Owners Manual

Aerating Fountains

3400JF & 3400HJF

4400JF & 4400HJF

Contents

Important Safety. . . . pg2

General Instructions. . . . pg2

Cord Gauge Chart. . . . pg3

Unit Specs. . . . pg3

3400JF, 3400HJF Parts Included. . . . pg4

3400JF, 3400HJF Assembly. . . . pg4

4400JF, 4400HJF Parts Included. . . . pg6

4400JF, 4400HJF Assembly. . . . pg7

Nozzle Options. . . . pg9

Installation Instructions. . . . pg10

Control Panel Installation. . . . pg11

C-25 Timer Control Instructions. . . . pg12

C85 non-metallic Wiring Diagram. . . . pg14

C85 / C95 non-metallic and 3 Phase Control Panel Timer. . . . pg15

Maintenance Recommendations. . . . pg16

Warranty Policy. . . . pg17

Troubleshooting Tips. . . . pg18

3400J Replacement Parts. . . . pg20

4400J Replacement Parts. . . . pg21

Customer Repair Form. . . . pg22

Registration Information. . . . pg24

C

Intertek

3020379

ANSI/UL 778, 5th Ed. 2010

CAN/CSA C22.2 No. 108-M89

UL 50, 11th Ed. 1995

Kasco Marine, Inc.

800 Deere Rd.

Prescott, WI 54021

PH (715) 262-4488

FAX (715) 262-4487

www.kascomarine.com

Rev. 07/29/13

THANKS

We at Kasco Marine, Inc. would like to both thank and

congratulate you on your purchase of the JF model

aerating fountain. We appreciate you choosing Kasco

and for your purchase. Your decision to purchase Kasco’s JF model Aerating Fountain will not disappoint

you. The JF model Aerating Fountain will be a great

addition to your body of water. It will help improve

the water quality by adding much needed oxygen and

circulation. It will also enhance the aesthetics of the

pond or lake with a beautiful fountain pattern. The

lighting package (if purchased) will illuminate your

fountain for beauty at night. We thank you for choosing Kasco for your fountain needs and want you to be

completely satised with your purchase.

Important Safety

Please read and follow these extremely important

safety and handling instructions for your Kasco equipment. Following these instructions will help ensure

your safety and the quality performance of your equipment.

PFD. (Personal Flotation Device)

• The fountain is supplied with an internal grounding conductor and a grounding-type attachment

plug. To reduce the risk of electrical shock,

be certain that the fountain is plugged into the

C-25 Control Box (120V) or C-85 Control Panel

(240/208V) supplied by Kasco and that the C-25

is plugged into a properly grounded, grounding

type receptacle or the C-85 is wired properly. The

GFCI breakers should be tested upon each installation and every month thereafter to ensure proper

operation.

General Instructions

INSPECT THE SHIPMENT

Immediately inspect your Kasco Fountain shipment

for any visible damages. Also cross reference the

parts supplied with the Parts Included sheet to check

for shortages. Shortages should be reported immediately to your Kasco Marine distributor or representative and damages reported to your carrier and Kasco

Marine.

• Under NO circumstances should anyone enter the

water with the electrical equipment plugged in

and/or in operation. All Kasco equipment is ETL

approved to UL and CSA standards for safety in

water and all fountain models include control panels with GFI protection. However, it is NEVER

recommended to enter the water with the equipment in operation.

• Caution should be used when dealing with any

electrical equipment with moving parts.

• NEVER run the unit out of water. It will damage

the seals and create a dangerous situation for the

operator.

• Extreme caution should be used around water,

especially cold water, such as in Spring, Fall, and

Winter, which poses a hazard in and of itself.

• NEVER lift or drag the fountain by the power or

light cord. If you need to pull the unit to the side

of the pond, use the anchoring ropes.

• Do not use waders in deep ponds/lakes or ponds/

lakes with drop-offs, drastic slopes, or soft bottom

material.

• Do not use boats that tip easily for fountain installation, such as a canoe, and follow all boating

safety rules and regulations, including wearing a

CAUTION

WARNING: Under NO circumstances should anyone

enter the water with the unit in operation. Always

operate the unit in the water and keep people and objects clear of the propeller. Do not lift or pull the unit

by the electrical cord. Always use extreme caution

around electrical equipment and water situations.

ASSEMBLY & INSTALLATION

Please see the proper Assembly and Installation In-

structions enclosed in this manual. Each is specic for

your model and size of Fountain. Note: Use a nylon

tie to help keep the power cords for the unit and lights

free of the propeller by tying each cord to either side

of the oat. If you have a light kit, make sure that the

unit cord is tied to one side of the oat and the light

cord to the other for balance. Note: It is extremely

important to test the GFI breaker in the control panel

upon each installation/reinstallation of the unit to ensure proper functioning.

WARRANTY

Kasco Fountains are the result of over 40 years of

design and engineering. Kasco products are built to

withstand the toughest conditions. Kasco Marine

2

backs each 3400JF model Fountain with a 2 Year Warranty. This warranty covers any and all manufacturers defects within 2 years from the date of purchase

(See Warranty & Return Policy). Please register your

Fountain online at: www.kascomarine.com (Under the

Technical tab)

tant to store them upside down if they are going to be

sitting for long periods of time. Units that sit upright

on a shelf for many months, or even years have a

greater likelihood of seals drying out. Storing upside

down will ensure oil is lubricating the seals and prevent drying.

USE AND OPERATION

Kasco Fountains are designed and engineered for

continuous duty, such as on sh farms or other aquaculture applications, or on-demand use, as needed in a

recreational water feature.

During otation operation, the water is pulled from

O

360

around the unit and from below the unit. The

water is pulled upward and thrust through the otation

collar into the air.

Your Kasco Marine Fountain is ready for immediate

use (after installation). The motor and ball bearings

are submerged in oil and no further lubrication is

needed. Make sure to keep the motor housing clean

from hard water deposits and/or algae. (See Maintenance Recommendations.)

It is extremely important that proper and sufcient

voltage (120V or 240/208V) is supplied to the Fountain motor. Each 120V Fountain is supplied with a

UL and CSA approved C-25 GFI Protected Control

Box. The Fountain is to be plugged into the C-25

outlet labeled “UNIT” and the C-25 plugged into a

properly grounded receptacle (See C-25 Instructions

on page 12). Each 240V Fountain is supplied with a

UL and CSA approved C-85 GFCB Protected Control

Panel. The Fountain is to be plugged into the external

outlet on the C-85 or hardwired into C-85 panel. The

C-85 must have 4 wire service (L1, L2, neutral, and

ground) installed by a qualied electrician. (See Wiring Instructions). It is extremely important to test the

GFI breaker in the control panel upon each installation

and reinstallation and every month thereafter to ensure

proper operation.

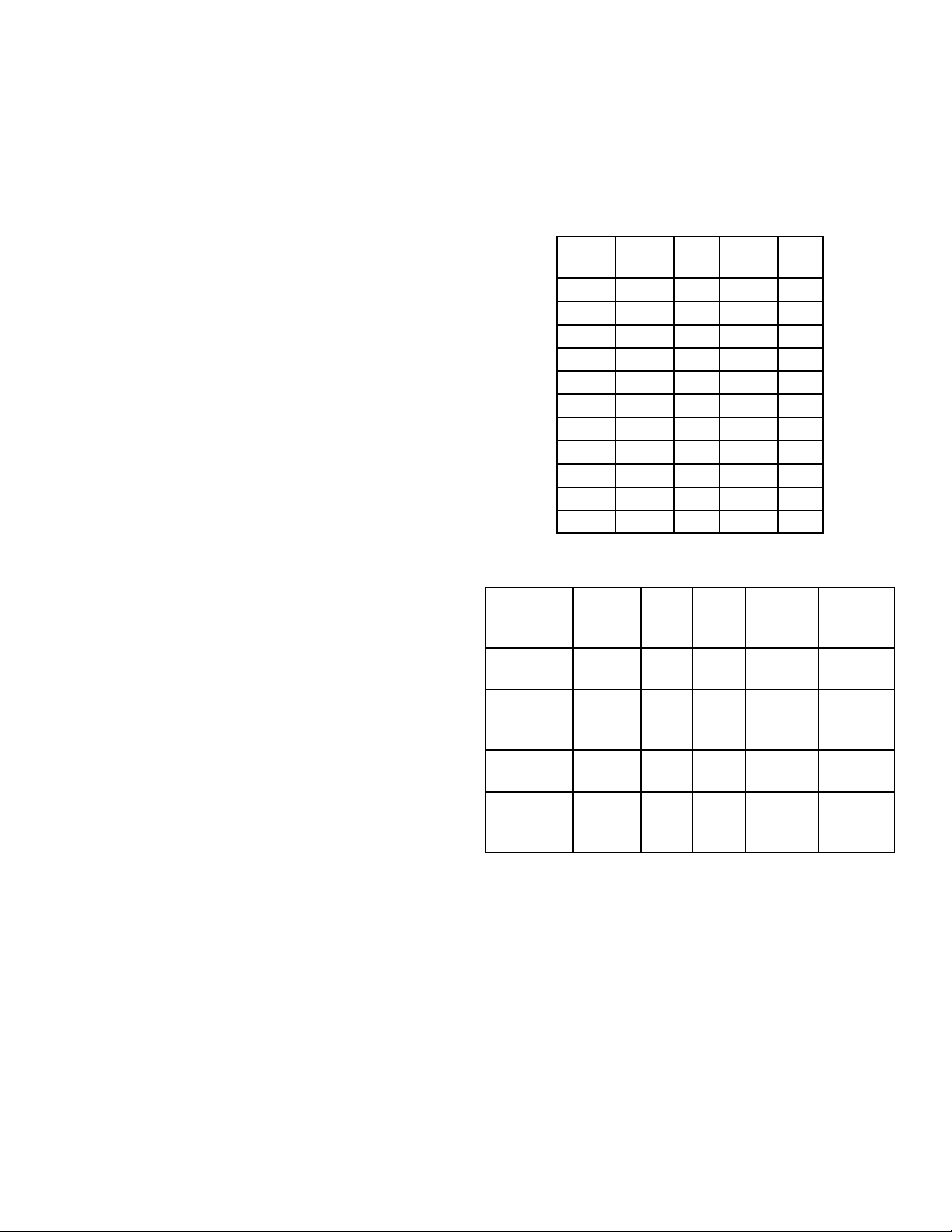

Cord Gauge Chart

Length Gauge 3400 3400H

4400H

50’ 16 x

50’ 14 x x

100’ 14 x x

100’ 12 x

150’ 12 x x

150’ 10 x

200’ 12 x x

200’ 10 x

250’ 12 x

300’ 12 x

400’ 12 x

4400

Unit Specs

Model Voltage Amps Lock

rotor

amps

3400JF 110-120 7.3 18 C-25

3400HJF 208-240 3.7 9 Hardwire

4400JF 110-120 11 40 C-25

4400HJF 208-240 5.5 20 Hardwire

Control

box con-

nection

plug in

C-85

plug in

C-85

Fountain

connec-

tion

Plug into

C-25

plug into

or hard-

wire C85

Plug into

C-25

plug into

or hard-

wire C85

Kasco Fountains are lightweight, energy efcient, and

easy to install and operate. We strive to produce products that exceed customer expectations. We hope you

enjoy your Kasco Fountain.

UNIT STORAGE

When storing units during the offseason, it is impor-

3

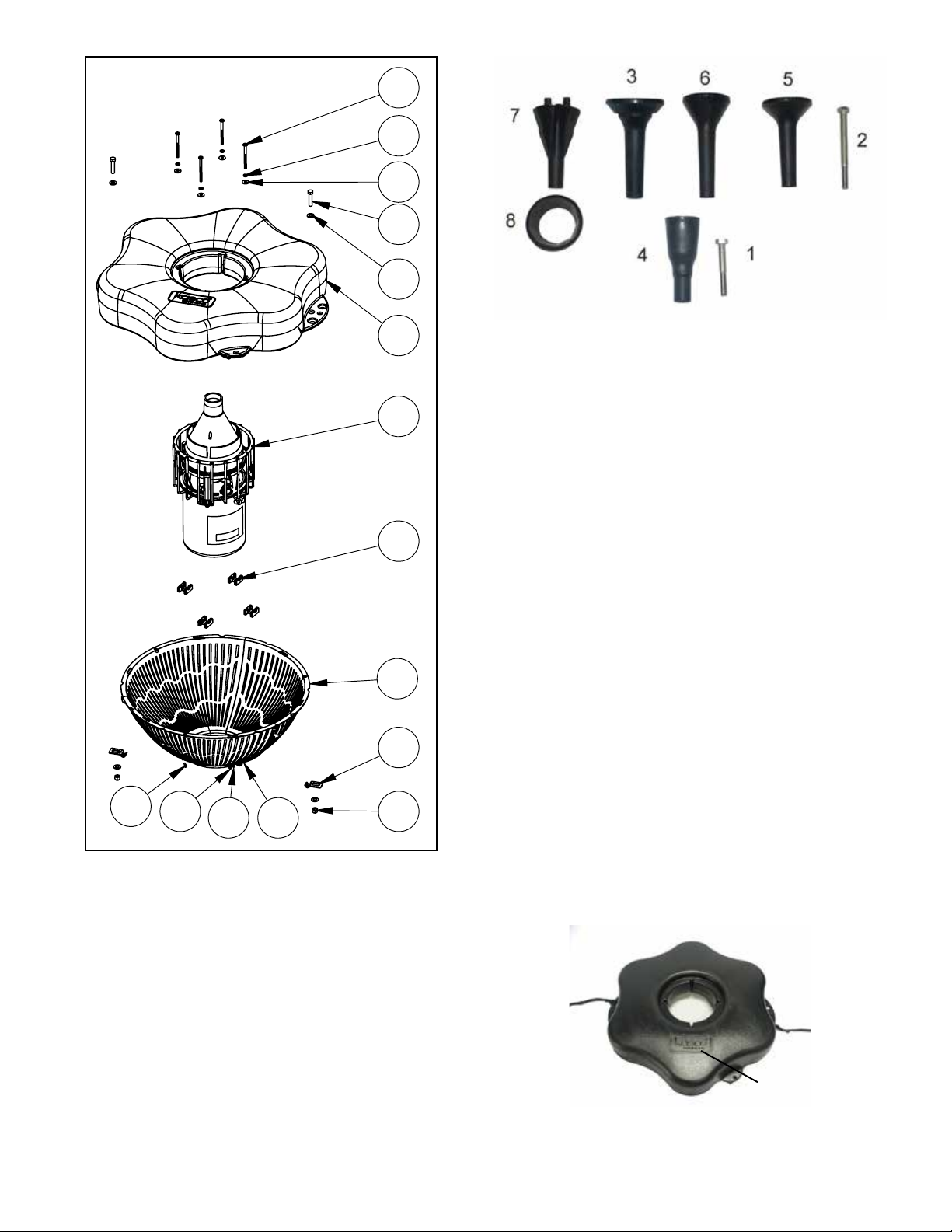

3400JF, 3400HJF Parts Included

REV.

ECO#

DESCRIPTION

1

INITIAL RELEASE

DO NOT SCALE DRAWING

X

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES.

MATERIAL:

1. 3400JF Aerating Fountain (Unit with cord or unit

with Disconnect) (1)

2. Float (with two 50’ mooring ropes attached) (1)

3. 1/4-20 x 3 1/2” Phillips Pan Head Screw (4)

4. 1/4” split washers (4)

5. 1/4” (3/4” outer diameter) Flat Washer (4)

6. 3/8”-16 x 1-3/4” Hex Head Bolt (2)

7. 3/8” Flat Washer (4)

8. Cushions for Legs (4)

9. Bottom Screen section (3)

10. Bottom Screen Clips (2)

11. 3/8”-16 Nylon Lock Nut (2)

12. #8 nut (6)

13. #8 at washer (12)

14. #8 lock washer (6)

15. #8 x 1/2” Screw (6)

Set of 5 Interchangeable Nozzles (5)

1. 3/8” x 2.25” bolt (1)

2. 3/8” x 4” bolt (1)

3. Linden Nozzle (1)

4. Sequoia Nozzle (1)

5. Juniper Nozzle (1)

6. Willow Nozzle (1)

7. Cypress Nozzle (1)

8. Collar for Cypress Nozzle (1)

3

4

Also Included:

• Mooring Rope Tube Weights (2)

5

• Cord in separate box (1) (depending on size of

cord)

6

• Control Box (C-25 for 120V units in Float box

or C-85 for 240V units in separate box) (1) (Not

7

2

Pictured)

TOOLS & SUPPLIES NEEDED

• Anchors or stakes for installing unit (2)

• # 2 Phillips head screw driver

• 120V or 240V Electrical Supply near pond on a

8

post with room for mounting the C-25 or C-85

• #10 x 1” long or longer screw(s) for mounting the

1

C-25 (3) or C-85 (4)

• 9/16” Socket and Ratchet

• 9/16” Wrench

• 11/32” wrench (for #8 fasteners)

9

1. Make sure you have all the parts needed. If any short-

ages are found, contact your Kasco representative immediately.

10

2. Set motor housing upright (stainless steel can down) on

a at surface.

12

4

1113 14 15

3. Peel off the adhesive on one of the Cushions for the

fountain housing legs (Part 8). Stick to the top of the fountain housing leg and repeat for the other three cushions.

3400JF, 3400HJF Assembly

Rest the oat on the 4 legs of the housing making sure logo

on oat is up.

cushion

logo

7. Secure the 3 sections of the screen together in 6 places

using #8 screw (Part 15), #8 lock washer (part 14), two

#8 at washers (part 13), and #8 nut (part 12). Do not

overtighten. Alternately, use cable ties instead of hardware

for a quicker assembly of the screen.

For quicker assembly:

Use cable tie instead

4. Ensure correct alignment by twisting the oat gently

around the motor housing until the power cord guide lines

up with the cord. See diagram below of bottom side of

oat. The 4 bolt holes in the oat should line up with bolt

receptacles on unit.

power cord

Bolt holes

guide

5. Use one of the 1/4”-20 x 3-1/2” Phillips Pan Head

Screws (Part 3), one 1/4” split washer (Part 4), and a 1/4”

Flat Washer (Part 5) to secure the oat. Make sure the split

washer goes between the bolt head and the at washer.

Insert screw with washers through bolt hole in oat

Tighten until snug with a Phillips Head screw driver and

repeat for 3 remaining screws.

6. Turn secured assembly upside down so the top of the

oat (logo side) is face down on the at surface. Bring the

3 bottom screen sections (part 9) together.

#8 nut

#8 screw

#8 lock washer

#8 lock washer

#8 screw

#8 flat washer

For quicker assembly:

Use cable tie instead

#8 nut

#8 flat washer

8. Make sure the cord is coming out of the power cord

guide in the oat before attaching the screen to the oat.

9. Use a stainless steel Bottom Screen Clip, 3/8”-16 x

1-3/8” Bolt, two 3/8” Flat Washer, and 3/8”-16 Nylon Lock

Nut to secure the screen to the oat. Align a clip so the two

prongs overlap the rim of the screen as seen in the picture.

Insert bolt with washer so the top of the bolt is facing the

top of oat (now in down position). Place the second

washer and the locking nut with nylon insert on the end of

the bolt and tighten using the 9/16” (14mm) Socket and

Ratchet on the nut end and the 9/16” (14mm) Wrench on

the bolt end. Tighten until snug and repeat with remaining

clip.

5

3/8” lock nut

3/8” flat washer

Bottom screen clip

3/8” flat washer

3/8” bolt

10. Turn the assembly upright again. At this time, if the

cord contains a metal strain relief, you can use the chain

connector and attach it in one of the opening at the rope

placement. The chain connector will easily t if installed

from the bottom or top side of the opening. It will not t

if installed from side of opening. Use the Nylon Cable Tie

included to secure the power cord to a molded hole in the

oat to prevent cord damage if there is no strain relief on

the cord. If a Strain Relief is present on the cord, you may

disregard the Nylon Tie. On cords with a Quick Disconnect, the disconnect should be tightened properly to avoid

leaking. If installing a new Quick Disconnect, refer to

Quick Disconnect Instructions.

12. Thread one rope through one weighted tube rope

Weight and position it approximately 6’ from the oat.

Next, thread the end of the rope back through the opening

facing the oat (as shown). Repeat with the second rope

and weight. If ready to install in the pond, go to Installation instructions. Light Kits can also be installed at this

time, go to Light kit instructions.

4400JF, 4400HJF Parts Included

1. 4400JF Aerating Fountain (Unit with cord or unit with

Disconnect) (1)

2. Float (with two 50’ mooring ropes attached) (1)

3. 1/4-20 x 3 1/2” Phillips Pan Head Screw (4)

4. 1/4” split washers (4)

5. 1/4” (3/4” outer diameter) Flat Washer (4)

6. 3/8”-16 x 1-3/4” Hex Head Bolt (2)

7. 3/8” Flat Washer (4)

8. Float Retaining Clips (4)

9. Bottom Screen section (3)

10. Bottom Screen Clips (2)

11. 3/8”-16 Nylon Lock Nut (2)

12. #8 nut (6)

13. #8 at washer (12)

14. #8 lock washer (6)

15. #8 x 1/2” Screw (6)

11. Select a nozzle (See JF Nozzle Options). Insert the

Shaft Bolt into the Nozzle Head so it ts snugly into the

molded socket. Install the Nozzle by threading it into the

inner cone of the pump. Make sure to tighten the Nozzle

all the way down.

6

3

REV.

ECO#

1

INITIAL RELEASE

DO NOT SCALE DRAWING

C.A.D. GENERATED DRAWING

X

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES.

DIMENSIONS IN [ ] ARE MILLIMETERS.

MATERIAL:

4

5

6

7

12

14 15

2

1

8

9

10

1113

Also Included:

• Cord in separate box (1) (depending on size of cord)

• Control Box (C-25 for 120V units in Float box or C-85

for 240V units in separate box) (1) (Not Pictured)

TOOLS & SUPPLIES NEEDED

• Anchors or stakes for installing unit (2)

• # 2 Phillips head screw driver

• 120V or 240V Electrical Supply near pond on a

post with room for mounting the C-25 or C-85

• Two 12” pieces of 1” galvanized pipe or weighted

tubing for weighting ropes (optional)

• #10 x 1” long or longer screw(s) for mounting the

C-25 (3) or C-85 (4)

• 9/16” Socket and Ratchet

• 9/16” Wrench

• 11/32” wrench (for #8 fasteners)

4400JF, 4400HJF Assembly

1. Make sure you have all the parts needed. If any short-

ages are found, contact your Kasco representative immediately.

Set of 5 Interchangeable Nozzles (5)

1. 3/8” x 2.25” bolt (1)

2. 3/8” x 4” bolt (1)

3. Linden Nozzle (1)

4. Sequoia Nozzle (1)

5. Juniper Nozzle (1)

6. Willow Nozzle (1)

7. Cypress Nozzle (1)

8. Collar for Cypress Nozzle (1)

2. Set motor housing upright (stainless steel can down) on

a at surface. With motor housing upright, slide Float (Part

2) over pump housing making sure the surface with the

Kasco logo is up.

logo

Rest the oat on the cage top ring.

7

3. Ensure correct alignment by twisting the oat gently

around the motor housing until the power cord guide lines

up with the cord. See diagram of bottom side of oat.

power cord

Bolt holes

guide

4. Use one of the 1/4”-20 x 3-1/2” Phillips Pan Head

Screws (Part 3), one 1/4” split washer (Part 4), and a 1/4”

Flat Washer (Part 5) to secure the oat. Make sure the split

washer goes between the bolt head and the at washer.

Insert screw with washer through bolt hole in oat

Use one oat retaining clip (Part 8) under the top ring of

the cage. There is a U-shaped indent in the clip that will t

snug against the top ring of the cage. The 1/4”-20 x 3-1/2”

will then thread into the retaining clip.

oat retain

ing clip

7. Secure the 3 sections of the screen together in 6 places

using #8 screw (Part 15), #8 lock washer (part 14), two

#8 at washers (part 13), and #8 nut (part 12). Do not

overtighten.

#8 nut

#8 screw

#8 lock washer

#8 flat washer

5. Tighten until snug with a Phillips Head screw driver and

repeat for 3 remaining screws.

6. Turn secured assembly upside down so the top of the

oat (logo side) is face down on the at surface. Bring the

3 bottom screen sections (part 9) together.

8

#8 screw

#8 lock washer

#8 flat washer

#8 nut

8. Make sure the cord is coming out of the power cord

guide in the oat before attaching the screen to the oat.

9. Use a stainless steel Bottom Screen Clip, 3/8”-16 x

1-3/8” Bolt, two 3/8” Flat Washer, and 3/8”-16 Nylon Lock

Nut to secure the screen to the oat. Align a clip so the two

prongs overlap the rim of the screen as seen in the picture.

Insert bolt with washer so the top of the bolt is facing the

top of oat (now in down position). Place the second

washer and the locking nut with nylon insert on the end of

the bolt and tighten using the 9/16” (14mm) Socket and

Ratchet on the nut end and the 9/16” (14mm) Wrench on

the bolt end. Tighten until snug and repeat with remaining

Loading...

Loading...