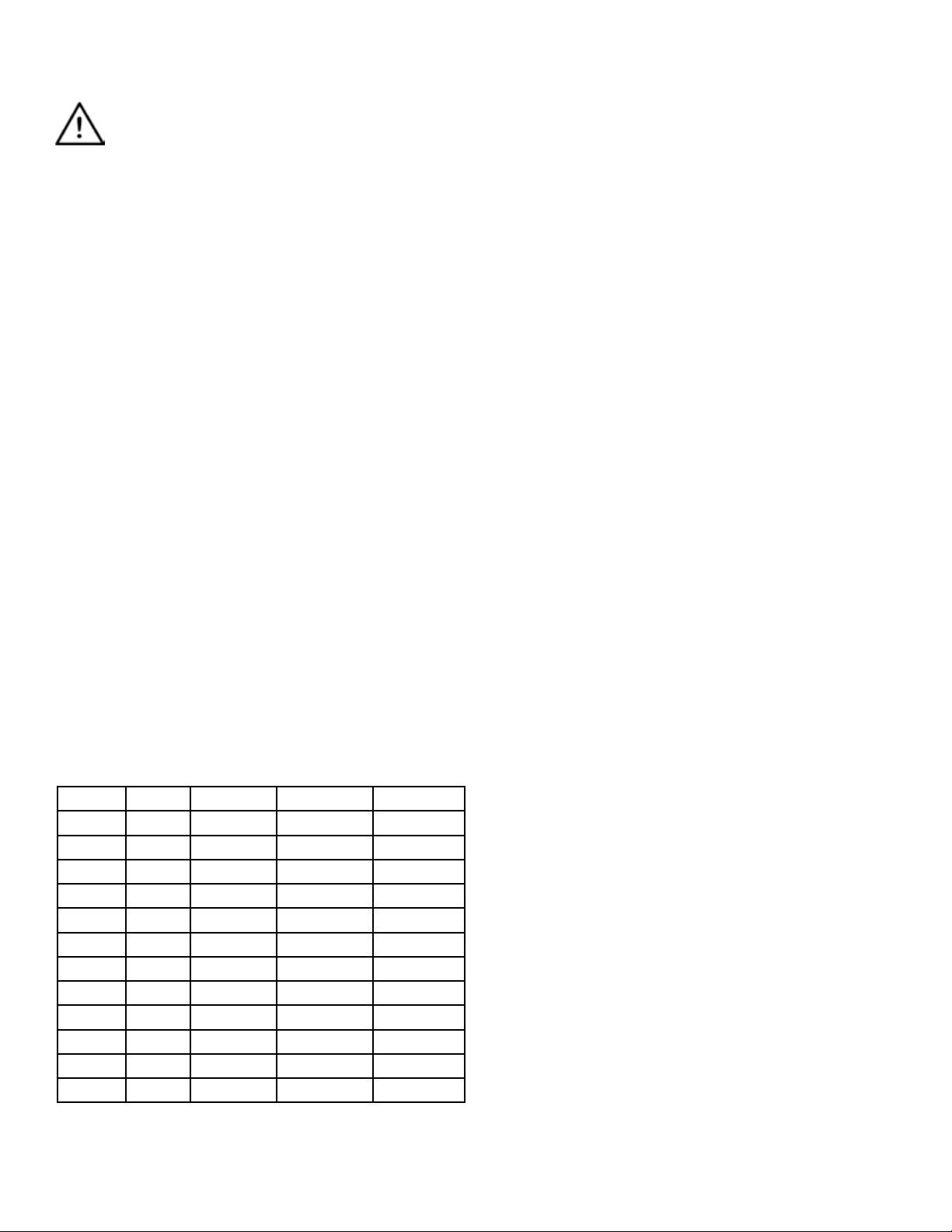

Unit Specs

Model* Voltage # diffusers

RA1 120 1 1 3.6

RAH1 240 1 1 1.8

RA2 120 2 1 5.4

RAH2 240 2 1 3.0

RA3 120 3 1 5.4

RAH3 240 3 1 3.0

RA4 120 4 2 10.8

RAH4 240 4 2 6.0

RA5 120 5 2 10.8

RAH5 240 5 2 6.0

RA6 120 6 2 10.8

RAH6 240 6 2 6.0

*you may have a sufx at the end of your model. “NC”

stands for “no cabinet”. “PM” stands for “post-mount cabinet”. No sufx denotes the standard base-mount cabinet.

# compressors

Total amps

The specs should be used by your qualied electrician

to ensure properly sized circuits are installed. For all

RAH systems and systems RA1 - RA3, a dedicated 15

amp circuit is sufcient to supply power to the system.

For RA4 – RA6 systems, a dedicated 20 amp circuit is

recommended. For RA(H)4 – RA(H)6 systems (two

compressors and two fans), it may be useful to have

two dedicated 15 amps circuits available. This will

allow for one compressor/fan combination to continue

operating if the other compressor were to fail, be down

temporarily for maintenance or to allow sets to be run

intermittently during start-up to prevent a turn-over

(see start-up procedure for more info). Always consult

with a qualied electrician.

ROBUST-AIRE® DIFFUSER ASSEMBLY

Parts Included

• (1) Robust-Aire® Diffuser Assembly

• (1) Vent Plug

• (1) 3/8” Tubing Clamp

• (1) 5/8” Tubing Clamp

• (1) ½” NPT x 3/8” Barb Elbow

• (1) ½” NPT x 5/8” Barb Elbow

• (1) 3/8” Tubing Strain Relief

• (1) 5/8” Tubing Strain Relief

• (1) ¼”-20 x 1-3/8” Lg Hex Head Capscrew

• (2) ¼” Flat Washer

• (1) ¼”-20 Lock Nut

*Not all ttings will be used. Use 3/8” ttings with

3/8” SureSink ™ Aeration Tubing and 5/8” ttings

with 5/8” SureSink ™ Aeration Tubing.

Installation Tools & Materials

• 7/8” Open End Wrench or Pliers

• 20-30 lbs (.25-.375 cu.ft.) of pea gravel

• Length of ¼” – 3/8” nylon rope (or equivalent).

Rope length to be at least twice the water depth

• 7/16” socket wrench

• 7/16” box or open end wrench

• 5/16” Socket wrench or screwdriver

• PTFE thread sealant (teon tape)

2

On Shore Preparation

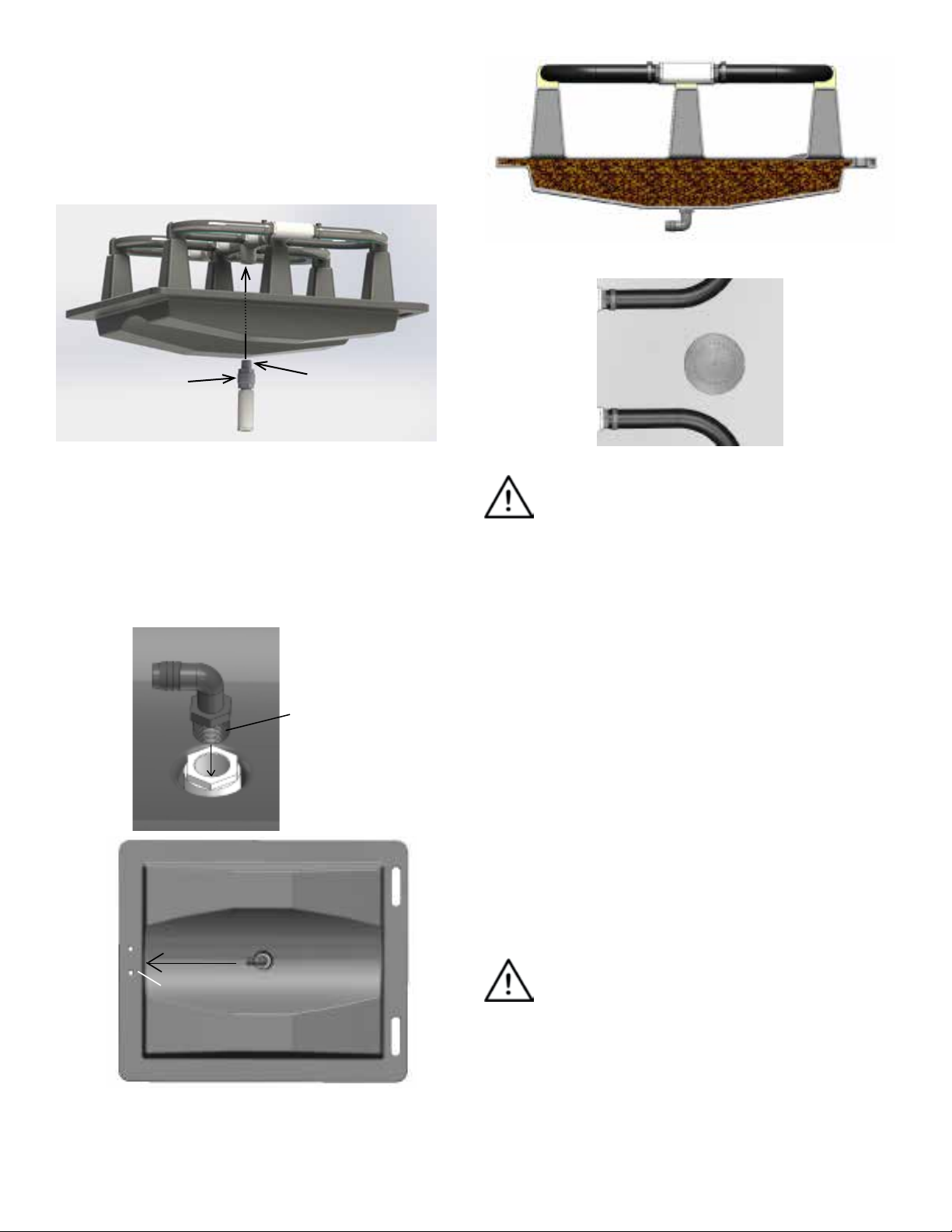

1. Apply PTFE Thread Sealant to male threads on check

valve. Slide check valve inlet assembly through diffuser base and into threaded port of the diffuser air

distribution assembly. Install hand tight only. Do not

overtighten.

4. Install vent plug once base is completely full.

Check valve

PTFE

Thread

Sealant

2. Install appropriate elbow tting into inlet port

located on the bottom side center of the diffuser

assembly. Install until hand tight. Continue

turning using 7/8” open end wrench until barbed

portion of the tting is pointing towards the edge

of the diffuser assembly with the strain relief

holes.

PTFE thread

sealant

Orientation of Fitting

CAUTION: Once the diffuser base has been

lled with gravel, do not lift assembly by diffuser hose

or PVC structure. Use outer edges of base to pick up

assembly.

If a boat is being used for diffuser placement, load the

boat with weighted diffuser assembly and remaining

parts kit. Do not use boats that tip easily for installation, such as a canoe.

Diffuser Assembly Installation

The effectiveness of the Robust-Aire® Diffuser is

greatly dependant on where the diffusers are located in

the pond. Therefore, proper placement is key. Space

the Robust-Aire® Diffusers equally from each other in

a depth that embodies the majority of the pond. Please

contact Kasco Marine if there are any questions on

placement.

Strain relief holes

3. Fill diffuser base with pea gravel to allow it to

ow easily into the base.

CAUTION: Do not use boats that tip easily for

installation, such as a canoe, and follow all boating safety

rules and regulations, including wearing a PFD. (Personal

Flotation Device)

5. It is recommended to place a buoy for each diffuser to

mark the area that it is to be placed.

6. Unroll the SureSink™ Aeration Tubing on shore to

remove any twists or knots. The performance will

3

decrease if the tube is not properly uncoiled.

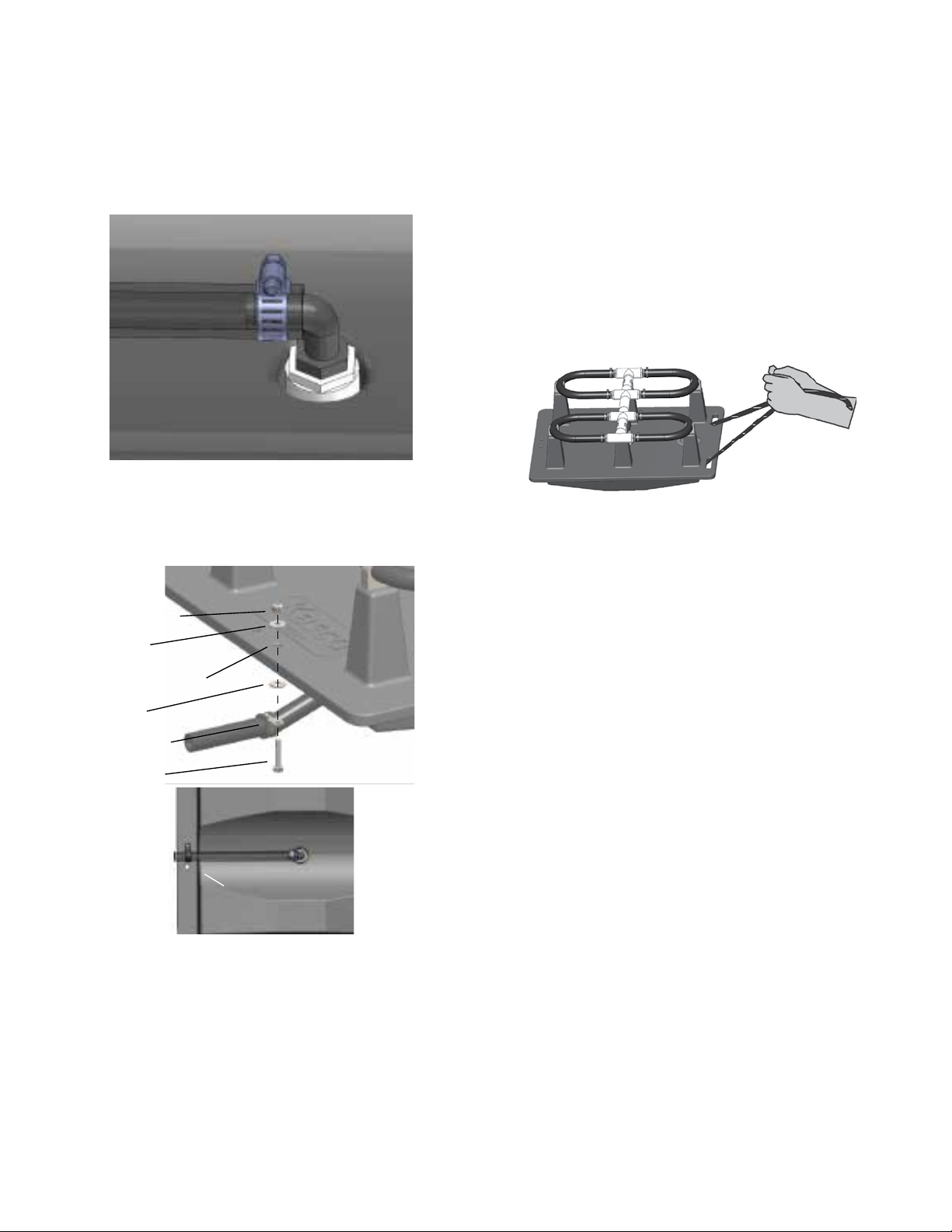

7. On the end of the SureSink™ Tube that will be con-

nected to the diffuser assembly, slide a clamp over the

tubing and connect the end of the tubing to the barbed

tting on the diffuser assembly. Position clamp over

tubing and barbed tting and tighten using a 5/16”

socket driver or screwdriver. Do not over tighten

clamp.

SureSink

Clamp

™ tubing

Bottom of Diffuser Assembly

1/2” NPT X

3/8” or 5/8”

Elbow

8. Install strain relief over tubing and secure to diffuser

base as shown using 7/16” socket and wrench. A prop-

erly installed strain relief will prevent any damage to

the diffuser assembly when it is lowered in the water or

pulled up at a later date for maintenance.

1/4” lock nut

washer

Diffuser Base hole

washer

strain relief

1/4” screw

off at shore before connecting to the compressor lead.

10. Tie off shore end of the SureSink™ Tubing by the com-

pressor cabinet. Make sure you have a few extra feet

of tubing to work with so that the tube will reach the

cabinet after trenching the tube between the shore and

the compressor.

11. Assembled Diffuser(s) can be loaded onto the boat.

Possible additional tubing kits and assembly tools

should be loaded on the boat if not already connected.

12. Make sure the boat is in reverse to avoid damaging the

boat prop and slowly make your way to the marking

buoy pulling the tubing as you go.

13. Once you reach the marked buoy, thread a rope through

the two slots of the diffuser base. Pull through until the

rope is at the midway point by the diffuser base.

14. While holding the two ends of the rope, gently lower

the diffuser assembly into the water. Submerge the

assembly and allow the air to escape from the vent plug

as the base lls with water.

15. When the air has been removed from the base, continue lowering the assembly slowly until it reaches the

bottom of the pond. Using this method, the diffuser

should not invert while lowering.

16. Pull up on only one side of the rope to bring it back.

The Robust-Aire® Diffuser should now be seated

properly on the bottom of the pond. (Optional: For

ease of future maintenance, it is recommended to leave

rope looped through diffuser base and tie both ends to

marker-buoy or duck decoy. This will allow diffusers to

be located easily and pulled up for maintenance.)

17. Repeat the process for additional Robust-Aire® Diffuser

locations.

Strain relief

9. If you anticipate running out of tubing (each tube is

100’) before reaching the buoy, connect any additional

tubes according to the SureSink™ Tube instructions.

Make sure to unroll these tubes as you did with the rst

tube. If you are unsure how many rolls of tubes will be

needed to reach the diffuser location, you can load the

unconnected diffuser assemblies and tubing kits into

the boat and connect as needed while making your way

to the marked buoy. You can also connect an ample

number of 100’ lengths together and have someone assist feeding it from shore. The excess tubing can be cut

4

Compressor Connections

18. When back on shore, nish connecting the tubing

to the lead hose from the compressor with the

supplied barb tting from the tubing kit. Secure

and tighten clamps to both supply tubing and

compressor hose.

Loading...

Loading...