Horizontal Float

Assembly & Installation Instructions

PARTS INCLUDED

A. Circulator (Unit with cord) (1)

B. Float in separate box (1) (Diagram to Right)

1. Float (1)

2. Base Strap (1)

3. Adjustment Bracket (1)

4. Angle Bracket (3)

5. Draw Band (1)

6. U-Bracket (2)

7. Spacer Bracket (2)

8. 1/4” x 1/2” Stainless Steel Bolt (8)

9. 1/4” x 1” Stainless Steel Bolt (3)

10. 1/4” x 1-1/4” Stainless Steel Bolt (2)

11. 1/4” Stainless Steel Lock Nut (8)

12. 1/4” Stainless Steel Hex Nut (2)

13. 1/4” Stainless Steel Lock Washer (5)

14. 50’ Black Nylon Ropes (2)

15. Nylon Tie (1)

TOOLS & SUPPLIES NEEDED

• 7/16” Wrench (1)

• 7/16” Socket & Ratchet (1)

• Felt-Tip Marker (1)

STEP ONE

Remove all contents from package and place on a

clean, flat surface. Inspect the shipment for any damages. If damages are found, immediately notify your

carrier and your Kasco Marine, Inc. representative.

Next, cross reference the parts included in the shipment with the Parts Included sheet in this manual on

page 14. Make sure you have all the parts needed. If

any shortages are found, contact your Kasco representative immediately.

STEP TWO

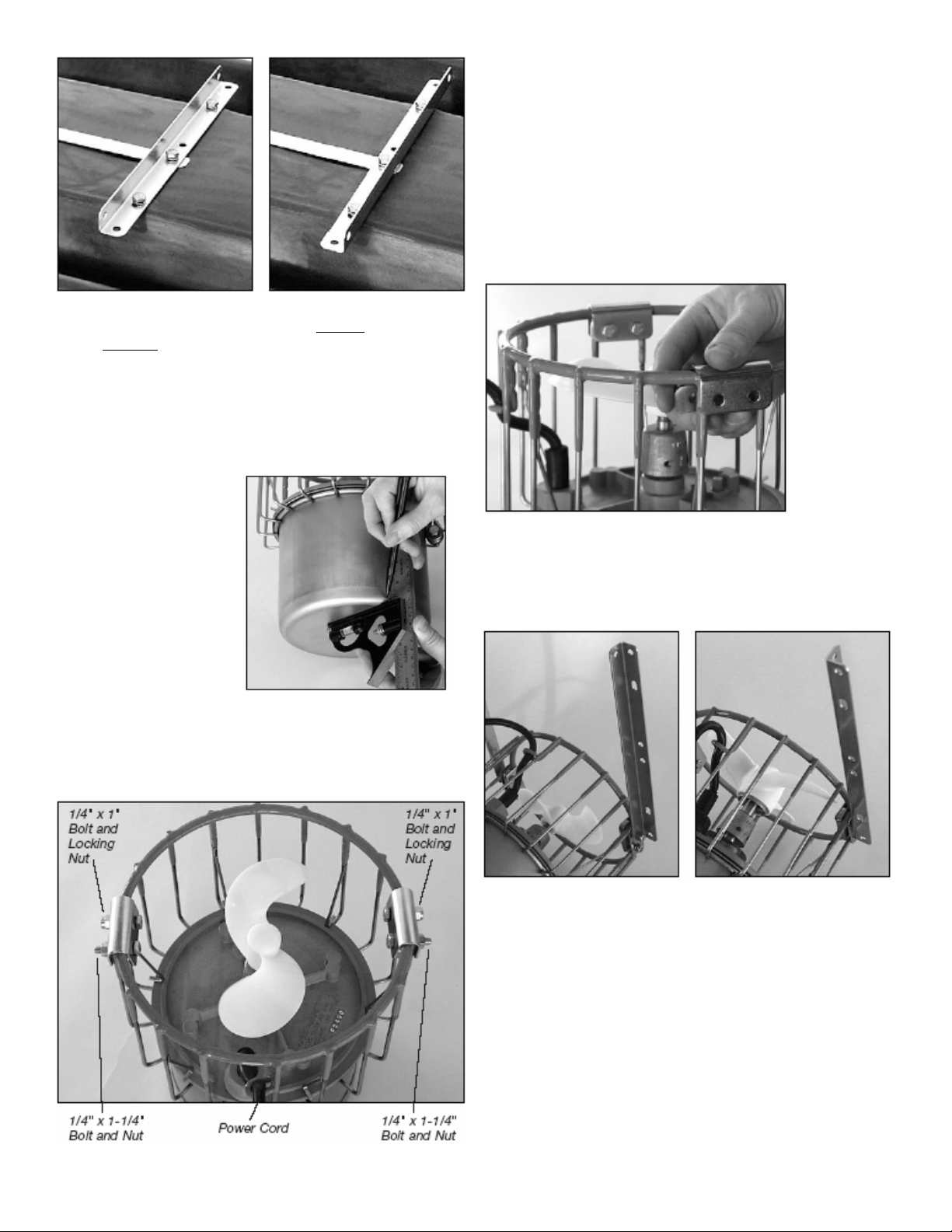

Position the Float upside down (lengthwise channels

facing up) and place the Base Strap so the three holes

in the Base Strap align with the three threaded holes

that comprise the lengthwise midline of the Float.

• Anchors or Stakes for Installation (2)

• 12” pieces of 1” galvanized pipe for weighting

ropes (optional) (2)

STEP THREE

Position the Adjustment Bracket over the two holes at

the back end of the Float and Base Strap. Loosely

secure the Adjustment Bracket to the Float using two

1/4” x 1/2” Stainless Steel Bolts and two Stainless

Steel Lock Washers. (See photo above for orientation.)

STEP FOUR

Place one of the three Angle Brackets perpendicular

to the Base Strap at the front end of the Base Strap.

One of the two center holes of the Angle Bracket

should be positioned over the hole in the Base Strap

and the threaded hole in the Float. Secure the Angle

Bracket to the Float using three 1/4” x 1/2” Stainless

Steel Bolts and three Stainless Steel Lock Washers.

(See photos on the next page for specific instructions

based on the size circulator purchased.) Tighten all

hardware at this time with the 7/16” socket and

wrench.

Models F2400, F3400

and 4400 - Angle

posterior

to bolts.

Model 8400 - Angle

anterior to bolts.

STEP FIVE

With a felt-tip marker, draw three to four marks

around the circumference of the motor housing at the

appropriate measurement from the back (or bottom)

of the motor housing

given below:

Model F2400: 3/4”

Model F3400: 3-3/8”

Model 4400: 3-3/8”

Model 8400: 3-1/4”

STEP SIX

Place the two U-Brackets directly across from each

other (180O) over the top ring of the motor cage. The

cord clamp on the cage should be 90O from each of

the U-Brackets. (See pictures on next page)

STEP SEVEN

Insert the Spacer Bracket under the U-Bracket and

inside the cage. Secure this assembly using one 1/4”

x 1” Bolt and a 1/4” Lock Nut, and one 1/4” x 1-1/4”

Bolt and a 1/4” Hex Nut. The longer bolt should be

on the side of the U-Bracket that is closer to the cord

clamp. Tighten the hardware using the 7/16” wrench

and socket & wrench until the U-Bracket clamps

firmly around the cage (U-Bracket should pull together slightly). Repeat with the second U-Bracket.

STEP EIGHT

Attach an Angle Bracket to each of the longer (11/4”) bolts on the U-Brackets (See photo for orientation) with a 1/4” Lock Nut.

Models F2400, F3400

and 4400

Model 8400

STEP NINE

Wrap the Draw Band around the motor housing and

position so that the back of the Draw Band touches

the marks drawn in Step Five. There is no front or

back to the Draw Band itself - it is reversible. Orient

the arm of the Draw Band so it aligns with the cord

clamp on the cage of the motor housing and is parallel to the Angle Brackets attached in Step Eight. Secure using a 1/4” x 1” Stainless Steel Bolt and a 1/4”

Lock Nut. (See photo on next page.)

Step Nine

STEP TEN

Attach the Angle Bracket on the motor to the Angle

Bracket on the Float using two 1/4” x 1/2” Bolts and

two 1/4” Lock Nuts (one set for each Bracket). See

photos for orientation based on model size. Also, the

cord clamp on the cage should be oriented toward the

Float.

Models 2400, 3400

and 4400

Model 8400

STEP ELEVEN

Attach the Draw Band on the motor to the Adjustment Bracket on the Float using a 1/4” x 1/2” Bolt

and a 1/4” Lock Nut. Select one of the five possible

positions to mount the Draw Band for your preferred

direction of flow (three are pictured on next page).

We do not recommend the two outer (most upward

and most downward) mounting positions for 8400

models.

Horizontal Angled Up Angled Down

STEP TWELVE

Attach the Ropes to the front (on the cage) and back

(around the Draw Band) of the motor. At this time,

use the Nylon Tie provided to connect the power cord

and front Rope to prevent the cord from tangling in

the prop. Also, if the power cord has a Quick Disconnect and Additional Strain Relief, attach the

Strain Relief to the cage of the unit and double check

the threaded collar on the Quick Disconnect to ensure

it didn’t loosen during shipping.

STEP THIRTEEN

Float the circulator in the water and position where

desired. Tie the front Rope to a stake on the shore or

weight. If a weight is used sink weight in front of

unit so rope is taught. (Circulator create great force,

make sure weight is enough to prevent movement.)

Tie back Rope to a stake on opposite shore or weight.

Sink weight behind the unit so rope is taught. At this

time take up any slack in the line.

The Industry Leader in

Ice Control Engineering.

KASCO MARINE, INC.

800 Deere Road

Prescott, WI 54021-1241

Phone (715) 262-4488 * Fax (715) 262-4487

www.De-Icer.com * sales@kascomarine.com

Rev. 7/10/06

820650

Loading...

Loading...